#Abrasion Resistance Steel Plate Manufacturer

Text

Abrasion Resistance Steel Plates Supplier

Chhajed Steel & Alloys is a Abrasion Resistant Plate stockholders and suppliers, delivering to the whole of the world.we are ISO 9001:2008 accredited and supplies Abrasion Resistant Plate to internationally approved quality standards for applications. Abrasion Resistant Plate have excellent quality to fully satisfy customer’s requirements.

The Abrasion Resistant Plate supplied by us are accepted by clients in various spheres of the industries ranging from basic industries such as Sugar, Paper, Textile, Dairy, Engineering to more complex such as Oil & Gas, Petrochemical, Chemical & Fertilizers, Power Generation and Nuclear Industries.

Chhajed Steel & Alloys specializes in Abrasion Resistant Plate .With years of experience in manufacturing Abrasion Resistant Plate we offer high quality, lower cost but the best service. As a result to that our export account today is in various countries like Saudi arabia, Kuwait, Qatar, Oman, Yemen, UAE, Iran, Turkey, Kazakhstan, Greece, Singapore, Thailand, Indonesia, Vietnam, South Africa,South America,Brazil, India, Australia, Egypt.We welcome your inquiries.

We offer high grade Abrasion Resistant Plate at affordable price. These Abrasion Resistant Plate are manufactured using finest grade raw material available to ensure international quality. These Abrasion Resistant Plate are available in different shape size and thickness according to the needs of our customer. Owing to highly experienced group of qualified professional and use of latest technology machinery, Chhajed Steel & Alloys have supplied high quality Abrasion Resistant Plate and profiles to customers throughout the worldwide.

As well as being available from stock all Abrasion Resistant Plate can be cut to size and shape according to your fabrication and design requirements and all work is governed by our independently accredited and regularly audited quality systems.Our Abrasion Resistant Plate are sourced from the highest quality steel manufacturers in the world and, like all our suppliers, these manufacturers have been vetted and assessed by our procurement team.

Abrasion Resistant Plate Grade and Specification

Item:-Abrasion Resistant Plate

Material:- Abrex 500, Abrex 400, Abrex 450, SUMIHARD ,NICRODUR ,BRINAR ,DUROSTAT ,DILLIDUR ,JFE EVERHARD

Thickness:- 3-200mm

Width:- 500-3000mm

Length:- 1000-12000mm

Heat Treatment:- N, Q+T

Surface Paint:- EP, PE, HDP, SMP, PVDF

Export to:- Saudi arabia, Kuwait, Qatar, Oman, Yemen, UAE, Iran, Turkey, Kazakhstan, Greece, Singapore, Thailand, Indonesia, Vietnam, South Africa,South America,Brazil, India, Australia, Egypt

For More Information

Website:- https://www.chhajedplates.com/abrasion-steel-plates-supplier-stockist-importers-distributors.html

Phone No:- +91-932-111-3630

Email:- [email protected]

#Abrasion Resistance Steel Plate#Abrasion Resistance Steel Plate Manufacturer#Abrasion Resistance Steel Plates Supplier

0 notes

Text

Abrex 600 Sheet Plates

Since the fundamental limit of ABREX is to give assurance from scratched territory, in this way we try to manufacture precision fabricated Abrex 600 Plates, which are extensively known for their positive conditions like high insurance from effect, weld breaking point, handiness, and significantly more. One progressively included piece of breathing space that goes with the usage of ABREX 600 sheets and plates is that the greatness of the fundamental part reduces enormously, which shows to be of authentic help with truly grinding working conditions. This associates in growing the future of the mechanical parts related with these sheets and plates.

At Vandan Steel & Engg. co., we attempt to cling ourselves to all the fundamental worldwide models and benchmarks of collecting, to retreat the entire methodology. In addition, the amassing of Abrex 600 Abrasion Resistant Plates and Sheets, is done in proximity of all the skilled and experienced partners, who work relentlessly towards collecting the best grouping of things for our customers.

Our entire workplace is outfitted with the best extent of equipment and mechanical assembly, which makes the age of Abrex 600 Wear Resistant Plates and Sheets especially smooth and mix-up free. All these Abrex sheets and plates are caused available to our customers at a completely moderate an incentive to go.

Abrex 600 plates have a lot of characteristics given by solidified steel make it a convincing candidate in materials decisions. Solidified steel is subsequently low carbon steel which contains chromium at extra by weight. It is the extension of chromium that gives the steel of its novel flawless, spoil restricting properties.

ABREX 600 STEEL PLATE SPECIFICATION

Thickness : 5mm to 150mm

Width : 1,500mm to 2,500mm

Length : 6,000mm to 12,000mm

Heat Treatment : N, Q+T

Surface Paint : EP, PE, HDP, SMP, PVDF

Material : ABREX 600 Plate

APPLICATION

Machine building

Pylons and other architectural structures

Lifting and mobile equipment

Construction of bridges

Wearing plates

Framework structures

Crane booms, Rail cars

Stone or iron chutes

Truck frames, Containers

Vehicles and transport equipment

Anti drill plates such as security doors, shot blasting equipment and tumbling machine

For More Information :

Visit Our Website: http://wearplates.co.in/

Contact No: +91-8828813630

E-Mail ID: [email protected]

5 notes

·

View notes

Text

The Role of MSERW Pipe in the Oil and Gas Industry: Applications and Challenges

Introduction

In the oil and gas industry, the transportation of fluids and gases over long distances is crucial. To ensure the safe and efficient movement of these resources, various types of pipes are utilized. One such pipe that plays a vital role in the industry is the MSERW pipe. In this blog, we will explore the applications and challenges associated with MSERW pipes and highlight the importance of finding a reliable MSERW pipe distributor, dealer, supplier, and provider in Gujarat.

Understanding MSERW Pipe

MSERW stands for Mild Steel Electric Resistance Welded. MSERW pipes are constructed using low-carbon steel, which is known for its strength, durability, and resistance to corrosion. These pipes are manufactured by forming flat steel plates into cylindrical shapes and then welding the edges together using electric resistance welding techniques.

Applications of MSERW Pipe in the Oil and Gas Industry

Transporting Oil and Gas:

MSERW pipes are extensively used for the transportation of oil and gas products. These pipes provide a cost-effective solution for delivering crude oil, natural gas, and refined petroleum products from extraction sites to refineries, storage facilities, and distribution networks. Their ability to withstand high pressure and temperature variations makes them an ideal choice for long-distance oil and gas pipelines.

Offshore Drilling Operations

The oil and gas industry heavily relies on offshore drilling for exploration and production activities. MSERW pipes are commonly employed in the construction of subsea pipelines and risers. These pipes offer excellent structural integrity and are resistant to harsh environmental conditions, making them suitable for deepwater drilling applications.

Oil and Gas Processing Plants

Within oil and gas processing plants, MSERW pipes are utilized for various purposes. They are often used in the construction of storage tanks, separators, heat exchangers, and other equipment required for the processing and refining of crude oil and natural gas. MSERW pipes' versatility and reliability ensure the smooth operation of these critical facilities.

Challenges Associated with MSERW Pipe

While MSERW pipes have numerous advantages, they also face some challenges in the oil and gas industry. It is essential to be aware of these challenges and take appropriate measures to mitigate them:

Corrosion and Erosion

One of the primary concerns with MSERW pipes is their susceptibility to corrosion and erosion. Exposure to corrosive substances and abrasive particles in the oil and gas flow can lead to degradation of the pipe's surface, reducing its lifespan. Regular inspections, protective coatings, and cathodic protection systems are implemented to minimize the impact of corrosion and erosion.

Weld Quality and Integrity

The integrity of the welded joints in MSERW pipes is crucial for their performance. Weld defects such as porosity, cracks, and lack of fusion can compromise the strength and reliability of the pipe. Quality control measures during manufacturing and rigorous inspection procedures help ensure that welds meet industry standards and specifications.

Finding a Reliable MSERW Pipe Distributor in Gujarat

To address the growing demand for MSERW pipes in Gujarat's oil and gas industry, it is essential to collaborate with a trustworthy MSERW pipe distributor, dealer, supplier, and provider. The following factors should be considered while choosing the right partner:

Quality Assurance: Look for a distributor that sources MSERW pipes from reputable manufacturers who adhere to stringent quality control procedures and industry standards.

Product Range: Ensure that the distributor offers a wide range of MSERW pipe sizes, grades, and specifications to cater to various project requirements.

Timely Delivery: Reliability in terms of on-time delivery is crucial to avoid project delays. Choose a distributor with a track record of timely and efficient order fulfillment

#MSERW Pipe Distributor in Gujarat#MSERW Pipe dealer in Gujarat#MSERW Pipe Supplier in Gujarat#MSERW Pipe Provider in Gujarat

7 notes

·

View notes

Text

Best Slip On, High Ankle Lace-less Safety Shoes, S3 SRC

Upper: Black smooth cow leather

Lining: Air mesh lining & amp; Resistant to Abrasion

Insock: Anti-static, and ventilated EVA

Outsole: PU/PU dual density injection

Tested By: UK Intertek lab (Approved body:0362)

Toe: Steel toecap 200 joules

Penetration: Steel plate 1100 newtons

Color: Black

Applications:

200 Joule Toe Cap, Slip-Resistant, Shock Absorption, Anti-static, Petrol and Chemical Resistant, Anti-nail Mid sole, Water Resistant, Oil Resistant, Electro Static Discharge

Sizes - 38-46

6 Months Warranty Against Manufacturing Defect

2 notes

·

View notes

Text

stainless steel coil 316Ti 316 Mo2Ti for resisting sulfuric acid phosphoric acid acetic acid

316Ti stainless steel coil is a metal material, which is added to SUS316 stainless steel coil to improve the resistance to intergranular corrosion. 316TI stainless steel coil, also called Mo2Ti or 316 ti satinless steel coils, is applied to resist sulfuric acid, phosphoric acid, acetic acid equipment.

316Ti stainless steel coil Specifications: Thickness: cold rolled 2B plate (0.09 -- 6.0mm); Hot rolled industrial plate No.1(3-50mm) medium thick plate, chemical plate, high temperature plate; Width: 5mm-- 850mm stainless steel strip coils; 1000, 1219, 1250, 1500, 1800, 2000mm 316Ti stainless steel coil plate, stainless steel flat sheet plate; Surface: 2B smooth surface, No.1 industrial surface, BA (6k) mirror, 8K mirror, 9K mirror, drawing surface, abrasive surface.

Stainless steel coil is widely used in chemical, food, pharmaceutical, paper, petroleum, atomic energy and other industries, as well as construction, kitchenware, tableware, vehicles, household appliances and other types of parts.

Shandong Chengshun Metal Material Co., LTD is a professional manufacturer engaged in the research, development, production, sale and service. Our main products include PPGI, galvanized steel, steel plate, round bar, steel pipe, Stainless steel product, angle bar, steel sheet pile, H beam, I beam, Channel flat steel etc. Main market distributes in North America, South America, Africa, Southeast Asia as well as Oceania. Up to now, we have established long-term and win-win partnership with many large steel manufacturers, such as Baosteel, Laiwu Steel, Rizhao Steel, Handan Iron and Steel, Angang and Maanshan Iron and Steel. Sincerely wish to build a long and regular business with you forever by our good quality and sincere service.

2 notes

·

View notes

Text

Abrex 500 Plate

Abrex 500

In the world of engineering and construction, materials that can withstand extreme conditions are essential. Abrex 500 is one such material, renowned for its exceptional hardness and wear resistance. This high-performance steel is specifically designed to handle the most demanding applications, making it a preferred choice in industries like mining, construction, and heavy machinery manufacturing. In this article, we will delve into what Abrex 500 is, its key properties, specifications, benefits, and why it stands out in the realm of abrasion-resistant steels.

What is Abrex 500?

Abrex 500 is a type of abrasion-resistant steel that belongs to the family of wear plates. The "500" in its name refers to its hardness level, measured in Brinell Hardness (HBW). With a hardness rating of 500 HBW, Abrex 500 offers outstanding resistance to wear and tear, making it ideal for applications that involve high levels of friction, impact, and stress. This steel is typically used in environments where durability is paramount, such as in the construction of heavy machinery, dump trucks, hoppers, crushers, and other equipment that endures harsh working conditions.

Key Properties of Abrex 500

High Hardness: The primary feature of Abrex 500 is its exceptional hardness. With a Brinell hardness of 500 HBW, it is designed to resist wear and abrasion over long periods, even under extreme conditions.

Toughness: Despite its high hardness, Abrex 500 maintains a good level of toughness, enabling it to absorb shocks and impacts without cracking or breaking.

Wear Resistance: This steel offers superior resistance to wear, making it suitable for applications where surfaces are subjected to constant friction, such as in mining equipment, construction machinery, and industrial machinery.

Machinability: Abrex 500 can be cut, welded, and machined, although specialized tools and techniques are often required due to its hardness. With proper handling, it can be fabricated into complex shapes and components.

Versatility: Abrex 500 is available in various thicknesses and sizes, allowing for customization based on specific application needs.

SPECIFICATION ABREX 500:

Size: 5mm ~ 120 mm

Width: Up to 3000 mm

Length: Up to 12000 mm

APPLICATION:

Dump Truck Liners

Cutting Edges

Drag line Bucket Wear Liners

Screen Plates - Chute Liners

Conveyor Buckets

Hoppers

Ore Scrapers

Abrex 500 is a wear resistant plate series form NSSMC. The utilization of abrasion resistance ABREX 500 steel plate particularly lessens the weight of structural parts presented to serve grating conditions. Contrast and consistent steel, ABREX steel plate decreases structural weight and conveys monetary benefits. Selection of elite abrasion resistant ABREX 500 will delay the administration life of apparatus and part.

Benefits of Abrex 500

Extended Service Life: The high wear resistance of Abrex 500 ensures a longer service life for equipment and components, reducing maintenance costs and downtime.

Cost Efficiency: While the initial cost of Abrex 500 may be higher than standard steel, its durability leads to cost savings in the long run due to fewer replacements and repairs.

Improved Performance: Equipment made from Abrex 500 performs better in harsh environments, leading to increased productivity and reliability in operations.

Versatility in Applications: From mining to construction, Abrex 500 can be used in a wide range of industries, making it a versatile solution for various engineering challenges.

Customizable: The availability of different thicknesses and sizes allows manufacturers to tailor Abrex 500 to specific project requirements, ensuring optimal performance.

Conclusion

Abrex 500 is a premium abrasion-resistant steel that stands out for its exceptional hardness, toughness, and versatility. Whether it's in the mining, construction, or industrial sector, this material offers unparalleled wear resistance, extending the lifespan of equipment and enhancing overall performance. By choosing Abrex 500, industries can reduce downtime, lower maintenance costs, and ensure that their operations run smoothly, even in the most challenging environments. As technology continues to advance, materials like Abrex 500 will remain at the forefront, providing reliable and durable solutions for the demands of modern engineering.

For More Information:

Visit Our Website: https://www.wearplates.co.in/

Call Us: +91-8828813630

E-mail: [email protected]

#abrex 500#Abrex 500 Plate#Abrex 500 Plate Manufacturers#Abrex 500 Plate Suppliers#Abrex 500 Plate Stockists#Abrex 500 Plate Exporters#Abrex 500 Plate Manufacturers in India#Abrex 500 Plate Suppliers in India#Abrex 500 Plate Stockists in India#Abrex 500 Plate Exporters in India#Vandan Steel

1 note

·

View note

Text

Spanner with plastic handle

PRODUCT PARAMETER

Features:Made of high-torque, long-lasting, wear-resistant special alloy steel. Wear-resistant special alloy steel. Through high-temperature heat treatment and hard grid plating treatment, it can effectively prevent the abrasion of the hexagonal part, and improve the toughness (not easy to break) to ensure the reliability and safety of operation while ensuring high strength.Dimensions:mmHead shape: StandardHead diameter: 0.71-14Material: 45 gauge steel CRV steelSelling unit: Piece

0 notes

Text

Enhancing Operational Efficiency with Slurry Pumps, Auto Shredder Parts, and More

In the industrial and construction sectors, the quality and efficiency of your equipment can significantly impact productivity. From slurry pumps to ball mill or SAG mill liners, having the right components is crucial for optimal performance. This article explores various parts and attachments, highlighting their importance and benefits.

Slurry Pumps: Efficient Fluid Handling Solutions

Slurry pumps are essential for transporting abrasive and viscous fluids in industries such as mining, wastewater treatment, and construction. High-quality slurry pumps ensure efficient fluid handling, reducing wear and tear on the equipment and minimizing maintenance costs. Regular maintenance and timely replacement of worn parts can significantly enhance the pump's performance and longevity.

Auto Shredder Parts: Enhancing Shredding Efficiency

Auto shredders are critical for recycling and waste management operations. Ensuring you have durable and high-performing auto shredder parts, such as hammers, anvils, and grates, is essential for efficient shredding. Investing in quality auto shredder parts reduces downtime and improves the overall efficiency of your shredding operations.

Bucket Elevators: Reliable Material Handling

Bucket elevators are used for vertical transportation of bulk materials in industries like agriculture, mining, and manufacturing. High-quality bucket elevators ensure smooth and efficient material handling, reducing operational costs and downtime. Regular inspection and maintenance of bucket elevators are crucial for maintaining optimal performance.

Ceramic Insert Blow Bars: Durable Impact Crusher Components

Ceramic insert blow bars are designed to improve the durability and performance of impact crushers. These blow bars offer superior wear resistance compared to traditional steel bars, ensuring longer service life and consistent performance. Using ceramic insert blow bars can enhance your impact crusher's efficiency and reduce maintenance needs.

Toolholder for Cold Milling: Precision and Efficiency

Toolholders for cold milling machines are essential for precise and efficient milling operations. High-quality toolholders ensure secure attachment of milling tools, reducing vibration and improving cutting performance. Regularly inspecting and replacing worn toolholders can enhance milling accuracy and extend the lifespan of your milling equipment.

Crusher Wear Parts: Extending Crusher Life

Crusher wear parts, including jaw plates, concaves, and mantles, are critical for the efficient operation of crushers. Investing in high-quality wear parts ensures reliable performance, reduced downtime, and extended equipment life. Regular maintenance and timely replacement of these parts are essential for optimal crusher performance.

Skid Steer Attachment: Versatility and Productivity

Skid steer attachments, such as buckets, grapples, and augers, enhance the versatility and productivity of skid steer loaders. High-quality attachments ensure reliable performance and increase the machine's functionality. Investing in durable skid steer attachments can significantly improve your operational efficiency and expand the range of tasks your skid steer can perform.

Wheel Loader Attachment: Enhancing Material Handling

Wheel loader attachments, including forks, buckets, and rakes, are crucial for efficient material handling and loading operations. High-quality wheel loader attachments ensure reliable performance and enhance the machine's versatility. Regular maintenance and timely replacement of attachments can improve your wheel loader's productivity and operational efficiency.

Mini Skid Steer Attachment: Compact Efficiency

Mini skid steer attachments, such as trenchers, augers, and buckets, are designed to maximize the efficiency of mini skid steers in confined spaces. These attachments provide versatility and enhance the machine's capability to perform various tasks. Investing in high-quality mini skid steer attachments can improve your project's efficiency and reduce labor costs.

Mini Excavator Attachment: Precision in Tight Spaces

Mini excavator attachments, including breakers, augers, and buckets, are essential for precise and efficient operations in tight spaces. These attachments enhance the functionality of mini excavators, making them ideal for urban construction, landscaping, and utility work. High-quality mini excavator attachments ensure reliable performance and improve operational efficiency.

Ball Mill or SAG Mill Liners: Protecting Your Investment

Ball mill and SAG mill liners are crucial for protecting the mill's shell from wear and ensuring efficient grinding operations. High-quality liners made from wear-resistant materials can significantly extend the lifespan of your mills and improve grinding efficiency. Regular inspection and replacement of mill liners are essential for maintaining optimal mill performance.

0 notes

Text

Abrex 400 Plates Distributors

Chhajed Steel Limited is an Abrex 400 Plate traders, suppliers and stockists, passing on to the entire of the world.We are having most obvious stock and arranged stack of around 1000 tons of Abrex 400 Plate in various size, examinations and cuts.Our fabricating structure is kept up by extended in-house thing appraisal and testing and state to meet all the most watched general benchmarks, including ISO 9001:2008

Chhajed Steel Limited has some inclination in Abrex 400 Plate .With 25 extended lengths of relationship in giving and passing on Abrex 400 Plate we offer marvelous, cleave down cost notwithstanding the best association.

We are had possible duty in offering precision demonstrated Abrex 400 Plate , which are utilized as a bit of different building applications and can be benefitted in different appraisals like Abrex 400 Plate, Abrasion Resistant Steel Plates these assessments are accessible as Abrasion Resistant Steel Plate

Abrex 400 steels are the most all around used of the wear safe assessments. Abrex 400 demonstrates a surprising setting of high quality to affect, support, weld limit and imperviousness to scratched locale. Abrex 400 has around 3 times the scratched an area check of standard steel plate and helps drawing out the affiliation life of mechanical parts.

#Abrex 400 in India#Abrex 400 Equivalent in India#Abrex 400 Plates in India#Abrasion Resistance Plate Manufacturers in India#Abrex 400 Plates Suppliers in India#Abrex 400 Steel Plates Stockists in India#Abrex 400 Plates Exporters in India

0 notes

Text

Abrex 400 Plates Manufacturers

INTORDUCTION

We are had reasonable inclusion in offering accuracy arranged Abrex 400 Plate , which are utilized as a bit of different structure applications and can be benefitted in different evaluations like ABREX 400 Plate, Abrasion Resistant Steel Plates these appraisals are accessible as Abrasion Resistant Steel Plate.

ABREX 400 steels are the most for the most part used of the wear safe assessments. ABREX 400 demonstrates a momentous solidifying of high invulnerability to influence, usefulness, weld purpose of imprisonment and solidness to scratched zone. ABREX 400 has around different occasions the scratched zone deterrent of standard steel plate and helps drawing out the affiliation life of mechanical parts.

In the realm of industrial materials, Abrex 400 stands out as a formidable force, offering unparalleled strength and durability. Let's delve into the world of Abrex 400 steel and discover why it's the go-to choice for applications demanding top-notch performance.

2 notes

·

View notes

Text

Advantages of Jindal Spiral Welded Pipes in Pipeline Systems

Introduction

In the ever-evolving world of pipeline systems, the choice of pipes plays a crucial role in ensuring the efficiency and longevity of the infrastructure. One name that stands out in the industry is Jindal, a renowned manufacturer of high-quality spiral welded pipes. Tubetrading Co. takes pride in being a leading Jindal Spiral Welded Pipes dealer in Vadodara and a trusted distributor in Gujarat. In this blog, we will delve into the distinct advantages of Jindal Spiral Welded Pipes and why they are the preferred choice for various pipeline applications.

Superior Quality Construction

Jindal Spiral Welded Pipes are crafted with precision and adhere to the highest quality standards. The manufacturing process involves helical welding of steel plates to form a robust and seamless pipe. This method ensures uniformity in thickness, resulting in pipes with exceptional structural integrity. As a Tubetrading Co. Jindal Spiral Welded Pipes distributor in Gujarat, we can vouch for the superior quality that these pipes bring to diverse pipeline projects.

Durability and Longevity

Pipeline systems are exposed to a myriad of challenges, including corrosive environments, extreme temperatures, and varying pressure conditions. Jindal Spiral Welded Pipes are designed to withstand these challenges with remarkable durability. The helical welding technique creates pipes that are not only strong but also resistant to corrosion, making them ideal for long-term use. When investing in pipeline infrastructure, longevity is a key consideration, and Jindal Spiral Welded Pipes deliver on that front.

Versatility in Applications

One of the significant advantages of Jindal Spiral Welded Pipes is their versatility. These pipes find applications across diverse industries such as oil and gas, water supply, wastewater management, and more. Whether it's for transporting fluids, gases, or bulk materials, Jindal Spiral Welded Pipes provide a reliable and cost-effective solution. Tubetrading Co., as a Jindal Spiral Welded Pipes dealer in Vadodara, has witnessed the widespread use of these pipes in various projects due to their adaptability.

High Resistance to Pressure and Stress

Pipeline systems often operate under high pressure, especially in industries dealing with oil, gas, or chemicals. Jindal Spiral Welded Pipes are engineered to withstand these demanding conditions. The helical welding technique ensures uniform distribution of stress along the pipe's circumference, preventing weak points that could compromise its integrity. This makes Jindal Spiral Welded Pipes an excellent choice for applications where pressure resistance is paramount.

Cost-Effective Solution

Cost efficiency is a crucial factor in any construction project, and Jindal Spiral Welded Pipes offer a cost-effective solution without compromising on quality. The seamless manufacturing process and the durability of these pipes contribute to lower maintenance costs and fewer replacements over time. As a Jindal Spiral Welded Pipes distributor in Gujarat, Tubetrading Co. understands the importance of delivering value for money to clients, and these pipes align perfectly with that objective.

Ease of Installation

Time is of the essence in construction projects, and the ease of installation is a significant advantage that Jindal Spiral Welded Pipes bring to the table. Their lightweight yet sturdy construction facilitates quicker and more straightforward installation compared to traditional pipe materials. This not only accelerates the project timeline but also reduces labor costs, making Jindal Spiral Welded Pipes an efficient choice for pipeline installations.

Coated Pipes for Enhanced Protection

Jindal Spiral Welded Coated Pipes add an extra layer of protection to the pipes, enhancing their resistance to corrosion and abrasion. The coating acts as a barrier against environmental elements, chemicals, and other factors that could compromise the pipe's surface. Tubetrading Co. takes pride in offering a variety of Jindal Spiral Welded Coated Pipes as part of our product range. As a Jindal Spiral Welded Pipes dealer in Vadodara, we understand the importance of providing comprehensive solutions to our clients, and coated pipes play a vital role in extending the lifespan of pipelines.

Conclusion

In the realm of pipeline systems, the choice of pipes is a critical decision that can significantly impact the overall performance and longevity of the infrastructure. Jindal Spiral Welded Pipes, available through Tubetrading Co. as a trusted dealer and distributor, offer a host of advantages that make them the preferred choice for various applications. From superior quality construction to versatility, durability, and cost-effectiveness, these pipes embody the qualities essential for a reliable and efficient pipeline system. As industries continue to evolve, the demand for robust and high-performance pipes like Jindal Spiral Welded Pipes is set to rise, ensuring a sustainable and resilient future for pipeline projects across the globe.

#Jindal Spiral Welded Coated Pipes#Jindal Spiral Welded Pipes Dealer in Vadodara#Jindal Spiral Welded Pipes Distributor in Gujarat#Jindal spiral welded Pipes

6 notes

·

View notes

Text

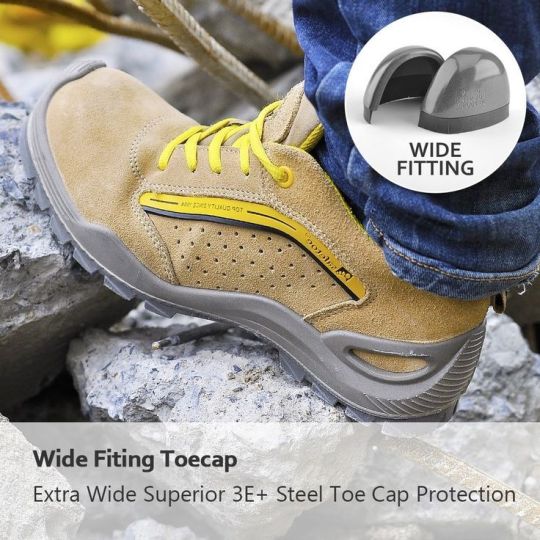

Best Sport Low Ankle Shoe, S1 SRC

Upper: Brown suede cow leather

Lining: Air mesh lining & amp; Resistant to Abrasion

Insock: Anti-static, and ventilated EVA

Outsole: PU/PU dual density injection

Tested By: UK Intertek lab (Approved body:0362)

Toe: Composite Toe, Steel toecap 200 joules

Penetration: Steel plate 1100 newtons

Applications:

200 Joule Toe Cap, Slip-Resistant, Shock Absorption, Anti-static, Petrol and Chemical Resistant, Anti-nail Mid sole, Oil Resistant, Electro Static Discharge

Color: Camel

Sizes: 38-46

6 Months Warranty Against Manufacturing Defect

2 notes

·

View notes

Text

BDI Wear Parts: Your Trusted Source for High-Quality Crusher Components

Amid the demanding and competitive world of heavy-duty crushing equipment, BDI Wear Parts shines as a symbol of quality and dependability. As a top supplier of crusher parts, we serve the mining, quarrying, construction, and recycling industries, providing a wide range of components designed to improve the efficiency and longevity of crushing machinery.

Our Key Solutions: Complete Range of Crusher Components

1. Jaw Crusher Parts: Durability Combined with Precision

At the heart of our product portfolio are jaw crusher parts, essential for primary crushing applications. Our jaw plates, available in various profiles and materials including high-manganese steel, are engineered to withstand extreme compressive forces and abrasive wear. Precision-machined to ensure a seamless fit, these parts minimize downtime and optimize crushing efficiency. Our commitment to durability ensures that you can rely on BDI Wear Parts to keep your jaw crushers running smoothly for longer.

2. Cone Crusher Parts: Power in Simplicity

Moving further down the crushing line, our cone crusher parts represent the epitome of engineering excellence. From bowl liners and mantles to concaves and adjusting rings, every component is crafted from premium materials such as high-chrome iron and manganese steel. These parts are designed to balance wear resistance with cost-effectiveness, ensuring maximum production with minimal downtime. With BDI Wear Parts, you can count on precise fitment, enhanced performance, and a lower total cost of ownership.

3. Impact Crusher Parts: Versatility Meets Durability

For applications requiring high throughput and versatility, our impact crusher parts are the ultimate solution. Our blow bars, hammers, and impact plates are constructed from the toughest alloys available, withstanding the intense impacts and abrasive wear characteristic of impact crushing. By utilizing advanced heat treatment and surface finishing techniques, we enhance the durability of these crusher parts for sale, extending their service life and reducing the need for frequent replacements.

4. Cutting Edge Components: Leading the Way in Innovation

BDI Wear Parts is constantly pushing the boundaries of innovation with our cutting-edge components. Our cutting edges, designed for screen decks, conveyor belts, and other applications, incorporate advanced materials like tungsten carbide to improve wear resistance and performance. Whether you’re looking to increase the throughput of your screening system or prolong the life of your conveyor components, our cutting-edge products offer the perfect solution.

In-House Manufacturing & Streamlined Logistics: Your Edge in the Market

What sets BDI Wear Parts apart is our advanced in-house manufacturing and efficient logistics network. Equipped with state-of-the-art machinery and skilled technicians, our facilities ensure that every component meets the highest standards of quality and precision. Coupled with our optimized logistics system, we deliver parts swiftly to customers around the globe, reducing downtime and boosting operational efficiency.

Conclusion

In summary, BDI Wear Parts is the go-to source for premium crusher components that enhance the performance and longevity of your crushing equipment. From jaw crusher parts to cone crusher parts for sale Canada, impact parts, and cutting-edge components, our extensive product range caters to the diverse needs of the mining, quarrying, construction, and recycling industries. With our in-house manufacturing and streamlined logistics, we are dedicated to delivering the best solutions for your crushing needs. Choose BDI Wear Parts today and discover the impact that quality and reliability can have on your operations.

0 notes

Text

Abrex 400 Plate Stockists

The longevity and operational effectiveness of heavy machinery and equipment are greatly impacted by the materials chosen, especially in industries where these items are subjected to tremendous wear and tear. Abrex 400 is one such material that has become more well-known in these applications. This superior wear-resistant steel is designed to endure the most demanding conditions, offering increased dependability and longevity. This post will explain what Abrex 400 is, as well as its main characteristics, features, advantages, and reasons for being a well-liked option for heavy-duty applications in many industries.

What is Abrex 400?

Abrex 400 is a type of wear-resistant steel plate, specifically designed for applications that demand high resistance to abrasion and impact. It is part of the Abrex series, which includes various grades, but Abrex 400 is the most commonly used due to its balance between hardness and toughness. Manufactured using advanced metallurgical techniques, Abrex 400 provides a hardness level of 400 HBW (Brinell Hardness), making it ideal for use in industries such as mining, construction, and material handling.

Key Properties of Abrex 400

The key properties of Abrex 400 make it a versatile and reliable material for a wide range of demanding applications. Some of the most significant properties include:

High Hardness: Abrex 400 has a hardness rating of 400 HBW, which provides excellent resistance to wear and abrasion. This makes it suitable for environments where equipment faces constant friction and impact.

Toughness: Despite its high hardness, Abrex 400 maintains good toughness, allowing it to absorb impact without cracking or failing. This is essential in applications where both abrasion and impact resistance are required.

Weldability: Abrex 400 can be welded using standard welding techniques, making it easier to fabricate and integrate into existing machinery or structures.

Formability: While it is a hard material, Abrex 400 still offers a degree of formability, allowing it to be shaped and customized to meet specific requirements.

SPECIFICATION ABREX 400:

Size: 5mm ~ 120 mm

Width: Up to 3000 mm

Length: Up to 12000 mm

Vandan Steel & Engg. co. is a ABREX 400 Plate importers, suppliers and stockists, conveying to the entire of the world.We are having biggest stock and prepared load of around 1000 tons of ABREX 400 Plate in various size, grades and cuts.Our fabricating system is upheld by escalated in-house item assessment and testing and authorize to meet all the most perceived global principles, including ISO 9001:2008

Benefits of Abrex 400

The use of Abrex 400 in industrial applications offers several significant benefits:

Extended Service Life: Due to its high wear resistance, components made from Abrex 400 have a longer service life compared to those made from standard steel, reducing the frequency of replacements.

Cost-Effective: Although the initial cost of Abrex 400 may be higher than regular steel, its durability and extended lifespan lead to lower overall maintenance and replacement costs, making it a cost-effective choice in the long run.

Reduced Downtime: With improved wear resistance, equipment downtime due to maintenance and repairs is minimized, leading to increased productivity and efficiency in operations.

Versatility: Abrex 400's combination of hardness, toughness, and weldability makes it suitable for a wide range of applications, from earthmoving machinery to crushers, conveyors, and hoppers.

Improved Safety: By maintaining its structural integrity even in harsh environments, Abrex 400 enhances the safety and reliability of equipment, reducing the risk of failures and accidents.

Conclusion

Abrex 400 has become the material of choice for applications requiring exceptional wear and impact resistance. It is a dependable option for increasing machinery longevity and cutting operating expenses due to its special blend of hardness, toughness, and adaptability. Abrex 400 offers exceptional performance in mining, construction, and material handling, guaranteeing that machinery can endure even the most demanding circumstances. Industries can increase their total efficiency, safety, and productivity by selecting Abrex 400, making it a wise investment for long-term success.

For More Information:

Visit Our Website: https://www.wearplates.co.in/

Call Us: +91-8828813630

E-mail: [email protected]

1 note

·

View note

Text

MN13 Grade High Manganese Steel Plates

Introduction

MN13 Grade High Manganese Steel Plates are renowned for their high wear resistance and toughness. These steel plates, commonly used in the mining, construction, and heavy engineering industries, are ideal for applications that require a high level of abrasion resistance. The high manganese content in MN13 steel, typically around 12-14%, gives it the unique ability to harden on impact, making it suitable for high-wear environments.

Applications of MN13 High Manganese Steel Plates

Given their unique properties, MN13 Grade High Manganese Steel Plates are widely used across various industries:

Mining and Quarrying: The plates are ideal for manufacturing components like excavator buckets, crusher jaws, and impact hammers that face extreme wear and tear in the mining and quarrying industries.

Railway and Transportation: Due to their high impact resistance, MN13 steel plates are used in manufacturing components like railway crossings and track work that endure constant impact and friction.

Construction and Earthmoving: MN13 plates are utilized in construction equipment, such as bulldozer blades, loader buckets, and dump truck liners, that need to withstand abrasive materials like sand, gravel, and rocks.

Cement and Power Plants: The steel plates are used in cement and power plants for applications such as chutes, hoppers, and liners, where material handling equipment is exposed to high levels of abrasion and impact.

Military Applications: Due to their hardness and resistance to shock, MN13 steel plates are also used in military applications for making ballistic protection equipment and armor plates.

Advantages of MN13 Grade High Manganese Steel Plates

Superior Durability: MN13 plates offer exceptional durability and a longer lifespan than other types of steel, reducing the need for frequent replacements.

Cost-Effective: The reduced need for frequent repairs or replacements lowers operational costs, making it a cost-effective choice for many heavy-duty applications.

Versatility: Suitable for a wide range of industries and applications, these plates provide versatility in design and functionality.

High Impact Resistance: MN13 steel plates withstand extreme impact without deformation, making them ideal for high-impact applications.

Environmentally Friendly: The long lifespan and reduced need for replacement help in minimizing waste and the environmental impact of manufacturing.

Chajed Steel Limited is a victor among the most anticipated Supplier, importers, Exporter in a wide degree of MN13 High Manganese Steel Plates High Yield in India. Broad Ready Stock Inventory Certified to MN13 High Manganese Steel in Warehouse and Processing Facility. Most Trusted Supplier of MN13 High Manganese Steel Plates. Mn13 is to some degree high manganese steel material, which is the best choice for disavowing high impacts, high loads among wear-safe steels.

Mn13 Hot Rolled Steel Plates have shocking properties in restricting strong impacts scratched a territory and high weight scratched zone. In like manner, Mn13 Steel Plates won't be pummelled when in application and are unquestionably not hard to be catted, welded and mutilated when taking mechanical machining works. Stockist and Stockholder of High Manganese Steel Plates to request MN13.

Main feature High Manganese Include

Severe wear on the surface has a work-hardening effect on the austenitic structure of this steel.

This, when combined with the level of carbon in accordance with the international standards, leads

To increase hardness from 200BHN (in as delivered plate) up to an in-service hardness of at least 600BHN.

This work-hardening capability renews itself throughout in-service life. The under layers not work-hardened maintain an excellent resistance to shock and a very high ductility

Chemical Composition

C

Mn

Si

P

S

0.90-1.20

11-14

0.30-0.80

max 0.035

max 0.030

Conclusion

MN13 Grade High Manganese Steel Plates stand out for their excellent wear resistance, work hardening properties, and high toughness. These features make them an ideal choice for industries and applications where components are exposed to severe wear and impact. The ability of MN13 steel to harden under stress, combined with its high ductility and toughness, ensures a high-performance material that meets the demanding needs of modern engineering and industrial applications.

For More Information:

Visit Our Website -https://www.chhajedman.com/

Call Us – +91-932-111-3630

Email Us- [email protected]

0 notes

Text

Essential Components for Crushing and Milling Equipment: A Detailed Overview

In the industrial and mining sectors, the efficiency and longevity of machinery depend heavily on the quality of its components. This guide explores key parts and accessories for crushing and milling equipment, including cone crusher parts, jaw crusher parts, impactor blow bars, vertical roller mills rollers or tires, hammer mills hammers, wear blocks, cutting edges, storage shelters, stretch hood tubes, and general crusher parts.

Cone Crusher Parts

Cone crushers are used extensively in various industries for secondary and tertiary crushing. Key parts include the mantle, concave, main shaft, and bushings. These components are essential for the efficient functioning and durability of the machine. High-quality materials and precision engineering ensure that cone crusher parts can withstand the high levels of pressure and abrasion they encounter during operation.

Jaw Crusher Parts

Jaw crushers are primary crushers widely used in mining and aggregate production. Important parts include jaw plates, toggle plates, and cheek plates. These components play a critical role in breaking down large rocks into smaller, manageable pieces. Durability and strength are crucial for jaw crusher parts to handle the constant impact and wear they endure.

Impactor Blow Bars

Impactor blow bars are vital for impact crushers, which are used to crush materials by striking them with high-speed rotating bars. These bars must be tough and wear-resistant to handle the intense impact and abrasion. High-chrome and manganese steel blow bars are commonly used for their durability and ability to provide a consistent crushing performance.

Vertical Roller Mills Roller or Tire

Vertical roller mills are used in the cement and mining industries to grind raw materials. The rollers or tires are critical components that apply pressure to the material being ground. These parts must be made from wear-resistant materials to ensure longevity and efficiency. Proper maintenance and timely replacement of rollers or tires can significantly enhance the performance of vertical roller mills.

Hammer Mills Hammers

Hammer mills are used to crush and pulverize materials in various industries. The hammers, which repeatedly strike the material, must be robust and wear-resistant. Alloy steel or manganese steel hammers are commonly used due to their high impact resistance and durability. Regular inspection and replacement of hammers are essential for maintaining the efficiency of hammer mills.

Wear Blocks

Wear blocks are protective components used in various types of crushing and milling equipment to prevent excessive wear and extend the lifespan of the machinery. They are often made from hardened steel or other wear-resistant materials. Proper installation and regular monitoring of wear blocks can help reduce maintenance costs and downtime.

Cutting Edge

Cutting edges are critical for earthmoving and construction equipment, such as bulldozers and graders. These parts are designed to withstand high levels of stress and abrasion while maintaining a sharp edge. High-carbon steel and carbide-tipped cutting edges are popular choices due to their durability and cutting efficiency.

Storage Shelter

Storage shelters are essential for protecting machinery and equipment from the elements. These structures can significantly extend the lifespan of equipment by shielding it from rain, snow, and UV radiation. Properly designed storage shelters also help in maintaining a clean and organized work environment.

Stretch Hood Tube

Stretch hood tubes are used in packaging to secure and protect products during transportation and storage. They provide a tight and secure cover, which helps in preventing damage and contamination. Stretch hood tubes are widely used in various industries, including construction, agriculture, and manufacturing.

Crusher Parts

General crusher parts encompass a wide range of components used in various types of crushers, including jaw crushers, cone crushers, and impact crushers. These parts include bearings, shafts, liners, and gears. High-quality crusher parts are crucial for the reliable and efficient operation of crushing equipment. Regular maintenance and timely replacement of worn-out parts can prevent breakdowns and extend the service life of crushers.

Understanding the essential components of crushing and milling equipment and their respective roles is crucial for maintaining efficient and reliable operations. Whether it's cone crusher parts, jaw crusher parts, or impactor blow bars, using high-quality materials and ensuring proper maintenance can significantly enhance the performance and longevity of machinery. Additionally, protective measures such as wear blocks and storage shelters play a vital role in safeguarding equipment and reducing operational costs.

0 notes