Don't wanna be here? Send us removal request.

Text

The Marvel of High - Precision Stainless - Steel Metal Washers

Hey there, Tumblr fam! Ever wondered about the unsung heroes of precision engineering? Let's talk about high - precision stainless - steel metal washers.

Our team dives deep into the world of micro - tolerances to create these little wonders. We start with the finest stainless - steel, a material renowned for its strength and resistance to rust and corrosion. But it's not just about the raw material; it's the process that makes our washers stand out.

Using state - of - the - art machinery and advanced machining techniques, we carve and shape each washer with an accuracy that's mind - blowing. These aren't your average washers you find in a hardware store. Our high - precision versions are designed for industries where even the slightest deviation can spell disaster, like aerospace, medical devices, and high - tech electronics.

Whether it's a washer for a delicate medical implant or a crucial component in a high - speed aircraft engine, we've got the skills and technology to deliver. So, the next time you see a complex machine working flawlessly, remember, there might just be one of our high - precision stainless - steel metal washers quietly doing its job, ensuring everything runs smoothly.

this Tumblr - style post capture the essence of what you want to convey about your washer processing? If you have any specific elements like a more personal touch or additional technical details, I can refine it further.

#cnc swiss#precision#machining#precision hardware products#precision machining#StainlessSteel#PrecisionMachining#MetalWashers

0 notes

Text

Precision Swiss Component Machining: Unrivaled Quality

In the world of manufacturing, Swiss component machining stands out for its unbeatable precision. Swiss craftsmanship, long renowned for its fine watches, has seamlessly transitioned into creating high - end industrial components.

Advanced CNC machines are at the heart of the process, enabling micron - level accuracy in cutting, milling, and drilling. Skilled artisans then add the final touches, using their expertise honed over generations. This blend of state - of - the - art technology and traditional know - how results in components of extraordinary quality.

Industries like aerospace, medical, and electronics rely heavily on Swiss - made parts. Rigorous quality control measures ensure every component meets the strictest standards. From raw material selection to the final inspection, no detail is overlooked. Whether it's a tiny part for a medical device or a crucial component for an aircraft, Swiss precision machining delivers reliability and performance. #SwissMachining #PrecisionComponents #ManufacturingExcellence

#cnc swiss#precision parts#precision machining manufacturer#non-standard custom processing#precision hardware processing#precision machining#precision#precision hardware products

0 notes

Text

🌟Unleash the wonder of high - precision precision castings! 🚀 These aren't ordinary metal parts. They're crafted with incredible finesse, using techniques like investment and die casting. The outcome? Components accurate to the micron level!

💥Imagine the intricate internal cavities and delicate thin walls these castings can achieve. They're not only a marvel of engineering but also a game - changer in various industries. In aerospace, they form vital turbine blades; in automotive, engine blocks are revolutionized; and in medicine, they're the key to life - saving implants.

📌If you're fascinated by cutting - edge manufacturing or seeking inspiration for your next project, this is it! Save this pin to explore more about these amazing high - precision castings and how they're reshaping our world.

0 notes

Text

Hey, Tumblr fam! 🤘 Ningbo YIYI crafts insane stainless - steel shafts and precision parts. Made with top - notch materials, they're corrosion - proof. Ultra - precise, ideal for auto & medical. Customize using our cool CAD/CAM tech. Let's connect and level up your projects! 💥 #PrecisionMachining #StainlessSteelParts

#precision machining manufacturer#shaft#cnc swiss#non-standard custom processing#precision hardware products#precision#machining

1 note

·

View note

Text

Hey there! At Ningbo YIYI, we're all about precision in high - end hardware. Our top - notch hardware parts and pipe metal joints are crafted using cutting - edge tech. Each item is engineered to be super accurate and incredibly durable. Whether it's for industrial machinery or complex piping systems, we've got the perfect solutions. Trust us for all your precision hardware needs. #HighPrecision #HardwareSolutions #IndustrialExcellence##fittings #connectors #turnedparts #precisionparts

www.yyprecision.com

#fittings#connectors#turnedparts#precisionparts#cnc swiss#precision#precision parts#precision machining manufacturer

0 notes

Text

Precision meets perfection with NingBo YIYI's high - precision hardware parts! 🛠️ Our parts are crafted to an astonishing tolerance of 0.05mm, setting a new standard in the industry. These aren't just ordinary components; they're the unsung heroes powering innovation across aerospace, electronics, and machinery. In aerospace, every detail matters. Our precision parts ensure aircraft engines run smoothly, withstanding extreme conditions. In the electronics world, they enable sleek, high - performing devices. Tiny yet mighty, they're the secret behind seamless data transfer in your smartphones. And for machinery, our parts mean longer - lasting equipment, reducing maintenance and downtime. But what makes our hardware parts truly stand out? It's the combination of top - notch materials and cutting - edge manufacturing techniques. They're tough as nails, fitting together flawlessly to enhance performance. Whether you're an industry pro or a DIY enthusiast looking to up your game, these parts are for you. Let's team up and bring your projects to life! 💪 Tag someone who could use a precision upgrade.

#HighPrecisionHardware#InnovationInMotion#engineeringexcellence#Customized machining#Swiss components#Stainless steel fittings

0 notes

Text

Hey Tumblr fam! 🎉 Get ready to be blown away by this precision - machined shaft that's taking the industrial world by storm! 🌪️

This isn't your average run - of - the - mill mechanical part. It's a testament to the marriage of art and engineering. Our team, fueled by an unquenchable passion for precision, has painstakingly crafted this beauty. We've sourced only the crème de la crème of materials, ensuring it can brave the toughest conditions, all while flaunting a sleek and rock - solid design. 💪

Thanks to the wizardry of state - of - the - art CNC machining, every curve, every measurement on this shaft is a masterpiece of micro - scale perfection. It's like a hidden gem, full of intricate details that are a wonder to explore. 🔍

Now, let your creativity soar! Imagine this shaft breathing new life into your classic car restoration project. Picture the engine roaring with new - found power and efficiency as this precision - engineered wonder works its magic. 🚗 Or, for all you DIY enthusiasts with a penchant for industrial - themed decor, this shaft could be the pièce de résistance that adds a super cool, modern - functional touch to your space. It's not just a component; it's a conversation starter! 🛠️

For businesses, this shaft is the secret weapon that can transform production lines. It's the game - changer that optimizes processes, slashes downtime, and gives a major boost to productivity. 📈

We know you're all about getting top - tier quality without emptying your wallet. And guess what? This precision - machined shaft offers the ultimate balance of high - end performance and affordability. It's a win - win! 💰

So, whether you're a DIY maven always on the hunt for the next big project or a business whiz looking to up your innovation game, this shaft is the upgrade you've been craving. Don't let this opportunity slip through your fingers! Let's embark on a journey of precision - engineered excellence together. 💫

#PrecisionMachining #stainless steel #shaft#shaft processingshaft

#Precision hardware processing#machining#precision hardware products#non-standard custom processing#shaft#stainless steel shaft#processingshaft

0 notes

Text

Stainless steel bushings have a wide range of applications. They are mainly used to reduce friction and wear between mechanical components, playing a role in protecting the main parts. They are also used to provide support and positioning in various equipment and machinery. In addition, they are often seen in pipelines to ensure sealing and connection stability. They are widely used in industries like automotive, machinery manufacturing and aerospace.

0 notes

Text

Hardware processing #High precision parts processing #Machining #Precision parts#

0 notes

Text

There are many types of parts and components that are widely used in many fields, and the following are some common parts:

### Automotive field - **Engine parts**: such as engine shaft parts, including crankshafts, camshafts, etc., the centering machine can process high-precision shaft journals, keyways and other structures to ensure the power transmission and valve timing of the engine; There is also a fuel injector needle valve, whose precise size and shape requirements, the centering machine can be realized through multi-axis linkage processing to ensure the accuracy of fuel injection. - **Transmission parts**: Like the gear shaft of the transmission, the centering machine can complete a variety of processes such as turning, milling, and drilling on a single bar stock, and process a gear shaft with complex structures such as gears and splines to improve transmission efficiency and stability; As well as the shift fork, the fork and mounting hole of the fork can be accurately processed to ensure the accuracy and reliability of the shift.

### Electronics - **Connector**: The pins of various electronic connectors, the centering machine can process the pins of different diameters, lengths and shapes, with smooth surface and high dimensional accuracy, to ensure good contact with the socket and electrical performance; There is also a USB interface shell, which can quickly process a shell with high-precision card slots and positioning holes to ensure the plugging life and stability of the interface. - **Electronic shaft parts**: such as micro motor shafts, the centering machine can process motor shafts with small diameter and high precision, which can meet the high-precision requirements of micro motors for rotating shafts, reduce friction and vibration, and improve the performance and life of the motor; There is also a focus axis in the camera module, which can realize precise turning and grinding processing, ensuring the accuracy and stability of focusing.

### Medical field - **Orthopedic implants**: such as intramedullary nails, the centering machine can process intramedullary nails with different pitches and thread shapes, with high surface finish and good biocompatibility, which is conducive to the fixation and healing of fracture sites; There is also a shank for artificial joints, which can be precisely machined to achieve ergonomic shapes and sizes, improving the stability and comfort of joints. - **Dental Instruments**: The transmission shaft of the dental handpiece, the centering machine can process the high-precision transmission shaft, ensure the speed and torque of the dental handpiece, and improve the efficiency and quality of medical operations; There are also root canal files, which produce root canal files with fine spiral grooves and cutting edges for pulp cleaning and shaping in root canal treatment.

### Other areas - **Watch parts**: such as watch shafts, spring shafts, etc., the centering machine can process small shaft parts with extremely high precision to ensure the accurate operation of the watch movement; There is also a strap attachment shaft for the case, which can be machined to create a smooth surface and precise dimension, making the connection between the strap and the case more firm and beautiful. - **Aerospace parts**: fuel nozzles for aircraft engines, the centering machine can process complex shape nozzle structures to ensure the atomization effect and combustion efficiency of fuel; There are also some shaft parts and connectors of the aircraft landing gear, which can ensure its strength and reliability through the precision machining of the centering machine, and meet the high requirements of aerospace.

0 notes

Text

Stainless steel pressed riveted nut

www.yyprecision.com

What is the main use of stainless steel riveted nuts?

Sheet joint

Precision equipment manufacturing

Furniture and decoration industry

Other fields

0 notes

Text

Stainless steel hub nuts mainly have the following uses:First, fix the wheel1. Secure the connection1. Stainless steel wheel hub nuts are used to firmly connect the wheel to the wheel hub of the car. In the process of vehicle driving, the wheel will be subjected to various forces from the ground, such as the vertical direction of the vehicle's own gravity, the horizontal direction of acceleration and braking generated inertial force, as well as the impact from the uneven road surface. The hub nut can withstand these forces, prevent the wheel from loosening or even falling off during the driving process, and ensure driving safety.2. Precise assembly1. They ensure precise assembly between the wheel and the hub. A suitable hub nut can make the wheel very upright on the hub, ensuring that the center of rotation of the wheel and the center of rotation of the hub exactly coincide. This can reduce the vibration and noise of the vehicle while driving, improve the comfort of the ride, and also help to extend the service life of related components such as tires and vehicle suspension system.Second, anti-corrosion1. Adapt to harsh environmentsStainless steel has corrosion resistance. In the daily use of vehicles, especially in humid, salty (such as driving on seaside roads) or in an environment polluted by chemical substances, common metal nuts are easy to rust. Stainless steel hub nuts can resist these corrosion factors and maintain their structural integrity and mechanical properties. This can not only prevent the disassembly difficulties caused by nut corrosion, but also avoid the safety risks caused by the loss of nut strength caused by corrosion.

0 notes

Text

Stainless steel pagoda connector

0 notes

Text

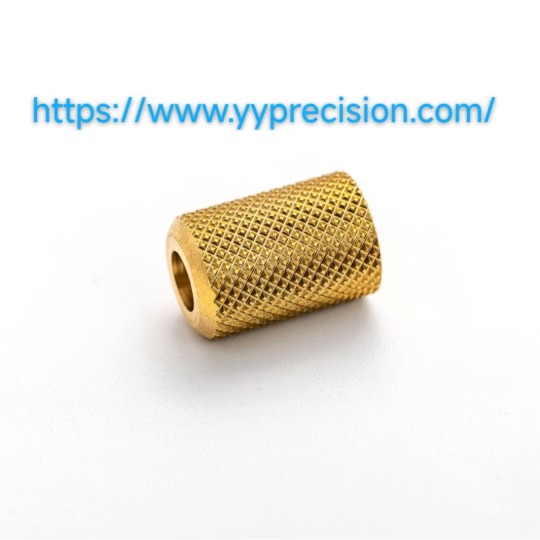

Fastening connection function:

In mechanical equipment: used to connect two or more mechanical parts to ensure the stable operation of the equipment. For example, in some small transmission devices, instruments and other equipment, circular knurled nuts can firmly connect different parts together, withstand a certain vibration and tension, and prevent parts from loosening or separation.

In the field of construction: It can be used to connect various components in the building structure, such as in steel structure buildings, round knurled nuts can be connected to steel beams, steel columns and other components to ensure the stability and safety of the building structure.

Easy to manually operate and adjust: The pattern on the surface of the knurled nut can increase the friction, and it is convenient for people to directly twist the nut by hand without the help of other tools, which is very practical in some occasions that need to be adjusted or disassembled frequently. For example, on some equipment that requires frequent adjustment of height or Angle, the use of circular knurled nuts can be easily adjusted manually.

For injection molding and embedding process: In the injection molding process of plastic products or other materials, the round knurled nut is pre-buried in the mold, and then the injection molding is carried out to make the nut and the plastic part tightly. This can form a strong threaded connection structure on the plastic products, which is convenient for subsequent assembly and use. For example, in the shell of electronic equipment, auto parts, toys and other plastic products, this kind of embedded round knurled nut is often used.

As a connector for thin plate connection: in the connection of some metal sheets, such as in the manufacture of chassis, cabinets, metal furniture, etc., round knurled nuts can be used with the pull riveting process. The nut is fixed on the thin plate by the rivet gun to realize the connection between the thin plate, which is both firm and beautiful, and can avoid welding or tapping operations on the thin plate, and reduce the damage to the thin plate.

In furniture manufacturing: used for the assembly and connection of furniture, such as the frame connecting tables and chairs, the panel fixing furniture, etc. The appearance of the knurled nut can be selected according to the design requirements of the furniture, which meets the functional requirements of the connection without affecting the aesthetics of the furniture.

0 notes

Text

Non-standard precision machining # stainless steel shaft machining # precision shaft machining # galvanized shaft# step shaft# turning parts #transmission shaft#automobile part#

#precision machining manufacturer#shaft#non-standard precision machining#stainless steel shaft machining

0 notes

Text

Hex plug/Carbon steel Hex plug /DIN 906 plug/Blackened oil plug/Electroplated oil plug/Electroplated blue zinc plug/Taper thread plug/Taper thread hex plug/carbon steel environmentally friendly zinc hex plug

DIN906 plug is a threaded pipe fitting used to plug the ports of pipes or other connectors. It is usually made of metal materials, such as stainless steel, carbon steel, etc.

DIN906 plug features include:

• Threaded connection: There are threads on the plug, which can be threaded with the corresponding specifications of the pipe or connector to ensure tight connection and prevent leakage.

• Blocking effect: Its main role is to block the pipe port to prevent liquid or gas leakage, but also to prevent dust, debris, etc., from entering the pipeline.

• Multiple specifications: DIN906 plugs are available in a variety of specifications to accommodate different diameters and thread sizes of pipe.

• Easy installation: The installation of the plug is relatively simple, just screw it into the pipe port.

When using DIN906 plug, the following points need to be noted:

• Select the right specifications and materials to ensure match and reliability with the pipe.

• Before installation, ensure that pipe ports are clean and free of debris and damage.

• Follow the correct installation method to avoid excessive tightening or damage to the thread.

• Check the status of the plug regularly, and replace it in time if it is damaged or leaked.

0 notes

Text

Forging hardware/metal processing/forging/metal forming/forging process/Straight plate bracket/laminate bracket

1. Simple structure: It is usually composed of a supporting part and a fixed device, and the design is simple.

2. Easy installation: Use screws or other simple fixing methods, easy to install on the wall or cabinet.

3. Moderate bearing capacity: can support a certain weight of the partition, to meet the needs of daily use.

4. Save space: the partition can increase the storage space in the vertical direction.

0 notes