I am Patrick Fraser, an enthusiast of American Standard Circuits (ASC), deeply interested in the world of PCB manufacturing. With a focus on global sourcing and American standards in circuit board production, I appreciate ASC's commitment to custom PCB solutions and exceptional customer service. My interest spans from ENIG processes to Camtech innovations, highlighting the excellence of printed circuit board manufacturers in America.https://asc-i.com/

Don't wanna be here? Send us removal request.

Text

ASC: The Ultimate Destination for High-Performance Digital PCB and PCB Digital Solutions

In the digital age, the backbone of every advanced electronic device is a reliable and efficient digital PCB. At American Standard Circuits (ASC), we specialize in delivering world-class PCB digital solutions that cater to the needs of innovators across a spectrum of industries. From aerospace and automotive to medical, telecommunications, and green energy, ASC’s commitment to quality, speed, and technical expertise makes us the preferred partner for digital PCB manufacturing and design.

Unmatched Expertise in Digital PCB Manufacturing

ASC’s reputation as a leader in digital PCB manufacturing is built on decades of experience, state-of-the-art facilities, and a relentless pursuit of innovation. We offer a comprehensive range of PCB digital services, from the simplest single-sided boards to intricate multilayer and HDI (high-density interconnect) designs. Our advanced capabilities allow us to support even the most complex digital PCB requirements, ensuring your products are equipped for maximum performance and reliability.

Our digital PCB manufacturing capabilities include:

Multilayer and HDI digital PCB fabrication: Up to 40+ layers for sophisticated electronic systems.

Controlled impedance and high-speed signal management: Critical for data-intensive and high-frequency digital applications.

Blind, buried, and microvias: Enabling compact, space-saving PCB digital layouts.

Conductive and non-conductive via filling: Supporting advanced circuit design and reliability.

Edge plating, castellations, and custom finishes: For specialized connectivity and enhanced durability.

Lead-free and RoHS-compliant processes: Meeting global environmental and safety standards.

We partner with top-tier material suppliers such as Isola, Nelco, Panasonic, Shengyi, and Taconic, ensuring every digital PCB we produce meets the highest industry standards.

Rapid Turnaround and Certified Quality

At ASC, we understand that speed is essential in bringing your innovations to market. That’s why we offer quick-turn digital PCB services, with some projects completed in as little as 24 hours. Our robust quality assurance program is backed by Class III and MIL certifications, making us a trusted supplier for mission-critical applications where failure is not an option.

Every PCB digital solution undergoes rigorous inspection and testing, guaranteeing reliability, performance, and consistency. Our commitment to quality means you can trust ASC to deliver digital PCBs that exceed your expectations.

End-to-End Support and Engineering Excellence

From initial concept to final delivery, ASC’s team of digital PCB experts is dedicated to your success. We provide comprehensive engineering support, including design-for-manufacturability (DFM) reviews, material selection guidance, and rapid prototyping. Our responsive customer service ensures that most technical questions are answered immediately, helping you avoid costly delays and keep your project on track.

Serving a Wide Range of Industries

ASC’s digital PCB and PCB digital solutions are integral to the success of companies in:

Aerospace & Defense: Certified, rugged digital PCBs for high-reliability environments.

Automotive: Advanced PCB digital systems for next-generation vehicles.

Medical: Precision digital PCBs for diagnostic, imaging, and monitoring equipment.

Telecommunications: High-frequency, high-speed digital PCB solutions for modern networks.

Industrial & Green Energy: Durable and efficient digital PCBs for automation and sustainable energy systems.

Choose ASC for Your Digital PCB Needs

When you choose ASC, you’re partnering with a leader in digital PCB and PCB digital innovation. Our advanced manufacturing capabilities, certified processes, and experienced team ensure your digital PCB projects are completed on time, within budget, and to your exact specifications.

0 notes

Text

Cutting-Edge Rigid Flex PCB Solutions for Modern Electronics

ASC provides advanced rigid flex PCB solutions, blending rigid and flexible circuit technologies for enhanced durability and performance. Ideal for complex applications in industries such as aerospace, medical, and consumer electronics, our rigid flex PCBs offer exceptional reliability, compact design, and cost-efficiency. Trust ASC for high-quality, custom rigid flex PCBs tailored to meet the specific demands of your electronic projects.

#rigid flex pcb#rigid flex pcbs#flex circuit manufacturer#flex pcb manufacturer#flex circuit board manufacturers#flexible pcb manufacturers#flex rigid pcb manufacturer#rigid flex pcb manufacturers#rigid flex pcb supplier#fast turn rigid flex pcb#rigid flex pcb manufacturer#flexible printed circuit board manufacturers#flex rigid pcb

0 notes

Text

Comprehensive RF Testing for RF PCB Manufacturers

ASC provides specialized RF testing services for RF PCB manufacturers, ensuring optimal performance and compliance with industry standards. Our advanced testing solutions, including signal integrity and thermal analysis, guarantee the highest reliability in RF PCB designs. With a focus on precision and quality, ASC supports manufacturers in delivering top-tier RF products across various industries, ensuring long-term success and performance excellence.

0 notes

Text

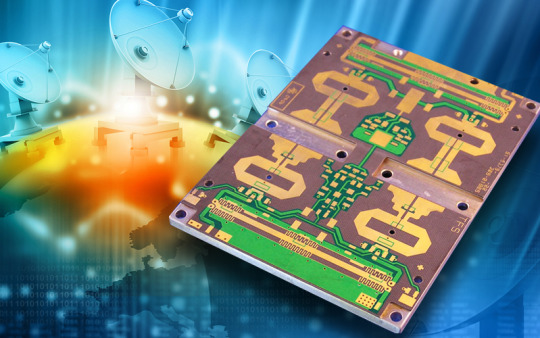

Top Microwave PCB Manufacturer for High-Quality RF Microwave PCB Fabrication

ASC-I is a leading microwave PCB manufacturer, specializing in the design and microwave PCB fabrication of high-performance RF microwave PCBs. Our microwave PCBs are engineered for precision, durability, and superior signal integrity, making them ideal for industries such as aerospace, defense, telecommunications, medical, and automotive. With advanced manufacturing techniques and high-frequency materials, we ensure that every RF microwave PCB meets the highest standards of quality and reliability.

Why Choose ASC-I for Microwave PCB Fabrication?

1. Expert Microwave PCB Manufacturer with Proven Industry Experience

With years of expertise, ASC-I delivers cutting-edge microwave PCB fabrication solutions. Our team of engineers and technicians specializes in producing high-frequency RF microwave PCBs that offer minimal signal loss and exceptional thermal stability.

2. High-Performance Materials for Microwave PCBs

We use advanced laminates like Rogers, Teflon, and ceramic-filled PTFE in our microwave PCB fabrication process. These materials provide low dielectric loss, high-frequency stability, and superior thermal resistance, ensuring optimal performance for microwave PCBs in demanding environments.

3. Custom RF Microwave PCB Solutions for Complex Applications

ASC-I offers customized RF microwave PCB solutions to meet specific requirements. Whether you need single-layer, double-layer, or multilayer microwave PCBs, we provide tailored designs with precise impedance control and optimized performance.

4. Advanced Manufacturing & Rigorous Testing

As a trusted microwave PCB manufacturer, we follow strict quality control protocols. Our microwave PCB fabrication process includes signal integrity analysis, impedance verification, and environmental testing to ensure that every RF microwave PCB meets industry standards for reliability and efficiency.

Applications of Microwave PCBs

Our microwave PCBs are designed for high-frequency applications across multiple industries, including:

Aerospace & Defense: Radar systems, satellite communication, avionics, and military-grade RF technology.

Telecommunications: 5G base stations, RF transceivers, and high-speed wireless communication.

Medical Technology: MRI, CT scanners, and RF-based diagnostic systems.

Automotive & IoT: ADAS (Advanced Driver Assistance Systems), vehicle-to-vehicle communication, and IoT applications.

ASC-I: Your Trusted Partner for Microwave PCB Fabrication

As a premier microwave PCB manufacturer, ASC-I is committed to delivering high-quality RF microwave PCBs with industry-leading performance. Our microwave PCB fabrication expertise, combined with cutting-edge technology and stringent quality control, ensures that we provide the best microwave PCBs for your specific applications.

If you need reliable, high-performance RF microwave PCBs, ASC-I is the perfect choice. Contact us today to discuss your microwave PCB fabrication requirements and experience top-tier manufacturing solutions.

0 notes

Text

Superior American Circuits for Advanced Electronic Systems

ASC-I offers cutting-edge American circuits designed to elevate the performance of electronic systems. Our circuits are crafted with precision and built to meet the highest standards of quality and durability. Whether for industrial, automotive, or consumer electronics, ASC-I's American circuits provide reliable solutions that enhance innovation and ensure seamless functionality. Trust in our expertise to deliver custom circuit designs that cater to your specific needs. Choose ASC-I for American circuits that drive efficiency, reliability, and success in every application.

#american circuits#asc inc#advanced circuit boards#circuits board#advanced circuit board#thermal circuits inc#us pcb manufacturers#advanced printed circuit board#advanced printed circuits#american pcb manufacturers#american circuit

0 notes

Text

Unlock Unmatched Efficiency with RF Metal Backed PCBs

In today's high-performance electronic applications, RF (Radio Frequency) circuits require exceptional thermal management, mechanical strength, and signal integrity. These requirements are especially critical for RF devices used in communication, aerospace, medical technology, and industrial sectors. To meet these needs, metal backed PCBs have become a vital solution. ASC-I offers high-quality RF metal backed PCBs, providing unmatched reliability, durability, and performance for demanding RF applications.

What Are Metal Backed PCBs?

A metal backed PCB is a type of printed circuit board that integrates a metal base, such as aluminum or copper, instead of the traditional fiberglass laminate. This metal substrate offers superior thermal conductivity, providing better heat dissipation than standard PCBs. In high-frequency RF applications, where excessive heat generation is a concern, metal backed PCBs allow for effective heat management, helping to prevent component failure and maintain optimal performance.

Why RF Applications Need Metal Backed PCBs

RF circuits typically operate at high frequencies and often encounter significant power levels. These conditions generate excess heat, which, if not managed properly, can lead to poor performance, overheating, or permanent damage to the circuit. Here’s why metal backed PCBs are the perfect solution for RF applications:

Superior Thermal Management: Thermal management is a key challenge in RF applications. Metal backed PCBs excel at dissipating heat due to their metal base layer, which effectively pulls heat away from the components and spreads it across the surface. By keeping the circuit cool, these PCBs prevent overheating and help maintain the longevity and reliability of RF devices.

Increased Durability: The metal layer in metal backed PCBs offers enhanced mechanical strength compared to traditional PCBs. This makes them highly resistant to physical stress, bending, or warping, especially in environments where vibrations or extreme conditions are common. This added durability is crucial in RF applications where the performance of the device must remain stable over time, even in harsh conditions.

Improved Signal Integrity: RF signals are sensitive to noise and interference, and maintaining signal clarity is crucial. The metal backing on these PCBs provides additional shielding from electromagnetic interference (EMI) and radio-frequency interference (RFI), ensuring that the RF signals remain clean and undistorted. This results in more reliable communication and data transmission in RF devices.

Compact and Efficient Design: Metal backed PCBs help reduce the overall size of the PCB while maintaining thermal efficiency. Because these PCBs can dissipate heat more efficiently, they allow for denser circuit designs without overheating issues. This is particularly advantageous in RF devices, where compact size and efficient space utilization are essential.

Cost-Effectiveness: Despite the advanced materials and manufacturing process, metal backed PCBs are cost-effective due to their durability and long lifespan. They reduce the need for additional cooling mechanisms and complex heat sinks, making them a more affordable option in the long run.

Applications of RF Metal Backed PCBs

The superior properties of metal backed PCBs make them an excellent choice for a variety of RF applications. Here are some industries and devices that benefit from these high-performance circuit boards:

Telecommunication Devices: From smartphones to base stations and wireless routers, telecommunication devices rely on RF circuits that demand high thermal management and signal clarity. Metal backed PCBs provide the necessary performance for such devices to operate smoothly under heavy use.

Radar and Satellite Systems: RF systems used in radar equipment and satellite communication require exceptional durability and heat management. Metal backed PCBs ensure these systems continue to function reliably in extreme conditions, providing consistent performance without thermal breakdown.

Medical Devices: Certain medical equipment such as MRI machines, diagnostic imaging devices, and therapeutic RF equipment rely on high-frequency RF circuits. Metal backed PCBs ensure these sensitive devices maintain the necessary temperature and electrical performance, offering stability and safety.

Automotive Electronics: RF circuits are integral to modern automotive technologies, including GPS, communication systems, and sensor technologies. Metal backed PCBs provide the reliability and heat dissipation necessary for automotive electronics, ensuring long-term performance in dynamic environments.

Industrial Equipment: Many industrial systems utilize RF technology for automation, wireless communication, and power management. Metal backed PCBs deliver the reliability and performance required to keep these systems running smoothly even in harsh environments.

Why Choose ASC-I for Your RF Metal Backed PCBs?

At ASC-I, we are dedicated to delivering the highest quality metal backed PCBs that meet the rigorous demands of RF applications. Our extensive expertise and commitment to excellence allow us to provide tailor-made solutions to help your project succeed.

Why ASC-I Stands Out:

Expert Engineering Team: ASC-I’s team of engineers has vast experience in RF design, ensuring that our metal backed PCBs meet the specific thermal and mechanical requirements of your RF applications.

Advanced Manufacturing Processes: Our state-of-the-art manufacturing facilities use cutting-edge technology and the highest-quality materials to produce reliable, high-performance metal backed PCBs. We prioritize precision and consistency in every unit we produce.

Customization for Your Needs: At ASC-I, we understand that each project has its unique challenges and requirements. That’s why we offer fully customizable metal backed PCBs tailored to your specifications, ensuring that your RF application performs at its best.

Global Reach and Support: ASC-I serves clients around the world, providing global support and flexible solutions for businesses of all sizes. We understand the importance of timely delivery and customer satisfaction, and we work hard to ensure your project stays on track.

Commitment to Quality: Every metal backed PCB produced by ASC-I undergoes rigorous quality control testing. We ensure that each product meets or exceeds industry standards, giving you the confidence that your RF devices will perform reliably.

Conclusion

Metal backed PCBs are an essential component in the world of RF applications, providing superior thermal management, mechanical strength, and signal integrity. ASC-I’s RF metal backed PCBs offer a reliable and cost-effective solution for a wide range of high-performance applications, ensuring that your devices continue to perform at their best.

Whether you’re working in telecommunications, aerospace, medical technology, or industrial systems, ASC-I has the experience, technology, and dedication to provide the right solution for your RF needs. Contact ASC-I today to learn more about our metal backed PCBs and how they can enhance the efficiency, durability, and performance of your next RF project.

0 notes

Text

Elevate Your Manufacturing with ASC Global PCB Sourcing

For businesses looking to optimize their PCB procurement strategy, ASC Global offers tailored, high-quality PCB solutions from global manufacturing leaders. Their focus on quality control, cost-efficiency, and advanced supply chain management ensures manufacturers receive PCBs that meet their exact specifications while maintaining affordability.

0 notes

Text

RF & Microwave PCBs: Key Considerations for Fabrication and Performance

In high-frequency applications like radar systems, satellite communications, and wireless networks, RF & microwave PCBs play a crucial role in ensuring seamless signal transmission. These specialized circuit boards require precision engineering, advanced materials, and expert fabrication techniques. Choosing the right RF microwave PCB manufacturer is essential for optimal performance and reliability.

Key Considerations in RF & Microwave PCB Fabrication

1. Material Selection

The foundation of any RF microwave PCB lies in the materials used. Standard FR4 substrates are unsuitable for high-frequency applications due to high dielectric loss. Instead, manufacturers rely on advanced materials such as:

Rogers Laminates – Low-loss, high-frequency stability

PTFE (Teflon) Substrates – Excellent signal integrity at GHz frequencies

Taconic and Arlon Materials – Enhanced thermal and electrical performance

A high-quality RF microwave PCB manufacturer will provide a range of materials tailored to your specific frequency and application needs.

2. Controlled Impedance & Precision Etching

Maintaining controlled impedance is critical in RF and microwave applications. Any variation in trace width, dielectric thickness, or copper weight can affect signal integrity. Advanced manufacturing techniques like laser direct imaging (LDI) and precision etching ensure accurate impedance matching and minimal signal loss.

3. Thermal Management Solutions

RF and microwave circuits generate significant heat, which can impact performance and longevity. Effective thermal management solutions, including thermal vias, heat sinks, and advanced copper plating techniques, help dissipate excess heat and maintain operational stability.

4. Surface Finishes for RF Performance

The choice of surface finish affects signal integrity and board longevity. Common finishes for RF microwave PCBs include:

ENIG (Electroless Nickel Immersion Gold) – Corrosion-resistant and highly conductive

Silver Plating – Low insertion loss for improved high-frequency performance

OSP (Organic Solderability Preservative) – Cost-effective and environmentally friendly

Why Choose ASC for RF & Microwave PCBs?

For high-performance RF microwave PCB manufacturing, Advanced Circuits (ASC) is a trusted industry leader.

Why Work with ASC?

✅ Expertise in RF & microwave PCB fabrication

✅ High-quality materials for superior signal performance

✅ Precision manufacturing with controlled impedance

✅ Fast prototyping and large-scale production capabilities

For reliable RF microwave PCB solutions, choose ASC. Contact them today to get started on your next high-frequency project!

0 notes

Text

Leading the PCB Industry with Design for Manufacturability

ASC and Sunstone Circuits combine over 50 years of expertise to create a powerhouse in PCB manufacturing. ASC specializes in Ultra HDI, rigid, metal-backed, RF/microwave, flex, and rigid-flex PCBs, making them a go-to provider for diverse industry needs.

0 notes

Text

High-Tech Flex and Rigid-Flex PCB Solutions by ASC

ASC is a trusted PCB manufacturer specializing in flex and rigid-flex PCB assembly. Their solutions include single-sided, double-sided, multilayer, and rigid-flex designs, ideal for compact electronics packaging. ASC delivers high-tech, reliable PCBs—contact them today for more details!

0 notes

Text

Designing Thermal Circuits for Maximum Performance and Reliability

In advanced electronic systems, managing heat effectively is critical to ensuring both performance and longevity. Poor heat dissipation can lead to overheating, reduced efficiency, and even failure of critical components. This is where thermal circuits play a vital role, offering a structured approach to analyzing and optimizing heat transfer. By designing efficient thermal circuits, engineers can achieve maximum performance and reliability, even in the most demanding applications.

A thermal circuit models the flow of heat within a system, much like an electrical circuit models the flow of current. It consists of key elements such as heat sources (components that generate heat, like processors), thermal resistance (barriers to heat flow, such as interfaces or insulators), and heat sinks (components that dissipate heat into the environment). Understanding and optimizing these components is essential for achieving effective heat management.

Heat in a thermal circuit transfers through conduction, convection, and radiation. Conduction occurs through solid materials, such as heat sinks or thermal pads. Convection involves fluid movement, often aided by fans or liquid cooling systems. Radiation, although less significant in many electronics, can still contribute to heat dissipation. By balancing these mechanisms, engineers can create a thermal circuit that ensures components remain within safe operating temperatures.

For those seeking advanced solutions, ASC’s Thermal Management Technology provides cutting-edge tools and expertise in thermal circuit design. Their innovative approach includes advanced materials that enhance heat conduction, custom cooling solutions tailored to specific needs, and precise thermal analysis to optimize performance. These solutions are designed to tackle the most complex thermal challenges, ensuring systems operate reliably under extreme conditions.

Designing effective thermal circuits is not just about managing heat—it’s about enabling systems to perform at their peak while maintaining long-term reliability. With the right tools and expertise, such as those offered by ASC’s Thermal Management Technology, engineers can overcome heat-related challenges and unlock the full potential of their electronic designs. Embrace optimized thermal circuits to ensure your systems excel in performance and reliability.

0 notes

Text

Reliable RF Microwave PCB Solutions: Tailored for High-Performance Needs

As a trusted microwave PCB manufacturer, ASC offers highly reliable RF microwave PCBs designed for demanding applications. Our microwave PCB fabrication process guarantees precision and performance, with an emphasis on low-loss and high-frequency capabilities. We specialize in custom solutions that meet specific design and product requirements, ensuring top-quality results. With our advanced technology and experienced engineers, ASC guarantees superior microwave PCB solutions for every project.

0 notes

Text

How to Identify Reliable Metal Core PCB Manufacturers

Choosing the right metal core PCB manufacturer is a critical step in ensuring the success of your electronics project. Metal core PCBs (MCPCBs) are essential for high-performance applications, especially in industries where thermal management is a top priority, such as LED lighting, power electronics, and automotive systems. Finding a PCB metal core supplier that offers high-quality products and reliable service is key to maximizing performance and durability. But how do you identify a manufacturer that meets your needs? Here are some key factors to consider:

1. Industry Experience and Expertise

A reliable metal core PCB manufacturer should have substantial experience in producing high-quality PCBs for demanding applications. Look for companies with a proven track record in manufacturing PCB metal core solutions for industries like automotive, telecommunications, and consumer electronics. Their experience will ensure they can handle your specific design and thermal management needs effectively.

2. High-Quality Materials and Manufacturing Standards

The material quality and manufacturing standards are crucial when selecting a manufacturer. Metal core PCBs typically use metals like aluminum or copper, which must meet certain thermal conductivity and strength requirements. A reputable manufacturer will use high-quality materials and adhere to international standards for PCB production, ensuring reliability and performance. Check if the manufacturer provides information on the materials used and whether they comply with relevant quality certifications.

3. Customization and Flexibility

Each project is unique, and a good metal core PCB manufacturer will offer flexible solutions tailored to your specific requirements. Whether you need specialized dimensions, custom copper thickness, or unique layer stacking, choose a manufacturer that can accommodate your design specifications. The ability to customize ensures that the PCB metal core solution you receive is optimized for your product’s performance needs.

4. On-Time Delivery and Excellent Customer Service

A reliable metal core PCB manufacturer should offer timely delivery and provide outstanding customer support. Delays in PCB production can result in costly setbacks for your project. Look for manufacturers who are known for their punctuality and responsiveness, ensuring your product gets to market on schedule.

Why Choose ASC ’s Metal Core PCBs?

ASC is a trusted metal core PCB manufacturer known for delivering high-performance PCB metal core solutions. Their advanced manufacturing processes, commitment to quality, and customer-focused approach make them an ideal partner for your thermal management needs. Whether you're designing for LEDs, power electronics, or automotive applications, ASC’s products are built to ensure reliability, efficiency, and durability. Explore their offerings and see how ASC-I can support your next project.

Choosing the right metal core PCB manufacturer can make all the difference in the performance and success of your product. By focusing on experience, quality, customization, and reliability, you can ensure that your designs meet the highest standards of excellence.

0 notes

Text

Your Partner for Metal Core PCB Excellence

American Standard Circuits is your go-to metal core PCB supplier, offering expertly crafted metal backed PCBs and advanced PCB metal core technology. Contact us today to learn more about our tailored solutions!

0 notes

Text

Top Reasons to Use Metal Core PCBs in High-Power Electronics

When it comes to high-power electronics, metal core PCBs (Printed Circuit Boards) offer an unmatched solution for efficient heat management and enhanced durability. Designed with a metal substrate, typically aluminum or copper, metal core PCBs outperform standard boards by effectively dissipating heat, which is crucial for maintaining the longevity and performance of high-power devices. Here’s why metal core PCBs are a top choice for high-power electronics and the benefits they bring to demanding applications.

1. Superior Thermal Management

One of the main reasons metal core PCBs are essential in high-power electronics is their superior thermal conductivity. Unlike traditional PCBs, which may struggle with heat buildup, metal core PCBs are designed to pull heat away from heat-generating components, reducing the risk of damage. This makes them ideal for applications like LED lighting, power supplies, and automotive electronics, where components are subjected to high temperatures.

2. Enhanced Durability and Stability

The metal layer in metal core PCBs provides additional strength and stability, making them more robust than standard PCBs. This added durability allows the board to withstand mechanical stress, vibrations, and thermal cycling. For high-power electronics, where devices may be exposed to extreme conditions, this durability ensures reliable performance over time.

3. Improved Efficiency for High-Power Applications

High-power electronics need to operate at optimal efficiency, and metal core PCBs play a critical role in achieving this. By effectively managing heat, metal core PCBs allow components to operate within their safe temperature range, reducing power loss and boosting efficiency. This is especially beneficial for applications like RF amplifiers and motor drives, where consistent power delivery is crucial.

4. Compact and Lightweight Designs

Despite their strength, metal core PCBs can be manufactured in compact, lightweight designs, making them ideal for modern electronic devices. The metal core allows for thinner boards without compromising thermal management capabilities, which is advantageous in applications where space is limited.

Discover High-Quality Metal Core PCBs

For high-performance metal core PCBs designed to meet the demands of high-power electronics, explore American Standard Circuits. Their RF metal-backed PCB solutions offer the reliability and efficiency required in demanding applications, from LED lighting to power electronics, ensuring your devices run cooler and last longer. Choose American Standard Circuits to experience the full benefits of advanced metal core PCB technology.

0 notes

Text

ASC - Flex PCB Manufacturer Committed to Innovation

As a premier flex circuit manufacturer, American Standard Circuits (ASC) has been serving North America since 1988. Over the past seven years, we’ve successfully diversified into flexible PCB manufacturing, providing cutting-edge flex and rigid-flex products that have strengthened our position in the market.

0 notes

Text

How MCPCB Improves Durability and Performance in Electronics

As electronic devices become more advanced and power-intensive, the need for efficient heat management and durability is more important than ever. One solution to this growing demand is the use of Metal Core Printed Circuit Boards (MCPCBs). These specialized circuit boards not only improve the longevity of electronic components but also enhance their overall performance, making them a popular choice in various industries. One company that has been at the forefront of MCPCB technology is American Standard Circuits, providing high-quality solutions for demanding applications.

What is an MCPCB?

A Metal Core Printed Circuit Board (MCPCB) is a type of circuit board that incorporates a metal core, typically aluminum or copper, which helps in dissipating the heat generated by high-power components. The metal core serves as a heat sink, drawing heat away from sensitive components, reducing the risk of overheating, and ensuring reliable performance over time. This capability makes MCPCBs particularly valuable in applications where heat management is critical to operational success.

Enhanced Durability

One of the key benefits of MCPCBs is their ability to improve the durability of electronics. By effectively managing heat, MCPCBs prevent thermal damage to components, which is a common issue in high-power applications. This translates into longer lifespans for devices, reduced maintenance costs, and fewer component failures. American Standard Circuits specializes in producing MCPCBs that are designed to meet the rigorous demands of industries like automotive, industrial equipment, and LED lighting.

Improved Performance

In addition to durability, MCPCBs enhance the performance of electronic devices. Efficient heat dissipation ensures that components can operate at optimal temperatures, leading to better functionality and reliability. Whether it’s in automotive LED lighting, power supplies, or motor controls, MCPCBs allow systems to run more efficiently without the risk of overheating, ultimately boosting performance.

Why Choose American Standard Circuits?

American Standard Circuits is known for its expertise in manufacturing high-quality MCPCBs for a wide range of industries. Their commitment to innovation and precision ensures that their boards meet the specific needs of today’s high-performance electronics.

In conclusion, MCPCBs are essential for improving the durability and performance of modern electronics, and American Standard Circuits continues to lead the industry in providing cutting-edge solutions.

0 notes