#ATEX LED lighting

Explore tagged Tumblr posts

Text

Looking for safe and reliable lighting for your hazardous environment, look no further.

Our ATEX LED lighting collection features high-quality LED lights that are designed to meet the stringent safety requirements of ATEX and IECEx certifications.

0 notes

Text

Navigate hazardous zones confidently with our Ex Proof ATEX LED Lighting solutions. Designed for reliability, these lights ensure visibility in environments where flammable gases and vapors pose potential risks. #ATEXLED #ExProof #SafetyLighting

0 notes

Text

Explosion proof portable work light - ATEX approved

Explosion-Proof Work Lights are attached with movable wheels below the gadget and may be moved from one location to another. They are very practical and simple to move. Due to the outside aluminum die-casting, polished surface, and epoxy coating of these lights, they are also quite durable. These 360-degree adjustable lights are perfect for Zones 1&2 and 21&22 and offer improved illumination. The device incorporates an easily adjustable manual valve that controls the lift for simpler operation. Work lights that are portable, strong, and explosion-proof are perfect for explosive conditions.

Key Features

Zones 1 & 2, Zones 21 & 22

Housing made of die-cast aluminum with an epoxy coating for a lovely appearance; lighting angle is adjustable by 120 degrees. Wheels that are simple to move are attached to the bottom of the light box.

Upward and downward adjustment, 360-degree rotation, and complete lighting

Control the lift by using a manual valve or an air pump.

The generator set's bottom has universal wheels that can be used on the pit's train lines and paved surface. Small and lightweight, making it simple to carry.

#Explosion Proof Work Light#Explosion Proof Work LED Light#Intrinsically safe work lighting#ATEX/IECEx LED WORKLITE#ATEX Work Lights

0 notes

Text

Hazardous Lighting Market: Regional Insights and Growth Potential 2025–2032

MARKET INSIGHTS

The global Hazardous Lighting Market size was valued at US$ 1.45 billion in 2024 and is projected to reach US$ 2.23 billion by 2032, at a CAGR of 5.7% during the forecast period 2025-2032.

Hazardous lighting refers to specialized lighting solutions designed for use in explosive or flammable environments where standard lighting could ignite gases, dust, or vapors. These lighting systems feature explosion-proof enclosures, corrosion resistance, and stringent safety certifications (ATEX, IECEx, NEC). Common product types include LED, fluorescent, high-pressure sodium, and incandescent luminaires used across oil & gas, mining, chemical plants, and other high-risk industries.

The market growth is driven by stringent industrial safety regulations, increasing energy-efficient LED adoption (projected to hold 68% market share by 2032), and rising investments in hazardous location infrastructure. The U.S. accounted for 32% of global revenue in 2024, while Asia-Pacific shows the fastest growth due to expanding industrial sectors. Key players like Dialight, Eaton, and Hubbell Incorporated dominate through continuous product innovation – for instance, Dialight launched its Intrinsically Safe LED lineup in Q1 2024 for Zone 0/1 petroleum applications.

MARKET DYNAMICS

MARKET DRIVERS

Stringent Regulatory Standards and Safety Compliance to Propel Market Expansion

The hazardous lighting market is experiencing significant growth due to increasingly stringent regulatory standards across industries such as oil & gas, mining, and chemicals. Governments worldwide are mandating strict safety protocols for hazardous locations, compelling industries to adopt explosion-proof and intrinsically safe lighting solutions. For instance, the ATEX directive in Europe and OSHA standards in North America enforce rigorous requirements for electrical equipment in explosive atmospheres. Compliance with these regulations is not optional but a legal necessity, driving substantial demand for certified hazardous lighting products. The globalization of workplace safety standards further amplifies this trend, ensuring steady market growth across regions.

Industrial Expansion in Emerging Economies to Accelerate Adoption

Rapid industrialization in emerging economies presents a major growth opportunity for hazardous lighting solutions. Countries like China and India are witnessing massive investments in oil refineries, chemical plants, and mining operations – all high-risk environments requiring specialized lighting. The Asia-Pacific region alone accounts for over 35% of global hazardous area lighting demand, with double-digit annual growth projections. This expansion is fueled by both new facility construction and retrofitting projects aimed at upgrading outdated lighting infrastructures to modern LED-based hazardous lighting systems.

MARKET RESTRAINTS

High Initial Costs and Budget Constraints to Limit Market Penetration

While the hazardous lighting market continues to expand, high initial acquisition costs present a significant barrier, particularly for small and medium-sized enterprises. Certified explosion-proof lighting solutions typically cost 3-5 times more than conventional lighting fixtures. This price premium stems from specialized materials, rigorous testing requirements, and certification processes. In price-sensitive markets, organizations often delay upgrades or opt for non-certified alternatives despite safety risks. The total cost of ownership consideration becomes particularly challenging when retrofitting large industrial facilities that may require hundreds of lighting units.

Complex Certification Processes to Delay Product Introductions

Navigating the complex web of international certifications for hazardous location lighting creates substantial challenges for manufacturers. Products often require multiple approvals such as ATEX, IECEx, UL, and CSA certifications to achieve global market access. The testing and documentation process for a single product can take 9-12 months and cost hundreds of thousands of dollars. These regulatory hurdles significantly extend time-to-market for new innovations and create barriers for smaller manufacturers lacking dedicated compliance teams.

MARKET CHALLENGES

Technical Limitations in LED Implementation for Hazardous Environments

While LED technology dominates the broader lighting market, its adaptation for hazardous locations presents unique engineering challenges. Maintaining explosion-proof integrity while managing heat dissipation from high-power LED arrays requires sophisticated thermal management solutions. Many existing LED hazardous lights struggle with lumen depreciation and color consistency in extreme operating temperatures ranging from -40°C to 60°C. These technical constraints compel manufacturers to invest heavily in R&D to develop ruggedized LED solutions that maintain performance while meeting strict safety certifications.

Workforce Safety Training Gaps to Impact Product Effectiveness

The hazardous lighting market faces an often overlooked challenge in ensuring proper installation and maintenance by trained personnel. Statistics indicate that nearly 25% of explosion-proof lighting failures stem from improper installation rather than product defects. Many industrial operators lack specialized electrical teams familiar with hazardous area classifications and installation requirements. This knowledge gap can compromise system safety and performance, leading some facility managers to view hazardous lighting upgrades as higher risk than sticking with aging but familiar systems.

MARKET OPPORTUNITIES

Smart Hazardous Lighting Integration to Open New Revenue Streams

The emergence of Industrial IoT presents transformative opportunities for hazardous lighting solutions. Connected lighting systems that integrate sensors for environmental monitoring, predictive maintenance, and energy optimization are gaining traction. These smart systems can monitor gas concentrations, temperature fluctuations, and equipment health while providing illumination – creating additional value beyond basic lighting functions. Early adopters report 30-40% reductions in maintenance costs through predictive analytics enabled by smart hazardous lighting networks.

Energy Efficiency Mandates to Drive LED Adoption in Hazardous Areas

Global initiatives to reduce industrial energy consumption are accelerating the transition from traditional HID fixtures to LED-based hazardous lighting. Modern LED solutions offer 50-70% energy savings compared to conventional lighting while providing superior lifespans exceeding 50,000 hours. Many governments now offer tax incentives and rebates for industrial facilities upgrading to energy-efficient lighting, significantly improving ROI calculations. As enterprises face mounting pressure to meet sustainability targets, the demand for green hazardous lighting solutions will continue rising.

HAZARDOUS LIGHTING MARKET TRENDS

Rising Adoption of LED Technology in Hazardous Environments

The hazardous lighting market is experiencing a significant shift toward LED-based solutions, driven by their superior energy efficiency, longer lifespan, and enhanced durability in extreme conditions. LED technology now accounts for over 65% of the hazardous lighting market, owing to its ability to reduce operational costs by up to 50% compared to traditional lighting solutions. Recent advancements in explosion-proof LED fixtures further reinforce safety compliance in oil & gas, mining, and chemical processing industries. Furthermore, the integration of smart controls and IoT-enabled lighting systems is creating new opportunities for predictive maintenance and real-time monitoring in hazardous zones.

Other Trends

Stricter Safety Regulations Driving Market Growth

Governments and regulatory bodies worldwide are enforcing stringent safety standards for hazardous environments, particularly in sectors such as oil & gas, mining, and petrochemicals. Standards like ATEX, IECEx, and NEC mandate the use of certified lighting solutions to mitigate explosion risks. Compliance with these regulations is propelling demand for intrinsically safe lighting fixtures, with the oil & gas sector alone contributing nearly 35% of the global market revenue. Additionally, increasing awareness about worker safety in emerging economies is accelerating the replacement of outdated lighting systems with modern explosion-proof alternatives.

Growth in Industrial Infrastructure Projects

The expansion of industrial infrastructure, particularly in Asia-Pacific and Middle Eastern regions, is fueling the demand for hazardous lighting solutions. Countries like China, India, and Saudi Arabia are investing heavily in refineries, chemical plants, and mining operations, where lighting must withstand corrosive, explosive, and high-temperature conditions. The market is also benefiting from retrofitting activities in aging facilities across North America and Europe. With global industrial production expected to grow at 3-4% annually over the next decade, the hazardous lighting market is poised for steady growth across both developed and developing economies.

COMPETITIVE LANDSCAPE

Key Industry Players

Strategic Innovation and Expansion Define Market Leadership in Hazardous Lighting

The global hazardous lighting market features a dynamic competitive environment with established multinational corporations and specialized manufacturers vying for market share. Dialight PLC emerges as a market leader, commanding a significant position through its cutting-edge LED hazardous location lighting solutions and robust distribution network across North America and Europe. The company’s focus on energy-efficient and explosion-proof lighting systems has been pivotal to its market dominance.

Eaton Corporation and Hubbell Incorporated represent other major players, together accounting for approximately 25% of the 2024 market revenue. Their strong foothold is bolstered by comprehensive product portfolios catering to oil & gas, mining, and industrial applications. Both companies have recently expanded their R&D investments to develop smart lighting solutions with IoT integration, addressing the growing demand for connected hazardous area lighting systems.

The market also features aggressive competition from Emerson Electric and Acuity Brands, which are rapidly gaining traction through strategic acquisitions and product innovation. Emerson’s 2023 acquisition of a specialized hazardous lighting manufacturer significantly strengthened its position in the chemical processing segment, while Acuity Brands continues to lead in luminaire design innovation for extreme environments.

While large corporations dominate revenue share, niche players like Kenall Manufacturing and Nemalux are carving out specialized segments through focus on healthcare and food processing applications. These companies demonstrate how targeted product development can create competitive advantages in specific hazardous lighting verticals.

List of Leading Hazardous Lighting Manufacturers

Dialight PLC (U.K.)

GE Lighting (U.S.)

Emerson Electric (U.S.)

Eaton Corporation (Ireland)

Hubbell Incorporated (U.S.)

Acuity Brands (U.S.)

AZZ Inc. (U.S.)

Kenall Manufacturing (U.S.)

Nemalux (Canada)

LDPI (U.S.)

Cree Lighting (U.S.)

ABB Ltd (Switzerland)

Phoenix Products (U.S.)

Larson Electronics (U.S.)

Unimar (U.S.)

Segment Analysis:

By Type

LED Segment Dominates the Market Due to Energy Efficiency and Longevity in Hazardous Environments

The market is segmented based on type into:

LED

Fluorescent

Incandescent

High Pressure Sodium

Others

By Application

Oil & Gas Sector Leads Due to Critical Need for Explosion-Proof Lighting Solutions

The market is segmented based on application into:

Oil & Gas

Mining and Steel

Railway

Electricity

Military and Public Safety

Others

By Hazardous Zone Classification

Zone 1 Classification Holds Major Share for Flammable Gas/Vapor Environments

The market is segmented based on hazardous zone classification into:

Zone 0

Zone 1

Zone 2

Zone 20

Zone 21

Zone 22

By Installation Type

Fixed Installation Segment Prevails Due to Permanent Lighting Requirements in Industrial Facilities

The market is segmented based on installation type into:

Fixed

Portable

Temporary

Regional Analysis: Hazardous Lighting Market

North America North America remains a dominant player in the hazardous lighting market, primarily driven by stringent occupational safety regulations from agencies like OSHA and NEC. The U.S. accounts for approximately 35% of the regional market share due to robust demand from oil & gas, mining, and manufacturing sectors. LED-based hazardous lighting solutions have gained significant traction, supported by technological advancements from key players like Dialight and Eaton. Canada follows closely with growing adoption in mining operations, particularly in Alberta’s oil sands region. Recent infrastructure modernization initiatives, such as the $1.2 trillion Bipartisan Infrastructure Law, are further accelerating demand for explosion-proof lighting systems in industrial applications.

Europe The European hazardous lighting market is characterized by strict ATEX directives and IECEx certifications governing equipment used in explosive atmospheres. Germany leads in adoption rates due to its strong manufacturing base, followed by the UK’s offshore energy sector. EU-wide initiatives like the Green Deal are pushing manufacturers toward energy-efficient LED solutions, with fluorescents being phased out gradually. However, high compliance costs and lengthy certification processes sometimes hinder SMEs from entering the market. Key suppliers like Emerson Electric and ABB are investing heavily in smart hazardous lighting solutions that integrate IoT capabilities for predictive maintenance in chemical plants and refineries.

Asia-Pacific APAC is the fastest-growing region, projected to register a CAGR of 7.3% through 2032, fueled by China’s expansive industrial sector and India’s growing oil & gas exploration activities. China dominates with over 40% regional share, where domestic players like Unimar compete internationally. While cost sensitivity still favors conventional lighting in Southeast Asian markets, Japan and South Korea prioritize high-end LED fixtures for petrochemical and semiconductor facilities. Infrastructure development under initiatives like India’s Make in India and China’s Belt & Road are creating new demand across railways and power generation sectors, though price competition remains fierce among local manufacturers.

South America This region presents moderate growth prospects, with Brazil being the primary market driven by offshore oil projects in the pre-salt basins. Argentina’s Vaca Muerta shale formation also contributes to demand for hazardous zone lighting. However, economic instability and reliance on imported lighting systems (particularly from North America) constrain market expansion. Mining operations in Chile and Peru increasingly adopt LED solutions to reduce energy costs, but inadequate regulatory enforcement in some countries leads to inconsistent safety standards across industries.

Middle East & Africa The Middle East, particularly GCC countries, leads regional demand due to massive investments in oil & gas infrastructure. Saudi Arabia’s NEOM project incorporates smart hazardous lighting solutions across its industrial zones. Africa shows fragmented growth—while South Africa’s mining sector utilizes advanced systems, other nations rely on basic fixtures due to budget limitations. The UAE’s focus on industrial diversification and Egypt’s expanding Suez Canal zone present key opportunities. However, political instability in parts of Africa and fluctuating oil prices impact long-term investment decisions in hazardous lighting upgrades.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Hazardous Lighting markets, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global hazardous lighting market was valued at USD 872 million in 2024 and is projected to reach USD 1.2 billion by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (LED, fluorescent, incandescent, high-pressure sodium), application (oil, mining & steel, railway, electricity, military & public safety), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. The U.S. market is estimated at USD 245 million in 2024, while China is projected to reach USD 318 million by 2032.

Competitive Landscape: Profiles of leading market participants including Dialight, GE Lighting, Emerson Electric, Eaton, and Hubbell Incorporated, covering their product portfolios, market share (top 5 players held ~42% share in 2024), and strategic developments.

Technology Trends & Innovation: Assessment of LED adoption trends (projected to grow at 6.2% CAGR), explosion-proof designs, smart lighting integration, and energy-efficient solutions for hazardous environments.

Market Drivers & Restraints: Evaluation of factors including stringent safety regulations, industrial automation growth, and oil & gas sector expansion, along with challenges like high product certification costs.

Stakeholder Analysis: Strategic insights for lighting manufacturers, industrial facility operators, system integrators, and regulatory bodies regarding evolving market requirements and opportunities.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/inductive-proximity-switches-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cellular-iot-module-chipset-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/sine-wave-inverter-market-shifts-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/pilot-air-control-valves-market-cost.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/video-multiplexer-market-role-in.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/semiconductor-packaging-capillary.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/screw-in-circuit-board-connector-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wafer-carrier-tray-market-integration.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digital-display-potentiometer-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/glass-encapsulated-ntc-thermistor.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/shafted-hall-effect-sensors-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/point-of-load-power-chip-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/x-ray-grating-market-key-players-and.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/picmg-single-board-computer-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lighting-control-dimming-panel-market.html

0 notes

Text

ATEX Beacons and Hazardous Location Beacons | Qlight

Qlight’s ATEX beacons and hazardous location beacons are designed to deliver safe and reliable visual signaling in environments where explosive gases, vapors, or dust are present. These beacons are ATEX and IECEx certified, making them suitable for use in Zone 1, Zone 2, Zone 21, and Zone 22 hazardous areas. The devices are built with explosion-proof aluminum or stainless-steel housings that prevent any internal sparks or flames from igniting the surrounding atmosphere.

Equipped with high-intensity LED or Xenon light sources, Qlight’s beacons provide bright and highly visible alerts in the form of flashing, strobe, or steady lights. They are available in multiple colors—including red, amber, green, blue, and white—allowing operators to indicate different machine statuses or levels of warning using a single device. These models also support a wide voltage range (AC and DC), making them easy to integrate into various industrial systems.

Designed for harsh environments, the beacons feature high ingress protection ratings such as IP66 or IP67, offering resistance to dust, water, and extreme weather.

The key benefits of Qlight’s Atex beacons and hazardous location beacons include maximum operational safety, enhanced visual communication, and low maintenance due to their long-lasting components. They are ideal for use in industries such as oil and gas, chemical processing, marine, mining, and industrial automation, where reliable signaling is critical to worker safety and operational efficiency.

If you are looking for atex beacons and hazardous location beacon, you can get them from Qlight.

Click here to contact Qlight.

View more: ATEX Beacons and Hazardous Location Beacons

0 notes

Text

How Industrial LED Lighting Enhances Workplace Safety

Industrial environments demand lighting that’s not just bright, but engineered for life safety. Modern life safety LED lighting fixtures deliver the clarity, resilience, and emergency performance industries need—helping reduce accidents, comply with safety codes, and protect both people and property.

1. Clear, Reliable Visibility in All Conditions

Solid-state LEDs offer crisp, high-CRI illumination that sharply improves visibility—essential in preventing slip, trip, and fall incidents. Unlike fragile fluorescents that dim when dirty or aged, industrial LEDs sustain brightness and color accuracy, enabling workers to spot hazards quickly—even in low-light or emergency scenarios.

2. Emergency-Ready: EVAC Series LED Fixtures

****The EVAC Series LED life safety fixtures are built for emergency preparedness. With 90-minute battery backup, durable A356T6 aluminum housing, and customizable exit signage, these units ensure illumination and clear egress during power outages—critical for occupational safety compliance and evacuation.

3. Resilient in Hazardous and Industrial Zones

From corrosive chemicals to heat and vibration, many industrial settings push lighting to the limit. Military��grade LED fixtures, like those from Tactik, resist no lumen loss at high temperatures and shed dust and debris to maintain performance . The Brigadier Series offers IP66/IK08 protection and stainless steel components, ensuring over a decade of corrosion resistance—even in harsh/hazardous environments.

4. Explosion-Proof for Dangerous Areas

In zones with flammable gases or dust, explosion-proof LED lighting is vital. Such fixtures are designed to contain any ignition source, complying with safety standards like ATEX, IECEx, and UL844. These explosion proof LED lights not only safeguard against sparks or heat, but also deliver low-energy, long-lasting illumination—protecting both personnel and operations.

5. Reduced Hazmat Risks and Lower Maintenance

Unlike fluorescent lamps, LEDs contain no mercury—eliminating hazmat exposure and simplifying disposal. Their long lifespans (up to 100,000 hours) drastically reduce ladder work, electrical hazards, and ongoing maintenance—keeping the workplace safer and more efficient.

6. Tailored Solutions: Fit for Every Application

Emergency & Exit lighting: Battery-backed LED units with clear signage, essential for safe evacuation.

Hazardous-location lighting: Rigorously certified fixtures (e.g., Explosion Proof, Shield, Apache, Vanguard Series) built for zones classified by NEC or ATEX/IECEx.

Heat-, dust-, vapor-, and vibration-resistant LEDs: Deployed in steel mills, manufacturing floors, rubber plants—designed to endure real-world industrial stresses.

7. Energy Savings with Safety Gains

These fixtures often consume significantly less energy than traditional lighting, lowering costs while improving safety. Features like 1–10 V dimming and DALI control allow fine-tuning of light levels based on task or occupancy, ensuring optimal visibility exactly when it’s needed.

Conclusion

Upgrading to industrial LED lighting—especially purpose-built life safety, explosion proof, and military-grade fixtures like the EVAC and Brigadier Series—is more than a technical upgrade; it's a strategic safety investment. These systems provide:

Reliable emergency illumination

Strong, collapsible-free performance

Robust protection in extreme environments

Lower maintenance and environmental risk

Energy efficiency with intelligent controls

By implementing advanced industrial LED lighting, facilities not only enhance employee well-being but also reinforce compliance, reduce operational risk, and support sustainable performance.

Featured Solutions from Tactik Lighting

EVAC Series LED life safety fixture: emergency-ready, energy-efficient, customizable signage.

Brigadier Series LED explosion proof fixture: rock-solid corrosion resistance and IP66/IK08 durability.

Military-grade industrial LEDs: high-heat tolerance, dust-shedding design—ideal for thermally intense facilities.

0 notes

Text

The Role of Explosion Proof Emergency Lighting in Industrial Safety

In high-risk industrial environments, safety is never optional. One of the most overlooked yet critical components of workplace safety is emergency lighting. In facilities where flammable gases, vapours, or dust are present, standard emergency lighting systems may pose a serious risk. That’s where explosion proof emergency light systems come into play.

These specialised lights are designed not just to provide illumination during emergencies but to do so without creating any ignition risk. In environments like oil refineries, mining tunnels, and chemical processing plants, this difference can save lives.

Why Emergency Lighting Matters in Hazardous Zones

Power outages, equipment failures, or fires can plunge a worksite into darkness. In such scenarios, the ability to see and safely evacuate becomes essential. Emergency lighting provides a backup source of illumination to guide workers to exits, highlight obstacles, and keep safety signage visible.

In hazardous environments, however, emergency lights must also eliminate any potential source of sparks or heat that could ignite flammable materials. This is where explosion proof lights differ from conventional ones.

Built for the Most Dangerous Conditions

Explosion proof emergency lights are enclosed in sealed, impact-resistant housings. These units are engineered to contain any sparks, heat, or arcs produced internally so they do not ignite surrounding hazardous materials. Mineglow’s explosion proof models are certified for use in ATEX and IECEx rated zones, which means they meet the highest global safety standards.

This level of protection is essential for industries where an explosive atmosphere can form during normal operations, maintenance, or equipment malfunctions.

Instant Response and Long-Lasting Performance

When an emergency hits, lighting must activate instantly and operate reliably. Explosion proof emergency lights often come with built-in battery backups that automatically trigger during power loss. The lights stay on for a set period, typically 90 minutes or more, giving personnel enough time to exit or stabilise operations.

Mineglow’s lights are designed for longevity and reliability. They perform efficiently even in extreme temperatures, damp conditions, or areas with high vibrations. Their LED technology ensures consistent brightness without delay, flickering, or warm-up time.

Supporting Compliance and Risk Management

Regulations across mining, oil and gas, and industrial sectors require proper emergency lighting systems in place. Using explosion proof solutions not only helps meet legal standards but also reduces liability in the event of accidents or audits.

Incorporating certified emergency lighting demonstrates a commitment to occupational health and safety and reassures both staff and stakeholders that risks are being managed responsibly.

Energy Efficiency and Reduced Maintenance

Modern explosion proof emergency lights use LED technology, which consumes far less energy than older systems. This not only reduces operational costs but also contributes to sustainability goals. The long life of LED components means fewer replacements and less maintenance, which is especially valuable in hard-to-access or high-risk areas.

A Smarter Safety Investment

Implementing explosion proof emergency lighting is not just about compliance, it’s about proactive safety. These systems are a smart investment in protecting personnel, assets, and operational continuity. From confined mine shafts to sprawling refinery complexes, they offer the peace of mind that illumination will be available when it’s needed most, without increasing the risk of ignition.

If your site operates in a hazardous environment, upgrading to explosion proof emergency light systems from trusted providers like Mineglow is a crucial step toward ensuring workplace safety.

0 notes

Text

Top Benefits of Explosion Proof Lighting from Gulf Trans Power

In industries such as oil and gas, petrochemical plants, mining, and other hazardous environments, safety is paramount. One critical element that ensures workplace safety and operational efficiency is the use of explosion proof lighting. Gulf Trans Power, a trusted Explosion proof Lighting Supplier based in Saudi Arabia, offers state-of-the-art lighting solutions designed to withstand hazardous conditions and deliver reliable performance.

In this article, we explore the top benefits of choosing explosion proof lighting from Gulf Trans Power and why it is the preferred choice for industrial safety and compliance.

What Is Explosion Proof Lighting?

Explosion proof lighting is a type of lighting fixture specifically designed to prevent ignition of surrounding gases, vapors, or dust that could cause explosions in hazardous environments. These lights are built with robust materials and sealing techniques that contain any sparks or flames within the fixture, thereby protecting the workplace and personnel from potential disasters.

As a leading Explosion proof Lighting Supplier, Gulf Trans Power offers a wide range of certified explosion proof lighting products that meet international safety standards, ensuring durability, safety, and optimal lighting performance.

1. Enhanced Safety in Hazardous Areas

The primary benefit of explosion proof lighting is improved safety. Industrial environments, especially in the Eastern Province of Saudi Arabia, often have flammable gases or combustible dust that pose serious risks. Using standard lighting fixtures in such areas can lead to catastrophic accidents.

Gulf Trans Power’s explosion proof lighting solutions are engineered to contain any electrical sparks or heat inside the fixture, preventing ignition of hazardous substances nearby. This critical safety feature significantly reduces the risk of workplace fires and explosions, safeguarding lives and assets.

2. Compliance with International Safety Standards

Compliance with safety regulations is non-negotiable in hazardous industries. Gulf Trans Power, known also as a reliable Optical Ground Wire supplier in Saudi Arabia, understands the importance of adhering to rigorous standards such as ATEX, IECEx, and NEC.

Their explosion proof lighting products are rigorously tested and certified, ensuring they meet or exceed these standards. Choosing Gulf Trans Power means your facility stays compliant with local and international regulations, avoiding costly fines and shutdowns.

3. Durability in Harsh Conditions

Explosion proof lighting from Gulf Trans Power is built to last. These fixtures feature rugged enclosures made from high-grade metals such as aluminum or stainless steel, which resist corrosion, impact, and extreme temperatures.

Whether installed in offshore platforms, refineries, or underground mines, the lighting systems maintain their performance even in the most challenging environments. This durability translates to longer lifespans and reduced maintenance costs, making them a smart investment for industrial operators.

4. Energy Efficiency and Cost Savings

Modern explosion proof lighting from Gulf Trans Power integrates energy-efficient LED technology. Compared to traditional lighting options, LEDs consume significantly less power, reducing energy bills and environmental impact.

The combination of energy efficiency and long operational life means fewer replacements and lower downtime. For industries managing tight budgets and sustainability goals, Gulf Trans Power’s lighting solutions offer excellent cost-effectiveness.

5. Superior Lighting Quality

Safety depends not only on the explosion proof nature of the fixture but also on adequate illumination. Gulf Trans Power ensures their explosion proof lights provide bright, uniform lighting to improve visibility and reduce accidents caused by poor lighting conditions.

Advanced optics and high color rendering indexes (CRI) enable workers to perform their tasks accurately and safely, boosting productivity and reducing human error.

6. Wide Range of Applications

Gulf Trans Power’s expertise as an Explosion proof Lighting Supplier extends to multiple sectors. Their products are suitable for:

Oil and gas extraction and processing

Chemical plants and refineries

Mining operations

Food processing facilities with combustible dust

Pharmaceutical manufacturing

No matter the application, Gulf Trans Power provides customized lighting solutions tailored to your specific needs.

7. Integrated Solutions with Optical Ground Wire Supply

In addition to lighting, Gulf Trans Power is a renowned Optical Ground Wire supplier in Saudi Arabia, supplying high-quality optical ground wires essential for telecommunications and power transmission systems.

Combining expertise in explosion proof lighting and optical ground wires allows Gulf Trans Power to offer integrated solutions for power and communication infrastructures in hazardous zones, ensuring both safety and connectivity.

8. Expert Support and Service

Choosing Gulf Trans Power means more than just purchasing a product. The company offers expert consultation, installation guidance, and after-sales support to ensure your explosion proof lighting system performs optimally.

Their experienced team works closely with clients to assess the environment, recommend the best products, and provide timely maintenance services — building lasting partnerships based on trust and reliability.

Conclusion

For industries operating in hazardous environments, investing in reliable explosion proof lighting is a critical safety measure. Gulf Trans Power, a leading Explosion proof Lighting Supplier and Optical Ground Wire supplier in Saudi Arabia, offers high-quality, durable, and energy-efficient lighting solutions designed to protect your workforce and assets.

For more info please click the link:

0 notes

Text

Explore SharpEagle's explosion proof portable solutions, including LED work lights and portable CCTV systems designed for maximum safety in hazardous industrial environments.

0 notes

Text

Step-by-Step Guide to Using Nylon Rope Effectively

In the rapidly evolving industrial landscape, lighting plays a vital yet often underestimated role. From enhancing workplace safety to improving energy efficiency, the right lighting solution can significantly transform industrial environments. Among the leading brands making a substantial impact in this domain is XULFT—a global innovator in industrial LED lighting. Based in China with a growing international footprint, XULFT specializes in high-performance, durable LED lighting for factories, warehouses, oil and gas sites, tunnels, and more. 绳状尼龙 With a reputation for reliability, innovation, and customization, XULFT is redefining how industries think about lighting solutions.we explore how XULFT is helping businesses modernize their lighting infrastructure, reduce energy costs, and meet safety and environmental standards—without compromising on performance.

The Critical Role of Industrial Lighting:

Here’s why it matters: Safety Compliance: Proper lighting reduces workplace accidents by improving visibility and preventing errors in high-risk environments.

Energy Efficiency: Replacing outdated systems with LEDs can cut power consumption by up to 80%.

Durability: Harsh industrial conditions require lighting that withstands dust, vibration, moisture, and chemicals.

Productivity: Adequate lighting reduces eye strain, fatigue, and improves worker morale and focus.

Cost Reduction: Long-life LEDs reduce maintenance and replacement costs significantly over time.

That’s where XULFT steps in—with industrial-grade LED solutions tailored to specific environments and industries.

XULFT’s Mission: Efficient, Reliable, Intelligent Lighting:

XULFT was founded on the principles of innovation, efficiency, and global responsibility. With years of research and development, they’ve crafted a portfolio that delivers powerful illumination, long lifespan, and cutting-edge smart features for industries worldwide.

The company's mission is simple yet ambitious: “To illuminate the industrial world with safe, smart, and sustainable LED lighting.”

From heavy-duty manufacturing facilities to complex oil refineries and tunnel networks, XULFT ensures that every light fixture is purpose-built and performance-tested.

Extensive Product Line for Industrial Applications:

XULFT offers a diverse range of LED lighting products engineered for heavy-duty industrial use. Their catalog includes:

🔹 LED High Bay Lights

Perfect for high-ceiling warehouses, production plants, and distribution centers. These fixtures are designed to deliver powerful brightness, uniform light distribution, and high energy efficiency.

🔹 Explosion-Proof Lights

In hazardous areas where flammable gases or dust are present, explosion-proof LED lights ensure safe operation. These are ATEX and IECEx certified, making them ideal for oil & gas, petrochemical, and mining sectors.

🔹 Flood Lights

Robust and weather-resistant, XULFT’s LED flood lights are perfect for outdoor applications like parking lots, shipyards, and stadiums. High lumen output and advanced optics ensure wide coverage.

🔹 Tunnel Lights

Designed to maintain visibility in long, enclosed environments like tunnels and underpasses. These lights are corrosion-resistant and offer glare control for safe driving conditions.

🔹 Linear LED Lights

Great for tight, linear installations in corridors, cleanrooms, or workstations. They offer consistent brightness, low heat, and sleek design.

🔹 Street Lights

XULFT’s LED street lights are designed for roads, campuses, and industrial parks, combining high efficacy with smart controls.

Key Features That Set XULFT Apart:

�� Superior Thermal Management

Overheating shortens LED lifespan. XULFT integrates aluminum alloy heat sinks, fins, and smart airflow designs to maintain stable operating temperatures and extend longevity.

✅ IP & IK Ratings

XULFT’s lights meet high IP65, IP66, and IK08/IK10 ratings, ensuring they are waterproof, dustproof, and resistant to mechanical impact—essential for industrial applications.

✅ Smart Control Systems

Many XULFT products support DALI, Zigbee, PIR motion sensors, daylight harvesting, and remote app controls. These intelligent options allow facilities to save energy, schedule lighting patterns, and monitor performance.

✅ Custom Optics & Beam Angles

Whether you need a wide beam for general lighting or a narrow beam for precision tasks, XULFT offers customizable optics and lenses to suit your application.

Each of these sectors demands robust lighting solutions tailored to their operating conditions—and XULFT delivers with precision and customization.

Case Studies: Real-World Success:

📍 Automated Warehouse, Germany

XULFT provided high-bay LED fixtures equipped with motion sensors for a logistics giant in Germany. The result: 70% reduction in energy bills and significantly improved visibility for automated robots.

📍 Oil Refinery, Middle East

ATEX-certified explosion-proof lights from XULFT were installed across multiple processing zones. The client reported improved safety compliance, zero lighting failures, and reduced maintenance costs.

📍 Tunnel Project, Southeast Asia

XULFT’s tunnel lights enhanced driver visibility and reduced glare in a major expressway project. With smart dimming features, the project achieved 45% energy savings annually.

Why Clients Trust XULFT:

🔧 Engineering Excellence

XULFT’s design team blends technical know-how with creativity, ensuring that every product is optimized for durability, performance, and aesthetics.

🛠️ Tailored Solutions

No two facilities are alike. XULFT works closely with clients to understand their needs and provide customized lighting plans, including CAD simulations and lighting layouts.

🌱 Sustainability Focus

With a sharp focus on green manufacturing, energy efficiency, and recyclable components, XULFT helps clients meet ESG and environmental goals.

💬 Exceptional Support

From project planning to post-installation support, XULFT’s multilingual team is known for fast response times, clear communication, and technical expertise.

Partnership Opportunities: Write for XULFT:

If you’re passionate about lighting technology, smart infrastructure, or energy sustainability, XULFT invites you to contribute to its blog and resource center.

Guest posts, white papers, and product reviews are all welcome. Collaborate with a global leader and showcase your expertise to a niche professional audience.

Final Thoughts

Lighting is one of the most powerful tools to drive safety, productivity, and sustainability in industrial settings. With its expansive portfolio, international certifications, and dedication to innovation, XULFT is shaping the future of industrial LED lighting.Whether you're upgrading your facility, managing a large infrastructure project, or distributing LED products, XULFT provides world-class solutions tailored to your needs.

0 notes

Text

Illuminate Your Worksite with ATEX Head Lamps and Hand Lamps

In hazardous environments, ensuring proper lighting is crucial for safety and efficiency. ATEX Head Lamps and ATEX Hand Lamps are essential tools for professionals working in explosive atmospheres, providing reliable illumination while meeting strict safety standards.

Why Choose ATEX-Certified Lighting?

ATEX certification guarantees that lighting equipment is safe to use in environments where flammable gases, vapors, or dust particles are present. Whether working in oil refineries, chemical plants, or offshore platforms, ATEX lighting minimizes risks and ensures compliance with industry regulations.

Benefits of ATEX Head Lamps

ATEX head lamps offer hands-free lighting solutions, making them ideal for confined spaces and precision tasks. These lamps provide:

Explosion-proof design for hazardous areas Lightweight and ergonomic fit for prolonged use High-intensity LED illumination with adjustable brightness Durable, impact-resistant construction

Advantages of ATEX Hand Lamps

ATEX hand lamps are versatile, portable, and designed for rugged industrial applications. Their key features include:

Robust, shock-resistant casing for durability Rechargeable and long-lasting battery life Waterproof and dustproof protection Easy handling for spot inspections and emergency lighting

Enhance Workplace Safety with ATEX Lighting

Investing in ATEX-certified lighting solutions like head lamps and hand lamps improves operational safety and efficiency. For a wide range of ATEX lighting solutions, explore the latest offerings at Daly-ME and equip your team with reliable, explosion-proof lighting today.

0 notes

Text

Explosion Proof 60W LED Linear Light, this ATEX certified luminaire is suitable for use in many hazardous areas. Quality construction using Bridglux LEDs lifud Driver.

Available in 40W, 60W and 80W! Connect with us now for more details.

0 notes

Text

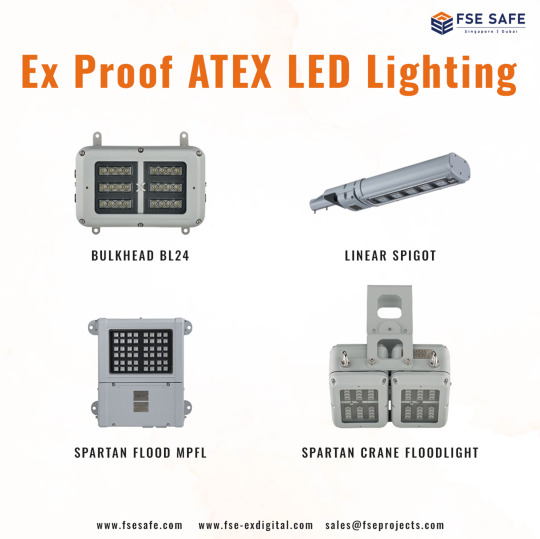

Ex Proof ATEX LED Lighting - FSE SAFE

Enhance safety protocols in areas with explosive atmospheres using our Ex Proof ATEX LED Lighting. These lights are engineered for safety, providing a secure and well-lit workspace in challenging environments. #ATEXLED #ExProof #SafetyLighting

0 notes

Text

ATEX flashlight - Explosion proof - Intrinsically Safe

Explosion proof flashlights are advanced and dependable lighting solutions specially designed for use in hazardous environments. Crafted and rigorously tested to comply with ATEX standards, ensuring optimal performance in potentially explosive atmospheres. These intrinsically safe lights are Ideal for industries such as oil and gas, chemical plants, and mining, this flashlight prioritizes safety without compromising on illumination prowess.

Key Features

IP rate: IP65, IP68

Led light source

Zone 1&2, Zone 21&22

High hardness aluminum alloy shell, surface sandblasted anodized, beautiful appearance

Lithium-ion battery, no memory, large capacity, long life, stable performance, low self-discharge rate

Bright light, working light, stroboscopic three modes adjustable

#Explosion Proof Flashlight for sale#Intrinsically Safe Flashlight Rechargeable#Explosion proof torch lights#intrinsically safe flashlights#Intrinsically Safe LED Flashlight#ATEX flashlights#atex zone 0 flashlight

0 notes

Text

Zalux ACQUEx LED-M

The Zalux ACQUEx LED-M is a lighting solution designed to provide a simple, safe, and reliable option for ATEX Zone 2 and 22 environments. This luminaire offers a straightforward approach to illumination in hazardous areas, ensuring compliance with relevant safety standards.

One of the key features of the ACQUEx LED-M is its safe installation design. The luminaire incorporates an internal diffuser that prevents direct contact with the Ex lighting Light LED module. This added layer of protection enhances the overall safety of the fixture, reducing the risk of accidents or damage to the light source.

0 notes

Text

Leading Global Manufacturer Specializing in Visual Signaling Devices | Qlight

Qlight is a leading global manufacturer specializing in visual signaling devices that enhance safety, communication, and process efficiency across various industrial environments. These devices are widely used in industries such as battery manufacturing, semiconductor, automotive, automation, shipbuilding, marine, offshore, iron & steel, and petrochemical.

Key Products in Qlight’s Visual Signaling Device Line up:

LED Tower Lights (Signal Towers)

Multicolor, stackable units

Available with buzzer, MP3, wireless, or network (USB/Ethernet) options

Designed for equipment status indication, alarm systems, and machine control panels

Warning Lights & Beacons

Rotating, strobe, or flashing types

Suitable for outdoor and indoor applications

Options for explosion-proof (ATEX, IECEx certified) environments

LED Work Lights

Compact and energy-efficient

High brightness for machine tool and workspace illumination

Explosion-Proof Visual Signals

Designed for hazardous areas

Certified by ATEX, IECEx, NEPSI, and other global safety standards

Modular Signal Lights

Customizable with multiple signal options (light, buzzer, MP3)

Quick-connect modular design for ease of installation and maintenance

Features of Visual Signaling Devices

High Visibility with Powerful LED Light Sources: Qlight’s devices use high-intensity LEDs that offer bright and clear signaling, even in daylight or smoky environments. The LEDs have long lifespans and low power consumption, ensuring reliable performance and reduced maintenance over time.

Wide Voltage Compatibility (AC/DC): Qlight products support a range of AC (Alternating Current) and DC (Direct Current) input voltages. This ensures easy integration with various industrial systems, whether they are powered by standard factory mains or custom control panels.

Available in Multiple Sizes and Mount Types: Qlight offers signaling devices in various diameters, lengths, and configurations. You can choose compact beacons, large-diameter tower lights, or panel-mount indicators depending on the visibility range and available space.

Looking for high-performance audible signals? Qlight offers industry-certified, reliable solutions for every environment.

Contact Qlight today to learn more about our visual signaling devices.

View more: Leading Global Manufacturer Specializing in Visual Signaling Devices

0 notes