Don't wanna be here? Send us removal request.

Text

How To Get As-Built Drawings?

The documents that depict a building or project in its final, constructed state are known as as-built drawings or record drawings. These documents reflect all the changes made during the construction and accurately record the completed work.

Obtaining as-built drawings can be crucial for facility management, renovations, and problem-solving. In future construction or maintenance projects, an understanding of the procedure can save time, money, and potential problems.

Steps To Get As-Built Drawings

As-built drawings are generally submitted by a contractor upon completion of a project. You can get in touch with the project's original architect, engineer, or contractor to get as-built drawings.

They typically maintain these records detailing the final construction layout and changes made during the build process. If unavailable, consult the local building departments or hire a professional surveyor to create updated drawings based on existing structures.

Step 1: Initial Preparation

The initial preparation phase is crucial for setting the stage for accurate as-built drawings. To begin, thoroughly examine the project's original design drawings, blueprints, and specifications to learn how it will be built.

You’ll easily find the original design drawings and blueprints in the local municipality or you can contact the project designer or builder. Familiarity with the project’s scope is essential for identifying potential deviations and modifications during the construction phase.

Equally important is gathering the necessary tools and materials, such as laser measurements, cameras, GPS devices, and measuring tapes.

Step 2: Site Survey And Data Collection

When creating as-built drawings, the site visit is a fundamental step. During these visits, pay close attention to the project's current state and compare it to the original design drawings.

It is important to accurately measure any deviations from the original plans. Take help from precise measuring tools to capture changes such as the relocation of walls, doors, windows, electrical outlets, plumbing, and HVAC systems.

Keep a record of any alterations, adjustments made in the field, changes made to the design, or unforeseen issues that were resolved during the construction process.

Step 3: Drafting Of As-Built Drawings

Now, begin by incorporating the information gathered during the site visit into the original design drawings. Drafting your as-built drawings can be accomplished with assistance from a draftsperson or professional CAD drafting firms.

Include any new installations or structures that were not part of the original design, as well as ensure that all measurements, notes, and specifications are accurate. To produce accurate as-built drawings, this phase necessitates precision and attention to detail.

Step 4: Review And Verification Process

The review and verification stage is critical for ensuring the accuracy of as-built drawings. Verify that each change has been accurately captured and documented by working with contractors, engineers, and project managers.

You can also conduct a final site inspection to confirm no additional changes have occurred, and make any necessary adjustments to the drawings based on the final inspection findings, ensuring the as-built drawings reflect the actual constructed environment.

Step 5: Finalization And Submission

Start with cleaning and removing any temporary notes or construction markings from the drawings. This makes sure that the drawings are clear, organized, and professional. Generate the digital copies of the as-built drawings in PDF and CAD formats.

Now, submit the finalized as-built drawings to the client, project manager, or relevant authorities for approval and record-keeping. This step ensures the drawings are formally recognized and archived.

0 notes

Text

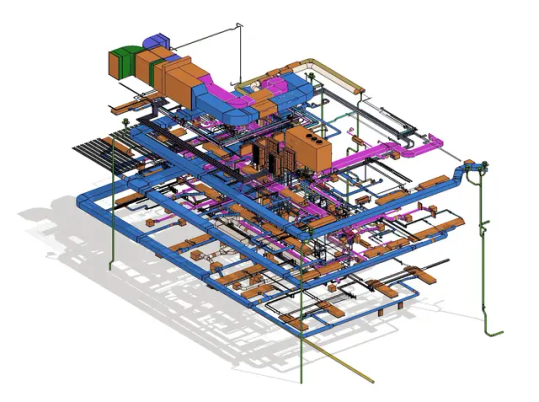

Tips for Effective MEP Coordination in Your Next Project

Construction projects cannot be successfully completed without efficient Mechanical, Electrical, and Plumbing – MEP coordination services. Skilled labor in several technical disciplines, including as welding, erecting, electrical, and plumbing, is required for these operations. It can be challenging to find enough workers for these kinds of projects, which is why so many construction companies turn to labor supply agencies for help.

The Importance of (MEP) Work in Building Projects

The integration of mechanical, electrical, and plumbing – MEP BIM Services works – is crucial in the construction industry for ensuring a building's systems' efficient operation. Successful completion of any construction project necessitates an understanding of the critical role these works play.

Properly implemented MEP coordination services can save maintenance costs, increase energy efficiency, and boost building occupant comfort. However, installation errors of MEP systems can result in significant delays, operational difficulties, and safety risks. The building process can be made more efficient and prevent future issues by investing time and money in the careful design and execution of MEP drawing and activities.

Creating a Comprehensive Project Plan

To begin, clearly define the project's objectives and parameters. The exact specifications for the plumbing, electrical, and mechanical systems must be determined in order to make sure they meet the needs of the building and its occupants.

Next, create a detailed calendar that outlines the MEP BIM services, milestones, and deadlines in chronological sequence. It is absolutely necessary to take into consideration things like procurement lead times, coordinating with other trades, and any specific installation requirements.

Conducting Thorough Site Analysis and Assessment

To get started, take a close look at the topography, soil type, and any infrastructure that may be present on the site. This investigation aims to ascertain the viability and practicality of various Mechanical, Electrical, and Plumbing (MEP) system installations. After that, assess the site’s accessibility and logistical factors. Take into consideration things like how easy it is to get to transportation routes, how much space there is for storing things, and how close utility connections are.

For the equipment and supplies to move smoothly throughout the MEP installation process, effective planning in these areas is crucial. In conclusion, it is essential to ascertain any potential dangers to safety and any applicable legal requirements for the location. Understanding these aspects will make it easier to take the right safety precautions and ensure that all relevant laws and guidelines are followed.

Employing Skilled MEP Contractors and Engineers

Start by thoroughly evaluating potential candidates. Look for individuals or groups with extensive experience in MEP installation and drawing. Consider their track record on similar projects and their expertise in overseeing complex MEP systems.

Additionally, assess the degree of cooperation and communication displayed by the possible MEP engineers and contractors. Working with professionals who are perceptive, proactive, and skilled at effectively collaborating with other project stakeholders is essential.

Bringing Cross-Discipline Collaboration and Coordination in MEP Works

The effective execution of Mechanical, Electrical, and Plumbing (MEP) works in building projects is contingent upon the development of strong coordination and cooperation among diverse disciplines. MEP engineers, architects, structural engineers, and other relevant specialists must communicate and work together effectively to ensure that MEP systems seamlessly integrate with the project's overall design.

To achieve this objective, it is essential to initiate open lines of communication and adopt a collaborative mentality from the beginning of the project. Members of the team need to be encouraged to meet on a regular basis and share information in order to quickly identify and resolve any potential disagreements or coordination issues.

In addition, it's a good idea to use technology in ways and tools that make it easier to work together and coordinate. Software for building information modeling (BIM) is especially helpful in this setting. BIM facilitates the creation of a single digital model that encompasses all project components and enables real-time collaboration and visualization.

0 notes

Text

Role of BIM in Disaster Management

The construction industry is being transformed by Building Information Modeling (BIM), which makes it possible to make better decisions based on data. One of its most critical applications is in disaster management and resilient infrastructure development. Governments and construction professionals can design structures that can withstand natural disasters like earthquakes, floods, and hurricanes by integrating BIM with risk assessment, emergency planning, and post-disaster recovery.

1. Risk Assessment & Hazard Simulation

Using real-time data, BIM lets architects and engineers simulate various disaster scenarios. Before beginning construction, professionals can evaluate flood-prone regions, seismic activity zones, and wind impact models by integrating Geographic Information Systems (GIS). Structures that are able to withstand natural disasters can be designed with the assistance of predictive modeling.

2. Resilient Infrastructure Design

BIM facilitates performance-based design, ensuring that buildings, bridges, and other infrastructure can endure extreme conditions. Features like material strength analysis, load distribution simulations, and energy efficiency modeling help in constructing disaster-resistant structures.

3. Emergency Response Planning

BIM provides 3D visualizations and digital twins that emergency responders and urban planners can use for rescue operations. BIM models assist in determining escape routes, emergency exits, and structural damage prior to human intervention in the event of a disaster, ensuring faster and safer response measures.

4. Post-Disaster Recovery and Reconstruction

After a disaster, BIM plays a crucial role in damage assessment and reconstruction planning. Engineers can quickly estimate the extent of damage, estimate the cost of repairs, and develop effective rebuilding strategies by comparing models before and after the disaster.

Conclusion

BIM is a game-changer in disaster management and resilient infrastructure. By adopting BIM-based risk assessment, simulation, and reconstruction planning, engineers and architects can create structures that minimize disaster impact and ensure public safety.

0 notes

Text

What Are “As-Built” Drawings In Construction

A crucial component of every construction project is the use of as-built drawings. The fundamental motivation behind the as-built drawing serves is to replicate how the contractor built the project and identify what changes were made throughout the course of constructing the project. The final arrangements of as-built drawings contain important information, such as changes to the shop drawing, changes to the plan, changes to the field, affirmed and objected changes made during development, and any small or big change made to the project's end result. A current version of the as-built drawings should be available for reference at some random point during the project.

What is an “as-built” drawing?

By definition, an as-built drawing is a modified arrangement of drawings put together by a temporary endless supply of a construction project. as-built drawings show the dimensions, geometry, and location of all components of the project. Walls, windows, doors, and plumbing fixtures are typical of these two-dimensional floor plans. One of the primary motivations behind an as-built drawing is to be able to document any changes made during the construction of the project that strays away from the original design.

Prior v/s construction software and BIM As-Built Documentation

The traditional method of assessing as-built drawings was a failure in project execution, building recovery, and remodel in the future as it needed legitimate records for a current structure, its change orders, and as-built drawings documentation. Throughout the course of a project's lifecycle, traditional as-built drawings presented numerous challenges when it came to managing and maintaining construction projects.

Why As-built Drawing is basic and who gets profited by it?

As a model is constructed in its underlying phases of construction or arrangement, construction projects are not precise. In contrast to the first plan, changes made to the model encourage temporary workers to collect data for establishments of segments, causing contract-based workers to keep track of changes made to the arrangement or drawings.

As-built drawings have two generous chief purposes, which is fundamental documentation in any construction project. We can implement future improvements based on the information in the drawings, such as changing or redesigning existing structures. It is simpler and effective for the contractual workers to recover as-built reports for accessing the information on drainage systems, ducts, etc.

0 notes

Text

Explain The Key Role of Discipline Coordination in BIM

The AEC sector has been transformed by BIM, which is also revolutionizing project design, planning, and execution. In addition to creating 3D models, BIM Modeling Services encourages collaboration among all project-related disciplines.

By incorporating architectural, structural as well as MEP systems into a cohesive framework, BIM facilitates the seamless communication and coordination. This interconnected approach ensures that every stakeholder works with accurate, up-to-date information thereby reducing the errors, saving the costs as well as delivering the superior outcomes.

The significance of coordinating efforts across various fields cannot be overstated in a time when construction projects are becoming increasingly complex. Effective BIM Coordination Services eliminates the silos, promotes the transparency as well as enables all the parties to work towards the common goals.

Moreover, the ripple effects of such coordination extends beyond the construction. It has an impact on the buildings' long-term performance and sustainability.

What is BIM Coordination?

BIM coordination is the process of integrating and harmonizing various disciplines into a single coherent digital model. This unified model helps to identify and resolve conflicts. The coordination process ensures that all stakeholders work from a single source of truth ultimately reducing the discrepancies and miscommunications.

Why is Coordination Crucial?

1) Eliminating Design Conflicts

Clash Detection: Before construction begins, BIM tools integrate designs from various disciplines to identify overlaps or conflicts in structural, architectural, or MEP systems.

Prevention of Delays: When conflicts are resolved during the design phase, on-site disruptions are kept to a minimum, keeping the project on schedule and within budget.

2) Fostering Collaboration

Centralized Models: A unified BIM model ensures that every stakeholder accesses to the consistent and up-to-date information.

Efficient Workflow Integration: The coordinated workflows make it much easier to complete the tasks and reduce the number of redundant steps.

Transparency in Roles: The well-defined responsibilities and shared accountability build trust and reduce misunderstandings.

3) Enhancing Design Accuracy

Unified Data Sets: In order to ensure design consistency, comprehensive models combine inputs from all disciplines.

Visual Simulations: Advanced tools enables the realistic simulations, helping teams anticipate performance outcomes and refine designs.

Informed Decision-Making: Better decisions are supported by accurate data, which ultimately leads to optimized designs.

4) Optimizing Resources

Material Accuracy: Waste is reduced as a result of precise material estimations made possible by thorough planning.

Labor Optimization: Schedules that are coordinated reduce downtime and boost worker productivity.

Cost Control: Streamlined workflows and fewer errors enhances the financial predictability.

5) Ensuring Compliance

BIM Protocols: Standardized procedures maintains the consistency across all the project stages.

Regulatory Alignment: Reworks and approval delays are cut down when designs are checked against local building codes by integrated models.

6) Streamlining Construction

Reduced Rework: Addressing potential issues in pre-construction phases minimizes the on-site corrections.

Accelerated Progress: Execution speeds up when workflows and documentation are clear.

Improved Safety: Visualized plans highlights and mitigates the potential risks before they escalate into hazards.

7) Delivering Lifecycle Value

Facility Management Insights: Rich data in BIM models aids maintenance, operations as well as the future renovations.

Sustainable Practices: Coordinated designs fosters energy-efficient solutions and environmentally conscious decisions.

0 notes

Text

How BIM Clash Detection Services Prevent Costly Construction Errors

In construction projects, design mistakes are a common source of frustration. It results in costly delays and rework when systems clash, such as plumbing obstructing HVAC ducts or electrical wiring tangled with structural beams. But with Building Information Modeling (BIM), these issues can be caught early, saving time and money before work even begins. The way construction teams prevent errors and keep projects running smoothly is being transformed by BIM clash detection in the following ways.

The Impact of Design Clashes on Construction Costs & Delays

Design clashes can blow up your construction budget. These conflicts between different building systems, like plumbing, electrical, and HVAC, often go unnoticed until construction is underway. When discovered, it means halting work, reevaluating designs, and spending extra money to fix problems that could have been avoided. That’s where BIM steps in, allowing teams to catch these issues in the planning phase—well before it’s too late.

How BIM Clash Detection Helps in Early Error Identification

Imagine having a virtual model of your entire building before you break ground. With BIM, project teams can visualize how every system—structural, electrical, HVAC, plumbing—fits together. Conflict detection helps you find conflicts early, allowing you to make changes before construction starts. This proactive approach not only helps keep the project on schedule but also helps save money.

What is BIM Clash Detection?

Using digital models to find and resolve conflicts between systems in a building's design is called BIM clash detection. The entire project is modeled in 3D to identify potential conflicts before they become a problem, as opposed to waiting for physical issues to arise during construction.

Benefits of BIM Clash Detection Services

Saves Time & Costs: By identifying issues early, you reduce the chances of costly rework and delays. This helps keep the project on track and within budget.

Improves Collaboration: Communication between teams (architects, engineers, and contractors) becomes seamless when everyone is working on the same 3D model.

Enhances Safety: A safer job site can be achieved by identifying potential safety hazards prior to construction beginning.

Challenges in Clash Detection & How to Overcome Them

Despite its value, BIM clash detection does have some drawbacks:

Complex Models: It can be challenging to manage intricate designs on large projects.

Team Coordination: Software differences between teams may result in compatibility issues.

To overcome these hurdles, it’s important to work with experienced BIM providers who know how to manage complex models and resolve clashes efficiently.

0 notes

Text

How BIM saves money and reduces waste?

The BIM Engineers' motto, "Leading in the World of BIM," is supported by the fact that BIM is a potent tool that improves the precision, effectiveness, and sustainability of construction projects. Building information modeling (BIM) is not just about creating 3D digital models of buildings; rather, it is also about meticulously detailing these models to a level of precision that ultimately has far-reaching implications. To say that precision is important in BIM is not an exaggeration.

The Intersection of Precision and BIM

In the context of BIM, precision refers to the level of accuracy and detail contained in our 3D models. How closely the digital models will match the final physical structures is determined by this level of precision. The likelihood that the actual construction project will adhere to the intended design, schedule, and budget is increased when the model is more precise.

A Case for Precision: Eliminating Errors Early On

The prompt identification and correction of design and construction errors is an essential component of BIM precision. Such errors frequently went unnoticed until the construction phase in traditional methods, resulting in costly rework. However, by using precise BIM models, potential errors can be found early in the design process, saving a lot of time and money. According to a study, 75% of businesses that implemented BIM saw positive returns on their investment, largely due to the reduction in errors.

How Precision in BIM Reduces Waste

Beyond financial savings, precision in BIM has significant environmental implications as well. One of the leading global producers of waste is the construction industry. However, given its emphasis on precision,

BIM may be able to assist in reducing this waste. Ordering too many materials to make up for mistakes or design changes is a big source of waste in traditional construction. Project managers, on the other hand, can order exact quantities with BIM's precise calculations and 3D visualizations, thereby reducing waste and surplus orders.

A Case Study: The Impact of Precision BIM on Waste Reduction

Take for instance the construction of Europe's tallest skyscraper, The Shard, in London. BIM was used during its construction to guarantee a high level of precision and significantly reduce waste generation. The project team was able to order just the right amount of materials thanks to the precise and detailed BIM models, which significantly reduced waste and surplus2.

The case of The Shard is a good example of how precise BIM can be and how it can help build buildings that are better for the environment around the world.

How Precision in BIM Saves Costs

In the world of construction, small miscalculations can lead to substantial financial overruns. Cost management undergoes a paradigm shift thanks to BIM's emphasis on precision. BIM enables stakeholders to fully visualize the project, plan more effectively, and make decisions with greater confidence by creating detailed and accurate models.

Through clash detection, one of the primary ways in which BIM contributes to cost savings is Before construction begins, BIM eliminates costly delays and rework by identifying conflicting elements within a design, such as intersecting structural elements or building services.

Additionally, BIM makes it easier to perform more precise quantity take-offs, which improves budgeting and reduces waste. A BIM model can accurately calculate the project's required materials, drastically reducing the likelihood of over- or under-ordering. This not only reduces waste but also lowers project costs overall.

The Future of Precision in BIM

Already, the precision of BIM has demonstrated its tremendous value in terms of cost savings and waste reduction. But what is in store for the future?

BIM should be integrated with other cutting-edge technologies like artificial intelligence, augmented reality, and machine learning, according to emerging trends. It is anticipated that these integrations will result in further advancements in precision. In addition, we can anticipate a rise in global BIM usage, enhanced software capabilities, and improved regulatory acceptance4

BIM will become more than just a design and construction tool in the future. It will develop into a comprehensive solution for managing buildings throughout their lifecycle, bringing the advantages of precision into operation and maintenance in addition to the construction phase, resulting in additional cost reductions and efficiency enhancements.

0 notes

Text

Best Practices for BIM Coordination in Construction Projects

Building Information Modeling (BIM) has fundamentally transformed the way construction projects are planned and executed. It makes it easier to work together, makes designs more accurate, and makes workflows for different stakeholders easier. However, careful coordination among all participants—architects, engineers, contractors, and subcontractors—is necessary for BIM to be truly effective. BIM coordination ensures that everyone works from the same, up-to-date model, which helps to reduce costly errors, clashes, and rework during the construction process. In order to guarantee that construction projects are carried out with the utmost efficiency and the fewest possible complications, this blog will examine the best practices for BIM coordination.

1. Create a Clear BIM Execution Plan (BEP)

The BIM Execution Plan (BEP) is the roadmap for how BIM will be implemented throughout the project. It lays the groundwork for BIM coordination by outlining the project's scope, goals, and procedures for each team member to follow. A comprehensive BEP should include important information such as:

Level of Development (LOD):

The level of detail and accuracy provided by a model at various project stages is referred to as LOD. LOD 100, for instance, could be a conceptual model, while LOD 400, on the other hand, could be a detailed model with all of its components ready for construction. By specifying the required LOD for different phases (concept, design, construction), the BEP ensures that everyone is clear about what needs to be delivered at each stage.

File-sharing protocols:

It’s critical to set up rules for how models, documents, and data are shared between team members. This includes defining which file formats should be used, how versions will be tracked, and how models will be exchanged. This prevents multiple teams from working on outdated versions and helps streamline the data flow across the project.

Roles and responsibilities:

A well-defined BEP should specify who is responsible for what. For example, who will update the architectural model, who will review structural clashes, and who will handle coordination with subcontractors. Having this clarity helps prevent misunderstandings and inefficiencies.

Coordination schedules:

Regular meetings and checkpoints should be scheduled to review progress, resolve issues, and ensure that the project is on track. The BEP should detail these timelines, setting expectations for when models should be updated, when clash detection is to occur, and how often the project team will meet to review updates and resolve issues.

2. Use a Common Data Environment (CDE)

A Common Data Environment (CDE) is a centralized, cloud-based platform where all project data is stored, accessed, and updated in real-time. This eliminates the problem of outdated models or conflicting information between team members. A well-organized CDE not only ensures that all stakeholders have access to the latest versions of project files, but it also helps to:

Real-time updates:

The CDE allows every team member to access the most up-to-date models, plans, and project data. As one party updates the model or documents, the CDE instantly reflects these changes, eliminating the risk of team members working with outdated information.

Version control:

In a construction project, revisions are frequent. It is simple to track which model version is the most recent and which changes have been made thanks to a CDE, which ensures that each new version is correctly stored and logged. This eliminates confusion when teams are reviewing or using models.

Structured data management:

The CDE is able to organize all of the data in categories and folders that are simple to use. This includes both 3D models and other essential documents like schedules, cost data, and design guidelines. This structure ensures that team members can find exactly what they need without delays.

Secure access control:

A CDE offers controlled access, ensuring that only authorized personnel can make changes to specific parts of the project. This is especially important for sensitive data or documents. Team members might have view-only access to some files while others may have editing rights, allowing for greater security and proper data management.

0 notes

Text

Challenges faced while Outsourcing Wood Framing Shop Drawings Services

It has always been a challenging task for clients to outsource their work to a construction company. It becomes necessary for the company to delegate some of their work to another company. As a result, the team decides to outsource a portion of the project to dedicated engineers with only experience in a particular service in order to reduce workload. Several challenges are faced while offshoring the work and it is very important to overcome them instantly, for the smooth flow of the construction project. Likewise, while allocating the work of Wood Framing Shop Drawings, various provocations arise that need to be encountered efficiently.

The client provides precise planning, construction documentation, on-paper requirements, and essentials of the patrons for the construction of the building while outsourcing the work to Wood Framing Shop Drawings Services. The outsourcing company has dedicated engineers and fraudsters who effectively select the appropriate components and elements for the client's precise Shop Drawing structuring. The steps of the drawing take place while formulating drawings, framing the plans, scheduling the table, collecting the components, and designing as per the needs with additional information provided by the clients.

Shop Drawings in specific is the 4 pillars of the construction industry, which help in structuring every drawing. The wood industry benefits from the precise CAD Detailing Services offered by the company. The company provides several other services apart from the Wood Framing Shop Drawing Outsourcing Services that includes, including Structural, MEP, HVAC, and several others.

Kitchen cabinets, doors, windows, and other small drawers can be customized using the Wood Framing Shop Drawing. The customers' ideas are used to craft the wood. Wood mill service providers manufacture millwork, an essential housing component.

Here are the major challenges that are faced while Outsourcing Wood framing Shop Drawing Services :

Quality Assurance : The major challenge to encounter while outsourcing Wood Framing Shop Drawing is the assurance given by the fabricators for the components used for preparing the Drawings. At the time of manufacturing and integration of the models, several clashes or the indifferences arise cause of the constituents used, which brings several problems at the time of implementation. For overcoming the issues and challenges, the AEC experts must specialize themselves in working on different software for delivering quality-based finished products, in turn reducing the cost of manufacturing. With production expertise and consistency in key areas, CAD outsourcing facilitates project management.

Expertise and Protection of Work : The second challenge and the most critical one is a having heavy experience in terms of providing the service and managing the data efficiently. For meeting the purpose, the company must have the best in-house team that follows an untroubled process of construction. The company follows the operational efficacies and computer security which safeguards confidential reports and papers that the company provides to the client. This also helps in determining the reliability of the client based on the past clients, and professionalism.

Large and Superior Projects : An outsourcing company when dealing with several clients has tedious work to tackle both the preparation and execution of the drawings and documentation of Shop Drawing prepared. When a company works on small projects, there is a scarcity of labor force, resources, and undersupply of revenue pre-owned in the processing. The projects in the market might fluctuate, leading to increasing or decreasing as per the needs and specifications of the clients. Because of the condition, it becomes difficult to acquire the necessary resources at a reasonable cost. This is the biggest problem of the construction industry to meet the needs with the provided budget. For overcoming the challenge, CAD Outsourcing with its drafting skills can forego some costs, which might minimize the cost to some extent.

Modern Equipment and Technology : Not catering to the modern equipment in formulating the service that lacks modern tools and technology, puts the company behind the competition. For overcoming the challenge the company must pre-own the advanced technologies and tools that are essential for the in-house company, which requires heavy expenses in providing the training.

0 notes

Text

Why BIM Clash Detection is a Game-Changer for MEP Coordination

In the construction industry, staying ahead of potential conflict is paramount for a seamless project execution. Conflict in construction refers to disagreements among structural, HVAC, mechanical, electrical, and plumbing (MEP) systems. These systems constitute the entire project, providing it with the diverse expertise necessary to put the execution in motion. Any conflict can put the project on hold, significantly disrupting the timeline and elevating expenses. That’s where BIM clash detection can emerge as a lifesaver. Let’s understand how BIM simplifies the MEP coordination while staying aligned with project goals.

Understanding BIM Clash Detection

Building Information Modeling (BIM) Clash Detection is primarily used for transforming the entire project into a real-world 3D environment, spanning all the elements, including design and dimensions. It enables stakeholders to see how accurately the project is executed, how many resources are left, and the time required to complete the upcoming phase. Plus, it can render a simulation of possible conflicts that may occur among different systems.

For example, it can track that a piping installation can derail the HVAC phase due to space constraints. Or, it can spot design irregularities that occur after the fabrication of a certain architectural component.

Clash detection software, like Navisworks or Revit, is among the top software used for clash detection. They can seamlessly run simulations and flag conflicts where system components overlap or interfere.

What is MEP Coordination?

MEP Coordination provides grounds for a unified design wherein the MEP system aligns with the architectural and structural framework of a building. It reinforces seamless coordination among all systems, ensuring they are aligned, code-compliant, and accessible for maintenance.

Typically, every stakeholder has access to this system so that they cannot stay aloof whenever changes occur, preventing costly delays, rework, and on-site conflicts.

Traditional coordination is tedious and time-consuming, as it requires going back and forth with 2D drawings and manual reviews, leading to misinformation, delays, inefficiencies, and redundancies.

Why BIM Clash Detection is a Game-Changer for MEP Coordination

1. Early Detection of Conflicts

One of the standout features of BIM Clash Detection is its ability to spot conflicts during the design phase. It is a kind of guiding light for stakeholders, ushering them to the correct path every single time.

Suppose your project is halfway through and is about to kickstart a plumbing operation. But before you do that, you decide to run a quick simulation through the software, as we discussed above.

As soon as the simulation completes, you stumble upon an unexpected design flaw that can make electrical conduct intersect with a plumbing line. With this preemptive approach, the concerned stakeholders can rework their plan, saving significant money and time in the process.

2. Enhanced Collaboration Among Stakeholders

BIM Clash Detection fosters collaboration among stakeholders by facilitating key data and views at the right time, reinforcing a unified system. Additionally, it can give real-time updates concerning project progress or changes made while keeping everyone in the loop. It can significantly improve how stakeholders make decisions, no matter how complicated or sizeable the project is.

3. Improved Accuracy and Efficiency

Manual coordination of MEP systems is not a walk in the park. It requires extreme mental legwork and steadfast oversight—it is like running into a hamster wheel with no clarity on anything.

The BIM tools can fill this gap by bringing every stakeholder on the same page. Its ability to provide real-time updates and 3D simulations enables a higher level of accuracy at all stages of project development. It keeps redundancies and inefficiencies at bay, ensuring streamlined workflows from start to finish.

4. Reduced Rework and Project Delays

Construction rework is an Achilles’ heel in any project. It not only disrupts the timeline but also attracts a significant budget, hindering the cost-effectiveness.

By resolving conflicts in the virtual stage, BIM clash detection mitigates the scope for on-site modifications. It enables stakeholders to have an explicit view of project progress with optimal control over material take-off. In short, it significantly reduces rework expenses and schedule overruns.

5. Better Design Optimization

The combination of precision-driven clash reports and 3D views enables project teams to optimize the layout of MEP systems. This paves the ground for improved space management, seamless maintenance access, and enhanced energy efficiency.

6. Compliance and Risk Mitigation

BIM tools support a wide range of building codes and safety standards, including local and international regulations. Thus, they can be configured based on the project’s location. Automated clash detection can prevent stakeholders from committing expensive mistakes when it comes to ensuring the building’s safety.

0 notes

Text

How Companies Can Use BIM as a Business Tool

Building information modeling is often associated with building design in 3D, but that is only a small part of what BIM represents. The true value of BIM comes from combining detailed information with virtual geometric models of buildings. This concept goes beyond the three spatial dimensions, and it can include information like project scheduling, cost estimates, actual costs, energy performance, building operation parameters, and maintenance data.

BIM originally evolved as a design tool, but it can be used to manage many aspects of construction and building operations. BIM also has applications in business management, given how accurately it describes projects. For example, developers can use advanced building models as part of the documentation when applying for a loan. A digital twin can also be used to market a building among potential buyers and tenants, even before starting construction.

How BIM Simplifies Communication in Building Projects

Geometric models in 3D are the logical evolution of conventional 2D drawings, and BIM adds many layers of information that enrich the model. However, the advantages of BIM are not only technical:

A 2D drawing is a very simplified representation of a project, and the information contained is only evident for construction professionals and skilled tradesmen. Individuals from other professional backgrounds may have a harder time analyzing the drawings, especially if they lack construction experience.

A detailed 3D model is visually identical to the building it represents. This means it can be understood without having a background in the building industry. However, the model can also contain technical information for architects, engineers, and contractors. In other words, BIM describes projects more effectively, especially for non-technical audiences.

BIM is not only useful for design and construction management. Since 3D models are easier to understand than 2D drawings, they can be used for all types of meetings - presenting projects to investors, negotiating loans, discussing contracts with law firms, etc.

BIM also includes detailed information that can be accessed directly from models. This is much easier than matching components in 2D drawings with their respective specifications:

You can visualize the project in first person with virtual reality headgear, and you can “click” on components to display their costs and other properties.

Navigating information in a virtual environment is more intuitive than using 2D drawings and large bills of quantities in table format.

A BIM model can contain the same information as a set of 2D drawings and specifications, but make it much easier to visualize.

In existing facilities, BIM is useful to analyze and discuss the implications of building upgrades and renovations. On the other hand, when a building is poorly documented, architects and engineers must set aside enough time for a detailed inspection. There may be unpleasant surprises and change orders even when working with professionals since buildings have many hidden components.

Visiting a Complete Building Virtually Before Starting Construction

When BIM is combined with virtual reality (VR) or augmented reality (AR), a building that does not exist yet can be visited. This also applies to renovations, where BIM can be used to model an existing building after the modifications. For example, when negotiating with potential investors, a virtual tour of the finished project gives a better impression than sitting down to discuss plans and specifications.

Engineering departments within companies can also use BIM to discuss projects with internal clients. For example, engineers can present many equipment options or layouts that meet the same requirement. The advantages and limitations of each option can be easily discussed with other departments and the upper management, before spending capital.

In general, BIM demonstrates that the construction professionals in a project are technically capable. This provides confidence in the project, which is beneficial for financing, sales, and leasing. BIM also makes communication simpler - 2D plans and specifications can be misinterpreted more easily, causing confusion and mistakes, but a virtual building model is clear.

0 notes

Text

How As-Built BIM Modeling Supports Lifecycle Management

One of the key benefits of as-built BIM models is their ability to streamline maintenance planning. Facility managers can confidently schedule maintenance tasks and part replacements because they can refer to precise, up-to-date information about structural elements, mechanical systems, and critical components. This foresight not only helps prevent unexpected failures and costly repairs but also ensures that maintenance activities are conducted at the optimal times, extending the lifespan of building assets and reducing operational disruptions.

It is easier to monitor energy efficiency, wear and tear, and regulatory compliance with as-built BIM models because they provide a robust framework for tracking building performance over time. By maintaining accurate data on the building’s systems and structural conditions, facility managers can identify trends in energy usage, detect areas requiring efficiency upgrades, and address signs of wear before they escalate into larger issues. This continuous tracking contributes to a proactive management approach, allowing for adjustments that improve the facility’s sustainability, safety, and operational efficiency year after year.

Challenges in As-Built BIM Modeling and How to Address Them

Addressing challenges is essential for creating a reliable as-built model that effectively supports long-term facility management and lifecycle needs.

Data Collection Complexity

Collecting data in the field can be complicated by various factors, such as site restrictions, limited access, and environmental conditions. Buildings with high security or limited accessibility, such as hospitals or industrial facilities, may restrict the times or areas where data collection can occur. Additionally, environmental factors like lighting, weather, or confined spaces can impact the accuracy and completeness of the data gathered. To overcome these challenges, teams often use specialized scanning equipment, including compact or portable 3D laser scanners and drones, to access hard-to-reach areas. Planning data collection during low-traffic times and using versatile tools helps ensure thorough and accurate scanning, even in complex environments.

Point Cloud Processing and Model Creation

Another significant obstacle is turning point cloud data into models that can be used, as the large file sizes and intricate geometry can put a strain on computing resources and take a long time to process. This phase involves cleaning, filtering, and segmenting the data to remove noise and align elements accurately, transforming it into a manageable form for BIM modeling. Efficient workflows and advanced software solutions play a critical role here, allowing teams to manage the data effectively. Additionally, using cloud-based processing or specialized modeling tools can streamline this phase, enabling faster turnaround times and more efficient handling of extensive data sets.

Consistency and Standardization

In as-built BIM modeling, consistency and standardization are crucial, especially for large-scale or phased projects where multiple teams may be involved over extended periods. Without uniform data and modeling standards, the final as-built model may suffer from inconsistencies that limit its effectiveness. To address this, it’s essential to establish clear standards for data collection, modeling processes, and model elements from the outset. Using a standardized template, adhering to industry standards (such as ISO 19650 for BIM processes), and conducting regular quality checks ensure that the model maintains consistency and can be used confidently by all stakeholders.

0 notes

Text

How MEP Engineering Adds Value to Your Project

Through the use of BIM technology, MEP Engineers can collaborate with building owners and designers to develop working visualizations of a building’s mechanical, electrical, and plumbing (MEP) systems. This opens the door to system awareness and system improvements that can have both immediate and long term benefits.

Energy Analysis and Savings

Revit software allows MEP engineers to create detailed 3D models of individual rooms and systems within a BIM to ensure that all systems are buildable as designed and will work seamlessly together. MEP Engineers can evaluate the amount of energy that the MEP systems will consume throughout each design phase of a BIM thanks to the advanced technological capabilities of Revit.

Two common MEP systems that consume significant amounts of energy are HVAC systems and lighting. In commercial buildings in the United States, HVAC systems alone are the largest source of energy demand, accounting for 40% of the overall energy consumption. Through energy analysis, however, MEP Engineers can make informed decisions to reconfigure a system’s settings or recommend updates to improve the system’s efficiency and energy demand.

Similarly, indoor lighting systems have been measured to account for roughly 17% of energy consumption in commercial buildings in the United States. With the help of MEP engineering, this amount can also be dramatically reduced through skillful use of natural light, automation, and timing systems.

Re-Commissioning

MEP engineering can save on long term costs and headaches as well. If BIM is used to model a building during its initial conception, then those models will be extremely useful during the re-commissioning and lifespan of the structure. Re-commissioning takes places when a building has been in use for a certain number of years, at which point, the building owner will want to ensure that all systems such as HVAC and lighting are functioning at maximum efficiency.

Having access to BIM and Revit software allows MEP engineers to analyze the current operational states of MEP systems, including viewing difficult-to-access areas, and allowing the engineers to prescribe settings adjustments and/or updates to system technology. This type of analysis can lead to immediate benefits like less waste, less maintenance, and reduced energy consumption, yet it can also improve the lifespan and function of MEP systems over the long haul.

0 notes

Text

What is a structural engineer?

A structural engineer frequently serves as a consultant to architects or building contractors. They are responsible for defining loads, determining the structural system, calculating stresses and specifying which materials to use. Structural engineers work with a palette of materials including steel, concrete, masonry, timber and glass.

Do I need a structural engineer?

When making renovations, adding on, or doing anything else that could affect your home's stability, you might need the help of a structural engineer. A structural engineer works with your architect and building contractor by offering information essential to the renovation process, including structural drawings, calculations, and specifications.

Planning permission, listed building consent, and compliance with building control regulations may also require this information.

What does a structural survey cost?

The structural survey cost and indeed whether you need a structural engineer will be dependent on the project that you have planned. A structural survey cost can depend on a variety of factors including the size, type, and location of the property and also the size of the project.

They are often required for solar panel installation, beam calculations for extensions, loft conversions, door and window modification, internal wall modification, underpinning, and chimney removal.

0 notes

Text

HOW 3D BIM MODELING WORKS?

The real needs of the client are the primary focus of BIM Modeling. Due to its need to build lean buildings and its usability across disciplines, the building services, engineering, and architectural teams have all adopted the BIM concept. The use of 3D modeling has been around for a long time, and the industry is also adjusting to the new BIM process workflows. But the owners do not have clarity so as to what could be actually achieved at an optimum cost using these models.

We will tell you about how and when to use and to what extent using BIM are beneficial in this article. By using Autodesk Revit Architecture, Revit MEP and Revit Structure, creation of pre-construction planning design data is possible for a diverse range of projects with the same family of software. Alongside Closed BIM approach, an Open BIM environment uses common file formats such as IFC (industry foundation classes) to reduce software interoperability issues and delays. Firstly, it is important to know the difference between parametric BIM models and non-BIM 3D CAD models.

BIM Models are embedded with parametric details which are highly useful from design to management of the environment. While 3D CAD Models only provide visual details, they are a virtual representation of a building. 3D CAD models used in design, development, and construction are created using tools like AutoCAD architecture and AutoCAD MEP.

Gaining a deeper understanding of the model's intended use is one of the primary factors that determines whether BIM is required or not. Numerous customers request a BIM model when all they need is a smart 3D model that can assist us in displaying the construction drawings. In rare instances, the BIM model may serve as the foundation for project planning, design, construction, and management.

In these scenarios, stakeholders with extensive project experience must have access to the BIM model at various stages of the project's life. Therefore, the information contained within a BIM model is the most significant determinant of its success. Data sharing and interoperability standards, which facilitate smooth collaboration, may also be responsible for the success story.

Regardless of whether a BIM model or a non-BIM CAD model is required, the AEC industry has been forced to adopt a more progressive approach as a result of BIM's widespread adoption. Virtual planning and intelligent development techniques for architectural and building services have been embraced by the entire supply chain as a result of this.

0 notes

Text

How MEP BIM Coordination Helps Contractors in Construction Process

MEP BIM-enabled conflict resolution powers seamless fabrication, installation and construction processes with minimal errors and uncompromised quality. Contractors are increasingly unlocking the BIM clash resolution advantages to optimize project costs and shrink project timelines.

Inaccurate or clash-ridden MEP systems can seriously jeopardize fabrication and onsite installation. Designing and building complex projects requires perfect synchronization and harmony between multiple MEP components. Identifying and resolving clashes and any discord at the pre-construction stage through visual 3D MEP models improves onsite installation efficiency through reduced rework, fewer project delays and minimal cost overruns.

How BIM-based MEP coordination system overcomes these challenges

Enhances 3D visualization of clashes and eases clash resolution

The coordinated BIM model provides a three dimensional view of the entire building project during pre-construction, enabling MEP contractors to easily visualize any design clashes.

Contractors are able to examine the actual or precise space that is available thanks to the in-depth 3D views of the corridors, fire walls, interstitial space, and sheer walls. This makes it easier to accommodate all of the services and prevents MEP systems from physically interfering with one another. MEP contractors and general contractors can easily mitigate construction delays caused due to rework by devising alternate solutions for the clashes. For example: changing the conduit sizes or the service routes.

Enhanced visualization of a public park in US speeds up MEP fabrication process

A construction firm in the US, needed BIM LOD 300 models of architecture, structural and MEP disciplines for a public park. Rightserve developed a clash-free MEP model to guarantee that the newly constructed portion of the utility system installation will not disrupt the existing MEP systems

The enhanced 3D visualization helped the MEP contractors detect and resolve the clashes between the existing and the proposed architectural and MEP elements both above and below the ground. The coordinated MEP models minimized delays and RFIs, while speeding up the MEP fabrication process and project delivery.

Automates clash detection process

The distribution of MEP elements such as ductwork, electrical equipment, plumbing water pipes, VAV boxes etc. makes construction projects complex. It also results in numerous conflicts in MEP coordination.

BIM (Building Information Modeling) based MEP coordination systems automate the coordination and clash detection process by identifying soft clashes, hard clashes and workflow interferences at the pre-construction stage. This eliminates the need for hundreds of manual labor hours.

Automated MEP clash-detection saves construction cost for a multistorey building, US

An architectural firm in US specializing in hospitality, required coordinated and clash free models for all trades for a multi-storey building. The team at Rightserve created 3D Revit models at LOD 300 for architectural, structural, MEP and FP systems.

The coordinated 3D BIM model helped the MEP contractors optimize the placement of components in congested spaces and decreased RFIs. The client saved on construction cost, while meeting the project’s aggressive schedule.

Gets stakeholders on the same page in initial kick-off meetings

If various disciplines are not in sync, MEP coordination and clash-free installation becomes virtually impossible. A 3D coordinated MEP BIM model integrates all the project information into one model, making it a one-stop reference for all the different teams. This increases the effectiveness of the kick-off meetings in the pre-construction stage, allowing contractors and various stakeholders to be on the same page and gain better clarity.

Increased collaboration from 3D MEP model enables firm make informed decisions, Asia

An Asian architectural firm required a Revit model of all disciplines, including BOQ and clash detection reports for a data center. The team at TrueCADD created architectural, structural, and MEP BIM Revit models and provided clash detection reports using Navisworks®.

The client was able to plan and manage on-site activities more effectively and reduce construction waste thanks to the 98% accuracy of quantity estimations and increased collaboration brought about by the conflict-free 3D MEP models.

0 notes

Text

The Importance of MEP (Mechanical, Electrical, Plumbing) Coordination in Construction and Design Project

Coordination of MEP is essential for construction advancements that improve performance, functionality, and sustainability, reduce conflicts, and save costs.

The process of creating a design that is not only functional but also an effective structure that can meet all of the needs is complex and requires collaboration between various work disciplines.

One of the focal points of MEP coordination is MEP, where the flow of the three major systems of the building, mechanical, electrical, and plumbing, are synchronized into one convenient system. Through the lens of this blog entry, we will go through the importance of MEP coordination in the design of buildings and how it is a success for construction projects.

What is MEP Coordination?

In order to improve the building's efficiency, the mechanical, electrical, and plumbing system designers integrate and work together at the coordination between MEP stage. They group these systems in such a way that they can operate without getting in the way and produce the expected results. MEP coordination ought to come to us to settle disputes, cut costs, and improve the building's efficiency.

MEP Coordination Process: Typical Stages in MEP Coordination

Each of the key stages in the MEP coordination process is crucial to the smooth and effective integration of the mechanical, electrical, and plumbing systems.

Project Initiation

Since the MEP coordination process is the first step, project goals, scope, and specifications are being determined, followed by MEP coordination. One of the first steps is to pinpoint the main stakeholders and make a perfect communication plan to operate through the following stages.

Develop a BIM Execution Plan (BEP)

Based on a BIM Execution Plan specifying the roles, responsibilities, level of detail for each building system, and the procedures for data interoperability and cooperation, the team proceeds with the project.

MEP 3D Modeling

With the assistance of Building Information Modeling software, such as Autodesk Revit, the generation process moves on to the creation of 3D models for various MEP systems in the following phase. Conflict detection is made possible by these models, which are used for the physical representation of system layouts and functionality.

Clash Detection and Resolution

Clash Detection software is applied to these situations to identify whether there are conflicts between different elements. Coordination meetings and subsequent updates of models then follow these consultations.

Coordination Meetings

Technical management meetings are scheduled twice a year to keep track of the problems, talk about them, and decide on design changes with a central coordinator.

Model Updates and Revisions

The course on the MEP models is crucial as they are change and revised along the way as the design progresses. As a result, the models never lose their credibility or become out of date.

Validation and Verification

The step in MEP coordination that comes last involves triple-checking all the models to ensure they comply with the requirements and regulations of the building codes and the project goals.

Final Documentation

The final step in this process is the production of the final documentation, which includes drawings, specifications, a schedule, and so forth, following the completion of the MEP coordination. This document serves to strengthen the buildings.

As-Built Documentation

For the next step after the construction, the as-built documentation is prepared to follow the design and reflect the changed or modified design during the construction.

Benefits of MEP Coordination in Building Design

There was less time and construction work required.

The two benefits of using an improved performance and energy efficiency system.

Improved quality of the Inside environment and a better chance of survival in case of an accident.

It lowered maintenance, supplies, and heating/cooling expenses.

It helped disciplines work together and communicate more effectively across borders.

Take a listen to the provided audio, in which a speaker discusses the significance of higher education in determining young people's career paths. Pay attention to the speaker's tone, emphasised words, and key points. Then, rewrite the audio as a sentence using your own words.

Quicker project completion and less rework

0 notes