Text

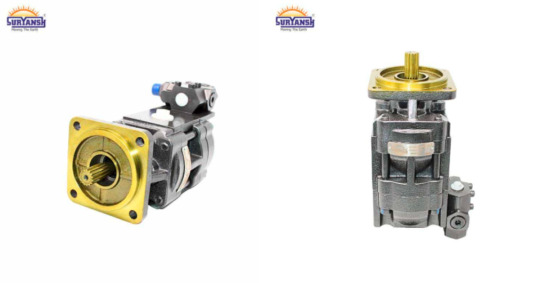

Tractor Loader 60LPM SD Hydraulic Gear Pump: Powering Agricultural Efficiency

The Tractor Loader 60LPM SD (Single Delivery) Hydraulic Gear Pump is a robust solution designed for tractor loaders in agriculture and other industries. Manufactured in India, this pump delivers reliable performance for demanding tasks. With its durable construction and efficient design, it’s a top choice for enhancing productivity in tractor loader machines. This article explores its features, benefits, and applications, highlighting why it’s a valuable asset for professionals.

What is the 60LPM SD Hydraulic Gear Pump?

This hydraulic gear pump is engineered for tractor loaders, providing consistent power to hydraulic systems. Made from high-quality FG 260 material, the pump body ensures durability and longevity. As a single-delivery pump, it efficiently channels hydraulic fluid to drive machinery, making it ideal for agricultural and industrial applications. Its engine-powered operation guarantees dependable performance in tough conditions.

Key Features of the Tractor Loader Pump

The 60LPM SD pump boasts a flow rate of 60 liters per minute, offering ample power for tractor loader operations. Its FG 260 pump body provides excellent resistance to wear and tear, ensuring reliable performance over time. Designed for engine-driven systems, it integrates seamlessly with tractor loaders, delivering smooth and efficient hydraulic power.

Manufactured in India, this pump meets high-quality standards, ensuring compatibility with various tractor loader models. Its compact design allows for easy installation, while its robust construction handles the rigors of heavy-duty tasks. This makes it a practical choice for professionals seeking dependable hydraulic solutions.

Benefits of Using the 60LPM SD Hydraulic Gear Pump

This pump enhances the efficiency of tractor loaders, enabling smooth operation of attachments like buckets and forks. Its high flow rate ensures quick response times, boosting productivity in agricultural tasks such as loading, lifting, and material handling. The durable FG 260 material reduces maintenance needs, saving time and costs for operators.

The pump’s single-delivery design simplifies hydraulic systems, reducing the risk of leaks or failures. By providing consistent power, it minimizes downtime, keeping projects on schedule. For farmers and industrial workers, this pump offers a balance of performance and reliability, making it a smart investment.

Why Choose an Indian-Made Hydraulic Pump?

Opting for a hydraulic gear pump made in India ensures access to a high-quality product at a competitive price. Indian manufacturing is known for its precision and adherence to global standards, and this pump is no exception. Its robust design is tailored for the demanding conditions of agriculture and industry, offering long-lasting performance.

Choosing this pump also supports local industry while delivering a component built for durability. Its compatibility with tractor loaders makes it a versatile option for various applications, from farming to construction.

Applications in Agriculture and Industry

The 60LPM SD hydraulic gear pump is designed for tractor loaders used in agriculture and other sectors. It powers hydraulic systems for tasks like loading crops, moving soil, or handling materials in warehouses. Its versatility makes it suitable for farms, construction sites, and industrial facilities where tractor loaders are essential.

Conclusion

The Tractor Loader 60LPM SD Hydraulic Gear Pump is a reliable and efficient solution for powering hydraulic systems in agriculture and industry. Its durable FG 260 construction, high flow rate, and engine-driven design make it ideal for demanding tasks. Manufactured in India, it offers quality and value, ensuring smooth operation of tractor loaders. For professionals seeking a dependable hydraulic pump, this product delivers performance and longevity.

0 notes

Text

SGP-NM01012919A16 Hydraulic Gear Pump: Boost JCB Telehandler Efficiency

In the fast-paced world of construction, agriculture, and industrial operations, JCB Telehandlers rely on robust components to handle heavy lifting tasks. The SGP-NM01012919A16 Hydraulic Gear Pump is a high-performance solution designed to power these machines with precision and reliability. Featuring a three-stage design and a priority valve, this pump ensures smooth operation in demanding environments. Whether you’re lifting materials on a construction site or managing farm tasks, the SGP-NM01012919A16 delivers unmatched efficiency.

What is the SGP-NM01012919A16 Hydraulic Gear Pump?

The SGP-NM01012919A16 is a three-stage hydraulic gear pump tailored for JCB Telehandler machines, with an OEM part number of 20/925588 and a Suryansh part number of SGP-NM01012919A16. Crafted from durable FG 260 material, it offers displacement capacities of 29/19/16 CC, making it versatile for various hydraulic needs. Proudly Made in India, this pump reflects quality craftsmanship and is built to support the heavy lifting demands of JCB Telehandlers in construction, agriculture, and industrial settings.

Key Features of the SGP-NM01012919A16

This hydraulic gear pump stands out for its advanced design and durability. Here’s what makes it exceptional:

Three-Stage Configuration: With 29/19/16 CC displacement, the pump adapts to varying hydraulic demands, ensuring optimal performance for diverse tasks.

Priority Valve Integration: Enhances fluid distribution to prioritize critical functions like lifting, improving safety and precision.

FG 260 Construction: The high-strength FG 260 body material withstands harsh conditions, ensuring long-lasting reliability.

Precision Fluid Flow: Delivers consistent pressure and flow, reducing energy loss and boosting Telehandler efficiency.

Seamless Compatibility: Designed for easy integration with JCB Telehandlers, minimizing downtime during installation.

Benefits of the SGP-NM01012919A16 for JCB Telehandlers

Using the SGP-NM01012919A16 Hydraulic Gear Pump offers several advantages for Telehandler operators:

Reliable Lifting Power: The three-stage design and priority valve ensure smooth, precise lifting, enhancing productivity.

Cost Savings: Efficient fluid dynamics lower fuel consumption, reducing operational costs.

Durable Performance: FG 260 material minimizes wear, extending the pump’s lifespan and reducing maintenance needs.

Enhanced Safety: The priority valve prioritizes essential functions, ensuring safer operation during heavy-duty tasks.

Quality Assurance: As a Made in India product, it meets high manufacturing standards, offering dependable performance.

Applications of the SGP-NM01012919A16

The SGP-NM01012919A16 is designed for JCB Telehandlers, supporting a range of industries:

Construction: Powers precise lifting of materials like steel beams and concrete blocks on job sites.

Agriculture: Handles tasks like moving hay bales and equipment, ensuring efficiency in farm operations.

Warehousing: Supports smooth stacking and transporting of heavy pallets, minimizing damage risks.

Industrial Tasks: Provides reliable power for handling machinery components in manufacturing settings.

Landscaping: Moves materials like soil and gravel, maintaining performance in rugged conditions.

Choosing the Right Hydraulic Gear Pump

To select the best pump for your JCB Telehandler, consider these tips:

Check Compatibility: Ensure the pump matches your machine’s OEM part number (20/925588) and displacement needs (29/19/16 CC).

Evaluate Task Demands: Choose a pump suited for your specific lifting and material handling tasks.

Focus on Durability: Opt for high-quality materials like FG 260 for long-term reliability.

Partner with Trusted Suppliers: Work with reputable suppliers offering warranties and support for quality assurance.

Maintenance Tips for Optimal Performance

To keep the SGP-NM01012919A16 running smoothly, follow these maintenance practices:

Monitor Hydraulic Fluid: Use high-quality fluid and check levels regularly to prevent contamination.

Inspect for Leaks: Regularly check the pump and system for leaks to maintain efficiency.

Clean Filters: Replace or clean filters to ensure proper fluid flow and avoid clogs.

Check for Wear: Inspect the pump during routine maintenance to address wear early.

Follow Guidelines: Adhere to manufacturer recommendations for optimal pump longevity.

Sourcing the SGP-NM01012919A16

For the SGP-NM01012919A16 Hydraulic Gear Pump, partner with a trusted supplier specializing in JCB Telehandler parts. Look for providers offering high-quality components, competitive pricing, and expert support. Contact suppliers like J.B. Industries for inquiries or quotes to secure this reliable pump for your operations.

Conclusion

The SGP-NM01012919A16 Hydraulic Gear Pump is a powerful, durable, and efficient solution for JCB Telehandlers, delivering precision and reliability in construction, agriculture, and industrial applications. Its three-stage design, priority valve, and FG 260 construction ensure smooth lifting, cost savings, and long-lasting performance. For operators seeking a high-quality hydraulic pump to boost Telehandler efficiency, the SGP-NM01012919A16 is a top choice that stands up to the toughest challenges.

0 notes

Text

SCP008 Charging Pump for HM 2021 Wheel Loader – Built for Power and Performance

In industries like construction, mining, agriculture, and material handling, heavy-duty machines need reliable hydraulic systems to deliver uninterrupted performance. One such key component that powers these systems is the Suryansh SCP008 Charging Pump (AVTEC 23011646) — specifically engineered for the HM 2021 Wheel Loader.

This charging pump helps keep your hydraulic system healthy, efficient, and primed for performance, even in the most rugged environments.

What is a Charging Pump?

A charging pump plays a crucial role in any hydraulic system. It supplies low-pressure hydraulic oil to the main pump, ensuring it remains properly lubricated and primed. Without it, the main pump may suffer from cavitation, leading to loss of pressure, excessive wear, or system failure.

The SCP008 Charging Pump keeps the hydraulic circuit in your HM 2021 Wheel Loader running efficiently, reducing stress on internal components and extending machine life.

Key Features of SCP008 Charging Pump

Built with performance and reliability in mind, the SCP008 Charging Pump includes features that make it a trusted choice across heavy industries:

Durable Build (FG 260 Cast Iron) Made from high-grade FG 260 cast iron for long-lasting performance under pressure.

OEM Compatible (AVTEC 23011646) Precisely designed to meet OEM standards for the HM 2021 Wheel Loader, ensuring a perfect fit.

Made in India Proudly manufactured in India with strict quality control and engineering precision.

Compact, Efficient Design Space-saving structure that doesn’t compromise flow rate or performance.

Consistent Hydraulic Flow Maintains steady fluid delivery, preventing wear and ensuring system stability.

Why Choose the SCP008 Charging Pump?

Here’s why equipment owners and operators prefer the SCP008 over generic alternatives:

1. Heavy-Duty Construction

Its rugged FG 260 body is designed to withstand extreme working conditions, high temperatures, and pressure surges.

2. Perfect Match for HM 2021

As an OEM-equivalent part (AVTEC 23011646), it’s tailor-made for the HM 2021 Wheel Loader, ensuring zero compatibility issues and faster installation.

3. Cost-Efficient in the Long Run

Reduces wear on the main pump, minimizes maintenance costs, and extends the overall life of the machine.

4. Trusted in Harsh Environments

Performs consistently in dusty, muddy, or rough terrains typical of construction, mining, and agriculture.

Where Is the SCP008 Charging Pump Used?

This pump is built exclusively for the HM 2021 Wheel Loader, which is a multipurpose machine used across sectors like:

Construction: Lifting, digging, and site clearing.

Mining: Hauling and material loading in tough geological zones.

Agriculture: Handling feed, grain, and soil movement on farms.

Material Handling: Moving heavy goods in industrial facilities or yards.

Its versatile application and reliable performance make the SCP008 a valuable addition to any fleet.

Maintenance Tips for SCP008 Charging Pump

Keeping the charging pump in top condition ensures long-lasting performance. Here are some practical maintenance steps:

Regular Fluid Checks: Use clean hydraulic oil to prevent clogging or pump damage.

Leak Inspection: Routinely check the system for oil leaks.

Pressure Monitoring: Operate within recommended hydraulic pressure ranges.

System Cleaning: Flush out dirt and debris from filters and tanks.

Scheduled Servicing: Have a technician inspect the system regularly for early signs of wear.

How to Identify the Right Pump

Before placing an order, always verify:

Part Number: SCP008 / AVTEC 23011646

Application: HM 2021 Wheel Loader

Material Spec: FG 260 (Cast Iron)

Getting the right pump ensures optimal performance and avoids costly returns or downtime.

Trusted Sourcing: Where to Buy the SCP008

To ensure you’re buying authentic and high-performance parts, source the SCP008 Charging Pump from a trusted supplier. For quotes or bulk orders, contact: [email protected]

A reliable supplier provides not just parts, but technical support, quick delivery, and post-sales service — ensuring complete peace of mind.

Final Words!

The Suryansh SCP008 Charging Pump (AVTEC 23011646) is more than just a component — it’s a performance booster for your HM 2021 Wheel Loader. Built tough, designed for compatibility, and made to last, it ensures your machine works harder, longer, and smarter.

By choosing the SCP008, you’re not only investing in a part — you're investing in uptime, efficiency, and long-term savings.

0 notes

Text

Powering Precision: The Essential Hydraulic Gear Pump for Your LeeBoy 785 Motor Grader

In the demanding arenas of construction, mining, and agriculture, the LeeBoy 785 motor grader stands as a trusted workhorse, renowned for transforming rough terrain into perfectly graded surfaces. At the core of its formidable capability lies a critical component: the hydraulic system, powered by the SGP-M011720C18 Hydraulic Gear Pump.

This precision-engineered pump isn't just a part; it's the vital force multiplier ensuring smooth operation, accurate blade control, and unwavering reliability under the toughest conditions.

Understanding the Heartbeat of Hydraulic Power

A hydraulic gear pump, like the SGP-M011720C18, serves as the engine of a motor grader's hydraulic system. It operates as a positive displacement pump, utilizing interlocking gears to create a vacuum that draws hydraulic fluid in and then forces it out under significant pressure.

This continuous, pressurized flow of fluid is the lifeblood that powers essential functions – precisely adjusting the grader blade, enabling responsive steering, and facilitating smooth articulation. For operators of the LeeBoy 785, the efficiency and durability of this pump directly translate to the machine's ability to perform intricate grading tasks with consistency and power.

The SGP-M011720C18: Engineered for LeeBoy 785 Excellence

Specifically designed for the LeeBoy 785, the SGP-M011720C18 hydraulic gear pump is a testament to focused engineering. Powered directly by the grader's engine, this pump delivers the consistent, high-pressure hydraulic flow required for peak performance.

Its robust construction is purpose-built to withstand the relentless challenges of job sites: pervasive dust, extreme temperature fluctuations, heavy vibrations, and prolonged operation. Professionals choose this pump because it seamlessly integrates with the LeeBoy 785, ensuring the hydraulic system operates at maximum potential.

Key Features Driving Unmatched Performance

The SGP-M011720C18 distinguishes itself through a blend of high efficiency, exceptional durability, and intelligent design. Its optimized gear geometry ensures smooth and consistent fluid delivery, maximizing the grader's operational output while minimizing parasitic energy loss.

Crafted from high-quality, resilient materials, the pump shrugs off the abrasive dust common on construction sites and the punishing workloads encountered in mining operations. Despite its powerful output, the pump boasts a remarkably compact footprint, allowing for efficient installation within the LeeBoy 785's hydraulic circuit without adding unnecessary weight or complexity.

This precision engineering translates directly to accurate fluid control, enabling operators to make minute blade adjustments for unparalleled grading accuracy. Furthermore, the pump is engineered for reliability, demanding minimal maintenance and significantly reducing costly machine downtime, keeping critical projects on schedule.

Why the SGP-M011720C18 is the Indispensable Choice for LeeBoy 785 Owners

Selecting the SGP-M011720C18 means investing in tangible performance benefits for your LeeBoy 785. Experience enhanced overall grader capability, tackling precise road smoothing, field leveling, or mining site preparation with greater ease and control.

The pump's inherent toughness guarantees reliable operation even in the harshest, dust-laden, or temperature-extreme environments, preventing unexpected failures. By optimizing hydraulic fluid flow and minimizing energy waste, the pump contributes directly to improved fuel efficiency, lowering operational expenses over time.

Sourced from reputable manufacturers like Suryansh, users gain peace of mind through proven quality and dependable support. Ultimately, the pump's robust design and low-maintenance nature translate directly to reduced downtime, maximizing productivity and project throughput.

Versatile Power Across Industries

The LeeBoy 785, empowered by the SGP-M011720C18 pump, excels in diverse applications. In construction, it delivers the power for flawless road grading, runway preparation, and foundational site leveling. Within agriculture, the pump enables precise land contouring and field preparation, optimizing conditions for planting and irrigation.

Mining operations rely on its robustness to clear and level access roads and work areas efficiently. Even large-scale landscaping projects benefit from the pump's ability to provide the precise hydraulic control needed for shaping terrain with accuracy and finesse.

Ensuring Longevity and Peak Performance

Maximizing the lifespan and efficiency of your SGP-M011720C18 pump involves adherence to best practices. Professional installation by a technician experienced with the LeeBoy 785 hydraulic system is crucial for optimal setup and integration.

Conducting regular inspections for leaks, damage, or contamination, particularly in challenging environments, helps catch minor issues before they escalate. Using clean, manufacturer-recommended hydraulic fluid is paramount to prevent internal damage and maintain peak performance.

Strictly following the manufacturer's maintenance schedule and proactively monitoring the grader's hydraulic system performance ensures the pump continues to operate reliably for years.

The Foundation of Reliable Grading

In industries where equipment uptime, precision, and productivity are non-negotiable, the quality of hydraulic components cannot be compromised. The SGP-M011720C18 hydraulic gear pump stands as a cornerstone of reliability for the LeeBoy 785.

Its superior engineering delivers consistent power, enhances fuel efficiency, and minimizes maintenance demands, directly contributing to lower operating costs and increased profitability. Choosing this high-quality pump from trusted sources is an investment in the sustained performance and longevity of your vital motor grader asset.

For professionals who demand precision grading power day in and day out, the SGP-M011720C18 hydraulic gear pump is the essential component that keeps your LeeBoy 785 operating at its formidable best.

0 notes

Text

Hydraulic Gear Pump with Priority Valve for L&T Case 770 EX Backhoe Loader: A Complete Guide

In construction and excavation, machines like the L&T Case 770 EX Backhoe Loader need reliable components to handle tough jobs. One critical part is the hydraulic gear pump with a priority valve.

This pump ensures the machine’s hydraulic system works smoothly, powering tasks like digging, lifting, and steering. Let’s explore why this pump matters and how it boosts the L&T Case 770 EX’s performance.

What is a Hydraulic Gear Pump?

A hydraulic gear pump is a mechanical device that moves hydraulic fluid to power heavy machinery. It uses rotating gears to create fluid flow, generating pressure for functions like lifting buckets or steering. For the L&T Case 770 EX, this pump is paired with a priority valve to prioritize critical systems. For example, the valve ensures steering gets hydraulic power first for safety, even when other parts (like the loader) are active.

Key Features of the Hydraulic Gear Pump for L&T Case 770 EX

This pump is built to match the demands of the L&T Case 770 EX, a 74 HP machine weighing 7,780 kg. Here’s what makes it stand out:

Efficient Fluid DeliveryPrecision gears provide steady hydraulic flow for smooth operation of the loader, backhoe, and steering.

Priority Valve for SafetyDirects fluid to steering first, ensuring control during maneuvers.

Durable BuildMade from cast iron or aluminum alloy, it withstands dust, vibrations, and heavy loads.

High-Pressure PerformanceSupports heavy tasks like lifting up to 1,330 kg and digging through tough soil.

Low Noise DesignReduces operational noise, improving comfort for operators.

Easy MaintenanceSimple to inspect, repair, or replace, minimizing downtime.

How It Works in the L&T Case 770 EX

The pump draws hydraulic fluid from the machine’s reservoir. Gears pressurize the fluid, sending it to systems like the loader bucket or backhoe arm.

The priority valve ensures steering always gets fluid first. This setup keeps operators safe and in control, even when lifting heavy loads or working on uneven terrain.

Benefits for Operators

Safety First: Responsive steering reduces accident risks.

Higher Productivity: Smooth hydraulic flow speeds up digging and lifting.

Fuel Efficiency: Optimized fluid use lowers engine strain and fuel costs.

Long Lifespan: Tough materials cut maintenance needs and costs.

Where Is This Pump Used?

The L&T Case 770 EX relies on this pump for:

Construction: Digging foundations, moving earth.

Landscaping: Grading, trenching, and shaping land.

Excavation: Breaking through rocky soil.

Infrastructure: Road building, pipeline installation.

Why Choose This Pump?

This hydraulic gear pump meets or exceeds OEM standards. Brands like J.B. Industries (maker of Suryansh pumps) produce high-quality versions tested for durability. It’s a smart investment to keep your L&T Case 770 EX running efficiently for years.

Where to Buy

Look for this pump at:

Online platforms: eBay, CEParts.in, Global Lifters.

Heavy equipment suppliers: Check for warranties and certified refurbished options.

Manufacturers: Contact ISO-certified companies like J.B. Industries directly.

Always confirm compatibility with the L&T Case 770 EX before purchasing.

Final Thoughts

The hydraulic gear pump with a priority valve is the backbone of the L&T Case 770 EX’s hydraulic system. Its focus on safety, efficiency, and durability makes it essential for construction and excavation work.

Whether you’re a fleet manager or operator, this pump ensures your machine performs reliably in the toughest conditions.

Ready to upgrade? Check trusted suppliers today to keep your backhoe loader at peak performance!

0 notes

Text

Reliable Hydraulic Pump for JCB Backhoe Loaders

When it comes to keeping JCB backhoe loaders running smoothly in tough construction and marine environments, the 20/925279 Hydraulic Pump 3D Double Delivery NM is a standout choice.

Designed specifically for JCB models like the 3CX, 3D, and 4CX, this pump ensures efficient hydraulic performance, making it a go-to for operators needing reliable power for digging, lifting, and other heavy-duty tasks.

Whether you’re working on a marine vessel or a construction site, this pump delivers the durability and precision you need.

What Is the 20/925279 Hydraulic Pump?

The 20/925279 Hydraulic Pump is a double delivery gear pump tailored for JCB backhoe loaders. Manufactured by trusted brands like Suryansh, it’s built with a sturdy mild steel body to withstand harsh conditions, including the salty, corrosive environments often found in marine applications.

This pump is compatible with models like the JCB 3D, 3CX, and 4CX, offering a seamless fit and easy installation. Its double delivery design provides consistent hydraulic flow, ensuring smooth operation for tasks like powering hydraulic brakes or auxiliary systems on towed equipment.

With a supply ability of around 10 units per week from suppliers like J.B. Industries, it’s readily available for marine and construction needs.

Why Choose the 20/925279 for Marine and Construction?

This pump’s robust design makes it ideal for marine settings, where equipment faces constant exposure to saltwater and vibrations. Its high-rigidity steel construction protects against wear, ensuring long-lasting performance.

The 20/925279 delivers precise hydraulic pressure, which is critical for tasks like operating backhoe attachments or maintaining stability in marine hydraulic systems.

For example, in marine construction or shipyard operations, this pump supports heavy lifting and precise control, reducing downtime and boosting productivity. Its compatibility with multiple JCB models also makes it a versatile choice for fleet operators.

Key Features and Benefits

The 20/925279 Hydraulic Pump stands out for its efficiency and reliability. It’s designed to handle medium to high-pressure fluid systems, delivering the force needed to move hydraulic fluid effectively.

The double delivery mechanism ensures a steady flow, which is crucial for maintaining consistent performance in demanding tasks. Installation is straightforward, saving time for marine engineers or construction crews.

Plus, its durable build means it can handle the tough conditions of marine environments, from salty air to constant mechanical stress, making it a cost-effective solution for long-term use.

Where to Source the 20/925279 Pump

You can find the 20/925279 Hydraulic Pump through reputable suppliers like J.B. Industries in Rajkot, India, or online platforms like eBay and Amazon. These vendors often provide quick shipping and competitive pricing, with some offering aftermarket or OEM options.

For marine operators, sourcing from trusted suppliers ensures you get genuine or high-quality aftermarket parts that meet JCB’s standards. Always verify compatibility with your JCB model’s serial number before purchasing to ensure a perfect fit.

Tips for Maintenance and Installation

To maximize the lifespan of the 20/925279 Hydraulic Pump, ensure proper installation and regular maintenance. Check hydraulic fluid levels and filters regularly to prevent contamination, especially in marine environments where debris can be an issue.

Calibration is key to matching the pump’s output to your backhoe’s needs. With proper care, this pump can keep your JCB running smoothly for years, whether on a ship or a construction site.

Conclusion: A Trusted Choice for JCB Operators

The 20/925279 Hydraulic Pump 3D Double Delivery NM is a reliable, durable solution for JCB backhoe loaders in marine and construction settings. Its robust design, easy installation, and steady performance make it a favorite among operators.

Ready to power up your JCB? Contact trusted suppliers today to get this pump and keep your operations running without a hitch!

0 notes

Text

Top Reasons Bull Hydraulic Gear Pumps Excel in Tractor Loaders

Bull hydraulic gear pumps are the backbone of tractor loader attachments, driving tasks like lifting crops or moving soil with ease. Built by Bull Machines, these pumps are known for their reliability and power in agriculture. This article highlights why Bull hydraulic gear pumps are the best choice for tractor loaders, covering their features and benefits.

With over 24 years of expertise, Bull delivers equipment farmers trust. Whether you’re a seasoned farmer or new to tractors, these insights will help you maximize your loader’s performance with Bull hydraulic gear pumps.

Why Bull Hydraulic Gear Pumps Lead

Bull hydraulic gear pumps power tractor loaders with unmatched efficiency, making tough farm jobs simpler. Here’s why they excel:

Tough Build: Made with ductile iron, they withstand dust and moisture for long-lasting use.

Smooth Operation: They deliver steady hydraulic flow for fast, precise loader movements.

Wide Compatibility: Bull pumps work with over 84 tractor models, supporting attachments like 6-in-1 buckets.

Bull Machines states their pumps help loaders lift up to 800 kg, ideal for heavy farm tasks, as noted in their 2024 product guide.

Ready for Farm Challenges

Tractor loaders face dirt, heavy loads, and long hours. Bull Tractor Loader hydraulic gear pumps are engineered to endure these conditions, using wear-resistant materials to ensure consistent performance during harvesting or land clearing.

Key Features of Bull Hydraulic Gear Pumps

Bull pumps come with features that boost loader productivity. These make them a top pick:

High-Power Delivery

With pressures up to 3000 PSI, Bull pumps ensure smooth lifting of heavy loads like manure or sugarcane, reducing strain on your tractor.

Space-Saving Design

Their compact size fits easily on tractors, even older models, minimizing frame stress and simplifying installation.

Simple Upkeep

Bull pumps have accessible parts for quick cleaning or repairs, keeping downtime low during busy seasons.

Tips for Optimal Performance

Maximize your Bull hydraulic gear pump with these tips:

Check Fluid Monthly: Use Bull-recommended oil to prevent damage.

Inspect for Wear: Look for leaks or cracks weekly to catch issues early.

Follow Load Limits: Stay within the 600–800 kg capacity for safety.

Common Mistakes to Avoid

Avoid these errors to keep your pump running well:

Wrong Fluid: Non-recommended oil reduces efficiency. Use Bull’s specs.

Overloading: Exceeding capacity wears the pump. Check load ratings.

Skipping Maintenance: Regular checks prevent costly repairs.

Real-World Success

A farmer in Punjab upgraded to a Bull hydraulic gear pump for his sugarcane loader. He reported a 25% faster loading time compared to his old pump, saving fuel and boosting productivity, showcasing Bull’s reliability.

Conclusion

Bull hydraulic gear pumps are a top choice for tractor loaders, offering durability, power, and versatility. Their smart design and easy maintenance help farmers tackle tough tasks efficiently. Start by checking your loader’s needs and exploring Bull’s pump options. Use these tips to keep your equipment running strong! Share your experiences in the comments.

0 notes

Text

Tractor Loader Single Delivery Hydraulic Gear Pump: A Comprehensive Guide

Single delivery hydraulic gear pumps are essential for powering tractor loader hydraulic systems, delivering reliable performance for tasks like lifting, tilting, and steering. Known for their durability, affordability, and ease of maintenance, these pumps are a cornerstone of agricultural and industrial operations. This article explores their features, benefits, applications, and maintenance, highlighting their value for tractor loaders.

What is a Single Delivery Hydraulic Gear Pump?

A single delivery hydraulic gear pump is a positive displacement pump using two interlocking gears to move hydraulic fluid through a sealed housing. Designed for single-circuit applications, it provides consistent pressure for tractor loader functions. Its simple design ensures reliability and ease of maintenance, making it ideal for demanding environments.

Key Features

Single delivery hydraulic gear pumps are built for efficiency and durability:

Robust Construction: Made from cast iron or aluminum to withstand harsh conditions.

Compact Design: Small footprint simplifies integration into tractor systems.

High-Pressure Capability: Operates up to 250 bar (3625 PSI) for heavy-duty tasks.

Cost-Effective: Requires less energy than vane or piston pumps.

Simple Mechanism: External gear design ensures reliable fluid displacement.

Versatile Mounting: Offers flanged/threaded ports and various shaft types.

Rotational Flexibility: Supports clockwise or anti-clockwise rotation.

These features ensure dependable performance in tractor loaders.

Benefits

These pumps offer significant advantages:

Reliability: Fewer moving parts reduce failure risks.

Affordability: Cost-effective compared to other pump types.

Ease of Maintenance: Simple design minimizes downtime.

Energy Efficiency: Optimized to lower fuel consumption.

Wide Compatibility: Suits brands like John Deere and Kubota.

Durability: High-quality materials ensure long service life.

Fast Availability: Readily available from suppliers like TVH.

These benefits enhance efficiency and reduce operational costs.

Applications

Single delivery hydraulic gear pumps power a range of tractor loader tasks:

Agriculture: Lifts hay bales and handles grain.

Construction: Drives loaders for digging and material handling.

Landscaping: Supports grading and mulch transport.

Forestry: Facilitates log handling.

Material Handling: Powers pallet lifting in warehouses.

Snow Removal: Operates snow plows and blowers.

Their versatility suits both light and heavy-duty applications.

Maintenance and Selection

Regular maintenance extends pump life:

Fluid Checks: Replace contaminated fluid.

Filter Replacement: Protect against debris.

Seal Inspection: Prevent leaks.

Gear Monitoring: Address wear promptly.

When selecting a pump, consider flow rate, pressure, shaft configuration, and tractor compatibility. Tools like TVH’s MyPartsFinder and expert consultation simplify the process.

Conclusion

Single delivery hydraulic gear pumps are reliable, cost-effective solutions for tractor loaders, powering essential functions across agriculture, construction, and more. With robust construction, high-pressure output, and easy maintenance, they ensure efficient operation and long-term value. By choosing high-quality pumps and following maintenance best practices, operators can maximize performance and minimize downtime. Explore suppliers like Magister Hydraulics or Hy-Capacity to find the right pump for your needs.

0 notes

Text

Bull Tractor Loader Hydraulic Gear Pump: Driving Agricultural Efficiency

In modern agriculture and construction, reliable equipment is key to productivity. The Bull Tractor Loader Hydraulic Gear Pump is a critical component, transforming mechanical energy into hydraulic power for tasks like lifting, digging, and material handling. Engineered for the tough conditions of farming, this pump ensures consistent performance in dusty, wet, and high-load environments.

How It Works

The Bull Tractor Loader Hydraulic Gear Pump operates as a positive displacement pump, using precision gears to move fluid efficiently:

Fluid Intake: Gears separate to draw hydraulic oil into the pump.

Fluid Transport: Gears carry oil around the housing.

Pressure Output: Meshing gears push fluid out, generating hydraulic power.

Its design includes:

Precision Gears: Minimize leakage for steady flow.

Tight Clearances: Optimize efficiency without friction.

Robust Bearings: Handle high loads and resist contamination.

Key Features for Tough Conditions

Durable Materials: A corrosion-resistant alloy housing and case-hardened steel components withstand moisture and heavy loads.

Contamination Resistance: Features multi-stage filtration, labyrinth seals, and self-cleaning gears to prevent particle buildup.

Thermal Efficiency: Optimized fluid paths and heat-dissipating housing prevent overheating, supporting extended operation.

High Pressure: Exceeds standard requirements by 25%, ideal for heavy tasks like clay excavation or bale handling.

Flow Consistency: Maintains ±2% flow stability, eliminating jerky operation.

Applications in Agriculture

The Bull Pump powers a range of tractor loader tasks:

Front-End Loaders: Handles hay bales and heavy materials smoothly.

Hydraulic Attachments: Supports quick-coupled tools for versatility.

Construction Tasks: Manages industrial material moving with ease.

Its multi-viscosity performance ensures efficiency with standard, biodegradable, or cold-weather fluids, while pulse dampening reduces vibrations for operator comfort and equipment longevity.

Benefits for Operators

Enhanced Productivity: Delivers 15-20% faster cycle times, boosting work output.

Fuel Efficiency: 92%+ volumetric efficiency lowers fuel use and heat generation.

Reduced Downtime: 60% fewer repairs and shorter maintenance periods.

Longer Equipment Life: Robust design extends component durability.

Higher Resale Value: Premium components increase tractor marketability.

Maintenance Made Simple

The Bull Pump is designed for easy upkeep:

Modular Design: Simplifies repairs and reduces spare parts inventory.

Diagnostic Ports: Enable quick pressure and flow checks without disassembly.

Extended Service Intervals: Longer oil changes, seal life, and filter replacements cut costs.

Quick-Coupling: Supports rapid attachment swaps and leak-free connections.

Choosing the Right Pump

When selecting a Bull Hydraulic Gear Pump, consider:

System Compatibility: Match with pressure valves, reservoirs, and controls.

Environmental Needs: Assess dust, temperature, and chemical exposure.

Future-Proofing: Ensure compatibility with new attachments or telematics.

Fluid Type: Verify suitability for your hydraulic oil choice.

Economic Impact

While the upfront cost is a factor, the Bull Pump’s value shines in:

Lower Operating Costs: Reduced fuel and maintenance expenses.

Increased Uptime: Higher equipment availability maximizes productivity.

Resale Advantage: Premium components boost tractor resale value.

Conclusion

The Bull Tractor Loader Hydraulic Gear Pump is a game-changer for agricultural and construction operations. Its durable construction, precise performance, and smart design tackle the challenges of demanding environments. By delivering consistent power, reducing downtime, and enhancing efficiency, this pump empowers operators to work smarter. For farm managers seeking a competitive edge, the Bull Pump is an investment in reliability, productivity, and long-term savings.

0 notes

Text

Planet Hub 5 Hole: A Durable Choice for Heavy Machinery

When it comes to heavy machinery like JCB backhoe loaders, every part matters Planet Hub 5 Hole is a critical component that keeps things rolling smoothly. This sturdy wheel hub, often used in models like the JCB 3DX, ensures wheels stay secure and equipment runs reliably on tough job sites.

What Is the Planet Hub 5 Hole?

The Planet Hub 5 Hole is a wheel hub designed for heavy-duty equipment, especially JCB backhoe loaders like the 3DX and 4DX. It’s a key part of the wheel assembly, connecting the wheel to the axle and allowing smooth rotation under heavy loads. The “5 Hole” refers to its five-bolt pattern, which secures the wheel tightly to the hub for stability and safety.

Made from high-strength materials like steel or aluminum, this hub is built to handle rough terrains, heavy weights, and constant use. It’s a popular choice in construction, landscaping, and other industries where machines face dirt, rocks, and long hours.

Key Features of the Planet Hub 5 Hole

Here’s what makes the Planet Hub 5 Hole stand out:

Strong Build Quality Crafted from durable materials, the hub resists wear, corrosion, and damage. It’s designed to last, even in muddy, dusty, or wet conditions.

Five-Bolt Design The five-hole bolt pattern (often 5 on 4.5" or 5 on 5") ensures a secure fit for the wheel, reducing wobble and improving safety. This design is common in JCB models for balanced load distribution.

Precision Fit With part numbers like 450/12401 or 450/10216, the hub is made to fit specific JCB models perfectly, making installation quick and hassle-free.

High Load Capacity Built for heavy machinery, it can handle thousands of pounds, ideal for carrying heavy loads or digging deep.

Easy Maintenance The hub’s design allows for straightforward repairs or replacements, keeping downtime low and machines running.

Why Choose the Planet Hub 5 Hole?

The Planet Hub 5 Hole is a favorite for several reasons. First, it’s reliable. Construction sites are tough on equipment, and a weak hub can lead to wheel issues or breakdowns. This hub’s solid construction prevents that, ensuring wheels stay in place and work keeps moving.

Second, it’s versatile. While it’s a star in JCB 3DX models, similar 5-hole hubs work in other heavy equipment or trailers, making it a flexible choice. Whether you’re digging trenches or hauling materials, it performs.

Third, it’s cost-effective. Prices for a quality Planet Hub 5 Hole, like those from J.B. Industries, range from $200-$350, depending on the supplier. That’s a small price for a part that prevents costly repairs or accidents.

Applications of the Planet Hub 5 Hole

This hub shines in:

Construction: Powers JCB backhoes for digging, lifting, and moving earth.

Landscaping: Supports machines on uneven ground for grading or trenching.

Agriculture: Used in equipment for tasks like plowing or hauling.

Trailers: Some 5-hole hubs fit trailers with 3,500-lb axles, showing its range.

For example, on a JCB 3DX, the hub keeps wheels stable during heavy digging, ensuring the machine doesn’t tip or slip.

Installation and Maintenance Tips

Installing a Planet Hub 5 Hole is straightforward but needs care:

Check Compatibility: Confirm the part number (e.g., 450/10221) matches your machine.

Use Proper Tools: A torque wrench ensures bolts are tightened evenly to avoid warping.

Inspect Regularly: Look for cracks, rust, or loose bolts during routine checks.

For maintenance, clean the hub to remove dirt buildup, and grease bearings if included. If the hub shows wear, replace it promptly to avoid wheel failure. Always use genuine parts from trusted suppliers like Suryansh or Amazon for the best fit.

Meeting Industry Needs

The Planet Hub 5 Hole aligns with industry standards for heavy machinery. It’s often ISO 9001:2015 certified, as seen with manufacturers like J.B. Industries, ensuring quality and consistency. The five-bolt pattern meets safety requirements for load-bearing equipment, giving operators confidence on the job.

Where to Buy the Planet Hub 5 Hole

You can find the Planet Hub 5 Hole from:

J.B. Industries (Suryansh): Offers hubs for JCB 3DX, priced $200-$350.

Amazon: Stocks hubs with part numbers like 450/12401, often with fast shipping.

Local Dealers: JCB service centers or heavy equipment shops carry them.

Check reviews before buying to ensure quality. For instance, Amazon listings note the hub’s solid fit but warn about verifying spindle size to avoid returns.

Things to Watch For

While the Planet Hub 5 Hole is top-notch, double-check your machine’s specs. Some hubs fit 3,500-lb axles, while others are for lighter loads. Also, ensure the bolt circle (e.g., 4.5" or 5") matches your wheel to avoid installation headaches.

Final Words!

The Planet Hub 5 Hole is a small but mighty part that keeps heavy machinery like JCB backhoes moving strong. Its durable build, secure five-bolt design, and easy upkeep make it a smart choice for construction, landscaping, and more. Whether you’re replacing a worn hub or upgrading, it delivers safety and performance without breaking the bank.

0 notes

Text

20/925588 Hydraulic Pump Small 3 Stage with Priority Valve: Perfect Fit for JCB Telehandlers

The 20/925588 Hydraulic Pump is a small, three-stage pump with a priority valve, specially designed for JCB telehandler machines. If you’re in construction, agriculture, or any industry that relies on telehandlers, this pump could be a game-changer. It powers the hydraulic system, ensuring your machine lifts, steers, and operates smoothly. In this article, we’ll break down what makes this pump special, how it works, and why it’s a great match for JCB telehandlers.

What Is the 20/925588 Hydraulic Pump?

The 20/925588 is a triple-stage hydraulic pump, meaning it has three sections that work together to move hydraulic fluid. Each stage handles a different flow rate, making it versatile for tasks like lifting heavy loads or steering with precision. It’s built by trusted brands like Parker and fits perfectly with JCB telehandler models such as the 531-70, 533-105, 535-125, 536-60, and 550-140, among others.

What sets this pump apart is its priority valve. This clever feature ensures that critical functions—like steering—get hydraulic power first, even when the system is under heavy load. Imagine lifting a massive pallet while turning the machine; the priority valve keeps everything running safely and smoothly.

How Does It Work on JCB Telehandlers?

JCB telehandlers are known for their strength and flexibility, and the 20/925588 hydraulic pump is a big part of that. Here’s how it works: the pump pulls hydraulic oil from the tank and sends it through the system at a steady flow—up to 110 liters per minute, depending on the model.

The three stages (typically 29cc, 19cc, and 16cc per revolution) divide the workload. The first stage might power the boom, the second handles steering, and the third supports smaller functions.

The priority valve steps in to manage oil flow. If you’re lifting and steering at the same time, it makes sure the steering gets enough pressure first. This prevents jerky movements or loss of control, which is vital when working on uneven ground or tight job sites.

Plus, the pump runs at 2200 RPM and can handle pressures up to 3650 PSI, so it’s tough enough for demanding tasks.

Why Choose the 20/925588 for Your JCB Telehandler?

There are plenty of reasons this pump is a top pick. For one, it’s compact but powerful, making it ideal for smaller JCB telehandler models that still need strong hydraulics. Its three-stage design means it can multitask without slowing down, saving you time on the job.

Whether you’re moving dirt, stacking materials, or loading trucks, this pump keeps your machine responsive.

Another big plus is durability. Made with high-quality materials, it stands up to rough conditions like dust, heat, and constant use. It’s also easy to install, with a standard SAE B mounting flange and a splined shaft that fits JCB systems perfectly.

And because it’s a genuine part (sometimes listed as 20-925588 or 20925588), you know it’s built to last.

Benefits for JCB Telehandler Operators

Using the 20/925588 hydraulic pump brings real advantages. It improves fuel efficiency by delivering just the right amount of power where it’s needed—no waste, no strain on the engine.

The priority valve boosts safety, especially in tricky spots where precise steering is a must. And since it’s designed for JCB telehandlers, you won’t have to worry about compatibility issues—just plug it in and get to work.

Final Thoughts

The 20/925588 Hydraulic Pump Small 3 Stage with Priority Valve is a reliable, efficient choice for JCB telehandler machines. Its smart design, tough build, and safety features make it a standout for anyone who needs their equipment to perform day after day.

If you’re looking to replace a worn-out pump or upgrade your telehandler, this one’s worth a look. It’s the kind of tool that keeps your work on track—simple, strong, and built for the job.

0 notes

Text

Why the 20/925552 Pump Matters for JCB

If you own or operate a JCB 3CX or 4CX backhoe loader, you know how important it is to keep every part working smoothly. One key component that keeps these machines running strong is the 20/925552 Transmission 914 Charging Pump. This little powerhouse plays a big role in making sure your backhoe loader performs at its best. So, what exactly is it, and why should you care? Let’s break it down.

What Is the 20/925552 Charging Pump?

The 20/925552, often called the Transmission 914 Charging Pump, is a vital part of the transmission system in JCB 3CX and 4CX backhoe loaders. Its main job is to supply hydraulic fluid to the transmission, keeping everything lubricated and moving properly. Without it, your machine could face sluggish performance, overheating, or even a complete breakdown. This pump is designed specifically for these JCB models, ensuring a perfect fit and reliable operation.

Think of it like the heart of your transmission—it pumps fluid where it’s needed, keeping the system alive and healthy. Whether you’re digging trenches or loading materials, this pump helps your backhoe tackle tough jobs with ease.

Why It’s Important for JCB 3CX and 4CX

The JCB 3CX and 4CX are popular backhoe loaders known for their versatility and power. They’re used in construction, landscaping, and more, which means they need parts that can handle heavy workloads. The 20/925552 charging pump is built tough to meet those demands. It maintains steady pressure in the transmission, so your machine shifts gears smoothly and responds quickly.

A faulty pump can lead to jerky movements or delays, slowing down your work. That’s why keeping this part in good shape—or replacing it with a genuine or high-quality aftermarket version—is a smart move for any operator.

Benefits of Using the 20/925552 Pump

First off, it’s reliable. Made to match JCB’s high standards, this pump ensures your backhoe loader runs efficiently, even on long days. It’s also durable, designed to withstand the wear and tear of rough job sites. Plus, it’s easy to install if you’re swapping out an old or worn-out pump, saving you time and hassle.

Another bonus? It helps with fuel efficiency. A well-working transmission pump keeps the system running smoothly, reducing strain on the engine. That means less fuel wasted and more money saved over time.

Trust in Quality and Expertise

The 20/925552 pump comes from JCB, a brand with decades of experience in construction equipment. Their parts are trusted worldwide for their quality and performance. Whether you buy an original JCB part or a compatible aftermarket option, you’re investing in something backed by expertise and proven results.

Final Thoughts

The 20/925552 Transmission 914 Charging Pump is a small but mighty piece of your JCB 3CX or 4CX backhoe loader. It keeps your transmission in top shape, ensuring your machine works hard when you need it most. If you’re noticing transmission issues, it might be time to check this pump. With the right part, you’ll keep your backhoe running smoothly for years to come!

0 notes

Text

Main Relief Valve Spool (MRV): A Key Component for System Safety

If you’re involved in managing hydraulic or pneumatic systems, you’ve likely come across the Main Relief Valve Spool (MRV). It might not be the most glamorous part of your setup, but it plays a huge role in keeping things running safely and smoothly. Let’s take a closer look at what the MRV does and why it’s so important.

What Is the Main Relief Valve Spool (MRV)?

The Main Relief Valve Spool (MRV), is a critical component in pressure regulation systems. Found in hydraulic or air-powered machinery—like those on ships, industrial equipment, or even heavy vehicles—it acts as a safety guard. Its job? To control and release excess pressure so your system doesn’t get overwhelmed. Think of it as a pressure escape hatch that kicks in when things get too intense.

I’ve always found it amazing how such a small piece can prevent big problems. Whether it’s in a marine air compressor or a factory pump, the MRV ensures the pressure stays within safe limits, protecting both the equipment and the people around it.

Why It Matters

So, what makes the MRV so special? For one, it’s all about safety. If pressure builds up too much, it can damage pipes, seals, or even cause dangerous blowouts. The MRV steps in by opening up to release that extra pressure, then closing again once things stabilize. It’s like having a trusty friend who knows exactly when to step in and help.

Another thing I like about it is its simplicity. The spool design—usually a sliding piece inside the valve—makes it reliable and easy to maintain. It doesn’t need constant attention, which is perfect for busy crews or operators who’d rather focus on the job than on repairs.

Key Benefits of the MRV

The MRV brings some practical perks to the table. It’s durable, often made from tough materials like steel or brass to handle harsh conditions—think salty sea air or gritty industrial settings. It’s also precise, letting you set the pressure limit you need so your system runs just right. And since it’s low-maintenance, you won’t be stuck replacing it every few months.

I’ve talked to mechanics who say a good MRV can extend the life of their whole system. By keeping pressure in check, it reduces wear and tear on other parts, saving time and money in the long run.

Wrapping Up

The Main Relief Valve Spool (MRV) might not steal the spotlight, but it’s a hardworking hero in any pressure-based system. It’s simple, sturdy, and keeps things safe—qualities you can’t overlook. Whether you’re on a ship or in a workshop, having a reliable MRV means one less thing to worry about. So, next time you’re checking your equipment, give this little component a nod—it’s doing more than you might think!

0 notes

Text

Why Does an Engine Oil Cooler Cover Plate Matter?

An engine oil cooler cover plate might not sound exciting, but it’s a small part that plays a big role in keeping vehicles running smoothly. This piece helps manage oil temperature, protecting the engine from wear and tear. Let’s dive into what it does and why it’s worth knowing about for anyone who cares about their ride.

Purpose of the Part

This cover plate is part of an oil cooler system. It seals the cooler, directs oil flow, and helps maintain proper pressure. By keeping oil at the right temperature, it prevents overheating, which can damage engine parts over time. It’s a simple component with a critical job.

Importance for Engine Health

Engines work hard, and heat builds up fast. Without proper cooling, oil breaks down, losing its ability to lubricate moving parts. The cover plate ensures the cooler does its job, reducing friction and extending engine life. It’s especially handy in high-performance or heavy-duty vehicles that push limits.

How It Works

The plate sits over the oil cooler, usually bolted in place. It channels oil through the cooler’s fins, where heat dissipates before the oil cycles back to the engine. Made from durable materials like aluminum or steel, it’s built to handle heat and pressure without cracking or leaking.

Signs It Needs Attention

A failing cover plate can cause trouble. Look out for oil leaks, rising engine temperatures, or strange noises under the hood. If the plate warps or corrodes, it won’t seal properly, letting oil escape or air sneak in. Catching these issues early saves bigger headaches later.

Who Needs It

This part matters most for drivers with demanding setups—think trucks, sports cars, or anything towing heavy loads. Hot climates or long hauls also make it a key player. Even regular sedans benefit from a solid cover plate to keep things running smoothly over the miles.

Benefits of a Good One

A well-made plate boosts reliability. It keeps oil flowing right, cuts down on heat stress, and can even improve fuel efficiency by reducing engine strain. Plus, it’s a low-cost piece that prevents pricey repairs, making it a smart investment for maintenance-minded folks.

Finding the Right Fit

Need a replacement or an upgrade? Quality counts—look for something sturdy and precise to match your vehicle’s specs. For more on what’s out there, check this page on engine oil cooler cover plates. It’s a quick way to see options that work.

Easy Maintenance

This part doesn’t demand much upkeep. Regular oil changes and a glance during tune-ups keep it in check. If it’s part of a bigger cooler system, cleaning the fins now and then helps too. A little attention goes a long way to keep it doing its job.

An engine oil cooler cover plate might be small, but its impact isn’t. It’s a quiet hero that keeps oil cool and engines happy, mile after mile. For anyone who values performance and longevity, it’s a piece worth appreciating—and keeping in good shape.

0 notes

Text

How to Reduce Noise and Vibration in Hydraulic Systems?

Hydraulic systems are widely used in industrial machinery, construction equipment, and automotive applications due to their efficiency and power. However, noise and vibration are common issues in these systems, leading to reduced performance, increased wear, and operator discomfort. Excessive noise and vibration can also indicate underlying problems such as cavitation, misalignment, or fluid turbulence.

In this article, we will explore the causes of noise and vibration in hydraulic systems and practical solutions to minimize them.

Causes of Noise and Vibration in Hydraulic Systems

Pump Cavitation – When air or vapor bubbles form in the hydraulic fluid due to low pressure, they collapse violently, creating noise and damaging pump components.

Fluid Pulsation – Pressure fluctuations in the hydraulic fluid cause pulsations, leading to vibration and noise in the system.

Component Misalignment – Poor alignment of hydraulic pumps, motors, and actuators creates excessive vibration.

Improper Mounting – Loose or improperly mounted components can amplify vibrations and noise.

Flow Turbulence – Sudden changes in fluid direction or speed cause turbulence, increasing noise levels.

Worn-Out Components – Old or damaged hydraulic pumps, hoses, and valves can contribute to excessive noise and vibration.

How to Reduce Noise and Vibration in Hydraulic Systems

1. Prevent Cavitation

Ensure the pump receives an adequate flow of hydraulic fluid by maintaining proper reservoir levels.

Use the correct hydraulic fluid with the recommended viscosity.

Minimize restrictions in the suction line by using properly sized hoses and filters.

Keep the inlet pressure within the pump's specified range to avoid air bubbles forming in the fluid.

2. Use High-Quality Hydraulic Components

Choose precision-engineered pumps and valves to minimize fluid pulsations.

Invest in dampers and accumulators to absorb pressure fluctuations and reduce noise.

Use high-quality hoses and fittings that can handle system pressure without excessive vibrations.

3. Optimize System Design

Use flexible hoses instead of rigid piping where possible to absorb vibrations.

Ensure smooth fluid flow by reducing sharp bends and sudden directional changes in piping.

Install noise-dampening materials such as rubber mounts and isolation pads to absorb vibrations.

4. Properly Maintain Hydraulic Equipment

Regularly inspect and replace worn-out components like bearings, seals, and hoses.

Keep the hydraulic fluid clean by using high-quality filters and changing the fluid at recommended intervals.

Check for air leaks in the system and bleed trapped air to prevent aeration and noise.

5. Secure Mounting and Alignment

Ensure hydraulic pumps, motors, and actuators are correctly aligned to minimize mechanical vibrations.

Tighten all bolts, brackets, and supports to prevent loose parts from amplifying noise.

Use anti-vibration mounts to isolate components from the machine frame.

Conclusion

Reducing noise and vibration in hydraulic systems enhances efficiency, prolongs equipment life, and improves operator comfort. By addressing common issues such as cavitation, fluid pulsation, misalignment, and improper mounting, businesses can ensure smoother and quieter hydraulic operations. Regular maintenance, high-quality components, and proper system design are key to achieving optimal hydraulic performance.

1 note

·

View note

Text

How to Reduce Downtime with Predictive Maintenance for Hydraulic Pumps?

Downtime in industrial operations can be costly, especially when it comes to hydraulic systems that power essential machinery. Unexpected failures of hydraulic pumps not only lead to delays but also increase maintenance costs and reduce overall efficiency. To combat this, many industries are turning to predictive maintenance, a proactive approach that helps identify potential issues before they cause a breakdown.

By implementing predictive maintenance strategies, businesses can significantly reduce downtime, extend the lifespan of hydraulic pumps, and improve overall productivity. This article explores how predictive maintenance works and the best practices to implement it for hydraulic pumps.

What is Predictive Maintenance?

Predictive maintenance is a data-driven approach that uses condition monitoring, sensors, and analytics to predict equipment failures before they happen. Unlike reactive maintenance (fixing equipment after it fails) or preventive maintenance (servicing equipment at scheduled intervals), predictive maintenance relies on real-time data to assess the health of hydraulic pumps and anticipate potential issues.

By continuously monitoring key performance indicators (KPIs) such as pressure, temperature, vibration, and fluid contamination levels, predictive maintenance helps detect anomalies early, allowing maintenance teams to address problems before they lead to costly breakdowns.

How Predictive Maintenance Reduces Downtime for Hydraulic Pumps

Real-Time Monitoring of Equipment Health Predictive maintenance uses IoT-enabled sensors and advanced analytics to track the real-time condition of hydraulic pumps. These sensors measure key parameters, such as:Vibration levels (indicating misalignment or wear)Oil contamination (signaling possible internal damage)Fluid temperature and pressure (showing inefficiencies or blockages)If abnormal patterns are detected, alerts are generated so that maintenance teams can take immediate action, reducing the risk of pump failure.

Early Fault Detection and Prevention Instead of waiting for a pump to fail, predictive maintenance helps identify minor issues before they escalate. For example, detecting small fluctuations in hydraulic pressure could indicate a developing leak or clog. Addressing such issues early prevents unplanned downtime and costly repairs.

Optimized Maintenance Scheduling Traditional maintenance schedules are based on set time intervals, which can lead to unnecessary servicing or missed failures between inspections. Predictive maintenance allows maintenance to be scheduled only when needed, based on real-time data. This reduces downtime and eliminates unnecessary maintenance costs.

Extended Equipment Lifespan Keeping hydraulic pumps in optimal condition through predictive maintenance helps prevent excessive wear and tear. Well-maintained pumps last longer, reducing the need for frequent replacements and improving return on investment (ROI).

Reduced Emergency Repairs and Costs Emergency repairs often involve high costs, including expensive parts, labor, and lost productivity. Predictive maintenance minimizes these unexpected expenses by addressing potential issues before they result in a complete pump failure.

Best Practices for Implementing Predictive Maintenance in Hydraulic Pumps

Install Condition Monitoring Sensors Equip hydraulic pumps with IoT-based sensors to collect real-time data on pressure, temperature, vibration, and fluid condition.

Use Predictive Analytics Software Utilize machine learning algorithms and predictive analytics to analyze data trends and detect anomalies before they turn into failures.

Establish a Maintenance Action Plan Define clear protocols for responding to alerts and scheduling repairs based on predictive insights.

Train Maintenance Teams Ensure your team understands how to interpret predictive maintenance data and take proactive actions to prevent failures.

Conclusion

Predictive maintenance is a game-changer for reducing downtime in hydraulic systems. By leveraging real-time data and analytics, businesses can detect issues early, optimize maintenance schedules, and extend the lifespan of their hydraulic pumps. Investing in predictive maintenance not only enhances efficiency but also leads to significant cost savings and improved operational reliability.

0 notes

Text

Why Hydraulic Gear Pumps are Vital in Heavy Machinery Operations?

Hydraulic gear pumps play a crucial role in the seamless operation of heavy machinery across various industries. From construction and mining to agriculture and material handling, these pumps provide the necessary power to drive hydraulic systems efficiently. Their ability to generate high pressure, maintain consistent fluid flow, and operate under extreme conditions makes them indispensable in heavy machinery operations.

1. Powering Hydraulic Systems in Heavy Machinery

Heavy machinery such as excavators, bulldozers, loaders, and cranes rely on hydraulic systems for movement and functionality. Hydraulic gear pumps are responsible for converting mechanical energy into hydraulic energy, enabling these machines to lift, push, and pull heavy loads with precision.

Excavators and Loaders: Hydraulic gear pumps control the movement of the arm, bucket, and boom, ensuring smooth operation.

Cranes and Lifting Equipment: These pumps generate the hydraulic force needed to lift and lower materials safely.

2. High Efficiency and Consistent Performance

Hydraulic gear pumps are designed for efficiency, ensuring a continuous and reliable fluid flow. This consistency is crucial for maintaining productivity in industries where downtime can lead to significant losses.

Steady Fluid Flow: The positive displacement mechanism ensures a uniform and controlled output.

Quick Response Time: Heavy machinery requires instant power, and hydraulic gear pumps deliver fast and efficient performance.

3. Durability and Reliability in Harsh Conditions

Heavy machinery operates in demanding environments such as construction sites, mines, and agricultural fields. Hydraulic gear pumps are built to withstand these conditions, offering long-lasting durability.

Robust Construction: Made from high-strength materials to endure extreme pressures and temperatures.

Low Maintenance: Designed for prolonged operation with minimal maintenance requirements, reducing downtime.

4. Versatility Across Multiple Applications

Hydraulic gear pumps are widely used in various heavy machinery applications due to their adaptability and efficiency.

Agriculture: Powering tractors, harvesters, and irrigation systems.

Mining: Supporting drill rigs, conveyors, and hydraulic shovels.

Material Handling: Used in forklifts and hydraulic lifts for smooth load handling.

Conclusion

Hydraulic gear pumps are the backbone of heavy machinery operations, ensuring optimal performance, efficiency, and reliability. Their ability to deliver high pressure, withstand extreme conditions, and provide consistent power makes them essential for industries that depend on hydraulic-driven equipment. Investing in high-quality hydraulic gear pumps guarantees seamless operations and long-term productivity in heavy machinery applications.

0 notes