Don't wanna be here? Send us removal request.

Text

youtube

Automatic drilling machine can be customized

#cnc drilling machine#cnc tapping machine#automatic drilling machine#tapping machine#drilling machine#Youtube

0 notes

Text

youtube

Rotary multi-axis automatic tapping machine#factory #machine #cnc

0 notes

Text

Transform Production with Elite CNC Lathe Machines for Sale

In precision-driven industries, CNC lathe machines for sale are the linchpin of efficiency, accuracy, and scalability. For automotive suppliers, aerospace manufacturers, and engineering firms, upgrading to advanced CNC lathe technology isn’t just an investment—it’s a strategic leap toward dominating competitive markets. The High-Speed Drilling And Tapping Center Series Lathe Machine T600-21T redefines industrial machining, blending cutting-edge automation with robust engineering to tackle the most demanding production challenges.

Why CNC Lathe Machines Are Critical for Industrial Excellence CNC lathe machines eliminate human error, reduce waste, and slash cycle times through automated precision. Outdated equipment risks costly delays, rework, and inconsistent quality. For TOB clients, the T600-21T delivers:

High-Speed Machining: Spindle speeds up to 4,000 RPM handle steel, titanium, and composites with surgical precision.

Multi-Tool Versatility: Turret systems enable seamless transitions between drilling, tapping, and threading operations.

Vibration-Dampening Bed: The reinforced structure ensures stability during high-torque tasks, maintaining ±0.003mm tolerances.

Automated Feed Control: Optimizes tool paths to reduce material waste by 30% and accelerate production.

Unmatched Engineering for High-Stakes Applications

Precision Components: Hardened steel cross slide and carriage guarantee durability in 24/7 operations.

Tailstock Flexibility: Supports long workpieces for complex geometries in shafts, pins, and hydraulic fittings.

Smart Speed Adaptation: Adjustable spindle settings cater to materials from aluminum to hardened alloys.

Industry 4.0 Integration: Real-time monitoring and predictive maintenance compatibility for smarter workflows.

Applications Driving ROI Across Sectors

Aerospace: Crafting turbine blades, landing gear, and engine components.

Automotive: Machining transmission systems, brake rotors, and custom fasteners.

Medical Devices: Producing implants, surgical tools, and diagnostic equipment.

Energy Sector: Fabricating valves, pump connectors, and pipeline parts.

Tailored Solutions for Your Production Line Beyond standard models, we offer customization for spindle configurations, control interfaces, or specialized tooling. Whether you need high-volume throughput or prototype agility, the T600-21T adapts to your workflow, ensuring seamless integration into existing systems.

Why Partner with Us?

Decades of Expertise: Proven track record in CNC lathe innovation and industrial solutions.

End-to-End Support: Installation, training, and maintenance services to maximize uptime.

Custom-Built Flexibility: Modify machines to meet regional standards, niche applications, or unique specs.

Upgrade to Unrivaled Precision Today Don’t let inefficiencies hold back your growth. The T600-21T CNC Lathe Machine combines speed, durability, and intelligence to future-proof your operations. Contact us to schedule a demo, request a quote, or discuss bulk-order incentives—and position your business as a leader in precision manufacturing.

Elevate Efficiency with CNC Lathe Machines for Sale—Connect Now!

0 notes

Text

Revolutionize Production with Advanced CNC Lathe Machines

In precision manufacturing, CNC lathe machines are the backbone of efficiency, accuracy, and scalability. For workshops, automotive suppliers, and aerospace fabricators, investing in cutting-edge CNC lathe technology isn’t just an upgrade—it’s a competitive necessity. At Sukejjie, we deliver solutions like the High-Speed Drilling And Tapping Center Series Lathe Machine T600-21T, engineered to transform complex workflows into seamless, profit-driving operations.

Why CNC Lathe Machines Dominate Modern Manufacturing CNC lathe machines automate intricate tasks—turning, drilling, threading—with micron-level precision. Outdated equipment risks errors, wasted materials, and delayed deadlines. For TOC clients, our machines minimize downtime, enhance repeatability, and adapt to high-mix production demands, ensuring every component meets exact specifications.

Unmatched Capabilities of the T600-21T CNC Lathe Machine

High-Speed Drilling & Tapping: Integrated spindle speeds (50–4,000 RPM) handle steel, titanium, and composites with ease.

Rigid Bed Design: Vibration-dampening structure ensures stability during heavy-duty operations.

Multi-Tool Turret System: Rapid tool changes reduce cycle times for complex part geometries.

Smart Feed Mechanisms: Automated or manual control for precision facing, grooving, and threading.

Durable Construction: Hardened steel components withstand 24/7 industrial use.

Applications Across Industries

Automotive: Crafting engine shafts, brake rotors, and transmission components.

Aerospace: Machining turbine blades, hydraulic fittings, and landing gear parts.

Medical: Producing surgical tools, implants, and diagnostic device housings.

Energy: Fabricating valves, pump connectors, and pipeline components.

Why Choose Our CNC Lathe Machines?

Precision Engineering: Achieve tolerances within ±0.005mm for flawless part consistency.

Versatility: Switch between turning, drilling, and tapping without recalibration.

Cost Efficiency: Reduce material waste by 25%+ with optimized cutting paths.

Scalability: Ideal for prototyping, small batches, or high-volume production runs.

Tailored Solutions for Your Needs Beyond standard models, we offer customization for spindle configurations, software integration, or bespoke tooling. Whether you require a compact bench lathe or a multi-axis powerhouse, we adapt to your workflow.

Upgrade to Unmatched Precision Today Don’t let outdated equipment stifle growth. The T600-21T CNC Lathe Machine combines speed, durability, and intelligence to future-proof your production line. Contact us for a consultation and discover how our CNC lathe machines can elevate your output, margins, and market reputation.

Precision. Performance. Profit.—Transform Manufacturing with Our CNC Lathe Machines!

0 notes

Text

Smart Investment: Navigating the Cost of CNC Lathe Machines

Understanding the cost of CNC lathe machines is critical for manufacturers aiming to balance upfront expenses with long-term ROI. The High-Speed Drilling and Tapping Center Series Lathe Machine T600-21T offers a strategic solution, combining advanced automation, precision engineering, and durability to minimize total ownership costs for TOC clients in the automotive, aerospace, and medical industries. Designed for high-volume production and complex prototyping, this machine delivers rapid payback through reduced labor, material waste, and downtime.

Key Factors Influencing the Cost of CNC Lathe Machines

Automation Level: Programmable toolpaths and multi-axis control reduce manual labor by up to 60%, lowering long-term operational costs.

Material Versatility: Adjustable spindle speeds (20–4000 RPM) and adaptive feed mechanisms handle materials from aluminum to titanium, minimizing the need for multiple machines.

Durability: A rigid cast-iron bed and heat-resistant components ensure 24/7 reliability, reducing maintenance expenses over time.

Applications Maximizing ROI

Automotive Component Production: Mass-produce shafts, bushings, or engine parts with ±0.005mm tolerances, reducing scrap rates by 25%.

Medical Device Manufacturing: Achieve micron-level precision for surgical tools or implants, avoiding costly rework.

Aerospace Machining: Machine high-strength alloys for turbine components with minimal tool wear, extending cutter lifespan.

Technical Advantages Reducing Total Cost

12-Tool Turret: Eliminates frequent tool changes, cutting setup time by 50% and labor costs.

Energy Efficiency: Optimized power consumption reduces energy bills by 15–20% compared to conventional models.

Predictive Maintenance Alerts: Real-time diagnostics prevent unplanned downtime, safeguarding production schedules.

Strategic Investment for Competitive Manufacturing

While the initial cost of CNC lathe machines varies, the T600-21T ensures value through:

Faster Cycle Times: High-speed drilling and tapping capabilities slash production time by 30–40%.

Scalability: Compatible with CAD/CAM software, adapting to evolving design demands without costly upgrades.

Resale Value: Industrial-grade construction retains market value for future resale or trade-in.

Optimize Your Budget with Precision Engineering

The High-Speed Drilling and Tapping Center Series T600-21T transforms the cost of CNC lathe machines into a competitive advantage. Its blend of automation, accuracy, and durability ensures rapid ROI while future-proofing your operations.

Request a Customized Cost-Benefit Analysis Today Contact us to explore financing options, bulk discounts, or tailored configurations—equip your facility with technology designed to maximize efficiency and minimize the cost of CNC lathe machines!

0 notes

Text

Strategic Insights: CNC Lathe Machine Price & Value

Evaluating the CNC lathe machine price requires balancing upfront investment with long-term operational efficiency and ROI. The High-Speed Drilling and Tapping Center Series Lathe Machine T600-21T exemplifies this balance, offering manufacturers in the automotive, aerospace, and medical sectors a high-precision solution that reduces per-part costs through automation, durability, and material optimization.

Factors Impacting CNC Lathe Machine Price

Automation Capabilities: Programmable multi-axis control and 12-tool turret systems minimize labor costs and setup time, justifying higher initial CNC lathe machine pricethrough 30–40% faster production cycles.

Material Adaptability: Adjustable spindle speeds (20–4000 RPM) and adaptive feed mechanisms handle stainless steel, titanium, and plastics, eliminating the need for multiple machines.

Industrial-Grade Durability: A cast-iron bed and thermal-stable components ensure 24/7 operation with minimal maintenance, lowering lifetime ownership costs.

Applications Maximizing ROI

High-Volume Automotive Parts: Produce shafts or bushings with ±0.005mm tolerances, reducing scrap rates by 25%.

Aerospace Components: Machine turbine blades from high-strength alloys, extending tool life and minimizing rework.

Medical Prototyping: Achieve micron-level accuracy for implants, avoiding costly post-processing.

Technical Advantages Reducing Operational Costs

Energy Efficiency: Optimized power consumption cuts energy bills by 15–20% versus older models.

Real-Time Diagnostics: Predictive alerts for tool wear or alignment issues prevent unplanned downtime.

Compact Footprint: Saves floor space in small workshops or large factories, reducing facility expenses.

Why the T600-21T Justifies Its CNC Lathe Machine Price

Scalable Automation: Compatible with CAD/CAM software for seamless upgrades as production needs evolve.

Rapid ROI: High-speed drilling and tapping reduce cycle times by 40%, accelerating payback periods.

Resale Value: Industrial-grade build retains market value for future resale or trade-in opportunities.

Invest in Precision, Not Just Equipment

While the CNC lathe machine price varies, the T600-21T transforms capital expenditure into a strategic asset. Its precision engineering and automation slash per-unit costs, ensuring competitiveness in tight-margin industries.

Request a Customized Quote Today Contact us to analyze your production needs and explore flexible financing options. Discover how the High-Speed Drilling and Tapping Center Series T600-21T delivers unmatched value per dollar—schedule a demo or request an ROI forecast now!

0 notes

Text

Core Components of CNC Lathe Machines for Unmatched Precision

In precision manufacturing, the integrity of components of CNC lathe machines determines operational efficiency, product quality, and long-term ROI. The Heavy Drilling and Tapping Center Series Lathe Machine V-600 exemplifies engineering mastery, combining industrial-grade durability with advanced automation for TOC clients in sectors like automotive, aerospace, and custom prototyping. Designed to excel in high-volume and high-complexity tasks, its components ensure seamless performance in drilling, threading, and turning operations.

Critical Components of CNC Lathe Machines Redefined

Vibration-Resistant Bed: Built to absorb shocks and maintain stability during high-speed operations, ensuring micron-level accuracy even under heavy loads.

High-Torque Headstock: Integrates a precision-balanced spindle and motor for rotational accuracy within 0.005mm, ideal for aerospace-grade shaft production.

Multi-Functional Tailstock: Supports complex drilling and tapping tasks while accommodating diverse workpiece lengths without recalibration.

Automated Carriage System: Programmable feed mechanisms reduce cycle times by 35% compared to manual setups, optimizing throughput.

Modular Cross Slide: Enables rapid lateral tool adjustments for intricate grooving and facing, minimizing downtime between operations.

Applications Maximizing ROI From mass-producing automotive bushings to crafting medical device prototypes, the V-600’s components of CNC lathe machines deliver:

Material Versatility: Adjustable spindle speeds (20–3000 RPM) handle stainless steel, titanium, and engineering plastics with minimal tool wear.

24/7 Durability: Industrial-grade construction with IP65-equivalent protection ensures reliability in harsh, coolant-heavy environments.

Labor Efficiency: Automated tool changers and CAD/CAM compatibility reduce dependency on skilled operators, cutting labor costs by up to 50%.

Strategic Advantages for Competitive Manufacturing The Heavy Drilling and Tapping Center Series Lathe Machine V-600 transforms components of CNC lathe machines into long-term assets. Its modular design allows upgrades for evolving production needs, while real-time diagnostics minimize unplanned downtime.

Elevate Your Production Capabilities Today Invest in components of CNC lathe machines engineered for precision and endurance. Contact us to schedule a live demo or request a tailored ROI analysis—equip your facility with technology designed to outperform industry benchmarks and drive sustainable growth!

0 notes

Text

Precision CNC Lathe Machine Parts for Industrial Durability

In high-stakes manufacturing environments, the reliability of CNC lathe machine parts directly impacts productivity, precision, and long-term operational costs. The Heavy Drilling and Tapping Center Series Lathe Machine V-600 exemplifies engineering excellence, offering TOC clients a robust solution for industries ranging from automotive to aerospace. Designed with industrial-grade components, this machine ensures consistent performance in demanding applications like shaft production, prototyping, and complex threading operations.

Critical CNC Lathe Machine Parts and Their Advantages

High-Rigidity Bed: Constructed to absorb vibrations and resist deformation, ensuring stability during high-speed drilling, tapping, and turning.

Dual-Function Headstock: Integrates a powerful motor and precision spindle for rotational accuracy up to 0.001mm tolerance, ideal for aerospace components.

Modular Tailstock: Supports heavy workpieces and accommodates drilling tools, enabling seamless transitions between operations without recalibration.

Automated Carriage System: Equipped with programmable feed mechanisms, reducing cycle times by 30% compared to manual systems.

Multi-Tool Cross Slide: Enables lateral cutting tool adjustments for complex facing and grooving tasks, minimizing setup downtime.

Applications Driving Efficiency From mass-producing automotive bushings to crafting custom medical device prototypes, the V-600’s CNC lathe machine parts deliver versatility and precision. Key benefits include:

Reduced Material Waste: Adaptive speed control optimizes cuts for metals, plastics, and composites, minimizing scrap rates.

24/7 Operational Readiness: Durable components withstand continuous use in harsh industrial environments, backed by IP65-equivalent protection.

Labor Cost Savings: Automated tool changes and programmable workflows reduce dependency on skilled operators.

Strategic Investment for Competitive Manufacturing The Heavy Drilling and Tapping Center Series Lathe Machine V-600 transforms CNC lathe machine parts into long-term assets. Its modular design allows future upgrades, while compatibility with CAD/CAM software ensures agility in adapting to design changes.

Upgrade Your Production Line Today Maximize ROI with CNC lathe machine parts engineered for precision and endurance. Contact us to schedule a demo or request a customized cost-benefit analysis—equip your workshop with technology designed to outperform and outlast!

0 notes

Text

Master Precision: Core Components of CNC Lathe Machines

For manufacturers and engineers, understanding the components of CNC lathe machines is key to unlocking peak performance. Each part’s design and durability directly impact productivity, precision, and operational costs. The Heavy Drilling and Tapping Center Series Lathe Machine V-800 exemplifies how advanced engineering of components of CNC lathe machines drives efficiency in high-stakes industries. Discover how its architecture sets new benchmarks.

Critical Components of CNC Lathe Machines Explained The components of CNC lathe machines work synergistically to transform raw materials into precision parts. The V-800 elevates this synergy through purpose-built design:

Vibration-Absorbing Bed:

Material: High-grade cast iron minimizes chatter during heavy drilling or tapping, ensuring surface finishes within 0.2µm Ra.

Function: Acts as the machine’s foundation, stabilizing operations even at 3,500 RPM spindle speeds

Multi-Tasking Headstock:

Spindle Range: 50–3,500 RPM with automatic speed adjustment, handling materials from soft plastics to hardened steel.

Motor Integration: Direct-drive motors eliminate belt slippage, boosting torque by 25% for demanding cuts.

Adaptable Tailstock:

Tool Compatibility: Supports live tooling for drilling and threading, enabling complex operations without repositioning.

Hydraulic Clamping: Secures workpieces up to 150mm in diameter with zero deflection

Precision Carriage and Cross Slide:

Linear Guideways: Enable smooth, frictionless movement for tolerances within ±0.003mm.

Quick-Change Tool Posts: Swap tools in seconds, reducing downtime between jobs

Smart Feed Mechanism:

Automated Control: Programmable feeds optimize chip load and cutting speed, slashing cycle times by 30%.

Applications Demanding Superior Components

Aerospace: Machine turbine shafts with zero runout, meeting AS9100 standards.

Automotive: Produce high-volume engine components with repeatable accuracy.

Medical Device Prototyping: Craft intricate surgical tools using micro-turning capabilities.

Why the V-800’s Components Outperform Unlike generic components of CNC lathe machines, the V-800 integrates innovations that redefine reliability:

IP54-Rated Enclosures: Protect against coolant ingress and metal dust in harsh workshops.

Modular Upgrades: Retrofit IoT sensors for predictive maintenance or integrate cobots for lights-out production.

Energy Recovery Systems: Convert braking energy into reusable power, cutting energy costs by 18%.

ROI-Driven Engineering Investing in the V-800’s components of CNC lathe machines delivers measurable returns:

40% Faster Setup: Automated tool alignment and preset programs reduce idle time.

50% Longer Tool Life: Precision alignment minimizes edge wear on cutting tools.

20% Lower Scrap Rates: Vibration damping and real-time corrections ensure first-pass accuracy.

Elevate Your Production Line Today Don’t let outdated components of CNC lathe machines hold back your potential. Explore the Heavy Drilling and Tapping Center Series Lathe Machine V-800 and experience how its engineered excellence transforms manufacturing. Contact us for a customized demo, bulk order discounts, or technical consultations—equip your workshop with components built to dominate precision machining.

0 notes

Text

Precision Engineered: Unlocking CNC Lathe Machine Parts’ Potential

For manufacturers and workshops, the performance of CNC lathe machine parts dictates productivity, precision, and profitability. Subpar components lead to inefficiencies, frequent breakdowns, or costly rework. The Heavy Drilling and Tapping Center Series Lathe Machine V-800 redefines expectations, combining industrial-grade CNC lathe machine parts with intelligent design to deliver unmatched reliability. Discover how its engineering elevates every operation.

Why High-Performance CNC Lathe Machine Parts Matter CNC lathe machine parts form the backbone of precision manufacturing. From vibration-dampening beds to multi-tool turrets, each component impacts output quality and operational costs. The V-800 integrates next-gen features:

Industrial Bed: Cast iron construction absorbs vibrations, ensuring micron-level accuracy during heavy drilling or tapping.

Modular Headstock: Adjustable spindle speeds (50–3,500 RPM) handle materials from aluminum to titanium without recalibration.

Turret-Ready Tailstock: Supports automatic tool changes for drilling, threading, or facing in a single setup.

Critical Components Driving Efficiency

Vibration-Dampening Bed:

Eliminates chatter during high-speed operations, reducing surface finish defects by 30%.

Extends cutting tool lifespan by minimizing stress on edges.

Precision Carriage and Cross Slide:

Linear guideways ensure smooth lateral movement, achieving tolerances within ±0.005mm.

Compatible with carbide, ceramic, or diamond-tipped tools for versatile applications.

Automated Feed Mechanism:

Programmable feeds optimize chip removal and cutting speed, slashing cycle times by 25%.

Reduces manual intervention, lowering labor costs in high-volume production.

Applications Where Quality Parts Shine

Aerospace Machining: Craft turbine shafts or landing gear components with zero tolerance deviations.

Automotive Prototyping: Rapidly iterate engine parts or bushings using CAD/CAM-compatible automation.

Tool and Die Repair: Restore molds or dies with precision threading and drilling capabilities.

Why the V-800’s Components Outperform Unlike generic CNC lathe machine parts, the V-800 is engineered for resilience and adaptability:

IP54-Rated Enclosures: Protect internal gears and electronics from coolant, dust, and humidity.

Quick-Change Tool Posts: Swap cutting tools in seconds, minimizing downtime between jobs.

Energy-Efficient Motors: Cut power consumption by 20% while maintaining torque output.

Maximize ROI with Superior Engineering Investing in premium CNC lathe machine parts like those in the V-800 pays dividends:

40% Faster Job Completion: Automated feeds and multi-tool operations boost throughput.

50% Lower Maintenance Costs: Hardened steel components resist wear, even in 24/7 environments.

Future-Proof Upgradability: Retrofit smart sensors or IoT modules to stay ahead of industry trends.

Upgrade Your Workshop Today Don’t let outdated CNC lathe machine parts limit your potential. Explore the Heavy Drilling and Tapping Center Series Lathe Machine V-800 and experience how precision-engineered components drive efficiency. Contact us for tailored quotes, leasing options, or onsite demonstrations—transform your production line with parts built to outperform.

0 notes

Text

Float Switch Precision: Master Fuel Level Monitoring

In the marine and transport industries, accurate fuel management is non-negotiable. A reliable float switch ensures optimal tanker boat and caravan operations—preventing costly leaks, engine failures, or supply disruptions. However, traditional float sensors often lack precision, durability, or compatibility with modern telemetry systems. Our Analog 0-5V Tanker Boat Fuel Level Sensor with Indicator redefines fuel monitoring with high-precision analog output, rugged stainless steel construction, and seamless integration for critical applications.

Why Traditional Float Switches Fall Short Legacy float switches struggle with corrosion, limited measurement ranges, or incompatible outputs for IoT-enabled systems. These shortcomings lead to inaccurate readings, frequent recalibrations, and increased maintenance costs. Our solution addresses these gaps by combining analog signal precision (0-5V) with marine-grade materials, ensuring real-time, drift-free fuel level data even in harsh environments.

Key Features of Our Fuel Level Sensor

1. Stainless Steel Durability: Built with corrosion-resistant stainless steel, it withstands saltwater, diesel, biodiesel, and extreme temperatures.

2. Wide Measurement Range: Detect fuel levels from 150mm to 2300mm, ideal for compact caravan tanks or large marine vessels.

3. Analog Precision: 0-5V output provides granular data for integration with PLCs, dashboards, or telemetry systems.

4. ISO-Certified Reliability: Compliance with international standards, ensuring safety and performance consistency.

5. Compact & Lightweight: Single-unit packaging (50x50x50 cm, 3.0 kg) simplifies shipping and installation.

Applications Beyond Tanker Boats

· Marine Fleet Management: Monitor fuel consumption, prevent theft, or automate refills in cargo ships, yachts, or fishing vessels.

· Caravan/RV Systems: Track water or fuel reserves with precision, enhancing off-grid sustainability.

· Industrial Storage: Safeguard diesel generators, hydraulic tanks, or agricultural fuel depots.

Installation Best Practices

· Mount vertically using threaded fittings for stable float movement.

· Pair with shielded cables to reduce electromagnetic interference.

· Calibrate the 0-5V output range during setup to match tank dimensions.

· Use the LED indicator for instant visual status checks.

Why Partner with Us?

· Custom Solutions: Adjust cable lengths, output ranges (e.g., 4-20mA), or housing materials (e.g., PTFE for chemical resistance).

· Global Compliance: SCJ-branded sensors meet ISO standards, with 1-year warranty coverage.

· B2B Support: Access CAD files, wiring diagrams, and 24/7 technical assistance for fleet-wide deployments.

· Bulk Efficiency: Competitive pricing for high-volume orders and expedited global delivery.

0 notes

Text

Water Tank Float Switch: Reliable Level Control Made Simple

Accurate water tank level management is critical for industries ranging from agriculture to municipal utilities. Yet, traditional water tank float switches often fail under harsh conditions, leading to overflows, pump damage, or costly downtime. Our 304 Stainless Steel Side-Mounted Double Float Switch redefines reliability with a corrosion-resistant design, dual-sensor redundancy, and customizable controls—ensuring uninterrupted operations in even the most demanding environments.

Why Upgrade Your Water Tank Float Switch? Standard plastic or low-grade metal switches degrade quickly when exposed to chemicals, temperature extremes, or abrasive liquids. This results in false triggers, maintenance headaches, and compromised safety. Our solution tackles these challenges head-on:

· Robust 304 Stainless Steel Construction: Resists rust, UV exposure, and corrosive fluids like chlorine or saline.

· Dual-Float Redundancy: Two independent floats minimize failure risks, providing backup detection for high/low level alerts.

· Side-Mounted Flexibility: Easily installs horizontally in tight spaces, ideal for retrofitting existing tanks without structural changes.

· Custom Control Logic: Programmable for “tank up and down” automation, enabling precise pump activation, refill cycles, or alarm triggers.

Key Specifications for Seamless Integration

· Compact Design: Single-unit dimensions (12x5x6 cm) and lightweight (0.8 kg) simplify shipping and installation.

· Adaptable Mounting: Compatible with tanks, sumps, or pipelines via threaded fittings or brackets.

· Wide Compatibility: Works with freshwater, wastewater, oils, and mild chemicals.

Industries We Serve

· Agriculture: Automate irrigation reservoirs or livestock water troughs.

· Manufacturing: Monitor coolant tanks, prevent equipment dry-running.

· Municipal Water Systems: Manage storage tanks, prevent overflow in treatment plants.

· Marine: Withstand saltwater in ballast tanks or bilge pumps.

Optimize Performance with Pro Tips

1. Calibrate Float Angles: Adjust float positions to match liquid density (e.g., oil vs. water).

2. Use Sealed Connectors: Prevent moisture ingress in humid or submerged setups.

3. Pair with IoT Controllers: Enable remote monitoring and data logging for predictive maintenance.

Why Choose Our Solution?

· Tailored Customization: Modify cable lengths, switch thresholds (NC/NO), or connector types to fit unique needs.

· Durability Guaranteed: 304 stainless steel ensures a 5x longer lifespan than plastic competitors.

· Global Compliance: Meets ISO standards for quality and safety.

· Scalable Supply: Benefit from bulk pricing and expedited shipping for urgent projects.

0 notes

Text

Transform Production with Elite CNC Lathe Machines for Sale

In precision-driven industries, CNC lathe machines for sale are the linchpin of efficiency, accuracy, and scalability. For automotive suppliers, aerospace manufacturers, and engineering firms, upgrading to advanced CNC lathe technology isn’t just an investment—it’s a strategic leap toward dominating competitive markets. The High-Speed Drilling And Tapping Center Series Lathe Machine T600-21T redefines industrial machining, blending cutting-edge automation with robust engineering to tackle the most demanding production challenges.

Why CNC Lathe Machines Are Critical for Industrial Excellence CNC lathe machines eliminate human error, reduce waste, and slash cycle times through automated precision. Outdated equipment risks costly delays, rework, and inconsistent quality. For TOB clients, the T600-21T delivers:

High-Speed Machining: Spindle speeds up to 4,000 RPM handle steel, titanium, and composites with surgical precision.

Multi-Tool Versatility: Turret systems enable seamless transitions between drilling, tapping, and threading operations.

Vibration-Dampening Bed: The reinforced structure ensures stability during high-torque tasks, maintaining ±0.003mm tolerances.

Automated Feed Control: Optimizes tool paths to reduce material waste by 30% and accelerate production.

Unmatched Engineering for High-Stakes Applications

Precision Components: Hardened steel cross slide and carriage guarantee durability in 24/7 operations.

Tailstock Flexibility: Supports long workpieces for complex geometries in shafts, pins, and hydraulic fittings.

Smart Speed Adaptation: Adjustable spindle settings cater to materials from aluminum to hardened alloys.

Industry 4.0 Integration: Real-time monitoring and predictive maintenance compatibility for smarter workflows.

Applications Driving ROI Across Sectors

Aerospace: Crafting turbine blades, landing gear, and engine components.

Automotive: Machining transmission systems, brake rotors, and custom fasteners.

Medical Devices: Producing implants, surgical tools, and diagnostic equipment.

Energy Sector: Fabricating valves, pump connectors, and pipeline parts.

Tailored Solutions for Your Production Line Beyond standard models, we offer customization for spindle configurations, control interfaces, or specialized tooling. Whether you need high-volume throughput or prototype agility, the T600-21T adapts to your workflow, ensuring seamless integration into existing systems.

Why Partner with Us?

Decades of Expertise: Proven track record in CNC lathe innovation and industrial solutions.

End-to-End Support: Installation, training, and maintenance services to maximize uptime.

Custom-Built Flexibility: Modify machines to meet regional standards, niche applications, or unique specs.

Upgrade to Unrivaled Precision Today Don’t let inefficiencies hold back your growth. The T600-21T CNC Lathe Machine combines speed, durability, and intelligence to future-proof your operations. Contact us to schedule a demo, request a quote, or discuss bulk-order incentives—and position your business as a leader in precision manufacturing.

Elevate Efficiency with CNC Lathe Machines for Sale—Connect Now!

0 notes

Text

Revolutionize Production with Advanced CNC Lathe Machines

In precision manufacturing, CNC lathe machines are the backbone of efficiency, accuracy, and scalability. For workshops, automotive suppliers, and aerospace fabricators, investing in cutting-edge CNC lathe technology isn’t just an upgrade—it’s a competitive necessity. At Sukejjie, we deliver solutions like the High-Speed Drilling And Tapping Center Series Lathe Machine T600-21T, engineered to transform complex workflows into seamless, profit-driving operations.

Why CNC Lathe Machines Dominate Modern Manufacturing CNC lathe machines automate intricate tasks—turning, drilling, threading—with micron-level precision. Outdated equipment risks errors, wasted materials, and delayed deadlines. For TOC clients, our machines minimize downtime, enhance repeatability, and adapt to high-mix production demands, ensuring every component meets exact specifications.

Unmatched Capabilities of the T600-21T CNC Lathe Machine

High-Speed Drilling & Tapping: Integrated spindle speeds (50–4,000 RPM) handle steel, titanium, and composites with ease.

Rigid Bed Design: Vibration-dampening structure ensures stability during heavy-duty operations.

Multi-Tool Turret System: Rapid tool changes reduce cycle times for complex part geometries.

Smart Feed Mechanisms: Automated or manual control for precision facing, grooving, and threading.

Durable Construction: Hardened steel components withstand 24/7 industrial use.

Applications Across Industries

Automotive: Crafting engine shafts, brake rotors, and transmission components.

Aerospace: Machining turbine blades, hydraulic fittings, and landing gear parts.

Medical: Producing surgical tools, implants, and diagnostic device housings.

Energy: Fabricating valves, pump connectors, and pipeline components.

Why Choose Our CNC Lathe Machines?

Precision Engineering: Achieve tolerances within ±0.005mm for flawless part consistency.

Versatility: Switch between turning, drilling, and tapping without recalibration.

Cost Efficiency: Reduce material waste by 25%+ with optimized cutting paths.

Scalability: Ideal for prototyping, small batches, or high-volume production runs.

Tailored Solutions for Your Needs Beyond standard models, we offer customization for spindle configurations, software integration, or bespoke tooling. Whether you require a compact bench lathe or a multi-axis powerhouse, we adapt to your workflow.

Upgrade to Unmatched Precision Today Don’t let outdated equipment stifle growth. The T600-21T CNC Lathe Machine combines speed, durability, and intelligence to future-proof your production line. Contact us for a consultation and discover how our CNC lathe machines can elevate your output, margins, and market reputation.

Precision. Performance. Profit.—Transform Manufacturing with Our CNC Lathe Machines!

0 notes

Text

Rotary Drilling Tapping Machine: Streamlined Efficiency for Industrial Precision

For manufacturers seeking to optimize multi-process component fabrication, the Rotary Drilling Tapping Machine by Chinese Factory delivers unmatched productivity, precision, and cost-efficiency. Designed for high-volume production lines, this advanced system integrates drilling, chamfering, and tapping into a single automated workflow—reducing cycle times, minimizing defects, and slashing operational costs for automotive, aerospace, and machinery industries.

Why Partner with Our Rotary Machine?

All-in-One Process Integration Complete drilling, chamfering, and tapping in one seamless operation, eliminating repetitive clamping and reducing production time by up to 60%.

Zero-Defect Consistency Minimize product scratching and dimensional variance with precision-guided toolpaths, ensuring 99.9% part conformity across 10,000+ cycles.

Energy-Smart Operation Eco-friendly motors and optimized power consumption reduce energy costs by 30%, aligning with sustainable manufacturing goals.

Operator-Friendly Design One-button start functionality allows even entry-level workers to operate the machine confidently, reducing training overhead and human error.

Technical Excellence for Demanding Applications

Multi-Process Automation: Eliminate manual tool changes between drilling, chamfering, and tapping.

Hardened Tooling: Tungsten-carbide bits withstand high-speed operations (3,000 RPM) on stainless steel, aluminum, and alloys.

Rigid Frame Construction: A vibration-dampened cast iron base ensures micron-level accuracy (±0.005mm).

Safety Compliance: CE-certified emergency stops and automatic shutdown on overload.

Ideal Use Cases

Engine blocks, transmission housings, and hydraulic manifolds

Aerospace brackets and fastener plates

Industrial pump bodies and valve components

High-tolerance electronics enclosures

Transform Your Production Workflow Today The Rotary Drilling Tapping Machine by Chinese Factory isn’t just machinery—it’s a strategic upgrade for manufacturers prioritizing speed, precision, and ROI. By consolidating processes and reducing waste, our solution empowers you to meet tight deadlines and scale competitively.

Contact Our Team for a Customized Efficiency Proposal!

Limited Slots Available—Request a Live Demo or Quote Now!

0 notes

Text

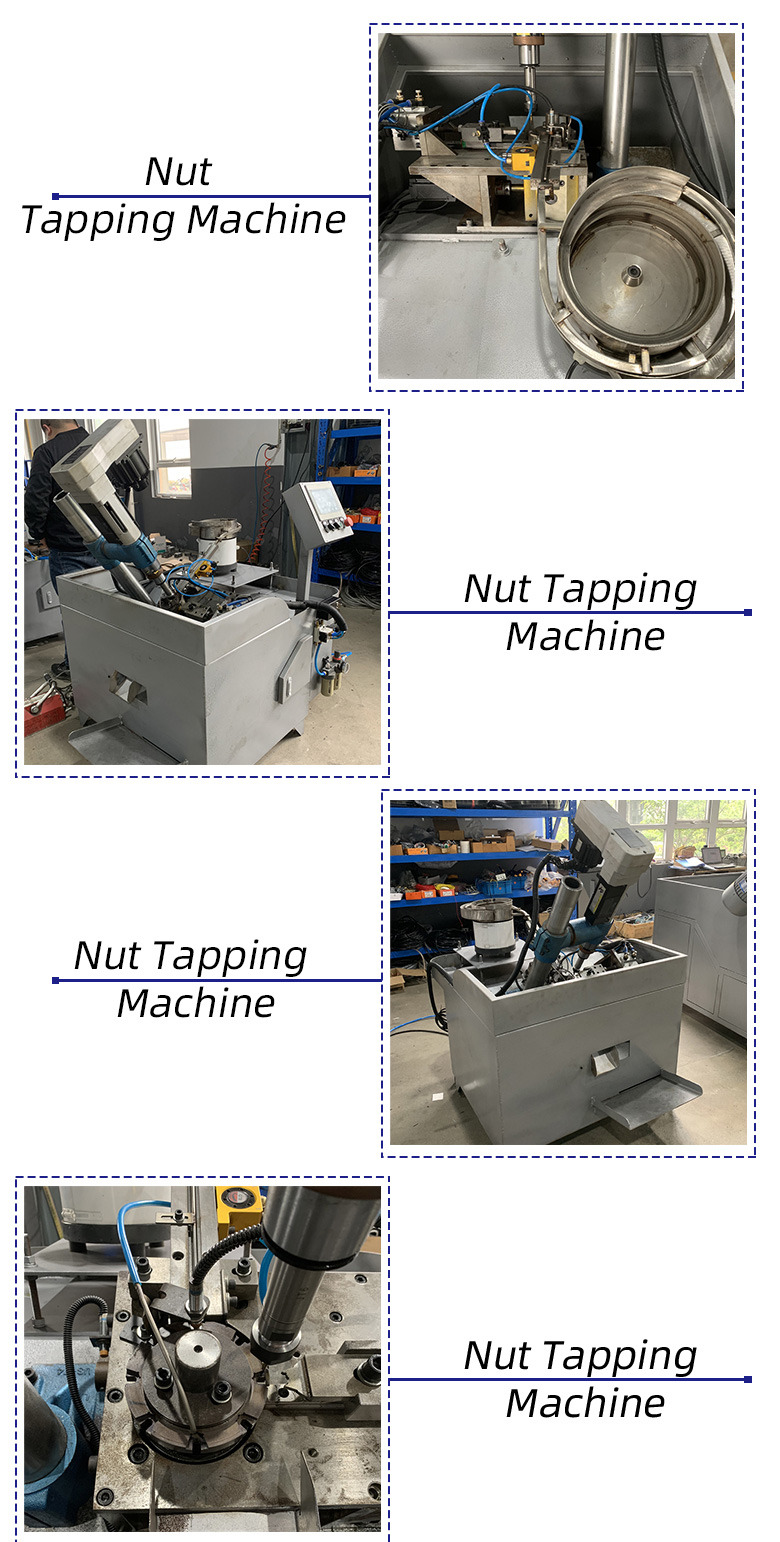

Automatic Non-Standard Nut Tapping Machine: Precision Meets Speed

For manufacturers requiring high-speed, high-precision solutions for non-standard nut production, the Automatic Non-Standard Nut Tapping Machine redefines efficiency and reliability. Designed for industrial workshops and OEM facilities, this advanced system integrates automatic loading, tapping, and unloading into a seamless workflow, ensuring consistent quality while slashing production costs and cycle times.

Why Choose Our High-Speed Tapping Machine?

End-to-End Automation Achieve uninterrupted production with fully automated loading, tapping, and unloading processes—ideal for high-volume runs of non-standard nuts with complex geometries.

Ratchet-Driven Precision A patented ratchet mechanism ensures micrometer-level positioning accuracy (±0.003mm), guaranteeing uniform thread depth and pitch across thousands of cycles.

Multi-Directional Chip Management Vertical, slant, or horizontal tapping orientations prevent chip accumulation, reducing downtime and tool wear in demanding environments.

Smart Fault Detection Infrared sensors instantly detect tap breakage or thread irregularities, halting operations to minimize material waste and costly rework.

Customizable Scalability Adapt to diverse nut sizes (M3–M24) and materials (stainless steel, titanium, and alloys) with modular tooling and bespoke configurations.

Technical Excellence for Industrial Demands

High-Speed Tapping: 5,000 RPM capability with adaptive torque control for hard-to-machine materials.

Flexible Orientation: Optimize chip evacuation for blind holes or intricate designs.

Safety Compliance: Optional safety covers and CE-certified emergency stops ensure operator protection.

Energy Efficiency: Regenerative braking reduces power consumption by 20% vs. conventional systems.

Ideal Applications

Automotive suspension nuts and custom fasteners

Aerospace titanium fittings and hydraulic connectors

Heavy machinery bolts and marine-grade components

Electronics enclosures and specialty hardware

Elevate Your Production Capabilities Today The Automatic Non-Standard Nut Tapping Machine isn’t just equipment—it’s a strategic asset for manufacturers tackling tight tolerances, exotic materials, or bespoke designs. By combining speed, precision, and adaptability, our solution empowers you to meet evolving market demands without compromise.

Contact Our Engineering Team for a Customized Production Analysis!

Limited Availability—Request a Demo or Quote Now!

0 notes