Text

In this episode, we explore how the Busbar Ultrasonic Welding Machine enhances manufacturing precision for EV batteries and energy storage systems.

#BusbarUltrasonicWelding#ManufacturingPodcast#BatteryTech#EVProduction#UltrasonicWeldingMachine#IndustrialAutomation#SemcoInfratech

0 notes

Text

youtube

Watch how the Busbar Ultrasonic Welding Machine delivers fast, reliable, and high-strength welds for busbars in lithium battery and EV production lines. ✔️ High-frequency ultrasonic technology ✔️ Consistent weld quality ✔️ Ideal for clean energy assembly setups

#BusbarUltrasonicWelding#WeldingAutomation#EVManufacturing#BatteryWelding#SemcoMachines#CleanEnergySolutions#UltrasonicWelding#Youtube

0 notes

Text

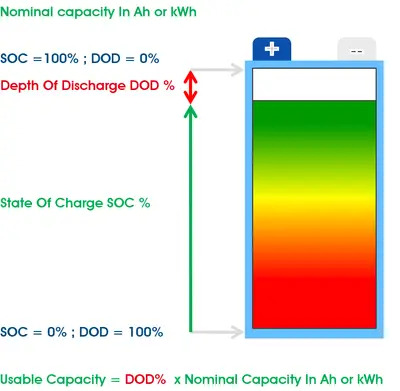

Advanced SOC Diagnostics for Lithium-ion Battery Health

Accurately determining the State of Charge (SOC) is vital for effective battery health management in today’s energy-driven world. Just as you rely on a fuel gauge in your car, SOC reflects how much usable energy remains in a lithium-ion battery, preventing sudden failures and optimizing performance.

Modern Battery Management Systems (BMS) use layered diagnostic algorithms to ensure SOC accuracy, compensating for variables that influence measurement reliability.

Advanced Methods for SOC Estimation

1. Ampere-Hour Integration (Coulomb Counting)

This method continuously tracks the current entering and exiting the battery. While fundamental to SOC calculation, it’s prone to drift errors due to sensor inaccuracies and battery self-discharge. Thus, it often requires correction from other techniques.

2. Charge & Discharge Voltage Correction

Lithium-ion batteries exhibit predictable voltage behaviours during charge/discharge cycles. By comparing these voltage/current patterns against predefined SOC curve libraries, systems refine their SOC accuracy and adjust readings based on real-world performance.

3. Open Circuit Voltage (OCV) Correction

OCV represents the battery voltage at rest and strongly correlates with SOC. Using a battery-specific OCV-SOC curve, systems can recalibrate SOC values periodically during rest intervals, ensuring greater accuracy across usage conditions.

4. Full/Empty Position Reset

When the battery reaches a full or empty state, the SOC is calibrated to 100% or 0%, respectively. These reset points are critical for avoiding long-term drift in battery state of charge monitoring and help align individual cell voltages within a battery cluster.

Real-World Scenario: SOC Step-Down Anomaly

At a project site, engineers noticed a recurring SOC drop, even while the battery was idle. Though OCV calibration was enabled, a step-down pattern appeared during rest periods. Investigation revealed the root cause: the default OCV table from the manufacturer had not been correctly configured in the BMS.

Surprisingly, disabling the OCV calibration didn’t solve the issue. Digging deeper, engineers discovered a “SOC loss power” reading of 2086W, signifying phantom energy loss. The cause? An erroneous power compensation setting within the system’s persistent memory.

The Fix: EEPROM Reset & Cache Cleaning

To correct the issue:

The team executed the “AAA4” command to reset the EEPROM, which holds configuration data and compensation values.

A full system refresh using “read all” restored accurate SOC levels.

An automatic cache cleaning function was added to purge stale or incorrect data from volatile memory.

Post-reset, SOC readings stabilized. No further drop was observed during a 2-hour rest, validating the correction.

Best Practices for SOC Troubleshooting

Always verify SOC-OCV data from the battery manufacturer.

Monitor and correct hidden settings like SOC loss power compensation.

Follow a structured battery diagnostics workflow.

Integrate memory cache maintenance into your software routine.

Conclusion

Maintaining optimal lithium-ion battery health hinges on accurate SOC diagnostics, robust algorithms, and meticulous system calibration. As this case study demonstrates, even minor misconfigurations can cause persistent problems. Through proactive diagnostics, firmware resets, and routine memory maintenance, engineers can ensure consistent SOC performance, safety, and battery lifespan optimization.

#State of Charge (SOC)#battery health management#lithium-ion battery#Battery Management Systems (BMS)#SOC calculation#battery self-discharge#SOC curve libraries#OCV-SOC curve#battery cluster#battery diagnostics#SOC loss power compensation#EEPROM#cache cleaning function#battery lifespan optimization

0 notes

Text

The Fiber Laser Cleaning Machine offers fast, non-contact, and eco-friendly surface cleaning—ideal for removing rust, paint, and contaminants from metal surfaces with high precision and no damage.

#FiberLaserCleaningMachine#LaserCleaning#IndustrialCleaning#RustRemoval#EcoFriendlyCleaning#SurfacePreparation#LaserTechnology#PaintStripping#MetalCleaning#WeldingPreparation#BatteryManufacturing#NonContactCleaning#ToolMaintenance#LaserAutomation#CNCManufacturing

0 notes

Text

Listen to the unique acoustic signature of ultrasonic welding as it bonds multi-strand wire harnesses. The sharp, controlled frequencies reflect a cutting-edge process utilized in the manufacturing of EVs, electronics, and energy storage systems. This audio clip captures the power of non-invasive, high-frequency joining.

🔊 Perfect for understanding industrial automation through sound.

Whether you’re into sound design, industrial tech, or engineering acoustics, this one's for you.

#ultrasonic welding sound#industrial audio#wire harness welding audio#manufacturing soundscape#precision engineering sound#machine acoustics#non-solder welding#high-frequency joining

1 note

·

View note

Text

youtube

This video demonstrates how ultrasonic welding is used to seamlessly fuse multi-strand wire harnesses. With no heat or solder, the process delivers a strong, conductive bond essential for automotive, battery pack, and electronic component applications.

🔹 Fast, precise, and reliable 🔹 Solder-free & eco-friendly 🔹 Perfect for high-volume production

Ideal for industrial automation, this welding technique is revolutionizing how electrical connections are made.

📽️ Learn more about ultrasonic welding systems and their role in smart manufacturing!

#ultrasonic welding#wire harness welding#multi-strand wire welding#battery wire assembly#electrical wire bonding#ultrasonic welding machine#automotive harness welding#high-speed industrial welding#electronic component assembly#Youtube

0 notes

Text

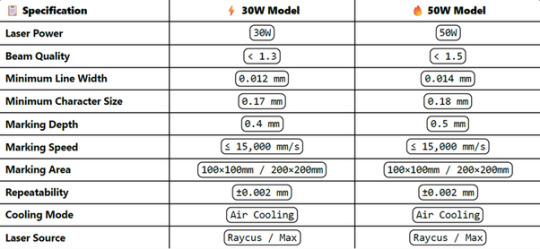

Empowering Smart Manufacturing: The Rise of Fiber Laser Marking Machines

As industries rapidly shift toward customization, miniaturization, and automation, the demand for high-precision marking and engraving technologies is more critical than ever. Fiber laser marking machines have emerged as a game-changing solution, delivering unmatched speed, accuracy, and long-term durability.

These systems are engineered for permanent marking of metals and select non-metals, making them indispensable in the electronics, automotive, medical device, and industrial manufacturing sectors.

What Is a Fiber Laser Marking Machine?

A fiber laser marking machine is an advanced, third-generation system that utilizes a fiber laser source and high-speed galvanometric scanners to mark, engrave, or etch surfaces with extreme precision. Operating at a wavelength of 1064 nm, these machines are ideal for marking stainless steel, aluminium, brass, and certain industrial plastics, ensuring clear, permanent identification marks.

Key Applications in Lithium-ion Battery Manufacturing

In the world of lithium-ion battery manufacturing, where precision, cleanliness, and traceability are paramount, fiber laser machines meet and exceed industry requirements:

Laser Cleaning of Cell Tabs and Terminals Removes oxides and contaminants from battery tabs, busbars, and cell terminals without damaging the surface, ensuring optimal electrical contact and weld integrity.

Traceability Marking on Cell Casings and Modules Permanently engraves QR codes, barcodes, and serial numbers on battery cells, modules, and pack casings for complete lifecycle traceability.

Marking Insulation Layers and Protective Films Enables non-invasive marking on insulation films and separators, aiding component identification during automated assembly processes.

Core Benefits of Fiber Laser Marking Machines

Ultra-Fine Marking Precision – Ideal for detailed micro-text, data matrix codes, and alphanumeric identifiers.

Fast, Continuous Operation – Speeds up production lines by minimizing cycle time.

No Consumables – A cost-effective, eco-friendly solution suited for cleanroom environments.

Maintenance-Free Design – Delivers up to 100,000 hours of reliable operation.

Air Cooling System – Simplifies system integration and reduces operational complexity.

Broader Industrial Applications

Electronics Industry – Circuit boards, microchips, mobile phone casings

Automotive Sector – Gears, engine components, VIN plates

Medical Field – Surgical tools, implants, product IDs

Consumer Goods – Watches, designer accessories

Tool Manufacturing – Precision tools, calibration equipment

Conclusion

Fiber laser marking machines are revolutionizing the landscape of smart manufacturing by delivering the precision, efficiency, and traceability that modern industries demand. Their critical role in lithium-ion battery production—from laser cleaning to traceability marking—ensures safer, smarter, and more streamlined production lines.

Whether you're handling microscopic components or large-scale battery packs, fiber laser technology empowers your operations with consistent marking and cleaning processes essential for high-volume, high-precision manufacturing.

#fiber laser marking machines#smart manufacturing#laser cleaning#traceability in battery production#laser engraving technology#high-precision marking#battery manufacturing equipment#non-contact marking systems

0 notes

Text

Compact and reliable Battery Testing System 120V 50A 4CH designed for accurate performance testing of lithium battery packs. Ideal for multi-channel, high-voltage testing in EV and energy storage applications.

#Battery Testing System 120V 50A 4CH#Multi-channel battery tester#Lithium battery pack tester#Battery testing equipment#High voltage battery tester#EV battery testing system#4 channel battery tester#Battery discharge and charge tester

0 notes

Text

Tune in to learn how aluminum foil welding for batteries helps improve their performance and safety. We discuss welding techniques, connection reliability, and its impact on efficient battery assembly.

#Battery aluminium foil welding#battery welding process#lithium-ion battery assembly#tab welding techniques#battery manufacturing audio#battery safety welding#foil welding insights

0 notes

Text

youtube

Watch how battery aluminium foil welding plays a key role in lithium battery manufacturing. This video covers ultrasonic and laser welding methods, equipment used, and how precise welding ensures strong connections in cylindrical, pouch, and prismatic cells.

#Battery aluminium foil welding#battery welding video#ultrasonic battery welding#laser welding lithium battery#battery manufacturing process#tab welding machine#battery pack assembly#Youtube

0 notes

Text

Overcoming Welding and Forming Challenges in Lithium-Ion Power Batteries

Welding and forming are foundational processes in lithium-ion battery assembly, directly impacting the quality and safety of the final product.

However, these processes come with their share of challenges, particularly when dealing with sensitive materials like aluminium and complex battery structures.

Common Welding Challenges in Power Battery Manufacturing

Aluminium Welding Issues: Due to aluminium’s reflective surface and low absorption rate, achieving precise laser welding is difficult. Common problems include porosity, spatter, and cracks.

Thin Battery Shells: These require meticulous control to prevent material burn-through or warping.

Welding Geometries: Corners and soft-wrapped ears are notoriously hard to weld without dedicated fixtures and high-precision techniques.

Modern Solutions in Battery Welding

To counter these issues, manufacturers are adopting:

Advanced Laser Welding Technologies, including adjustable ring-mode lasers (ARM) for improved control.

Ultrasonic Welding, ideal for soft materials with minimal thermal stress.

Surface Pre-Treatment techniques to ensure cleaner, stronger welds.

Optimized Fixture Design to improve part alignment and stability.

Continuous process optimization of welding parameters for consistent results.

Why Battery Assembly Equipment Matters?

A critical enabler of high-quality manufacturing is the use of advanced battery welding machines. Reliable battery equipment suppliers not only provide cutting-edge machinery but also ensure long-term performance through training and maintenance support.

Especially in India, top lithium-ion battery assembly equipment providers are helping local manufacturers meet international quality standards with their customized solutions.

Conclusion

By addressing key challenges in battery pack welding and forming, and leveraging innovations from top equipment suppliers, the battery manufacturing sector can achieve better efficiency, reliability, and product safety.

#power battery welding challenges#battery forming process issues#solutions for battery welding defects#power battery manufacturing problems#welding and forming in battery production

0 notes

Text

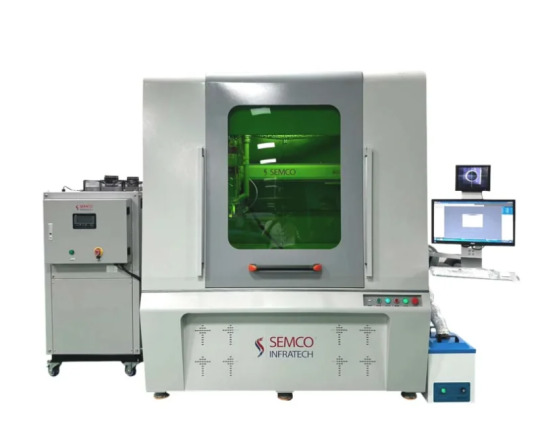

Improve traceability and efficiency in lithium-ion battery manufacturing with SEMCO Infratech’s 30W/50W Fiber Laser Marking Machine. Designed for high-speed, permanent marking on EV batteries, energy storage systems (ESS), and more, ensuring precision and long-lasting results for every application.

📞 +91-8920681227 📧 [email protected] 🌐 www.semcoinfratech.com

#FiberLaserMarking#LaserMarkingMachine#BatteryAssembly#EVBatteryProduction#LithiumIonBatteries#BatteryManufacturing#LaserEngraving#SemcoInfratech#IndustrialMarking#ESSProduction#EVManufacturing

0 notes

Text

youtube

This video showcases the ultrasonic welding process used to join copper and aluminium busbars in battery pack manufacturing. The technique ensures strong, clean, and reliable joints without melting the materials, ideal for EV and energy storage applications.

#Ultrasonic welding explained#Busbar welding podcast#Battery manufacturing insights#EV assembly techniques#Copper and aluminium bonding#Industrial welding audio#Welding process overview#High-efficiency battery welding#Smart manufacturing in batteries#Non-invasive welding methods#Youtube

0 notes

Text

In this short clip, I'd like you to discover how ultrasonic welding is revolutionizing the way copper and aluminum busbars are bonded. A must-hear for engineers, technicians, and battery manufacturers.

#Ultrasonic welding explained#Busbar welding podcast#Battery manufacturing insights#EV assembly techniques#Copper and aluminium bonding#Industrial welding audio#Welding process overview#High-efficiency battery welding#Smart manufacturing in batteries#Non-invasive welding methods

0 notes

Text

How OCV Tester Machines Power Battery Performance & Quality?

The Open Circuit Voltage (OCV) Tester Machine is a critical piece of battery testing equipment used extensively across the lithium-ion battery manufacturing sector. It measures the voltage of a battery without applying any load, offering vital insights into its State of Charge (SoC), State of Health (SoH), and consistency.

By conducting non-invasive voltage checks, OCV testing helps ensure batteries meet rigorous safety and performance standards before being installed in electric vehicles (EVs), energy storage systems (ESS), and consumer electronics.

How Does an OCV Tester Work?

Battery Placement: The battery is carefully placed in the tester to align precisely with high-accuracy probes.

Voltage Measurement:

High-precision probes contact battery terminals.

Measures open-circuit voltage with zero current draw.

Achieves millivolt-level accuracy.

Data Processing:

Compares voltage against predefined parameters.

Identifies irregularities linked to aging or defects.

Sorting & Classification:

Categorizes batteries based on OCV results.

Group similar cells for consistent battery pack assembly.

Flag defective batteries for quality control.

Mechanism Behind OCV Testing

OCV testing operates on the principle that the battery's open-circuit voltage correlates with its charge level and overall health.

Key features include:

High-precision electronics using advanced voltmeters.

High input impedance probes to ensure zero current flow.

Automated handling systems for high-speed processing.

Temperature compensation algorithms for accurate diagnostics.

Importance of OCV Testing

Quality Assurance:

Verifies adherence to design specifications.

Detects early-stage degradation.

Manufacturing Defect Detection:

Highlights issues like internal shorts or faulty coatings.

Battery Grading:

Ensures matched cells for EV and ESS packs.

Enhanced Safety & Reliability:

Identifies cells prone to thermal runaway or failures.

Formation & Aging Analysis:

Supports SEI layer monitoring during charge-discharge cycles.

Applications Across Industries

Electric Vehicles (EVs): Boost battery life and reliability.

Consumer Electronics: Ensures consistent performance in devices.

Energy Storage Systems (ESS): Guarantees long-term operation.

Aerospace & Defence: Assures performance under extreme conditions.

Selecting the Right OCV Tester

When choosing an OCV tester, manufacturers should consider:

Accuracy: Millivolt-level measurement capabilities.

Automation: For high-throughput production lines.

Data integration: For real-time analysis and traceability.

Compatibility: Across chemistries and battery formats.

Conclusion

From cell sorting to quality control, the OCV Tester Machine is essential for creating safe, high-performing lithium-ion batteries. As demand for batteries in EVs, ESS, and consumer electronics grows, OCV testing stands as a pillar of battery manufacturing efficiency.

#battery quality control#battery testing equipment#Lithium-Ion Battery Testing#OCV tester machine#OCV testing in lithium-ion batteries#open circuit voltage tester#state of charge (SoC) measurement

0 notes

Text

Experience advanced welding precision with the GCLW 6000W Laser Welding Machine—engineered for high-performance lithium battery production lines.

#GCLW6000W#LaserWeldingTechnology#BatteryPackWelding#HighPowerLaserWelder#BatteryProductionLine#LithiumBatteryWelding#AutomatedWeldingMachine#LaserWeldingSolutions#6000WLaserSystem#BatteryAssemblyEquipment

0 notes

Text

An audio breakdown of the Closed Cabinet 6000W Laser Welding Machine—its features, benefits, and role in battery manufacturing safety.

#LaserWeldingTech#6000WMachine#WeldingSolutions#IndustrialAudioGuide#BatteryWelding#SmartManufacturing

0 notes