#tensile strength tester

Text

Tensile strength testing is a crucial procedure in various industries, ensuring the quality and durability of materials. A Tensile Strength Tester is a specialized equipment designed to measure the force required to pull a material until it breaks.

A Tensile Testing Machine is a precision instrument comprising various components such as a load cell, grips, and a testing chamber. Selecting the appropriate tensile strength tester involves considering factors such as material type, testing frequency, and required accuracy. Practical tips will be provided to aid in making an informed decision.

Emphasizing the need for regular tensile strength testing in different industries to ensure ongoing quality, safety, and compliance with standards. You can email us at [email protected] or call us at +91 9555515525 for additional information about the tensile testing machine's price, uses, or applications.

#tensile strength tester#tensile testing machine#tensile tester#tensile test equipments#tensile tester manufacturer

0 notes

Text

Measure the Breaking Force of Materials with a Tensile Machine

Tensile Machine is one of the finest lab testing instruments ever made due to its ergonomic design and universal versatility which comes together in a complete package. This test machine is also known as the Tensile Strength Tester, and as the name indicates it is used for measuring the strength or the force required to break the specimen.

The machine is offered universally in all the manufacturing industries as a manufacturer would tend to buy Tensile Tester rather than a load of other machinery and instruments.

It becomes highly important to meter the breaking strength of your material before utilizing the material in the final product. The Tensile Machine Tester is henceforth designed to regulate and make certain changes at the manufacturer level and deliver a flawless final product.

Read More -- https://www.testing-instruments.com/blog/measure-the-breaking-force-of-materials-with-a-tensile-machine/

#tensile strength tester#tensile strength tester manufacturer#tensile strength tester price#tensile strength tester supplier#digital tensile testing machine

0 notes

Text

The i10™ Tensile Strength Tester from Paramount is an advanced piece of equipment, embodying the most up-to-date technology by employing the Constant Rate of Elongation (CRE) principle. It seamlessly integrates with sophisticated software provided with the equipment via the included laptop.

#paramountinstruments#qualitycontrol#textile#textileindustry#qualitycontrolassessment#tensile strength#tensile strength tester#elongation#seam- slipage#tear

0 notes

Photo

When Engineers get into Shibari

Those kinky dorks <3

0 notes

Text

Uses of Tensile Strength Tester

One of the most important and widely used types of mechanical testing of materials is tensile or tension testing. When using a tensile strength tester, a tensile force or stress is applied to a material until it fails or fails, and the response to the load is measured.'

0 notes

Text

Purpose and significance of tensile testing in various sectors, its application in plastic industry.

Tensile testing is a common mechanical test used to determine the mechanical properties of materials. It involves subjecting a sample to a controlled tension force until it breaks, measuring various parameters along the way. Tensile testing finds numerous applications across various industries. In industries like aerospace and automotive, where materials are subjected to extreme conditions, tensile testing is vital. It ensures that materials used for constructing critical components, such as engine parts, aircraft structures, or safety harnesses, meet the required strength and performance standards. Tensile testing is extensively used in manufacturing industries to assess the strength and quality of materials. It helps determine the ultimate tensile strength, yield strength, elongation, and modulus of elasticity, which are crucial parameters for evaluating material suitability for specific applications. Tensile testing plays a vital role in material research and development. It helps scientists and engineers understand how materials behave under different loading conditions, aiding in the development of new materials or improving existing ones. Tensile testing also facilitates the assessment of factors such as fatigue resistance, creep behavior, and fracture toughness. Tensile testing is an essential component of quality control processes. It ensures that manufactured products meet industry standards and specifications. Tensile testing is often required for certification purposes to comply with regulations and safety standards in various industries. Tensile testing is employed in the medical industry to evaluate the mechanical properties of materials used in medical devices and implants. It helps ensure the safety and reliability of products such as surgical sutures, orthopedic implants, stents, and catheters.

The tensile test is a fundamental mechanical test used to evaluate the mechanical properties of materials under tension. It provides valuable information about a material's behavior and performance, which is crucial for various industries. The tensile test helps in the selection of materials for specific applications. By determining parameters such as ultimate tensile strength, yield strength, elongation, and modulus of elasticity, engineers can choose materials that can withstand the expected loads and stresses in a particular industry. Tensile testing plays a vital role in quality control processes. Manufacturers use it to ensure that materials and finished products meet industry standards and specifications. By conducting tensile tests on samples from production batches, companies can identify any inconsistencies or defects in the material properties and take corrective actions. Industries such as aerospace, automotive, and construction rely on tensile testing to design structures that can withstand anticipated loads and stresses. Tensile test data helps engineers determine the strength and ductility of materials, allowing them to design structures with appropriate safety margins and ensure structural integrity. Tensile testing assists in optimizing manufacturing processes. By conducting tests on material samples subjected to different processing conditions (e.g., heat treatment, welding), engineers can evaluate the impact of these processes on the mechanical properties of the material. This information helps in optimizing process parameters to achieve desired material characteristics. Tensile testing is used in product development and research to evaluate the performance of new materials or assess the effects of material modifications. It aids in understanding factors such as fatigue resistance, creep behavior, and fracture toughness, which are essential for developing innovative and reliable products. Many industries have specific standards and regulations that materials and products must adhere to. Tensile testing provides the necessary data to demonstrate compliance with these standards, ensuring the safety, reliability, and quality of products in industries such as automotive, aerospace, and medical devices. In the event of a component or material failure, tensile testing can be used to analyze the cause. By examining the fractured sample and analyzing its mechanical properties, engineers can identify the factors contributing to the failure and take corrective measures to prevent future incidents.

Advantages of the tensile test:

Material Characterization: The tensile test provides valuable insights into the mechanical properties of materials, including the yield strength, ultimate tensile strength, modulus of elasticity, elongation, and fracture behavior. This information helps in material selection, design, and engineering applications.

Standardized Test: The tensile test is a well-established and widely used standardized test method, which means that the testing procedures and equipment are standardized across industries. This allows for consistent and comparable results between different laboratories and facilitates data sharing and analysis.

Simple Test Setup: The equipment required for a tensile test is relatively simple and straightforward. It typically involves a universal testing machine, grips to hold the specimen, and strain and load measuring devices. This simplicity makes it accessible and cost-effective for many industries.

Non-Destructive Testing: Tensile testing allows for the evaluation of material properties without damaging the entire specimen. A small, representative sample can be used for the test, leaving the rest of the material intact for further use or testing.

Versatility: The tensile test can be applied to a wide range of materials, including metals, plastics, composites, rubbers, and textiles. This versatility makes it applicable to various industries, such as automotive, aerospace, construction, and manufacturing.

Disadvantages of the tensile test:

Uniaxial Stress: The tensile test applies a uniaxial stress state to the specimen, which means it measures the material's response to tension along a single axis. However, real-world applications often involve complex stress states, such as bending or torsion. The tensile test may not fully capture the material's behavior under these different loading conditions.

Time-Consuming: Tensile testing requires careful preparation of specimens and the application of a gradual load until failure occurs. This process can be time-consuming, especially when testing large quantities of samples or materials with slow deformation rates.

Sample Size Limitations: The dimensions and geometry of the specimen used in the tensile test can influence the test results. Small or irregularly shaped samples may yield inaccurate or non-representative results. Additionally, obtaining samples from certain materials or components can be challenging or even impossible.

Material Anisotropy: Some materials, such as composites or rolled metals, can exhibit anisotropic behavior, meaning their properties differ in different directions. The tensile test may not fully capture this anisotropic behavior since it applies stress along a single axis.

Environmental Sensitivity: The tensile test results can be influenced by environmental factors such as temperature and humidity. Material properties can change under different environmental conditions, which may affect the test outcomes. Special considerations and testing procedures may be necessary to account for these effects.

The purpose of tensile testing is to evaluate the mechanical properties of materials under tension. It involves applying a gradually increasing force to a specimen until it fractures, while simultaneously measuring the resulting elongation and load. Tensile testing is a valuable tool in the plastic industry. It enables the characterization of plastic materials, aids in material selection, supports quality control efforts, facilitates process optimization, assists in product development, and ensures compliance with industry regulations. These applications help manufacturers produce high-quality plastic products that meet the performance and safety requirements of various industries. In the plastic industry, tensile testing serves several important purposes like material characterization, material selection, quality control, process optimization, product development and regulatory compliance.

#universal testing machine#Peel Strength Test#tensile test of materials#Tensile Strength Machine#Paper Tear Strength Test#Pull Of Adhesion Test#auto tensile tester

0 notes

Text

#Peel Strength Test#tensile test of materials#universal tensile testing machine#Tensile Strength Machine#Paper Tear Strength Test#Pull Of Adhesion Test#auto tensile tester

0 notes

Text

We have been serving our admired clients by offering many Tensile Testing machines. Our offered range is user-friendly which gives the customer the utmost satisfaction.

#Automatic tensile testing machine#Computerized Tensile Strength Testing Machine#hydraulic tensile testing machine#instron tensile testing machine#PEEL BOND STRENGTH TESTER#tensile machine test#tensile strength testing machine#tensile testing machine#tensile testing machine manufacturers#tensile testing machine manufacturers in india#tensile testing machine suppliers#universal tensile testing machine

0 notes

Text

#Linear density of yarn#Mass per unit area#Thickness of fabric#Synthetic blood penetration test#Splash reistance#Tensile strength and elongation#Tearing strength of the fabric by Trapezoid Procedure#Hydrostatic Head tester#Martindale piling test#Differential pressure test#Fit test#Total inward leakage test#Simulated wearing treatment#Temperature conditioning#Field of vision#Flammabillity of filtering half mask#Valve seat retention test#Mechanical strength test

0 notes

Text

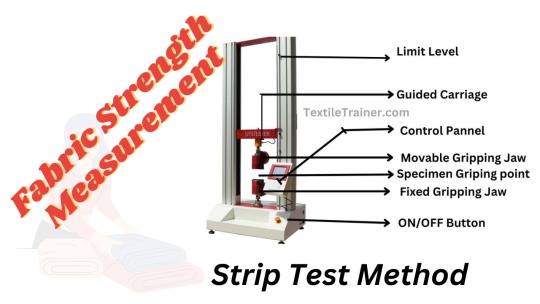

Determine the Tensile Strength of a Woven Fabric by Strip Test Method/Lab Report-01

Introduction:

Tensile strength is one of the most important properties of fabric. The strength of fabric may be determined from three approaches. They are its resistance to a tensile load, its resistance to a tearing force, and its resistance to a bursting force. Each of these three measurements has its own usefulness. The breaking strength measures the fabric’s resistance to a tensile load or…

View On WordPress

0 notes

Text

@stuckinuniformdevelopment

(prev)

Each word of Reverend Miriam’s scathing lecture was a weight on Theodore’s already battered shoulders. He numbly nodded along while wincing at particularly pointed or gruesome parts.

And with each wince, his grimace gradually grew, and his body grew taunt as if stretched in a tensile tester. By the end he swore that he had reached his peak strength and was nearing his fracture point. Meanwhile, his grimace had become as wide as it would be on a far more expressive person.

“I…” Teddy pushed hard on his thighs to keep himself upright. Then he cleared his throat before projecting his voice to a normal volume.

“…Certainly learned patience. Which will be applied to…” He paused to force himself to consciously breathe.

Then Doctor Walters’ expression hardened as made direct eye contact. Once he restarted his tone was as cold as ice. Just like when he delivered an oral report on the CAPT Project’s most recent failure.

“I’ll stick to mundane potential solutions for developing necessary materials. No matter how many years it takes. Even if I shrivel up and die without succeeding.”

Finally, Doctor Walters slouched as he gave up on resisting the pressure Reverend Miriam exerted. He looked off to the side as he bitterly muttered,

“In hindsight: It would never be able to exit the prototyping phase anyways…”

There was one point that he was tempted to argue on: Having no genuine interest in alchemy. But he wisely managed to restrain himself from saying how he perceived alchemy as a branch of materials science.

Also he really was a quick reader.

When Dr. Walters was done, Miriam relaxed her posture and finally averted her intense gaze. She gave a simple nod of acknowledgement in response to his statements. Good, seems he understood. Contrary to popular belief, she didn't particularly revel in crushing people's spirits... Well, except for those she actively disliked. But Dr. Walters wasn't one of those, even despite a few incidents that irked her. Miriam gathered her robe in her arms and stood from her chair.

“I won’t tell anyone.”

Suddenly, the door at the top of the stairs creaked open. Voices could be heard: “Hey, the door opens!” “I doubt Bowtie’s even there anymore.”

Sure enough, the deacons Autumn and Lola peered down the stairs. But when they saw a peeved Reverend Miriam glaring back up at them, they stumbled back.

“Shit, RUN!” The two turned heel and fled.

Miriam shifted her robe to one arm, then picked up the chair she was sitting in. In lieu of her usual long winded parting remarks, she glanced at Dr. Walters and said “take care.”

With that, she darted up the stairs, chair in hand.

2 notes

·

View notes

Text

Perfect Equipments India

My Name Is Aryan I am from India Today I want to tell you about Perfect Equipments India - A prominent and trusted manufacturer and supplier of the latest technology testing equipment & measuring instruments covering the various types of industries & products. 1400+ satisfied clients worldwide marking our footprints globally. Established in the year 2009.

Contact Number :- +91 9650480777, +91 8851528648

Perfect Instruments || Perfect Equipments || pet Bottle Testing Instruments || Bottle thickness gauge || Bottle Cap Torque Tester || Peel bond strength tester || Melt Flow Index Tester || Drop Tester || Bursting Strength tester || Box Compression Tester || Heat Seal Tester || Vacuum Leak Tester || Gas volume tester || Top Load Tester || Secure Seal Tester || Packaging Testing Instruments || Preform Testing Instruments || Tensile Testing Machine || Polariscope ||

2 notes

·

View notes

Text

Measuring the tensile strength of the products is essential to measure its reliability and strength and also to measure the actual working life of the products. The tensile testing machine is highly recommended to evaluate the tension strength of the products. Presto offers high quality tensile tester that is used to test the tensile property of the materials. The jaws of the device are moved in opposite direction with the help of a motor that comprises of a lead screw arrangement and a gear box. The machine is also provided with a load sensor with the load cell that helps to sense the accurate point at which the sample breaks. The tensile test provides valuable information about the material's mechanical properties, including its tensile strength, yield strength, elongation, and modulus of elasticity. To operate the machine, there is a standard working procedure that must be followed to operate the testing machine efficiently. You can even take a FREE sample testing session just by giving us a call at +91 9210903903 or email at [email protected]. They have a team of technical experts that will guide you well regarding all your testing instrument needs.

0 notes

Text

Paramount's Exclusive Solutions for the Automotive Industry

As we all know, organizations believe in innovation to achieve their business objectives, but it is also true that sometimes they underestimate the testing part due to a lack of knowledge. Therefore, Paramount Instruments designs and develops the best and most sophisticated feature-rich equipment that will enhance your productivity and efficiency.

Quality Control plays an incredibly significant role in the Automotive Industry. That is why Paramount has a separate domain to cater to the Automotive Industry. We offer complete solutions and World Class Testing Instruments for the Automotive Industry which includes - Automotive Textiles, Automotive Interiors and Trims, Automotive Parts and many more.

Here we have shared top-notch quality control instruments for the automotive industry:

Paramount’s Next GenerationTensile Strength Tester i12™️ is a unique equipment used to determine various quality parameter of tensile, peeling, tearing, adhesive strength, pulling and other properties of AUTOMOTIVE Textile Industry.

It comes in a Complete Package with Latest Laptop duly Loaded with specialized QCVATION®️ software, a Colored Printer, and a Special ergonomic Table to accommodate the complete Package alongside the Advanced Tensile Strength Tester.

Read More at: reddit.com

0 notes

Text

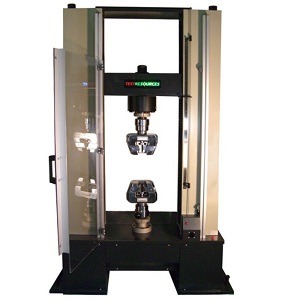

Tensile Testing Machine Manufacturer in India

A tensile tester or tensile testing machine is used to determine the strength and deformationbehavior of a material up to the point of fracture. It is used to find out how strong a material is and also how much it can be stretched before it breaks. This test method is used to determine yield strength, ultimate tensile strength, ductility, strain hardening characteristics, Young's modulus and Poisson's ratio. To perform a tensile test, an operator will load a specimen into the two specimen grips of the machine. After loading the specimen, the operator selects the correct rate of movement for the material type. The tester then pulls the specimen apart until failure. The data obtained by tensile testing ensures the integrity and safety of materials, components and products. It helps manufacturers to ensure the quality of their final product and are fit-for-purpose.

For more details clicks here - https://www.indiantradebird.com/product/tensile-testing-machine-

0 notes

Text

https://www.testronixinstruments.com/bottle-burst-tester-digital/

TIPS FOR CHOOSING AND BENEFITS OF UNIVERSAL TENSILE TESTERS

Choosing a universal tensile tester can be a crucial decision for many industries and research fields where material strength and quality testing are essential. If you are looking for the best tester, do not miss out on reading this article. There are certain factors to be taken into consideration. Since the online platform has become so vast these days, selecting the right supplier has become so confusing. Isn’t it? It will put anyone in a dilemma. Continue reading to know more about this amazing tester!

0 notes