Don't wanna be here? Send us removal request.

Text

When Should You Choose Turret Punching Over Laser Cutting?

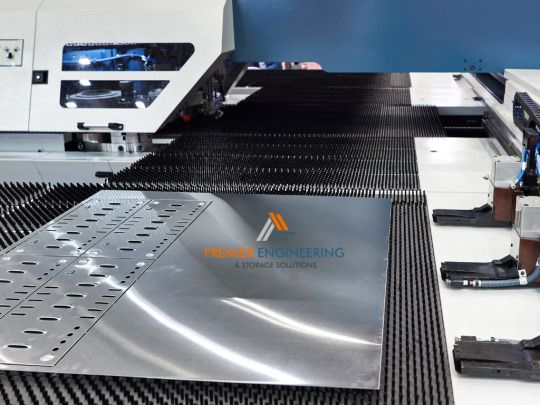

Turret punching services use a special machine with a rotating tool turret that punches holes or shapes into sheet metal. Each turret holds different tools for cutting, forming, or shaping metal. The sheet moves under the punch, and the tool presses down to make a clean, quick cut. It’s a mechanical process that’s especially fast for repeating patterns or producing the same shapes again and again.

Unlike laser cutting, turret punching doesn’t rely on heat or melting. It uses physical force, which can make it more efficient for certain projects—especially when you want forms like dimples, louvers, or countersinks that a laser can’t do easily.

Is it faster or more affordable than laser cutting?

For many jobs, yes. turret punching services are often faster and more affordable when the design includes standard shapes like circles, rectangles, or slots. Since tools are preloaded in the turret, switching between shapes takes seconds. This makes it ideal for medium to high production runs where time and cost are important.

In contrast, laser cutting offers more design freedom and can handle very intricate cuts, but it might take longer and cost more per part—especially if you're not running large volumes. So, if you're working on high-volume orders with simple shapes, turret punching is often the smarter choice.

turret punching is also gentler on power usage and doesn’t require expensive optics or gases. That means more savings, especially for long-term production.

When Do Metal punching services Make More Sense for Your Project?

Is punching better for mass production?

Yes, Metal punching services are a great fit for large-volume jobs. If your design includes many repeated shapes or holes—like in ventilation panels or control boxes—turret punching offers fast production with consistent results. It’s much quicker than laser cutting when dealing with the same pattern over and over.

Can you get clean results with metal punching?

Absolutely. Metal punching creates crisp, clean edges, especially in aluminum, stainless steel, and mild steel sheets. When done by experienced operators, the result is just as professional-looking as laser-cut work—sometimes even better for basic forms.

What Are the Best Materials and Thicknesses for turret punching services?

Can turret punching handle thick or coated sheets?

Yes, but there are limits. turret punching services work best on thin to medium-thickness metal sheets—typically up to about 6mm, depending on the machine and tooling. If the material is too thick, laser or waterjet cutting may be more efficient. But for coated or galvanized metals, turret punching often outperforms lasers by avoiding unwanted burns or marks.

What metal types work best?

Mild steel, stainless steel, and aluminum are all perfect for turret punching. These materials are strong enough to hold shape but flexible enough for clean cuts and formed features like bends and embossing.

Can You Still Get Complex Shapes with turret punching services?

Are rounded or slotted designs possible?

Yes. turret punching can produce rounded edges, slots, keyholes, and even hex patterns using the right tooling. While it may not achieve the super fine detail of a laser, it handles most common design needs with ease and speed.

What about louvers or embossed parts?

That’s one of turret punching’s strengths. It can form shapes—not just cut them. That means you can create louvers for airflow or emboss text for part IDs, something laser cutting doesn’t do easily. If your part needs texture or depth, turret punching is the way to go.

How Does turret punching Work with a sheet metal press brake?

Can parts be cut and bent in one workflow?

Yes. After using turret punching services to cut holes or notches, many companies move the parts straight to a sheet metal press brake for bending. This forms the metal into angles, flanges, or enclosures—perfect for boxes, panels, and structural parts.

What’s the advantage of pairing both?

The real benefit is efficiency. You can go from a flat metal sheet to a formed, usable part quickly and accurately. For full production capabilities—including laser cutting, cnc punching, and bending—many businesses turn to trusted names like Premier Engineering & Storage Solutions. They offer complete manufacturing workflows, including turret punching services, Metal punching services, sheet metal press brake, Shelving Units and Storage Cabinets, and Machining, all under one roof. It’s the one-stop solution for custom fabrication.

What Role Do turret punching services Play in cnc sheet metal fabrication?

Is turret punching part of a CNC system?

Yes. Modern turret punches are CNC-controlled, meaning they follow digital design files with high accuracy. That makes turret punching services an essential part of cnc sheet metal fabrication workflows.

How do turret punches help in mass fabrication?

They reduce waste, increase repeatability, and allow for continuous production. When your fabrication process includes punching, forming, and bending—all controlled by software—you get faster turnarounds and consistent parts every time.

How Do You Choose Based on engineering manufacturing and fabrication capabilities?

Should you choose based on your supplier’s equipment?

Definitely. Some shops are better equipped for laser cutting, while others specialize in turret punching. Look at your design needs, material type, and budget, then match those with a supplier’s engineering manufacturing and fabrication capabilities.

What if your design needs both laser and punching?

Many complex jobs do. That’s why some companies offer hybrid solutions—using turret punching for large areas and laser cutting for fine details. Talk to your supplier about combining techniques. The right team will know how to get the best of both worlds.

#laser#cnc machining#cnc punching#engineering#welding#metal press#laser cutting australia#lasercutting#metal fabrication#engineering manufacturing

1 note

·

View note

Text

What’s the Difference Between CNC and Manual Steel Cutting Methods?

Manual steel cutting is the traditional way to cut metal using handheld tools or simple machinery. This method relies heavily on the skill and physical effort of the worker. Tools like hacksaws, angle grinders, cutting torches, and mechanical shears are commonly used on-site.

These tools are ideal for basic or smaller cuts. Workers measure and mark the steel by hand, then cut along the lines using these tools. This method is usually slower and needs careful control to get a straight or clean cut. It can also produce more rough edges, especially on thicker or harder materials.

Even when an industrial steel cutting machine is not available, experienced workers can still get the job done using manual techniques. But it takes time, attention to detail, and the right safety gear.

When Manual Cutting Is Still Common on Worksites

Manual cutting is often used on construction sites, small workshops, and during urgent repair jobs. It’s handy when you need to make a quick adjustment or when there’s no power source for heavy machinery. It's also used when only one or two small pieces need trimming and setting up a CNC machine would be overkill.

However, while it gets the job done, it can be slower, less accurate, and more physically demanding than using a machine. That's why many professionals now prefer more advanced options like cnc cutting services or laser cutting, especially for jobs that need speed, accuracy, and consistency.

What Is a CNC Industrial Steel Cutting Machine?

How Computer Programs Control Cutting Precision

A CNC industrial steel cutting machine uses computer software to guide its movements. CNC stands for Computer Numerical Control. This means that the entire cutting process is pre-programmed for accuracy. The operator enters a design into the machine, and the CNC system follows the exact path, cutting the metal with precision that’s nearly impossible to match by hand.

The cutting tools move smoothly across the material, guided by the program. This removes the chance of human error and ensures the same result every time. It’s a game-changer for industries that need reliable parts made to tight tolerances.

Why cnc cutting services Are Widely Used in Modern Fabrication

Cnc cutting services are now standard in many workshops and factories. They're perfect for cutting complex shapes or repeating a design across multiple pieces. Whether you're working with steel, aluminium, or cnc stainless steel, CNC technology allows you to get the job done faster and with less waste.

CNC machines are often used for sheet metal fabrication, signage, construction materials, and more. For businesses that want to deliver high-quality work, CNC machines offer speed, safety, and accuracy.

How Does Laser Cutting Fit Into the CNC Process?

What Makes Laser Cutting Different from Other Methods

Laser cutting is one of the most precise methods available today. Instead of using a blade or a drill, it uses a focused laser beam to cut through metal. It works well on both thin and thick sheets of steel and leaves clean, polished edges that usually don’t need additional work.

Laser technology is often part of a CNC system, combining the benefits of both. The laser is controlled by software, allowing for detailed patterns, curves, and angles to be cut with minimal effort.

When to Use a Laser Cutting Service for Sharp, Clean Cuts

A laser cutting service is the best option when you need very accurate, smooth cuts—especially on decorative pieces, signs, or parts with tight corners. It's also great for cutting cnc stainless steel, which is tough and can dull traditional blades quickly.

If the goal is detail and a smooth finish, laser is the way to go. It's fast, clean, and reduces the need for post-cutting clean-up or grinding.

Which Method Is More Accurate and Consistent?

Why cnc stainless steel Cutting Delivers Precise Results

When working with cnc stainless steel, accuracy is crucial. CNC machines don’t rely on a steady hand—they follow programmed instructions to the millimetre. The result is a consistent finish across all pieces. This is especially useful when working with strong materials like stainless steel that demand precision.

Laser or CNC systems also reduce waste because they maximise the use of your material. Less scrap means better efficiency and lower costs for large projects.

Common Errors Found in Manual Jobs vs. CNC Projects

Manual cutting can lead to mistakes like uneven edges, poor fit, and wasted material. It’s hard to repeat the same result over and over. In contrast, CNC and laser cutting eliminate most of these problems. The software guides the cut, reducing human error and increasing productivity.

What About Speed and Efficiency—CNC or Manual?

How Automated Tools Save Time on Repeat Jobs

Using an industrial steel cutting machine like a CNC system speeds up the entire process. Once the design is set, the machine can keep producing identical parts quickly. No need to stop and measure every time. This is a big benefit for manufacturers handling large orders or tight deadlines.

Manual cutting takes more setup, more measuring, and more effort. That makes it slower and less efficient, especially for complex or repeat work.

Why CNC Systems Help Meet Tighter Project Deadlines

Businesses that need to stick to a strict timeline rely on automation. That’s where Premier Engineering & Storage Solutions comes in. They provide services like cnc cutting services, laser cutting service, cnc stainless steel, and full access to an industrial steel cutting machine setup. Whether you need a quick turnaround or detailed parts, their expert team ensures your job is done right and on time.

What Skills and Tools Are Needed for Each Cutting Method?

What Operators Need to Know for Manual vs. CNC Work

Manual cutting requires a steady hand, a good eye, and plenty of experience. Workers need to understand steel behaviour, tool handling, and safety. On the other hand, CNC operators focus more on computer work. They need to understand software, design files, and how to maintain the machines.

Both methods need skill, but CNC tends to be more technical, while manual work is more hands-on.

How Training Differs Between Old-School and High-Tech Cutting

Manual training focuses on tool use and safety. CNC training includes learning software, understanding coordinates, and adjusting machine settings. Technicians may also need to know how to change tools, calibrate machines, and read technical drawings.

The learning curve for CNC might be steeper, but once you’re trained, the process is much faster and more efficient.

Which Option Is Right for Your Next Steel Project?

When to Choose CNC, Laser Cutting, or Manual Methods

Manual methods work for one-off jobs, simple repairs, or projects in tight spaces. But for precision, speed, and scale, cnc cutting services or laser cutting are the better choice. If your job involves detailed designs, or you need consistent quality, CNC and laser will save you time and money.

Projects involving cnc stainless steel or large quantities of parts benefit the most from machine accuracy.

How to Decide Based on Project Size, Budget, and Detail

Think about your project: Is it a one-time fix or a bulk production run? Does the steel need tight angles or curves? Are you on a budget, or do you need top-tier quality? These answers will guide you.

For most professional jobs today, CNC and laser cutting service options offer the best mix of quality and value—especially with trusted providers like Premier Engineering & Storage Solutions ready to assist.

#laser#cnc machining#cnc punching#welding#engineering#manufacturer#laser cutting australia#lasercutting#precision machining#steel cutting australia

0 notes

Text

How Accurate Are Turret Punching Services Compared to Other Methods?

Turret punching services are a popular choice for shaping and cutting sheet metal. They use a machine called a turret punch press, which holds multiple punching tools on a rotating disc—called a turret. Each tool is used to stamp different shapes like holes, slots, or cutouts into the metal.

The beauty of turret punching lies in its speed and versatility. With a single setup, the machine can switch between tools automatically, allowing it to punch various patterns without needing to stop. This is what makes Metal punching services using turret presses perfect for both custom parts and high-volume production runs.

The Role of Punch Tools and CNC Programming

Modern turret punching services rely heavily on CNC technology. CNC stands for “Computer Numerical Control.” This means the machine’s movements and tool selections are controlled by a programmed set of instructions—making the process both precise and repeatable.

The tools in the turret vary in shape and size. Each tool is designed to make a specific cut or feature in the sheet metal. Thanks to CNC programming, the machine knows when to rotate the turret and which tool to use based on the design file you provide (usually a DXF or DWG file).

In many workshops, turret punching operates side by side with a cnc cutting machine to cover different types of jobs. While laser and plasma machines offer extreme cutting precision, turret presses shine in jobs that need repeated punches, fast output, and formed features.

What Is Considered “Accurate” in Metal Fabrication?

Defining Tolerances and Repeatability in Metal Punching Services

In the world of Metal punching services, accuracy is all about achieving tight tolerances—how close the final cut or hole is to the intended design. In most sheet metal work, accuracy is measured in millimetres or even fractions of a millimetre. The smaller the tolerance, the higher the precision.

Turret punching services often maintain tolerances within ±0.1 mm, depending on the tool condition and material. That level of precision is usually more than enough for most commercial and industrial applications like control panels, enclosures, or HVAC components.

Why Precision Matters for Part Fit, Assembly, and Appearance

Even a tiny variation can cause a part to fit poorly, interfere with other components, or affect the look of a finished product. That’s why accuracy in cnc punching service work isn’t just a technical requirement—it’s key to saving time during assembly and ensuring a clean, professional result.

Different industries require different tolerance levels. Aerospace and electronics may demand stricter accuracy than, say, general construction parts. A quality punching service understands how to adjust accordingly.

How Accurate Are Turret Punching Services in Real Jobs?

Typical Tolerances Achieved in Turret Punching Services

When done right, turret punching services can consistently deliver high accuracy across long runs of parts. With well-maintained tools and correct machine calibration, tolerances of ±0.1 to ±0.2 mm are typical. That’s more than sufficient for most sheet metal jobs in fabrication, signage, or electrical enclosures.

Consistency is where turret punching shines. Because the same tool and path are used repeatedly under CNC control, every part is virtually identical.

Comparison of Manual vs CNC-Based CNC Punching Service

Manual punching, though still used in basic workshops, can’t match the speed or repeatability of a cnc punching service. Manual methods depend on the operator’s skill and can lead to human error. CNC-controlled turret punches eliminate that guesswork.

Professional workshops like Premier Engineering use advanced CNC punching machines to handle everything from one-off prototypes to bulk runs. They rely on skilled operators and high-end equipment to ensure your parts are accurate, clean, and ready for use—saving you time on rework or adjustment.

Turret Punching vs CNC Cutting Machine: Which Is More Precise?

Overview of CNC Cutting Machine Precision

A cnc cutting machine—especially one using laser or waterjet—can cut with extremely fine detail. For very intricate or sharp-edged designs, CNC cutting might offer slightly tighter tolerances. However, it also tends to be more expensive for certain part types.

When Turret Punching Delivers Equal or Better Results

For parts with repetitive features like holes, slots, or vents, turret punching often matches or outperforms cutting in terms of both speed and cost. It’s particularly efficient when multiple features are needed on a single part.

Choosing between turret punching services and a cnc cutting machine depends on your specific design, material, and budget. Often, combining both in a hybrid workflow delivers the best of both worlds.

What Kind of Designs Work Best with Turret Punching Services?

Jobs That Require High Repeatability

Turret punching services are ideal for parts that need the same feature punched over and over again. Things like control boxes, mounting plates, or ventilation grilles are great candidates.

Because the tool hits are consistent and fast, you get excellent repeatability with very little variation from piece to piece—even across large production runs.

Parts with Holes, Slots, Notches, and Formed Features

While cnc cutting machines excel at complex curves or decorative edges, turret punching is better suited to standard shapes like circles, rectangles, tabs, and knockouts.

It also handles forming tasks, such as dimples or louvers, which add strength or airflow features directly into the part. The process is fast, reliable, and ideal for use with mild steel, stainless steel, and aluminium up to moderate thicknesses.

How Technicians Maintain Accuracy in CNC Punching Service

The Importance of Skilled Setup and Programming

Accuracy isn’t just about the machine—it’s about the people behind it. Skilled technicians know how to position the sheet, select the right tools, and program efficient tool paths. A high-quality cnc punching service relies on proper calibration and careful part alignment.

If the sheet isn’t clamped down properly or the wrong tool is selected, even the best machine can make a mistake. Experienced operators make all the difference.

How Software Boosts Tool Alignment and Cut Quality

Modern software used in Metal punching services makes it easy to layout parts in ways that minimise waste and improve consistency. It also tracks tool usage and wear, so technicians can replace worn punches before they affect quality.

Routine checks, software updates, and machine maintenance are key parts of keeping everything aligned and sharp—especially during high-volume jobs.

When to Use Turret Punching for Speed, Cost, and Accuracy

Comparing Turret Punching to Laser or Plasma in Terms of Cost

While laser cutting may win on detail, turret punching services often win on efficiency—especially when you're punching hundreds or thousands of the same part. The tooling is faster, and the process is less expensive for certain part types.

You’ll spend less on long runs, and with the right design, you won’t be sacrificing accuracy.

Why It’s a Top Choice for Mid-to-High Volume Production

When it comes to mid-to-large production batches of metal parts with repetitive shapes, turret punching is one of the best choices. It’s fast, repeatable, and delivers solid accuracy with minimal waste.

For jobs where cost, speed, and good tolerances all matter, turret punching hits the sweet spot—making it a go-to solution for many industries from construction to electronics.

#cnc machining#cnc punching#laser#Metal punching#TurretPunchingServicesSydney#cnc cutting services#industrial steel buildings#laser cutting australia#lasercutting

0 notes

Text

Creative Projects You Can Make with a Laser Cutting Service

When it comes to home décor, a laser cutting service opens up endless creative options. You can make everything from wall art and name plaques to decorative panels and personalized coasters. Many people also love using laser cutting to create unique mirrors, lampshades, and photo frames. The precision of laser cutting means you can add delicate patterns, intricate designs, and stylish lettering that would be nearly impossible to do by hand.

Whether you want a one-of-a-kind centerpiece for your living room or custom kitchen signs, laser cutting makes it easy to bring your ideas to life. It’s also perfect for crafting seasonal decorations like holiday ornaments or garden décor that adds a personal touch to your outdoor space.

How laser cutting adds a professional finish to your designs

One of the best things about using a laser cutting service is the polished finish it delivers. Unlike manual cutting methods, laser cutting creates smooth, clean edges that look sharp and professional. Whether you’re working with wood, acrylic, or metal, the result is a high-quality piece that looks store-bought—even when it’s completely custom-made.

This precise finish not only makes your décor look fantastic but also ensures it’s durable and long-lasting. So if you want your home to stand out with beautiful, personalized touches, laser cutting is the perfect way to make it happen.

Personalized Gifts That Wow: Ideas Using Laser Cutting

What are some popular gift ideas with laser cutting?

If you’re looking for memorable gifts, a laser cutting service can help you create something truly unique. Popular items include personalized keychains, engraved photo frames, custom cutting boards, and bespoke wine boxes. You can also design intricate jewelry pieces or customized wall signs that carry a personal message or design.

These gift ideas are great for birthdays, weddings, anniversaries, or corporate events where a personal touch makes all the difference.

Why personalized gifts stand out from the rest

A personalized gift shows thought and care, making it more meaningful than a store-bought item. Thanks to the precision of laser cutting, you can add names, dates, logos, or even detailed artwork with ease. The crisp, clean look of laser cutting ensures your gifts are not only beautiful but also durable, creating keepsakes people will treasure for years.

Business Signage and Displays: Stand Out with CNC Cutting Services

How laser cutting and cnc cutting services enhance business signs

For businesses, first impressions matter. That’s why using laser cutting and cnc cutting services is a smart move for creating professional signage. These services allow you to design bold, precise logos, 3D lettering, and custom displays that reflect your brand’s quality.

Whether it’s for shopfront signs, office plaques, or trade show displays, precision-cut signage grabs attention and makes your business stand out.

Why precise cuts matter for professional displays

Clean edges and exact measurements are crucial for professional-looking signage. Using a laser cutting service combined with cnc cutting services ensures every detail is flawless. For the best results, companies trust experts like Premier Engineering, known for delivering high-quality, eye-catching business signs that are built to last.

Whether you need a simple logo or a full display setup, their expertise in laser cutting and cnc cutting machine work ensures your business always looks its best.

Unique Furniture and Art Pieces You Can Make

Can a laser cutting service help with custom furniture?

Yes! A laser cutting service can create detailed parts for custom furniture, including chair backs, table legs, and decorative panels. You can design intricate cutouts or geometric patterns that turn ordinary furniture into stunning statement pieces.

Whether you’re an interior designer or a DIY enthusiast, laser cutting offers a way to craft furniture that is both functional and artistic.

How to bring your creative art designs to life

Artists love laser cutting for its ability to handle delicate, detailed designs. Whether you’re working on a metal sculpture or a wooden wall hanging, laser technology can bring even the most complex patterns to life. You can create layered artworks, mixed-media pieces, or decorative installations with precision and ease.

Detailed Industrial Parts with an Industrial Steel Cutting Machine

What industrial projects work best with laser cutting?

In the industrial world, precision is everything. Laser cutting is ideal for creating machine parts, brackets, and custom enclosures that require exact measurements. It’s widely used in industries like automotive, aerospace, and construction to produce high-quality, reliable components.

For heavier projects, pairing laser cutting with an industrial steel cutting machine ensures both strength and precision—making it the go-to method for tough jobs.

How an industrial steel cutting machine boosts precision

An industrial steel cutting machine is built for cutting thick, durable materials with pinpoint accuracy. This machine handles large-scale projects smoothly, allowing businesses to produce detailed parts in bulk without compromising quality. When combined with laser cutting, it offers unbeatable precision for all types of industrial applications.

Mixing Technology: Using a CNC Cutting Machine for Added Versatility

What’s the benefit of pairing laser cutting with a cnc cutting machine?

Sometimes, a project needs the best of both worlds. Using a laser cutting service alongside a cnc cutting machine allows you to handle a wider range of materials and project types. While laser cutting is excellent for fine details and thin materials, a cnc cutting machine excels at cutting thicker, more rigid materials like hardwood and metals.

This combo ensures that no matter your design’s complexity, it gets done right.

How to handle complex projects with combined cutting methods

By mixing technologies, we can tackle projects that involve multiple steps—like cutting a thick metal frame with a cnc cutting machine and adding detailed engravings with laser cutting. This approach keeps your project efficient and ensures every element meets the highest standard of quality and precision.

Crafting One-of-a-Kind Accessories with Laser Cutting

What types of fashion or jewelry items can you make?

Laser cutting is perfect for creating stylish accessories. You can make custom earrings, pendants, bracelets, and even belt buckles with intricate designs. Fashion designers also use laser cutting services to add unique detailing to clothing, handbags, and shoes.

The precision of laser cutting means you can experiment with bold shapes and delicate patterns that catch the eye.

Tips for designing small, detailed pieces

When designing accessories, it’s important to keep your cuts clean and balanced. Using materials like acrylic, leather, and thin metal sheets works best for small items. A laser cutting service ensures each piece is made with care, providing sharp lines and a flawless finish that makes your accessories look high-end and professional.

0 notes

Text

What Is a Sheet Metal Bending Press and How Does It Work?

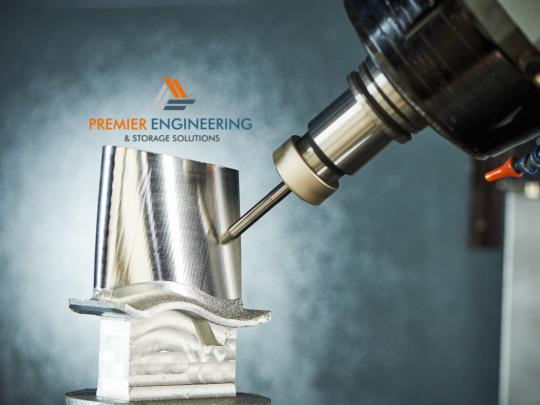

A sheet metal bending press is a machine used to bend flat metal sheets into specific shapes and angles. It’s an essential tool in metal fabrication, especially when creating components that need to fit precisely—like brackets, enclosures, or frames.

This machine forms metal by pressing it between a punch and a die, giving it a clean, accurate bend. It's commonly used to shape steel, aluminium, and other metals into parts used in construction, manufacturing, automotive, signage, and architectural projects.

Where you’ll see it in action

Whether it’s a large-scale industrial job or a custom fabrication for a retail display, you’ll often find sheet metal bending press machines in workshops that also offer laser cutting, turret punching services, or full metal forming solutions. It's a key part of turning raw sheet material into functional, real-world products.

How Does a Sheet Metal Bending Press Actually Work?

The press brake process made simple

At its core, a sheet metal bending press uses two main parts: a punch (the top tool) and a die (the bottom tool). The metal sheet is placed between them, and the punch pushes down to form a bend. This setup is known as a sheet metal press brake, and it's one of the most common machines for bending applications.

This controlled force can shape the metal at different angles depending on the depth and shape of the die. The result is a clean, sharp bend with high repeatability.

How it differs from other methods

Unlike laser cutting, which slices through metal with heat, or turret punching services, which punch holes or patterns, the sheet metal press brake is strictly for shaping and forming. It's the step that brings flat parts to life—turning them into brackets, boxes, and frames.

What Are the Main Components of a Bending Press?

Key parts of the machine

A standard sheet metal bending press includes several key components:

Punch – The top tool that presses into the metal

Die – The bottom tool that supports the bend

Ram – The moving part that forces the punch downward

Back gauge – Helps position the sheet for accurate bends

Each part plays a role in shaping the metal precisely and consistently. Together, they allow fabricators to bend metal sheets into a wide range of angles and shapes.

CNC control brings precision to the process

Many modern sheet metal press brake machines now use CNC (Computer Numerical Control) systems. These systems automate setup, positioning, and movement, allowing for greater accuracy and less manual error. CNC controls also store programs, making it easy to repeat exact bends for large production runs.

If your fabrication shop also offers laser cutting service or turret punching services, there’s a good chance they rely on CNC bending to complete the job with precision and efficiency.

What Materials Can Be Bent with a Sheet Metal Bending Press?

Popular metals for bending

A sheet metal bending press can work with a wide range of metals, depending on the type and thickness. Common materials include:

Steel – great for structural components and general use

Aluminium – lightweight and corrosion-resistant, perfect for enclosures or trims

Brass and copper – often used for decorative or electrical applications

The machine's tonnage (pressing force) will determine how thick a metal sheet it can handle. For very thick or hard materials, a high-tonnage sheet metal press brake is needed.

How it compares to cutting methods

While laser cutting is excellent for creating precise patterns or edges in flat sheet metal, it doesn’t bend or shape. Likewise, turret punching services are better for making repeated holes or slots. If you need a 3D form or fold, bending is the only way to go—making the sheet metal bending press an essential part of any fabrication workflow.

How Is a Bending Press Different from Other Sheet Metal Tools?

When to bend, cut, or punch

Each tool in a metal workshop plays a specific role. A sheet metal bending press is used to fold or angle metal sheets. It doesn’t remove material—it reshapes it. On the other hand, a laser cutting service slices clean lines through metal, and turret punching services create shapes, holes, or louvres by punching through the sheet.

Why they work best together

In most professional settings, all three are used in combination. For example, a part might first go through laser cutting for its outline, then turret punching for internal cutouts, and finally a sheet metal press brake for final shaping. Together, they turn flat stock into fully formed, ready-to-install components.

What Types of Sheet Metal Bending Presses Are Available?

From manual to fully automated

There are several types of sheet metal bending press machines to choose from, each suited to different needs:

Manual press brakes – simple and budget-friendly, ideal for small shops or one-off jobs

Hydraulic press brakes – strong and reliable, suitable for a wide range of metal types

Electric press brakes – energy-efficient and precise, good for high-speed work

CNC press brakes – the most advanced, perfect for repeatable and complex bending tasks

Choosing the right fit for the job

For workshops that handle regular production runs or need high accuracy, a CNC sheet metal press brake is often the best choice. It combines speed, safety, and programmable precision—especially when integrated into full-service operations that include laser cutting or turret punching services.

Why Precision and Setup Matter in Sheet Metal Bending

Accuracy is everything

When it comes to bending, even a few millimetres off can ruin a part. That’s why setup and alignment are so important. The type of die, the position of the back gauge, and the thickness of the material all affect the outcome. Springback—when metal tries to return to its original shape after bending—also needs to be compensated for during setup.

Trained operators and CNC make the difference

Skilled technicians or CNC machines can account for these variables with ease. A modern sheet metal press brake with CNC capabilities can store bend sequences, calculate bend allowances, and even adjust for material behaviour in real time. That level of precision ensures every part is consistent—no matter how many you’re producing.

1 note

·

View note