Don't wanna be here? Send us removal request.

Text

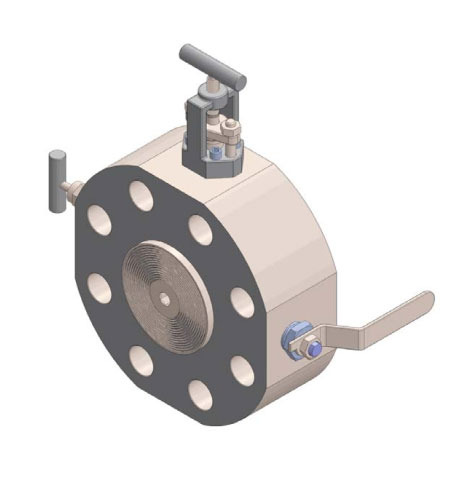

How Does ICCL Ensure Precision and Durability in Mono Flange Design?

In high-performance sectors where every inch counts and safety is paramount, mono flange valves have emerged as the go-to option for engineers and project managers alike. These valves are crafted for tight installations and crucial isolation, providing both efficiency and space-saving benefits. However, it’s important to note that not all mono flange valves are created equal.

At ICCL (Industrial Component Corporation Limited), precision and durability are more than just buzzwords — they’re integral to every mono flange product, from the initial concept all the way to commissioning. Here’s how ICCL ensures top-notch quality and reliability in its mono flange valve designs, setting a standard for excellence worldwide.

What Are Mono Flange Valves?

Before we delve into ICCL’s engineering prowess, let’s take a moment to understand what a mono flange valve actually does. These valves merge the functions of a block valve and a bleed valve into one compact unit. They’re commonly found in instrumentation and control systems, playing a vital role in offshore platforms, refineries, and high-pressure processing setups.

Some key benefits of mono flange valves include:

- Fewer leak paths

- A compact installation footprint

- Lightweight design

- Reduced joints and connections

- Improved safety and compliance

ICCL's Design Philosophy: Precision from the Inside Out

At ICCL, precision begins with smart design. Each mono flange valve is crafted using cutting-edge CAD modeling, flow simulation, and pressure analysis tools to guarantee peak performance across various service conditions.

Key Design Highlights:

- Tight dimensional tolerances for consistent sealing

- High Cv (flow coefficient) to reduce pressure drop

- Anti-blowout stem design for enhanced operator safety

- Compliance with ASME, API, and ANSI standards

This meticulous attention to detail ensures that ICCL mono flange valves provide reliable control and leak-free operation, even in the most demanding industrial settings.

Here’s the text we’re diving into: SS 316/316L

Duplex and Super Duplex Stainless Steel

Inconel and Hastelloy (perfect for those tough corrosive environments)

Carbon Steel (with protective coatings against corrosion)

ICCL also offers NACE-compliant valves designed for sour service in oil and gas applications, making them a great fit for both offshore and onshore setups.

Precision Manufacturing: Where Technology Meets Craftsmanship

Manufacturing excellence is a cornerstone of ICCL’s promise of durability. All machining takes place in CNC-controlled environments, guaranteeing exceptional repeatability and accuracy. Each mono flange valve undergoes a detailed production process:

Precision machining to ensure tight tolerances

Lapping and polishing of sealing surfaces

Automated welding where necessary

Surface treatment for corrosion protection

ICCL also conducts in-house helium leak testing, hydro testing, and seat leakage testing to confirm performance under real-world pressure conditions.

Quality Control That Goes Beyond the Basics

Every ICCL mono flange valve is rigorously tested and verified according to international standards. Their ISO 9001:2015 certified quality management system ensures that no product leaves the factory without passing:

Hydrostatic pressure testing

Pneumatic seat leakage testing

Dimensional inspection

Visual & NDT checks (DPT, UT, RT as required)

Material test reports (MTRs) and certificates

Plus, ICCL provides complete traceability documentation, including PMI (Positive Material Identification), test certificates, and serial numbering.

Customization for Your Industry Needs

Different industries have unique requirements. ICCL gets this, offering custom configurations for:

Pressure class ratings up to 10,000 psi

End connections (flanged, threaded, butt weld, socket weld)

Instrument integration (for direct mounting of gauges or transmitters)

Exotic materials for chemical resistance

No matter if you're in petrochemicals, marine, food processing, or pharmaceuticals, ICCL customizes its mono flange valve designs to ensure top-notch compatibility and performance.

Global Trust and Industry Compliance

ICCL has built a reputation for precision and durability, winning the trust of EPC contractors, OEMs, and plant operators worldwide. Their mono flange valves are actively used in:

- Offshore oil rigs in the Gulf of Mexico

- Petrochemical plants in the Middle East

- FPSOs and refineries throughout Southeast Asia

- Water treatment facilities in Europe

All ICCL valves meet major international standards, including:

- API 6A / 6D

- ASME B16.34

- NACE MR0175

- PED & CE marking (available upon request)

Final Thoughts: Why Choose ICCL Mono Flange Valves?

If your operations require reliable, compact valves that can withstand years of pressure, investing in ICCL mono flange valves is a wise choice. With a solid track record, state-of-the-art manufacturing, and thorough testing, ICCL guarantees precision and durability at every step.

From space-efficient installations to high-pressure applications, ICCL's mono flange valves are designed for reliability—because your project deserves the best.

0 notes

Text

ICCL Female Pipe Fittings – Trusted Connections for Global Industrial Projects

In the world of industrial piping systems, even the tiniest connection is crucial for maintaining safety and efficiency. Whether it’s in offshore rigs, petrochemical plants, or high-purity process lines, the dependability of pipe fittings is essential. Among these, female pipe fittings are vital components that create strong threaded connections in instrumentation, process, and hydraulic systems.

ICCL (Instrumentation Control & Components Ltd) is recognized as a leading global manufacturer of precision-engineered female pipe fittings, earning the trust of engineers and EPC contractors worldwide. With a reputation for engineering excellence, adherence to international quality standards, and a broad global presence, ICCL provides high-performance fittings for critical flow control applications across the oil & gas, power, marine, and chemical sectors.

What Are Female Pipe Fittings?

Female pipe fittings are designed with internal threads (like NPT, BSP, ISO, etc.) to accommodate male-threaded piping or tubing. They facilitate safe and secure connections in both low and high-pressure systems, making assembly, maintenance, and system flexibility a breeze.

Some common types of female pipe fittings include:

- Female Elbows (90° or 45°)

- Female Tees

- Female Couplings

- Female Connectors

- Female Crosses

- Female Adapters

These fittings are indispensable for:

- Instrumentation panels

- Chemical dosing lines

- Hydraulic equipment

- Fuel and gas supply systems

- Water treatment pipelines

Why ICCL Female Pipe Fittings Are Exceptional

Top-Quality Raw Materials

ICCL sources only certified, corrosion-resistant metals such as:

- SS316 / SS316L

- Brass

- Duplex and Super Duplex

- Monel, Inconel, and other exotic alloys (available upon request)

This commitment ensures durability, even in challenging environments like saltwater, aggressive chemicals, or high-temperature systems.

Precision Engineering

Every fitting is CNC-machined to exacting tolerances, guaranteeing accurate threading, perfect alignment, and leak-free performance.

ICCL offers female fittings in:

- NPT, BSPT, BSPP, ISO, and SAE threads

Pressure ratings can go as high as 6000 PSI, with sizes available from 1/16” to 2”.

Compliance with International Standards

ICCL products are designed to meet key global standards, including:

ASME B1.20.1, ISO 7-1, and DIN thread specifications.

Manufactured under ISO 9001:2015 certification.

Compliant with NACE MR0175 for sour gas applications.

Perfectly suited for projects with Aramco, ADNOC, Petrobras, and Shell.

Global Industrial Applications of ICCL Female Fittings

ICCL female pipe fittings find their place in a variety of industries:

Oil & Gas Exploration & Refining

Ideal for chemical injection skids, control panels, gas sampling, and instrumentation.

Petrochemicals & Process Plants

Utilized in high-pressure and high-temperature lines for monitoring and flow regulation.

Power Generation (Thermal, Hydro, Nuclear)

Installed in turbine instrumentation systems, water treatment loops, and steam circuits.

Marine & Offshore Platforms

Corrosion-resistant stainless steel and Monel fittings are perfect for seawater exposure.

Pharmaceutical & Food Processing

Designed for sterile environments, featuring hygienic-grade fittings and surface finishes.

Why Engineers and EPC Contractors Prefer ICCL

Leak-Free Performance

All fittings undergo rigorous testing to ensure tight, durable connections even in high-stress situations.

Material Traceability

With MTCs, batch numbers, and third-party test certificates, we guarantee full accountability.

Custom Orders Available

ICCL offers tailored solutions to meet the unique needs of your projects.

Competitive Global Pricing

We combine the efficiency of Indian manufacturing with top-notch international quality.

Post-Sales Support

We provide installation guidelines, CAD drawings, and technical documentation to assist you.

Sustainability & Future Readiness

ICCL is committed to the future, investing in:

Lead-free and RoHS-compliant fittings.

Digital documentation and QR-coded traceability.

Eco-friendly manufacturing processes and waste reduction.

As the demand for sustainable engineering grows, ICCL is dedicated to supporting global infrastructure development through responsible manufacturing and reliable product solutions.

0 notes

Text

ICCL Male Connector Fittings – Precision Engineering for Global Industries

In today’s fast-paced industrial landscape, where systems are pushed to their limits and reliability is non-negotiable, every connection plays a crucial role. One of the key players in instrumentation and flow control systems is the male connector fitting. These small but vital components ensure that fluid and gas lines are tightly sealed, secure, and resistant to vibrations.

ICCL (Instrumentation Control & Components Ltd) stands out as a reliable global manufacturer of male connector fittings, delivering precision-engineered solutions to clients in the oil and gas, petrochemical, marine, power, and pharmaceutical sectors. With a strong commitment to quality, adherence to international standards, and performance in challenging environments, ICCL has earned its reputation as a trusted brand for instrumentation fittings around the globe.

What Are Male Connector Fittings?

Male connectors are tube fittings designed to link tubes to female-threaded ports. They come equipped with a male NPT, BSPT, or metric thread on one end and a ferrule/tube fitting on the other. Their primary role is to ensure a secure, leak-proof seal, even when faced with high pressures, thermal fluctuations, and vibrations.

You’ll typically find them in:

- Instrumentation panels

- Gas and fluid lines

- Hydraulic systems

- Offshore rigs

- Power plants and refineries

ICCL’s Male Connector Fittings – Key Features

High-Precision Machining

ICCL fittings are crafted using cutting-edge CNC machinery, ensuring they meet stringent dimensional tolerances. This guarantees proper alignment, seal integrity, and reliable performance.

Premium Materials

- SS316 / SS316L for outstanding corrosion resistance

- Brass, Monel, Inconel, Hastelloy, and other specialized alloys available upon request

- Engineered to endure harsh chemicals, saltwater, and extreme temperatures

Thread Options

ICCL provides a variety of thread types, including NPT, BSPT, BSPP, ISO, SAE, and metric threads, catering to a broad range of regional and international connection needs.

Zero-Leak Performance

When paired with ICCL ferrule systems, these connectors deliver exceptional sealing capabilities, suitable for pressure ranges of up to 6000 PSI.

ICCL male connectors are designed to work seamlessly with other global fitting systems like Swagelok®, Parker®, and Hoke®. This means that replacing or integrating them into existing setups is a breeze.

Applications Across Global Industries

You’ll find ICCL male connector fittings in a variety of sectors, including:

Oil & Gas

Used in control panels, gas skids, and pipeline instrumentation.

Petrochemical Plants

Essential for measurement lines, analyzers, and process skids.

Power Generation

Perfect for monitoring steam and water lines, as well as turbine instrumentation.

Marine and Offshore

Corrosion-resistant options are available for ships and offshore platforms.

Pharma and Biotech

Ideal for high-purity connections in sterile environments.

Food & Beverage

Designed with hygiene in mind for processing and flow control.

Whenever there’s a need for fluid or gas flow measurement and control, you can count on ICCL fittings to deliver reliable performance.

Why Choose ICCL for Male Connector Fittings?

International Standards Compliance

ISO 9001:2015 Quality System

Meets ASME, ANSI, DIN, and EN standards

NACE MR0175 compatibility for sour gas applications

Customization

ICCL provides tailored fitting solutions based on size, material, pressure ratings, and end connections.

Inspection & Testing

Every fitting goes through 100% dimensional checks, thread gauging, and leak testing. We also offer optional third-party inspections and material traceability documentation.

Cost Efficiency

Thanks to in-house manufacturing and economies of scale, we offer competitive pricing without sacrificing quality.

Engineering Support

The ICCL team is here to help clients choose the right fittings, calculate tolerances, and ensure successful installations.

Sustainability & Future Innovation

ICCL is committed to investing in automated production lines, lead-free materials, and digital documentation to keep up with the changing needs of global industries. With a growing emphasis on renewable energy projects, hydrogen fuel systems, and green chemical plants, ICCL is evolving its fitting solutions to support sustainable engineering.

0 notes

Text

Supplying Reliable Ball Valves to Projects Around the Globe – Insights from ICCL Manufacturing

In critical sectors such as oil and gas, petrochemicals, energy, and marine, ball valves are essential for managing the flow of fluids and gases. These valves need to perform reliably under extreme pressures, temperatures, and environmental conditions. As global infrastructure projects increasingly demand higher reliability and efficiency, the need for dependable valve manufacturers has never been more pressing.

ICCL (Instrumentation Control & Components Ltd) has established itself as a top-tier global manufacturer of high-performance ball valves, exporting to over 30 countries across North America, South America, Europe, the Middle East, and Asia. Renowned for its precision engineering and adherence to international quality standards, ICCL ball valves are the go-to choice for flow control systems around the world.

What Sets ICCL Ball Valves Apart on a Global Scale?

1. Strong Engineering & Design

ICCL ball valves are crafted to ensure consistent, leak-free operation. Made from high-quality stainless steel, carbon steel, duplex, and exotic alloys, these valves are built to withstand aggressive fluids, high pressures (up to 10,000 PSI), and a wide range of temperatures.

Available in both 2-way and 3-way configurations, ICCL’s valves are versatile enough for various applications—from oil refineries and power plants to marine systems and process industries.

2. Extensive Product Line

ICCL offers a diverse range of products, including:

- Floating Ball Valves

- Trunnion Mounted Ball Valves

- Multi-Port Ball Valves

- High-Pressure Ball Valves

- Fire-Safe and Anti-Static Ball Valves

- Full Bore & Reduced Bore Options

Every valve undergoes rigorous 100% testing for pressure and leak tightness, guaranteeing uncompromised quality before it leaves the facility.

3. Adherence to International Standards

ICCL valves meet key global standards, including:

- API 6D / API 608

- ASME B16.34

- ISO 9001:2015 Quality System

- Fire-safe API 607

- NACE MR0175 for sour services

This compliance ensures that ICCL valves are ready for projects with major clients like Aramco, ADNOC, Petrobras, BP, Total, Shell, Chevron, and others worldwide.

Discover the Global Reach with Local Impact

ICCL's valves are making a difference in essential infrastructures all around the world, including:

- Oil & Gas Pipelines in the USA

- LNG Plants in Saudi Arabia and Qatar

- Refineries in Venezuela and Brazil

- Petrochemical Complexes in Germany and Italy

- Water Treatment Facilities in Canada and Australia

- Power Plants in India, UAE, and South Africa

What sets ICCL apart from local competitors is its knack for delivering tailored solutions right on schedule, no matter where you are.

Manufacturing Excellence from India to the World

ICCL’s manufacturing facilities in India boast:

- CNC machines for top-notch precision machining

- In-house hydro and pneumatic testing

- Surface finishing, coating, and clean-room assembly

- CAD/CAM design capabilities for bespoke projects

This integrated approach gives ICCL complete control over quality, costs, and delivery timelines, making it a go-to OEM partner on a global scale.

Why Global Engineers and EPC Contractors Rely on ICCL

On-Time Global Delivery

ICCL has a solid track record in exports, complete with documentation, packaging, and customs compliance to ensure smooth international shipping.

Custom Solutions

Looking for a valve with specific end connections, materials, or testing needs? ICCL’s engineering team works hand-in-hand with EPCs and plant engineers to make it happen.

Competitive Pricing

By taking advantage of cost efficiencies in manufacturing while adhering to international standards, ICCL delivers exceptional value worldwide.

Post-Sales Support

We provide remote installation guidance, maintenance manuals, and technical datasheets to ensure everything runs smoothly.

Industries ICCL Serves

- Oil & Gas

- Petrochemical

- Power Generation

- Offshore & Marine

- Water & Wastewater

- Mining

- Pharma & Biotech

Wherever flow control is crucial, ICCL is there with certified and dependable ball valve solutions.

Future Outlook – Smart Valve Integration

As the industry embraces automation, ICCL is stepping up with actuated ball valves and smart valve monitoring systems. These advancements will enable remote monitoring, predictive maintenance, and real-time diagnostics for high-performance valves that are essential in mission-critical systems.

Final Thoughts

With a footprint in over 30 countries, ICCL is more than just a valve supplier—it’s a global partner in flow control. Our ball valves are designed for precision, performance, and durability, ready to tackle the toughest engineering challenges. Whether you’re gearing up for a major refinery upgrade or a specialized offshore project, ICCL brings the expertise, quality, and reliability that clients around the world trust.

Visit https://icclksa.com to check out our complete range of ball valves and request a quote for your next international project.

0 notes

Text

ICCL – Global Manufacturer of DBB Valves for Oil, Gas, and Petrochemical Projects

In the fast-paced world of oil, gas, and petrochemical industries, safety, reliability, and efficiency are absolutely essential. A key player in achieving all three is the Double Block and Bleed (DBB) Valve—an expertly designed valve solution tailored for high-risk situations. Among the top manufacturers worldwide, ICCL (Instrumentation Control & Components Ltd) has earned a solid reputation for producing top-notch DBB valves that adhere to the strictest international standards.

What exactly is a DBB Valve?

A Double Block and Bleed Valve is a sophisticated valve setup that ensures positive isolation of fluid flow by utilizing two seating surfaces (blocks) along with a bleed mechanism in between. This design allows for maintenance and testing to be carried out without the need to shut down the entire system. DBB valves are particularly vital in settings where preventing leaks and ensuring operational safety are critical, such as offshore drilling platforms, oil refineries, and chemical plants.

ICCL’s Expertise in DBB Valve Manufacturing

ICCL has been leading the charge in manufacturing instrumentation valves and fittings, with DBB valves being a standout product in their lineup. These valves are engineered to perform flawlessly under extreme pressure and temperature conditions, meeting global standards like API 6A, API 6D, ASME, ANSI, and ISO certifications. Clients from the USA, Saudi Arabia, Brazil, Canada, Germany, UAE, and beyond trust ICCL’s DBB valves.

Key Features of ICCL DBB Valves:

Dual Isolation and Bleed: Offers exceptional leak protection by isolating flow from both upstream and downstream sources.

Compact Design: Merges multiple valve functions into a single unit, saving weight and space.

Corrosion Resistance: Crafted from high-grade stainless steel and alloy materials to endure harsh chemicals and saline environments.

Customization Available: Tailored solutions to accommodate various flange standards, end connections (flanged, threaded, welded), and pressure ratings up to 10,000 PSI.

Applications in the Oil, Gas & Petrochemical Industries

ICCL’s DBB valves are utilized in a variety of settings:

Oil & Gas Pipelines: Perfect for isolating sections of the pipeline during maintenance or repairs.

Petrochemical Plants: Guarantees safe chemical processing with a promise of zero leaks.

LNG Terminals: Keeps process integrity intact even in cryogenic conditions.

FPSOs and Offshore Platforms: Provides compact, corrosion-resistant solutions ideal for tight spaces.

Global Presence with Local Support

ICCL caters to customers worldwide, boasting a strong foothold in regions such as:

United States – Where precision-engineered DBB valves are essential for process safety and EPA compliance.

Middle East (Saudi Arabia, UAE, Qatar) – Supporting Aramco projects and offshore infrastructure developments.

South America (Brazil, Colombia, Venezuela) – Reliable flow control is crucial in oil exploration and refining centers.

Europe (Germany, Italy, UK) – Focused on advancements in clean energy and petrochemical upgrades.

With a robust distribution network and strategic partnerships, ICCL guarantees timely delivery and technical support, no matter where your project is located.

Commitment to Quality and Compliance

ICCL adheres to ISO 9001:2015 Quality Management Systems, ensuring consistency from design through to delivery. Every valve undergoes rigorous pressure testing, leak testing, material certification, and thorough documentation for traceability. ICCL also provides Factory Acceptance Testing (FAT) and third-party inspections upon request.

Why Engineers Choose ICCL DBB Valves?

Proven Track Record: Trusted by engineers and EPC contractors in over 25 countries.

Comprehensive Product Range: From mono flange DBB valves to modular double isolation systems.

Expert Engineering Support: Assistance with selection, sizing, and documentation is readily available.

Competitive Lead Times: Quick production and delivery schedules.

Compliance with International Standards: Complete documentation and certifications for project approvals.

As industries around the globe strive for greater efficiency, cleaner energy, and safer operations, ICCL is at the forefront of innovation. By investing in research and development for low-emission valve technology, digital integration, and modular valve assemblies, ICCL is ensuring that its product roadmap aligns with future sustainability objectives.

Final Thoughts

When it comes to oil, gas, or petrochemical projects that need reliable and compact flow isolation, ICCL’s Double Block and Bleed valves are the go-to choice in the industry. With a global presence, rigorous quality control, and extensive industry knowledge, ICCL is powering some of the world’s most essential energy projects.

Whether you’re an EPC contractor, project manager, or maintenance engineer, ICCL provides a top-notch DBB solution customized for your specific needs. Check out the complete DBB valve range at https://icclksa.com and take your first step towards enhanced operational safety and efficiency.

0 notes

Text

Top 5 Reasons Engineers Choose ICCL Needle Valves for Critical Applications

In sectors like oil and gas, petrochemicals, power generation, and instrumentation, needle valves are essential for precise flow control. The quality of these valves has a direct effect on the safety, accuracy, and efficiency of fluid systems, particularly in high-pressure or corrosive settings.

That’s why engineers and plant operators around the globe rely on ICCL (Instrumentation Control Components Ltd.), a top-notch needle valve manufacturer recognized for its engineering excellence and unwavering commitment to quality.

In this blog, we’ll dive into the top five reasons why engineers opt for ICCL needle valves in their most critical applications.

Precision Flow Control You Can Rely On

ICCL needle valves are crafted for meticulous flow regulation, making them perfect for situations where controlling small volumes of fluid or gas with high precision is crucial. Whether you’re using them in calibration lines, gauge lines, or sampling systems, ICCL valves guarantee smooth operation without any pressure surges or fluctuations.

Each valve is machined to tight tolerances, ensuring a perfect fit between the needle and seat. This leads to:

Smooth linear flow control

No leakage

Minimal hysteresis

Reliable performance over extended periods

Built for Extreme Conditions

Needle valves frequently function in high-pressure, high-temperature, or corrosive environments. ICCL provides a variety of material options to tackle every challenge:

SS316 / SS316L – The go-to choice for oil and gas

Duplex / Super Duplex – Ideal for highly corrosive offshore and subsea applications

Monel / Inconel / Hastelloy – Perfect for aggressive chemical environments and sour service

These material selections, combined with fire-safe designs and adherence to NACE MR0175 / ISO 15156, make ICCL needle valves suitable for both upstream and downstream industries.

Quality You Can Trust That Meets Global Standards

ICCL’s needle valves are produced under rigorous quality assurance systems and comply with international standards, including:

ISO 9001:2015 certified manufacturing

Here’s the text we’re looking at: PED 2014/68/EU

API 6A compliance (where applicable)

Every valve goes through 100% in-house testing:

- Hydrostatic pressure test

- Helium leak detection

- Functional operation test

- Visual and dimensional inspection

This rigorous process ensures that each ICCL valve shipped meets global reliability and safety standards, giving engineers total peace of mind.

Compact Designs with Maximum Flexibility

ICCL needle valves come in a variety of configurations:

- Straight & angle patterns

- Integral bonnet & screwed bonnet designs

- Options with or without lockable handles

- Panel mount or inline versions

- Sizes ranging from 1/8” to 1” (or custom sizes)

Connection types include:

- NPT, BSPT, BSPP

- Socket weld

- Tube OD

- Compression fitting (double ferrule)

This variety makes it a breeze for engineers to incorporate ICCL valves into their existing pipelines or custom instrumentation setups—without any design compromises.

Global Support & Fast Delivery

One of ICCL’s standout features is its global reach and speedy delivery. With manufacturing and distribution based in Saudi Arabia, ICCL provides valves to:

- Middle East and GCC countries

- USA and Canada

- Europe and Southeast Asia

- African oil fields and energy plants

Thanks to a responsive sales and engineering team, ICCL offers:

- Quick technical support

- Custom valve options (for OEMs and EPCs)

- Fast order turnaround for urgent project needs

For large infrastructure and shutdown projects, ICCL is often the preferred manufacturer due to its ability to deliver high-quality components on tight schedules.

Common Applications of ICCL Needle Valves

ICCL needle valves are utilized in:

- Instrumentation panels

- Pressure gauge lines

- Chemical injection skids

- Hydraulic and pneumatic systems

- Offshore platform control rooms

- Refineries and process plants

Engineers in these fields appreciate reliable shut-off, precise metering, and resistance to vibration and shock—all of which are key features of ICCL products.

In industries where performance is key, ICCL needle valves really shine thanks to their precision, durability, and top-notch engineering. With global certifications, materials that resist corrosion, and quick support, ICCL has earned its reputation as the go-to choice for engineers all over the globe.

0 notes

Text

How ICCL Mono Flange Valves Improve Safety in Offshore Platforms

In the challenging and high-stakes environment of offshore oil and gas platforms, safety and performance are absolutely essential. One key player in maintaining system integrity in these settings is the Mono Flange Valve. These valves are designed to simplify instrumentation, minimize leak paths, and enhance accessibility, making them the go-to choice for offshore installations.

Among the top manufacturers in this field, ICCL (Instrumentation Control Components Ltd.) has established itself as a reliable name for high-performance Mono Flange Valves, particularly in critical offshore and subsea applications.

In this blog, we’ll dive into how ICCL Mono Flange Valves boost safety on offshore platforms and why engineers and procurement teams worldwide trust ICCL for their valve requirements.

What is a Mono Flange Valve?

A Mono Flange Valve is a sleek, one-piece valve solution that combines isolation (block) and bleed functions into a single unit. Unlike traditional setups that rely on multiple valves, fittings, and connections, mono flanges streamline the entire operation—resulting in a smaller size, lighter weight, and, most importantly, reduced leak potential.

Key Safety Challenges in Offshore Platforms

Offshore oil and gas rigs face extreme conditions, including:

- High pressure (up to 10,000 psi or more)

- Corrosive seawater environments

- Limited installation space

- Risk of gas or fluid leaks

- Significant temperature fluctuations

- Compliance with strict industry standards (e.g., API, ASME, NACE)

Every extra connection in a piping system raises the risk of failure or leakage, making it vital to use compact and leak-proof components like ICCL’s MonoFlange valves.

How ICCL Mono Flange Valves Enhance Safety

Reduced Leak Paths

ICCL Mono Flange Valves replace multiple components (ball valve + needle valve + fittings + flanges) with a single forged body. This change can eliminate up to 70% of potential leak points, which is crucial for preventing dangerous leaks, especially when dealing with volatile fluids or gases.

Fire-Safe and Pressure-Tested Design

Every ICCL Mono Flange Valve undergoes thorough testing for fire safety, hydrostatic pressure, and helium leakage. They’re built to comply with API 6FA and ISO fire-safe standards, ensuring they perform reliably when it matters most.

Compact and Lightweight

Space can be a real challenge on offshore platforms. That’s why ICCL’s Mono Flange design is all about reducing the size and weight of valve installations. This makes installation in tight or elevated spaces not just easier, but also safer for everyone involved. Plus, it helps keep maintenance personnel safe by limiting their exposure.

Corrosion-Resistant Materials

ICCL is committed to using top-notch materials like SS316, Duplex, Super Duplex, Inconel, and Hastelloy. These materials provide excellent corrosion resistance in marine environments, which means a longer lifespan and a lower risk of failure due to material wear and tear.

Double Block & Bleed Capability

Many of the ICCL Mono Flange models come with a DBB (Double Block and Bleed) configuration. This feature guarantees complete isolation of pressure in both upstream and downstream directions, which is crucial for safety during maintenance, calibration, or shutdowns.

Compliance with Offshore Standards

ICCL Mono Flange Valves are designed to meet several important standards:

NACE MR0175 / ISO 15156 (for sour service)

API 6A / 6D (for pressure containment)

PED 2014/68/EU (European compliance)

This ensures they are reliable and accepted worldwide.

Applications in Offshore Environments

ICCL Mono Flange Valves are widely used in:

Pressure transmitter connections

Chemical injection skids

Wellhead control panels

Subsea pipeline monitoring

Manifold and riser systems

FPSO vessels and topside facilities

In these situations, safety isn’t just a priority—it’s essential. ICCL valves guarantee zero leakage, require minimal maintenance, and ensure safe operation, even in the toughest environments.

ICCL: A Trusted Name in Instrumentation Valves

Based in Saudi Arabia with a global reach, ICCL is recognized for:

Precision-engineered valves and fittings

Customizable valve configurations

Quick lead times and worldwide distribution

Customizable valve configurations

Quick lead times and worldwide support

Dedicated to ISO, CE, and international certifications

Their committed engineering team collaborates closely with EPCs, plant operators, and procurement teams to provide customized valve solutions for both onshore and offshore projects.

In the world of offshore oil and gas operations, you need components that can handle the pressure—both in terms of performance and reliability. ICCL’s Mono Flange Valves are built to tackle these challenges, offering safety, dependability, and efficiency all in one compact design.

Whether you're looking to upgrade an existing system or design a new offshore platform, think about the long-term safety, reliability, and performance advantages of choosing ICCL Mono Flange Valves.

0 notes

Text

"ICCL: Trusted Manufacturer of Stainless Steel Male Connectors for Instrumentation Systems"

In industries where precision and high pressure are the name of the game, even the tiniest component can have a huge impact on performance, safety, and overall system efficiency. One such vital piece is the male connector fitting, which is essential for any instrumentation, hydraulic, or pneumatic system. These fittings create strong, leak-proof connections between tubes and threaded ports, making sure that flow control and pressure containment are reliable.

ICCL (Instrumentation Controls Co. Ltd.), a top manufacturer of instrumentation fittings in India, provides a full range of stainless steel male connectors that are built to perform in the toughest industrial settings. Renowned for their quality, precise dimensions, and resistance to corrosion, ICCL’s male connector fittings are trusted by industries around the globe, including oil & gas, power, chemicals, and marine sectors.

🔍 What Is a Male Connector Fitting?

A male connector fitting is a type of tube fitting that connects a tube to a female-threaded port or component. It usually has:

A male NPT/BSPT/BSPP/UNF thread on one end

A tube fitting ferrule system on the other end

A body made from high-quality stainless steel or specialized alloys

These connectors are crucial for ensuring leak-tight performance, even when faced with high pressures, vibrations, and temperature changes.

🛠️ Applications of Male Connectors in Instrumentation Systems

ICCL’s stainless steel male connectors are commonly found in:

Instrumentation Panels & Skids

Process Control Systems

Hydraulic & Pneumatic Circuits

Fuel Gas Distribution

Chemical Dosing Units

Cryogenic & Steam Applications

They are vital for systems that need:

Accurate pressure monitoring

Connections for transmitters and gauges

Transport of clean gases and fluids

Isolation and shut-off functions

🔩 Why Choose ICCL for Male Connector Fittings?

ICCL has earned a reputation as a global leader in instrumentation components thanks to its dedication to quality engineering and innovation driven by customer needs. Here’s why you should consider ICCL’s male connector fittings

✅ 1. High-Grade Stainless Steel Construction

ICCL creates fittings using SS316 / SS316L, which are celebrated for their resistance to corrosion, impressive strength, and ability to thrive in tough environments. We also offer other material choices like:

Monel

Inconel

Hastelloy

Duplex & Super Duplex Steel

Brass (available upon request)

✅ 2. Leak-Proof Design

Every fitting is crafted with precision-machined threads, dual ferrule gripping technology, and tight tolerances to guarantee bubble-tight performance, even in high-vibration or high-pressure situations.

✅ 3. Global Thread Standards Supported

ICCL supplies male connectors with a range of thread options:

NPT (National Pipe Tapered)

BSPT / BSPP (British Standard)

ISO / Metric Threads

UNF / SAE Standards

This ensures that ICCL fittings are compatible with process and instrumentation systems worldwide.

✅ 4. Broad Size Availability

Tube OD Range: 1/8” to 2” (Imperial), 6mm to 50mm (Metric)

Thread Sizes: 1/8” to 2” NPT/BSP/UNF

✅ 5. Pressure Ratings

Rated for up to 6,000 PSI, depending on size and material. ICCL also provides special high-pressure variants for test rigs and hydraulic systems.

📐 Precision Engineering & Quality Assurance

At ICCL, each male connector undergoes:

CNC machining with micron-level tolerances

Thread gauging and ferrule testing

100% visual and dimensional inspection

Hydrostatic pressure testing (upon request)

Surface finishing to ensure clean assembly and protection against corrosion

ICCL fittings are produced in ISO 9001:2015 certified facilities and meet global engineering and safety standards.

🌍 Industries That Trust ICCL Male Connectors

ICCL’s stainless steel male connectors are relied upon worldwide for critical projects:

🛢️ Oil & Gas

Offshore platforms, refineries, LNG terminals

Perfect for sour service and high-vibration systems

🔋 Power Generation

Thermal, hydro, nuclear, and solar plants

Utilized in feedwater, steam, and coolant systems

Here’s the text we’re looking at:

🧪 Chemical & Petrochemical

Acid dosing systems, reactors, and transfer lines that stand strong against corrosive fluids and harsh gases.

🌊 Marine & Shipbuilding

Designed to resist saltwater, ensuring a longer service life—perfect for engine room instrumentation and ballast systems.

🏭 Pharmaceuticals & Food Processing

Options that are cleanroom-friendly, complete with electropolished finishes available.

🔧 Customization & OEM Support

ICCL is here to assist OEMs, EPC contractors, and MRO teams with:

Tailored sizing and threading

Laser engraving for part numbers, pressure ratings, and more

Assembly kits that include tubing, nuts, and ferrules

Bulk packaging and private labeling options.

additionally, we offer actuated ball valves equipped with pneumatic, electric, or electro-hydraulic actuators, all of which are thoroughly tested and calibrated before they leave our facility.

📞 Looking for DBB Valves for Your Application? Get in Touch with ICCL Today!

If your system needs compact, leak-tight isolation, ICCL’s DBB valves are the perfect choice. Don’t hesitate to reach out for catalogs, drawings, or any custom requirements.

📧 Email: [[email protected]]

🌐 Website: [https://icclksa.com/]

📍 Exporting Worldwide | ISO & PED Certified

#MaleConnectorFittings

#ICCLValves

#InstrumentationFittings

#StainlessSteelConnectors

#TubeFittingsIndia

#ProcessFittings

#OilGasFittings

#LeakFreeConnections

#NPTBSPFittings

#InstrumentationSystems

0 notes

Text

ICCL: Trusted Manufacturer of Stainless Steel Male Connectors for Instrumentation Systems

In industries where precision and high pressure are the name of the game, even the tiniest component can have a huge impact on performance, safety, and overall system efficiency. One such vital piece is the male connector fitting, which is essential for any instrumentation, hydraulic, or pneumatic system. These fittings create strong, leak-proof connections between tubes and threaded ports, making sure that flow control and pressure containment are reliable.

ICCL (Instrumentation Controls Co. Ltd.), a top manufacturer of instrumentation fittings in India, provides a full range of stainless steel male connectors that are built to perform in the toughest industrial settings. Renowned for their quality, precise dimensions, and resistance to corrosion, ICCL’s male connector fittings are trusted by industries around the globe, including oil & gas, power, chemicals, and marine sectors.

🔍 What Is a Male Connector Fitting?

A male connector fitting is a type of tube fitting that connects a tube to a female-threaded port or component. It usually has:

A male NPT/BSPT/BSPP/UNF thread on one end

A tube fitting ferrule system on the other end

A body made from high-quality stainless steel or specialized alloys

These connectors are crucial for ensuring leak-tight performance, even when faced with high pressures, vibrations, and temperature changes.

🛠️ Applications of Male Connectors in Instrumentation Systems

ICCL’s stainless steel male connectors are commonly found in:

Instrumentation Panels & Skids

Process Control Systems

Hydraulic & Pneumatic Circuits

Fuel Gas Distribution

Chemical Dosing Units

Cryogenic & Steam Applications

They are vital for systems that need:

Accurate pressure monitoring

Connections for transmitters and gauges

Transport of clean gases and fluids

Isolation and shut-off functions

🔩 Why Choose ICCL for Male Connector Fittings?

ICCL has earned a reputation as a global leader in instrumentation components thanks to its dedication to quality engineering and innovation driven by customer needs. Here’s why you should consider ICCL’s male connector fittings

✅ 1. High-Grade Stainless Steel Construction

ICCL creates fittings using SS316 / SS316L, which are celebrated for their resistance to corrosion, impressive strength, and ability to thrive in tough environments. We also offer other material choices like:

Monel

Inconel

Hastelloy

Duplex & Super Duplex Steel

Brass (available upon request)

✅ 2. Leak-Proof Design

Every fitting is crafted with precision-machined threads, dual ferrule gripping technology, and tight tolerances to guarantee bubble-tight performance, even in high-vibration or high-pressure situations.

✅ 3. Global Thread Standards Supported

ICCL supplies male connectors with a range of thread options:

NPT (National Pipe Tapered)

BSPT / BSPP (British Standard)

ISO / Metric Threads

UNF / SAE Standards

This ensures that ICCL fittings are compatible with process and instrumentation systems worldwide.

✅ 4. Broad Size Availability

Tube OD Range: 1/8” to 2” (Imperial), 6mm to 50mm (Metric)

Thread Sizes: 1/8” to 2” NPT/BSP/UNF

✅ 5. Pressure Ratings

Rated for up to 6,000 PSI, depending on size and material. ICCL also provides special high-pressure variants for test rigs and hydraulic systems.

📐 Precision Engineering & Quality Assurance

At ICCL, each male connector undergoes:

CNC machining with micron-level tolerances

Thread gauging and ferrule testing

100% visual and dimensional inspection

Hydrostatic pressure testing (upon request)

Surface finishing to ensure clean assembly and protection against corrosion

ICCL fittings are produced in ISO 9001:2015 certified facilities and meet global engineering and safety standards.

🌍 Industries That Trust ICCL Male Connectors

ICCL’s stainless steel male connectors are relied upon worldwide for critical projects:

🛢️ Oil & Gas

Offshore platforms, refineries, LNG terminals

Perfect for sour service and high-vibration systems

🔋 Power Generation

Thermal, hydro, nuclear, and solar plants

Utilized in feedwater, steam, and coolant systems

Here’s the text we’re looking at:

🧪 Chemical & Petrochemical

Acid dosing systems, reactors, and transfer lines that stand strong against corrosive fluids and harsh gases.

🌊 Marine & Shipbuilding

Designed to resist saltwater, ensuring a longer service life—perfect for engine room instrumentation and ballast systems.

🏭 Pharmaceuticals & Food Processing

Options that are cleanroom-friendly, complete with electropolished finishes available.

🔧 Customization & OEM Support

ICCL is here to assist OEMs, EPC contractors, and MRO teams with:

Tailored sizing and threading

Laser engraving for part numbers, pressure ratings, and more

Assembly kits that include tubing, nuts, and ferrules

Bulk packaging and private labeling options.

additionally, we offer actuated ball valves equipped with pneumatic, electric, or electro-hydraulic actuators, all of which are thoroughly tested and calibrated before they leave our facility.

📞 Looking for DBB Valves for Your Application? Get in Touch with ICCL Today!

If your system needs compact, leak-tight isolation, ICCL’s DBB valves are the perfect choice. Don’t hesitate to reach out for catalogs, drawings, or any custom requirements.

📧 Email: [[email protected]]

🌐 Website: [https://icclksa.com/]

📍 Exporting Worldwide | ISO & PED Certified

0 notes

Text

ICCL – Trusted Ball Valve Manufacturer in India for Industrial Flow Control

In any industrial setting where precise and dependable control of fluids or gases is essential, ball valves are absolutely vital. Renowned for their robustness, user-friendly operation, and minimal leakage, these valves find their place in various sectors, including oil & gas, petrochemicals, power generation, and marine applications.

As a prominent ball valve manufacturer in India, ICCL (Instrumentation Controls Co. Ltd.) has built a solid reputation among engineers and project managers around the globe. With decades of experience in manufacturing, a range of global certifications, and a steadfast commitment to quality, ICCL provides ball valve solutions that consistently perform well, even in the toughest conditions.

This blog delves into the basics of ball valves, their applications in industry, and what makes ICCL a top choice for clients seeking performance, precision, and durability.

🔧 What Is a Ball Valve?

A ball valve is a quarter-turn valve that utilizes a rotating ball with a central hole (bore) to manage the flow of fluid or gas. When you turn the valve handle 90 degrees, the ball spins to either permit flow (open) or stop it (closed).

Ball valves are favored in process industries for several reasons:

- Quick operation (fast shutoff/on)

- Minimal pressure drop

- Bubble-tight sealing

- Low maintenance needs

They come in various designs, such as:

- Two-piece or three-piece valves

- Full port (full bore) or reduced port

- Floating ball or trunnion-mounted ball

- Manual, pneumatic, or electric actuators

🏭 ICCL’s Expertise in Ball Valve Manufacturing

ICCL produces a comprehensive range of industrial-grade ball valves, designed to meet a wide array of pressure, temperature, and flow specifications. Our valves are manufactured in India and distributed worldwide, adhering to international quality standards.

Key Product Highlights:

✅ Size Range: 1/4" to 12"

✅ Pressure Ratings: Up to 10,000 PSI (700 bar)

✅ End Connections: Threaded, Flanged (ANSI/ASME), Socket Weld, Butt Weld, Tube Fittings

✅ Material Options: SS316, SS304, Monel, Inconel, Duplex, Super Duplex, Hastelloy, Brass, and more

✅ Seal Options: PTFE, RPTFE, Graphite, and Metal-to-Metal seats designed for high-temperature and abrasive service.

ICCL also provides customized OEM ball valves tailored to meet specific process needs, including applications involving high pressure, high temperature, and corrosive media.

🛡️ Why Go with ICCL Ball Valves?

1. Unmatched Quality

Every ICCL valve is put through rigorous 100% pressure testing, visual inspections, and dimensional checks. Our valves are crafted to meet ISO 9001:2015, ASME B16.34, and PED standards.

2. Worldwide Certifications

ICCL valves adhere to CE, ATEX, and IBR guidelines, making them perfect for international projects and EPC contracts.

3. Built to Last in Tough Conditions

Whether it’s -50°C for cryogenic applications or +400°C for steam service, ICCL ball valves are rigorously tested to perform under extreme pressures and challenging environments.

4. Leak-Free Performance

Our ball valves are engineered for bubble-tight shutoff and a long lifespan, featuring options like live-loaded packing, blowout-proof stems, and anti-static designs.

5. Simple Maintenance

With a three-piece design, these valves allow for quick in-line servicing and seat replacements, reducing downtime during maintenance.

6. Quick Turnaround

Thanks to our large inventories and modular production lines, we can ensure fast delivery for both domestic and international orders.

🌍 Industries That Rely on ICCL Ball Valves

ICCL's ball valves are trusted across various sectors where precise flow control is essential:

🔹 Oil & Gas

Ideal for upstream production, midstream transmission, and downstream refining operations

Reliable even in high-pressure and sour gas environments

🔹 Petrochemical & Chemical

Perfect for managing corrosive, flammable, and high-temperature media

Available in both PTFE and metal-seated options

🔹 Power & Energy

Utilized in thermal, hydro, and renewable energy facilities

Engineered to handle superheated steam and cooling water lines

🔹 Water Treatment & Marine

Constructed from corrosion-resistant alloys for desalination and marine applications

At ICCL, we take pride in collaborating closely with OEMs, EPC contractors, and end-users to create customized ball valve solutions that truly meet your needs. Whether it’s special coatings or unique alloys, our design team is here to support a variety of applications, including:

- High-pressure hydraulic lines

- Natural gas metering

- Cryogenic isolation valves

- Chemical dosing systems

Additionally, we offer actuated ball valves equipped with pneumatic, electric, or electro-hydraulic actuators, all of which are thoroughly tested and calibrated before they leave our facility.

📞 Looking for DBB Valves for Your Application? Get in Touch with ICCL Today!

If your system needs compact, leak-tight isolation, ICCL’s DBB valves are the perfect choice. Don’t hesitate to reach out for catalogs, drawings, or any custom requirements.

📧 Email: [[email protected]]

🌐 Website: [https://icclksa.com/]

📍 Exporting Worldwide | ISO & PED Certified

0 notes

Text

What Are DBB Valves? ICCL’s Engineering for Safer Fluid Control

In industries that are critical to our daily lives, like oil and gas, petrochemicals, power generation, and marine operations, ensuring safety and preventing leaks is absolutely essential. A key player in maintaining process integrity and safety during maintenance is the DBB valve, which stands for Double Block and Bleed valve.

As a top-notch manufacturer of instrumentation valves in India, ICCL (Instrumentation Controls Co. Ltd.) provides high-performance DBB valves that adhere to rigorous safety, pressure, and material standards. With a commitment to precision engineering and zero-leak technology, ICCL has earned the trust of clients worldwide for their instrumentation, isolation, and pressure control solutions.

In this blog, we’ll take a closer look at DBB valves — what they are, how they function, and what makes ICCL’s designs a cut above the rest in the industry.

🧠 What Is a DBB Valve?

A Double Block and Bleed (DBB) valve is a unique valve assembly crafted to isolate a section of pipeline or equipment from both ends (double block) while also allowing for the venting or draining of any trapped fluid or pressure (bleed) in between.

Instead of relying on multiple valves and fittings, a DBB valve cleverly combines all three functions — block, block, and bleed — into one compact unit.

0 notes

Text

In industries where precision is key, managing the flow of fluids or gases accurately is essential. That’s where needle valves come into play — they provide exceptional control and a leak-tight shutoff, making them perfect for instrumentation and process systems.

As a reliable needle valve manufacturer in India, ICCL (Instrumentation Controls Co. Ltd.) delivers top-notch needle valves designed for the toughest industrial settings. With years of experience and a strong global export presence, ICCL has established itself as a go-to partner for sectors like oil & gas, chemicals, petrochemicals, power, and marine.

🔍 What Is a Needle Valve?

A needle valve is a specialized flow control valve featuring a slender, tapered point (like a needle) that fits snugly into a conical seat. This unique design allows for precise adjustments to the flow rate by slowly opening or closing the passage.

You’ll typically find needle valves in:

- Instrumentation lines

- Sampling systems

- Pneumatic and hydraulic applications

- Low- to high-pressure process pipelines

🛠️ Key Features of ICCL Needle Valves

ICCL needle valves are crafted with precision and rigorously tested to meet global standards. Here are some standout features:

✅ Fine Flow Regulation

The needle-point plunger enables gradual and accurate flow control, making it ideal for calibration and measurement tasks.

✅ Leak-Tight Shutoff

The seats are engineered for bubble-tight sealing, even under high pressure and temperature conditions.

✅ Wide Pressure Range

ICCL valves can handle working pressures up to 6000 psi (414 bar) and even more upon request.

✅ Temperature Resistance

They perform reliably in both cryogenic and high-temperature environments.

✅ Material Options

Available in SS304, SS316, Monel, Inconel, Hastelloy, Duplex, Super Duplex, and various other alloys.

✅ End Connections

Choose from threaded (NPT/BSP), compression tube ends, socket weld, butt weld, or flanged ends to fit any piping system.

🔩 Construction of a Needle Valve

A standard needle valve is made up of:

- Valve body – the main chamber that houses the seat

- Stem with a tapered needle – used to adjust the flo:

- Bonnet – seals the stem and provides easy access.

- Packing & gland – ensures that the stem moves without leaks.

Handle (T-bar or round) – for manual operation.

ICCL’s valves are designed with blow-out proof stems and use PTFE or Graphite packing to ensure a long service life.

⚙️ Applications of Needle Valves in Industry

ICCL needle valves find their place in a variety of both general and critical applications, including:

1. Oil & Gas

These valves are essential in pressure relief lines, chemical injection skids, and gas sampling panels.

2. Petrochemical & Refining

They provide precise control over corrosive and high-temperature media in both lab and field settings.

3. Power Plants

Perfect for steam systems, turbine monitoring lines, and managing high-pressure water.

4. Chemical & Pharma Industries

Used in reactor feed lines, measuring devices, and sterile processes that require precise dosing.

5. Hydraulic & Pneumatic Systems

They help regulate flow in actuators, pumps, and instrumentation control panels.

6. Water Treatment & Marine Systems

Ideal for seawater lines and demineralized water systems, thanks to their corrosion-resistant materials.

🎯 Benefits of ICCL Needle Valves

Here’s why engineers and OEMs choose ICCL’s needle valves:

📊 ICCL vs Competitors: Why Choose Us?

🏭 Made in India, Exported Worldwide

ICCL serves customers across Asia, Europe, the Middle East, and North America.

🔬 In-House R&D

We provide custom designs, special seat options (metal/PTFE), and quick prototyping.

📦 Large Inventory & Fast Delivery

We ensure fast turnaround times with strict quality control at every step.

📜 Certifications & Compliance

We’re proud to be ISO 9001:2015 certified, PED-compliant, and have undergone rigorous testing according to ASTM and BS EN standards.

📞 Need a Needle Valve? Team Up with ICCL

If you’re in the market for a dependable needle valve manufacturer, look no further than ICCL. We offer customized solutions tailored to your process control requirements. Whether you need just one valve or a large order, you can count on us for exceptional quality, competitive prices, and timely delivery.

📧 Reach out to us at [[email protected]]

🌐 Check out our website at [https://icclksa.com/]

📍 We offer global shipping and custom OEM manufacturing options.

0 notes

Text

What Is a Monoflange Valve? Complete Guide by ICCL Experts

In industrial settings where space, safety, and efficiency are top priorities, selecting the right valve design is crucial. MonoFlange valves stand out as one of the most compact and dependable options for fluid control and isolation. As a prominent manufacturer in the instrumentation valve sector, ICCL (Instrumentation Controls Co. Ltd.) focuses on crafting high-performance Mono Flange valves tailored for the rigorous demands of the oil & gas, petrochemical, and power industries.

This guide will take you through everything you need to know about MonoFlange valves, including their definition, design, features, working principles, benefits, and industrial applications. Plus, we’ll explore why ICCL is regarded as one of the most reliable names in this field.

🧩 What Is a Monoflange Valve?

A MonoFlange valve is a single, compact unit that combines two isolation valves and a bleed valve into one forged body, often referred to as a Double Block and Bleed (DBB) valve in a flange-mounted design.

Unlike traditional valve assemblies that require multiple components and fittings to achieve similar functionality—thereby increasing the risk of leaks—a Mono Flange minimizes this risk by consolidating everything into a single flange-mountable unit. This design allows for direct installation onto pressure vessels or pipeline systems.

🛠️ Working Principle of Mono Flange Valves

MonoFlange valves generally consist of:

Two Isolation Valves (Ball or Needle type): These are used to block the flow of process fluid or gas from both directions.

One Bleed Valve (Needle type): This valve is used to drain or release trapped pressure between the isolation valves.

Operation:

Both isolation valves are closed to isolate the section from the upstream and downstream flow.

Next, the bleed valve is opened to release pressure or drain fluid between the two blocks.

This process ensures complete double isolation and safe venting, which is vital for maintenance or safety checks.

🔩 Key Design Features of ICCL Mono Flange Valves

ICCL’s MonoFlange valves are designed with performance, durability, and safety in mind:

✅ Compact & Lightweight Construction

Say goodbye to bulky assemblies! Our design cuts down on weight, making it perfect for offshore and tight spaces.

✅ Leak Proof Double Block & Bleed Design

Safety first! This feature prevents cross-contamination and allows for zero-pressure checks.

✅ High-Pressure Ratings

We offer a range from ANSI Class 150 to 2500 and API pressure classes, ideal for even the toughest service conditions.

✅ Corrosion-Resistant Materials

Choose from SS316, Duplex, Super Duplex, Monel, Hastelloy, Inconel, and other specialized materials tailored to your process needs.

✅ Threaded, Flanged, or Welded Ends

Our valves are designed to seamlessly integrate with various piping systems and meet international standards (ANSI/ASME/API/BSEN).

✅ Fire-Safe & Blow-Out Proof Design

Rest easy knowing our products are tested and certified to comply with API 607 and ISO fire-safe standards.

✅ Integral Mounting Connections for Transmitters or Gauges

These valves are often paired with pressure transmitters, gauges, or other instruments for direct installation.

⚙️ Why Choose ICCL Mono Flange Valves?

ICCL is a leader in the instrumentation valve manufacturing scene, and here’s why:

- Over 25 years of engineering know-how

- In-house design and customization options

- Adherence to global export quality standards (ISO 9001, CE, PED, ATEX)

- 100% pressure and leak testing before shipping

- Trusted by key players in the Oil & Gas, Chemical, Refining, and Energy sectors

Whether you're working with harsh chemicals, high pressures, or offshore conditions, ICCL guarantees that every valve is built to endure and certified for safety.

🔍 Typical Industrial Applications of Mono Flange Valves

ICCL MonoFlange valves are the go-to choice in these industries:

1. Oil & Gas Industry

Perfect for wellheads, manifolds, and separators, ensuring no leaks during calibration or maintenance.

2. Petrochemical Plants

Ideal for reactors and pipelines, providing pressure isolation and safe venting of toxic or corrosive fluids.

3. Refineries

Essential for pressure monitoring systems where safety and precision are paramount.

4. Power Plants

Perfect for steam and water systems, particularly in high-temperature environments.

5. Marine & Offshore Platforms

Thanks to their compact design and corrosion-resistant materials, MonoFlange valves are a great fit for offshore rigs and FPSO units.

📈 Benefits of Using Mono Flange Valves

🔐 Enhanced Safety – Allows for safe isolation and depressurization during maintenance

🔧 Easy Installation – Directly mounts to pipeline or instrument taps

💧 Fewer Leak Points – The one-piece body minimizes connection joints and potential failure areas

📦 Space & Weight Savings – Especially beneficial for offshore and modular skid systems

🔁 Versatile Compatibility – Can be customized to fit any pressure class or fitting standard

📞 Looking for High-Performance Mono Flange Valves? Reach out to ICCL Today

Whether you’re upgrading a refinery or constructing an offshore platform, ICCL has Mono Flange solutions designed just for your needs.

📧 Get in touch with our valve experts today at [your email] or visit our website [your site link] to request a catalog, sample drawing, or quote.

0 notes

Text

What Makes ICCL Mono Flange Valves Ideal for Industrial Applications

In today’s fast-paced industrial world, being compact, reliable, and leak-proof isn’t just a nice-to-have — it’s essential, especially in industries like oil and gas, petrochemicals, power, and marine engineering. That’s where ICCL’s Mono Flange Valves really shine as a go-to solution for engineers around the globe.

✅ What Is a Monoflange Valve?

A MonoFlange Valve is a sleek, single-body component crafted to save space and weight in piping systems. It cleverly combines isolation (block) and venting (bleed) functions into one unit, making it perfect for applications where every bit of space matters, along with safety and efficiency.

🔹 Why Choose ICCL Mono Flange Valves?

1. Compact & Lightweight Design

ICCL’s mono flange valves are designed for tight installations, particularly on offshore platforms or skid-mounted equipment, where every inch is precious.

2. High-Pressure and Temperature Resistance

Built to endure tough conditions, ICCL valves are made from high-quality stainless steel, alloy steel, and duplex materials, making them ideal for high-pressure industrial systems.

3. Leak-Proof Performance

Thanks to precision machining, these valves ensure zero leakage at sealing points. ICCL offers either metal-to-metal seats or soft seals, tailored to customer needs.

4. Easy Installation and Maintenance

With flanged inlet and outlet configurations, installing ICCL mono flange valves is a breeze. Their single-body design minimizes potential leak paths, making maintenance simpler.

5. Compliance with International Standards

ICCL valves adhere to international standards like ASME, API 6A/6D, and ISO, making them perfect for export and global industrial projects.

6. Customizable Configurations

ICCL provides mono flange valves in both single block & bleed and double block & bleed (DBB) versions to meet specific industrial requirements.

🌍 Industrial Applications

ICCL Mono Flange Valves are commonly found in:

✅ Oil and Gas Refineries

✅ Petrochemical Plants

✅ Offshore Platforms

✅ Power Generation Systems

✅ Chemical Processing Facilities

✅ Marine and Shipbuilding

For unmatched precision, safety, and durability, look no further than ICCL’s Mono Flange Valves, which excel in industrial-grade applications. With a diverse global client base and a passion for engineering excellence, ICCL remains a top choice for valve solutions across many industries.

0 notes

Text

ICCL – Trusted Manufacturer of Instrumentation Valves and Fittings for Precision-Control Systems

In today’s industrial landscape, where managing the flow of fluids or gases is crucial, instrumentation valves and fittings are vital for ensuring precise flow control, leak-proof operation, and overall system integrity. At ICCL (Instrumentation Control Co. Ltd.), we take pride in our expertise in designing, manufacturing, and supplying top-notch instrumentation valves and fittings for a wide range of applications — from oil and gas to chemical processing, pharmaceuticals, and beyond.

As a prominent Indian manufacturer, ICCL stands out for its reliability, performance, and the ability to customize solutions that cater to the rigorous demands of modern industrial operations.

What Are Instrumentation Valves and Fittings?

Instrumentation valves and fittings are finely crafted components that help control, isolate, measure, or regulate the flow of liquids and gases in various process systems. You’ll typically find these components in control panels, manifolds, pressure testing equipment, analyzers, and hydraulic systems, where precision and zero leakage are non-negotiable.

Here are some key product categories we offer:

- Needle Valves

- Ball Valves

- Double Block & Bleed (DBB) Valves

- Check Valves

- Gauge Valves

- Manifold Valves (2-way, 3-way, 5-way)

- Tube Fittings (Male/Female Connectors, Unions, Elbows, Tees)

Why Choose ICCL?

With over 20 years of manufacturing expertise, ICCL has earned a reputation as a reliable name in the instrumentation valve and fitting sector. Our products are crafted to meet international standards like ASTM, ASME, API, and DIN, and are celebrated for their:

- High resistance to pressure and temperature

- Outstanding surface finish and dimensional precision

- Corrosion-resistant materials

- Long-lasting performance and easy maintenance

- Dependable operation in critical applications

100% of your text is likely AI-generated

ICCL’s Core Strengths

1. Advanced Manufacturing

At our ISO 9001:2015 certified facility, we pride ourselves on having cutting-edge CNC machines and automated inspection systems, all backed by a talented technical team dedicated to ensuring precision in every single component. We maintain rigorous quality controls throughout the entire production process — from inspecting raw materials to the final packaging.

2. High-Grade Materials

We only work with certified materials, including:

- Stainless Steel 304/316/316L

- Brass

- Duplex and Super Duplex

- Monel, Inconel, Hastelloy

- Alloy 20 and other exotic metals

Every product is traceable through heat numbers and comes with Material Test Certificates (MTCs) for your peace of mind.

3. Comprehensive Product Range

ICCL provides a diverse selection of both standard and custom-built instrumentation valves and fittings, catering to everyone from small-scale operations to large EPC contractors.

4. Custom Engineering

Got a unique thread, a special coating, or a high-temperature requirement? ICCL specializes in delivering custom-engineered solutions tailored to your specific process needs.

5. Global Reach

With customers in over 30 countries and a growing footprint in the Middle East, Europe, Southeast Asia, and Africa, ICCL’s extensive network guarantees prompt support and swift delivery no matter where you are.

Applications of ICCL Instrumentation Products

Our valves and fittings play a crucial role in systems that demand:

- Leak-proof shutoff and flow control

- Accurate pressure regulation

- Safe sample extraction and venting

- High corrosion resistance in challenging environments

These products find their way into various industries, including:

- Oil & Gas Exploration and Refineries

- Chemical and Petrochemical Plants

- Power Plants and Energy Systems

- Pharmaceutical and Biotech Industries

- Food & Beverage Processing

- Marine and Offshore Installations

- Water Treatment and Environmental Systems

Quality You Can Trust

At ICCL, quality isn’t just a target — it’s our promise. Our valves and fittings undergo:

- Hydrostatic and pneumatic pressure testing

- Helium leak testing (available upon request)

- Surface finish inspections

- Dimensional checks using calibrated gauges

If you're on the hunt for a trustworthy manufacturer of instrumentation valves and fittings, look no further than ICCL. We blend cutting-edge engineering, top-notch manufacturing, and a focus on customer service to establish ourselves as a global partner in flow control solutions.

0 notes

Text

ICCL – High-Precision Female Pipe Fittings for Leak-Proof Industrial Connections

In the world of fluid handling and instrumentation, pipe fittings are absolutely vital for creating leak-proof, stable, and safe connections. Among these, female pipe fittings are key for connecting to male-threaded pipes or components. At ICCL (Instrumentation Control Co. Ltd.), we take pride in designing and manufacturing top-notch female pipe fittings that deliver reliability, durability, and outstanding performance across various industrial applications.

What Are Female Pipe Fittings?

Female pipe fittings are threaded components that connect pipes or tubes to male-threaded ends. They come with internal threads (typically NPT, BSP, or metric) that securely screw onto male connectors, valves, or other components, ensuring a tight seal. These fittings are essential in many systems where secure, pressure-resistant, and corrosion-proof connections are a must.

Common materials include stainless steel, brass, carbon steel, and specialized alloys, depending on the media and pressure conditions. The most frequently used types are elbows, tees, couplings, adapters, and connectors with female threads.

Why Choose ICCL Female Pipe Fittings?

ICCL has built a solid reputation in the field of instrumentation and industrial fittings, boasting over twenty years of experience in providing solutions that adhere to international standards. Our female pipe fittings are engineered to withstand high pressures, aggressive media, and varying temperatures without sacrificing sealing integrity.

Key Benefits of ICCL Female Fittings:

- Made from high-grade materials like SS 304, SS 316, Brass, Monel, Inconel, and Hastelloy

- Available in various thread standards – NPT, BSP, BSPT, ISO, and custom threads

- Exceptional corrosion resistance for use in tough and corrosive environments

- Leak-free performance under both vacuum and pressure

- Precision machining using advanced CNC technology

- Compliance with ASTM, ASME, DIN, and ISO standards

Every ICCL fitting undergoes thorough quality checks, pressure tests, and cleaning to ensure they’re ready for critical environments like oil & gas, chemical processing, pharmaceuticals, and water treatment.

Product Range of Female Pipe Fittings

ICCL provides a wide selection of female-threaded fittings, including:

- Female Elbows (90° and 45°) – Perfect for changing the direction of pipes

- Female Tees – Ideal for creating three-way connections in your system

- Female Connectors – Designed to link male-threaded pipes or components

- Female Adapters – Great for transitioning between different thread types or sizes

- Female Couplings – Used to join two male-threaded pipes together

- Bulkhead Female Fittings – Perfect for panel-mount installations

All fittings come in standard sizes ranging from 1/8” to 2” and can be customized to meet specific client needs.

Technical Specifications

Our female pipe fittings are crafted to ensure tight tolerances and exceptional sealing efficiency. Typical specifications include:

- Material: SS 316/316L, Brass, Alloy 20, Duplex Steel, Monel

- Size Range: 1/8” to 2” (or 6mm to 50mm)

- Thread Standards: NPT, BSP, BSPT, ISO, UNF

- Pressure Rating: Up to 6000 PSI (414 bar)

- Temperature Range: -60°C to +400°C (depending on the material)

- Surface Finish: Electro-polished or passivated as needed

These fittings are also suitable for oxygen service, hydraulic lines, and instrumentation panels where cleanliness and precision are crucial.

Applications Across Industries

ICCL's female pipe fittings are designed to excel in the most demanding industrial sectors:

- Oil & Gas pipelines and skids

- Chemical and petrochemical processing units

- Pharmaceutical and biotech facilities

- Power plants and energy systems

- Water treatment and desalination plants

- Marine, defense, and aerospace

Our fittings guarantee a long service life, require minimal maintenance, and ensure maximum safety, even in extreme operating conditions.

ICCL's Commitment to Quality

Every ICCL fitting is manufactured under strict quality control standards. Our facility is ISO 9001:2015 certified and equipped with:

Global Supply with Reliable Support

ICCL boasts a robust presence both domestically and internationally, serving over 30 countries across Europe, the Middle East, Southeast Asia, and Africa. Whether you're an OEM, an EPC contractor, or an industrial end-user, ICCL is committed to providing quick response times, dependable delivery, and technical support every step of the way.

We keep a ready stock of standard sizes and offer expedited delivery for project-based orders. Our engineering and sales teams collaborate closely with customers to pinpoint the perfect fitting for each application.

Why Choose ICCL?

✅ Over 20 years of manufacturing excellence

✅ Trusted by leading industrial clients worldwide

✅ Fast turnaround with tailored solutions

✅ Comprehensive quality assurance

✅ Extensive product range and inventory

When it comes to performance, safety, and reliability, ICCL female pipe fittings are the way to go. Crafted with precision and backed by engineering expertise, our fittings support critical systems across various industries. With ICCL, you can rely on leak-proof connections, durable construction, and unparalleled quality.

0 notes

Text

ICCL – Precision-Engineered Male Connector Fittings for Industrial

When it comes to creating leak-proof connections in instrumentation systems, male connector fittings are absolutely crucial. These fittings are specifically designed to link a tube to a female-threaded port, serving as a key component in fluid and gas handling systems across a wide range of industries. At ICCL (Instrumentation Control Co. Ltd.), we pride ourselves on manufacturing high-performance male connector fittings that guarantee safety, durability, and precision, even in the toughest conditions.

What Are Male Connector Fittings?