#1055 High Carbon Steel

Text

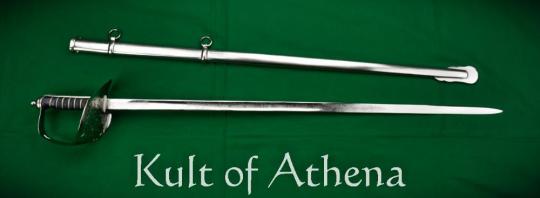

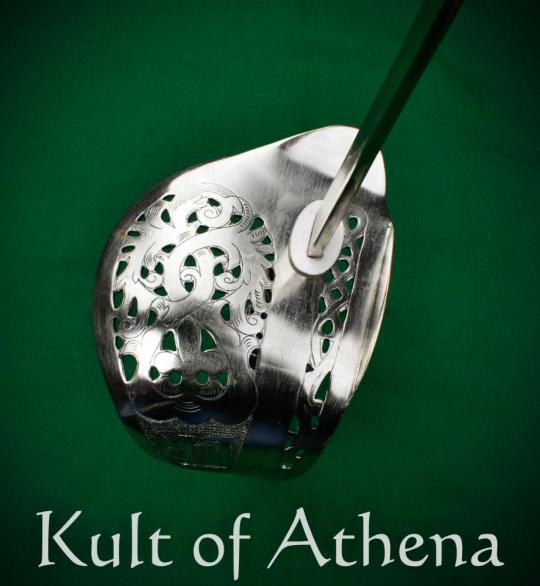

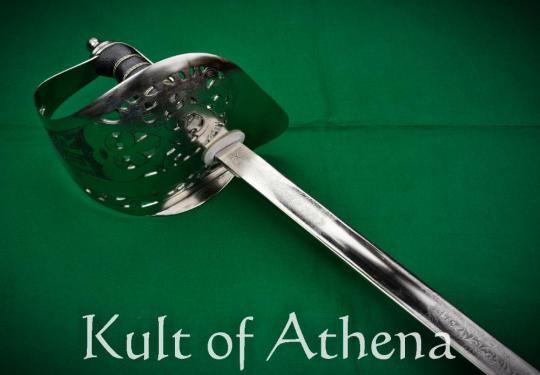

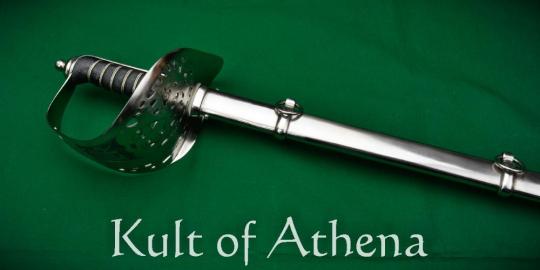

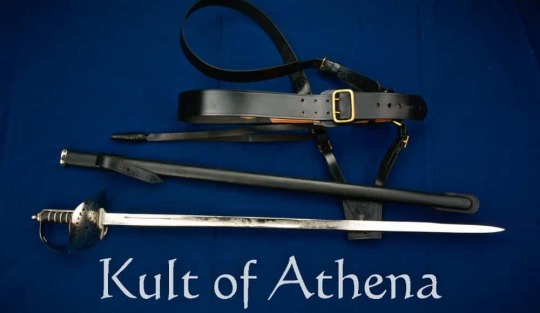

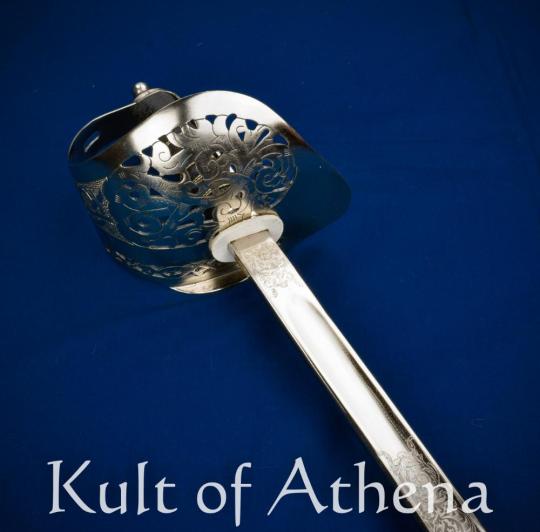

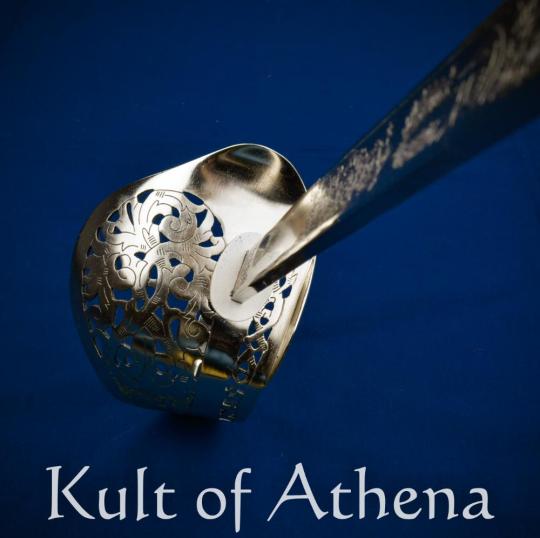

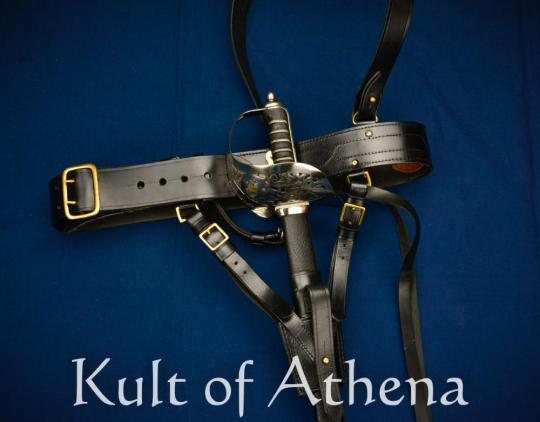

British 1897 Infantry Officer’s Saber with Steel Scabbard – Universal Swords

This reproduction of the British 1897 Infantry Officer’s Sword has a blade is forged from tempered 1055 high carbon steel and is lavishly embellished on both sides with etched filigree and royal military design. The hilt is crafted from steel and the grip is wood with a tight binding of faux rayskin which is overlaid with beautifully braided steel wire. The sword is paired with a scabbard of steel with steel hanging rings.

The 1897 British Infantry Officer’s Sword is still the current regulation issue sword of the British military and the sword has a long history of service from the late 19th century colonial conflicts and right throught the world wars.

#Kult of Athena#KultOfAthena#New Item Wednesday#Universal Swords#British 1897 Infantry Officer’s Saber with Steel Scabbard#British 1897 Infantry Officer’s Saber#sword#swords#weapon#weapons#blade#blades#Early Modern Swords#Early Modern Weapons#19th century#British Swords#British Weapons#1055 High Carbon Steel#Battle Ready#European Swords#European Weapons

4 notes

·

View notes

Text

I'm sure I forgot stuff but I tried to cover as much about her as possible.

Neon's Character Concept and Bio

Chaos Neon

Age: 18 (pre time skip)/20 (post time skip)

Height: 160cm

Blood Type: TBD

Birthday: 12/12

Affiliation: Straw Hats, Heart Pirates

Hair: Navy Blue, untamed curls/waves

Eye color: Red

Personality:

Growing up with Luffy, she actually has a very similar personality to him, though she has more brain cells and is willing to talk things out rather than fight all the time.

Trusting in an almost blinding fashion and devotion so strong she will put her needs last when her crew needs more attention.

Neon is as socially dumb as Luffy, but does have more common sense. She mostly doesn't understand things around romance, dating, and things of sexual nature besides what she experiences from Sanji and Brooks's preverted habits.

She is also very petty. The price will always be paid, just don't know when or how.

Out of the A.S.L. Neon is more like Sabo, where as Luffy and Ace are more similar. In disagreements it would be Neon & Sabo vs. Ace & Luffy or Ace & Sabo vs Luffy & Neon. It was a blue moon is any other combos happened.

Abilities:

Knife throwing+Accuracy

Neon has learned how to throw knives and works on her accuracy all the time. Yes, she can juggle the knives as well

Flexibility+Balance

Luffy likes to say Neon is part rubber from how flexible she is. She possesses double jointed and trained her body extensively all because as a child Ace and Sabo wanted to see how much she could fold her body in weird and odd ways. She liked the freak out it keeps practicing.

Neon also has amazing natural balance. I haven't figured out the full extend of this balance, but girl is a hard worker and keeps pushing her limits.

Haki

During the two year time skip, Neon learns and masters observation and armament haki.

Weapons:

Throwing Daggers:

Weight: 15.9oz Blade Thickness: 5mm Blade Length: 7-1/2" Blade Steel: 1050 High Carbon Handle Length/Material: 6-1/2" Overall Length: 14" Style: Knife Product Family: Thrower Steel Family: High Carbon Steels

Throwing Knives:

Weight: 6.4oz Blade Thickness: 3.5mm Blade Steel: 1055 Carbon Overall Length: 10" Style: Knife Product Family: Flight Sport Steel Family: High Carbon Steels

A leather whip

Concept History:

Neon originally started off as the Female Main Character for an original fiction work of mine called Neon Red Eyes. It was a Stardust-inspired fantasy world where Neon was the Hybrid Daughter of the terrible Demon King and a Powerful Witch. Her mother would eventually understand why the Demon King sought her out as the mother of his child and fled while heavily pregnant. 18 years later, Neon would come home to their little cabin to find her mother murdered and the King’s right hand waiting for her. She was tossed into the dungeon since emotional distress sealed away her powers the King was after. There, she would meet a Pirate Captain, who had been captured before her. His crew would pull off a heist and rescue their captain, bringing Neon along with them. It was mainly romance focused on Neon and the Captain, who would eventually take down the Demon King, but it never worked that part out.

When I finally caved and started One Piece, I took Neon and added her after making some changes that would make sense to the One Piece world. Having Magic and Demonic powers didn’t. Her being Buggy’s daughter was supposed to be funny and stuck. I wanted her to be Luffy’s childhood friend because that guy needs someone more consistently by his side. As I got further into the show, my inner simp was sad that I hadn’t found my favorite character. No one was tickling my fancy.

Then Trafalgar Law started to show up on my tiktok fyp, but he hadn’t appeared in show for me yet. I speed ran to Sabaody. Now my tiktok had been giving me Japanese dub Wano clips, nothing English dub. I watch dub because I multitask while watching my shows. I got to Sabaody, and I heard him speak. Matt Mercer. Sold. I found my favorite character and wanted to punch Kid in the face.

Now I won’t lie, Neon was meant for Luffy. Childhood friends to lovers cliché since I don’t do it often. But Trafalgar Law took over, Grumpy x Sunshine, Enemies to Lovers, it held more of my favorite troupes. The power dynamics and struggles. Her being bratty and him always wanting his plans to work out. I started my self indulgence dabbles that are now posted.

I do have a Luffy AU in my mind but to post both seems like too much work. There are differences but nothing huge. I could post all of pre-time arcs and then branch off after time skip but I’m not sure about posting both. I will write my Luffy AU dabbles and keep them for myself. Unless my sister and friends talk me into posting like they did with my Dabbles with Law.

Her last name being Chaos is super recent. I had brewed up a Crack AU where Della married Shanks during his year long stay in Windmill village, then stole Ace, Sabo and Luffy from Dadan and Garp wasn’t gonna fight Della.

I called it Chaos House AU, because of the chaos caused by the kids, yes, Uta would have stayed with them becoming Neon’s sister. So five chaotic children being raised by a pirate and a woman who thrives in chaos… the family name for Della and Neon being Chaos fit too well.

#one piece original character#one piece oc#one piece#original character#trafalgar d water law#trafalgar law x oc#trafalgar law#monkey d luffy x oc#monkey d. luffy#straw hats#buggy the clown#buggy one piece#buggy

4 notes

·

View notes

Photo

The wood hilt of this Roman dagger is paired with a fully tempered 1055 high carbon steel blade. Comes with a wood scabbard covered in leather with brass parts. Overall 19-1/4 inches.

2 notes

·

View notes

Photo

New Cold Steel Weeping Heart Tomahawk made with 1055 high carbon steel. After fulfilling pre-orders we only have TWO left in stock!! Be sure to order yours now at dragonImpact.com. #yyj #Victoria #tomahawk #throwingaxes (at Dragon Impact : Martial Art Equipment and Supplies) https://www.instagram.com/p/CBMNjKglXl5/?igshid=1c1cw3ij769fl

0 notes

Text

CS90TA-BRK Trail Boss- Garden Axe

New Post has been published on https://bit.ly/2qFWuhC

CS90TA-BRK Trail Boss- Garden Axe

CS90TA BRK Trail Boss Garden Axe

It is important in gardening, wood cutting, any purposes with high efficiency and performance

Construction: 1055 high carbon steel; Genuine Hickory handle. Light and compact, yet extremely tough. Extensively field tested. Bulk packed.

Why to choose this axe ?

Hawk Length: 6 1/2 – Inch

Handle: American Hickory

Overall Length: 26 – Inch

Steel: Drop Forged 1055 Carbon

Primary Edge: 4 1/2 – Inch

Weight: 2.70 lbs.

Drop Forged 1055 Carbon Steel

#CS90TA BRK#CS90TA BRK Trail Boss#CS90TA BRK Trail Boss amazon#CS90TA BRK Trail Boss garden axe#CS90TA BRK Trail Boss review#garden axe review#high quality garden axe#the best garden axe

0 notes

Text

Ranking the 10 Best Hatchets and Axes of 2018

A hatchet or axe is a strong, thick bladed, wood chopping tool. In a survival situation if you don’t have a chainsaw handy, your hatchet is going to be your best friend.

A vital part of any survival situation is fire, and you will not have fire if you don’t have something to burn. Even if you are gathering fallen branches instead of chopping down your tinder, you are still going to want to have a tool that can chop your wood down to size and clear up stray branches in order to control your flame.

Axes, hatchets, and tomahawks are excellent blades to have for any hiking, camping, or outdoor adventures. Be sure to check out our Buyer’s Guide if you want help deciding what tool would be best for you and for more information about the difference between an axe and hatchet.

1. Gransfors Bruk Small Forest Axe

Click here for the lowest price on Amazon

The Gransfors Bruk is the ultimate axe. You will not find a higher quality ax anywhere else. This camping ax is very traditional style from the Swedish company that is known for excellence and comes with a 20 year warranty.

With a 19 inch long handle and weighing 2 pounds, this ax is small enough to fit in your pack but still feels heavy-duty enough to finish any wood chopping project with ease. This axe comes razor sharp out of the box. It is expensive, but the traditional built quality and ‘you-get-what-you-pay-for’ saying really applies with this ax. If you are looking for high-end quality that won’t let you down, buy the Gransfors bruk!

2. Husqvarna 13” Wooden Hatchet

Click here for the lowest price on Amazon

This little hatchet is another solid choice that is high quality at a price that can’t be beat. The Husqvarna hatchet has a hickory handle which provides a more authentic look. The head is attached to the handle with a wooden wedge and a steel wedge to ensure it’s securely attached to give you the trust you need to get your job done.

This hatchet has a 13” long handle and is 15” long total, weighing about 2 pounds. The Husqvarna brand is based in Sweden and this hatchet is forged from high quality Swedish steel. It also comes with a leather edge cover for safety and to protect the edge.

3. Fiskars x7 Hatchet

Click here for the lowest price on Amazon

If you are looking for a great hatchet on a budget, Fiskars brand axes and hatchets will not disappoint. We love the X7 Hatchet as an option that gives the great strength and wood cutting power of an axe at a lighter weight than other options out there.

The Fiskars X-series is also more of a high-tech design with additional features that you won’t find with a wood handled traditional axe or hatchet. This axe has a fibercomp handle with a non-slip grip and a vibration absorbing chamber. All these features built in to the handle help make a powerful hatchet that is virtually unbreakable. This 14” hatchet even comes with a sheath and a lifetime warranty.

4. Estwing Sportsman’s Axe 14” Camping Hatchet

Click here for the lowest price on Amazon

This Estwing Camping Hatchet is a good quality tool that is proudly made in the USA. This hatchet is uniquely forged from one piece of 1055 high carbon steel. That provides a more durable hatchet.

The handle is uniquely wrapped in leather and hand sanded and leathered to provide comfort and support. The Hatchet is 14 inches overall and weighs 1 pound 12 ounces so it is a great size for carrying and camping. It also comes with a ballistic nylon sheath to keep the hatchets edge ready for use!

5. SOG 11.5” Hand Axe

Click here for the lowest price on Amazon

The SOG hand axe is smaller and easier to transport than other hatchets we’ve reviewed. At 11.5 inches long and weighing barely over 1 pound, it’s the perfect tool to carry in a bug out bag without noticing the extra weight.

The hatchet is perfectly designed for hammering and chopping and also has a more modern design with a glass reinforced nylon handle. It also comes with a protective sheath. SOG also includes a lifetime limited warranty to protect against defects.

6. Gerber Gator Combo Axe II

Click here for the lowest price on Amazon

The Gerber Gator Combo Axe II is a unique axe that includes a small coarse saw that stores inside the handle. This saw adds more options for use with brush and small branches. It may seem like a gimmick to have a hollow handled axe with a 10.24 inch long saw inside, but Gerber does a great job still providing high quality tools with this multipurpose axe.

The axe itself is 15.6 inches long and the glass filled nylon handle is very lightweight and durable, despite being hollow. The saw stays inside the handle with magnets so you don’t have to worry about it coming loose when chopping wood. The handle also has the Gator Grip signature handle to add more confidence with use. The head is made of forged steel and comes with a ballistic nylon sheath for blade protection.

7. Kershaw Camp Axe

Click here for the lowest price

The Kershaw Camp Axe has a drop forged high carbon steel to provide durability and prevent the axe head from breaking off the handle. It is only 11 inches long and weighs 14.5 ounces, making it easy to carry. The handle is made of a non-slip krayton to help provide a better grip. It also comes with a plastic sheath to protect the blade.

8. Schrade SCAXE 2 Stainless Steel Small Axe

Click here for the lowest price on Amazon

The Schrade SCAXE 2 is another great bug out bag option. It is 11.8 inches long with a glass fiber filled handle. The handle also is rubberized to provide added grip comfort and confidence. The head is 3Cr13 Titanium Coated Stainless Steel which is strong and durable.

As added weather protection, the axe comes with a thermoplastic sheath that can be worn on the belt. On the back of the head there is a hammer pommel, and inside the sheath there is a ferro rod for fire starting. The multipurpose features of this axe give you a lot of survival gear for your buck.

9. CS90TA-BRK Trail Boss

Click here for the lowest price on Amazon

If you are looking for a heavy duty full-sized axe, look no further than the Cold Steel Trail Boss. This axe is 26 inches long, with a beautiful American Hickory handle. The head is Drop Forged 1055 Carbon Steel and will help you split any wood with ease.

If storage space and weight isn’t a concern, this heavy duty axe will get the job done. It has good weight and balance and for the price, it is a solid choice in an axe. The only downside is it does not come with a sheath to protect the blade.

10. Gerber Bear Grylls Survival Hatchet

Click here for the lowest price on Amazon

For the price, the Gerber Bear Grylls Survival Hatchet is a great choice to have in your bug out bag. Weighing only 1.4 pounds, this hatchet is cleverly designed to be able to still put out a lot of force for its small size. The handle design helps, as it has a rubberized non-slip grip with a finger hold below the head to allow you to choke up your grip.

It also has a hole at the bottom of the handle for a lanyard for extra safety. The hatchet is full tanged with a high carbon steel head. The back of the head has a cross-hatched striking surface, perfect for hammering. The hatchet also comes with a military grade, mildew-resistant sheath that has loops to easily attach to a belt or pack. As an added bonus, it also comes with Bear Grylls’ “Priorities of Survival” pocket guide.

–

Buyer’s Guide

Although we have grouped Axes and Hatchets together, there are some differences in size and utility that are important to know when deciding what to purchase. Axes are generally bigger and longer than a hatchet. On average, a hatchet is about 12 inches long, while axes are over 22 inches long. Having that much longer of a tool gives much more leverage and force when swung. So Axes are the ideal tool for chopping wood.

However, the size means that axes are not always ideal in a camping or survival situation. If you are not worried about storage space, weight, and have some real logs to chop an axe is a great choice and will make any job you have much easier!

However, if you are looking for an ax that you can take with you camping or to carry in a bug out bag or survival situation you may appreciate the lightweight and smaller option of a hatchet. Having a tool that is easier to carry is also helpful in a self-defense situation. If you are looking for something to throw and use primarily for self-defense, but also do a little wood processing, be sure to check out our information on tactical tomahawks.

First, to understand what makes a quality axe or hatchet we need to look at the anatomy of an axe or a hatchet:

The Handle

Traditionally, the handle or shaft of the axe was made of wood-often hickory. The handle is what the head attaches to and what provides the force for the blade to chop when swung. The handle needs to be durable to withstand the forces being applied to it.

When selecting an axe with a wood handle, be sure to examine what direction the grain goes by looking at the bottom of the handle. The strongest wood will have a grain aligned in the same direction as the blade. If the grain is horizontal to the blade, the handle will not be able to withstand the force from the chopping and is much more likely to break.

Handles are also made of plastic, fiberglass, or metal to provide a strong alternative to the traditional wood handles.

The Head

The head of the axe or hatchet is what provides your chopping power. We usually prefer a carbon blade with a head made of forged steel. This will make the axe cheaper in price, while still providing the strong durable blade you want. Be wary of axes made entirely of stainless steel, it tends to not be as strong as carbon steel.

There are some important characteristics to look for when purchasing a high quality axe or hatchet:

Weight

The weight of the axe effects its chopping ability and ease of use. A heavier axe can chop through thicker pieces of wood, but is harder to swing and not as convenient to carry. However, be cautious of getting a tool that is so lightweight that you are doing all the work to chop anything.

It’s best to find a happy medium based off what you intend to use the axe for- go a little lighter if you want to be able to take it backpacking or store in a bug out bag, or look for something heavier if you want to do some serious wood chopping.

Balance

The balance of an axe refers more to how the tool feels when you swing it in the air. The more balanced the handle and head are, the better you will able to ensure that you can hit your target with each swing. Handles with a slightly curved design are easier to weild and help ensure that your swings are balanced and accurate.

Length

The length of the axe is going to determine how easily you can pack around or carry it. But the length also is going to determine how the axe is used- a shorter axe is generally used for quicker and smaller chopping needs around camp.The short handle makes it easier to do fast, accurate strikes. A longer axe can handle much harder tasks and greatly adds to your actual cutting strength when you need to chop logs and thicker wood.

Sharpness

The sharpness of an axe is important for the longevity of the tool. A brand-new axe is sharp out of the box, but how long the blade will hold its edge is going to be determined by the type of metal it is. Look for a high dense metal or steel. Also be aware that part of the maintenance of an axe is learning how to sharpen it.

Conclusion

Ultimately, you’re always going to be grateful having an axe or hatchet in addition to your knife in a survival situation. If you have the luxury or storage space such as your truck bed, having the heavier duty head and longer handle of an axe is going to make your shelter building, game processing, or fire building chores much easier.

If you want the convenience of being able to carry your wood processing tool in a bug out bag or possibly use in a self-defense situation, the lighter weight, compact hatchet will not let you down.

Via https://bestsurvival.org/best-hatchets-and-axes/

source http://bestsurvivalus.weebly.com/blog/ranking-the-10-best-hatchets-and-axes-of-2018

0 notes

Text

Ranking the Best 10 Machetes of 2018

The machete is the largest hunting tool and can be used as a crucial tool in many different survival, hunting, and outdoor situations.

The need for a long bladed knife to help cut down vegetation in survival situations has been an important tool for thousands of years. The name “machete” derives from Spanish and originated in South America when the need to clear vines and jungle brush was a necessity for survival.

However, this concept was developed in many areas around the world for survival, and has evolved into the varying blade styles of machetes that you can find currently on the market. For example, the Panga style is from East Africa, the Prang from Malaysia, the Barong from the Philippines, and the Indonesian Golok.

With all the different options out there for machetes, we have compiled our Top Ten Machete list to help you get the most chopping power for your money. Be sure to check out our Buyer’s Guide to learn more about the common characteristics of machetes and which style would be right for you!

1. CRKT Halfachance Parang Machete

Click here for the lowest price on Amazon

The CRKT Parang style machete is made of 65Mn Carbon Steel with a black powder coat for extra corrosion protection. The drop point blade is ideal for chopping whatever vegetation you may get yourself into. This machete also features an ergonomic handle with multiple lanyard holes for different hand holds to help ease fatigue. The machete also comes with a reinforced nylon sheath that allows you to carry the blade snug against your belt or dangling down, depending on your preference.

2. Gerber Gator Machete

Click here for the lowest price on Amazon

Gerber has created a machete that is the most budget friendly option we reviewed. This machete is 25” overall, with a multi-purpose 15” fine edge blade on one side and an 18” high performance saw blade on the other. The blade is high carbon stainless steel with a gator grip handle. This comfortable rubberized texture is designed to give added security and safety, even when wet. The machete also comes with a black 400 denier nylon sheath.

3. Cold Steel Barong Machete

Click here for the lowest price on Amazon

Don’t let the low price scare you, the Cold Steel Barong Machete is a great all-purpose durable machete. It is based off the Filipino Barong style machetes. It features the classic leaf-shaped blade traditionally used in agriculture and warfare.

The Barong is used in Filipino martial arts and is capable of creating deep cuts. This blade is 18” long, with an overall length of 24.5”. It is made of 1055 carbon steel with a black matte finish that is baked on to provide additional rust protection. The handle is curved to help it easier form to your hand and stay there during use, and is made of polypropylene. This machete also comes with a sheath made of Cor-Ex for safety and convenience.

4. Condor Golok Machete

Click here for the lowest price on Amazon

The Condor Golok Machete is 19” long with a 14” blade. Although slightly on the smaller side, it’s lightweight blade makes it easier to wield with control. It is made of heavy duty 1075 high carbon steel and has a black powder epoxy finish for added rust protection and durability.

It also has a walnut handle which gives it more of an authentic look. This machete also comes with a 100% leather sheath as an added bonus to make it that much easier to carry.

5. Ka-Bar Kukri Machete

Click here for the lowest price on Amazon

The Ka-Bar Kukri machete is based off the traditional Kukri style from Nepal. This blade is 11.5” long, 17” total and weighs 1.7 pounds. The black 1085 carbon steel blade is durable and weighted to provide excellent chopping power in a smaller sized machete. Although it cannot clear as much at once, the compact machete is great at clearing brush and vegetation.

It has a Kraton thermoplastic elastomer handle that is ergonomically designed with a non-slip grip. This machete also comes with a sheath made of a combination of black leather and cordura.

6. Cold Steel Latin Machete

Click here for the lowest price on Amazon

This Latin-style machete from Cold Steel is a long 24” blade (29” overall), ideal for clearing large areas. The blade is made of 1055 Carbon Steel with a black matte anti-rust finish. It also features a non-slip polypropylene handle.

This straightback blade has even weight distribution and is excellent for vegetation, also known as a Bush machete. Although this machete does not come with a sheath, the low price point makes it a great value for this bushwacking machine.

7. Ontario SP8 Machete

Click here for the lowest price on Amazon

The Ontario Knife Company has designed a great all-purpose survival blade with their SP8. It has a 1095 black epoxy high carbon steel blade that is 10” long, making it compact and easier to handle. The wedge style tip and sawtooth back make this lightweight machete very versatile. It comes with a fitted nylon sheath and Kraton handle for added comfort and accessibility.

8. Condor Parang Machete

Click here for the lowest price on Amazon

Another Parang style machete from Condor Knife & Tool, this blade is 17.5” of 1075 high carbon steel with a black epoxy powder coating. This machete has more of a traditional look compared to the CRKT Parang style that we reviewed, with a more traditional Parang handle design made of hardwood. This drop point blade comes with a heavy duty black leather sheath.

9. Ka-Bar Grass Machete

Click here for the lowest price on Amazon

This machete is a 14” straight back blade made of 1085 high carbon plain tool steel, and is 19.5” overall. This blade is heavier than most other compact machetes as it is ¼” thick, but this creates a machete that is strong and able to chop thicker vegetation. It is advertised with use in all branches of the military. The handle is designed for comfort and made from black kraton g. As a bonus, it also comes with a heavy duty cordura sheath.

10. Cold Steel All Terrain Chopper

Click here for the lowest price on Amazon

This All Terrain Chopper from Cold Steel is a 21.5” blade capable of clearing pretty thick vegetation. At 30.5” overall, this machete is made of 1055 high carbon steel with a baked on black anti-rust finish. The polypropylene handle brings added comfort to your chopping, and this long blade is capable of clearing a variety of vegetation with one motion. It comes with a black cor-ex sheath and lanyard hole for added carrying convenience.

–

Buyer’s Guide

There are several key factors to look for when deciding what machete would be best for your personal use. We’ve narrowed it down to the 4 most important characteristics: Blade Style, Blade Length, Blade Thickness, and Blade Material.

Blade Style

Throughout history, many different cultures created their version of a blade to help in agriculture and survival. Those ancient blade styles have unique characteristics based off the needs of the region they were developed in. In our day, they have all been classified as “machetes” but still provide some of the same benefits of the original design. Ultimately, these styles are based off the tradition of their origin and which style you choose depends greatly on personal preference and what you will use your machete for!

Machetes are generally divided into two main styles, either the lightweight, thin, long blade designs for cutting down soft vegetation, or a thick, heavier, short blade better for chopping wood.

For example, the Panga style was developed in East Africa and the Caribbean. These blades are designed to have all the weight towards the front, which allows the blade to more easily chop woody plants and trees. They also have an extreme point at the front for incisions.

The Barong style comes from the Philippines and has more of the weight of the blade in the middle. These leaf-shaped blades provide more control when swung and was traditionally used in hunting and slaughtering animals.

The Kukri style is found in Nepal. This machete type is more of an all-purpose blade with 3 different sections. The pointed tip for stabbing, the wide blade for chopping which then narrows as it goes into the handle creating a blade good for whittling and carving.

Parang style machetes are also called Golok machetes and came from Indonesia. They have a curved blade much like a scimitar, with the curve on both the spine and the edge. With a thicker blade, this style is great for chopping woody vegetation.

Latin-style machetes originated in Latin America. These blades have a popular straightback blade which creates a more even weight distribution and can easily be sheathed. This style is also referred to as Bush machetes, and is great for cutting down loose vegetation and makes an excellent all-purpose blade.

Bowie machetes were developed in the United States and are named after American Frontiersman Jim Bowie. These blades are characterized by a clip point ideal for skinning animals. This style has become popular among survivalists and hunters.

Weighted/ Heavy style machetes are the best choice for chopping woody or thick vegetation. This blade is weighted toward the top to create its immense chopping power. It is characterized by a dull tip and a flat cutting edge geared towards chopping instead of slicing. This machete is a strong cross between an axe and a knife.

Ultimately, the style of machete you choose should be based off of the tasks you will be doing with your blade.

Blade Length

Machetes vary greatly in size, usually ranging from as small as 10” to longer than 28”. The smaller the blade, the less it will weigh. A shorter blade is easier to control and also easier to wear. A longer blade creates more momentum when swung and can clear a larger area with one swing. However, a long blade creates more of a hassle to transport. The average machete length is around 18”.

Blade Thickness

The thickness of the machete blade can determine its durability and what type of vegetation or wood you can successfully chop. Most blades are around ⅛” thick. This provides a very thin blade that is easy to maneuver and is ideal for chopping through brush and jungle-like vegetation. However, because the blade is so thin if you try to chop something too thick and strong you run the risk of damaging your blade.

There are machetes that are closer to the ¼” thickness. These blades will be much stronger and can more easily chop woody vines and tree branches. However, the thicker blade means a heavier machete which is more difficult to wield.

Blade Material

Another thing to keep in mind is blade material. Most blades are either made of stainless steel or carbon steel. Carbon steel is more commonly found in machete blades and is an alloy of carbon and iron. The addition of carbon helps make the iron stronger and the blade will stay sharper for a longer period of time. However, because the carbon steel is so strong, it is harder to re-sharpen. Carbon steel is cheaper than stainless steel, but it also can rust and needs to be oiled regularly to prevent moisture from rusting the blade. Because carbon steel is less expensive and stronger, it is most often found in survival and agricultural blades.

Stainless steel is actually carbon steel with nickel and chromium added in. These additional metals create a protective barrier and prevent the steel from rusting. Stainless steel generally requires less maintenance since it is naturally rust-resistant. It is also a softer metal which means it doesn’t hold its edge as well and needs to be sharpened more frequently, however it is easier to sharpen than carbon steel. Stainless steel is more expensive than carbon steel and is usually found in more decorative blades.

To combine the best characteristics of both carbon steel and stainless steel, high-carbon stainless steel has been developed. Blades made of this material have the benefits of a strong metal that holds its edge longer, combined with the rust-resistant benefits of stainless steel. Blades made of high-carbon stainless steel are more expensive, but are a great option for survival purposes.

Conclusion

A machete is a long blade that is ideal for survival situations. It’s no wonder that so many different cultures in completely different regions around the world all developed some version of a “machete” to better help their people to chop vegetation and better cultivate their region in which they lived. These blades have served their purpose for thousands of years, and are a great blade for the modern-day survivalist.

source https://bestsurvival.org/best-machetes/

0 notes

Photo

Cold Steel Tactical Tanto Machete 19-3/8" Length, Black, 13"

https://huntinggearsuperstore.com/product/cold-steel-tactical-tanto-machete-19-38-length-black-13/

13 inch wide curved tanto point blade Solid steel tsuba made from heat treated 1055 high carbon steel with baked on anti-rust coating Full tangs are injection over-molded with high impact Polypropylene

0 notes

Text

BAREBONES PULASKI AXE

Barebones have introduced the beautiful Pulaski Axe. Inspired by tools used by woodland firefighters, the tool features a head made from 1055 high carbon steel, which combines an axe and an adze. Inside the Beech wood handle runs a solid steel core that secures the head with a tightening hex bolt and connects it to the steel pommel end. This helps you maneuver easily around rooting and trenching. The Pulaski also comes with a leather sheath.

Learn more from Barebones or grab one from Amazon

0 notes

Text

✨British 1897 Infantry Officer’s Saber with Brown Leather Wood Core Scabbard – Universal Swords✨

#Universal Swords#British 1897 Infantry Officer’s Saber with Brown Leather Wood Core Scabbard#British 1897 Infantry Officer’s Saber#sword#swords#weapon#weapons#blade#blades#Early Modern Swords#Early Modern Weapons#19th century#British Swords#British Weapons#1055 High Carbon Steel#Battle Ready#European Swords#European Weapons

5 notes

·

View notes

Text

Guide to Sword Steel – Everything You Didn’t Know You Needed to Know

When it comes to picking a sword, it’s not uncommon to hear the question “What is the best sort of sword steel”. This type of the question is not easily answered, the best sort of steel depends largely on what the sword will be used for and what budget the buyer has. For example, someone that is looking purely for a decorative display piece will likely want a steel that remains shiny with very little maintenance. A stainless steel sword will probably meet this buyers requirements, the sword will remain bright and polished for years, however the sword will be useful for very little else apart from hanging on the wall. If on the other hand the shopper would like a real battle ready sword, one which is capable of taking and retaining a cutting edge, then the choice of steel is a little harder. Additionally, we may need to consider sword tempering and forging methods. We’ll go into more depth in the article below.

Sword Tempering

A sword begins its life as a billet of steel, this billet is heated and roughly formed into a sword like shape. This process may take a couple of hours, or a couple of dozen hours, largely depending on the size and type of sword required. Once the sword has been shaped into its final form, the sword will most often go under a procedure called tempering. Tempering is a key aspect of producing a functional sword, the steps involved are quite technical in nature and have a significant impact on the swords capabilities. Essentially tempering involves heating the sword to pre-defined temperatures, the sword is then rapidly cooled in oil or water (but not too rapidly). The tempering process is key to producing a hardened and tough blade. However, if the sword is cooled too quickly then the sword may end up being brittle or cracking. Many thousands of swords have met an untimely end during the tempering process. Sword tempering will have one of the biggest effects on the final swords capabilities, sometimes more than the type of steel chosen.

Most swords are either mono hardened or differentially hardened. In a mono hardened sword, the whole sword is heated to the same uniform temperature and cooled at the same rate. In a differentially hardened sword, clay or other similar pastes are added to the blade in order to insulate part of the sword from the heating and cooling process. When this occurs the clay covered part will cool at a slower pace compared to the exposed part of the blade, this works to increase the hardness of the exposed blade while allowing the covered portion to remain flexible. The differential hardening process is very common in Japanese swords such as a Samurai Sword, creating the distinctive Hamon line. A Hamon line is the separation between the hard cutting edge and the softer flexible spine. A flexible spine allows the sword to absorb impacts which would otherwise dent or crack the sword.

Mono tempered swords are typically marketed at beginners, they are able to take more abuse and are less likely to chip or become permanently misshapen. Despite the association with beginners, there are a lot of good arguments for buying a mono tempered sword over a traditional differentially tempered variety. Most of the swords originating from medieval Europe where forged using mono tempering methods, which was better suited to the slashing blows against armour and shields, the mono temper is better suited to taking punishment without chipping or breaking.

If you’re experienced using a sword for cutting, then you may wish to consider a differentially tempered. These swords typically have a harder cutting edge, but you’ll need to be wary of form and technique, a misguided sword stroke may lead to the blade being chipped or irrevocably damaged.

Most experienced sword makers today are well versed in the art of sword tempering, so there’s little concern around receiving a cracked or chipped sword, simply choose the tempering you’d like.

Sword Steel Guide

Now that we’ve managed to cover tempering and what the means for your sword, we can move onto the types of sword steel that are available. Picking a steel for your sword is only really important if you’re looking to have a battle ready sword. If you’re only looking for a display sword then you’re probably better of getting a sword made from stainless steel, they are cheaper to buy and require very little maintenance, they are however not recommended for any substantial cutting. I’m not trying to imply that all stainless steel swords are terrible for cutting, but I wouldn’t expect to slice through 3 inches of bamboo with one either.

So what about carbon steel? Carbon steel is the go to sword steel for battle ready swords, at the lower end of the scale we start at 1045 carbon steel. The number assigned to the carbon steel describes the carbon content of the metal. For example, 1045 is classed as medium carbon content and will contain 0.45% carbon. Continuing with the naming convention, 1060 carbon steel has 0.60% carbon content and so on. Most carbon steel swords you’ll find for sale are 1045, 1060 or 1095. Some sword smiths are embracing newer types of steel for use in swords such as 9260 and other types of spring steel, these have added silicon which increases the blades toughness. This naming convention is very similar to the carbon steel, the key difference is that the first two numbers have been changed. The 92 in 9260 signifies that Silicon Manganese has been incorporated into the steel. The chart below shows all the different sorts of steel that are available, not all are used in sword making.

10XX

Carbon steels

Plain carbon, Mn 1.00% max

11XX

Resulfurized free machining

12XX

Resulfurized / rephosphorized free machining

15XX

Plain carbon, Mn 1.00-1.65%

13XX

Manganese steel

Mn 1.75%

23XX

Nickel steels

Ni 3.50%

25XX

Ni 5.00%

31XX

Nickel-chromium steels

Ni 1.25%, Cr 0.65-0.80%

32XX

Ni 1.75%, Cr 1.07%

33XX

Ni 3.50%, Cr 1.50-1.57%

34XX

Ni 3.00%, Cr 0.77%

40XX

Molybdenum steels

Mo 0.20-0.25%

44XX

Mo 0.40-0.52%

41XX

Chromium-molybdenum steels

Cr 0.50-0.95%, Mo 0.12-0.30%

43XX

Nickel-chromium-molybdenum steels

Ni 1.82%, Cr 0.50-0.80%, Mo 0.25%

47XX

Ni 1.05%, Cr 0.45%, Mo 0.20-0.35%

46XX

Nickel-molybdenum steels

Ni 0.85-1.82%, Mo 0.20-0.25%

48XX

Ni 3.50%, Mo 0.25%

50XX

Chromium steels

Cr 0.27-0.65%

51XX

Cr 0.80-1.05%

50XXX

Cr 0.50%, C 1.00% min

51XXX

Cr 1.02%, C 1.00% min

52XXX

Cr 1.45%, C 1.00% min

61XX

Chromium-vanadium steels

Cr 0.60-0.95%, V 0.10-0.15%

72XX

Tungsten-chromium steels

W 1.75%, Cr 0.75%

81XX

Nickel-chromium-molybdenum steels

Ni .30%, Cr 0.40%, Mo 0.12%

86XX

Ni .55%, Cr 0.50%, Mo 0.20%

87XX

Ni .55%, Cr 0.50%, Mo 0.25%

88XX

Ni .55%, Cr 0.50%, Mo 0.35%

92XX

Silicon-manganese steels

Si 1.40-2.00%, Mn 0.65-0.85%, Cr 0-0.65%

93XX

Nickel-chromium-molybdenum steels

Ni 3.25%, Cr 1.20%, Mo 0.12%

94XX

Ni 0.45%, Cr 0.40%, Mo 0.12%

97XX

Ni 0.55%, Cr 0.20%, Mo 0.20%

98XX

Ni 1.00%, Cr 0.80%, Mo 0.25%

In this chart the first 2 numbers describe the type of steel and the last two numbers signify the carbon content. It’s easy to be confused by all the options available. To simplify matters, most of the sword we’ll be interested in are made from either 1045, 1060 or 1095 carbon steel, with a couple of exceptions thrown in. In the rest of the article we’ll cover the most commonly used sword steels available today and what properties they impart to the sword.

Types of Sword Steel

1045 Carbon Steel

1045 carbon steel has a carbon content of 0.45%, while a steel such as 1095 has 0.95% carbon content, contrariwise 1045 has more manganese content than 1095. This means that 1095 carbon steel is harder and better able to resist wear and tear, but it’s also less tough. 1045 is capable of taking an edge, but 1095 is easier to sharpen and the edge will last longer. If you’re a beginner, you might want to pick a 1045 carbon steel sword, they are better suited to taking abuse and are most often the cheapest battle ready sword available.

1050-1055 Carbon Steel

1050 carbon steel is a robust and resilient medium-high carbon steel. It has a carbon content of 0.50% and is good choice for anyone looking for a tough tool such an axe, hatchet or sword.

1055 carbon steel is right on the dividing line between steel classed as medium carbon content and steel classed as high carbon content. Typically 1055 carbon steel will have a manganese content between 0.60% and 0.90%. These factors contribute to any sword made from 1055 steel being incredibly tough and durable. When a 1055 sword is expertly tempered, it produces a crystalline structure which is free from excess carbides, in turn this avoids the brittleness which is common with high carbon materials. 1055 steel is very well suited to applications where impact resilience and outstanding toughness are highly desirable. This steel is capable of producing blades which are incredibly resilient to damage.

1060-1065 Carbon Steel

1060 and 1065 carbon steel is a fairly common steel used in battle ready swords. The carbon content is between 0.60% and 0.65%, with manganese being the only other addition. This sort of carbon steel is very tough and is able to take and retain an edge very well.

1065 is an ideal steel for differential hardening, often producing a visible temper line on the finished sword. Of course any hardening that takes place will also reduce the impact resilience of the finished piece.

1075 Carbon Steel

1075 carbon steel would be considered high carbon content steel. 1075 steel is excellent at taking and retaining an edge, the blade is very tough and is very resilient. The steel is very well suited for swords, axes, machetes, knives or any other sort of blade which requires a sharp edge and is subject to significant usage.

1095 Carbon Steel

1095 carbon steel is a standard production carbon steel, the steel is characterised by it’s low resistance to corrosion and it’s medium edge retention. A sword made from 1095 carbon steel is very easy to sharpen to a razor sharp long lasting edge. When this steel is expertly tempered, the sword is has amazing properties, no other steel can compare when expertly sharpened. We do not recommend this sword to beginners as it needs to be cared for correctly to avoid rusting and can be damaged if not used with proper technique and methods. In the correct hands a battle ready 1095 steel katana is incomparable.

65Mn Steel

65Mn steel is a widely used and available Chinese steel that was created in order to provide good hardness and increased wear resistance. The carbon content of this steel is classed as medium, allowing for a high degree of toughness and resistance. 65Mn steel also contains manganese which also improves the swords hot working characteristics, meaning it’s easy to forge into sword blades, knives and any other tool which sees significant impacts.

1566 Spring Steel

1566 Spring Steel is a high-carbon and manganese content steel. The steel is very well suited to differential hardening tempering processes. The hardened steel is characterised by a consistent crystalline microstructure which ensures a resilience and long life for any demanding tools that require an edge.

T-10 Steel

T-10 steel is the Chinese created equivalent of the western 1095 steel, but with a crucial difference which sees silicon being added to the alloy mix in order to improve the overall strength of the steel and additionally to increase its wear resistance. T-10 steel swords take to tempering very well, producing a sword which takes and retains an edge. In the same vain as 1095 steel, T-10 steel has low resistance to corrosion, therefore must be carefully looked after in order to avoid rust.

5160 Spring Steel

5160 is a very high end steel which is increasingly popular with sword forgers. The steel is a fairly generic spring steel with the added benefit of chromium, the additional of chromium works to harden the metal. 5160 steel is well renowned for its edge holding capabilities, but it’s even better known for its extreme toughness. The steel is often used in swords or knives and tomahawks.

440 Stainless Steel

440 stainless steel is a form of high grade cutlery steel, which typically has a higher carbon content, allowing for the steel to better take and retain an edge. When 440 steel has been correctly heat treated in can become one of the hardest stainless steels available. Due to its relative cheap price and hardness, most display only pieces and replica swords you’ll encounter will likely be made from 440 stainless steel. 440 is commonly available in four distinct grades:

440A contains the least amount of carbon and is the most corrosion and stain resistant.

440B contains slightly more carbon and is slightly harder but also slightly less stain resistant.

440C has the largest amount of carbon content out of the 440 grades, it’s the strongest 440 steel and is the most desirable type for swords or knives. The exception to this is knives that are designed for use by divers, these will invariably be made from 440A steel.

440F is a free machining variant of 440 steel and it contains the same carbon content as 440C

3CR13 Steel

3CR13 Steel is most commonly used for knives and is a form of Chinese stainless steel. It is similar in many respects to 420J2 (AUS 4) stainless steel..

L6 Bainite Steel

L6 steel is a brilliant steel which is suitable for many applications, it’s equally practical for knives as well as swords. When used in a sword, L6 steel will likely be heat treated until a Bainite microstructure is formed, this process is complicated and expensive to perform. The steel is very popular in for use when forging Japanese Katana and its influence is spreading to other forgers creating non-Japanese swords. As the process spreads we’ll likely see efficiencies in formation of Bainite, leading to a reduction in the cost and the swords will likely see mass market distribution.

It relatively uncommon to see L6 used in production knives or swords, the steel is very difficult to work with and as such it’s really only found in custom pieces or high priced items.

Damascus Steel

Damascus steel swords are highly desirable due to their inherit beauty and practical application. Modern Damascus swords are formed from special types of billet steel. The billet steel is made up from several types of layers of steel and iron welded together, which is what creates the unique pattern present in Damascus steel.

Folded Steel

Folded steel swords are fascinating for their aesthetic attractiveness and their traditional heritage. One of the best known aspects of the Japanese traditional sword forging process involves folding the steel, the process involves repeatedly folding and hammering out the steel billet. Traditionally the process was performed in order to even out the carbon content of the steel throughout the sword, now the process is mostly performed due to aesthetics and to adhere to traditional techniques. The process is heavily referenced in much of Japanese popular culture is not synonymous with Japanese sword forging.

K120C Powder Steel

ASSAB K120C powder steel is made in Japan under a license agreement from SSAB of Sweden. The steel is typically considered to be similar to 1095 carbon steel.

Aluminium Swords

Most swords produced in Japan are not made of steel as you would expect, in fact they are invariably made from aluminium alloys. The overriding reason for this is the cost of a true Japanese sword is far in excess of what most people can afford. Japanese sword laws are incredibly strict and forges can make a maximum of two swords a month, which pushes the price up to a significant amount. This forces most martial artist practitioners to opt for a aluminium sword. Aluminium is significantly cheaper than a steel sword, but it also cannot be sharpened and doesn’t have the same heft as a real steel katana.

from Bladespro.co.uk - Blog https://www.bladespro.co.uk/blogs/news/guide-to-sword-steel-everything-you-didn-t-know-you-needed-to-know

from BladesPro https://bladesproco.tumblr.com/post/163227841412

0 notes

Link

Cold Steel is attributed with promoting the tanto blade in America; tanto blades are durable and give the drawer with remarkable stamina in lethal scenarios. The swords are built mainly of the most robust Damascus steel and 1055 high carbon steel.

0 notes

Text

Guide to Sword Steel – Everything You Didn’t Know You Needed to Know

When it comes to picking a sword, it’s not uncommon to hear the question “What is the best sort of sword steel”. This type of the question is not easily answered, the best sort of steel depends largely on what the sword will be used for and what budget the buyer has. For example, someone that is looking purely for a decorative display piece will likely want a steel that remains shiny with very little maintenance. A stainless steel sword will probably meet this buyers requirements, the sword will remain bright and polished for years, however the sword will be useful for very little else apart from hanging on the wall. If on the other hand the shopper would like a real battle ready sword, one which is capable of taking and retaining a cutting edge, then the choice of steel is a little harder. Additionally, we may need to consider sword tempering and forging methods. We’ll go into more depth in the article below.

Sword Tempering

A sword begins its life as a billet of steel, this billet is heated and roughly formed into a sword like shape. This process may take a couple of hours, or a couple of dozen hours, largely depending on the size and type of sword required. Once the sword has been shaped into its final form, the sword will most often go under a procedure called tempering. Tempering is a key aspect of producing a functional sword, the steps involved are quite technical in nature and have a significant impact on the swords capabilities. Essentially tempering involves heating the sword to pre-defined temperatures, the sword is then rapidly cooled in oil or water (but not too rapidly). The tempering process is key to producing a hardened and tough blade. However, if the sword is cooled too quickly then the sword may end up being brittle or cracking. Many thousands of swords have met an untimely end during the tempering process. Sword tempering will have one of the biggest effects on the final swords capabilities, sometimes more than the type of steel chosen.

Most swords are either mono hardened or differentially hardened. In a mono hardened sword, the whole sword is heated to the same uniform temperature and cooled at the same rate. In a differentially hardened sword, clay or other similar pastes are added to the blade in order to insulate part of the sword from the heating and cooling process. When this occurs the clay covered part will cool at a slower pace compared to the exposed part of the blade, this works to increase the hardness of the exposed blade while allowing the covered portion to remain flexible. The differential hardening process is very common in Japanese swords such as a Samurai Sword, creating the distinctive Hamon line. A Hamon line is the separation between the hard cutting edge and the softer flexible spine. A flexible spine allows the sword to absorb impacts which would otherwise dent or crack the sword.

Mono tempered swords are typically marketed at beginners, they are able to take more abuse and are less likely to chip or become permanently misshapen. Despite the association with beginners, there are a lot of good arguments for buying a mono tempered sword over a traditional differentially tempered variety. Most of the swords originating from medieval Europe where forged using mono tempering methods, which was better suited to the slashing blows against armour and shields, the mono temper is better suited to taking punishment without chipping or breaking.

If you’re experienced using a sword for cutting, then you may wish to consider a differentially tempered. These swords typically have a harder cutting edge, but you’ll need to be wary of form and technique, a misguided sword stroke may lead to the blade being chipped or irrevocably damaged.

Most experienced sword makers today are well versed in the art of sword tempering, so there’s little concern around receiving a cracked or chipped sword, simply choose the tempering you’d like.

Sword Steel Guide

Now that we’ve managed to cover tempering and what the means for your sword, we can move onto the types of sword steel that are available. Picking a steel for your sword is only really important if you’re looking to have a battle ready sword. If you’re only looking for a display sword then you’re probably better of getting a sword made from stainless steel, they are cheaper to buy and require very little maintenance, they are however not recommended for any substantial cutting. I’m not trying to imply that all stainless steel swords are terrible for cutting, but I wouldn’t expect to slice through 3 inches of bamboo with one either.

So what about carbon steel? Carbon steel is the go to sword steel for battle ready swords, at the lower end of the scale we start at 1045 carbon steel. The number assigned to the carbon steel describes the carbon content of the metal. For example, 1045 is classed as medium carbon content and will contain 0.45% carbon. Continuing with the naming convention, 1060 carbon steel has 0.60% carbon content and so on. Most carbon steel swords you’ll find for sale are 1045, 1060 or 1095. Some sword smiths are embracing newer types of steel for use in swords such as 9260 and other types of spring steel, these have added silicon which increases the blades toughness. This naming convention is very similar to the carbon steel, the key difference is that the first two numbers have been changed. The 92 in 9260 signifies that Silicon Manganese has been incorporated into the steel. The chart below shows all the different sorts of steel that are available, not all are used in sword making.

10XX

Carbon steels

Plain carbon, Mn 1.00% max

11XX

Resulfurized free machining

12XX

Resulfurized / rephosphorized free machining

15XX

Plain carbon, Mn 1.00-1.65%

13XX

Manganese steel

Mn 1.75%

23XX

Nickel steels

Ni 3.50%

25XX

Ni 5.00%

31XX

Nickel-chromium steels

Ni 1.25%, Cr 0.65-0.80%

32XX

Ni 1.75%, Cr 1.07%

33XX

Ni 3.50%, Cr 1.50-1.57%

34XX

Ni 3.00%, Cr 0.77%

40XX

Molybdenum steels

Mo 0.20-0.25%

44XX

Mo 0.40-0.52%

41XX

Chromium-molybdenum steels

Cr 0.50-0.95%, Mo 0.12-0.30%

43XX

Nickel-chromium-molybdenum steels

Ni 1.82%, Cr 0.50-0.80%, Mo 0.25%

47XX

Ni 1.05%, Cr 0.45%, Mo 0.20-0.35%

46XX

Nickel-molybdenum steels

Ni 0.85-1.82%, Mo 0.20-0.25%

48XX

Ni 3.50%, Mo 0.25%

50XX

Chromium steels

Cr 0.27-0.65%

51XX

Cr 0.80-1.05%

50XXX

Cr 0.50%, C 1.00% min

51XXX

Cr 1.02%, C 1.00% min

52XXX

Cr 1.45%, C 1.00% min

61XX

Chromium-vanadium steels

Cr 0.60-0.95%, V 0.10-0.15%

72XX

Tungsten-chromium steels

W 1.75%, Cr 0.75%

81XX

Nickel-chromium-molybdenum steels

Ni .30%, Cr 0.40%, Mo 0.12%

86XX

Ni .55%, Cr 0.50%, Mo 0.20%

87XX

Ni .55%, Cr 0.50%, Mo 0.25%

88XX

Ni .55%, Cr 0.50%, Mo 0.35%

92XX

Silicon-manganese steels

Si 1.40-2.00%, Mn 0.65-0.85%, Cr 0-0.65%

93XX

Nickel-chromium-molybdenum steels

Ni 3.25%, Cr 1.20%, Mo 0.12%

94XX

Ni 0.45%, Cr 0.40%, Mo 0.12%

97XX

Ni 0.55%, Cr 0.20%, Mo 0.20%

98XX

Ni 1.00%, Cr 0.80%, Mo 0.25%

In this chart the first 2 numbers describe the type of steel and the last two numbers signify the carbon content. It’s easy to be confused by all the options available. To simplify matters, most of the sword we’ll be interested in are made from either 1045, 1060 or 1095 carbon steel, with a couple of exceptions thrown in. In the rest of the article we’ll cover the most commonly used sword steels available today and what properties they impart to the sword.

Types of Sword Steel

1045 Carbon Steel

1045 carbon steel has a carbon content of 0.45%, while a steel such as 1095 has 0.95% carbon content, contrariwise 1045 has more manganese content than 1095. This means that 1095 carbon steel is harder and better able to resist wear and tear, but it’s also less tough. 1045 is capable of taking an edge, but 1095 is easier to sharpen and the edge will last longer. If you’re a beginner, you might want to pick a 1045 carbon steel sword, they are better suited to taking abuse and are most often the cheapest battle ready sword available.

1050-1055 Carbon Steel

1050 carbon steel is a robust and resilient medium-high carbon steel. It has a carbon content of 0.50% and is good choice for anyone looking for a tough tool such an axe, hatchet or sword.

1055 carbon steel is right on the dividing line between steel classed as medium carbon content and steel classed as high carbon content. Typically 1055 carbon steel will have a manganese content between 0.60% and 0.90%. These factors contribute to any sword made from 1055 steel being incredibly tough and durable. When a 1055 sword is expertly tempered, it produces a crystalline structure which is free from excess carbides, in turn this avoids the brittleness which is common with high carbon materials. 1055 steel is very well suited to applications where impact resilience and outstanding toughness are highly desirable. This steel is capable of producing blades which are incredibly resilient to damage.

1060-1065 Carbon Steel

1060 and 1065 carbon steel is a fairly common steel used in battle ready swords. The carbon content is between 0.60% and 0.65%, with manganese being the only other addition. This sort of carbon steel is very tough and is able to take and retain an edge very well.

1065 is an ideal steel for differential hardening, often producing a visible temper line on the finished sword. Of course any hardening that takes place will also reduce the impact resilience of the finished piece.

1075 Carbon Steel

1075 carbon steel would be considered high carbon content steel. 1075 steel is excellent at taking and retaining an edge, the blade is very tough and is very resilient. The steel is very well suited for swords, axes, machetes, knives or any other sort of blade which requires a sharp edge and is subject to significant usage.

1095 Carbon Steel

1095 carbon steel is a standard production carbon steel, the steel is characterised by it’s low resistance to corrosion and it’s medium edge retention. A sword made from 1095 carbon steel is very easy to sharpen to a razor sharp long lasting edge. When this steel is expertly tempered, the sword is has amazing properties, no other steel can compare when expertly sharpened. We do not recommend this sword to beginners as it needs to be cared for correctly to avoid rusting and can be damaged if not used with proper technique and methods. In the correct hands a battle ready 1095 steel katana is incomparable.

65Mn Steel

65Mn steel is a widely used and available Chinese steel that was created in order to provide good hardness and increased wear resistance. The carbon content of this steel is classed as medium, allowing for a high degree of toughness and resistance. 65Mn steel also contains manganese which also improves the swords hot working characteristics, meaning it’s easy to forge into sword blades, knives and any other tool which sees significant impacts.

1566 Spring Steel

1566 Spring Steel is a high-carbon and manganese content steel. The steel is very well suited to differential hardening tempering processes. The hardened steel is characterised by a consistent crystalline microstructure which ensures a resilience and long life for any demanding tools that require an edge.

T-10 Steel

T-10 steel is the Chinese created equivalent of the western 1095 steel, but with a crucial difference which sees silicon being added to the alloy mix in order to improve the overall strength of the steel and additionally to increase its wear resistance. T-10 steel swords take to tempering very well, producing a sword which takes and retains an edge. In the same vain as 1095 steel, T-10 steel has low resistance to corrosion, therefore must be carefully looked after in order to avoid rust.

5160 Spring Steel

5160 is a very high end steel which is increasingly popular with sword forgers. The steel is a fairly generic spring steel with the added benefit of chromium, the additional of chromium works to harden the metal. 5160 steel is well renowned for its edge holding capabilities, but it’s even better known for its extreme toughness. The steel is often used in swords or knives and tomahawks.

440 Stainless Steel

440 stainless steel is a form of high grade cutlery steel, which typically has a higher carbon content, allowing for the steel to better take and retain an edge. When 440 steel has been correctly heat treated in can become one of the hardest stainless steels available. Due to its relative cheap price and hardness, most display only pieces and replica swords you’ll encounter will likely be made from 440 stainless steel. 440 is commonly available in four distinct grades:

440A contains the least amount of carbon and is the most corrosion and stain resistant.

440B contains slightly more carbon and is slightly harder but also slightly less stain resistant.

440C has the largest amount of carbon content out of the 440 grades, it’s the strongest 440 steel and is the most desirable type for swords or knives. The exception to this is knives that are designed for use by divers, these will invariably be made from 440A steel.

440F is a free machining variant of 440 steel and it contains the same carbon content as 440C

3CR13 Steel

3CR13 Steel is most commonly used for knives and is a form of Chinese stainless steel. It is similar in many respects to 420J2 (AUS 4) stainless steel..

L6 Bainite Steel

L6 steel is a brilliant steel which is suitable for many applications, it’s equally practical for knives as well as swords. When used in a sword, L6 steel will likely be heat treated until a Bainite microstructure is formed, this process is complicated and expensive to perform. The steel is very popular in for use when forging Japanese Katana and its influence is spreading to other forgers creating non-Japanese swords. As the process spreads we’ll likely see efficiencies in formation of Bainite, leading to a reduction in the cost and the swords will likely see mass market distribution.

It relatively uncommon to see L6 used in production knives or swords, the steel is very difficult to work with and as such it’s really only found in custom pieces or high priced items.

Damascus Steel

Damascus steel swords are highly desirable due to their inherit beauty and practical application. Modern Damascus swords are formed from special types of billet steel. The billet steel is made up from several types of layers of steel and iron welded together, which is what creates the unique pattern present in Damascus steel.

Folded Steel

Folded steel swords are fascinating for their aesthetic attractiveness and their traditional heritage. One of the best known aspects of the Japanese traditional sword forging process involves folding the steel, the process involves repeatedly folding and hammering out the steel billet. Traditionally the process was performed in order to even out the carbon content of the steel throughout the sword, now the process is mostly performed due to aesthetics and to adhere to traditional techniques. The process is heavily referenced in much of Japanese popular culture is not synonymous with Japanese sword forging.

K120C Powder Steel

ASSAB K120C powder steel is made in Japan under a license agreement from SSAB of Sweden. The steel is typically considered to be similar to 1095 carbon steel.

Aluminium Swords

Most swords produced in Japan are not made of steel as you would expect, in fact they are invariably made from aluminium alloys. The overriding reason for this is the cost of a true Japanese sword is far in excess of what most people can afford. Japanese sword laws are incredibly strict and forges can make a maximum of two swords a month, which pushes the price up to a significant amount. This forces most martial artist practitioners to opt for a aluminium sword. Aluminium is significantly cheaper than a steel sword, but it also cannot be sharpened and doesn’t have the same heft as a real steel katana.

Source: https://www.bladespro.co.uk/blogs/news/guide-to-sword-steel-everything-you-didn-t-know-you-needed-to-know

from BladesPro https://bladesproco.wordpress.com/2017/07/20/guide-to-sword-steel-everything-you-didnt-know-you-needed-to-know/

0 notes

Text

Guide to Sword Steel – Everything You Didn’t Know You Needed to Know

When it comes to picking a sword, it’s not uncommon to hear the question “What is the best sort of sword steel”. This type of the question is not easily answered, the best sort of steel depends largely on what the sword will be used for and what budget the buyer has. For example, someone that is looking purely for a decorative display piece will likely want a steel that remains shiny with very little maintenance. A stainless steel sword will probably meet this buyers requirements, the sword will remain bright and polished for years, however the sword will be useful for very little else apart from hanging on the wall. If on the other hand the shopper would like a real battle ready sword, one which is capable of taking and retaining a cutting edge, then the choice of steel is a little harder. Additionally, we may need to consider sword tempering and forging methods. We’ll go into more depth in the article below.

Sword Tempering

A sword begins its life as a billet of steel, this billet is heated and roughly formed into a sword like shape. This process may take a couple of hours, or a couple of dozen hours, largely depending on the size and type of sword required. Once the sword has been shaped into its final form, the sword will most often go under a procedure called tempering. Tempering is a key aspect of producing a functional sword, the steps involved are quite technical in nature and have a significant impact on the swords capabilities. Essentially tempering involves heating the sword to pre-defined temperatures, the sword is then rapidly cooled in oil or water (but not too rapidly). The tempering process is key to producing a hardened and tough blade. However, if the sword is cooled too quickly then the sword may end up being brittle or cracking. Many thousands of swords have met an untimely end during the tempering process. Sword tempering will have one of the biggest effects on the final swords capabilities, sometimes more than the type of steel chosen.

Most swords are either mono hardened or differentially hardened. In a mono hardened sword, the whole sword is heated to the same uniform temperature and cooled at the same rate. In a differentially hardened sword, clay or other similar pastes are added to the blade in order to insulate part of the sword from the heating and cooling process. When this occurs the clay covered part will cool at a slower pace compared to the exposed part of the blade, this works to increase the hardness of the exposed blade while allowing the covered portion to remain flexible. The differential hardening process is very common in Japanese swords such as a Samurai Sword, creating the distinctive Hamon line. A Hamon line is the separation between the hard cutting edge and the softer flexible spine. A flexible spine allows the sword to absorb impacts which would otherwise dent or crack the sword.

Mono tempered swords are typically marketed at beginners, they are able to take more abuse and are less likely to chip or become permanently misshapen. Despite the association with beginners, there are a lot of good arguments for buying a mono tempered sword over a traditional differentially tempered variety. Most of the swords originating from medieval Europe where forged using mono tempering methods, which was better suited to the slashing blows against armour and shields, the mono temper is better suited to taking punishment without chipping or breaking.

If you’re experienced using a sword for cutting, then you may wish to consider a differentially tempered. These swords typically have a harder cutting edge, but you’ll need to be wary of form and technique, a misguided sword stroke may lead to the blade being chipped or irrevocably damaged.

Most experienced sword makers today are well versed in the art of sword tempering, so there’s little concern around receiving a cracked or chipped sword, simply choose the tempering you’d like.

Sword Steel Guide

Now that we’ve managed to cover tempering and what the means for your sword, we can move onto the types of sword steel that are available. Picking a steel for your sword is only really important if you’re looking to have a battle ready sword. If you’re only looking for a display sword then you’re probably better of getting a sword made from stainless steel, they are cheaper to buy and require very little maintenance, they are however not recommended for any substantial cutting. I’m not trying to imply that all stainless steel swords are terrible for cutting, but I wouldn’t expect to slice through 3 inches of bamboo with one either.

So what about carbon steel? Carbon steel is the go to sword steel for battle ready swords, at the lower end of the scale we start at 1045 carbon steel. The number assigned to the carbon steel describes the carbon content of the metal. For example, 1045 is classed as medium carbon content and will contain 0.45% carbon. Continuing with the naming convention, 1060 carbon steel has 0.60% carbon content and so on. Most carbon steel swords you’ll find for sale are 1045, 1060 or 1095. Some sword smiths are embracing newer types of steel for use in swords such as 9260 and other types of spring steel, these have added silicon which increases the blades toughness. This naming convention is very similar to the carbon steel, the key difference is that the first two numbers have been changed. The 92 in 9260 signifies that Silicon Manganese has been incorporated into the steel. The chart below shows all the different sorts of steel that are available, not all are used in sword making.

10XX

Carbon steels

Plain carbon, Mn 1.00% max

11XX

Resulfurized free machining

12XX

Resulfurized / rephosphorized free machining

15XX

Plain carbon, Mn 1.00-1.65%

13XX

Manganese steel

Mn 1.75%

23XX

Nickel steels

Ni 3.50%

25XX

Ni 5.00%

31XX

Nickel-chromium steels

Ni 1.25%, Cr 0.65-0.80%

32XX

Ni 1.75%, Cr 1.07%

33XX

Ni 3.50%, Cr 1.50-1.57%

34XX

Ni 3.00%, Cr 0.77%

40XX

Molybdenum steels

Mo 0.20-0.25%

44XX

Mo 0.40-0.52%

41XX

Chromium-molybdenum steels

Cr 0.50-0.95%, Mo 0.12-0.30%

43XX

Nickel-chromium-molybdenum steels

Ni 1.82%, Cr 0.50-0.80%, Mo 0.25%

47XX

Ni 1.05%, Cr 0.45%, Mo 0.20-0.35%

46XX

Nickel-molybdenum steels

Ni 0.85-1.82%, Mo 0.20-0.25%

48XX

Ni 3.50%, Mo 0.25%

50XX

Chromium steels

Cr 0.27-0.65%

51XX

Cr 0.80-1.05%

50XXX

Cr 0.50%, C 1.00% min

51XXX

Cr 1.02%, C 1.00% min

52XXX

Cr 1.45%, C 1.00% min

61XX

Chromium-vanadium steels

Cr 0.60-0.95%, V 0.10-0.15%

72XX

Tungsten-chromium steels

W 1.75%, Cr 0.75%

81XX

Nickel-chromium-molybdenum steels

Ni .30%, Cr 0.40%, Mo 0.12%

86XX

Ni .55%, Cr 0.50%, Mo 0.20%

87XX

Ni .55%, Cr 0.50%, Mo 0.25%

88XX

Ni .55%, Cr 0.50%, Mo 0.35%

92XX

Silicon-manganese steels

Si 1.40-2.00%, Mn 0.65-0.85%, Cr 0-0.65%

93XX

Nickel-chromium-molybdenum steels

Ni 3.25%, Cr 1.20%, Mo 0.12%

94XX

Ni 0.45%, Cr 0.40%, Mo 0.12%

97XX

Ni 0.55%, Cr 0.20%, Mo 0.20%

98XX

Ni 1.00%, Cr 0.80%, Mo 0.25%

In this chart the first 2 numbers describe the type of steel and the last two numbers signify the carbon content. It’s easy to be confused by all the options available. To simplify matters, most of the sword we’ll be interested in are made from either 1045, 1060 or 1095 carbon steel, with a couple of exceptions thrown in. In the rest of the article we’ll cover the most commonly used sword steels available today and what properties they impart to the sword.

Types of Sword Steel

1045 Carbon Steel

1045 carbon steel has a carbon content of 0.45%, while a steel such as 1095 has 0.95% carbon content, contrariwise 1045 has more manganese content than 1095. This means that 1095 carbon steel is harder and better able to resist wear and tear, but it’s also less tough. 1045 is capable of taking an edge, but 1095 is easier to sharpen and the edge will last longer. If you’re a beginner, you might want to pick a 1045 carbon steel sword, they are better suited to taking abuse and are most often the cheapest battle ready sword available.

1050-1055 Carbon Steel

1050 carbon steel is a robust and resilient medium-high carbon steel. It has a carbon content of 0.50% and is good choice for anyone looking for a tough tool such an axe, hatchet or sword.

1055 carbon steel is right on the dividing line between steel classed as medium carbon content and steel classed as high carbon content. Typically 1055 carbon steel will have a manganese content between 0.60% and 0.90%. These factors contribute to any sword made from 1055 steel being incredibly tough and durable. When a 1055 sword is expertly tempered, it produces a crystalline structure which is free from excess carbides, in turn this avoids the brittleness which is common with high carbon materials. 1055 steel is very well suited to applications where impact resilience and outstanding toughness are highly desirable. This steel is capable of producing blades which are incredibly resilient to damage.

1060-1065 Carbon Steel

1060 and 1065 carbon steel is a fairly common steel used in battle ready swords. The carbon content is between 0.60% and 0.65%, with manganese being the only other addition. This sort of carbon steel is very tough and is able to take and retain an edge very well.

1065 is an ideal steel for differential hardening, often producing a visible temper line on the finished sword. Of course any hardening that takes place will also reduce the impact resilience of the finished piece.

1075 Carbon Steel

1075 carbon steel would be considered high carbon content steel. 1075 steel is excellent at taking and retaining an edge, the blade is very tough and is very resilient. The steel is very well suited for swords, axes, machetes, knives or any other sort of blade which requires a sharp edge and is subject to significant usage.