We are Delighted to Announce that 39 years of Research & Development in the field of Testing Instrumentation has been acknowledged and appreciated by the Industry and Presto been voted as the Top 10 Test & Measurement Equipment and Testing Instruments Manufacturers in Asia. Testing- instruments manufacturer low-cost Testing instruments for the plastic and packaging industry. Give us a call at +91 9210903903 or email us at [email protected] to know about the company, latest products and our services. Our website- https://www.testing-instruments.com/

Don't wanna be here? Send us removal request.

Text

Tensile Testing Machine Manufacturers in India: Who leads the industry?

Tensile Testing Machine Manufacturers in India are led by Presto Testing Instruments known for their exceptional quality and innovation. These manufacturers, often recognized for their commitment to precision engineering and cutting-edge technology, set the benchmark for the production of reliable and accurate tensile testing machines. With a focus on meeting diverse testing needs, they offer a range of models tailored to various industries. The competitive landscape includes renowned brands with a reputation for delivering top-notch test and measurement equipment, ensuring that customers receive robust solutions for material analysis, research, and quality assurance.

0 notes

Text

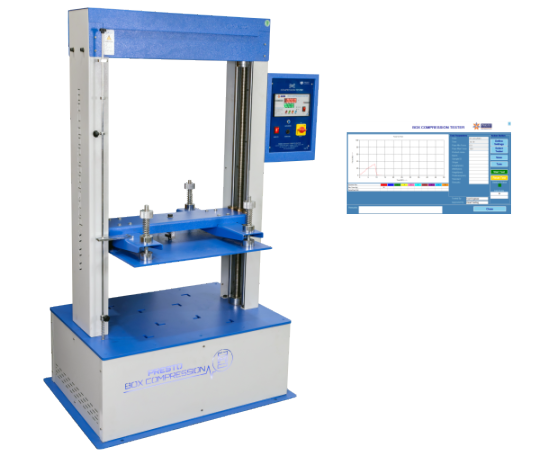

Box compression tester is an engineering perfect lab testing instrument designed to assess the ability of corrugated boxes to withstand the compression force while stacking. This lab testing instrument is created for the paper & packaging industries and the manufacturers of corrugated boxes are highly interested in attaining this engineering perfection by testing-instruments and measuring the compressive strength of their boxes with maximum accuracy.

It is necessary to determine the potential of cardboard used to make corrugated boxes to withstand a compressive force so that the items within the box remain safe as well as to calculate the number of boxes that can be stacked over a corrugated box by determining its compressive durability through the box compression tester. Presto digital box compression tester works well to test the compression strength of boxes accurately.

#box compression strength tester#box compression testing machine#box compression tester#carton box compression tester

0 notes

Text

Measure the Breaking Force of Materials with a Tensile Machine

Tensile Machine is one of the finest lab testing instruments ever made due to its ergonomic design and universal versatility which comes together in a complete package. This test machine is also known as the Tensile Strength Tester, and as the name indicates it is used for measuring the strength or the force required to break the specimen.

The machine is offered universally in all the manufacturing industries as a manufacturer would tend to buy Tensile Tester rather than a load of other machinery and instruments.

It becomes highly important to meter the breaking strength of your material before utilizing the material in the final product. The Tensile Machine Tester is henceforth designed to regulate and make certain changes at the manufacturer level and deliver a flawless final product.

Read More -- https://www.testing-instruments.com/blog/measure-the-breaking-force-of-materials-with-a-tensile-machine/

#tensile strength tester#tensile strength tester manufacturer#tensile strength tester price#tensile strength tester supplier#digital tensile testing machine

0 notes

Text

youtube

Mastering Color Harmony : Exploring the Color Matching Cabinet | Presto Group

Are you tired of inconsistent colour results in your product quality testing process? Do you want to ensure accuracy in product colours? If yes, then it is important for you to test the quality of colours accurately. Thus, we at Presto being Asia’s Top Lab Testing Instruments manufacturers has designed high-quality testing equipment known as Color Matching Cabinet- Spectrum Asia. This is one of the high-quality colour-matching testing instruments that can help manufacturers in testing the accuracy of colours present in the product and ensure that quality materials will be delivered to the customers. You can easily achieve perfect colour accuracy in your product with the help of this quality testing equipment.

https://www.prestogroup.com/products/colour-matching-cabinet-asia/

#colormatchingcabinet#colormatchingmachine#qualitycontrol#colormatchingtest#colourtester#colormeasurement#prestogroup#testingequipment#Youtube

0 notes

Text

youtube

Revolutionize Your Packaging with Box Compression Testing Tips | Presto Group

Box Compression Tester is a consistent tool to indicate the Compression strength of cardboard boxes so that it does not get deformed or crushed when stacked one above the other during storage or transit. Presto Box Compression Tester is used to measure the box compression strength (BCT), shape change and stacking capability of cartons, beehive crates, paper tanks, paper cases etc. Box Compression Tester is designed to evaluate compression strength of the corrugated box and the load range selected to completely collapse as peak load or may be with a pre-determined load for a given period to evaluate stacking load.

Learn More about this testing instrument: https://www.prestogroup.com/products/box-compression-tester/

0 notes

Text

Know About Flammability Tester: Testing-Instruments

A flammability tester is a device that measures the resistance of materials and products to ignition and combustion under controlled conditions. Flammability testers are widely used in industries where fire safety is a critical factor, such as textiles, plastics, electronics, automotive, aerospace, and construction. Flammability tester can help manufacturers, regulators, and consumers assess the fire hazards and risks associated with different materials and products, and ensure compliance with relevant standards and regulations.

If you are looking for a reliable and high-quality vertical flammability tester in India, you might want to check out the products from Presto Group, a leading manufacturer and supplier of laboratory testing instruments and equipment across India. You can find more information about the vertical flammability tester and other products from Presto Group. You can contact Testing-Instruments for a quote or more information by visiting their website or calling them at +91–9210903903.

#flammability test#flammability tester#flammability tester price#flammability testing equipment#vertical flammability tester

0 notes

Text

Know About Edge crush Tester: Testing-Instruments

An edge crush tester is a testing instrument that measures the edge-wise compression strength of paper and paperboard materials, such as corrugated board, cardboard, and solid fiberboard. It is used to evaluate the quality and performance of packaging materials in various industries. An edge crush tester Chart consists of a clamp, a load cell, a display, and a controller. The clamp holds the specimen securely and applies a compressive force along one edge. The load cell records the force applied to the specimen, and the display shows the edge crush strength, which is calculated from the force and the width of the specimen. The controller allows the user to set the desired speed, angle, and direction of the compression.

If you are looking for a reliable and high-quality edge crush tester in India, you might want to check out the products from Presto Group, a leading manufacturer and supplier of laboratory testing instruments and equipment across India. You can find more information about the edge crush tester and other products from Presto Group. You can contact Testing-Instruments for a quote or more information by visiting their website or calling them at +91–9210903903.

#edge crush test calculator#edge crush test chart#edge crush test formula#edge crush test units#edge crush tester

0 notes

Text

Know Torque Tester in Plastic Industry: Testing-Instruments

A torque tester is a testing instrument that measures the force required to open or close a plastic bottle cap or other similar closure. It is used to evaluate the quality and performance of plastic products in the packaging industry. A torque tester consists of a clamp, a load cell, a display, and a controller. The clamp holds the bottle or the cap securely and rotates it at a controlled speed and angle. The load cell records the force applied to the bottle or the cap during the rotation. The display shows the torque value, which is calculated from the force and the distance from the axis of rotation. The controller allows the user to set the desired speed, angle, and direction of rotation.

If you are looking for a reliable and high-quality torque testing machine in India, you might want to check out the products from Presto Group, a leading manufacturer and supplier of laboratory testing instruments and equipment across India. You can find more information about the torque testing machine and other products from Presto Group. You can contact Testing-Instruments for a quote or more information by visiting their website or calling them at +91–9210903903.

#torque meter#torque test#torque tester#torque tester price#torque tester supplier#torque testing machine

0 notes

Text

Know About Polariscope in Pet Industry: Testing-Instruments

A polariscope is a testing instrument that is used to detect defects and stresses in PET preforms, which are the raw materials for making PET bottles and containers. PET preforms are transparent plastic tubes that are heated and blown into various shapes and sizes. However, during the manufacturing process, PET preforms may develop internal strains or deformities that can affect the quality and performance of the final products. A polariscope works by using two polarized lenses and a light source to examine the PET preforms.

The polarized lenses filter the light and create a dark background. When a PET preform is placed between the lenses, any defect or stress in the material will refract the light and create a colorful pattern. By observing the pattern, the user can identify the type and location of the defect or stress in the PET preform. A polariscope can also measure the angle and intensity of the birefringence, which is the difference in the refractive index of the material along different directions.

If you are looking for a reliable and high-quality Polariscope Strain Viewer in India, you might want to check out the products from Presto Group, a leading manufacturer and supplier of laboratory testing instruments and equipment across India. You can find more information about the Polariscope and other products from Presto Group. You can contact Testing-Instruments for a quote or more information by visiting their website or calling them at +91–9210903903.

#polariscope#polariscope price#polariscope strain viewer#portable spectrometer#portable spectrophotometer

0 notes

Text

Know About Hot Air Oven : Testing-Instruments

A hot air oven is a laboratory instrument that uses dry heat to sterilize equipment and supplies. It is widely used in various industries, such as microbiology, pharmaceutical, and chemical. A hot air oven consists of a double-walled chamber, a heating element, a fan, a thermostat, and a controller. The chamber is insulated with glass wool to prevent heat loss and ensure uniform temperature distribution.

The heating element is located at the bottom or the sides of the chamber and provides the required heat for sterilization. The fan circulates the hot air inside the chamber and maintains a constant temperature. The thermostat regulates the temperature and prevents overheating. The controller allows the user to set the desired temperature and time for sterilization.

If you are looking for a reliable and high-quality Hot Air Oven in India, you might want to check out the products from Presto Group, a leading manufacturer and supplier of laboratory testing instruments and equipment across India. You can find more information about the humidity chambers and other products from Presto Group. You can contact Testing-Instruments for a quote or more information by visiting their website or calling them at +91–9210903903.

0 notes

Text

Know About Hot Air Oven : Testing-Instruments

A hot air oven is a laboratory instrument that uses dry heat to sterilize equipment and supplies. It is widely used in various industries, such as microbiology, pharmaceutical, and chemical. A hot air oven consists of a double-walled chamber, a heating element, a fan, a thermostat, and a controller. The chamber is insulated with glass wool to prevent heat loss and ensure uniform temperature distribution. The heating element is located at the bottom or the sides of the chamber and provides the required heat for sterilization. The fan circulates the hot air inside the chamber and maintains a constant temperature. The thermostat regulates the temperature and prevents overheating. The controller allows the user to set the desired temperature and time for sterilization.

If you are looking for a reliable and high-quality Hot Air Oven in India, you might want to check out the products from Presto Group, a leading manufacturer and supplier of laboratory testing instruments and equipment across India. You can find more information about the humidity chambers and other products from Presto Group. You can contact Testing-Instruments for a quote or more information by visiting their website or calling them at +91-9210903903.

0 notes

Text

youtube

Mastering Tensile Testing: Unravelling The Strength of Materials

Tensile testing is the key to understanding how materials respond to stress and strain. From engineering plastic materials to metal products, testing each and every aspect of material is important in ensuring accuracy of tensile testing results. Thus, with the Presto tensile strength testing instrument, manufacturers can easily and accurately conduct tensile tests on the materials. In this video, we break down the fundamentals of tensile testing and delve into its diverse applications across industries. Gain a deeper understanding of how this testing machine helps manufacturers in testing the integrity of materials.

#TensileTesting#MaterialStrength#EngineeringTests#MaterialsScience#QualityControl#MechanicalTesting#LabTesting#MaterialProperties#TensileStrength#MaterialTestingLab#prestogroup#Youtube

0 notes

Text

youtube

Peel Tester: Unveiling Precision in Material Adhesion Testing

Introducing the PRESTO Peel Strength Tester – your trusted companion for accurate and reliable assessments of peel strength in a wide range of materials including adhesives, BOPP packaging tapes, high pressure laminates and much more. In this video, you will get a deep dive in peel strength testing and how this quality testing equipment will be used to test the peel strength of materials accurately. To get more information, visit:

0 notes

Text

Explore Humidity Chamber Price in India: Testing-Instruments

A humidity chamber is a device that can simulate different levels of humidity and temperature for testing the effects of these environmental factors on various materials and products. A humidity chamber can help you evaluate the quality, durability, and performance of your products under different climatic conditions.

There are many types of humidity chambers available in the market, such as temperature humidity chamber, humidity cabinet, humidity test chamber, environmental test chamber, etc. The price of a humidity chamber depends on various factors, such as the size, capacity, features, specifications, brand, and quality of the device.

If you are looking for a reliable and high-quality humidity chamber in India, you might want to check out the products from Presto Group, a leading manufacturer and supplier of laboratory testing instruments and equipment across India. Presto Group offers a wide range of humidity chambers, such as temperature humidity chamber, humidity cabinet, humidity test chamber, environmental test chamber, etc. You can find more information about the humidity chambers and other products from Presto Group. You can contact Testing-Instruments for a quote or more information by visiting their website or calling them at +91-9210903903.

Know More -- https://www.testing-instruments.com/blog/why-humidity-chambers-are-used-in-testing-labs/

#humidity chamber#humidity chamber manufacturer#humidity chamber price#humidity chamber working principle#humidity test chamber#humidity test chamber price

0 notes

Text

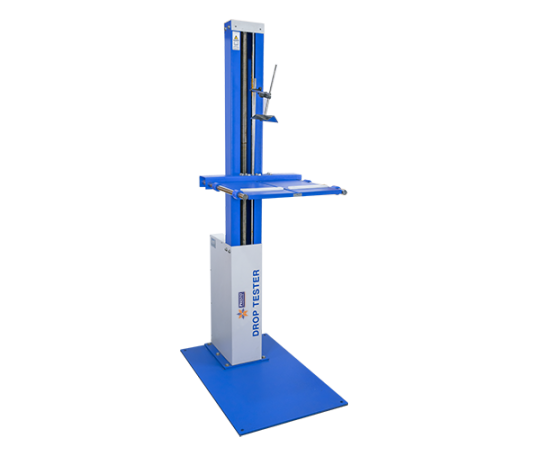

Drop Tester Machine for Paper & Packing Industry

A drop tester machine is a device that simulates the impact that a paper or packaging product may receive during transportation and handling. It is used to evaluate the quality and durability of the product and its ability to protect the contents inside.

A drop tester machine consists of a base unit, a drop unit, a specimen holder, a load cell, a display unit, and a control unit. The device works by dropping the drop unit onto the product, which is placed on the specimen holder, and measuring the impact force and the damage caused by the collision.

A drop tester machine can be used to test various types of paper and packaging products, such as bottles, pouches, cans, trays, corrugated boxes, and more. The device can perform different types of drop tests, such as straight drop, angular drop, rotational drop, and inclined drop, to assess the product from all angles. If you want to know more about the drop tester machines from Testing-Instruments, you can visit their website and Contact Us. +91-9210 903 903.

Know More -- https://www.testing-instruments.com/blog/drop-test-what-it-is-all-about/

#drop impact tester#drop test#drop tester#drop tester machine#drop tester manufacturer#drop tester price

0 notes

Text

Box Compression Tester Manufacturer — presto Group

Presto Group is a reputed manufacturer of box compression testers in India. They offer a variety of models that can measure the compressive strength and quality of cardboard boxes and other packaging materials. Presto Group’s box compression testers are designed according to the international standards and have features such as:

• High accuracy and precision: Presto Group’s box compression testers have a digital load indicator and a microprocessor-based controller that can display the peak load, load at break, and deformation of the sample. They also have a load cell and a pressure transducer that can measure the load and pressure with high accuracy and precision.

• User-friendly and versatile: Presto Group’s box compression testers have a touch screen display and a user-friendly interface that can facilitate the operation and data analysis. They also have a memory function that can store up to 1000 test results and a USB port that can transfer the data to a computer or a printer. They also have different test modes and parameters that can suit the needs of different customers and applications.

• Durable and reliable: Presto Group’s box compression testers are made of high-quality materials and components that can withstand the high load and pressure applied to the sample. They also have a safety mechanism that can prevent the overload and damage of the machine. They also have a warranty and after-sales service that can ensure the durability and reliability of the box compression tester.

To know more about Presto Group’s box compression testers, you can visit their website or contact them directly for quotations, specifications, and demonstrations. You can also refer to their product brochure and customer reviews to get a better idea of their box compression testers. Presto Group is the best box compression tester manufacturer for your needs.

0 notes

Text

How to Perform a Dart Impact Test on Plastic Films: A Step-by-Step Guide

A dart impact test is a method to measure the impact resistance of plastic films and laminates by dropping a dart on them from a certain height. The test can help evaluate the quality, durability, and performance of various plastic products and materials. The test can also help compare the effectiveness of different surface treatments, such as electroplating, galvanizing, painting, etc. The test is standardized by several national and international standards, such as ASTM B117, ISO 9227, JIS Z 2371, and ASTM G85.

To perform a dart impact test on plastic films, you will need a dart impact tester, a sample holder, a scale, a release mechanism, and a sample of the material to be tested. You can find some examples of dart impact tester online, such as Presto Group or Amazon. You can also compare the prices, features, and specifications of different models and brands and choose the one that suits your needs and budget.

Here are some steps that you can follow to perform a dart impact test on plastic films:

1. Prepare the sample of the material to be tested according to the standards and specifications. The sample should be large enough to extend beyond the sample holder by at least 25 mm at all points. The sample should also be representative of the material under study and should be taken from the sheet or tube in such a manner that the whole of the sheet is represented in the test. You can use a template to guide the cutting of the sample and a thickness gauge to measure the thickness of the sample.

2. Clamp the sample in the sample holder and connect the pneumatic pipe to the vacuum pump. Turn on the vacuum pump to hold the sample securely and prevent any air pockets. The sample should be clamped by the specimen holder ring and should have a slit that allows the dart to pass through and tear the sample.

3. Adjust the level of the machine with the spirit level and lock the leveling bolts in the proper position. Ensure that the apparatus does not vibrate and has a proper earthing connection. Connect the power supply cord of the device to a 3-pin 5-ampere socket on a single-phase 230 V AC supply line.

4. Choose the appropriate weight of the dart that is nearest to the expected impact failure weight. You can also add the required number of incremental weights to the dart shaft and put the locking collar in its place to set the weights in a particular location.

5. Adjust the height of the drop of the dart according to the standards and application requirements. You can use the release mechanism of the vertical channel support to set the height of the drop. The dropping height of the dart can be 660 mm or 1524 mm, depending on the type of test.

6. Place the dart in the release mechanism and align it with the center of the sample. Make sure that the dart is free from any dirt or dust and has a smooth surface.

7. Release the dart from the starting position by using the trigger or the button of the release mechanism. The dart will fall freely and hit the sample, causing it to tear. The force and the distance of the tear will be recorded by the scale and the display of the device.

8. Remove the sample from the sample holder and examine the damage caused by the dart. You can use a marker to record the maximum force reached by the pointer and the scale. You can also use a ruler to measure the length of the tear.

9. Calculate the Falling dart impact tester of the material by using the formula: Dart impact strength = Weight of the dart in grams / 10 min. You can also use a computer interface or software to generate graphical and numerical reports of the test results.

10. Repeat the test with different samples and weights of the dart to obtain an average value of the dart impact strength of the material.

I hope this guide helps you to perform a dart impact test on plastic films.

0 notes