Text

The Versatility of Stainless Steel 310S Sheets

Stainless steel is renowned for its durability, corrosion resistance, and versatility in various applications. Among its many grades, Stainless Steel 310S stands out for its exceptional properties, particularly when fabricated into sheets. In this blog post, we'll explore the versatility of Stainless Steel 310S sheets, delving into its characteristics, applications, and advantages.

Understanding Stainless Steel 310S Sheets:

Stainless Steel 310S Sheets are composed primarily of chromium and nickel, with additions of manganese and silicon. This alloy offers superior resistance to high temperatures and oxidation, making it suitable for applications in environments with elevated heat and corrosive elements.

Heat Resistance and Thermal Stability:

One of the key features of Stainless Steel 310S Sheets is their remarkable heat resistance. These sheets can withstand temperatures up to 2000°F (1093°C) without losing their mechanical properties, making them ideal for use in furnaces, heat exchangers, and other high-temperature environments.

Corrosion Resistance and Chemical Stability:

In addition to their heat resistance, Stainless Steel 310S Sheets exhibit excellent corrosion resistance against various corrosive agents, including sulfur-containing atmospheres and oxidizing environments. This makes them suitable for applications in chemical processing, petroleum refining, and other corrosive industries.

Versatile Applications in Various Industries:

The versatility of Stainless Steel 310S Sheets extends across a wide range of industries, including aerospace, automotive, pharmaceuticals, and food processing. These sheets are used in the fabrication of heat exchangers, reactors, pressure vessels, and other critical components where reliability and performance are paramount.

Fabrication and Formability:

Stainless Steel 310S Sheets are highly formable and machinable, allowing for easy fabrication into custom shapes and sizes to meet specific project requirements. They can be cold worked, welded, and formed without compromising their structural integrity, offering flexibility in design and construction.

Sustainable and Recyclable Material:

Beyond their functional benefits, Stainless Steel 310S Sheets are also environmentally sustainable. Stainless steel is 100% recyclable, with scrap being continuously recycled into new stainless steel products without loss of quality. This makes Stainless Steel 310S Sheets an eco-friendly choice for sustainable construction and manufacturing practices.

Conclusion:

In conclusion, the versatility of Stainless Steel 310S Sheets makes them indispensable in a wide range of industries and applications. From their exceptional heat resistance and corrosion resistance to their formability and sustainability, these sheets offer a combination of properties that meet the most demanding engineering requirements.

For inquiries or to explore how Stainless Steel 310S Sheets can enhance your next project, contact us at [email protected]. We invite you to share your thoughts and experiences with Stainless Steel 310S Sheets in the comments below. How have you utilized these versatile materials in your projects? Let's continue the conversation!

0 notes

Text

Stainless Steel 316 Sheets- The Perfect Choice for Corrosion-Resistant Applications

Stainless steel is by far the most sought-after metal in the manufacturing industry due to its excellent mechanical properties, high resistance to corrosion, and aesthetic appeal. Stainless Steel 316 Sheets have attained great importance in all grades due to their superior properties and vast applications.

This article will discuss some important aspects of Stainless Steel 316 Sheets, including their properties, applications, and benefits.

Properties of Stainless Steel 316 Sheets

Stainless Steel 316 Sheets belong to the austenitic group of stainless steel and are composed of a variety of elements, including chromium (16-18%), nickel (10-14%), and molybdenum (2-3%). Adding molybdenum enhances its corrosion-resistant properties and makes it highly resistant to pitting and crevice corrosion in chloride-containing environments.

An important property of Stainless Steel 316 Sheets is its high-temperature resistance. This property arises due to nickel, which helps retain the metal's structural strength and prevent deformation at high temperatures.

Stainless Steel 316 Sheet is also known for its excellent tensile and yield strength, making it ideal for heavy-load applications such as construction, automotive, and aerospace components.

Applications of Stainless Steel 316 Sheets

Stainless Steel 316 Sheets have found extensive applications in various industries due to their superior mechanical properties and corrosion resistance. Some of the most prominent applications include:

Marine and offshore structures: Stainless Steel 316 Sheets are ideal for marine and offshore structures due to their excellent corrosion resistance in harsh seawater environments. They are used in seawater desalination plants, boats, ships, and oil rigs.

Chemical processing: 316 Stainless Steel Sheets are commonly used in the chemical processing industry due to their excellent resistance to acidic and alkaline solutions. They are used to manufacture chemical processing equipment such as tanks, reactors, and heat exchangers.

Food and Beverage industry: SS 316 Sheets are suitable for food and beverage processing due to their corrosion resistance and ease of cleaning. They are used in producing dairy products, brewing, distilling, and wine-making.

Medical devices: Stainless Steel 316 Sheets are preferred due to their excellent mechanical properties and corrosion resistance. They are used in manufacturing surgical implants, orthopaedic instruments, and dental tools.

Benefits of Stainless Steel 316 Sheets

SS 316 Sheets offer numerous benefits compared to other grades of stainless steel. Some of the most notable benefits include:

Corrosion resistance: SS 316 Sheets exhibit excellent corrosion resistance, making them ideal for harsh and corrosive environments.

High-temperature resistance: Due to the presence of nickel, Stainless Steel 316 Sheets can withstand high temperatures without losing their structural integrity.

Aesthetic appeal- 316 Stainless Steel Sheets have an excellent appearance, which makes them ideal for use in decorative applications such as architectural facades, sculptures, and artwork.

Low maintenance: Stainless Steel 316 Sheets are easy to clean and maintain, reducing the cost of upkeep.

Conclusion:

Stainless Steel 316 Sheets are essential in manufacturing due to their excellent mechanical properties, corrosion resistance, and aesthetic appeal. Their high-temperature resistance, strength, and durability make them ideal for various industries, including marine, chemical, medical, and food processing. The benefits of Stainless Steel 316 Sheets make them the perfect choice for corrosion-resistant materials.

0 notes

Text

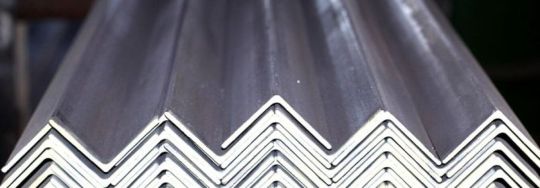

Stainless Steel Angles: A Versatile Solution for Various Applications

Stainless steel angles are among the construction industry's most commonly used steel structural shapes. The popularity of these angles stems from their superior strength, durability, and corrosion resistance. Stainless steel angles are formed by bending a steel alloy to create an "L" shape at a particular angle. They are commonly used in the construction of buildings, bridges, and other structures due to their strength and durability. In this article, we will discuss the various applications of stainless steel angles, their properties, and how they can be used effectively.

The Properties of Stainless Steel Angles

SS angles have a variety of properties that make them an excellent choice for a wide range of applications. One of the most desirable properties of stainless steel angles is their corrosion resistance. This is because they contain a high percentage of chromium, which creates a protective layer on the surface of the metal. This protective layer prevents the angle from rusting, corroding, or tarnishing, even in harsh environments. Also, SS angles have superior strength and can support heavy weights without bending or breaking. This strength makes them ideal for various structural applications.

Applications of Stainless Steel Angles

Stainless steel angles can be used in various applications in the construction industry and beyond. One of the most common uses of stainless steel angles is in the construction of buildings. Stainless steel angles support beams, columns, and other structural elements. They can also be used as lintels, as they are strong enough to support the weight of masonry above them. Furthermore, SS angles are ideal for use in marine environments due to their excellent resistance to rust and corrosion. They are used for mooring bollards, handrails, and other marine structures.

The manufacturing industry is another area where stainless steel angles are popularly used. Stainless steel angles are commonly used as a framework for assembly lines and production equipment. They can also be used to create support brackets, frames, and other components for machinery. As such, stainless steel angles are vital in producing tools and machinery parts.

SS angles are also essential in the transportation industry. They are widely used to build sturdy frames for trucks, trailers, and other vehicles that require strength and durability. Stainless steel angles are especially useful for transportation systems that operate in harsh environments, as they can withstand extreme weather conditions, rust, and corrosion.

Conclusion:

Stainless steel angles are an excellent choice for a wide variety of applications. Their strength, durability, and corrosion resistance make them ideal for construction, manufacturing, transportation, and beyond. Moreover, the versatility and easy availability of stainless steel angles make them desirable for many. These angles are readily available in various sizes and reasonably priced, making them popular in many markets. In conclusion, stainless steel angles are essential when building any structure, machinery or vehicle, as they provide superior strength, durability and prolonged resistance with minimum maintenance.

1 note

·

View note