#advanced printed circuit board

Explore tagged Tumblr posts

Text

Superior American Circuits for Advanced Electronic Systems

ASC-I offers cutting-edge American circuits designed to elevate the performance of electronic systems. Our circuits are crafted with precision and built to meet the highest standards of quality and durability. Whether for industrial, automotive, or consumer electronics, ASC-I's American circuits provide reliable solutions that enhance innovation and ensure seamless functionality. Trust in our expertise to deliver custom circuit designs that cater to your specific needs. Choose ASC-I for American circuits that drive efficiency, reliability, and success in every application.

#american circuits#asc inc#advanced circuit boards#circuits board#advanced circuit board#thermal circuits inc#us pcb manufacturers#advanced printed circuit board#advanced printed circuits#american pcb manufacturers#american circuit

0 notes

Text

#pcb#pcb manufacturer#united states#europe#switzerland#germany#advanced circuit#partnership#branding#contract#business#printed circuit board#ttm#scc

0 notes

Text

Explore A-Gas Electronic Material's range of advanced chemistries for PCB (Printed Circuit Board) production. Our offerings cater to high-performance PCBs, ensuring superior quality in electronic components and devices.

#PCB#PCB Production#Printed Circuit Boards#Advanced PCB Chemistries#High-Performance Printed Circuit Boards#Electronic Components Manufacturing#PCB for Electronic Devices#Quality PCB Manufacturing#Printed Circuit Board Expertise#AGAS

0 notes

Text

"As the world grows “smarter” through the adoption of smartphones, smart fridges, and entire smart houses, the carbon cost of that technology grows, too.

In the last decade, electronic waste has become one of the fastest-growing waste streams in the world.

According to The World Counts, the globe generates about 50 million tons of e-waste every year. That’s the equivalent of 1,000 laptops being trashed every second.

After they’re shipped off to landfills and incinerated, the trash releases toxic chemicals including lead, cadmium, arsenic, mercury, and so much more, which can cause disastrous health effects on the populations that live near those trash sites.

Fortunately, Franziska Kerber — a university student at FH Joanneum in Graz, Austria — has dreamed up a solution that helps carve away at that behemoth problem: electronics made out of recyclable, dissolvable paper.

On September 11, Kerber’s invention “Pape” — or Paper Electronics — earned global recognition when it was named a national winner of the 2024 James Dyson Awards.

When she entered the scientific competition, Kerber demonstrated her invention with the creation of several small electronics made out of paper materials, including a fully-functional WiFi router and smoke detector.

“Small electronic devices are especially prone to ending up in household waste due to unclear disposal systems and their small size, so there is significant potential to develop a more user-friendly end-of-life system,” Kerber wrote on the James Dyson Award website.

“With this in mind, I aimed to move beyond a simple recycling solution to a circular one, ensuring long-term sustainability.”

Kerber’s invention hinges on crafting a dissolvable and recyclable PCB board out of compressed “paper pulp.”

A printed circuit board (PCB) is a board that can be found in nearly all modern electronic devices, like phones, tablets, and smartwatches.

But even companies that have started incorporating a “dissolution” step into the end life of their products require deconstruction to break down and recover the PCB board before it can be recycled.

With Kerber’s PAPE products, users don’t need to take the device apart to recycle it.

“By implementing a user-friendly return option, manufacturers can efficiently dissolve all returned items, potentially reusing electronic components,” Kerber explained.

“Rapidly advancing technology, which forms the core of many devices, becomes obsolete much faster than the structural elements, which are often made from plastics that can last thousands of years,” Kerber poses.

PAPE, Kerber says, has a “designed end-of-life system” which anticipates obsolescence.

“Does anyone want to use a thousand-year-old computer?” Kerber asks. “Of course not. … This ensures a sustainable and reliable system without hindering technological advancement.”"

-via GoodGoodGood, September 13, 2024

#ewaste#e waste#e waste recycling#e waste management#e waste solutions#paper#sustainability#green tech#tech news#sustainable technology#recycling#good news#hope

586 notes

·

View notes

Note

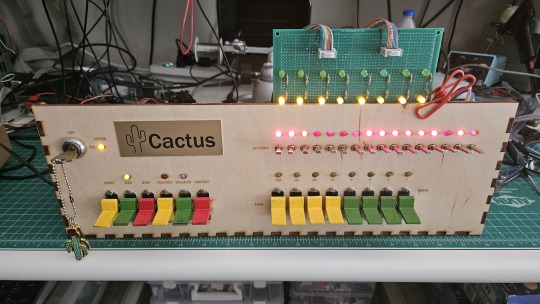

Cactus fascinates me, does it run on code similar to an existing instruction set or is it completely original on that front?

What can you do with it? What's it's storage?

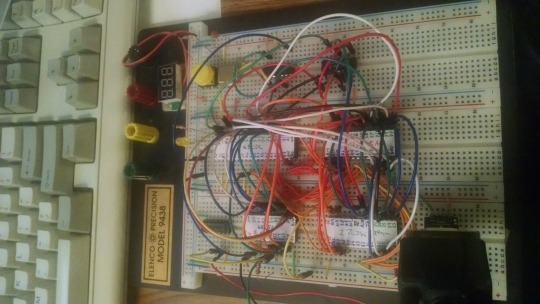

Both the Cactus (the original wooden prototype from years ago) and the new PCB Cactus(es) are essentially derived from a minimal 6502 computer design by Grant Searle for their core logic. Here's what that would look like on a breadboard:

There isn't much to it, it's 32K of RAM, 16K of ROM containing Ohio Scientific's version of Microsoft BASIC, a 6850 ACIA for serial interaction, some logic gates, and of course a 6502 microprocessor (NMOS or CMOS, doesn't matter which). You hook it into a terminal and away you go.

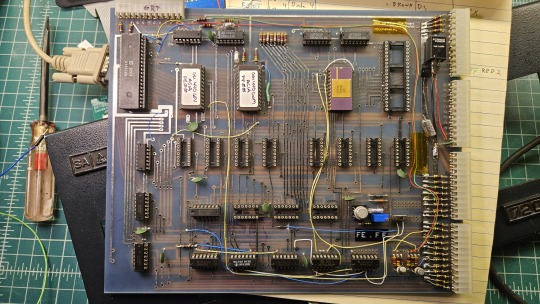

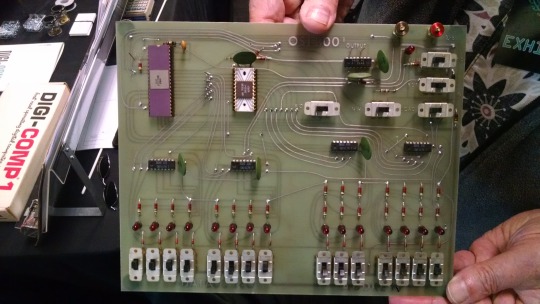

Grant's design in turn can be best described as a distilled, modernized version of the OSI Challenger series of computers. Here's an OSI-400 and a Challenger 4P respectively:

The left one is a replica of the 400 circa 1976, also called the Superboard. It was affordable, endlessly reconfigurable and hackable, but ultimately very limited in capabilities. No BASIC, minimal monitor ROM you talk to over serial, but you could connect it to a bus to augment its features and turn it into a more powerful computer.

Whereas the OSI C4P on the right from about 1979 has more RAM, a video card, keyboard, BASIC built in, serial interface, cassette tape storage, and that's just the standard configuration. There was more room to expand and augment it to your needs inside the chassis (alot changed in 3 years for home computer users).

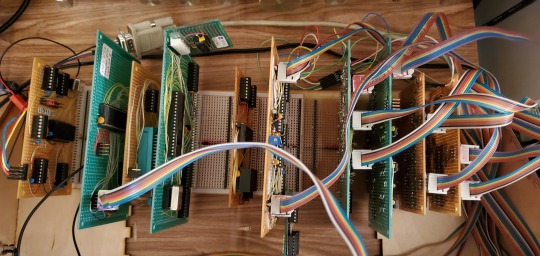

Grant's minimal 6502 design running OSI BASIC is a good starter project for hobbyists. I learned about the 6502's memory map decoding from his design. I modified and implemented his design on a separate cards that could connect to a larger backplane.

Here are the serial, ROM, RAM, and CPU cards respectively:

Each one is 100% custom, containing many modifications and fixes as I developed the design. However, that's only half of the computer.

I really wanted a 6502 machine with a front panel. People told me "nobody did that", or couldn't think of examples from the 1970s but that seemed really strange to me. Especially since I had evidence to the contrary in the form of the OSI-300:

This one I saw at VCF West back in 2018 illustrates just how limited of a design it is. 128 bytes of RAM, no ROM, no serial -- just you, the CPU, and toggle switches and LEDs to learn the CPU. I was inspired the first time I saw one in 2015 at VCF East, which is probably when this whole project got set in motion.

Later that year I bought a kit for a miniature replica OSI-300 made by Christopher Bachman, and learned really quickly how limited the design philosophy for this particular front panel was. It was a major pain in the ass to use (to be clear, that's by OSI's choice, not any fault of Christopher in his implementation)

So... I designed my own. Took awhile, but that's the core of what the Cactus is: my attempt at experiencing the 1970s homebrew scene by building the computer I would have wanted at the time. Over half of the logic in the Cactus is just to run the front panel's state machine, so you can examine and modify the contents of memory without bothering the 6502. I added in all of the things I liked from more advanced front panels I had encountered, and designed it to my liking.

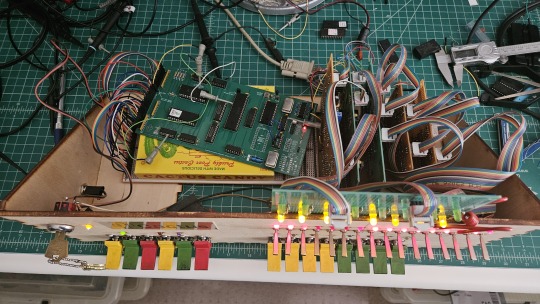

Here's the original front panel, accompanying logic, and backplane connected to the modern single board computer (SBC) version of the machine:

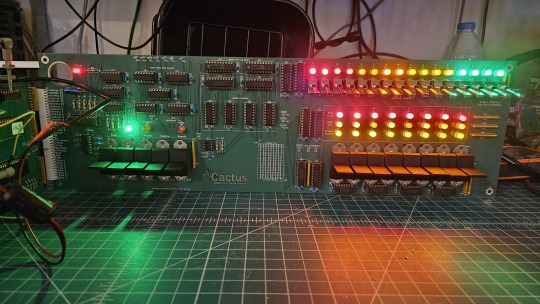

And here's the new Cactus SBC working with the new front panel PCB, which combines the logic, physical switch mountings, and cabling harnesses into a single printed circuit board.

So, what can you do with it? Pretty much the same things I do already with other contemporary 1970s computers: play around in BASIC, fire up the occasional game, and tinker with it.

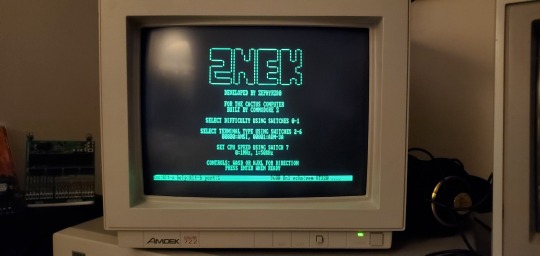

I've got no permanent storage designed for the Cactus as yet, it's been one of those "eventually" things. The good news is that a variety of software can be ported to the hardware without too much trouble for an experienced hobbyist. A friend of mine wrote a game called ZNEK in 6502 assembly which runs from a terminal:

Right now, you have to either toggle in machine programs from the front panel from scratch, burn a custom ROM, or connect it to a serial terminal to gain access to its more advanced features:

Here's it booted into OSI BASIC, but I have also added in a modern descendant of Steve Wozniak's WOZMON software for when I need to do lower level debugging.

I've also got a video card now, based on the OSI-440. I have yet to implement a keyboard, or modify BASIC to use the video board instead of the serial connection. Even if I did, screen resolution is pretty limited at 24x24 characters on screen at once. Still, I'm working on that...

Anyway, I hope that answers your question. Check the tags below to see the whole process stretching back to 2017 if you're curious to learn more of the project's history. I'm also happy to answer any more questions you might have about the project.

267 notes

·

View notes

Text

Inspired by nature: Leaftronics pave way for biodegradable electronics

A research team headed by Prof. Karl Leo at TUD Dresden University of Technology have developed an innovative, nature-inspired solution that could revolutionize the electronics industry: "Leaftronics." This innovative approach leverages the natural structure of leaves to create biodegradable electronic substrates with enhanced properties and offers a sustainable, efficient, and scalable solution to the global-waste problem. These findings have now been published in the journal Science Advances. Electronic devices, from toys to smartphones, consist of circuits. Specific substrates are used to manufacture these circuits. In commercial electronics, these are printed circuit boards (PCBs) made of glass fiber-reinforced epoxy resin.

Read more.

#Materials Science#Science#Biomaterials#Electronics#Plants#Dresden University of Technology#Biodegradable

14 notes

·

View notes

Note

Hi, I'm the human who got trapped inside a TARDIS.

Thank you for the help, I managed to open the interior doors a few days ago and went looking for the owner. No luck, but I found a swimming pool, a huge library, kitchens, bathrooms, bedrooms, science labs, entertainment rooms and what seems to be a huge park?

I don't know how on Earth something like this can even exist, but I guess there's all the time in the world to learn while waiting for rescue. I'm worried about the pilot though; isn't there a way to locate them, given how advanced this craft is?

Hi there, trapped human! Let's address your concerns about the pilot.

How to locate a TARDIS pilot

Do not attempt to operate the TARDIS flight controls without being absolutely sure it is safe. On earlier models, use of the console without a Symbiotic Nucleus may result in injury or a very slow and painful death.

Note: Most of the systems are in Gallifreyan. TARDISes do not tend to translate Gallifreyan, so you may not be able to read them.

Here are some methods you can try:

📡 Stattenheim Remote Teleport Control: Look for a small black disc stored in a transparent dome on the console. If properly calibrated, pressing this button may immediately transport you to the pilot. If it's not there, the pilot has taken it, or the TARDIS doesn't have the Mark X refit.

⏪ Fast Return Switch: This will return the TARDIS to an approximate time and location near where it last landed. It's clearly labelled on the console. Turn it clockwise to operate. [Use with caution]

📍 Locate the Doctor: Some models may have this feature. It is activated by pressing a button on the console labelled 'LTD' (your TARDIS may have another personalised variation). The Visual Display Unit will show the pilot's relative position on a map.

🧬 Passenger Adoption Scanning Terminal (PAST): This system registers and protects passengers. Due to how it works, if you’re registered, the pilot is likely still on board.

👥 Internal Monitor: A Mark II TARDIS can detect the number of sapient life forms onboard and display it on the Internal Monitor.

💻 The Scanner: The Scanner can locate the pilot's biodata within a two-mile radius outside the TARDIS. Some pilots have a preprogrammed switch by the scanner that will instantly display their pilot's location, but this is a modified feature.

🎤 Voice Interaction: Try speaking to the TARDIS. Some models respond to vocal commands for minor systems. If the TARDIS doesn’t respond, your voice print registration is required.

🔍 Artron Telepathic Radiation: If you find another Time Lord, they can scan for the pilot's ‘thumbprints’ left by their symbiotic nuclei to identify them.

🛠️ Cloister Room: This room contains telepathic circuits to communicate with the pilot, possibly providing an audiovisual link. It's accessible via a shortcut in the Secondary Control Room. Be cautious, as this room may have minor effects on your nervous system.

🚨 Extreme Emergency Lever: Crew members can use this lever to lock onto a pilot drifting in space and materialise around them.

🗝️ TARDIS Key: Use a key to locate anyone processed by the PAST (such as other crew members). Mix their blood with saline solution, coat the key, and suspend it in clear oil. The oxidised blood particles will 'point' in their direction.

🧠 Memory Store: Stores memories of TARDIS occupants, including audio-visual recordings of the Control Room. Useful to identify the pilot and the last time they were there.

💉 Medical Bay: The Automatic Diagnostic Terminal usually uses the pilot's avatar to communicate. You may be able to ask the avatar their identity, although responses may be limited.

If you need to take emergency action:

There is an 🚪Emergency Door located in the Power Stacks Room, leading outside. The 🚨 Fail-Safe Switch locks the TARDIS onto the nearest habitable environment, creating emergency doors. The 🆘 Emergency Emergency System (so emergent they named it twice) creates a wormhole to the nearest habitable planet. This is one way only, so there is no return to the TARDIS afterwards.

💀 Pilot Death & TARDIS Adoption

Usually, emergency systems will try to lock onto the pilot. If this is not happening, the pilot may have died without regeneration. TARDISes will normally go into a period of mourning following the death of their pilot, possibly involving a loss of power or shut down of many systems.

If you're finding systems are not shut down but have increasing suspicions the pilot may have died, this could be because:

The TARDIS has already gone through its period of mourning;

It has reactivated at your presence, hoping to establish a link with you;

It didn't really like its pilot very much.

It's not unheard of for humans to forge a bond with the TARDIS, especially if it's been left alone for some time. The TARDIS might be adopting you as its new caretaker, which would explain the access you've been granted. Some clues:

🎁 TARDISes sometimes leave gifts to welcome new arrivals. Look around for anything unusual or out of place.

💭 If you feel any strong intuitive pushes or thoughts, it might be the TARDIS trying to communicate with you.

🔑 If you're finding you have access to a lot of the TARDIS (including intricate systems), the TARDIS definitely likes you.

🏫 So ...

To locate the pilot or other crew members, try any of the procedures outlined above. Be sure to familiarise yourself with the main areas and secure access to food, water, and other necessities. The TARDIS can help—look for glowing arrows or symbols on the walls. These can lead you to important areas. Remember, the TARDIS is a complex and sentient machine. If it has adopted you, it will do its best to keep you safe, and it has a plethora of effective automated defences to achieve this.

Related:

🤔|🧬🛸What's the link between a Time Lord and their TARDIS?

💬|🧬🛸How does TARDIS symbiosis work for individuals and groups?: Details on this special Time Lord-TARDIS connection.

💬|🧬🛸How long can a bonded Time Lord be away from their TARDIS?: If extended absences can impact symbiosis, and also annoy your TARDIS.

Hope that helped! 😃

Any orange text is educated guesswork or theoretical. More content ... →📫Got a question? | 📚Complete list of Q+A and factoids →📢Announcements |🩻Biology |🗨️Language |🕰️Throwbacks |🤓Facts → Features: ⭐Guest Posts | 🍜Chomp Chomp with Myishu →🫀Gallifreyan Anatomy and Physiology Guide (pending) →⚕️Gallifreyan Emergency Medicine Guides →📝Source list (WIP) →📜Masterpost If you're finding your happy place in this part of the internet, feel free to buy a coffee to help keep our exhausted human conscious. She works full-time in medicine and is so very tired 😴

#gallifrey institute for learning#dr who#dw eu#ask answered#whoniverse#doctor who#gallifreyan culture#tardis#GIL: Asks#GIL: Biology/Foundations#GIL: Biology#GIL: Species/TARDISes#GIL: Species/Gallifreyans#GIL: Gallifrey/Technology#GIL

27 notes

·

View notes

Text

Giving Tuesday – KiCad open-source design #GivingTuesday 💻🔧🌍❤️🤝

KiCad is an open-source software suite for electronic design automation (EDA), enabling users to design schematics and printed circuit boards (PCBs). KiCad is a great, free, open tool for creating complex designs, from hobbyist projects to professional-grade hardware. As an open-source initiative, KiCad promotes accessibility and collaboration, making advanced EDA tools freely available. Supporting KiCad helps the development of features, bug fixes, and community-driven improvements, empowering engineers, educators, and hobbyists worldwide. Consider donating to KiCad to strengthen the open-source hardware community and help make high-quality EDA tools accessible to everyone.

In the past year, they posted this nifty chart that shows what your support can help accomplish.

If KiCad is valuable to you, please consider donating to help make it even better.

#kicad#kicadpcb#electronics#eda#schematic#pcbdesign#pcblayout#opensource#edatools#openhardware#donatetoday#engineeringdesign#communitysupport#openedsystems#opensourcecommunity#pcbtools#givingback#generositymatters#techforgood#makercommunity#electronicsdesign#designsoftware#kicaddonation#hardwaredesign#opensourceinitiative#techcommunity#sharekindness

11 notes

·

View notes

Text

Excerpt from this story from Anthropocene:

In a new spin on green electronics, researchers have made a biodegradable electronic circuit board from tree leaves. Such leaf-based electronics, or “leaftronics” as the team from Dresden University of Technology (TU Dresden) has dubbed it, could reduce millions of tons of waste that humans produce every year.

Today, the world produces over 50 million metric tons of electronic waste a year. That number that is slated to double by 2050. And printed circuit boards (PCBs) – the flat boards onto which all the circuit chips, wires and other components of an electronic gadget are soldered–-constitute a big share of this e-waste.

PCBs are typically made of fiberglass or a composite plastic. The material is difficult to recycle and is usually either dumped in landfills or burned to separate the valuable metals for reuse.

As detailed in the journal Science Advances, the team used the veiny, webbed skeleton of leaves to create their biodegradable substrates. This fine branched structure is made of the same lignocellulose compounds that give its toughness. Postdoctoral researcher Rakesh Nair and colleagues started by stripping away the cells of a magnolia leaf to leave behind the white veined skeleton. They dipped the scaffold into ethyl cellulose, a tough biodegradable polymer.

The resulting leaftronics substrate is smooth, flexible, transparent, and can handle high temperatures. In that sense it rivals plastic and glass, Nair says, but is biodegradable. The researchers could use a laser to cut the substrate, print circuits on it, as well as solder electronic components on top.

To degrade the substrate, the researchers placed it in an ultrasonic acid bath to remove the metals and circuit components. The boards began to degrade after about a month in compost.

“Up until now, substrates made of biodegradable polymers could not be used for electronic device or circuit fabrication, since they naturally do not handle elevated temperatures well,” Nair says. There are ways to improve the thermal and mechanical properties of biodegradable polymers. But, he says, they “often result in these polymers either no longer being biodegradable or requiring complex, high carbon-footprint, chemical processes,” he says.

Others have also made degradable PCBs using paper, silk, and mushroom skins. But the new method that relies on dipping a leaf scaffold in a biodegradable polymer is much simpler and should allow researchers to make specific biodegradable substrates with superior properties.

6 notes

·

View notes

Text

Exterminator

Gottlieb has always been a household name in the field of pinball tables and amusement machines, but much less so in the world of arcade coin-ops, where they are only remembered for Q*bert. The swearing orange weirdo is still fairly recognizable to this day, but all of Gottlieb’s few other coin-ops have been forgotten, despite getting made during the “golden age of arcades” and being well-regarded at the time. Exterminator, their very last one, released under the Premier Technology company (the only one that ever appeared under that brand, which was specialized in pinball tables),was designed and programmed mostly by Warren Davis, the same developer behind Q*bert. Despite this, it never was a big hit with arcade owners or gamers. That might have to do with the machine having a complex custom printed circuit board, designed to handle the game’s advanced graphics, that broke often. Or the fact that the dedicated cabinet was produced in only around 250 copies, while conversion kits were way more popular. Or maybe because it was such a dang weird game.

Read more...

#hardcore gaming 101#federico tiraboschi#review#exterminator#arcade#atari st#commodore 64#commodore amiga#ibm pc#shoot em up#unique visuals#zx spectrum#gottlieb#video games#retro games

14 notes

·

View notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Text

Advanced PCB Manufacturing Cost Effective Solutions Partnership

Introducing a one-stop solution for all your advanced PCB manufacturing needs such as rigid-flex pcb. We're not just a provider; we're your partner in innovation, serving customers globally with top-notch fabrication, solutions, and services. Join our Advanced PCB Manufacturing cost effective solutions for USA, EU, Germany, Switzerland.

#Advanced pcb#pcb manufacturer#usa#europe#germany#switzerland#technology#printed circuit board#affiliate program#partnership#electronic

1 note

·

View note

Text

Understanding Circuit Board Electronic Components: A Comprehensive Guide

In today's digital world, electronic devices have become an essential part of our daily lives. But what makes these devices tick? At the heart of every electronic device lies a circuit board—a masterpiece of tiny electronic components working together to perform complex tasks. In this article, we’ll dive deep into the fascinating world of circuit board electronic components, exploring each element’s role and how they contribute to the overall functionality of the device.

What is a Circuit Board?

A circuit board, often referred to as a PCB (Printed Circuit Board), is a flat board used to mechanically support and electrically connect various electronic components. These components work in unison to perform a specific task. Think of the circuit board as the skeleton and nervous system of an electronic device—it holds everything together and allows communication between parts.

Types of Circuit Boards

Single-sided PCB: Has one layer of conducting material.

Double-sided PCB: Contains two layers for components and connections.

Multi-layer PCB: Complex boards with multiple layers for advanced applications.

The Role of Electronic Components on a Circuit Board

Every electronic device you interact with is powered by a carefully designed circuit board filled with various components. These components might be tiny, but each one has a critical role in the operation of the device. Here's a breakdown of the most important electronic components you’ll find on a typical circuit board.

1. Resistors

Resistors are fundamental components that control the flow of electrical current. They resist the flow of electrons, hence the name "resistor." Their primary function is to reduce current flow, adjust signal levels, and divide voltages in a circuit. Without resistors, circuits would allow too much current to flow, potentially damaging other components.

Types of Resistors

Fixed resistors: Have a set resistance value.

Variable resistors: Allow adjustment of the resistance.

2. Capacitors

Capacitors store and release electrical energy in a circuit. They are often compared to small rechargeable batteries that quickly charge and discharge. Capacitors help smooth out fluctuations in voltage, filter noise, and store energy for future use.

Common Uses of Capacitors

Energy storage

Signal filtering

Voltage stabilization

3. Inductors

Inductors are components that store energy in a magnetic field when electrical current flows through them. They resist changes in current and are typically used in circuits to filter signals, manage power, and store energy.

Applications of Inductors

Power supplies

Radio frequency circuits

Noise suppression in circuits

4. Diodes

A diode is like a one-way valve for electricity, allowing current to flow in only one direction. They are vital in circuits to prevent reverse currents, which can damage components.

Types of Diodes

Light-emitting diodes (LEDs): Produce light when current flows through.

Zener diodes: Regulate voltage within a circuit.

5. Transistors

The transistor is a versatile component used to amplify or switch electronic signals. In essence, transistors are like tiny switches that turn signals on and off rapidly, making them essential in modern electronics.

Types of Transistors

NPN transistors: Allow current flow when a small voltage is applied to the base.

PNP transistors: Conduct when the base is negatively charged.

How Circuit Board Components Work Together

In a circuit, each component has a specific role, and together they form a cohesive system. For example:

Capacitors and resistors may work together to filter signals or smooth out voltage fluctuations.

Transistors and diodes ensure that signals are amplified or directed properly.

Integrated circuits handle the complex tasks, processing data, and controlling the overall system.

Choosing the Right Components for Your Circuit Board

When designing or repairing a circuit board, choosing the correct components is crucial. Some factors to consider include:

Voltage requirements

Power consumption

Signal type and frequency

Physical size and compatibility

Conclusion

Circuit boards are an integral part of any electronic device. The various components on the board each play a specific role in ensuring the device functions as intended. Understanding these components, from resistors to integrated circuits, is essential for anyone working with electronics, whether you're designing a new system or troubleshooting an existing one.

2 notes

·

View notes

Text

Explore the transformative impact of Advanced PCB Technology on modern electronics with A-Gas Electronic Materials. Dive into the evolution, significance, and future of PCBs in our latest article. Discover how PCBs are reshaping industries from consumer electronics to healthcare. Join the revolution and partner with A-Gas for cutting-edge electronic solutions. Read more now!

#Advanced PCB Technology#Modern Electronics#A-Gas Electronic Materials#Printed Circuit Boards#Electronic Components#PCB Evolution

0 notes

Text

PCB Manufacturing in Toronto: Expertise, Services, and Local Industry Insights

Discover PCB manufacturing in Toronto, a hub of innovation and quality in electronic manufacturing services. Learn about the specialized capabilities, technological advancements, and diverse offerings of PCB manufacturers Toronto. Explore how local expertise and cutting-edge facilities contribute to producing high-quality printed circuit boards for various industries and applications worldwide. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

2 notes

·

View notes

Text

Elevating Industry Standards: PVDF Materials by Petron Thermo Plast

In the dynamic landscape of industrial materials, Polyvinylidene Fluoride (PVDF) emerges as a standout choice, renowned for its exceptional properties and diverse applications. Petron Thermo Plast, a leading manufacturer in the field, specializes in delivering top-tier PVDF Materials crafted to surpass industry expectations. This blog meticulously explores the features, benefits, and applications of PVDF materials by Petron Thermo Plast, showcasing why they are the preferred solution for professionals worldwide.

Unveiling PVDF Materials

PVDF materials represent a pinnacle of innovation, characterized by their remarkable chemical resistance, thermal stability, and mechanical strength. Petron Thermo Plast’s PVDF materials are engineered with precision to offer unparalleled performance across a multitude of industrial settings.

Key Attributes of PVDF Materials

1. Chemical Resistance:

PVDF materials exhibit exceptional resistance to a wide spectrum of chemicals, including acids, bases, and solvents, making them ideal for corrosive environments.

2. Thermal Stability:

With a high melting point and remarkable heat resistance, PVDF materials maintain their integrity even under extreme temperatures, ensuring reliability in demanding conditions.

3. Mechanical Strength:

PVDF materials boast high tensile strength and durability, enabling them to withstand mechanical stress and pressure, thus guaranteeing longevity in challenging applications.

4. Low Permeability:

The low permeability of PVDF materials to gases and liquids prevents leakage, making them suitable for applications requiring excellent barrier properties.

5. Weatherability:

PVDF materials exhibit exceptional weather resistance, making them suitable for outdoor applications where exposure to UV radiation and harsh weather conditions is common.

6. Non-Toxicity:

PVDF materials are non-toxic and safe for use in applications involving potable water and food processing, adhering to stringent health and safety standards.

Applications of PVDF Materials

PVDF materials by Petron Thermo Plast find extensive applications across diverse industries:

Chemical Processing: Used for fabricating pipes, fittings, and linings in chemical plants due to their resistance to corrosive chemicals.

Construction: Employed in architectural cladding, roofing, and facades for their durability and weather resistance.

Electronics: Utilized in printed circuit boards and semiconductor manufacturing for their electrical insulation properties.

Transportation: Applied in aerospace and automotive industries for interior and exterior components due to their lightweight and high strength-to-weight ratio.

Medical: Used in medical equipment and devices requiring sterilizability and chemical resistance.

Advantages of Choosing Petron Thermo Plast

Advanced Manufacturing Techniques:

Petron Thermo Plast employs cutting-edge manufacturing processes and rigorous quality control measures to ensure PVDF materials meet the highest standards.

Customization Options:

The company offers PVDF materials in various formulations, sizes, and colors to meet specific customer requirements.

Expert Technical Support:

Comprehensive technical support and guidance are provided to assist customers in selecting the right PVDF materials and ensuring proper integration into their projects.

Sustainability Commitment:

Petron Thermo Plast is committed to sustainable manufacturing practices, ensuring their PVDF materials are environmentally friendly and compliant with global standards.

Why Choose PVDF Materials from Petron Thermo Plast?

Investing in PVDF materials from Petron Thermo Plast guarantees superior quality, reliability, and performance. Here are some compelling reasons to choose Petron Thermo Plast:

Unmatched Quality: PVDF materials from Petron Thermo Plast adhere to the highest quality standards, ensuring consistency and reliability.

Tailored Solutions: With a wide range of formulations and customization options available, you can find the perfect PVDF material for your specific application.

Technical Expertise: Petron Thermo Plast provides expert technical support to guide you through every stage, from material selection to project completion.

Sustainability: By choosing PVDF materials from Petron Thermo Plast, you are supporting environmentally friendly manufacturing practices and contributing to a greener future.

Conclusion

PVDF materials by Petron Thermo Plast redefine excellence in the industrial sector. Their unparalleled properties, reliability, and versatility make them indispensable across various industries. Choose Petron Thermo Plast for PVDF materials that exceed your expectations and elevate your projects to new heights of success.

#pvdf material#engineering plastics#pvc ball valve#pvc butterfly valve#pvdf pipe#explore#union ball valve#hdpe pipe fittings

2 notes

·

View notes