#ASME BPE Tubes

Text

ASME BPE Tubes: Revolutionizing Hygienic Tubing Solutions

ASME BPE Tubes, compliant with the American Society of Mechanical Engineers' Bioprocessing Equipment (ASME BPE) standards, are designed to meet the rigorous requirements of industries where hygiene is paramount. These tubes boast exceptional quality and performance, making them indispensable in critical processes.

Importance of ASME BPE Tubes in Industries

Hygienic Standards

In industries like pharmaceuticals and biotechnology, maintaining hygienic standards is non-negotiable. ASME BPE Tubes adhere to stringent cleanliness criteria, minimizing the risk of contamination and ensuring product purity.

Quality Assurance

ASME BPE Tubes undergo rigorous testing to guarantee consistent quality. Manufacturers adhere to strict guidelines to deliver tubes that meet the highest standards of performance and reliability.

Key Features of ASME BPE Tubes

Surface Finish

ASME BPE Tubes feature ultra-smooth surface finishes, reducing the risk of microbial growth and facilitating thorough cleaning processes.

Material Composition

Crafted from high-grade stainless steel and other corrosion-resistant materials, ASME BPE Tubes offer exceptional durability and longevity, even in harsh operating environments.

Dimensions and Tolerances

Precise dimensions and tight tolerances ensure seamless integration into existing systems, minimizing installation complexities and optimizing operational efficiency.

Applications of ASME BPE Tubes

ASME BPE Tubes find widespread use across various industries, including:

Pharmaceutical Industry: Critical for drug manufacturing processes where purity is paramount.

Biotechnology: Ideal for sterile fluid transfer and processing applications.

Food and Beverage: Ensures sanitary handling and transportation of consumable products.

Comparison with Traditional Tubing Solutions

Compared to conventional tubing materials like PVC or rubber, ASME BPE Tubes offer superior cleanliness, durability, and corrosion resistance, making them the preferred choice for industries with strict hygiene requirements.

Compliance with ASME BPE Standards

Certification Process

ASME BPE Tubes undergo rigorous certification processes to ensure compliance with industry standards and regulations, providing end-users with confidence in their performance and reliability.

Regulatory Compliance

Manufacturers adhere to ASME BPE guidelines and regulations, ensuring that their products meet the stringent requirements of regulatory bodies, thus enhancing consumer safety and product integrity.

Advantages of ASME BPE Tubes Over Conventional Tubing

Cleanability

The smooth surface finish of ASME BPE Tubes enables effortless cleaning and sterilization, minimizing the risk of bacterial contamination and ensuring product purity.

Durability

Constructed from robust materials, ASME BPE Tubes exhibit exceptional durability, withstanding harsh operating conditions and prolonged use without compromising performance.

Corrosion Resistance

ASME BPE Tubes are inherently resistant to corrosion, making them ideal for applications where exposure to corrosive substances is common, ensuring longevity and reliability.

Considerations for Selecting ASME BPE Tubes

When choosing ASME BPE Tubes, it's essential to consider factors such as budgetary constraints, compatibility with existing systems, and specific application requirements to ensure optimal performance and cost-effectiveness.

Installation and Maintenance Tips

Proper handling procedures and routine inspections are essential for the successful installation and maintenance of ASME BPE Tubes. Following manufacturer guidelines and best practices can prolong tube lifespan and prevent costly downtimes.

Future Trends in ASME BPE Tube Technology

Advancements in manufacturing processes and the emergence of novel materials promise to enhance the performance and versatility of ASME BPE Tubes, opening doors to new applications and opportunities.

Case Studies Highlighting Successful Implementation

Real-world examples demonstrate the efficacy of ASME BPE Tubes in improving operational efficiency, ensuring product quality, and meeting regulatory requirements across diverse industries.

Challenges and Limitations

Despite their numerous benefits, challenges such as cost implications and retrofitting complexities may hinder widespread adoption of ASME BPE Tubes, requiring innovative solutions and collaborative efforts from stakeholders.

Sustainability and Environmental Impact

Addressing concerns related to sustainability and environmental impact, manufacturers are exploring eco-friendly materials and production methods to minimize the carbon footprint of ASME BPE Tubes and promote a greener future.

Conclusion

In conclusion, ASME BPE Tubes represent a paradigm shift in hygienic tubing solutions, offering unmatched cleanliness, durability, and performance across diverse industries. As technology continues to evolve,

1 note

·

View note

Text

Your Guide To Essential Pharmaceutical Production Metal Fittings

The pharmaceutical industry is built on tight rules and regulations where precision and control are non-negotiable. Every stage or step in the manufacturing process, from raw ingredient handling to final packaging, requires meticulous attention to detail. One important element of this controlled environment is the use of essential pharmaceutical production metal fittings. These fittings play an essential role in ensuring the purity, consistency, and safety of medicines manufactured.

Why do Metal Fittings Matter in the Pharmaceutical Process?

In pharmaceutical production, even minor contamination can have life-threatening consequences. Unlike their plastic counterparts, metal fittings offer superior durability, high-temperature resistance, and a smooth, non-porous surface. This minimizes the risk of bacterial growth, product degradation, and chemical reactions that could impact the efficacy or safety of medications. Additionally, high-quality metal fittings can withstand the rigorous cleaning and sterilization procedures employed in pharmaceutical manufacturing.

Understanding Pharmaceutical Grade Metal Fittings

Not all metal fittings are created equal. Pharmaceutical applications demand a specific type of fitting known as Bioprocessing Equipment (BPE) fittings. These fittings adhere to strict industry standards set by organizations like the American Society of Mechanical Engineers (ASME) BPE standard and the International Organization for Standardization (ISO) 1127.

BPE fittings are designed to:

1. Minimize dead space: This reduces the risk of product stagnation and potential contamination.

2. Facilitate cleaning and sterilization: Smooth surfaces and crevice-free designs allow for thorough cleaning and sterilization processes.

3. Maximize liquid flow efficiency: Optimized designs minimize flow restrictions and ensure consistent product flow.

4. Maintain aseptic conditions: The use of high-quality materials and leak-proof connections minimizes the risk of contamination from the environment.

Common Materials for Pharmaceutical Metal Fittings

Several metal alloys meet the stringent requirements for BPE fittings in pharmaceutical production. Here are some of the most commonly used pharma metal fittings:

1. 316L Stainless Steel: The most widely used material due to its excellent corrosion resistance, high strength, and cleanability.

2. Hastelloy C-22: A nickel-chromium-molybdenum solid solution that offers superior resistance to highly corrosive chemicals and is often used in demanding applications.

3. Monel 400: A nickel-copper alloy 400 solid solutions well-suited for environments with high chloride concentrations and acidic conditions.

4. Tantalum: A high-performance material offering exceptional corrosion resistance but at a significantly higher cost.

Types of Pharmaceutical Metal Fittings

A diverse range of BPE fittings caters to the various needs of pharmaceutical production pipelines. Here are some essential types:

1. Tubes and Pipes: Form the backbone of the piping system, transferring liquids, gases, and other materials throughout the production process.

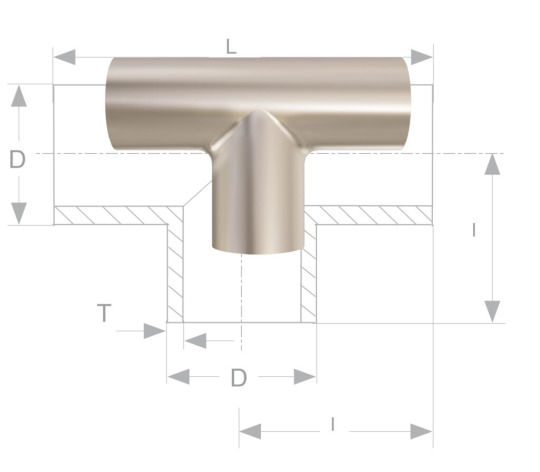

2. Bends and Elbows: Allow for directional changes in the piping layout.

3. Reducers and Increasers: Connect pipes of different diameters.

4. Unions and Couplings: Allows easy connection and disconnection of pipes for maintenance and cleaning.

5. Butterfly Valves: Control the flow of fluids within the system.

6. Clamps and Flanges: Provide secure connections and facilitate pipe sealing.

Benefits of Using High-Quality Pharmaceutical Metal Fittings

1. Improved Product Quality: Reduces the risk of contamination, ensuring the purity and consistency of medications.

2. High Production Efficiency: Minimizes downtime associated with leaks or equipment failure.

3. Reduced Maintenance Costs: Durable construction ensures longer service life and fewer maintenance needs.

4. Compliance with Regulations: Ensures adherence to stringent pharmaceutical manufacturing regulations.

Online Fittings: Your Trusted Supplier of Pharmaceutical Metal Fittings

Essential pharmaceutical production metal fittings are much more than just connecting components. They are important contributors to the safety and efficacy of medications. By understanding the types, materials, and benefits of BPE fittings, you can make informed decisions that ensure a successful and compliant pharmaceutical manufacturing operation.

At Online Fittings, we understand the critical role BPE fittings play in pharmaceutical production. We offer a comprehensive selection of high-quality BPE metal fittings from leading manufacturers, all compliant with industry standards. Our team of experts can help you choose the right fittings for your specific needs and ensure you have the reliable components needed to maintain a safe and efficient production process.

0 notes

Text

ASME BPE Stainless Steel DIN 1.4435 Sanitary Tubes Suppliers in India

Introduction

Universe Metal & Alloy is your premier destination for top-quality Stainless Steel DIN 1.4404 Sanitary Tubes. As leading Manufacturers, Suppliers, Stockists, and Exporters of Stainless Steel DIN 1.4404 Sanitary Tubes in the industry, we pride ourselves on delivering unparalleled products that meet the highest standards of excellence. Our commitment to excellence is evident in every aspect of our operations, from sourcing premium materials to employing cutting-edge manufacturing techniques.

Description

Universe Metal & Alloys manufactures ASME BPE stainless steel DIN 1.4404 sanitary tubes designed to meet the stringent standards required by industries that prioritize hygiene and purity. Stainless steel DIN 1.4404, also known as 316L, is renowned for its excellent corrosion resistance, durability, and hygienic properties.

These sanitary tubes are meticulously engineered to provide a high level of cleanliness and surface finish, which is essential for preventing contamination in sensitive applications. Produced using advanced manufacturing processes and subjected to rigorous quality control measures, these tubes meet ASME BPE standards. Universe Metal & Alloys offers a range of sizes and configurations to cater to diverse industry needs, ensuring that each product delivers optimal performance and reliability.

Benefits

Choosing ASME BPE stainless steel DIN 1.4404 sanitary tubes from Universe Metal & Alloys offers numerous benefits:

Superior Corrosion Resistance: The 316L grade provides excellent resistance to corrosion, making these tubes ideal for use in environments where purity and cleanliness are critical.

High Level of Cleanliness: The tubes are manufactured to meet ASME BPE standards, ensuring a smooth, polished surface that minimizes the risk of contamination and bacterial growth.

Durability and Strength: Stainless steel 316L is known for its durability and mechanical strength, ensuring long-lasting performance even in demanding applications.

Compliance with International Standards: Universe Metal & Alloys ensures that all products comply with ASME BPE and DIN standards, providing customers with confidence in the quality and safety of their sanitary tubes.

Versatility: Available in various sizes and configurations, these tubes can be used in a wide range of applications, from pharmaceutical processing to food and beverage production.

Precision Engineering: Each tube is crafted with precision, ensuring consistent quality and performance in critical applications.

Specification

Specification of 3A Stainless Steel DIN 14404 Sanitary Tubes

Size

12-168mm

W.T

0.7-3.0mm

Standard

ASTM A270, ASTM A249

Grades

304 / 304L / 316 / 316L / 409L / 430

Length

3000mm ~ 6000mm

Surface treatment

No.1 – 2B – Matte finish -#180 – #240 – #320 – #400 Bright – #600 Bright – 6K Mirror – 8K Mirror – Hair Line

Conclusion

Universe Metal & Alloys has established itself as a leading manufacturer of ASME BPE stainless steel DIN 1.4404 sanitary tubes in India. Their unwavering commitment to quality, innovation, and customer satisfaction has earned them a trusted reputation in industries where hygiene and performance are critical.

For more information or to place an order, contact Universe Metal & Alloys at [email protected] or call +91-22-66363360 / 66393788

0 notes

Link

WELCOME TO HYGIENIC STAINLESS STEELS LTD.

KNOWLEDGE AND EXPERTISE SERVING THE HYGIENIC PROCESS INDUSTRIES.

HSS is a leading supplier of Hygienic Stainless Steel Tubes, Valves, Fittings and accessories to the UK Processing Industries. We also serve Ireland, European and worldwide markets. Based in the North West, HSS is ideally located in Bamber Bridge, Preston, close to the M6, M65 motorways. We offer a next day delivery service throughout the UK as well as providing a fast and efficient service to our export customers. Established in 1987 we have earned a reputation for providing quality, value and performance across our complete product range. Our commitment to service is only a phone call away.

MISSION STATEMENT

To build on our position as a market leader for the supply of high quality Hygienic Stainless Steel Tubes, Valves and Fittings. To work directly with our customers and suppliers to ensure we provide the most cost effective and highest quality products on the market. To create a fully integrated supply chain to satisfy the needs of our customers.

FABRICATION

We provide a specialist Stainless Steel in-house fabrication service. We have a fully integrated fabrication facility using time served welders who produce high quality welding. We offer bespoke products to match client requirements. Tube Spools | Duplex Filters | Y Pieces | Swept Tees | Valve Assemblies | Manifolds | Bespoke items | Adaptors

QUALITY ASSURANCE

To ensure customer satisfaction we are fully committed to Total Quality. All our suppliers hold ISO 9001:2008 certification. We can supply BS EN 10204.3.1B material certificates on request. All our products are manufactured from fully traceable material and are fully tested before shipment.

DEDICATED SALES AND SERVICE

HSS is your single source supplier for complete packages of Stainless Steel Hygienic Tube, Valves and Fittings for all your Hygienic processing requirements. We hold extensive stocks of quality products. We have a dedicated and highly experienced team who will provide you with expert and professional service at all times.

INDUSTRIES SERVED

HSS understands that each segment of our industry has unique Stainless Steel requirements. HSS meets and exceeds these stringent requirements.• Food • Dairy • Brewing • Micro-Brewing • Distilling • Water • Pharmaceutical • Biotechnology • Cosmetics • Biomedical • OEM Equipment Manufacturers • General Pipework Industry • Water Treatment Plants • Petrochemical • Gas

PRODUCTS AND MATERIALS:

All our products meet International standards including BS, SMS, DIN, US3A and ASME BPE.

Our products are available in Stainless Steel grades 304, 316, 316L – 1.4301, 1.4404.Our Valves and Fittings are produced from Forgings to ensure the highest level of integrity and material traceability.We can provide full material certification and traceability on all products.

0 notes

Text

ASME BPE Stainless Steel DIN 1.4404 Sanitary Tubes Stockists

Introduction

Universe Metal & Alloy is your premier destination for top-quality Stainless Steel DIN 1.4404 Sanitary Tubes. As leading Manufacturers, Suppliers, Stockists, and Exporters of Stainless Steel DIN 1.4404 Sanitary Tubes in the industry, we pride ourselves on delivering unparalleled products that meet the highest standards of excellence. Our commitment to excellence is evident in every aspect of our operations, from sourcing premium materials to employing cutting-edge manufacturing techniques.

Description

Universe Metal & Alloys manufactures ASME BPE stainless steel DIN 1.4404 sanitary tubes, designed to meet the stringent standards required by the pharmaceutical, food, and biotechnology industries. Stainless steel DIN 1.4404, also known as 316L, is favored for its excellent corrosion resistance, durability, and hygienic properties.

These sanitary tubes are engineered to provide a high level of cleanliness and surface finish, essential for preventing contamination in sensitive applications. The tubes are produced using advanced manufacturing processes and are subject to rigorous quality control measures to ensure they meet the ASME BPE standards. Universe Metal & Alloys offers a range of sizes and configurations to cater to diverse industry needs, ensuring that each product delivers optimal performance and reliability.

Benefits

Choosing ASME BPE stainless steel DIN 1.4404 sanitary tubes from Universe Metal & Alloys offers numerous benefits:

Superior Corrosion Resistance: The 316L grade provides excellent resistance to corrosion, making these tubes ideal for use in environments where purity and cleanliness are critical.

High Level of Cleanliness: The tubes are manufactured to meet ASME BPE standards, ensuring a smooth, polished surface that minimizes the risk of contamination and bacterial growth.

Durability and Strength: Stainless steel 316L is known for its durability and mechanical strength, ensuring long-lasting performance even in demanding applications.

Compliance with International Standards: Universe Metal & Alloys ensures that all products comply with ASME BPE and DIN standards, providing customers with confidence in the quality and safety of their sanitary tubes.

Versatility: Available in various sizes and configurations, these tubes can be used in a wide range of applications, from pharmaceutical processing to food and beverage production.

Precision Engineering: Each tube is crafted with precision, ensuring consistent quality and performance in critical applications.

Specification

Specification of 3A Stainless Steel DIN 14404 Sanitary Tubes

Size

12-168mm

W.T

0.7-3.0mm

Standard

ASTM A270, ASTM A249

Grades

304 / 304L / 316 / 316L / 409L / 430

Length

3000mm ~ 6000mm

Surface treatment

No.1 – 2B – Matte finish -#180 – #240 – #320 – #400 Bright – #600 Bright – 6K Mirror – 8K Mirror – Hair Line

Conclusion

Universe Metal & Alloys has established itself as a leading manufacturer of ASME BPE stainless steel DIN 1.4404 sanitary tubes in India. Their unwavering commitment to quality, innovation, and customer satisfaction has earned them a trusted reputation in industries where hygiene and performance are critical.

For more information or to place an order, contact Universe Metal & Alloys at [email protected] or call +91-22-66363360 / 66393788.

0 notes