Don't wanna be here? Send us removal request.

Text

HOW DO INDUSTRIAL BATCH CODING MACHINES WORK?

Different industries require different batch coding machines capable of printing codes and data to a diversified range of products and packaging. In this blog, we will take you through details of two different technologies to guide you on how to do industrial batch coding machines work, and their applications in various industries and sectors.

Batch Coding Machines are types of equipment that execute the process of batch coding. Batch coding is a process of inscribing codes in the form of numbers and letters that implies the manufacturing dates, expiry dates, batch number, etc.

How Does a Coding Machine Work?

Here, we will discuss two major working principles of coding machines that are commonly used by many manufacturers. These are laser marking and thermal inkjet printing.

1. Laser Marking

Laser marking is the process where a highly focussed beam of light is used to mark the data on a product surface. This focussed beam of light targets a specified area on the product surface and creates a piece of accurate and precise information that is easy to read.

2. Thermal Inkjet Printing

Thermal inkjet printing is a process that uses a thermal inkjet printer or thermal foaming inkjet printer to mark the data on a product. The thermal inkjet printer heats the ink that prints the product.

Some semi-automatic and fully automatic machines also use hot stamps instead of ink, but they also work on the thermal printing principle, where heat is used to print the information on the product.

For more details please visit our full blog:

https://smartpackindia.com/blog/how-do-industrial-batch-coding-machines-work-/

0 notes

Text

Importance Of Shrink Wrapping Machine

Shrink-wrapping is a widely used packaging technique in small to large-scale businesses to increase the shelf life of their items at low costs. Here are 5 reasons why the importance of shrink-wrapping machines in the FMCG sector is a big hit.

1. It Keeps Edible Items Fresh: This packaging technique prevents moisture, dust, and oxygen from reaching the edible item enclosed inside. This, in turn, reduces the chances of the product getting degraded and increases its shelf life.

2. It Makes Product Visually Aesthetic: Some shrink wrapping packaging industries also use color-coded transparent films to categorize different products. It also allows the printing of important information like the expiry date and batch number on the packaging.

3. It Makes Tampering Detectable: Since the shrink-wrap film holds its shapes once sealed tightly, any external tampering would be noticeable. It is one of the significant reasons why shrink-wrapping machines are being favored by so many industries including pharmaceuticals to shrink wrap their products.

4. It Is Affordable: Be it a small-scale business or a large-scale, shrink wrapping machines have a versatile range to suit everyone's needs. These machines are low on maintenance and the operating costs can be kept minimum.

5. It Takes Less Space: The other major benefit of the shrink wrap technique is that it gets sealed tightly around the object without taking any excessive space. It reduces any extra transportation cost which in turn lessens fuel consumption.

For more details please visit our full blog:

https://smartpackindia.com/blog/importance-of-shrink-wrapping-machines-in-fmcg-sector/

0 notes

Text

HAND SEALING MACHINE

1. Hand Sealer 300 SPS Hot Bar Type:

" Hand Sealer" As the name suggests- it is a simple and handy tool for different types of packaging material ranging from polyethylene and polypropylene bags to thermoplastic packages.

This equipment is specialized in sealing food packaging material. The Hot Barsealers can be easily placed and carried around. The functioning of the hand sealer is quite easy. This does not require any technical knowledge.

2. Hand Sealer Impulse Type SPS 125:

This machine is also known as a bag sealer with cutter. As this seal and cut the packaging material all at one time. Also, this bag sealer seals a different kind of plastic material of high and low Thickness. In industries, this bag sealer is widely used food packaging items.

3. Hand Sealer Impulse Type SPS 200:

This equipment is specialized in sealing food packaging material. The impulsive sealers can be easily placed and carried around. The functioning of the hand sealer is quite easy. This does not require any technical knowledge. This machine is also known as a bag sealer with cutter. In addition to packaging, it also provides the feature of cutting the material so that it can be easily packed and cut and vice versa, For the sake of convenience.

0 notes

Text

Continuous Band Sealer Machine

What Is A Continuous Band Sealer?

A continuous band sealer is a kind of heat sealer that uses a conveyor belt for sealing different types of pouches and bags. These machines provide an excellent strong and secured seal while giving a visually appealing professional look.

Different Types Of Continuous Band Sealers?

Horizontal Band Sealer:

In a horizontal band sealer, the bags or pouches are placed horizontally or laid down on the conveyor belt and then move through the sealing machine. These band sealers are also equipped with a solid-ink coding system that prints the colored label on the pouch while sealing.

Vertical Band Sealer:

In a vertical band sealer, bags and pouches are placed vertically as they move through the continuous heat sealing machine. Some band sealing machines are quite flexible which means that the sealers can be adjusted horizontally or vertically as required.

What Are The Precautions Needed With A Continuous Band Sealer?

Operators must stay away from the heating block while operating the sealing machine.

The cooling fan should always be kept on during the operation of the machine.

Always switch off the heater first and keep the cooling fan and conveyor switched on for at least 10 minutes before shutting down the power completely. This ensures even heat distribution when the system is completely turned off.

The heating block should be cooled down to room temperature when doing any kind of repair work or component replacement.

0 notes

Text

How to buy Right Liquid Filling Machine

The world of liquid filling machines is vast and choosing the right type for your business can be as difficult as spotting a needle in a heap. In this article, we will give tips on how to buy the right liquid filling machine for your business.

To make the process a bit simpler, we will identify some key questions which will help you narrow down your efforts while looking for the right liquid filling machine that fulfills your objectives.

What Product Has To Be Filled?

When choosing liquid filling equipment it becomes important to be careful about the texture of the liquid. Not all liquids are the same, some have more viscosity, some are thin and the viscosity of some liquids tends to change with temperature.

The liquid filling machine and the liquid to be filled must be compatible with each other. For example, a piston filler is good for liquids having a thick texture, while a gravity filler is more suitable for thin liquids.

What Type Of Container Has To Be filled?

For many businesses more than the product, the container or bottle decides the type of liquid filling machine to be used. The dimensions of the container, the material it is made up of, the size of the mouth are some of the characteristics that hold importance in choosing the right liquid filling machine.

For example, an automatic liquid filler that grabs a container from the side may not be the best choice if your container has wide dimensions and a nozzle filler may not work best with the container having an unusually-shaped mouth.

0 notes

Text

Oil Pouch Packaging Machine

What Is An Oil Pouch Packaging Machine?

Pouch packaging machines clutches a pouch, fill it with fluids, and seal it. These machines can fill and seal the pouches at speeds of up to 150-200 bags per minute. This technique involves moving the bag or pouch in intermittent rotary positions to different heads that serve different tasks of filling and sealing the pouches.

Importance Of Pouch Packaging Machines For Oils

There are undoubtedly many advantages of employing pouch packaging machines for oils, but there are also important goals that can be achieved by using packaging machines that would increase efficiency and boost sales.

Protection Of Edible Oils:

Packaging Machines can protect them in many different ways. It keeps the product safe from external damage during transit and other environmental aggressors.

Preservation:

A well-sealed product is a preserved product. A secure seal ensures protection from the outside atmosphere, especially the oxygen that serves as a good environment for microbes to break down many products. A sealed package makes the inside content fit and safe for consumption.

Presentation:

The presentation of the packaging has a crucial role in targeting the right audience. It helps to introduce your product to the consumer and make them understand your brand.

If you are looking for ways to speed up and level up your oil production and packaging, then an oil pouch packaging machine is a one-stop solution. And it is at your reach with our team of experts at Smart Packaging Systems. Kindly contact us to buy your oil packaging machine and we promise to live up to your expectations.

0 notes

Text

Facts About Sealing Machine

The sealing machines generally work on two methods: heat sealing and cold sealing. Hot sealing is one of the most commonly used sealing methods in the sealing industry.

Materials Used For Sealing Machines:

The strength of the sealing bond depends highly on the materials used, climate factors, and applied pressure. Different sealing methods require different types of materials.

1. Cold Seal Materials

2. Heat Sealing Materials

Some Applications of Sealing Machine:

Sealing machines generally find their applications in the food, beverage, and medical sectors. Each sealing method caters to different types of businesses. For example, cold sealers are majorly used for snack bars, candy bars, and chocolates, while hot sealers are executed in preserving fresh vegetables and meat. From short businesses to large, our team at Smart Packaging Systems can help you with proper sizing, material selection, and correct sealer that fit your needs at an economical price.

0 notes

Text

Filling Machine and its types

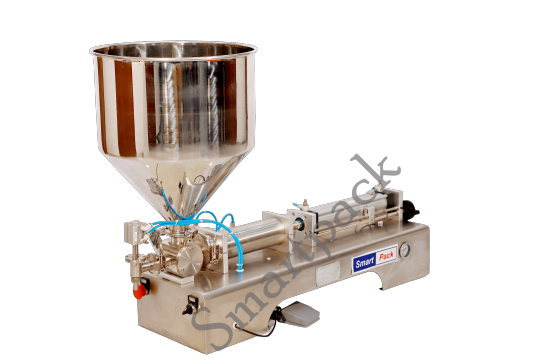

Liquid Filling Machine SPS 102 Pneumatic:

Smart Pack covers a wide range of standard liquid filling machines that suits the diversity of applications. Well, Liquid Filling Machine SPS 102 Pneumatic and Liquid Piston filler are a few of them to state. The benefit of these machines lies in the fact that they are cost and energy-effective and of course, easy to operate and handle. One could easily rely on fillers like these while dealing in the fluid industry, to get the maximum output in minimum time.

Paste Filling Machine SPS 103 Pneumatic Type:

Being a little different from the Liquid filling machine, Paste Filling Machines are required to do the needful filling of liquids with medium to high viscosity like pastes or putties in resultant jars, tins, or buckets. With high output abilities and cut-price value, these machines can do wonders for your business undoubtedly. Well, Paste fillers come in different models and SPS 103 Pneumatic is one of the types.

Double Nozzle Filling Machine SPS 201:

To begin with, Double Nozzle Filling Machines SPS 201 is considered for the filling and packaging of products in basically pharmaceutical and food industry. With double nozzles as an addition to the filling machine, one could probably experience the boost in their productivity, speed, and accuracy with proportion to the given time. These machines are resistant to corrosion, adding another important feature to it. Small models easy to maintain and handle, uniform filling, accurate weighing options, budget-friendly, and unparalleled efficiency are also some of the additional specifications of Double Nozzle Filling Machine SPS 201.

0 notes

Text

Packaging Machine and its types

SEALING MACHINE

Sealing Machines are used to seal the pouches, packets, or containers. Our company Smart Packaging Systems offer the best quality of Sealing Machines. Even we have great variety in Sealing Machine like hand sealing machine, food sealing machine and many others. These machines are used in Food industries, bakeries, food shops, and many other places. Even sealing machines are suitable for any food production.

BAND SEALING MACHINE

Our company Smart Packaging Systems is a leading supplier of Band Sealing Machine in India. We have different varieties in these machine-like Horizontal band sealers, Vertical band sealers, Heavy Duty Band Sealer, Double side Band Sealing Machines in India. We also have Vertical Sealer With Nitrogen Flush machine. This Band Sealing Machine is used for high-volume packaging and sealing thermoplastic materials.

BAG CLOSING MACHINE

Our Company Smart Packaging Systems offer a variety of Bag Closing Machine in India like Single thread and Double Thread bag closing machines. The main work of the machine is to close the ends of Bags by using threads. Single thread machines have Single needles and double threads have a double thread to seal the bags. These machines are used in all types of manufacturing industries.

0 notes

Text

Different types of strapping machine

Manual Strapping Tool For PET Strip

The tool is easy to handle and works steadily even when on the move. Since it doesn’t require power, enterprises can save on operational costs and limit their expenses. It is compact and can be carried without much effort.

Manual Strapping Tool For PP Strip

The Manual Strapping machine and their Tool Is Portable, Easy To Use, And Highly Reliable. It Can Be Used Vertically Or Horizontally To Seal The Ends Without Any Effort. The Tools Manufactured By Smart Pack Are From The Best Quality Raw Materials. This Makes The Tools Highly Durable. The Tool Being Lightweight Makes Is Almost Eligible For Small Scale Companies With Around A Strapping Rate Of Around 50 Straps Per Hour.

Manual Strapping Tool For MS Strip

MS strip is a steel strapping used for heavy-duty packaging. It provides the best banding to seal the packages that carry very heavy loads. It is also the oldest strapping material and has been in use for years in packaging heavy industrial equipment.

0 notes

Text

Bag Closing Machine

Our Company Smart Packaging Systems offers an vareity in Bag Closing Machine in India like Single thread and Double Thread bag closing machines. The main work of ths machine is to closes the ends of Bags by using threads. Single thread machine have Single needle and double thread have double thread to seal the bags. This machines are used in all types manufacturing industries.

Visit here for more details: https://smartpackindia.com/items/bag-closing-machine/

0 notes

Video

tumblr

Hand Sealing machine as the name suggests- it is a simple and handy tool for different types of packaging material ranging from polyethylene and polypropylene bags or pouches to thermoplastic packages.This equipment is specialized in sealing food packaging materials. The functioning of the hand sealer is quite easy. This does not require any technical knowledge.

Visit here for more details: https://smartpackindia.com/items/Hand-Sealing-Machine/

0 notes

Photo

Hand Sealing machine as the name suggests- it is a simple and handy tool for different types of packaging material ranging from polyethylene and polypropylene bags or pouches to thermoplastic packages.This equipment is specialized in sealing food packaging materials. The functioning of the hand sealer is quite easy. This does not require any technical knowledge.

Visit here for more details: https://smartpackindia.com/items/Hand-Sealing-Machine/

0 notes

Video

tumblr

Our company Smart Packaging System are the best supplier of Shrink Machine in India. Shrink packaging machines enable the shrink wrap of packets by tightening a thermoplastic films around the product and shrinking it by heat. The process adds strength to the stack or pallets and makes it waterproof and dust proof. These machine have automatic temperature control for convenient operations and packing.

Visit here for more details: https://smartpackindia.com/items/shrink-machine/

0 notes

Photo

Our company Smart Packaging System are the best supplier of Shrink Machine in India. Shrink packaging machines enable the shrink wrap of packets by tightening a thermoplastic films around the product and shrinking it by heat. The process adds strength to the stack or pallets and makes it waterproof and dust proof. These machine have automatic temperature control for convenient operations and packing.

Visit here for more details: https://smartpackindia.com/items/shrink-machine/

0 notes

Photo

Batch coding machine is the process of adding an identifying code, typically made up of a selection of letters and numbers, to a set of identical products that share the same production time, date, details and locations.We have best quality Batch coding machine in Indore.

Visit here for more details: https://smartpackindia.com/indore/items/batch-coding-machine/

0 notes

Text

Strapping Machine in India

Smart Packaging Systems is the leading supplier of all kind of Strapping Machine in all over India. Strapping Machines is used to Strap Bundle or cartons from all sides. Strapping machinery and their tools are designed to secured boxes and pallets for shipment of the items or packets. Many times, strapping is used in tandem with wrapping for pallets to secure product during the time of transport.

Visit here for more details: https://smartpackindia.com/items/strapping-machine/

0 notes