SuperSil Materials Co., Ltd. is a professional manufacturer of RTV silicone rubber located in Dongguan China

Don't wanna be here? Send us removal request.

Text

We are open

Dear my friend,

Our Chinese New Year holiday has concluded, and our office is now open for business. We appreciate your continued support and look forward to a successful year ahead.

Best regards, Matt www.super-silicon.com Silicone Rubber, Epoxy Resin, Polyurethane Rubber, Polyurethane Resin

0 notes

Text

Dear Valued Customers and Partners, Happy Chinese New Year! Our office will be closed for the Spring Festival holiday from January 17, 2025, to February 6, 2025. We will resume normal operations on February 7, 2025. During this time, we kindly ask for your understanding if there are any delays in responses. For urgent matters, please feel free to contact us, and we will do our best to assist you. Wishing you great luck and prosperity in the Year of the Snake! Warm regards, Super Silicon Team www.super-silicon.com Silicone Rubber | Epoxy Resin | Polyurethane Rubber | Liquid Plastic

0 notes

Photo

Some tips for sealing a Model Prior to Applying Silicone: 1.Opt for an acrylic spray. 2.Consider using petroleum jelly thinned with mineral spirits, ensuring to avoid leaving behind brush strokes, which the rubber can pick up and reveal on the mold's surface. 3.Utilize wax cautiously, being mindful to prevent brush strokes on the model. 4.Avoid wiping the model with alcohol before applying silicone rubber. 5.Steer clear of shellac! Its alcohol content can cause the rubber to bond to the model. 6.Refrain from using release agents containing silicone, as they may inadvertently prime the surface for silicone rubber bonding. 7.And always remember—when in doubt about the compatibility of a sealer or release agent with rubber, conduct a small test on a non-critical piece beforehand to mitigate any risks.

0 notes

Photo

We're back in action and ready to rock your world! If you need anything at all, whether it's placing an order, getting some support, or just want to say hi, don't hesitate to reach out to us. We're here for you! Thank you for sticking with us through the holiday break. Let's make this year even more successful than the last. Cheers to a fantastic year ahead! www.super-silicon.com

0 notes

Photo

Factory supply: RTV-2 silicone rubber for making “long-term durable, high-temperature resistant silicone molds” used for producing ornaments & decorative wall plates made of “POLYESTER RESIN” https://bit.ly/484jRVk

0 notes

Photo

The Ultimate Guide to Working with RTV-2 Silicones: Tips and Techniques https://bit.ly/3SbO5kk

0 notes

Photo

How to choose the correct hardness silicone for my products? Normally, different sizes of silicone mold should be selected according to different product features. For example : For products size ( within 20 cm ) : With fine designs, soft silicone is suitable, suggest 10-20 shore A. For products size ( 20cm-80cm ) : With fine designs, suggest 20-25 shore A. With simple designs, suggest 25-30 shore A. For products size ( 80cm-150cm ) : With fine designs, suggest 25 shore A. With simple designs, suggest 30-35 shore A. For products size ( more than 150cm ) : With fine designs, suggest 25-28 shore A. With simple designs, suggest 30-35 shore A. https://bit.ly/3MehCpQ

0 notes

Photo

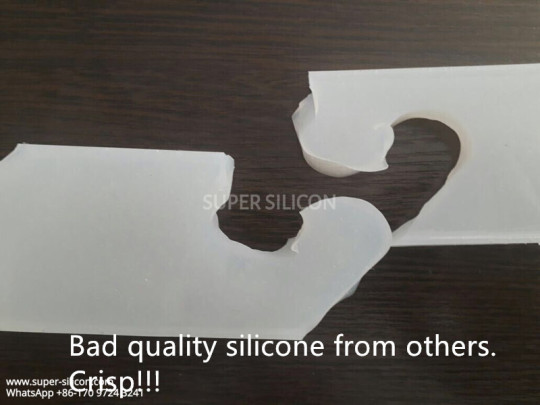

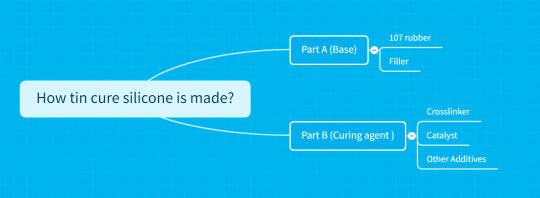

How RTV-2 silicone rubber is made? (tin cure silicone rubber) https://bit.ly/45yNJYe

0 notes

Photo

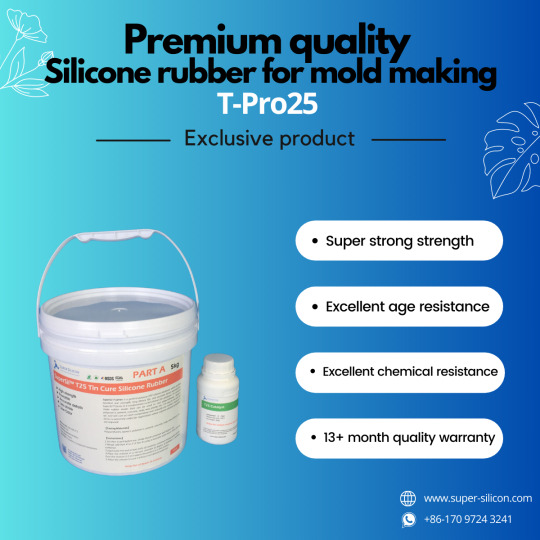

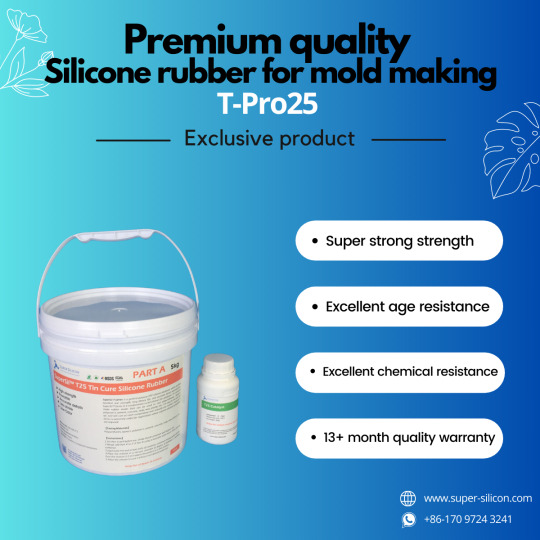

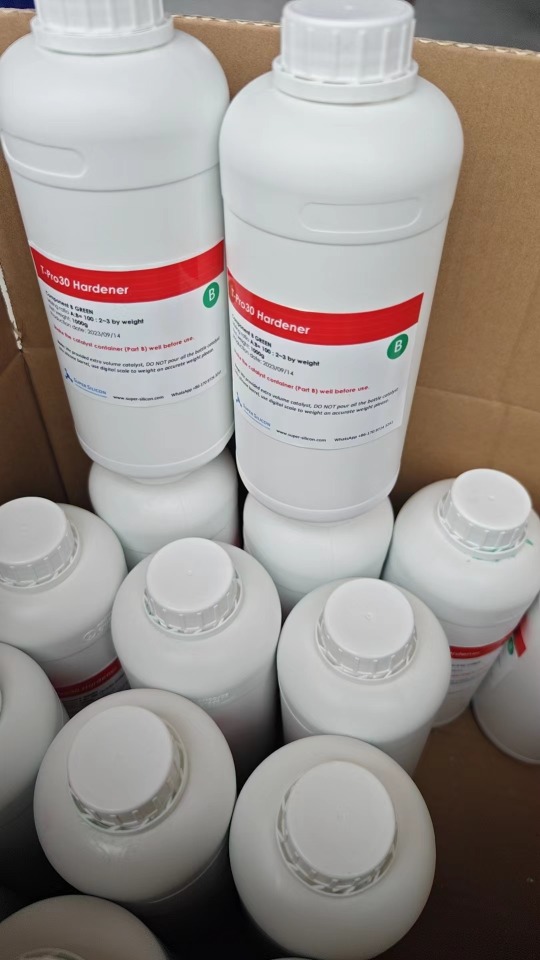

3000 kgs of our super-strong T-PRO25 RTV-2 silicone, ready to deliver Pakistan! 💪🚀 Don't miss with this unbeatable strength grade! Order now at https://www.super-silicon.com/product/tin-cure-rtv-silicone/

0 notes

Photo

How long can I store my rubber mold in a “mold library”? https://www.super-silicon.com/blog/how-long-can-i-store-my-rubber-mold-in-a-mold-library/

0 notes

Photo

Super Silicon Company 2023 Mid-Autumn Festival Holiday Notice Our office will be closed from Sep 29th to Oct 6th for the Mid-Autumn Festival. Normal operations resume on Oct 7th. Enjoy the festivities with loved ones! Super-Silicon Team www.super-silicon.com

0 notes

Photo

When it comes to our tin cure RTV-2 silicone for mold making, we offer three fantastic grades: T-Pro series, T-Flow series, and others. Let's dive into the differences between these options and see which one floats your boat! First up, we have the T-Pro series, which is our super strong strength grade. If you need a silicone that can withstand some serious pressure, this is the one for you. It's like the Hulk of silicone - incredibly tough and robust. Your molds will be able to handle even the most demanding casting materials without breaking a sweat. Next in line is the T-Flow series, our high-strength grade. While not as mighty as the T-Pro series, it still packs quite a punch. This silicone is perfect for molds that require a balance between strength and flexibility. It flows smoothly and effortlessly into every nook and cranny, ensuring precise detail reproduction. Now, let's talk about the other grades in comparison to these powerhouses. While they may not have their own fancy series name, they still deserve some recognition. These economical grade RTV-6 series silicons are an excellent choice for those on a budget or for less demanding applications. They offer decent strength and durability without breaking the bank. So, whether you need superhero-level strength with our T-Pro series, a balanced performance with our T-Flow series, or an economical option with our RTV-6 series, we've got you covered. Choose the grade that suits your needs and get ready to create molds with confidence! To learn more about the differences between these series, check out our blog post at https://bit.ly/3LBHFa1. Happy mold making!

0 notes

Photo

A Comparison: Tin-cured silicone vs. Platinum-cured Silicone Mold Rubbers.

Supersil T-series silicones are condensation-cure systems that shrink slightly on cure (~0.5%) compared to addition-cure silicones Supersil P-series , which do not shrink on cure.

Tin-cured silicones have shorter library life (2 to 5 years total) compared to platinum-cured silicones.

Tin-cured silicones are slightly less expensive than platinum-cured silicones.

Liquid platinum-cured silicones are more sensitive to certain materials (e.g., sulfur, tin compounds, Bondo) and suffer from cure inhibition (uncured surface material) more often than tin-cured silicones. (Supersil T-series)

Cured tin silicone molds can inhibit some casting materials, including Platinum cure silicones, and many polyurethane rubbers.

Platinum-cured silicones are skin safe, non-toxic, food-grade silicone.

www.siliconerubber.ae

0 notes