Swift Technoplast Pvt. Ltd is one of the renowned moulding facility based at Maharashtra, extending material handling solutions to most of the leading industries around the country. Established in 2007, as Industrial products Manufacturer & Supplier mainly focused on the market of “Plastic Pallets”. SWIFT has quickly established itself as a reliable brand name due to its customer oriented approach, consistent product quality, wider range of products and services. We have achieved expertise in Plastic Molding through our core strength of ability to innovate, design and manufacture wider range of products, suitable for all kind of industrial segments the collective efforts, infrastructure and modern approach of the company have resulted in SWIFT being the preferred choice of customers. SWIFT is an acknowledged leader of India's plastic pallets industry. We are known in the industry for our unique solution based services and awarded as “Best Plastic Pallets manufacturer and supplier in India” among other for their outstanding services and contribution to the business and service industry in India. The SWIFT vision is, “To be top 3 brand in Plastic Pallets in India by 2025 with most respectable, knowledgeable organization as an Expert of Plastic Pallets.” We adhere to our Core Purpose, Values & Brand Promise. Our Service Vision is, “To Create Pleasant Experiences at all the time to provide Magic of Satisfaction”. We strive for delivering all product & services with excellence because there is no joy greater than delivering customer happiness & Satisfaction by keeping customer first.

Don't wanna be here? Send us removal request.

Text

Swift’s Nirmalya Kalash Made from virgin plastic, it ensures a clean and eco-friendly way to collect and preserve sacred offerings.

#nirmalya kalash near temple#nirmalya kalash#nirmalya kalash near me#nirmalya kumbh kalash#nirmalya kalash manufacturer#nirmalya kalash price#निर्माल्य कलश

0 notes

Text

Swift’s Plastic crate ensures durability and space-saving storage for everyday operations.

#Multipurpose crates#Plastic Crates#Crates#Crate#Plastic Crate#Swift Technoplast#Plastic Crates Manufacturer#plastic crate manufacturers near me#plastic crates supplier#Industrial Plastic Crate#Milk Crates#heavy duty plastic crates

0 notes

Text

Top 5 Benefits of Using Drum Spill Containment Pallets in Your Facility

For any facility storing chemical drums or hazardous liquids, the risk of leaks and spills is always present. Without suitable safeguards, these accidents can lead to workplace -injuries, compliance issues, and environmental harm. Drum spill containment pallets are a simple yet effective way to manage these risks.

Here are five practical benefits of using Swift's drum spill containment pallets at your facility:

1. Prevents Environmental Contamination

Drums can leak, and when they do, it's -crucial to stop the spread quickly. Containment pallets with built-in sumps help -collect those leaks before they reach the floor or the environment. This helps prevent contamination and damage to nearby surfaces.

Swift’s Spillage Pallets are ideal for operations that require extra protection and environmental responsibility.

2. Enhances Workplace Safety

Leaking liquids on smooth floors are a common source of workplace accidents. By using containment pallets, leaks are immediately caught in the tray beneath, keeping walkways dry and -reducing the chance of injuries.

This adds an extra level of safety, especially in facilities where multiple drums are moved and handled every day.

3. Ensures Compliance with Safety Regulations

Regulations exist to protect both people and the planet. Proper use of containment pallets can support compliance with safety rules such as:

EPA 40 CFR 264.175

SPCC -(Spill Prevention, Control, and Countermeasure)

NPDES (National Pollutant Discharge Elimination System)

Using the right equipment helps simplify audits and avoid penalties while showing a -commitment to responsible operations.

4. Durable and Chemical-Resistant Construction

Swift’s pallets are made with high-quality LLDPE and molded in a single piece for extra strength. This -material is UV-resistant, chemical-resistant, and can handle tough working conditions.

They’re also forklift-friendly, making them easy to move without sacrificing stability or safety.

5. Promotes Organized Storage and Easy Handling

Beyond spill control, these pallets help keep storage areas organized. Swift offers models for 1, 2, or 4 drums, so you can choose what fits best in your space.

You can also pick between FRP or plastic tops depending on your cleanup needs. Both surfaces resist chemicals and are easy to maintain.

Conclusion

Spill containment pallets are a smart, necessary addition for any industrial operation storing hazardous materials. They boost safety, help meet regulations, and improve overall efficiency.

Swift offers solutions that combine performance, durability, and practical design. With years of experience and trusted products, Swift makes managing spills easier and safer.

Explore Swift’s range of drum containment pallets and find the right solution for your facility.

#Spill Containment Pallet#Spill Pallets#Spillage Pallet#Drum pallet#Drum Spill Containment Pallets#Drum Spill Pallets#drum spill containment#Oil Spill Pallet#secondary containment pallets#Oil Drum Pallet#Pallet for Oil Drum#secondary containment#plastic spill containment

0 notes

Text

Nirmalya Kumbh Kalash – Respecting Devotion, Protecting Nature

In India, every flower offered at a temple, every coconut broken in reverence, carries deep-spiritual meaning. These sacred remnants—known as Nirmalya symbolize our devotion. But once the rituals conclude, where do these offerings go?

Too often, they’re discarded in rivers or on streets, turning something holy into pollution. That’s where the Nirmalya Kumbh Kalash comes in—bridging the gap between faith and environmental responsibility.

🌺 What Is a Nirmalya Kumbh Kalash?

A Nirmalya Kalash is a dedicated container placed in temples, shrines, and public religious areas to collect sacred offerings after rituals. It provides a dignified, eco-friendly alternative to simply-discarding Nirmalya.

made with durable, UV-stabilized plastic, this container is built to withstand all seasons while maintaining cleanliness and ease of use. It’s not just a bin it’s a gesture of respect towards both our traditions and our planet.

🙏 Why Nirmalya kalash is useful?

1. Respecting the Sacred

Nirmalya isn’t waste—it’s sanctified. Throwing it into water bodies or on the ground is a form of disrespect. The Kalash honors the sanctity of rituals by offering a respectful place for these offerings.

2. Protecting the Environment

Religious waste, if left unmanaged, can lead to clogged drains, polluted rivers, and harm to-aquatic life. With the Kalash, biodegradable offerings can be easily composted or processed appropriately.

3. Keeping Temple Grounds Clean

During festivals, temples witness massive footfalls. The Kalash helps maintain hygiene and order, keeping the premises clean and serene.

4. Encouraging Devotee Awareness

When you install a Nirmalya Kalash, you send a clear message—spirituality and sustainability go hand in hand. It fosters a culture of mindfulness among devotees.

At Swift, we’ve designed our Nirmalya Kumbh Kalash units to be:

Lightweight and easy to handle

Weather-resistant and UV-stabilized

Wide-mouthed for convenient use during peak hours

Ideal for temples, municipalities, and festival organizers

With over 17 years of expertise, we’re proud to support both cultural traditions and eco-conscious practices.

As one temple trustee in Pune shared, “Since we introduced the Kalash, our temple looks cleaner and the devotees appreciate the thoughtfulness behind it.”

🌏 A Simple Step with a Big Impact

The Nirmalya Kumbh Kalash is more than a container—it’s a call for conscious devotion. It empowers communities to preserve the purity of both faith and nature.

So this festive season, let's ask ourselves:

Are we worshipping with awareness?

🌿 Let Your Devotion Leave Behind Blessings—Not Pollution.

#nirmalya kalash#flower offering#nirmalya kalash near me#nirmalya kumbh kalash#nirmalya kalash near temple#nirmalya

0 notes

Text

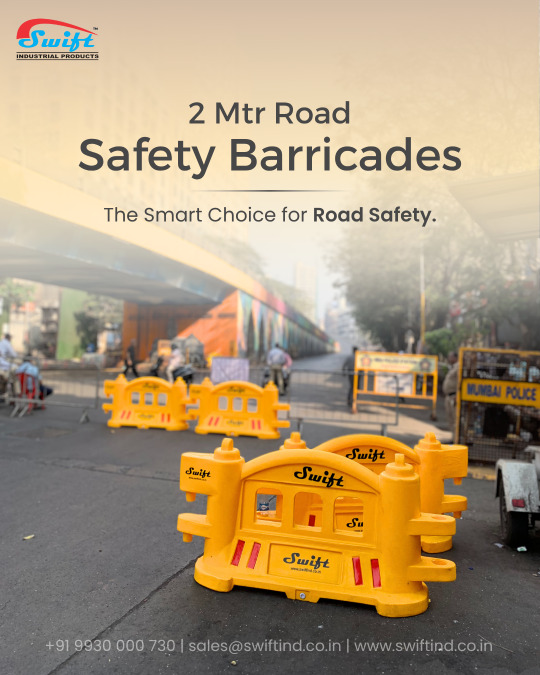

Swift 2 Mtr Road Safety Barricades 🚧

Built for strength, visibility & maximum road control.

The smart choice for traffic zones, events & urban safety.

✅ Long-Lasting Performance

✅ Superior Visibility

✅ Easy to Deploy

#Swift Technoplast#Road Safety#Barricades#Traffic Management#Safety First#Made In India#Smart infrastructure#road safety barricade#Plastic Barricades#Road Barriers#Barriers#Traffic Barriers#Mumbai Barricades#Checkpost Barricades

0 notes

Text

Why 2-Meter Barricades Are Ideal for Road Projects

In today’s fast-paced world, ensuring road safety is more critical than ever. From maintaining traffic and ensuring the safety of all commercial onlookers during construction to creating a safe environment for public events, road safety barriers are the best way to keep both workers and citizens safe from harm.

Among the many types of barricades available, the 2-meter road safety barricade has become a preferred choice for many infrastructure and traffic control projects. But why exactly is it so popular? Let’s find out.

1. Optimal Length for Effective Coverage

The 2-meter length provides a practical balance between portability and coverage. It’s just long enough to create a solid and continuous barrier which will prevent gaps that unauthorized users or accidents can pass through but not so long that it becomes hard to handle/lay down and set out as you move it around.

2. Highly Visible Colors

Visibility is key when it comes to road safety. Most 2-meter barricades are designed with bright colors like red, yellow and are often equipped with reflectors or reflective tape.

This makes the barricades highly visible during day and night, vastly reducing the dangers of incidents at twilight.

3. Durable and UV Stabilized Material

These barricades are made using LLDPE (Linear Low-Density Polyethylene) with Roto-molded construction for a strong, seamless build. The material is UV-stabilized, ensuring that the barricades resist sun damage and fading.

The roto-molding process provides uniform wall thickness and structural strength, making them highly durable.

4. Easy to Handle and Move

These barricades are designed for ease of use with feature interlocking systems, allowing them to be quickly set up or rearranged without the need for heavy equipment. This makes them an efficient solution for temporary or changing road work zones.

5. Interlocking & Fillable Design

2-meter barricades feature interlocking systems and water or sand fill options, allowing quick setup and added stability. This flexibility ensures they meet site-specific safety and functionality needs.

6. Versatile Applications

These barricades aren’t limited to roadworks. They are also widely used for:

Public event crowd control

Pedestrian walkway demarcation

Construction site safety

Petrol Pumps

Shopping Malls

Parking lot and traffic lane guidance

Their flexibility makes them a go-to solution across multiple sectors.

Conclusion

The 2-meter road safety barricade stands out for its ideal size, durable LLDPE material, and roto-molded strength. It balances the need for solid traffic control while being able to get the job done safely and efficiently and a good choice for anyone working on an infrastructure, construction, or public safety project.

If you're looking to enhance safety and streamline operations, Swift’s 2-meter barricades into your project could be the move that makes all the difference.

#road safety#Road Safety Barricade#traffic barricades#road barricades#water filled traffic barriers#plastic road barriers#road barriers types#parking barricades#traffic cone#plastic barricades#road safety signs#plastic traffic cone#road safety barriers#plastic traffic barriers

0 notes

Text

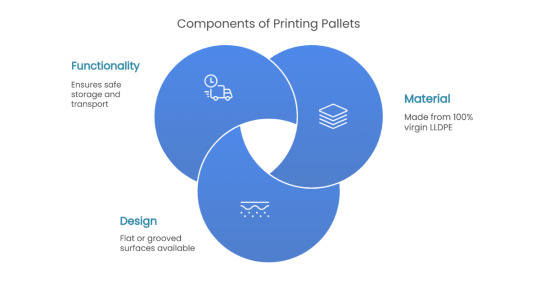

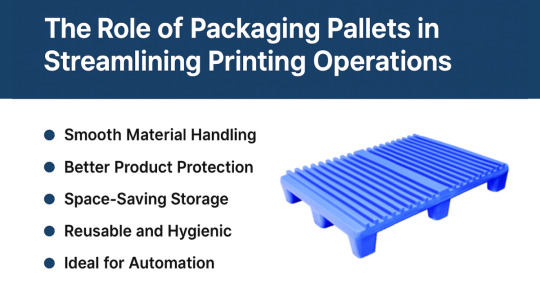

The Role of Packaging Pallets in Streamlining Printing Operations

In the fast-moving printing and packaging industry, efficient handling and storage of materials are crucial. When dealing with high quantities of paper, cartons, and printed goods every day spread across facilities, efficient material handling solutions matter.

Among these, packaging pallets play a key role in maintaining speed, safety, and organization.

Packaging Pallets Designed for Printing Applications

Printing operations demand precision. From freshly printed sheets to packed cartons, every product needs to be stored and transported without damage. Packaging pallets provide a reliable base to move and manage materials with minimal manual effort.

Our printing pallets are purpose-built for this industry—made using 100% virgin LLDPE material and designed to withstand the rigorous demands of printing environments. These pallets are available with flat or grooved surfaces, depending on your specific operational needs, ensuring versatility and performance in real-time production setups.

Key Benefits of Using Packaging Pallets in Printing Operations

1. Smooth Material Handling

Whether the job is moving raw materials to the press or transporting finished products to dispatch, pallets make it faster and safer. They pair nicely with forklifts and pallet jacks and aid in streamlining operations.

2. Better Product Protection

Printed materials are sensitive to creasing, bending, or pressure damage. A sturdy pallet provides a stable base to safeguard products during movement and storage.

3. Space-Saving Storage

Packaging pallets allow for organized stacking, maximizing warehouse space and improving accessibility. It reduces clutter and helps maintain a clean and efficient work environment.

4. Reusable and Hygienic

Unlike traditional, plastic pallets do not absorb moisture, making them easy to clean and maintain. Their long service life and low maintenance needs make them a cost-effective solution over time.

5. Ideal for Automation

In modern printing setups with conveyor systems or automated handling, uniform pallets ensure smooth flow without interruptions. This boosts productivity and reduces manual handling.

Final Thoughts For over 17+ years, Swift has delivered high-quality packaging pallets tailored to the printing and packaging industry. With durable construction, application-focused design, and surface options to match your workflow, our pallets help simplify day-to-day operations and keep your production line moving smoothly.

#printing pallets#Plastic pallet price#plastic pallets#plastic pallets manufacturer#plastic pallets supplier#industrial plastic pallets#blue plastic pallets#plastic pallet companies#roto molded plastic pallets#Rackable Plastic Pallets#Plastic Pallets for storage#plastic pallet business#plastic pallets for print#Printing Industry Pallets#packaging pallets

0 notes

Text

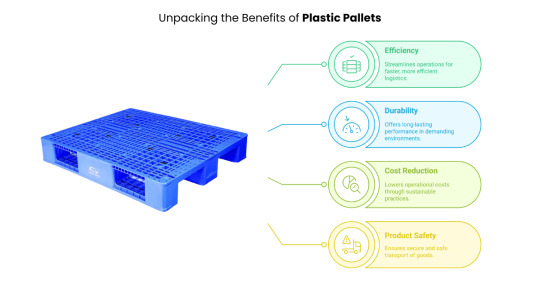

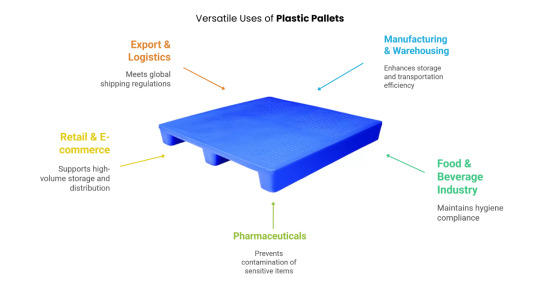

Plastic Pallets: The Smart Choice for Modern Material Handling

In today’s fast-paced industrial world, efficiency and durability are key factors in material handling. Businesses are constantly looking for solutions that optimize logistics, reduce costs, and ensure product safety.

Thus, following are the advantages which have made plastic pallets the best fit for every industry.

Why Choose Plastic Pallets?

Durability & Strength Plastic Pallets are made with superior materials that can bear load and accordingly the conditions, extreme. These are sturdy and built to last, saving you money in the long run as you don't have to keep replacing them.

Hygienic & Easy to Clean Hygiene becomes the most important factor in the industry like food processing, pharmaceuticals, etc. Plastic Plastic pallets are great because they don’t soak up moisture, which helps keep germs and bacteria at bay. This feature makes them super easy to clean and sanitize!

Lightweight & Easy to Handle Logistics aspect with huge importance on handling efficiency. Because they are lightweight and incredibly durable, they reduce physical labour, save money on shipping, and improve workplace safety.

Consistent Design & Standardization Unlike traditional options, Plastic Pallets maintain a uniform size and shape, ensuring smooth automation and stacking. They are precision-made, removing inconsistencies, and improving operational efficiency.

Eco-Friendly & Recyclable Plastic pallets contribute to the green supply chains in businesses worldwide by being made from recyclable materials and being reusable multiple times. In this case, sustainability becomes a core priority as a businesses.

Applications of Plastic Pallets

Manufacturing & Warehousing : These storage systems are great for efficiently storing and transporting goods.

Food & Beverage Industry: Ensures compliance with hygiene standards.

Pharmaceuticals: prevents contamination of delicate items.

Retail & E-commerce: Supports high-volume storage and distribution.

Export & Logistics: Offers compliance with global shipping regulations.

The Future of Material Handling

Designating Emerging Industry Standards for Plastic Pallets While their longevity, efficacy, and environmentally friendly features make them the go-to choice for companies looking for long-term solutions.

Upgrade to plastic pallets today and experience seamless, cost-effective, and sustainable material handling for your operations with Swift Technoplast.

#pallet plastic#plastic pallets manufacturer#plastic pallets supplier#hdpe pallet#plastic pallets for sale near me#plastic pallets manufacturers in india#Plastic pallet price#plastic pallet near me#pvc pallets#plastic pallets

0 notes

Text

Maximize storage efficiency with Swift's Drive-in rackable Plastic Pallets. It is designed with extended side edges for secure racking.

.

🏨 Swift Technoplast Private Limited ���� www.swiftind.co.in ☎ +91 9930 000 730 📨 [email protected]

#SwiftTechnoplast#RackablePallets#DriveInRacking#StorageSolutions#WarehouseEfficiency#PlasticPallets

0 notes

Text

IBC Spill Containment Pallets: Best Practices for Use and Benefits

Ensuring spill control and safety is crucial in businesses handling huge amounts of hazardous liquids. These liquids are frequently transported and stored in intermediate bulk containers (IBCs), yet there is a chance of spilling. IBC spill containment pallets are useful in this situation. Because these pallets are designed to reduce environmental damage and increase worker safety, These pallets are crucial for following the safety standards and protecting your business.

In this blog, we will discuss the use and benefits of IBC spill containment pallets.

Understanding IBC Spill Containment Pallets

Pallets designed for IBC spill containment are made especially to store liquids and stop leaks or spills. A containment basin in robust construction collects and holds spills. This prevents them from spilling into the surrounding space. It also stops spills from reaching the floor. The robust materials used to manufacture these pallets like polyethylene, which is resistant to chemicals ensure long-term usage and durability.

Proper Placement and Setup

Where to place: To ensure the best results with your IBC spill containment pallet, carefully place it on a flat, stable surface. Make sure the area around it is free from any obstructions and has easy handling and movement of your IBCs.

Leveling: Make sure the pallet is level to avoid spills brought on by tilting and uneven liquid distribution in the IBC.

Load Bearing Limits: Stick to the weight limits set by the pallet manufacturer. Overloading can compromise its integrity, resulting in spillage.

Handling and Transport

Proper Lifting: Forklifts or pallet jacks are suitable lifting equipment to use while moving IBCs onto and off the spill containment pallet. IBCs should not be dragged or dropped since this could harm the pallet as well as the container.

Secure Positioning: Make sure the IBC is steady and firmly positioned when it has been placed on the pallet. To prevent movement during handling or transportation, use straps or other fastening techniques as needed.

Load Management

Weight Limits: Observe the weight restrictions for the pallets as indicated by the manufacturer. Pallet overloading increases the chance of spills and can harm the structure.

Proper Loading: Position IBCs centrally on the pallets to ensure even weight distribution and stability. Avoid putting multiple IBCs on the same pallet unless it has been designed to handle such weights.

Benefits of Using IBC Spill Containment Pallets

1. Enhanced Safety

Swift’s IBC spill containment pallets are a game-changer for workplace safety. They offer a secure platform to store hazardous materials, giving you peace of mind. With their advanced secondary containment feature, any spills are contained, preventing them from spreading. This means a safer environment, less risk of accidents, and reduced exposure to dangerous chemicals.

2. Cost Savings

Spill and leak control may save you a lot of money. Spills can result in costly cleaning operations, penalties, and damage to equipment and the workplace. Investing in IBC spill containment pallets reduces the multiple costs.

3. Versatility

IBC spill containment pallets have many uses and show up in different industries such as food and drink processing, and chemical production. They can adapt to different needs, which makes them a key tool for any business working with liquids and chemicals. These pallets help keep people safe and make handling these materials more effective.

4. Easy Maintenance

These pallets are built to last and require minimal maintenance. Regular inspections and cleaning assure its longevity and efficacy, giving a long-term spill containment solution.

Conclusion

You may extend the life and efficacy of these pallets by being aware of their design and function, making sure they are positioned and set up correctly, and following safe handling and transportation procedures.

IBC spill containment pallets have many advantages, such as improved worker safety, cost savings from spill prevention, industry adaptability, and ease of maintenance. We at Swift Technoplast are dedicated to offering IBC spill containment pallets of the finest quality that meet industry standards and support the safety of your business.

Swift's products are made to provide 100% Environmentally friendly, sturdy, dependable containment solutions that guarantee worker safety. Invest in Swift Technoplast IBC spill containment pallets to enhance the safety and efficiency of your facility.

#Spill Pallets#Spill Containment Pallet#Spillage Pallet#Drum Spill Containment Pallets#ibc spill pallets#ibc spill containment pallet#ibc pallet#IBC Plastic Pallet#IBC Container Pallet#Intermediate Bulk Container Pallet#IBC Pallet Supplier#IBC Pallet Cost#oil containment pallet

0 notes

Text

The Essential Guide to Traffic Cones: Uses, Benefits, and More

It is common to see road safety traffic cones in public areas, construction sites, and on our roads. Traffic cones might seem straightforward, but they’re crucial for keeping safety and order in check, especially when managing risks or guiding people. We'll explore the applications, benefits, and reasons traffic cones are essential for road safety in this post.

What Are Traffic Cones?

Even though they look straightforward, traffic cones are very helpful. Its vivid red, orange, or yellow colors are intended to grab attention. They are manufactured from sturdy plastic material These bright colors grab attention even in dim light. To ensure your safety in all weather conditions, many cones additionally have reflective strips that allow them to light brilliantly at night or during bad weather conditions.

Primary Uses of Traffic Cones

Road Safety and Traffic Management: The most common application of traffic cones is traffic flow management, especially in regions undergoing renovation or construction. They are positioned to make lanes, direct traffic, and show where it is unsafe or forbidden to travel. Cones help vehicle redirection during roadwork or situations of emergency, protecting the safety of both drivers and people.

Construction Sites: On construction sites, cones are used to indicate dangerous places such as open pits, regions covered in trash, and areas where heavy machinery is being used. This protects pedestrians and employees from potential accidents.

Event Management: At public events, traffic cones are unsung heroes. They help manage crowds, direct parking, and mark off restricted areas. Whether it’s a marathon, parade, or concert, these cones keep everything running smoothly and help ensure everyone has a great time.

School Zones and Pedestrian Safety: Traffic cones are commonly used in school zones to reduce traffic, mark crosswalks, and safeguard people crossing the street. They are also used to temporarily close roadways or parking lots for school functions.

Benefits of Using Traffic Cones

Enhanced Safety: The biggest advantage of traffic cones is how they make our surroundings safer. Whether in a busy city or a quiet neighborhood, they help keep everyone out of harm’s way.

High Visibility: Traffic cones are easily identifiable even from a distance because their brightly colored and reflective strips. this visibility is essential for attracting the attention of workers, pedestrians, and cars and promoting everyone's safety.

Versatility: Traffic cones are amazingly flexible. They work just as well on busy highways as they do in quiet school zones. Plus, they’re easy to shift around or adjust whenever you need to.

Cost-Effective: Traffic cones are a budget-friendly option compared to other traffic control devices. They provide an effective way to manage traffic and keep everyone safe without the need for more expensive, complicated equipment. Their simplicity and low cost make them a smart choice for many situations.

Durability: Traffic cones are designed to withstand the elements and tough conditions and are made from durable materials that endure heavy impacts and extensive use. Their robust construction ensures they hold up over time, offering great value and longevity for businesses and communities alike.

Easy Deployment: Cones for traffic are lightweight and incredibly simple to assemble. They can be rapidly put or taken out by one person, which makes them ideal for addressing emergencies or temporary traffic management. They are a go-to tool when you need to respond quickly due to their ease of usage.

Conclusion

Traffic cones might look simple, but their role in safety is huge. These brightly colored markers are key to keeping things in order—whether it's guiding traffic, protecting workers, or ensuring pedestrians stay safe. They are the preferred choice for anybody in need of effective traffic control or safety marking because of their low cost, and durability.

Knowing Swift's traffic cones' purposes and benefits can help you decide where to use them as a business owner, event planner, or concerned citizen. The next time you see a traffic cone, consider the importance it is for keeping our roads, workplaces, and public areas safe.

#traffic cone#traffic cones for sale#parking cones#construction cones#road cones#traffic safety cones#no parking cones#street cones#plastic traffic cone#traffic cones with chain#parking cones with chains#pvc cone

0 notes

Text

Why Plastic Pallets Are in High Demand Across Industries in India

In today’s fast-paced and competitive industry environment, efficient logistics and safe product handling are critical to success. One such invention that has made a significant difference is Plastic pallets.

For businesses across India, where diverse industries operate in varying climates and conditions, plastic pallets are proving to be the ultimate choice. Here’s why:

1. Durability That Outlasts Traditional Options

Plastic pallets are designed to withstand significant weight and rigidity. Though classic pallets are susceptible to splitting, decaying or breaking completely, plastic pallets keep their basic shape and changes storage structure for years at a time.

For instance, Swift’s Roto Molded Plastic Pallets, made from 100% virgin material, provide superior strength and longevity, making them an ideal solution for heavy-duty applications.

2. Hygiene and Cleanliness: Perfect for Food and Pharma

High hygiene selectivity is imperative for the Food, Pharmaceutical and Chemical industries. Being non-porous, moisture resistant and easy to clean plastic pallets are an ideal choice where hygiene is the utmost concern. Swift’s Food-Grade Pallets, specifically designed for these industries, not only guarantee that hygiene requirements are fulfilled but also provide durability.

3. Weather-Resistant for India’s Diverse Climates

From the humid shores of Kerala to arid Rajasthan, India’s varied climates can be punishing on traditional pallets. On the other hand, plastic pallets are significantly impervious to climatic conditions ensuring reliability while sending products through ruthless summers or monsoon showers.

4. Lightweight Yet Strong

Plastic pallets are much lighter than traditional pallets, even though they are quite popular. Plastic pallets offer the best strength against breakage. Not only does this reduce shipping costs, but it’s also easier and safer for workers to handle. For Industries managing high volumes of logistics across India, Swift’s Rackable Pallets offer a perfect combination of lightweight design and heavy load-bearing capacity.

5. Eco-Friendly and Sustainable

As sustainability becomes more significant, plastic pallets are also a responsible choice. Most are created with recyclable materials to limit the environmental footprint. Plus their longevity also means fewer replacements, leading to less landfill waste. Swift’s Recyclable Pallets help Industries align with their green goals without compromising on quality.

6. Safety First

Plastic pallets do not have nails protruding at any point, making them safe to use; there are no sharp edges or splinters. This becomes particularly important in high handling applications like warehousing and distribution centers. Swift’s Safety Pallets, for instance, are designed with smooth edges and robust construction to prevent workplace injuries.

7. Customization for Specific Needs

Indian industries are as diverse, and their logistics requirements vary correspondingly. Plastic pallets can be customized for specific requirements whether it is for printed materials, electronic products or agricultural produce. For instance, Swift’s Printing and Packaging Pallets are designed specifically to meet the specialized needs of the printing industry.

8. Compliance with Global Standards

You have to fall in line with international shipping laws if your industry deals with export. Plastic pallets also comply with these standards, for example ISPM-15 legislation prohibits untreated conventional pallets in international trade. Swift’s Export Pallets are developed as per these regulations hence are a no-hassles choice for industries that seek to go global.

Case Study: A Leading Indian FMCG Company

A renowned FMCG company in India recently switched to Swift’s Food-Grade Plastic Pallets for transporting its packaged food products. The result? A significant reduction in product damage during transit and improved warehouse efficiency. The lightweight yet sturdy design of the pallets also led to a 15% decrease in shipping costs.

Conclusion

Plastic pallets have started revolutionizing the manner in which Indian industries operate their logistics and warehousing. They offer several benefits, including resistivity, cleanliness and sustainability as well as cost efficiency; things that are needed in varying degrees by various sectors of the Indian industry. Ultimately, transitioning to plastic pallets is investing in durability and future strength no matter your industry, whether manufacturing, warehousing or retail.

Upgrade your operations today with Swift’s Plastic Pallets—India’s choice for smarter, safer, and more sustainable industry solutions!

#plastic pallets manufacturers in india#plastic pallets#plastic pallets supplier#roto molded pallets#plastic pallet near me#cost of plastic pallets#blue plastic pallets#swifttechnoplast

0 notes

Text

Rebar Safety Caps: A Small Investment for Big Safety Benefits

In the construction industry, safety is paramount. One of the simplest yet most effective safety measures on a worksite is the use of rebar safety caps. Though they may seem like a small and negligible component,

the benefits of rebar safety caps are critical in preventing severe injuries and protecting workers from potentially fatal accidents.

The Hidden Dangers of Exposed Rebar

Reinforcing bars or rebars are important as they add strength to the concrete structures. But expose during construction and they prove dangerous. Exposed rebar have sharp ends on them which can become dangerous if, for instance, a worker trips/falls onto one. Exposed rebar can be very dangerous causing deep puncture wounds or impalements that can kill.

How Rebar Safety Caps Work

Safety caps, for rebar are created to shield the exposed tips of rebar and offer a barrier to reduce the risk of injuries. The most common types are:

Mushroom Caps: These are basic plastic caps that fit over the rebar ends. They are ideal for preventing minor scrapes and scratches.

Square Rebar Safety Caps: These are all metal caps built into a plastic outer shell These offer more protection by transferring the impact force across a larger area.

Safety Caps with Steel Inserts: For high-risk sites, these caps are supplemented by steel in order to reduce the risk of impalement even more.

Key Benefits of Using Rebar Safety Caps

Injury Prevention: Rebar safety caps are basically used to avoid injuries. They serve as an intercusion and have a protective function by limiting the risk of puncture and cut due to covering sharp, exposed ends.

Compliance with Safety Regulations: Most construction sites must adhere to strict safety regulations set by organizations such as OSHA (Occupational Safety and Health Administration). Using rebar safety caps helps companies meet these safety standards, reducing the risk of legal issues and fines.

Cost-Effective Safety Solution: Invest in safety caps for rebar as it is an investment that can lead to long term savings on costs. The costs associated with workplace injuries — medical bills, legal fees, lost productivity, and increased insurance premiums — far outweigh the minor expense of these caps.

Increased Worker Confidence: Visible safety measure helps workers feel secure and confident. In this way, productivity and less risk can improve the environment in general.

Choosing the Right Rebar Safety Caps for Your Project

Then again, not all rebar safety caps are the same and picking from a particular kind depends on what your construction site specifics. Consider the following factors:

Rebar Size and Diameter: Ensure the cap fits securely over the rebar to provide adequate protection.

Site Conditions: For sites with heavy machinery or high foot traffic, opt for heavy-duty caps with steel inserts.

Compliance Requirements: Check local safety regulations to ensure the chosen rebar safety caps meet the necessary standards.

Best Practices for Using Rebar Safety Caps

Inspect Regularly: Rebar safety caps should be inspected frequently for damage or wear and tear. Replace any that are cracked or deformed to maintain their protective function.

Train Workers: Educate your team on the importance of using rebar safety caps and the risks of exposed rebar. This helps foster a culture of safety on the site.

Standardize Usage: Make rebar safety caps a standard safety requirement on your construction sites. Consistent use reduces the chances of accidental injuries.

Conclusion

Rebar safety caps are a small but crucial investment that can significantly enhance the safety of your construction site. They save a lot of money as it keeps serious injuries away and comply with the safety laws for a low investment. Prioritizing such safety measures not only protects your workers but also helps build a reputation for safety and reliability in the industry. At Swift Technoplast, with 16+ years of expertise, we offer durable and eco-friendly rebar safety caps that meet industry safety standards. Choose Swift Technoplast for reliable solutions that keep your job site and team protected.

0 notes

Text

Eco-Friendly and Efficient: The Future of Plastic Pallets in Industry

In today’s evolving world, which prioritizes sustainability and environmental awareness, companies are increasingly seeking eco-friendly options that not only enhance efficiency but also positively impact the environment. An example of such a solution that is gaining popularity is the adoption of plastic pallets.

These versatile instruments signify a move, towards embracing eco methods, in the logistics and supply chain sectors.

The Benefits of Plastic Pallets

Sustainability: Plastic pallets are designed to be used and reused throughout their lifetime and are made of recyclable materials. They provide a more sustainable choice compared to other materials, aligning with eco-friendly business practices.

Durability and Longevity: Plastic pallets endure harsh conditions and heavy loads without splintering or warping over time, unlike traditional pallets. They are a choice as they last longer and reduce the amount of waste going to landfills.

Hygiene and Safety: In sectors, like the food and pharmaceutical industries cleanliness is crucial Plastic pallets boast porous surfaces that are simple to sanitize preventing contamination and meeting safety standards The absence of edges or splinters adds a layer of safety, for employees when handling and moving them

Cost-Effectiveness: Although plastic pallets may require an investment compared to alternative choices initially; their durability and minimal maintenance requirements can ultimately lead to cost savings in the long run. Moreover plastic pallets lighter weight can contribute to reduced transportation expenses and better fuel efficiency.

The Future of Plastic Pallets in Industry

The rising emphasis, on sustainability in industries is driving a growing need for friendly items such, as plastic pallets. Several trends indicate that plastic pallets will play a crucial role in the future of logistics and supply chain management:

Increased Recycling Initiatives: Many businesses are adopting closed loop systems to recycle plastic pallets once they have served their purpose aiming to minimize impact and promote an economy.

Technological Advancements: Advancements in manufacturing have led to the development of more effective plastic pallets with upgraded designs and materials, enhancing their capabilities across various uses.

Global Standards and Certifications: As companies prioritize sustainability as a measure of success, in the business landscape they will increasingly pursue certifications for their packaging and materials. In this context, plastic pallets that adhere to eco criteria are poised to emerge as the top choice, for businesses aiming to demonstrate their dedication to environmental responsibility.

E-commerce Growth: The rise of online shopping has led to an increased demand, for logistics services like never before Plastic pallets offer an lightweight solution that can improve effectiveness and reduce shipping costs making them an ideal option, for the e commerce sector.

Conclusion

It’s clear that there is a shift, towards logistics solutions lately. Plastic pallets are leading the way by providing eco friendly options that enable businesses to boost efficiency and lessen their environmental impact.

At Swift Technoplast, we provide innovative plastic pallet solutions that meet the demands of modern industries, helping you optimize your supply chain and promote sustainability.

#heavy duty plastic pallets#plastic pallets near me#pallet plastic#plastic pallets manufacturer#plastic pallets supplier#hdpe pallet#pvc pallets#shipping pallet

0 notes

Text

The Role of Plastic Pallets in Reducing Product Damage During Transport

The key in today’s fast-moving supply chain and logistics ecosystem is to ensure products aren’t damaged in transit. Damages can lead to financial losses, customer dissatisfaction, and supply chain inefficiencies. One effective approach is using plastic pallets, which offer clear advantages over other pallet types.

1. Consistent and Durable Structure

Plastic pallets have a uniform or smooth manufacture with a regular structure without naked lumber as compared to other pallets which may have irregularities or tendency to warp. Having consistent shapes helps to equalize the load in a product, improving the stability of the load during transport and reducing the odds of shuffling and tumbling.

2. Better Resistance to Impact and Environmental Factors

Transportation can be exposed to diverse environmental conditions such as humidity, rain, and temperature. These pallets are also moisture and damp-resistant, suitable for shipments that may be exposed to humid environments. They also do not soak up water, which can cause swelling and weakness that could threaten stability.

3. Design Options to Fit Specific Product Needs

There are different designs of plastic pallets depending on the use or the industry. Some pallets can be reinforced to support heavier loads and others are designed to stack, allowing for better organization of shipments preventing tipping or falling over during transit.

4. Smooth Surface for Gentle Product Support

The polished and splinter-free finish of plastic pallets makes them perfect, for transporting goods such as electronics and pharmaceutical or food items, without the risk of scratches or damages commonly seen with types of pallet materials. They effectively protect goods during transport.

5. Hygienic and Easy to Clean

Product damage can occur due, to contamination in industries such as food production and healthcare settings where maintaining cleanliness is crucial for product safety and quality assurance purposes Plastics pallets offer a nonporous surface that can be easily sanitized making them a preferred choice for handling sensitive products.

A clean plastic pallet plays a significant role, in reducing the likelihood of contamination impacting the integrity and safety of products during transportation.

6. Lightweight for Easier Handling and Reduced Strain

7. Long-Lasting Durability Means Fewer Replacements and Fewer Risks

Plastic pallets are known for their longevity. They don’t wear down easily, even with frequent use and movement. A pallet that can withstand repeated transit without degrading helps ensure consistent product protection. With fewer replacements needed, the likelihood of using old, damaged, or weakened pallets is reduced, further safeguarding the goods being transported.

Conclusion

These pallets reduce product damage in transit thanks to their robust design, durability, and versatile construction. Even in adverse logistics conditions, they protect goods effectively. For companies aiming to cut costs and enhance customer satisfaction, plastic pallets are a cost-effective, eco-friendly supply chain solution.

By ensuring product safety, minimizing losses, and streamlining logistics, plastic pallets from Swift Technoplast make a smart investment for businesses focused on safe, damage-free transport.

#swift technoplast#Plastic pallets#Export Pallets#shipping pallet#cargo pallet#plastic pallets suppliers#plastic pallet manufacturer

0 notes

Text

Introducing All New Drum Spill Pallets for Maximum Containment

Improve Your Spill Management! Managing hazardous liquids and chemicals requires top-notch spill containment solutions to protect your employees and the environment.

The all new drum spill containment pallets models, are designed to provide superior protection and efficiency in your workplace.

Here are the top reasons why these new pallets are the ideal choice for your spill containment needs:

1. High Sump Capacity for Maximum Protection

Swift’s Four Drum Spill Pallet features upto 525-liter sump capacity, making it the perfect solution for managing larger spills. The large sump ensures even in the event of heavy leaks; spills are contained and do not reach the floor, reducing slip hazards. On the other hand, the Two Drum Spill Pallet offers a reliable 200-liter sump capacity, providing effective containment for smaller spill management needs.

2. Built for Durability and Strength

Both the Drum Spill Containment Pallets are built from heavy-duty, long-lasting materials. These pallets are strong enough to carry dozens of drums at the same time without buckling or breaking under any conditions. If you have to keep chemicals, oils, and other hazardous liquids or even acid containers on these pallets, then there is certainly a peace of mind with their solid construction.

3. Compliance with Safety Standards

Our pallets ensure full compliance with EPA 40 CFR 264.175, SPCC, and NPDES regulations, making it easier for your business to meet all necessary safety standards. By choosing the Drum Containment Pallets, we can remain in compliance and prevent costly fines and dangerous spills that could harm nature.

4. User-Friendly Design for Easy Handling

With features like removable grates and a low-profile design, these pallets are not only easy to use but also easy to maintain. You can quickly load and unload drums using forklifts or manual lifting, while the grates simplify cleanup. Plus, the lightweight construction allows for seamless mobility and positioning within your workspace.

5. Versatile Solutions for Various Applications

These new drum spill containment pallets are ideal for many different industries. No matter if you would be using it in manufacturing, chemical handling these pallet specialization meets your spill containment needs. They are versatile drums, used in numerous different work environments due to their ability to accommodate a few drum sizes and configurations.

6. Cost-Effective Long-Term Investment

By choosing High quality Drum Spill Containment Pallets, you’re investing in a solution that saves money in the long run. These pallets help prevent spills that could lead to costly cleanups and equipment damage. This way, you reduce the probability of fines or legal problems.

In conclusion, All in all, Swift Technoplast introduces its new drum spill containment pallets the DSCP-SL2 for 200-liter capacities and the DSCP-SL4, which comes with a sump capacity of up to 525 liters, ensure complete protection while ensuring compliance throughout your business premises. Whether you need a compact solution or a high-capacity option, these pallets improve workplace safety and efficiency.

Don’t leave spill management to chance—upgrade to our all-new drum spill containment pallets today and safeguard your workspace, employees, and the environment.

#Spill Containment Pallet#Spill Pallets#Spillage Pallet#Drum pallet#Pallet Drum#pallet spill containment#Drum Spill Containment Pallets#Drum Spill Pallets

0 notes

Text

Swift introduces its new 4 Drum Spill Containment Pallet for Maximum hazardous Spill Prevention! Engineered to protect your workspace and the environment. . Swift Technoplast Private Limited www.swiftind.co.in +91 88888 25423 [email protected]

#swift technoplast#spill containment#Spill Pallets#Workplace Safety#Sustainability#Eco friendly#Plastic pallet#plastic pallets#plastic industry#plastic manufacturer#Drum Spill Containment Pallets#Drum Spill Pallets

0 notes