#ASM certification

Explore tagged Tumblr posts

Text

Mastering Efficiency: The Ultimate Guide to Agile and Scrum Training and Certification

In an era defined by rapid technological advancements and ever-evolving market demands, businesses are compelled to streamline their processes and foster innovation. Traditional project management methodologies often fall short in addressing the complexities and uncertainties of today’s dynamic business landscape. As a result, the Agile framework and Scrum methodology have emerged as leading solutions, empowering organizations to adapt swiftly, deliver value, and stay ahead of the curve.

Understanding Agile and Scrum

Agile methodology fosters a collaborative, iterative approach to project management that emphasizes flexibility and customer satisfaction. It enables teams to respond to unpredictability through incremental, iterative work cadences known as sprints. By promoting adaptive planning, evolutionary development, early delivery, and continuous improvement, Agile facilitates efficient and timely project completion while accommodating changes in requirements.

Complementing Agile, Scrum is a specific framework within which people can address complex adaptive problems, while productively and creatively delivering products of the highest possible value. By emphasizing teamwork, accountability, and iterative progress, Scrum allows teams to deliver tangible results rapidly and consistently. Through its defined roles, events, and artifacts, Scrum provides a clear structure for effective collaboration and project management.

The Need for Agile and Scrum Training

As businesses increasingly embrace Agile and Scrum methodologies, the demand for professionals skilled in these frameworks continues to rise. Employers seek individuals who can navigate the complexities of Agile and Scrum, driving successful project outcomes and delivering value to stakeholders. Consequently, professionals with comprehensive training and certification in Agile and Scrum are well-positioned to excel in their careers and contribute significantly to their organizations’ success.

Our Comprehensive Training Program

Our comprehensive Agile and Scrum training and certification program is meticulously designed to equip participants with the essential skills and knowledge required to excel in today’s fast-paced business environment. Led by industry experts with extensive experience in implementing Agile and Scrum practices across various domains, the program offers a blend of theoretical insights and practical hands-on experience.

Key Program Features:

In-depth Understanding: Gain a comprehensive understanding of Agile principles, Scrum framework, and their applications in real-world scenarios.

Practical Application: Acquire hands-on experience through immersive workshops, case studies, and interactive simulations that simulate real project environments.

Certified Instructors: Learn from certified instructors who bring a wealth of industry experience, enabling you to grasp the nuances and best practices of Agile and Scrum effectively.

Industry-Relevant Curriculum: Explore a curriculum that aligns with the latest industry standards and best practices, ensuring that you stay updated with the most current trends and methodologies.

Collaborative Learning: Engage in collaborative learning experiences, fostering teamwork and communication skills essential for successful Agile and Scrum implementation.

Benefits of Certification

Upon completing our Agile and Scrum training program, participants will be equipped to:

Effectively lead Agile projects and facilitate seamless communication among team members.

Implement Scrum methodologies to optimize project delivery and achieve exceptional results.

Drive a culture of continuous improvement and innovation within their organizations.

Boost their career prospects and stand out in a competitive job market with globally recognized Agile and Scrum certifications.

Join Us in Mastering Efficiency

Embark on a transformative journey that will equip you with the tools and knowledge needed to thrive in today’s competitive business landscape. Invest in your professional development and become an invaluable asset to your organization. Enroll in our Agile and Scrum training and certification program today to unlock your true potential and lead your team to unprecedented success in the world of Agile project management.

0 notes

Text

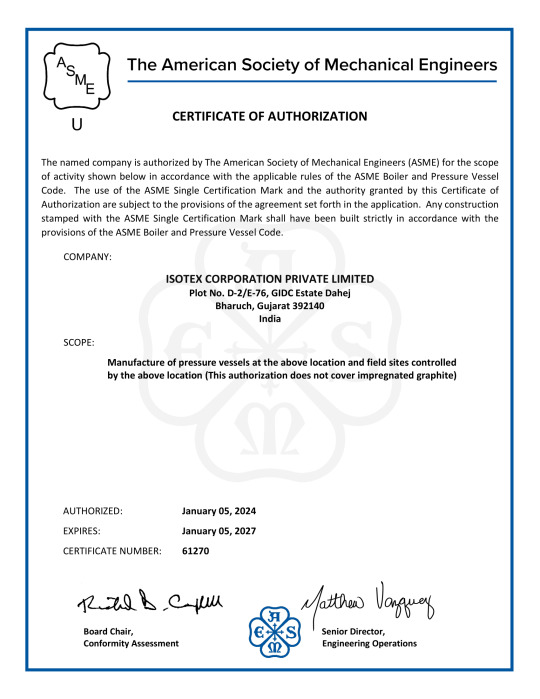

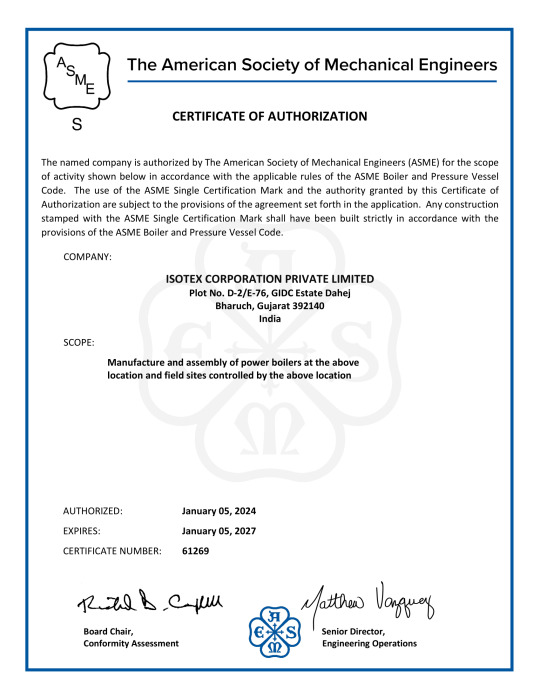

ASME Certification

One more achievement of Isotex Corporation Pvt Ltd for ASME certification. Kudos to team.

0 notes

Text

Buy SS 304 Blind Flange | Lowest Price in India

SS 304 Blind Flanges are a vital component for industrial piping systems, known for their durability, corrosion resistance, and strength. These flanges, made from stainless steel grade 304, are designed to seal the ends of pipes or valves, making them ideal for industries such as oil and gas, chemical processing, water treatment, and more. For businesses in India, finding SS 304 Blind Flanges at the lowest price is essential for minimizing operational costs while ensuring high-quality performance. With a wide range of suppliers offering competitive pricing, it's easier than ever to source these flanges at the best rates.

What is SS 304 Blind Flange?

SS 304 Blind Flanges are flat, circular components used to close off the ends of pipelines, valves, or pressure vessels. Unlike other flanges, the blind flange does not have a central bore, meaning it completely blocks the flow of liquid or gas through the pipe. This makes it useful for isolating sections of a piping system for maintenance, testing, or system shutdowns.

The material used in these flanges—stainless steel grade 304—is an austenitic alloy with high chromium (18%) and nickel (8%) content. This composition gives SS 304 its excellent corrosion resistance, making it a perfect choice for harsh industrial environments where chemicals, moisture, and high temperatures are present.

Benefits of SS 304 Blind Flange

1. Outstanding Corrosion Resistance: The SS 304 Blind Flange’s high chromium content allows it to form a passive layer of chromium oxide on its surface, which prevents rust and corrosion. This makes it ideal for use in chemical processing, oil refineries, water treatment plants, and other industries that deal with corrosive environments.

2. High Strength and Durability: SS 304 Blind Flanges are designed to withstand extreme pressures and temperatures. This makes them suitable for high-pressure applications, including oil and gas pipelines, steam systems, and heavy-duty processing plants. Their durability ensures long-term performance without frequent replacements, reducing maintenance costs.

3. Low Maintenance: Due to its superior resistance to corrosion and wear, SS 304 Blind Flanges require minimal maintenance compared to other materials. This makes them a cost-effective choice for industries where reliable performance and low upkeep are critical.

4. Versatile Applications: SS 304 Blind Flanges are used across a wide range of industries. They are suitable for temporarily sealing off pipelines during repairs or permanently closing off systems. Their versatility makes them valuable in oil and gas, petrochemical, marine, pharmaceutical, food processing, and water treatment industries.

Why Buy SS 304 Blind Flanges in India?

India is home to a vast array of suppliers and manufacturers offering SS 304 Blind Flanges at competitive prices. Buying locally ensures that you have access to high-quality products that meet Indian and international standards, such as ASTM or ASME certifications. Here are a few reasons why purchasing SS 304 Blind Flanges in India makes sense:

1. Cost-Effective Pricing: Indian suppliers offer some of the most competitive prices in the global market for SS 304 Blind Flanges. Whether you're looking to buy in small quantities or bulk, Indian manufacturers provide quality products at reasonable rates, often with the option to negotiate prices for large orders.

2. Fast Delivery and Local Availability: When you buy from Indian suppliers, you benefit from faster delivery times and lower shipping costs, especially for domestic orders. Many suppliers have stock readily available, ensuring that you can meet your project deadlines without delays.

3. Industry-Standard Certifications: SS 304 Blind Flanges manufactured in India often adhere to industry standards such as ASTM, ASME, or DIN. These certifications guarantee that the flanges meet the required quality and performance specifications, ensuring safety and reliability in industrial applications.

4. Bulk Discounts: Many suppliers in India offer discounts on bulk orders, making it more affordable for businesses that need large quantities of SS 304 Blind Flanges. Bulk purchasing not only reduces the unit price but can also lead to savings on transportation and logistics.

Applications of SS 304 Blind Flange

SS 304 Blind Flanges are used in various industrial settings due to their robust and corrosion-resistant properties. Common applications include:

Oil and Gas Industry: SS 304 Blind Flanges are used to close off pipeline sections during repairs or testing, especially in environments where corrosion is a concern.

Chemical Processing: In chemical plants, these flanges are used to block pipes that carry corrosive fluids, ensuring the system remains secure and sealed.

Water Treatment Plants: SS 304 Blind Flanges help in sealing off sections of water pipelines, providing a rust-resistant solution for water treatment facilities.

Marine Applications: Due to their resistance to seawater corrosion, SS 304 Blind Flanges are used in marine environments, including shipbuilding and offshore drilling operations.

Pharmaceutical and Food Industry: The non-reactive and hygienic properties of SS 304 make it an excellent choice for industries that require clean and sterile processing, such as pharmaceuticals and food manufacturing.

Tips for Finding SS 304 Blind Flanges at the Lowest Price in India

1. Compare Multiple Suppliers: When purchasing SS 304 Blind Flanges in India, it’s important to compare prices from several suppliers. This will allow you to find the most competitive pricing while ensuring the quality of the product.

2. Look for Bulk Discounts: If your project requires a large quantity of flanges, ask suppliers about bulk pricing. Many manufacturers offer substantial discounts for large orders, helping you reduce the cost per unit.

3. Check for Certifications: Make sure the supplier offers SS 304 Blind Flanges that meet industry standards like ASTM, ASME, or DIN. Certified products provide assurance that the flange will perform under the required conditions.

4. Negotiate for Better Pricing: Negotiation is common in the industrial supply market. If you’re placing a large order or planning a long-term partnership, don’t hesitate to ask for better terms or discounts.

5. Look for Seasonal or Promotional Offers: Some suppliers may offer seasonal discounts or promotional deals on SS 304 Blind Flanges. Stay on the lookout for such opportunities to get the best value for your money.

#SS304BlindFlange#BuySS304Flange#StainlessSteelFlange#IndustrialFlange#CorrosionResistantFlange#LowestPriceInIndia#PipelineSolutions#OilAndGasFlange#MarineFlange#WaterTreatmentFlange#BuyNow#IndiaFlangeDeals

5 notes

·

View notes

Text

The so-called “N-Stamp”, the certification that your organization, processes, and people are equal to the task of achieving the extreme quality requirements demanded for products to be used in civil nuclear energy contexts, is difficult and costly to acquire and maintain. British industry gave up on it ― because they had no new orders. Now they’re getting that capability back.

You can’t “suspend” an industry for years and then start it back up. If you try, you’re liable to find that it’s almost as difficult as building that industry was in the first place. When the French government agreed in the 1990s to a “pause�� in ordering new nuclear power plants, they set up the delays and cost over-runs which have plagued the EPR projects at Flamanville, Olkiluoto, and Hinkley Point. Need we add that this is exactly why the anti-nuclear campaigners demanded it?

2 notes

·

View notes

Text

All-Steel Stress, Blast and Coating

All-Steel Stress, Blast & Coating is a subsidiary steel heating treating company under the All-Steel Brand. All-Steel Stress, Blast and Coating provides heat treatment of steel, thermal stress relieving, industrial sandblasting/steel shotblasting and steel coating of: Fabricated weldments Machined parts Machine components Dry Outs

Their Massachusetts Facility offers a 40 Ton lifting capacity, 20 Ton forklift capacity and a dedicated, professional staff with over 50 years of combined experience in thermal stress relieving, sandblasting and priming/painting.

Thermal Stress Relieving, also referred to as Stress Relieving, Heat Treating, Post Weld Heat Treating (PWHT) and can also be referred to as annealing.

In our new, state of the art industrial size stress relieving oven we can stress relieve: Fabricated Weldments for post-weld heat treatment Machined Parts Metal Components In addition, we provide dry-out services for paint and refractory process curing. Our furnace will operate between 250 degrees F and 1600 degrees F. We perform quality inspections during the stress relieving process and we can provide our customers with Certificates of Compliance and detailed Heat Charts when required.

Our Stress Oven can accommodate customer jobs that are 12’H x 11’ W x 31’L and our rail-car capacity is 54,000lbs.

We meet the following standards: ASME Section I: (900 – 1300F) Stress relieve /post -weld heat treat in accordance with ASME Sect. I, PW-39 for carbon steel weldments. ASME Section VIII: (900 – 1300F) Stress relieve/post-weld heat treat in accordance with ASME Sect. VIII, USC-56 for carbon steel weldments. AWS D1.1 (900-1200F): Stress relieve/post-weld heat treat in accordance with AWS D1.1, 5.8 for carbon steel weldments. Westinghouse 83030QA: (1175F +/- 25F) Westinghouse-approved stress relieve procedure for carbon steel welded structures. General Electric P8A-AG1, P10G-AL-0003 & 0004: (1125 – 1275F, 1125-1200F and 125-1300F) General Electric-approved stress relieve procedures for carbon steel. Standard Stress Relieve: (1100-1200F) Applied to ferrous materials to reduce residual stresses for improved dimensional stability or reduced risk of premature failure in service. Low Temperature Stress Relieve: (325-775F) Typically applied to stainless steel and aluminum welded fabrications to reduce residual stresses with little or no effect of the corrosion resistance and/or mechanical properties. Industrial Sandblasting Services, also referred to as shot blasting can be done in our state-of-the-art facility in Central Massaschusetts. Our new, industrial-size facility provides our customers with sandblasting for: Fabricated Weldments Machined Parts Metal Frames and Components

In our modern, clean blast room, our experienced blasters can accommodate the most specific blast media required for the job. We can blast customer jobs that are 16’H x 13’W x 30’L; and we have 40,000lbs rail-car capacity for our blasting facility.

Steel Coating Services: Industrial Priming, Painting and Coating for Steel and other Metals. Our new coating facility will be capable of providing priming/painting/coating services up to 16’H x 20’W x 50’L and weigh up to 80,000lbs. Our painters have extensive experience coating: Fabricated Weldments Industrial Machine Bases Industrial Frames Construction Equipment Holding Tanks & Silos

Address: 84 Creeper Hill Road,North Grafton MA 01536 Phone: (508) 839-4471

Our Social Pages:

facebook

twitter

linkedin

youtube

pinterest

3 notes

·

View notes

Text

Behind the Scenes: How Ali Yaqoob Ensures Quality Control in Valve Supply Across the UAE

When UAE industries need the best valves, they use Ali Yaqoob Trading—Dubai valve suppliers in UAE that are among the most reliable valve suppliers in Dubai. From oil and gas to water treatment plants and petrochemical industries, our quality standards speak volumes. Here's an insider's look at how our stringent quality control process makes all the difference in the valve-supply market.

1. Stringent Vendor Selection & Product Standards

Our quality journey begins with selecting the right partners. We deal only with internationally certified manufacturers that adhere to API and ASME standards. These relationships enable us to provide an extensive variety of valves—gate, globe, ball, butterfly, check, pressure relief, needle, solenoid, and others—intended for industrial use.

Prior to onboarding a vendor, we perform extensive audits of their manufacturing process to ascertain if they are up to our material traceability, quality of welding, and dimensional accuracy standards.

2. Detailed Stock Management in Dubai

Located at Dubai Investment Park, Ali Yacoob Trading's warehouses are optimized for efficiency and management. We hold a wide stock of valves in several sizes, pressure classes, and materials—carbon steel, stainless steel, alloys—to meet quick delivery commitments to clients throughout the UAE.

Our facility has organized storage, humidity control, and FIFO procedures to maintain material integrity. Every batch is labeled and recorded electronically, correlating to source documents for complete traceability.

3. Technical Verification by Experienced Engineers

Every incoming valve has a comprehensive technical check. Our experts verify:

Physical dimensions versus specification sheets

Material certificates and heat-number tracking

Visual inspection for defects like burrs or corrosion

Pressure or seat tests to identify leaks

Our engineering staff, with decades of experience, guarantees each valve meets Ali Yaqoob's reputation for reliability.

4. Third-Party Testing for Critical Applications

For mission-critical applications—such as petrochemical or offshore—third-party testing is crucial. We collaborate with accredited laboratories to perform hydrostatic pressure testing, non-destructive testing (NDT), and performance testing. Test reports are included, with every shipment of valves, giving clients confidence to move forward.

5. Customized Testing and Certification

Realizing that industries are specific in their needs, we provide proprietary test packages that suit your project:

Specialized pressure tests

Control valve endurance cycling

Certification according to international specifications (ATEX, PED, NACE, etc.)

These extra tests confirm compatibility with operating conditions and regulatory compliance.

6. Order-Fulfilment: Precision, Packaging, and Shipping

When the customer orders, our personnel remove the specified valves, check batch and traceability, and package them safely—especially for overseas shipments that need export packing standards.

Our efficient logistics chain from our headquarters in Dubai facilitates timely despatch in the UAE and GCC.

7. Longevity and Post-Sale Support

Our dedication does not end with delivery. Customers enjoy:

Technical installation guidance

Maintenance instructions and inspection intervals

Field assistance for repair or replacement

This support maximizes valve performance throughout their lifespan.

8. Continuous Improvement Through Feedback

Ali Yaqoob Trading sees each delivery as a chance to get better. Feedback loops give visibility into field performance, warranty claims, and aftermarket behavior. This information allows us to optimize vendor selection, inspection techniques, and product assortment—bringing more value to customers.

Final Thoughts

Supplying valves is not enough—having each unit meet stringent quality standards is what really differentiates Ali Yaqoob Trading. As Dubai's and the UAE's top valve suppliers, we don't merely supply valves—we provide engineered assurance and peace of mind. Our strict quality control—from vendor qualification to field service—guarantees customers only the highest. Searching for a trusted valve supplier in UAE? Taste the difference of Ali Yaqoob Trading's unmatched quality and service.

0 notes

Text

Solvent Weld vs Thermal Weld Ball Valves: Critical Differences

Welded ball valves provide permanent, leak-tight connections in critical piping systems. Understanding the fundamental distinction between solvent welding and thermal welding is essential for proper valve selection:ParameterSolvent Weld Ball ValvesThermal Weld Ball ValvesConnection MethodChemical fusion of thermoplasticsMetal melting (TIG/MIG welding)MaterialsPVC, CPVC, PP, PVDRStainless steel, carbon steelMax Temperature140°F (60°C)1200°F+ (650°C+)Pressure RatingClass 150Class 150-2500ApplicationsChemical transfer, water treatmentOil/gas, steam, high-pressure lines

Welded Ball Valve Types Explained

1. Fully Welded Ball Valves

– Structure: Monolithic body with no flanges/gaskets

– Advantages: Zero-leak guarantee, 30+ year service life

– Standards: ASME B16.34, API 6D

– Use Cases: Underground pipelines, subsea applications, LNG terminals

2. Semi Welded Ball Valves

– Hybrid Design: Welded body + bolted bonnet

– Maintenance: Seal replacement without pipe cutting

– Industries: Power generation, pharmaceutical processing

– Pressure: Class 600-1500

3. Stainless Steel Welded Ball Valves

– Grades: 316L, 304, duplex, super duplex

– Corrosion Resistance: Withstands chlorides, acids, H₂S

– Certifications: NACE MR0175 for sour service

– Sanitary Options: 3A compliant for food/pharma

Industrial Applications by Type

IndustryRecommended Valve TypeKey BenefitChemical ProcessingSolvent weld CPVC valvesSulfuric acid resistanceOil & GasFully welded SS316 valvesAPI 6FA fire-safe certificationDistrict HeatingSemi-welded carbon steel valvesThermal shock resistancePharmaSanitary stainless steel valvesElectropolished surfaces

NSW: Certified Weld Ball Valve Manufacturer

As an ISO 9001 & API 6D certified weld ball valve manufacturer, NSW delivers:

- Unmatched Range: ½” to 60″ valves (ANSI 150 – 2500)

– Specialized Welding:

– Orbital welding for nuclear applications

– Cryogenic treatment (-320°F/-196°C)

– Hot tapping capability

– Material Expertise:

– ASTM A351 CF8M stainless steel

– Alloy 20, Hastelloy, titanium

– Lined PTFE/PFA options

– Testing Protocol:

– 100% helium leak testing

– API 598 seat tests

– Fugitive emissions (ISO 15848-1)

0 notes

Text

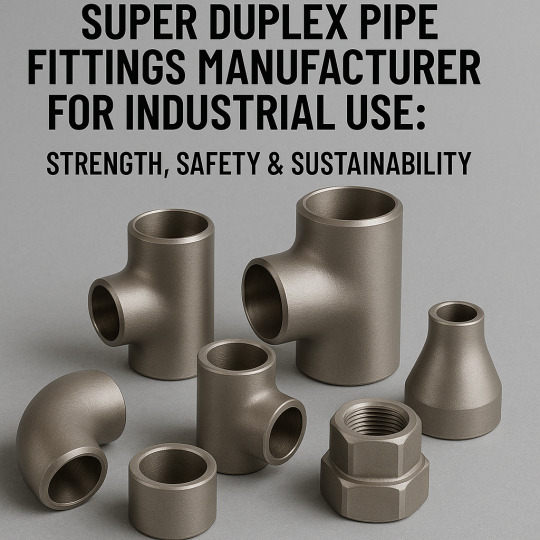

Super Duplex Pipe Fittings Manufacturer for Industrial Use: Strength, Safety & Sustainability

In the demanding world of industrial operations, the reliability of piping systems is non-negotiable. Whether in oil refineries, chemical plants, marine environments, or desalination facilities, the infrastructure must withstand extreme pressures, corrosive substances, and high temperatures. One material that consistently meets and exceeds these challenges is Super Duplex Stainless Steel — and with it, the need for a trusted Super Duplex pipe fittings manufacturer for industrial use becomes essential.

What Makes Super Duplex Steel So Unique?

Super Duplex stainless steel offers a perfect balance of strength and corrosion resistance. Composed of a dual-phase microstructure (austenitic and ferritic), it outperforms standard stainless steels and Duplex grades in critical industrial environments. This unique composition ensures:

High mechanical strength

Superior corrosion resistance (especially to chlorides)

Excellent weldability and fatigue resistance

Cost-effectiveness through longevity and reduced maintenance

These properties make Super Duplex pipe fittings ideal for use in highly corrosive and high-pressure systems — especially in industries where failure is not an option.

Applications of Super Duplex Pipe Fittings in Industrial Sectors

Super Duplex fittings are widely used across industries including:

Oil & Gas (onshore and offshore)

Petrochemical and Chemical Processing

Marine & Shipbuilding

Desalination Plants

Power Generation

Pulp & Paper

In these settings, fittings must perform under extreme operating conditions. Super Duplex pipe fittings ensure system integrity, reducing the risk of leaks, cracks, and corrosion-related failures.

Why Choosing the Right Manufacturer Matters

Not all fittings are created equal. For performance to match specification, selecting a reputed Super Duplex pipe fittings manufacturer for industrial use is crucial. A quality-focused manufacturer ensures:

Precision machining and dimensional accuracy

Certification to international standards (ASTM, ASME, NORSOK, etc.)

Full traceability and quality documentation

Testing for pressure, corrosion, and durability

By sourcing from a reliable manufacturer, industries gain peace of mind knowing that each fitting is engineered for long-term performance and safety.

Benefits of Super Duplex Fittings in Industrial Use

Extended Service Life: Ideal for long-term operations in aggressive environments

Reduced Maintenance Costs: Thanks to high corrosion resistance

Improved System Safety: Lower risk of failure under mechanical or thermal stress

High ROI: Durable materials lead to fewer replacements and lower lifecycle costs

Conclusion

For industries operating in critical conditions, material reliability can be the difference between smooth operations and costly shutdowns. Super Duplex pipe fittings are a powerful solution that delivers unmatched strength and corrosion resistance — making them indispensable in modern industrial infrastructure. Partnering with a trusted manufacturer ensures you're not just buying components, but investing in long-term operational success.

LPF is a globally recognized manufacturer and supplier of high-performance pipe fittings made from Super Duplex and other specialized alloys. With a commitment to engineering excellence, rigorous quality control, and client-focused service, LPF continues to support some of the world's most demanding industries with reliable and efficient piping solutions.

#super duplex fittings#china#india#duplex & super duplex fittings#Super Duplex pipe fittings#Super Duplex Pipe Fittings manufacturer for Industrial use

0 notes

Text

0 notes

Text

Marck Industries: Trusted Manufacturer of Premium Elevator Spare Parts

Why Reliable Spare Parts Matter in Elevator Systems

Elevators are essential in modern buildings—transporting people and goods swiftly and safely. Downtime due to broken or worn-out parts isn’t just inconvenient—it can impact safety, building efficiency, and tenant satisfaction. That’s why having a dependable source of high-quality spare parts is vital.

What Sets Marck Industries Apart

1. Decades of Expertise

With years of experience in manufacturing elevator components, Marck Industries understands the stringent requirements of vertical transportation—ensuring every part is engineered for precision, durability, and compliance with international safety standards.

2. Comprehensive Product Portfolio

From mechanical to electrical systems, we supply a full range of elevator parts, including:

Controller boards & PCBs

Inverter and VFD units

Proximity switches & sensors

Door lock and safety gear

Brake assemblies & drums

Buffers, rollers, and pulleys

Cabin fixtures: buttons, display panels, handrails

3. Precision Manufacturing

Utilizing CNC machining, injection molding, and automated PCB assembly, each component is produced to exact tolerances—ensuring fit and function with OEM performance or better. Strict quality checks, including EN 81, ASME A17.1, and ISO audits, guarantee consistency.

4. Certified Quality & Safety

Marck operates with certifications to:

ISO 9001 Quality Management

CE marking and compliance

Adherence to EN (Europe) and ASME (North America) elevator safety codes

These credentials ensure safe, global-grade parts.

5. Custom Solutions & Adaptability

Recognizing that every elevator system is unique, Marck Industries excels in custom engineering—from tailored connectors and cables to complete PCB re-engineering—while maintaining cost and lead-time efficiency.

Benefits of Partnering with Marck Industries

Advantage

Impact

High Uptime & Quick Delivery

Minimize downtime with rapid part replacement and fast shipping

Competitive Pricing

Optimized production lowers costs without compromising quality

Global Support Infrastructure

Sales and technical teams available round-the-clock across regions

Extended Product Warranty

Confidence via long-term warranty and support packages

Serving Diverse Market Segments

Residential Buildings: Reliable replacements for passenger-lift maintenance.

Commercial Complexes: Durable components suited for high-traffic usage.

Industrial Facilities: Heavy-duty parts designed for freight and goods lifts.

OEM Collaborations: Contract manufacturing aligned with global elevator brands.

Quality Control & Testing Procedures

Each batch undergoes:

Incoming Material Inspection (IQC)

In-Process Monitoring (IPC)

Performance Testing: Load, endurance, vibration, and electrical tests

Final Audits & Certification

Partnering with Marck: How It Works

Initial Consultation Understand your system specs, OEM models, and usage patterns.

Quotation & Sample Approval We provide detailed proposals and offer test samples for validation.

Order & Production Ranging from small spare lots to mass production, with regular updates.

Technical & After-Sales Support Including troubleshooting, field assistance, and prompt RMA processes.

Ongoing Relationship We offer lifecycle support—even for legacy elevators requiring obsolete part replacements.

Elevate Your Operations with Marck Industries

Your elevator fleet deserves nothing less than reliable, certified parts that stand the test of time. Choose Marck Industries for precision, safety, and peace of mind—backed by technical excellence and global service reach.

Ready to discuss your parts needs? Contact our sales team or request a quote through the Marck Industries website today.

0 notes

Text

ASME U Stamp Coded vessel

Asme U Stamp Coded Vessel work involves tasks and all client projects that are in accordance with the standards set by the Asme requirements. They consist of designing, producing and examining engineering systems and additives. One of its specific factors includes code vessels. These are boxes designed to preserve gases or beverages at a pressure notably exceptional from the ambient pressure vessel.

ASME U Stamp coded vessels are produced to pressure vessels that meet safety and performance areas.

Essential Pressure Vessel Requirements

The ASME Boiler and Pressure Vessel Code (BPVC) units forth guidelines for the layout, fabric choice, fabrication, and inspection of pressure vessels. Here is an outline of the requirements:

Design Requirements

The design standards set up by means of ASME make sure pressure vessels’ structural integrity and protection. Engineers adhere to those standards to create sturdy designs that may face up to the pains of operational conditions. Key considerations encompass the subsequent:

Loadings: Designers have to account for diverse loadings, which include inner strain, external forces, and capacity dynamic loads.

Maximum allowable strain: ASME specifies the maximum pressure a cloth can undergo under running conditions without risking failure.

Safety factors: These factors act as a buffer, offering an additional margin of protection past the calculated requirements.

Material Selection

The ASME standard is careful to expand the entire material for the production of a pressure vessel. This involves comprehensively studying mechanical residences, corrosion resistance, and different cloth traits. The choice of the impact of the vessel and the choice of the right substances for life is important in varied operating conditions.

Fabrication Standards

The code provides critical suggestions for the entire fabrication manner. Anpam includes welding processes, heat transfer strategies and functioning of compositions in the checklist. Adherence to these requirements is important to accomplishing regular and reliable production, which at once influences the structural integrity of the stress vessel.

Pressure Testing

Pressure vessels check to assess their ability to anpam to verify their structural integrity and safely include alleged pressure in the volume level. ASME affords specific guidelines for pressure testing, protecting critical factors which include conditions, length, and acceptance standards. Here are three issues:

ASME guidelines: These include the test period and the stress stages to which the vessel needs to be subjected. They additionally decide the standards for accepting or rejecting the take a look at consequences.

Hydrostatic or pneumatic checking out: This technique allows engineers to assess the vessel’s reaction to unique stress scenarios. It ensures that it is able to operate in the unique range.

Verification of structural integrity: This involves assessing its capability to face up to strain without experiencing leaks, deformations, or different screw ups.

Marking and Documentation

ASME mandates the right marking and documentation of pressure vessels, emphasizing a dependent technique to make sure traceability and compliance. Each ASME code vessel should tolerate a selected code image, actually indicating the following standards.

ASME Code Work at Anpam engineering

At Anpam engineering, we have a professional group of welders, fabricators, and machinists who can deal with an extensive variety of ASME Code work! We hold ASME U stamps and U certification, our fast dedication to excellence and compliance. We also can efficiently control the layout, fabrication, and completing techniques for numerous areas of expertise tanks and strain vessels.

Our capabilities demonstrate versatility in our services, increasing codes and non-code vessels. For ASME Section VIII, Div. 1 vessels, we adhere to the stringent requirements set by means of the code, making sure the very best levels of safety and performance.

0 notes

Text

Finding the Best Deals on GI Flange ASA 150

Understanding GI Flange ASA 150

GI Flange ASA 150 is a specific type of galvanized iron flange that adheres to the American Society of Mechanical Engineers (ASME) 150 standard. This standard ensures the flange's quality, dimensions, and pressure rating.

Key Factors to Consider

Quality: Ensure the manufacturer adheres to the ASME 150 standard.

Price: Compare prices from different manufacturers to find the best deal.

Delivery Time: Consider the manufacturer's location and shipping times.

Customer Service: Look for a manufacturer with good customer support.

Tips for Finding the Lowest Price

Online Research: Use search engines and industry directories to find manufacturers.

Request Quotes: Contact multiple manufacturers to get price comparisons.

Negotiate: Don't hesitate to negotiate for better deals, especially for bulk orders.

Check for Discounts: Inquire about any discounts or promotions.

Verify Certifications: Ensure the manufacturer has the necessary certifications.

Popular Online Platforms

Alibaba: A global online marketplace with a wide range of suppliers.

IndiaMart: An Indian online marketplace for manufacturers and suppliers.

Global Sources: Another global platform for sourcing products.

Additional Tips

Consider Local Manufacturers: Purchasing from local manufacturers can often reduce shipping costs and support the local economy.

Check for Certifications: Look for manufacturers with certifications such as ISO 9001, which indicate quality management systems.

Read Customer Reviews: Check online reviews to get feedback from other customers about the manufacturer's products and services.

By following these tips and utilizing online platforms, you can effectively find manufacturers of GI Flange ASA 150 at the lowest prices while ensuring quality and reliability.

#GI_flanges#ASA_150#industrial_components#manufacturing#engineering#procurement#supply_chain#quality_control#India#best_deal#lowest_price#negotiation#bulk_purchase#quality_assurance#certifications

5 notes

·

View notes

Text

Outsourcing Shop Drawing Services: Key Considerations for Choosing the Right Partner

As architectural, engineering, and construction (AEC) projects become increasingly complex and deadline-driven, outsourcing shop drawing services has emerged as a strategic move for many firms. By collaborating with specialized service providers, companies can access expert resources, improve turnaround times, and reduce in-house operational burdens.

However, not all outsourcing partners offer the same level of quality, reliability, and value. Choosing the right partner requires careful assessment across multiple criteria.

What Are Shop Drawing Services?

Shop drawings are detailed plans, diagrams, and schedules developed by contractors, fabricators, or manufacturers. They translate design intent into constructible components, playing a crucial role in ensuring that architectural, structural, and MEP (mechanical, electrical, plumbing) elements align on-site.

Types of shop drawings include:

Architectural shop drawings

Structural steel and rebar detailing

HVAC, electrical, and plumbing drawings

Millwork and cabinetry shop drawings

Precast concrete drawings

Curtain wall and façade systems

These drawings are often required for approval before fabrication or installation and must comply with industry codes and project specifications.

Why Outsource Shop Drawing Services?

Outsourcing shop drawings has grown in popularity due to numerous benefits. When done right, it enhances operational efficiency and accuracy.

Key benefits include:

Cost efficiency: Reduces in-house labor and infrastructure expenses.

Access to expertise: Gain access to a pool of experienced drafters and engineers.

Faster turnaround: Meet tight deadlines with around-the-clock support.

Scalability: Easily ramp up or down based on project volume.

Focus on core functions: Let your team focus on design and construction management.

What to Look for in an Outsourcing Partner

When evaluating potential outsourcing partners for shop drawing services, it's essential to look beyond cost. The right partnership is built on quality, trust, and performance.

1. Technical Expertise and Domain Knowledge

A competent partner must have strong industry-specific knowledge and expertise in drafting tools.

Look for:

Experience with AutoCAD, Revit, Tekla, SolidWorks, and other tools

Industry-specific knowledge (steel detailing, HVAC systems, etc.)

A team of qualified engineers, architects, and drafters

Familiarity with international building codes and standards (e.g., AISC, ASME, NFPA, etc.)

Questions to ask:

How many years of experience do they have in your project domain?

Can they share a portfolio of similar completed work?

2. Quality Assurance and Accuracy

Precision is paramount in shop drawings, as errors can lead to costly delays and on-site rework.

Ensure your partner has:

A structured quality control (QC) process

Multi-layered reviews by senior engineers

Software-aided clash detection and validation

Ability to adapt to project-specific quality checklists

Tips:

Request sample drawings to evaluate drawing consistency and detail quality.

Check for ISO certifications related to quality management.

3. Turnaround Time and Scalability

Timely delivery is critical, especially in fast-paced construction projects.

Consider these factors:

Average turnaround time for various drawing types

Ability to meet short deadlines and handle high-volume tasks

Time zone compatibility and work shift alignment

Availability of resources for ramping up as needed

Checklist:

Does the partner offer 24/7 support or flexible schedules?

Can they provide a dedicated project team?

4. Communication and Project Management

Clear, consistent communication is a cornerstone of successful outsourcing.

Check for:

Assigned project managers or points of contact

Regular updates and progress reports

Use of project management tools like Asana, Trello, or BIM 360

Capability to handle change requests and scope variations smoothly

Best Practices:

Set expectations for response times and meeting frequencies.

Use collaborative platforms for sharing files and revisions.

5. Data Security and Confidentiality

Your design data and intellectual property are sensitive and must be protected.

Evaluate their security measures:

Use of secure file transfer protocols (SFTP, VPN, encrypted cloud services)

NDA agreements and IP protection clauses

ISO 27001 or similar information security certifications

Restricted access to project data on a need-to-know basis

Security checklist:

Where is the data stored and who has access?

What happens to the data post-project?

6. Pricing and Contract Flexibility

Cost is important, but it shouldn't be the only factor. A clear, competitive, and fair pricing model is essential.

Look for:

Transparent pricing (hourly, per drawing, or fixed cost)

No hidden fees for revisions or urgent deliveries

Flexible contracts (short-term, long-term, or per-project basis)

Discount models for bulk work or repeat projects

Budget tip:

Compare multiple vendors, but weigh pricing against quality and turnaround.

7. Past Client Reviews and References

Social proof is a strong indicator of a partner’s reliability and credibility.

What to check:

Client testimonials or case studies

Google reviews or third-party platforms (like Clutch, GoodFirms)

References or contacts from completed projects

Ask directly:

What is their client retention rate?

Can they connect you with past clients for feedback?

Red Flags to Avoid

Even with an impressive pitch, some vendors may not meet expectations. Watch out for:

Overpromising on unrealistic timelines or pricing

Lack of domain-specific samples or references

Poor English or communication breakdowns

Vague contracts with ambiguous deliverables

No clearly defined QC process or project plan

Being vigilant about these red flags helps you steer clear of unreliable partners.

How to Streamline the Outsourcing Process

Once you've selected a partner, optimizing the workflow ensures better outcomes.

Steps to follow:

Define scope and deliverables clearly: Include formats, layers, standards, and any unique requirements.

Share reference files: Models, CAD files, architectural plans, and markups.

Set up a communication routine: Daily standups or weekly updates help maintain alignment.

Use collaborative platforms: Tools like BIM 360, Autodesk Construction Cloud, or Slack help improve visibility.

Monitor performance: Use KPIs such as accuracy, turnaround, and responsiveness.

Future Trends in Shop Drawing Outsourcing

As AEC industries evolve, outsourcing partners must stay ahead of trends like:

Integration with BIM and VDC workflows

Use of AI-powered drafting tools and automation

Cloud collaboration for real-time updates

Sustainability-focused designs

Greater adoption of ISO and LEED-compliant drawing practices

Partnering with forward-thinking service providers helps future-proof your operations.

Final Thoughts

Outsourcing shop drawing services can significantly boost your project efficiency, reduce costs, and provide specialized expertise when done with the right partner. However, due diligence is critical. From technical capabilities and turnaround times to security and communication, a detailed evaluation framework is essential before onboarding any vendor.

Treat the process not as a simple transaction but as a strategic alliance. A reliable outsourcing partner doesn’t just deliver drawings—they contribute to your project’s success by ensuring quality, consistency, and clarity throughout the construction lifecycle.

0 notes

Text

How Accromet Supplies 330 Stainless Steel Sheets That Meet Aerospace & Furnace Industry Standards

In industries where high temperatures, mechanical stress, and corrosion are part of daily operations, choosing the right materials can mean the difference between operational success and costly downtime. That’s why industrial leaders in the aerospace and furnace manufacturing sectors rely on Accromet’s aerospace grade 330 stainless steel for consistent performance and certified quality.

From heat treatment furnaces to jet engine exhaust components, 330 stainless steel sheets deliver unmatched durability. And when sourcing them, manufacturers trust Accromet — a leading industrial stainless steel sheet supplier — for quality, compliance, and expertise.

Why 330 Stainless Steel Is Ideal for High-Stress Applications

330 stainless steel is an austenitic, nickel-chromium alloy known for:

Exceptional oxidation resistance up to 2000°F (1093°C)

Creep resistance under prolonged thermal exposure

High strength retention in extreme heat

Corrosion resistance in oxidizing and carburizing environments

These properties make it ideal for:

Aerospace engine components

Industrial heat-treating equipment

Radiant tubes and muffles

High-temperature conveyor systems

Accromet’s Commitment to Aerospace & Furnace Industry Standards

At Accromet, supplying stainless steel isn’t just about inventory — it's about meeting critical performance standards for high-heat, high-demand environments. Our aerospace grade 330 stainless sheets are:

✅ Sourced from verified mills with traceable certifications ✅ Manufactured to AMS, ASTM, and ASME specs ✅ Delivered with mill test reports and material certificates ✅ Available in custom cut sizes and bulk volumes for industrial buyers

🗨️ Customer Testimonial: “Accromet's 330 stainless steel exceeded our expectations in both quality and documentation. It passed every compliance audit in our aerospace project without a hitch.” — Procurement Manager, Aerospace Supplier (Ohio)

How We Ensure Quality Compliance

Accromet follows a rigorous process to ensure that each 330 stainless steel sheet meets and exceeds regulatory and performance expectations:

🔍 Heat and lot traceability

🧪 Material testing certifications

📦 Secure packaging for surface integrity

🚚 Nationwide shipping with tracking & delivery scheduling

Whether you're sourcing for a turbine housing or an industrial furnace wall, our team ensures that every shipment matches your engineering specifications and industry code requirements.

Secondary Applications We Serve

In addition to aerospace and furnace manufacturing, our 330 stainless steel sheets are widely used in:

Chemical processing industries

Petroleum refining equipment

High-temperature fasteners and fixtures

This versatility, backed by Accromet’s supply chain reliability, makes us a preferred industrial stainless steel sheet supplier across the U.S.

Q&A: What Industrial Buyers Want to Know

Q1: What makes aerospace grade 330 stainless different from standard stainless steel? A: Aerospace grade 330 stainless undergoes stricter quality control, with certifications to meet AMS/ASTM standards. It has higher resistance to thermal fatigue and oxidation, making it suitable for aircraft and space applications.

Q2: Can I get custom-cut 330 stainless steel sheets for specific furnace builds? A: Absolutely. Accromet offers custom sizing, thickness options, and edge conditioning to fit your exact project needs.

Q3: Do you provide documentation with the material? A: Yes. Every order includes full mill test reports and compliance documents to support traceability and QA processes.

Benefits of Sourcing from Accromet

Here’s why U.S.-based industrial companies trust us:

🛠️ Expert technical support for selecting the right alloy

📈 Long-standing reputation in the metals supply industry

🔒 Reliable inventory and fast fulfillment

🌐 Nationwide reach for consistent B2B service

Call to Action

Looking for certified, high-performance 330 stainless steel sheet? Join aerospace and industrial furnace manufacturers across the U.S. who trust Accromet for their most critical applications.

👉 Contact Accromet today to request a quote or compliance documentation — and experience the difference of working with a reliable industrial stainless steel sheet supplier.

aerospace grade 330 stainless

industrial stainless steel sheet supplier

330 stainless steel sheet for aerospace

330 stainless steel for high-temperature furnaces

oxidation resistance

heat-resistant alloy

nickel-chromium stainless steel

AMS certified stainless sheet

0 notes

Text

Your Guide to Importing Valves in the UAE: Regulations, Quality, and Trusted Suppliers

In the United Arab Emirates' continually expanding industrial economy, the need for quality valves is essential. For oil and gas applications, water treatment processes, HVAC systems, or manufacturing, selecting the appropriate valves—and the appropriate supplier—can affect the operation and safety of entire systems.

For anyone looking to import valves into the UAE, there needs to be an understanding of local regulations, quality control procedures, and how to source reputable suppliers of valves in Dubai and the wider UAE. That's what this guide provides—with valuable information from one of the region's most trusted names, Ali Yaqoob Trading.

Understanding the UAE's Valve Market

UAE has a robust industrial hub, driven by industries such as petrochemicals, oil and gas, construction, and maritime. Valves, both automatic and manual, are essential to control fluid systems in these industries.

As infrastructure and international trade have grown, valve imports to the UAE have also increased consistently. However, gaining entry to this competitive arena demands expertise and trusted partners.

Major Regulations on Importing Valves in the UA

Prior to importing valves into the UAE, it is essential to know the compliance requirements and what documentation is needed. Here are the details:

1. Product Certification

Valves imported must adhere to globally accepted standards like:

API (American Petroleum Institute)

ASME (American Society of Mechanical Engineers)

ISO standards for industrial quality and safety

The UAE government usually demands certified product documentation to confirm safety and compatibility.

2. Emirates Conformity Assessment Scheme (ECAS)

Some industrial equipment, such as valves, have to undergo ECAS, an EU-type approval scheme that ensures the product's compliance with UAE's technical requirements.

3. Customs Documents

You'll require:

Commercial invoice

Certificate of origin

Bill of lading

Packing list

Import permit (if required)

Dealing with professional valve suppliers in UAE guarantees your adherence to all of these documents without any delays.

Quality Considerations: What to Look for in a Valve Supplier

When sourcing valves, quality is more than just build material—it’s about long-term performance, durability, and safety. Here’s what buyers should expect:

Corrosion Resistance: Especially in marine or oil & gas applications.

Pressure and Temperature Ratings: Suitability for the operational environment.

Testing Certifications: Look for pressure testing, fire safety ratings, and third-party verifications.

After-Sales Support: Includes spare parts availability and technical assistance.

This is where Ali Yaqoob Trading makes a difference.

Why Choose Ali Yaqoob Trading?

As one of the most reliable valve suppliers in Dubai, Ali Yaqoob Trading has been a leading name in fluid handling solutions for decades. Here's what sets them apart:

Expertise Across Industries

From oil refineries to water treatment plants, they supply a wide range of valves, including:

Ball valves

Gate valves

Butterfly valves

Check valves

Solenoid and control valves

Global Brands, Local Delivery

Ali Yaqoob Trading collaborates with internationally renowned manufacturers to provide consistent quality products. This enables UAE clients to get high-quality valves with quick local backup.

Regulatory Compliance

They provide complete documentation and assistance for UAE import compliance, including customs assistance, testing certificate assistance, and installation guidelines.

Technical Consultation

Their in-house technical specialists assist clients in selecting the correct valve as per pressure, flow, media type, and temperature—providing safety and efficiency.

Tips for Successful Valve Importing

The following are some useful tips for companies intending to import valves into the UAE:

Deal with Licensed Suppliers: Make sure they are experienced and registered in handling customs.

Ask for Full Documentation: Always insist on certification, test reports, and ECAS approval if necessary.

Steer Clear of Counterfeits: Cheap imports may not have quality certifications. Go with tried names such as Ali Yaqoob Trading.

Plan for After-Sales Service: Downtime costs money. Select suppliers that provide timely maintenance and spare parts.

Conclusion: Trust Experience, Trust Quality

In importing valves in the UAE, everything is at stake—performance and compliance. Getting around the laws, staying up to international standards, and selecting the right partners are all part of the process.

Whether you're an engineer, contractor, or procurement manager, Ali Yaqoob Trading provides the guarantee of compliance, experience, and quality. Supported by decades of sector experience and a reputable name as being among the leading valve suppliers in the UAE, they're the first option for organizations that believe in accuracy and reliability.

Contact Ali Yaqoob Trading today to discuss their extensive selection of industrial valves and remove the hassle of importing.

#valve suppliers in dubai#Valve suppliers in UAE#oil and gas valves Dubai#UAE valve trading companies#top valve distributors in UAE#quality valve manufacturers Dubai#industrial valves UAE market#how to import valves in UAE

0 notes

Text

All SS Pipe Sizes in One Chart – Seamless & ERW | Udhhyog India

When working with stainless steel (SS) pipes, selecting the right size is crucial for system compatibility, flow requirements, and installation accuracy. Whether you're in fabrication, plumbing, infrastructure, or industrial projects, having access to a complete SS pipe size chart for seamless and ERW pipes simplifies the process.

At Udhhyog India, we supply SS seamless and ERW pipes in all standard sizes, thicknesses, and finishes. This comprehensive guide includes our verified size chart, applicable standards (IS/ASTM), and downloadable reference tables for engineers, buyers, and contractors.

🔍 What Are Seamless and ERW Stainless Steel Pipes?

🔧 SS Seamless Pipe:

Manufactured without welding, seamless pipes offer uniform strength and pressure handling. Made by extrusion or hot rolling, they are ideal for:

High-pressure fluid systems

Oil & gas pipelines

Boiler and heat exchanger tubes

Pharma and sanitary pipelines

🔩 SS ERW Pipe:

ERW (Electric Resistance Welded) pipes are formed by rolling SS coils and welding the seam. ERW pipes are widely used due to cost efficiency, availability in large diameters, and smooth internal finish.

📌 Udhhyog supplies both types across all major grades: SS 304, 316, and 202.

📏 All SS Pipe Sizes in One Chart – Nominal Bore, OD, Thickness

Here is a consolidated chart of commonly used SS pipe sizes, suitable for IS, ASTM (ASME B36.19M), and DIN-based systems.

✅ Seamless & ERW Pipe Size Chart (Inches + mm):

NB Size (Inch)OD (mm)Wall Thickness (mm)SCH 10SSCH 40SSCH 80S½”21.31.65 – 3.73✓✓✓¾”26.91.65 – 3.91✓✓✓1”33.42.0 – 4.55✓✓✓1½”48.32.0 – 5.08✓✓✓2”60.32.0 – 5.54✓✓✓3”88.92.11 – 7.62✓✓✓4”114.32.11 – 8.56✓✓✓6”168.32.77 – 10.97✓✓✓8”219.13.18 – 12.70✓✓✓10”273.03.4 – 15.09✓✓✓12”323.83.96 – 17.48✓✓✓

🧾 Full PDF chart available from Udhhyog for sizes up to 24” and all thickness schedules.

🧰 Grades Supplied by Udhhyog

GradeApplicationsSS 202Economy-grade furniture, railings, light-duty useSS 304Plumbing, food processing, general structural useSS 316Chemical, coastal, pharma, and marine applications

All Udhhyog pipes are compliant with:

ASTM A312 / A554

IS 1239 / IS 3589

DIN 11850 / EN 10217-7

📦 Available Finishes

Mill Finish

Brush Finish (Matt)

Mirror Polish

2B or BA finish (for decorative & sanitary use)

💰 Pricing Guide (Indicative – June 2025)

SizeGradeTypePrice/Kg (₹)Price/Meter (₹)1”SS 304ERW₹270 – ₹285₹380 – ₹4202”SS 316Seamless₹360 – ₹375₹630 – ₹6903”SS 304ERW₹265 – ₹275₹740 – ₹7804”SS 304Seamless₹280 – ₹290₹1,050 – ₹1,150

📞 Get official quotation and updated bulk rate from Udhhyog sales team.

🏭 Industries We Serve

Udhhyog supplies SS pipes to a wide range of sectors:

✅ Real Estate & Infrastructure

✅ Food & Beverage

✅ Chemical & Petrochemical

✅ Water Treatment & RO Systems

✅ Fire Protection (Sprinkler Pipes)

✅ OEM Fabricators & EPC Projects

📘 Request Your Free Pipe Size Chart PDF from Udhhyog

The downloadable chart includes:

✅ Sizes from ½” to 24”

✅ OD, ID, and wall thickness

✅ Schedule 5S to 160

✅ Seamless and ERW data

✅ Weight per meter details

📎 [Click here to request Udhhyog’s 2025 SS Pipe Size Chart PDF]

🙋 Frequently Asked Questions (FAQ)

❓1. What is the difference between seamless and ERW SS pipe?

Answer: Seamless pipes have no weld seam and are ideal for high-pressure applications. ERW pipes have a welded seam and are more cost-effective for general usage.

❓2. What sizes are available in seamless vs ERW?

Answer: Seamless pipes are typically available from ½” to 12”, while ERW pipes are offered from ½” up to 24”. Udhhyog supplies both types with full MTC certification.

❓3. How do I select the correct thickness or schedule?

Answer: It depends on pressure, flow, and application. Udhhyog’s technical team helps clients choose the right SCH (Schedule 10, 40, 80, etc.) based on your requirements.

❓4. Are Udhhyog pipes ISI marked?

Answer: Yes. All ERW and seamless pipes conform to ISI, ASTM, or DIN standards, with ISI stamping available for government and civil tenders.

❓5. Can I buy custom-length pipes?

Answer: Absolutely. We offer cut-to-length, threading, and polish finishing for all pipe sizes. Minimum order quantity may apply for customized processing.

0 notes