#ASRS Shuttle solution

Explore tagged Tumblr posts

Text

Automated Storage and Retrieval Systems Market Growth Driven by Labor Shortages and Warehouse Automation Demands

The global Automated Storage and Retrieval Systems market is witnessing a robust expansion, powered by the continuous evolution in supply chain and warehouse automation. ASRS are a key solution in optimizing storage density, improving inventory control, and enhancing picking accuracy in warehouses and manufacturing facilities. These systems, including unit load, mini load, carousel-based, and shuttle-based ASRS, are enabling companies to increase operational efficiency and reduce labor dependency. The market growth is being driven by a range of significant factors, which are accelerating their adoption across sectors such as e-commerce, food & beverage, pharmaceuticals, automotive, and retail.

Growing Demand for Warehouse Automation One of the primary drivers of the ASRS market is the escalating demand for warehouse automation. With the global boom in e-commerce and omnichannel retailing, businesses are pressured to manage complex and high-volume order fulfillment operations. ASRS offer an automated solution to these challenges by optimizing inventory management, increasing throughput rates, and reducing operational costs. Companies are increasingly deploying ASRS to stay competitive and meet the rising expectations for rapid and accurate order deliveries. Automation also provides real-time inventory visibility, an essential requirement in modern warehousing.

Labor Shortages and Rising Labor Costs Another critical market driver is the global labor shortage, particularly in logistics and warehousing roles. As finding and retaining skilled warehouse staff becomes more difficult, businesses are turning to automated systems to fill the gap. Moreover, rising labor costs in developed economies are prompting companies to adopt ASRS as a cost-saving measure. By reducing the reliance on manual labor, these systems not only ensure consistent productivity but also improve workplace safety and reduce human error. This trend is particularly strong in regions like North America and Europe, where wages are higher and labor availability is declining.

Increased Need for Space Optimization Space utilization is a vital consideration for modern warehouses, especially in high-cost urban areas. ASRS enable high-density storage and allow vertical use of space, thereby reducing the overall warehouse footprint. This is particularly beneficial for businesses operating in cities where real estate costs are a significant burden. Space optimization through automated systems helps maximize storage capacity without the need for warehouse expansion, contributing to significant cost savings in the long run.

Technological Advancements and Integration with Industry 4.0 Technological innovation is another strong driver behind the ASRS market growth. The integration of ASRS with advanced technologies such as IoT, AI, machine learning, and data analytics has enhanced their functionality and appeal. These technologies enable predictive maintenance, performance monitoring, and smart decision-making in real-time. The emergence of Industry 4.0 has encouraged the adoption of intelligent automation solutions, and ASRS are a cornerstone of this digital transformation in logistics. As technology becomes more accessible and affordable, more small and medium enterprises are expected to adopt ASRS to stay technologically relevant.

Growth in E-commerce and Omnichannel Retailing The rapid expansion of e-commerce is significantly contributing to the adoption of ASRS globally. Online retailers deal with high order volumes, frequent returns, and a wide range of SKUs, all of which demand advanced storage and retrieval capabilities. ASRS enable e-commerce companies to manage inventory dynamically, streamline picking and packing processes, and meet tight delivery schedules. The trend of omnichannel retailing, which requires synchronization between online and offline channels, further strengthens the need for efficient warehouse solutions, propelling the ASRS market.

Government Initiatives and Supportive Regulations Governments in various countries are promoting the adoption of automation technologies through subsidies, incentives, and favorable regulations. These initiatives aim to enhance manufacturing and logistics infrastructure, increase industrial productivity, and create smart cities. Such policies are encouraging more companies to invest in ASRS and related technologies. For instance, government-backed initiatives in countries like China, Germany, and Japan are promoting smart manufacturing and digital logistics, thereby indirectly fueling the ASRS market growth.

Resilience in Times of Disruption The COVID-19 pandemic highlighted the vulnerability of supply chains that relied heavily on human labor. In response, many companies began investing in ASRS to increase operational resilience and reduce dependence on workforce availability. Automated systems are capable of maintaining operations even during periods of labor shortages, lockdowns, or health-related disruptions. This long-term shift towards resilient and flexible supply chains is expected to continue, with ASRS playing a vital role.

Conclusion The Automated Storage and Retrieval Systems market is being driven by a confluence of technological, economic, and social factors. The need for efficiency, speed, and resilience in logistics and warehousing is accelerating the adoption of ASRS across diverse industries. As businesses look to future-proof their operations and navigate an increasingly competitive landscape, the deployment of these systems is set to rise, positioning the market for substantial growth in the coming years.

0 notes

Text

Maximizing Efficiency with Advanced Automated Storage Systems

In today's fast-paced business environment, companies are under constant pressure to improve efficiency, reduce costs, and enhance overall productivity. One of the most effective ways to achieve these goals is by implementing automated storage systems. These advanced systems are transforming the way businesses handle inventory, streamline logistics, and manage warehouse operations. By reducing manual labor, minimizing errors, and optimizing space utilization, automation is setting new standards in the world of warehousing and distribution.

The Growing Need for Automation in Warehousing

The demand for efficient storage solutions has never been higher. As e-commerce continues to grow, businesses are dealing with larger inventories, increased order volumes, and tighter delivery deadlines. Traditional warehousing methods often struggle to keep up with these demands, leading to inefficiencies, misplaced inventory, and delays in order fulfillment. This is where asrs technology becomes invaluable.

These systems offer a fully automated approach to storing and retrieving goods, eliminating the need for excessive manual intervention. Whether it’s a retail giant handling thousands of daily orders or a manufacturing company managing complex parts and components, automated storage systems provide an optimized, seamless solution that enhances productivity.

How Automated Storage Systems Work

At the core of asrs system technology is the integration of robotics, artificial intelligence, and data-driven software. These systems use conveyors, robotic arms, and shuttles to transport items within a warehouse. The entire operation is controlled by software that ensures items are stored and retrieved efficiently, reducing the time spent on manual handling.

One of the most common types of automated storage systems.These systems are designed to maximize warehouse efficiency by utilizing advanced robotic mechanisms to store and retrieve items from designated storage locations. By using vertical space effectively, asrs system can significantly increase storage capacity without requiring additional warehouse expansion.

Benefits of Implementing Automated Storage and Retrieval Systems

1. Improved Space Utilization

One of the biggest challenges in warehousing is space management. Traditional storage methods often result in wasted space due to inefficient shelving and storage layouts. Asrs systems solve this issue by using compact, high-density storage solutions that make the most of vertical and horizontal space. This allows businesses to store more inventory within the same footprint, reducing the need for costly expansions.

2. Increased Efficiency and Productivity

Manual storage and retrieval processes can be slow and prone to human error. By implementing an automated storage and retrieval system, businesses can significantly increase the speed and accuracy of inventory handling. Orders can be processed faster, leading to shorter lead times and improved customer satisfaction. Employees are also freed from repetitive tasks, allowing them to focus on higher-value activities.

3. Reduced Labor Costs and Errors

Labor costs are one of the biggest expenses in warehouse management. Hiring and training workers, managing shift schedules, and addressing human errors all contribute to operational inefficiencies. Automated storage systems reduce reliance on manual labor, lowering costs and improving accuracy. With automated tracking and retrieval, businesses can minimize misplaced inventory, incorrect shipments, and stock discrepancies.

4. Enhanced Inventory Management

A well-organized warehouse is critical to maintaining accurate inventory levels. Asrs systems are equipped with real-time inventory tracking features, allowing businesses to monitor stock levels, movement, and usage patterns. This level of control helps prevent stockouts and overstock situations, ensuring that inventory is maintained at optimal levels at all times.

5. Increased Workplace Safety

Warehouses can be hazardous environments, especially when employees are required to lift heavy items, operate forklifts, or navigate cluttered storage spaces. Any automated storage and retrieval system technology reduces the risk of workplace injuries by minimizing the need for manual lifting and transportation. Employees can work in a safer environment, reducing accidents and associated liabilities.

6. Faster Order Fulfillment

With the rise of e-commerce and consumer demand for faster shipping, businesses must ensure quick and accurate order processing. Automated storage systems improve the speed at which products are picked, packed, and shipped, enabling companies to meet customer expectations more efficiently. This advantage is crucial in industries where speed and reliability determine customer satisfaction and brand loyalty.

7. Sustainability and Energy Efficiency

Sustainability is becoming an important factor in warehouse operations. Asrs systems contribute to greener supply chain practices by reducing energy consumption and waste. Automated systems optimize movement, ensuring that only necessary processes are carried out. This efficiency results in lower energy use and a reduced carbon footprint, helping businesses achieve their sustainability goals.

Industries That Benefit from Automated Storage Systems

Several industries have embraced automated storage and retrieval system technology to enhance their operations:

E-commerce and Retail: Faster order fulfillment and optimized storage for large inventories.

Manufacturing: Efficient handling of parts and components in production facilities.

Pharmaceuticals: Secure storage and tracking of medical supplies and drugs.

Automotive: Better organization and retrieval of spare parts and components.

Food and Beverage: Temperature-controlled storage and automated retrieval for perishable goods.

The Future of Automated Warehousing

As technology continues to evolve, automated storage systems are expected to become even more advanced. Integration with artificial intelligence, machine learning, and predictive analytics will further enhance efficiency, allowing businesses to anticipate demand fluctuations and adjust inventory accordingly. Future innovations may also include robotic picking systems that work alongside human workers for improved hybrid automation.

Investing in asrs systems is no longer a luxury but a necessity for businesses that want to remain competitive. Automation is transforming the way warehouses operate, and companies that adopt these solutions will enjoy improved efficiency, cost savings, and a streamlined supply chain.

0 notes

Text

Automated Storage Systems: Growing from $9.2B to $16.5B by 2034

Automated Storage and Retrieval Systems (ASRS) market is expected to expand from $9.2 billion in 2024 to $16.5 billion by 2034, with a CAGR of 5.8%. This industry encompasses technologies designed to automate inventory management and retrieval processes in warehouses and distribution centers. The sector includes a variety of systems such as carousels, vertical lift modules, and robotic shuttles, which enhance operational efficiency, reduce labor costs, and optimize storage space. ASRS is pivotal in sectors like manufacturing, retail, and logistics, driven by the growing demand for automation, e-commerce expansion, and supply chain optimization.

To Request Sample Report: https://www.globalinsightservices.com/request-sample/?id=GIS10342 &utm_source=SnehaPatil&utm_medium=Article

The ASRS industry is witnessing robust growth, propelled by the need for efficient inventory management and space optimization. Unit load ASRS systems lead the market, driven by their capacity to handle large volumes and heavy loads, thus catering to industries like automotive and electronics. Mini-load ASRS systems follow as the second-highest performing sub-segment, offering flexibility and speed for smaller items, crucial for e-commerce and retail sectors. Geographically, North America is at the forefront, benefiting from technological advancements and a strong logistics infrastructure. Europe ranks as the second-leading region, with its focus on automation and smart warehousing solutions. Within these regions, the United States and Germany are key players, leveraging their industrial prowess and innovation capabilities. Asia-Pacific is emerging rapidly, fueled by manufacturing growth and increasing investments in automation, particularly in China and Japan, which are pivotal markets within the region.

Buy Now : https://www.globalinsightservices.com/checkout/single_user/GIS10342/?utm_source=SnehaPatil&utm_medium=Article

In 2023, the Automated Storage and Retrieval Systems (ASRS) industry displayed robust segmentation, with the unit load ASRS segment capturing a substantial 45% of the market share. This was followed by the mini-load ASRS at 30%, and the vertical lift module segment at 15%. The remaining 10% was divided among other specialized ASRS types. The industry saw a volume of 300,000 units, expected to rise to 500,000 units by 2033. The dominance of the unit load segment is attributed to its efficiency in handling large volumes and its prevalence in industries such as automotive and food & beverage.

The competitive landscape is shaped by key players like Daifuku Co., Ltd., and Swisslog Holding AG, who are continually innovating to maintain market leadership. Regulatory frameworks, particularly in regions like the EU and North America, emphasize automation and safety standards, impacting operational strategies. The future outlook for the ASRS market remains promising, with a projected CAGR of 10% from 2023 to 2033. This growth is driven by increasing e-commerce demand and technological advancements such as AI integration. However, challenges such as high initial costs and integration complexities persist. Investment in R&D and strategic partnerships will be crucial for capturing emerging opportunities in this dynamic sector.

The ASRS industry is witnessing significant growth across various regions. North America stands as a prominent market, driven by the demand for automation in warehouses and distribution centers. The United States leads this growth due to its early adoption of advanced technologies and the presence of key market players.

Europe follows closely, with countries like Germany and the United Kingdom investing in ASRS to enhance operational efficiency. The focus on Industry 4.0 and smart logistics solutions further propels the market in this region. The European market is also supported by the increasing trend of e-commerce, necessitating efficient storage solutions.

Asia Pacific is experiencing rapid expansion in the ASRS industry, primarily due to the booming e-commerce sector in China and India. The region’s growing manufacturing sector also contributes to the demand for automated storage solutions. Government initiatives supporting industrial automation further boost the market.

Latin America and the Middle East & Africa regions are gradually adopting ASRS technologies. In Latin America, Brazil and Mexico are key contributors, driven by the modernization of logistics infrastructure. The Middle East & Africa region sees growth due to the expansion of the retail and manufacturing sectors, with the United Arab Emirates and South Africa leading the charge.

The ASRS industry is witnessing transformative shifts in market dynamics. The integration of advanced technologies like artificial intelligence and machine learning is enhancing system efficiency and accuracy. These innovations are driving a surge in demand, particularly in sectors such as e-commerce and manufacturing, where rapid and precise inventory management is crucial. Companies are increasingly investing in ASRS to optimize their supply chain operations, reduce labor costs, and improve warehouse space utilization. This trend is expected to significantly expand the market size over the coming years.

Pricing strategies in the ASRS industry are influenced by customization levels and technology integration. Systems that incorporate sophisticated software solutions and robotics command premium pricing. However, the growing competition among key players is exerting downward pressure on prices, making ASRS more accessible to small and medium-sized enterprises. Additionally, the push for sustainability is prompting manufacturers to develop energy-efficient systems, which, although initially more expensive, offer long-term cost savings.

#Automation #ASRS #Warehousing #SupplyChain #SmartLogistics #Industry40 #EcommerceGrowth #StorageSolutions #InventoryManagement #RetailTech #ManufacturingInnovation #LogisticsEfficiency #TechIntegration #AIinLogistics #FutureOfWarehousing

0 notes

Text

Revolutionizing Warehouse Management with Advanced Racking Solutions

In today’s fast-paced, competitive environment, effective warehouse management is critical for companies looking to optimize their logistics operations. Advanced racking solutions play a pivotal role in revolutionizing warehouse storage, improving inventory management, and enhancing overall productivity. Traditional storage methods are no longer sufficient to meet the high demands of modern warehouses. From automated systems to custom-designed racking, innovative storage solutions offer the flexibility and efficiency necessary for a range of industries.

At Sigma Racks, we are transforming warehouse management with innovative, advanced racking solutions designed to maximize space, enhance efficiency, and improve safety. Our range of racking systems—such as high-density pallet racks, ASRS-integrated shuttle systems, and multi-level mezzanine setups—ensures optimal space utilization and seamless inventory access. By integrating automation and safety features, Sigma Racks empowers businesses to streamline workflows, reduce damage, and increase productivity. With a focus on scalability and flexibility, our solutions cater to diverse warehousing needs, helping businesses stay competitive and prepared for future growth. Transform your storage with Sigma Racks—where innovation meets efficiency.

1. Optimizing Space Utilization

Maximizing storage space is a priority for warehouses with limited square footage and growing inventory needs. Advanced racking systems, such as high-density pallet racks, cantilever racks, and drive-in/drive-through racking, allow warehouses to utilize vertical and horizontal space effectively. For instance, drive-in racks are designed for last-in, first-out (LIFO) inventory systems, making them ideal for high-volume storage of uniform items. These systems drastically reduce the need for aisle space, enabling warehouses to store more products within the same footprint.

Additionally, vertical storage options like mezzanine systems and multi-level racking further expand storage capabilities without costly building expansions. By creating layers of storage, these systems make better use of the cubic space in a warehouse, offering a cost-effective solution for warehouses facing space limitations.

2. Enhancing Accessibility and Workflow Efficiency

The ability to access inventory quickly is essential for efficient warehouse operations. Advanced racking solutions, such as push-back and flow racks, streamline access to goods by facilitating better stock rotation and minimizing pick time. Flow racks use gravity to move products toward the picking aisle, ensuring a first-in, first-out (FIFO) process that is particularly beneficial for perishable goods or high-demand items. This kind of storage not only boosts accessibility but also enhances workflow efficiency, which is vital for maintaining a high standard of customer service.

For operations with fluctuating inventory demands, adjustable racking systems like longspan shelving offer great versatility. Longspan racks can be easily configured or reconfigured to accommodate different load capacities and item sizes, making them ideal for dynamic warehouse environments.

3. Incorporating Automation for Seamless Operations

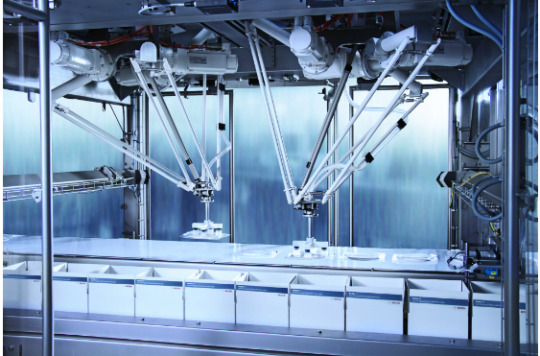

Automation in warehousing is no longer a trend—it’s an essential feature of modern logistics. Automated racking systems, such as Automated Storage and Retrieval Systems (ASRS) and shuttle racking, integrate seamlessly with warehouse management systems (WMS) to boost efficiency. ASRS, for example, utilizes robotic systems to locate, retrieve, and place items into storage, minimizing human error and drastically reducing the time spent on picking and stocking tasks.

These automated solutions work alongside racking systems like shuttle racks, where a shuttle device handles the movement of goods on the rails. This setup is ideal for high-density storage, as it allows products to be stored and retrieved without requiring aisles. The combination of automation and advanced racking enables 24/7 warehouse operation, supporting rapid order fulfillment and high-volume inventory management.

4. Improving Safety and Reducing Damage

Safety is paramount in warehouse environments, especially for those dealing with heavy or bulky items. Advanced racking solutions are designed with safety features to prevent accidental collapses or damages. Heavy-duty racks are built to withstand high loads, and safety accessories such as guardrails, wire mesh decks, and safety bars further enhance structural integrity. Additionally, automated racking minimizes the need for human intervention, reducing the likelihood of accidents and injuries.

Investing in advanced racking also protects inventory from damage. Secure, stable racking systems provide a safe environment for products, reducing the risk of loss due to falling or improperly stored items. This not only preserves the quality of goods but also cuts down on costs associated with product damage.

Conclusion

As the warehousing industry grows and demands for faster, more efficient storage solutions increase, advanced racking systems have become indispensable. From maximizing space utilization to incorporating automation, these solutions address the challenges of modern warehousing head-on. Investing in advanced racking not only enhances warehouse management but also positions businesses for future growth, ensuring they can keep up with evolving demands.

See more... https://sigmastorage.com/

#industrial storage rack manufacturer#cantilever racking#industrial racking#racking#mezzanine#pallet racking

0 notes

Text

India Warehouse Show 2024 Kicks Off Today: Visit Sigma Racks at Booth B25B

The much-anticipated India Warehouse Show 2024 starts today, bringing together industry leaders, innovators, and professionals from around the globe. This year's event, held at the prestigious Yashobhoomi ICCC in Dwarka, New Delhi, promises to be a hotspot for the latest advancements in warehouse and storage solutions. Sigma Racks is thrilled to be a part of this grand event, showcasing our cutting-edge products at Booth B25B from July 11-13.

Discover Sigma Racks' Innovative Storage Solutions

At Sigma Racks, we pride ourselves on offering state-of-the-art storage solutions tailored to meet the diverse needs of our clients. Here's a glimpse of what we have in store for you at the India Warehouse Show 2024:

1. Pallet Racking

Our Pallet Racking systems are designed for high-density storage and easy accessibility. They are ideal for warehouses that require efficient use of vertical space, allowing you to store large quantities of goods securely and systematically.

2. Drive-In/Drive-Through Pallet Rack

Maximize your storage capacity with our Drive-In/Drive-Through Pallet Racks. These systems are perfect for storing homogenous products in large quantities, providing a high-density storage solution that allows forklifts to enter the rack structure for loading and unloading.

3. Longspan Shelving

Longspan Shelving is versatile and easy to assemble, making it an excellent choice for storing a wide variety of items. Whether you need to store small parts or large, bulky items, our Longspan Shelving can be customized to suit your requirements.

4. Mezzanine System

Optimize your warehouse space with our Mezzanine Systems. These systems create additional floorspace within your existing warehouse, offering a cost-effective way to expand your storage capacity without the need for building extensions.

5. Cantilever Racks and Cable Tray Systems

Our Cantilever Racks are ideal for storing long, bulky items such as pipes, lumber, and steel bars. Coupled with our Cable Tray Systems, they provide a comprehensive solution for managing and organizing your inventory efficiently.

6. Skeleton Racks

Skeleton Racks are designed for heavy-duty storage needs. Their robust structure ensures durability and reliability, making them suitable for storing large and heavy items safely.

7. ASR Racking

Automated Storage and Retrieval (ASR) Racking systems are the future of warehouse management. These systems enhance productivity by automating the storage and retrieval process, reducing human error, and increasing operational efficiency.

8. Box Conveyor Systems

Streamline your warehouse operations with our Box Conveyor Systems. These systems facilitate the efficient movement of goods within your warehouse, improving workflow and reducing handling time.

9. Autonomous Mobile Robots (AMRs)

Our AMRs are designed to revolutionize your warehouse operations. These robots can navigate autonomously, transporting goods throughout your warehouse with precision and efficiency, thereby reducing labor costs and increasing productivity.

10. Carton Flow Racking

Carton Flow Racking is perfect for first-in, first-out (FIFO) inventory management. These systems use inclined shelves equipped with rollers, ensuring that products are always accessible and efficiently rotated.

11. Shuttle System Tray Building

Enhance your storage density and efficiency with our Shuttle System Tray Building. This automated system uses shuttles to move trays within the rack structure, optimizing space utilization and speeding up the storage and retrieval process.

Visit Us at Booth B25B

We invite you to visit Sigma Racks at Booth B25B during the India Warehouse Show 2024. Our team of experts will be on hand to demonstrate our innovative products and discuss how they can be tailored to meet your specific needs. Don’t miss this opportunity to explore the latest advancements in warehouse technology and network with industry leaders.

Join us from July 11-13 at Yashobhoomi ICCC, Dwarka, New Delhi, and see how Sigma Racks can transform your warehouse operations. We look forward to meeting you and exploring new opportunities together. See you at the show!

#warehousing racks#slotted angle racks#HDR#mezzanine system#pallet racking#cantilever racking system#racks#industrial racking#storage solutions

0 notes

Text

Nanjing Kingmore Logistics Equipment Manufacturing Co.,Ltd

Nanjing Kingmore Logistics Equipment Manufacturing Co.,Ltd. is a modern enterprise which incorporates product development, design, production, sales and service. Started as a small operation, we have focused on top quality storage and logistics equipment for over 13 years. Now we have become one of the leading suppliers in the racking equipment industry. Kingmore has been one of the top producers of quality pallet racking and other racking equipments, such as: drive-in rack, radio shuttle rack, push back rack, cantilever rack, mezzanine, steel platform, live rack, carton flow rack, medium duty shelving, light duty shelving, drawer rack, movable archive shelving and work apparatus. As a global supplier in the heavy duty, medium duty, light duty racking equipment and related accessories, Kingmore Racking is to create added value for customers around the world.

Pallet racking is a material handling storage aid system designed to store materials on pallets. Although there are many varieties of pallet racking, all types allow for the storage of palletized materials in horizontal rows with multiple levels. Pallet rack shelving improves the efficiency of warehouse operations by enabling more effective use of available space. They are also commonly referred to as beam racks, which are usually heavy racks and are the most common in domestic storage racking systems. They can be applied for varieties of both small and large quantities of goods. Kingmore warehouse storage rack is available with either bolted or welded (boltless) frames. It helps warehouse managers make better use of vertical space because they can store materials on high shelves without risk. It also makes warehouses neater, which improves efficiency and helps to prevent misplaced goods. Consistent use of racks for storage increases pick and put away time and improves the flexibility of existing space. Medium Duty Racking is suitable for the middle load, which can be used alone or freely joined together in any form and in any industries. We can provide with customized depth of upright according to your demands. The medium-sized shelves are solid and strong, with large carrying capacity. Medium-sized shelves are widely used in shopping malls, supermarkets, enterprise warehouses, and public institutions. Heavy duty metal racking is mainly consist of frame, beam and often equipped with wire decking, steel panel, which can be can be used to store anything from small parts to document file boxes. It comes in a wide variety of depths, widths and heights. It is suitable forklift working. The beams are made of cold-rolled steel, and it connect with column by the hooks with safety bin. As heavy duty rack manufacturers, we provide the most popular and economic storage system at present. Our pallet rack is very safe and convenient, which can make full use of warehouse space. Goods are packed on the pallet, then the pallet is picked up from racking by forklift easily and freely. It is widely used in warehouse,supermarket, distribution centers and other logistic places.

Industrial Racking are used in many warehouses and manufacturing factories for efficient storage of products stored on pallets or skids. It can help you provide all-purpose storage for both long and short materials. Heavy duty cantilever racks also called arm rack, which are a medium to extra heavy-duty storage solution with load-bearing arms anchored to a steel column. These frames leave the front of the racks unimpeded by structural elements for direct pick access to goods. Heavy duty cantilever racks help provide efficient storage and retrieval of long materials like steel bars and tubing. Drive in pallet racking and drive through rack systems decrease storage and retrieval time while increasing efficiency and productivity among workers. Not only do they benefit your operations, they can also decrease your bottom line by giving you more storage room per dollar spent on racking. Because these racks create a more uniform load in a confined storage area, your forklift operators working in the system become more skillful drivers. In addition, it is very energy efficient. Since the product is so densely loaded in this type of system, there is less air to be heated or cooled between your pallets and your forklifts don't need to drive as far to pick or place loads, thereby using less fuel. Teardrop pallet racking will offer direct access to each pallet for simple stock management. It is the most popular and versatile in the material handling industry and is your best answer for warehouse palletized products. Teardrop can be constructed for a variety of uses depending on your storage specifications. Our rack solutions offer a durable powder coating and baked enamel finish to ensure long life under the most challenging conditions.

Radio shuttle racking is one kind of high density storage system. It is a new kind of storage management systems, with high density storage racking and electrically powder pallet runners and working with forklifts. It consists of racking system, trolley & forklift. Such high density storage system can increase warehouse space utilization with less operation time, saving the labor cost.

Industrial racking systems are the simplest, most commonly used and most economical option industrial racking systems. It offers the best solutions for warehouses with palletized products and a wide variety of goods. Pallet racking is the most common form of warehouse racking systems, and they're basically a storage system designed to stack materials in horizontal rows with multiple levels. For example, metal racking systems are a kind of industrial racking system which are more suitable for metal goods. Push back racking system increases storage density and allows you to make the most of available warehouse space. If space in your warehouse is tight, push back pallet rack is the best choice. In terms of initial costs, push back racks are often more expensive than selective racks or drive in pallet racks. However, the improvements in efficiency and storage density can produce long-term profits, which in turn can drive smart investment in many applications. Automatic racking system is an automated warehouse of constructing by racking system. Automatic picking is achieved by manually and computer-operated stackers, conveyors, cranes and handling equipment. It is not only making full use of storage space so as to meet standards, but also realizing automation, reducing errors,saving labor and the storage of costs. Shuttle rack system is a racking system with high density storage including racking and electrically powered pallet runners which works with forklifts. The high efficient storage solution provides a new option to maximum use of warehouse volume.It makes a new concept for loading pallets and storage space, utilizes the warehouse space more adequately and flexibility comparing with other traditional storage styles. ASRS warehouse system consists of racking system, Crane system, conveyor system, management and controlling system. This system represents the most advanced automatic technology which is used in logistics industry. In the racking system, there are all standard sized storage locations. Automatic crane works inside the racking system and realize cargo access. AS/RS is widely used in mechanism industry, chemical industry, food industry, textile industry, pharmacy industry, transportation industry, etc. It uses selective pallet racking as the racking system. The main feature is that each level racking is made up of the same size of cargo. The opening is facing the racking channel, which is convenient for crane walking and accessing goods.

We want to help you achieve the results you’re looking for. If you have any questions or would like guidance implementing your new system, our pallet rack experts are here to help. Our experienced sales staff will always listen carefully to your needs before quoting products or services. Interested in learning more about pallet racking? Check out our official website for useful information to get started.

https://www.kingmoreracking.com/

1 note

·

View note

Photo

ASRS Shuttle Racking System manufacturer in India

SILVER LINING Storage's ASRS Shuttle, Automated Storage and Retrieval System provides extremely high storage density and high throughputs than any other ASRS available. ASRS Shuttle Racking provides greater flexibility and efficiency for compact storage and retrieval.

0 notes

Text

Automatic Storage and Retrieval System for Textiles

FABRIC ROLL STORAGE - ASRS

Wide range of fabric rolls, with and without pallets

Single rolls picking, eliminating labour

High bay cranes up to 35m (115 ft) with maximum space saving

Warehouse Management Software (WMS)

YARN STORAGE - ASRS

Multi-deep Shuttle+Crane System for high density yarn storage controlled with First in First Out (FIFO) logic and batch control with ERP synchronization. Also suitable for low to medium warehouse heights.

RIM STORAGE/ SAMPLE FABRIC ROLLS

Vertical storage on the shop floor for sewing trims, packaging trims, labels, and other small products, user access controlled inventory with ERP syn- chronisation, ranging in height from 3m to 24m.

CUSTOMIZED MATERIAL HANDLING SOLUTION

We also offer customised material handling solutions such as hoists, lifts, and overhead conveyor transfer systems for pallets/ fabric rolls.

Pallet ASRS Crane

Crane Shuttle ASRS

Multi Deep Shuttle ASRS

Shuttle Racking System

Mini Load ASRS Crane

Mini Load Shuttle

Mini Load Sorting and Conveying Systems

NOTE: This content is from Indotexnology Website.

0 notes

Text

Use of 5 Key Automation Technologies for Cold Food Storage

We are well aware of the fact that automation is required in order to help drive efficiencies in this inherently inefficient supply chain. Automation is the process that reduces expenses and costs for labor and increases storage density while creating ergonomic and socially distanced workstations.

If you are in search of the best food storage warehouse, then you can get in touch with Anyspaze; they are the best warehousing and inventory management solutions providers in the country.

Automation technology has evolved and is still evolving, from ASRS (automated storage and retrieval systems) technologies that have been modified for cold environments to robotic palletizing that helps with the increasingly common, mixed SKU pallets.

In this article, we will be discussing the top 5 key automation technologies for cold food storage. Also, if you are looking for a warehouse for FMCG company, then you must contact Anyspaze.

Automated Forktrucks (AGF)

Some operators might not be able to budget for the high expenses associated with a significant facility renovation. However, without requiring a significant refurbishment or investment, an automated fork truck or another automated vehicle can significantly improve these activities.

Mini Load Cranes

They feature lightweight alloys that increase speed and offer lower installation, operation, and maintenance costs. They are designed to store and retrieve small items in less time and space. In addition, they provide ergonomic workstations, variable speeds and acceleration, additional load stability, and low sound levels, much like unit-load cranes.

Pallet Shuttles

These quickly move pallets through deep-lane storage racks using a cart system. In addition, some choices allow you to lift pallets and move them vertically. This is the perfect solution to keep workers comfortable and offer more configuration options than conventional forklifts in freezer areas where temperatures are in the negative range.

Unit Load Cranes

Designed affordably to manage unitized loads going into and out of high-density storage. Lightweight cranes allow for variable acceleration and a range of horizontal and vertical speed possibilities. These maintain the highest operational speeds while enabling load stability and low noise levels.

Robot Picking

Another technique that has found its way into cold storage settings is full-layer picking. In order to create what is frequently referred to as a “rainbow pallet” or “mixed SKU” pallet, dependent on the customer’s order, robots can intentionally remove one or more layers from a pallet.

With more SKUs available to fill customer orders, this is a more and more usual requirement from businesses. In addition, robots can make cold storage warehouses more adaptive to market changes since they are versatile.

Choose Anyspaze to get your hands on the best food storage warehouse.

Source : https://ecommercewarehouse.wordpress.com/2022/11/25/use-of-5-key-automation-technologies-for-cold-food-storage/

0 notes

Text

The Rise of Automated Storage Systems: Transforming Warehousing for the Future

In today’s fast-paced supply chain environment, businesses are constantly seeking ways to improve efficiency, reduce costs, and optimize space utilization. One solution that has gained prominence is the Automated Storage and Retrieval System (ASRS). These advanced automated storage systems are revolutionizing warehousing and logistics by streamlining operations and maximizing productivity. Let’s dive into how ASRS systems are shaping the future of warehousing and why businesses are embracing this cutting-edge technology.

Understanding Automated Storage and Retrieval Systems (ASRS)

At its core, an automated storage and retrieval system is designed to store and retrieve goods with precision and minimal human intervention. These systems consist of automated machinery, software, and robotics that work together to efficiently manage inventory. Whether handling raw materials or finished products, ASRS systems enhance warehouse efficiency by reducing labor-intensive tasks and increasing throughput.

Why Businesses Are Turning to Automated Storage Systems

Traditional storage methods often lead to inefficiencies such as misplacement of goods, excessive labor costs, and slow retrieval times. Automated storage systems eliminate these issues by offering:

Faster and more accurate order fulfillment.

Optimized warehouse space through vertical storage solutions.

Reduced dependency on manual labor, minimizing human error.

Improved inventory control with real-time tracking.

With e-commerce and global trade booming, companies need systems that can keep up with increasing demand. ASRS systems provide the agility and accuracy required to meet these modern logistical challenges.

Types of ASRS Systems and Their Functions

There are several types of automated storage and retrieval systems, each designed for specific applications. Here are the most commonly used systems:

1. Unit-Load ASRS

This system is ideal for handling large and heavy loads. It uses cranes and robotic shuttles to move pallets efficiently within high-density warehouses, reducing storage space requirements and increasing picking speeds.

2. Mini-Load ASRS

Designed for handling smaller items, mini-load systems utilize totes and bins to store goods. They are perfect for e-commerce fulfillment centers and industries that require rapid order picking.

3. Shuttle-Based ASRS

Shuttle systems transport goods horizontally within racking structures, significantly improving storage density and retrieval speeds. They are scalable and can be expanded as business needs grow.

4. Vertical Lift Modules (VLMs)

VLMs work like high-tech filing cabinets, retrieving stored items automatically based on software commands. They maximize vertical space and improve accessibility, making them ideal for small parts storage.

5. Carousel-Based ASRS

These include horizontal and vertical carousels that rotate to present stored items to operators. They are widely used in order fulfillment and parts distribution due to their fast retrieval capabilities.

Key Benefits of ASRS Systems

1. Increased Efficiency and Productivity

With automated retrieval, workers spend less time searching for items and more time on value-added tasks. ASRS systems significantly speed up order processing and reduce downtime.

2. Space Optimization

By utilizing vertical storage and high-density configurations, automated storage systems free up valuable floor space, allowing businesses to store more inventory within the same footprint.

3. Reduced Labor Costs

With automation handling repetitive and labor-intensive tasks, companies can reduce reliance on manual labor. This not only cuts costs but also mitigates challenges related to labor shortages.

4. Enhanced Accuracy and Inventory Control

ASRS systems use software-driven precision to ensure accurate picking and storage. This minimizes errors and enhances inventory visibility, leading to improved stock management.

5. Improved Workplace Safety

Automation reduces the need for workers to operate forklifts or climb storage racks, decreasing the risk of workplace accidents and injuries.

Industries Leveraging Automated Storage and Retrieval Systems

E-commerce & Retail

Fast order fulfillment and real-time inventory tracking are crucial in e-commerce. ASRS systems enable seamless operations and quicker deliveries.

Manufacturing

From raw materials to finished goods, manufacturers use automated storage systems to optimize production workflows and manage inventory more efficiently.

Pharmaceutical & Healthcare

Accuracy and compliance are critical in healthcare. ASRS systems ensure proper storage and retrieval of medicines and medical equipment.

Automotive

Auto manufacturers and suppliers utilize ASRS systems to store parts systematically, ensuring just-in-time production and reducing waste.

Challenges of Implementing Automated Storage Systems

While the benefits are substantial, adopting ASRS systems comes with challenges:

High Initial Investment: The cost of installation and integration can be significant, but long-term savings justify the expense.

Training Requirements: Employees need training to operate and maintain the systems effectively.

Integration with Existing Systems: Aligning new automation solutions with legacy infrastructure requires careful planning.

The Future of Automated Storage and Retrieval Systems

As technology continues to evolve, ASRS systems are becoming even more sophisticated. Advancements in AI, machine learning, and robotics are driving improvements in predictive analytics, autonomous decision-making, and warehouse optimization. Future innovations will likely include:

AI-driven demand forecasting for better inventory management.

Enhanced interoperability between ASRS systems and other warehouse automation solutions.

Increased sustainability efforts, with energy-efficient designs and eco-friendly materials.

Conclusion

The rise of automated storage and retrieval systems marks a new era in warehousing and logistics. By improving efficiency, reducing costs, and optimizing space, ASRS systems offer a competitive edge in an increasingly complex supply chain landscape. As businesses continue to embrace automation, those investing in automated storage systems today will be the leaders of tomorrow’s logistics revolution.

0 notes

Text

Best Practices for Managing a Cold Storage Warehouse

Introduction

The global demand for cold chain products is increasing quickly at the moment. As the global market for perishable goods grows, efficient and effective cold storage management becomes increasingly important.

Cold storage refers to refrigerated or frozen storage facilities that are typically used to store food, chemicals, or other materials that require chilly or frigid temperature conditions to be preserved. Cold storage facilities are used in a variety of industries, including medicines, agriculture, chemicals, and many more. In the Temperature Controlled Services Cold storage facilities provide numerous benefits, including cost savings, extended product life, customizable temperature settings, increased storage capacity, and so on. However, to reap such benefits, adequate cold storage management is required.

The following are Best Practices for Cold Storage

1. Adopt Automation

Automation can improve cube utilization and hence optimize available cold storage space. Using high-density pallet racking systems with pallet shuttles, Automated Storage and Retrieval Systems (ASRS), or ASRS, allow for the most efficient use of vertical space.

Automation can also reduce the demand for human labor, resulting in significant savings. The use of Autonomous Guided Vehicles (AGVs) for product movement around the warehouse, as well as automated palletizers and depalletizers, allows cold storage units to function with a much smaller workforce. This has several advantages in addition to cost reductions.

2. Maintain Temperature Ranges

Temperatures must be adjusted in each section of the cold storage unit and must stay within their predetermined ranges. Refrigerated food, for example, must remain refrigerated, while frozen products must remain frozen.

The problem of storing all of these products in the same cold storage can be solved by constructing a barrier between the different temperature zones. As a result, for warehouses that require several temperature zones or where the types of items stored change regularly, a modular insulated curtain wall system that can be put up in and relocated from one building to another is a flexible, low-risk solution.

3. Minimize Heat Loss

Heat transfer must be carefully controlled to prevent it from flowing from high-temperature zones to lower-temperature zones. It is a difficult task in a cold storage warehouse because fresh products are constantly entering storage and the warehouse may need to be rearranged frequently.

Strip doors and high-speed or quick doors are viable solutions to this challenge. They efficiently confine refrigerated air while allowing people and vehicles unrestricted access to all regions of the site.

4. Use Suitable Equipment

A cold storage warehouse employs a variety of tools, machinery, and equipment, such as barcode scanners, computers, sensors, forklifts, pallet jacks, and so on. To perform the intended functions, such equipment should be designed or modified to withstand the low temperatures in which it is expected to operate. When wearing heavy gloves, for example, it can be difficult to operate a touchscreen. As a result, touchscreens on cold storage equipment are designed to be sensitive enough to respond to a gloved touch, while scanning device buttons are large enough to be felt through work gloves.

5. Ensure Employee Safety

Employees should also be trained to become acquainted with the frigid working conditions to minimize any health concerns and to ensure that the activities run smoothly. For example, if personnel are prone to leaving doors open to allow room temperature air in to keep themselves warm, temperature rules would be disobeyed, and a significant amount of chilled air would be lost. As a result, the ideal practice is to ensure that staff in cold storage warehouses are well-trained and can always find the proper cold storage zone equipment.

#3pl warehouse#3pl service provider#3pl logistics#value added services#value added services in logistics#warehouse management system#value added services in warehouse#Best Logistics Industry#best infrastructure of logistic company

1 note

·

View note

Text

Godrej Körber automates India’s Cold Chain storage sector; introduces advanced AS/RS technologies

~ Godrej Körber targets revenue contribution of 20% from the cold chain sector by FY25.

~ The business was present at the IDF World Dairy Summit hosted by India after 48 years in Greater Noida.

Mumbai, 15th September 2022: Godrej Körber, a joint venture company between Godrej & Boyce and Körber Supply Chain, a German company, is driving warehouse automation transformation for the Indian Cold Chain sector in India through differentiated automation solutions. Godrej Körber is steering for 20% contribution in revenue from India’s cold chain sector by introducing highly advanced high density AS/RS systems in FY23.

Cold storage sector encounter challenges that other ‘dry’ warehouses do not face. The higher cost of operations in the cold storages make it critically important that the space must be utilized in the best optimal manner. In India, the dairy or cold chain industry has not evolved in terms of intralogistics automation as companies ignore the benefits of modern cold storage design which also includes a high density storage system apart from advanced refrigeration technology. Aside from needing to pay the labour working in cold storage more than in a dry environment, there are also major concerns such as attrition and difficulty recruiting individuals to work in freezing warehouses. Automation technologies such as ASRS systems, Conveyors, and Layer Picker solutions can guarantee faster delivery, allowing for less footprint and maximised space utilisation in the facilities.

Godrej Körber is expecting 18% - 20% growth in the next 5 years as it has witnessed a major shift happening towards the adoption of automation in the supply chain after the pandemic and expects this trend to continue. Due to the growth of the manufacturing sector, development of organised 3PLs, Pharma, retail, e-commerce, and food service businesses, as well as shifting consumption patterns, the government is encouraging companies to invest into cold chain and cold storage facilities. Considering this, Godrej Körber is focussing on bulk handling in the automation industry, for leading private players as well as public-private partnership projects.

Suunil Dabral, Senior Vice President & Business Head, Godrej Körber stated, “An automated cold storage facility's purpose is to expedite procedures and increase safety for both staff and commodities. Godrej Körber aims to bring this transformation to India’s cold storage facilities by providing special high density storage automation solutions, including stacker cranes and shuttle based AS/RS solutions that let you fully control the storage of all palletized commodities without the need for manual handling. By integrating advanced technology and innovation, we aspire to tackle supply chain complexity across sectors and automate a large number of the cold chain warehouses in India.”

To further address the growing segment of Cold Chain storage, Godrej Körber exceeded order intake targets with order books full in FY22 and dominating an overall market size worth 4000 Crores owing to its successful coalition with global player Körber Supply Chain. Godrej Körber attended the IDF World Dairy Summit, which was held in Greater Noida for the first time in 48 years.

About Godrej & Boyce

Godrej & Boyce ('G&B'), a Godrej Group Company, was founded in 1897 and has contributed to India's journey of self-reliance through manufacturing. G&B patented the world's first springless lock and since then, has diversified into 14 businesses across various sectors from Security, Furniture, and Aerospace to Infrastructure and Defence. Godrej is one of India's most trusted brands serving over 1.1bn customers worldwide daily. To learn more visit: www.godrej.com

About Körber Supply Chain

Körber Supply Chain is a Business Area of Körber, an international technology group with around 10,000 employees and more than 100 locations worldwide. At Körber Supply Chain, we have a broad range of proven supply chain solutions to fit our customers' size, business strategy and appetite for growth. Our customers conquer the complexity of the supply chain thanks to our portfolio that includes software, automation, voice solutions, robotics and material handling — plus the systems integration expertise to tie it all together. Körber helps to manage the supply chain as a competitive advantage.

We are a global partner not just for today, but also as the needs of supply chains continue to evolve. Conquer supply chain complexity – with Körber. The Business Area Supply Chain is part of the global technology group Körber. Find out more on www.koerber-supplychain.com

0 notes

Link

In Shuttle racking system, a battery powered, radio controlled shuttle is used to deposit and retrieve pallets. These shuttles run on specially designed rails and the pallets are stored one behind another giving very dense storage without the forklifts entering the aisles.

0 notes

Text

Pallet Racking System

Industrial racking systems are the simplest, most commonly used and most economical option industrial racking systems. It offers the best solutions for warehouses with palletized products and a wide variety of goods. Pallet racking is the most common form of warehouse racking systems, and they're basically a storage system designed to stack materials in horizontal rows with multiple levels. For example, metal racking systems are a kind of industrial racking system which are more suitable for metal goods. Push back racking system increases storage density and allows you to make the most of available warehouse space. If space in your warehouse is tight, push back pallet rack is the best choice. In terms of initial costs, push back racks are often more expensive than selective racks or drive in pallet racks. However, the improvements in efficiency and storage density can produce long-term profits, which in turn can drive smart investment in many applications. Automatic racking system is an automated warehouse of constructing by racking system. Automatic picking is achieved by manually and computer-operated stackers, conveyors, cranes and handling equipment. It is not only making full use of storage space so as to meet standards, but also realizing automation, reducing errors,saving labor and the storage of costs. Shuttle rack system is a racking system with high density storage including racking and electrically powered pallet runners which works with forklifts. The high efficient storage solution provides a new option to maximum use of warehouse volume.It makes a new concept for loading pallets and storage space, utilizes the warehouse space more adequately and flexibility comparing with other traditional storage styles. ASRS warehouse system consists of racking system, Crane system, conveyor system, management and controlling system. This system represents the most advanced automatic technology which is used in logistics industry. In the racking system, there are all standard sized storage locations. Automatic crane works inside the racking system and realize cargo access. AS/RS is widely used in mechanism industry, chemical industry, food industry, textile industry, pharmacy industry, transportation industry, etc. It uses selective pallet racking as the racking system. The main feature is that each level racking is made up of the same size of cargo. The opening is facing the racking channel, which is convenient for crane walking and accessing goods.

https://www.kingmoreracking.com/push-back-rack/

0 notes

Link

The shuttle system is an automated solution for storage and retrieval of SKUs, particularly in the deep lane and compact storage situations. By eliminating the need for aisles, the shuttle system optimizes space utilization beyond any other solution.

0 notes

Link

Addverb is providing automation solutions in the field of Industrial Automation focusing on Industrial Internet of thing (IIOT), Robotics and Warehouse automation. We leverage technologies like IOT, Machine learning, Robotics, ASRS, Shuttles, Artificial Intelligence, Augmented reality to make supply chain efficient and effective.

0 notes