Don't wanna be here? Send us removal request.

Link

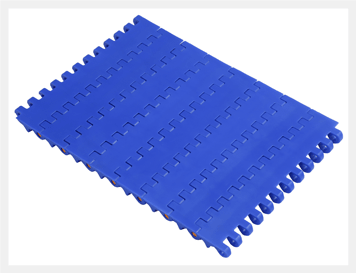

We are leading manufacturers in a high qualitative range of Modular Belt Conveyors. These Conveyors are made with the Highly advanced technology with optimum performance and durability

0 notes

Text

How Modular Conveyor belts helpful in Food Processing

Today’s conveyor belts constructed of polyurethane and other thermoplastics can stand up to most chemical, thermal, and mechanical challenges the food processing and packaging industries can throw their way. While food safety concerns remain paramount, the introduction of Modular conveyor belt materials has made them easier to clean and more resistant to biological and chemical agents, As a result, meat, dairy, bakery, confectionery, and other food-related manufacturers can consider other factors when deciding between the 2 major classes of food processing conveyor belts.

Modular conveyor belt materials have captured the lion’s share of food-grade belting applications in the production and packaging industry. Both are marked improvements over fabric belts, whose edges must be encapsulated to stop fraying which will contaminate foodstuffs. Choosing between modular plastic and monolithic belts depends largely on your plant’s applications. This article should help you decide which is best for your needs.

Built from an endless sheet of extruded homogenous material, the bulk of monolithic belts are positively driven, eliminating the necessity for friction rollers in most food applications. The tensionless propulsion from positive-driven belts simplifies the removal and reinstallation process for cleaning and maintenance tasks. It also reduces engineering costs, as they will be installed on lighter, less intensively designed carcasses. But their greatest feature is their cleanliness. Their non-porous surface and one-piece design prevent food particles from becoming lodged where they can attract harmful bacteria. This zero open space percentage makes them the simplest option for many applications handling raw, unpackaged meat and fruit and vegetable processing.

Quickly becoming the material of choice in high-care and high-risk food grade belting applications, monolithic conveyor belts add to their hygienic qualities by being resistant to most caustic and abrasive cleaning agents. Less infrastructure also makes them prime candidates for clean-in-place systems, which shortens downtime between batches.

Polymer construction resists staining and absorption of water, oil, and cross-contaminants. Additionally, the development from continuous sheets makes the belts both rugged and versatile.

Modular conveyor belts for food industries

Constructed of interlocking strips or pieces of plastic, modular plastic belts are generally driven by sprockets attached to both ends of the conveyor. They derive their greatest advantage over monolithic belts from their design options. The size of the modular pieces is often varied to suit different applications. Open space percentages are often modified to satisfy the standards for conveying packaged meat, raw fruit, bakery ingredients, etc. Large open spaces could also be perfect for cooling food, while smaller gaps would be best for moving small candies or allowing oil to empty from fried foods.

While the crevices created by the attachment of modular pieces to every other can create a rather harder cleaning environment, modular plastic conveyor belts boast versatility that monolithic bets cannot match. The drive system and modularity make these belts the higher choice in heavy or large load applications. Modular belts can also be routed around curves, a task monolithic belts cannot accomplish.

Belts made from plastic modules can also save companies money on repairs. In many cases, broken pieces can be removed and replaced individually. It’s much harder to repair cuts and tears in monolithic belts. Damaged belts often must be replaced.

0 notes

Text

Slat Conveyor Manufacturers

SS Slat Chain or crate conveyor chains are mainly used in areas where products are conveyed in trays, crates or containers like PET and glass bottles typically without direct contact with the product. A major advantage of Thermoplastic slat chain conveyors over plate link conveyors lies within the ability of the platelets of a slat conveyor to flex, and therefore turn corners, complex loops, and even spirals. This makes them highly regarded in continuous manufacturing processes, bottling guide plants, etc.

1 note

·

View note