#Absolute Rotary Encoders Industry

Explore tagged Tumblr posts

Text

Precision and Reliability with Absolute Rotary Encoders

Enhance your industrial operations with our range of Absolute Rotary Encoders. These advanced sensors ensure precision and reliability, offering absolute position feedback for rotating shafts without the need for recalibration after power cycles. Our encoders are designed for diverse applications, from robotics to industrial automation, with variations like Single-turn and Multi-turn models available. Trust in our Absolute Rotary Encoders to deliver high accuracy and durability in harsh environments. Explore our selection now to streamline your motion control needs with cutting-edge technology.

0 notes

Text

The Science Behind Hollow Shaft Rotary Encoders: Torque, Speed, and Accuracy

In the landscape of modern automation, sensors and feedback mechanisms are crucial for maintaining the precision and efficiency of machinery. One of the most indispensable devices in this category is the rotary encoder, especially the hollow shaft rotary encoder. These devices provide real-time data on angular position, velocity, and direction, enabling refined control over dynamic systems. Their unique hollow shaft design offers numerous advantages, particularly when integrating with rotating shafts and assemblies in compact or sensitive environments. This article delves into the scientific underpinnings of these encoders, examining how they measure torque, speed, and accuracy in industrial and robotic applications.

Basics of Rotary Encoders

Rotary encoders translate rotational motion into digital signals. They are broadly categorized into absolute and incremental types. Absolute encoders deliver a unique position value, whereas incremental encoders provide relative motion data. Hollow shaft rotary encoders, a sub-type of these devices, allow the shaft of the motor or machinery to pass through the encoder. This design minimizes axial load, reduces mechanical complexity, and facilitates easier installation. The hollow shaft construction is particularly beneficial in applications where space is limited or where quick replacement and alignment are essential. These encoders are primarily used in robotics, CNC machinery, elevators, and energy sector equipment.

Working Principle of Hollow Shaft Rotary Encoders

Hollow shaft rotary encoders typically use optical, magnetic, or capacitive sensing methods. Optical encoders employ a light source and photodetector array to read patterns on a rotating disk. Magnetic encoders detect changes in magnetic fields using Hall-effect sensors or magnetoresistive elements. Capacitive encoders utilize variations in capacitance caused by changes in geometry as the shaft rotates. Each method has its advantages in terms of resolution, durability, and environmental robustness. The hollow shaft design does not alter the fundamental sensing mechanism but allows the encoder to be mounted directly over a rotating shaft without additional couplings. This direct interface helps reduce backlash and enhances accuracy.

Measuring Torque with Hollow Shaft Rotary Encoders

Torque is the rotational analog of linear force. Although rotary encoders are not traditionally used as torque sensors, they play a significant role in torque estimation. By precisely measuring angular displacement and speed, and knowing the system's moment of inertia, torque can be inferred. In applications where torque sensors are either too bulky or expensive, high-resolution encoders serve as a cost-effective alternative. The key lies in correlating the angular velocity and acceleration data provided by the encoder with the mechanical characteristics of the system. For dynamic torque measurement, especially in systems with varying load conditions, encoders offer real-time feedback that can be analyzed via control algorithms to maintain performance consistency.

Speed Detection in Dynamic Systems

Speed detection is a primary function of rotary encoders. Incremental hollow shaft rotary encoders are particularly adept at delivering high-fidelity speed data. They generate pulses for every increment of rotation, which are counted over time to calculate speed. Higher pulse counts per revolution (PPR) mean greater resolution and more accurate speed readings. In applications like conveyor systems, turbines, or robotic joints, this level of speed precision ensures smoother operation and reduces wear and tear. Encoders are also favored for their minimal latency, allowing near-instantaneous speed adjustments. Furthermore, their digital output can be seamlessly integrated into programmable logic controllers (PLCs) or microcontrollers for real-time processing and control.

Ensuring Accuracy and Resolution

Accuracy in rotary encoders refers to the degree to which the measured position matches the actual position. Resolution, on the other hand, is the smallest change in position that the encoder can detect. High-resolution encoders are essential for systems requiring fine control, such as semiconductor manufacturing or surgical robotics. Hollow shaft rotary encoders often offer both high resolution and excellent accuracy due to their ability to directly interface with the rotating element. This reduces mechanical errors associated with couplings or misalignment. Optical encoders typically offer the highest resolution, while magnetic and capacitive types provide better resilience in harsh environments. Calibration and alignment during installation also play critical roles in maintaining accuracy.

The Importance of Zero Backlash

Backlash is the slight movement that occurs when direction is reversed in a mechanical system. This can cause significant errors in position sensing. Hollow shaft encoders help minimize backlash by allowing direct mounting onto the shaft, thereby eliminating intermediate couplings or gears that can introduce slack. Zero backlash is particularly critical in high-precision applications like robotics and CNC machining, where even minor errors can lead to defective outcomes. By integrating the encoder directly onto the shaft, manufacturers can achieve tighter control loops, reduced error margins, and more reliable performance. This direct integration also facilitates better synchronization between motor movement and feedback, enhancing overall system stability.

Environmental and Structural Considerations

Industrial environments often expose equipment to dust, moisture, temperature fluctuations, and vibrations. Hollow shaft rotary encoders are designed to withstand these conditions through robust housing, sealed bearings, and non-contact sensing technologies. Magnetic and capacitive encoders are particularly well-suited for such environments due to their resistance to contaminants and mechanical wear. Structural considerations also include the material of the encoder’s housing and shaft, which must align with the application’s requirements for durability and weight. The hollow shaft itself can be designed to accommodate different shaft diameters, increasing its adaptability across multiple systems. Proper installation and maintenance further ensure the encoder's longevity and consistent performance.

Integration into Closed-Loop Systems

Hollow shaft rotary encoders play a pivotal role in closed-loop control systems, where feedback is used to adjust and correct motion in real time. These systems require high-resolution and low-latency feedback to maintain accuracy and efficiency. The encoder sends position and speed data to a controller, which then adjusts the motor’s operation accordingly. This continuous feedback loop allows for precise control even in variable load conditions. Integration into such systems requires compatibility with control hardware, appropriate signal output formats, and real-time data processing capabilities. Encoders that support multiple output protocols, such as quadrature, SSI, or BiSS, offer greater flexibility in system design.

Case Study: Hollow Shaft Encoders in Robotic Arms

Robotic arms require exceptional precision and agility, often functioning in environments that demand both speed and safety. Hollow shaft rotary encoders enable these capabilities by offering accurate position and velocity feedback without adding bulk to the joints. Their compact design fits seamlessly into tight spaces, while their direct shaft interface ensures minimal mechanical error. For example, in medical robotics, where minute movements can have significant consequences, the encoder's resolution and accuracy become critical. Additionally, their ability to function reliably in varying environmental conditions makes them suitable for both cleanrooms and industrial settings. This case study illustrates how the theoretical benefits of hollow shaft encoders translate into practical performance gains.

Comparing Hollow Shaft and Solid Shaft Encoders

Solid shaft encoders require couplings or adapters for installation, which can introduce alignment issues and mechanical play. Hollow shaft encoders bypass these challenges by mounting directly onto the shaft, thereby reducing complexity and improving measurement fidelity. While solid shaft designs may offer slightly more mechanical robustness, they often necessitate more space and careful alignment. Hollow shaft encoders, by contrast, are easier to install and replace, which is beneficial in systems where downtime must be minimized. The choice between the two often comes down to the specific application requirements, including available space, desired precision, and environmental factors. Ultimately, hollow shaft models offer a compelling mix of convenience and performance.

Market Trends and Future Outlook

The market for rotary encoders is evolving rapidly, driven by advancements in automation, robotics, and smart manufacturing. Hollow shaft rotary encoders are gaining traction due to their compact design and enhanced integration capabilities. Innovations such as wireless data transmission, miniaturization, and improved environmental resistance are expanding their application scope. Additionally, the incorporation of edge computing and AI into encoder systems is enabling predictive maintenance and smarter feedback mechanisms. As industries continue to push for higher efficiency and precision, the demand for reliable and versatile encoders will only increase. In this context, the hollow shaft encoder emerges as a key component in future-ready systems.

Conclusion

The science behind hollow shaft rotary encoders encompasses a multidisciplinary understanding of mechanics, electronics, and systems engineering. Their ability to provide accurate, real-time data on torque, speed, and position makes them invaluable in a wide array of industrial and robotic applications. Their unique hollow design simplifies installation and enhances performance by reducing mechanical errors. From aiding in torque estimation to ensuring zero backlash and high-resolution feedback, these encoders are tailored for precision-driven environments. As technological advancements continue to refine their capabilities, the hollow shaft rotary encoder is poised to remain a cornerstone of intelligent motion control systems across industries.

0 notes

Text

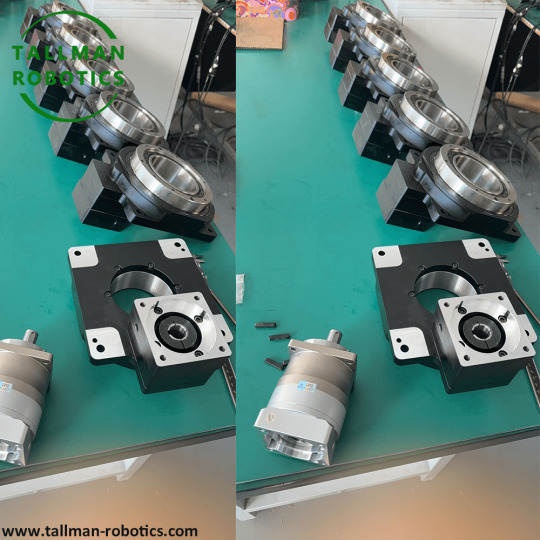

Precise Positioning Hollow Rotary Tables Will Be Delivered to Pakistan

Precise Positioning Hollow Rotary Tables are specialized rotational devices featuring a central hollow shaft, designed for high-accuracy angular positioning. The hollow core allows cables, pneumatic lines, or shafts to pass through, eliminating cable tangling and reducing system complexity.

https://youtu.be/ZP31od3m6Xc?si=KSzfpuXjjSW-2xnV Key Components and Features 1. Drive Mechanisms: Harmonic Drives: Preferred for near-zero backlash and high torque density. Direct Drive Motors: Offer smooth operation and precise control without mechanical reduction. Alternative systems like worm gears may be used but are less common in ultra-high-precision settings. 2. Bearings: Crossed Roller Bearings: Provide high rigidity and accuracy, handling both radial and axial loads efficiently. 3. Feedback Systems: High-resolution absolute encoders ensure accurate position tracking, even after power interruptions. 4. Materials and Construction: Made from rigid materials like aluminum or steel alloys to minimize deflection under load. Standardized mounting interfaces (e.g., ISO/SAE flanges) for easy integration with machinery. Applications of Large hollow shaft rotary tables CNC Machining: Enables multi-axis machining by rotating workpieces precisely. Semiconductor Manufacturing: Used in wafer handling and inspection systems. Optics and Medical Devices: Positions lenses or surgical tools with high accuracy. Robotics: Facilitates precise joint movements in automation and articulated robots. Advantages Over Standard Rotary Tables Hollow Design: Central pass-through avoids cable management issues, enhancing reliability. High Precision: Sub-arc-minute accuracy achievable with advanced feedback and drive systems. Versatility: Suitable for diverse industries due to customizable sizes and load capacities. Conclusion Precise Positioning Hollow Rotary Tables/Large hollow shaft rotary tables are critical in applications demanding exact angular positioning with central component pass-through. Their design combines mechanical precision with intelligent feedback systems, making them indispensable in advanced manufacturing and automation. You are welcome to watch more projects or visit our website to check other series or load down e-catalogues for further technical data. Youtube: https://www.youtube.com/@tallmanrobotics Facebook: https://www.facebook.com/tallmanrobotics Linkedin: https://www.linkedin.com/in/tallman-robotics Read the full article

#CNCHollowRotaryActuator#HeavyDutyHollowRotaryTables#HighPrecisionHollowRotaryTablesforCNCMachines#High-precisionrotarytable#HollowAxes#HollowRotaryPlatform#HollowRotaryTableRightAngleManufacturer#LargeApertureHollowRotaryTables#Largehollowshaftrotarytables#PlanetaryGearboxes#PrecisePositioningHollowRotaryTables#PrecisionHollowRotaryTable#PrecisionRightAngleRotaryTables#RotaryActuators

0 notes

Text

Precision and Performance with Aeliya Marine’s Encoders: The Key to Accurate Motion Control

In the world of automation, robotics, and motion control, encoders play a pivotal role in ensuring accuracy and reliability. Whether you’re designing a marine navigation system, robotics project, or industrial automation system, having the right encoder can make all the difference. Aeliya Marine offers a comprehensive collection of high-quality encoders that cater to various applications, ensuring that your systems function with the utmost precision.

Why Choose Aeliya Marine for Encoders?

1. Superior Accuracy and Performance Encoders are integral components in any motion control system, converting mechanical motion into electrical signals for feedback and control. Aeliya Marine’s encoders are designed to deliver superior accuracy, ensuring that your systems provide precise measurements and smooth operation. Whether you're working with rotational or linear motion, the encoders available at Aeliya Marine will meet your needs with exceptional precision.

2. Wide Range of Encoder Types Aeliya Marine understands that different applications require different types of encoders. To cater to various industries, they offer an extensive selection of encoders, including:

Rotary Encoders: These are ideal for measuring rotational position, speed, and direction in motors, turbines, and other rotating machinery. With Aeliya Marine’s rotary encoders, you can expect accurate feedback for continuous, high-speed rotation in both industrial and marine systems.

Linear Encoders: For applications where linear motion needs to be tracked, Aeliya Marine provides linear encoders that convert the position of a moving object into an electrical signal. These are perfect for applications like CNC machines, automated manufacturing systems, and other linear motion systems.

Incremental Encoders: Incremental encoders are great for applications where the measurement of position relative to a reference point is needed. These encoders are commonly used in industrial applications where rotation counts or speed feedback are essential.

Absolute Encoders: Unlike incremental encoders, absolute encoders provide a unique position value within a full rotation, even after power loss. This makes them a crucial choice for systems that require a constant reference to their position at all times.

3. Marine-Specific Encoders Aeliya Marine specializes in electronic components tailored to withstand harsh marine environments. Their encoders are designed with rugged durability, resistance to corrosion, and the ability to function in extreme weather and temperature conditions. This makes them the perfect choice for marine navigation, automation, and other critical systems that operate in demanding environments.

4. Reliable and Durable Construction The encoders offered by Aeliya Marine are built to last. Whether you need encoders for land-based projects or marine applications, you can trust that Aeliya Marine’s products are engineered to endure the rigors of continuous use. Their encoders are resistant to dust, moisture, vibration, and even saltwater exposure, ensuring longevity and reliable performance.

Applications of Encoders in Various Industries

Encoders are indispensable in a wide range of industries and applications. Here are just a few ways they are used:

Marine Systems: In marine applications, encoders are used to monitor and control the position and movement of various components, such as rudders, winches, and thrusters. Precise feedback ensures that systems remain operational even in tough maritime conditions.

Robotics and Automation: Encoders are essential for robots and automated machinery to track and control motion with high precision. From industrial robots to conveyor belts, encoders help maintain efficiency and reduce errors.

CNC Machines and Milling: Encoders provide accurate feedback on the position of the cutting tool in CNC machines, ensuring that milling, drilling, and cutting operations are precise.

Medical Equipment: In medical devices, encoders are used to track movement with high precision, such as in surgical robots, imaging equipment, or diagnostic instruments.

Industrial Machinery: Encoders help monitor the position, speed, and direction of moving parts in industrial machinery, ensuring optimal operation and reducing wear and tear.

Why Trust Aeliya Marine for Your Encoder Needs?

Expertise in Marine Electronics: Aeliya Marine has years of experience providing high-quality electronic components tailored for the marine industry. Their encoders are specially designed to thrive in maritime conditions, where durability and accuracy are critical.

Exceptional Customer Service: Whether you need guidance on selecting the right encoder for your application or assistance with installation, Aeliya Marine’s knowledgeable team is always ready to help. Their commitment to customer satisfaction ensures that you’ll receive the support you need.

Global Shipping: Aeliya Marine serves customers around the world, ensuring that no matter where you are located, you can access their premium encoder products.

Conclusion

When it comes to motion control, precision is key—and with Aeliya Marine’s collection of encoders, you can trust that your systems will operate with the utmost accuracy. Their broad selection of encoders, built for both land-based and marine applications, ensures that you get the right tool for the job, no matter the complexity of your project.

Explore Aeliya Marine’s Encoder Collection today and take the first step towards enhancing your systems with high-performance, durable encoders designed for any environment.

0 notes

Text

Single Turn Absolute Encoder

The Single-Turn Absolute Encoder by Hubner offers precise position measurement for single-turn applications. Known for robust design and high reliability, it's ideal for industrial automation, delivering accurate outputs even in challenging environments.

Visit at: https://www.huebner-giessen.com/en/products/absolute-rotary-encoders-singleturn/

0 notes

Text

The Encoder Market: Current Trends and Future Outlook

The Encoder Market is experiencing significant growth, driven by advancements in technology and the increasing demand for automation across various industries. Encoders are essential components in many applications, including robotics, manufacturing, and automotive systems, where they convert mechanical motion into electrical signals for control and monitoring purposes. As industries continue to embrace automation and digitization, the demand for high-performance encoders is on the rise. This blog explores the encoder market's current landscape, key players, market size, limitations, challenges, and future trends.

Key Players in the Encoder Market

TBaumer TBaumer is renowned for its innovative sensor solutions, including encoders. Their products are widely used in various industries, known for high precision and reliability.

BEI Sensors A subsidiary of the Dover Corporation, BEI Sensors specializes in providing custom sensor solutions, including encoders. Their focus on high-quality products and customer service makes them a significant player in the market.

Dynapar Dynapar, part of the Sensor Technology Group, offers a wide range of encoders, including rotary, linear, and absolute types. Their products are known for their durability and performance in challenging environments.

OMRON OMRON is a global leader in automation and control equipment, providing encoders that feature high accuracy and advanced functionality. They serve diverse sectors, including manufacturing and healthcare.

Rockwell Automation Rockwell Automation is a major player in industrial automation, offering a variety of encoder solutions. Their products are integrated into many industrial processes, ensuring seamless operations.

FAULHABER FAULHABER is recognized for its high-precision micro and servo motors, along with encoders. Their commitment to quality and innovation has established them as a leader in the encoder market.

Heidenhain Heidenhain specializes in precision measurement and control technology, offering high-quality encoders for various applications. Their products are particularly valued in industries requiring exact positioning.

Hengstler Hengstler provides a comprehensive range of encoders, known for their robustness and versatility. Their products are widely used in sectors like automation and packaging.

Ifm electronic Ifm electronic is known for its sensor technology, including encoders that enhance machine performance. Their focus on efficiency and reliability makes them a preferred choice for many businesses.

Maxon Motor Maxon Motor specializes in high-precision drives and motors, including encoders. Their products are utilized in various applications, including robotics and medical technology.

Pepperl Fuchs Pepperl Fuchs is a global leader in industrial sensors and automation technologies, providing a range of encoder solutions known for their reliability and performance in harsh environments.

Pilz Pilz specializes in automation technology and safety engineering, offering encoders that integrate seamlessly into complex systems, enhancing operational safety and efficiency.

Renishaw Renishaw is a pioneer in precision measurement and healthcare technology, providing high-performance encoders for applications demanding utmost accuracy.

SIKO SIKO specializes in measurement technology and provides a range of encoders for industrial applications, focusing on accuracy and user-friendly designs.

Turck Turck is known for its automation and sensor solutions, offering encoders that meet the diverse needs of industrial applications, ensuring high reliability and performance.

Get the sample pdf: https://www.reportprime.com/encoder-r1266?utm_source=LinkedIn-SEO&utm_medium=PEPIQ-1014-AA&utm_campaign=GP&utm_id=encoder

Market Size and Growth

The encoder market is witnessing robust growth, with a projected market size reaching USD 3.5 billion by 2026, expanding at a CAGR of 7.5% during the forecast period. The increasing adoption of automation in manufacturing, automotive, and other sectors is driving this growth. Moreover, the rise of Industry 4.0 and the Internet of Things (IoT) is further fueling demand for advanced encoder technologies that enhance precision and efficiency.

Limitations of the Encoder Market

Despite the promising growth, the encoder market faces several limitations:

Cost Constraints The initial investment for high-quality encoders can be significant, especially for small and medium enterprises. This can limit adoption, particularly in cost-sensitive industries.

Complexity of Integration Integrating encoders into existing systems can be complex, requiring specialized knowledge and training. This complexity can deter some organizations from adopting advanced encoder solutions.

Technological Limitations While encoders have advanced significantly, some still face limitations in resolution, speed, and environmental durability, which can restrict their application in certain industries.

Competition from Alternative Technologies Emerging technologies such as laser measurement and other non-contact sensing solutions pose competition to traditional encoders, potentially affecting market share.

Challenges in the Encoder Market

The encoder market also faces several challenges that could impact its growth trajectory:

Rapid Technological Changes The fast pace of technological advancements requires manufacturers to continuously innovate and upgrade their products. Failure to keep up can lead to obsolescence.

Supply Chain Disruptions Global supply chain disruptions, exacerbated by events like the COVID-19 pandemic, can affect the availability of components, leading to production delays and increased costs.

Skilled Labor Shortage The growing complexity of automation technologies, including encoders, requires a skilled workforce for installation, maintenance, and troubleshooting. A shortage of skilled labor can hinder market growth.

Regulatory Challenges Compliance with industry regulations and standards can pose challenges for manufacturers, requiring investments in testing and certification processes.

Conclusion

The encoder market is poised for significant growth in the coming years, driven by advancements in technology and the increasing demand for automation across various sectors. With key players such as TBaumer, BEI Sensors, Dynapar, and others leading the way, the market is expected to evolve rapidly, introducing innovative solutions to meet the needs of modern applications.

While the market presents promising opportunities, it is essential to address the limitations and challenges that could impede growth. Manufacturers must focus on developing cost-effective solutions, simplifying integration processes, and keeping pace with technological advancements. Additionally, addressing supply chain issues and investing in workforce development will be crucial for sustaining growth.

In summary, the encoder market stands at a pivotal juncture, where the right strategies and innovations can propel it to new heights, shaping the future of automation and control systems across industries. As businesses continue to prioritize efficiency and precision, the role of encoders will undoubtedly become more critical, paving the way for a more automated and intelligent industrial landscape.

0 notes

Text

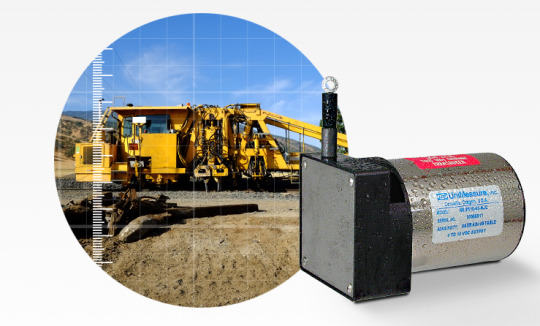

UniMeasure Inc

UniMeasure Inc

UniMeasure, Inc. has been manufacturing position and velocity sensors in Corvallis, Oregon since 1987. The company has steadily grown over the years to become a leader in the linear and rotary transducer industry with a focus on customer service, innovative design, and high-quality products. The Corvallis facility is ISO 9001:2015 certified with many raw materials and vendor services sourced in the local area. With a core group of long-standing employees, UniMeasure is dedicated to manufacturing position sensors in the USA and providing high-quality solutions while further enhancing customer experience.

UNIMEASURE LINEAR POSITION TRANSDUCERS

String Potentiometer

Often referred to as string pot, yo-yo pot, draw wire transducer, cable extension transducer, cable actuated transducer, UniMeasure extending wire rope linear position transducers have proven to be an attractive approach for a multitude of applications in many different industries. With relatively non-critical alignment requirements, compact size, and ease of installation wire rope actuated transducers are the linear position measurement system of choice in applications as diverse as bone densitometers in the medical industry, crash testing in the automobile industry, pump jacks in the crude oil extraction industry and irrigation and flood control in the water management industry. With a wide variety of electrical outputs, UniMeasure linear displacement measuring and position sensor products provide an extremely cost effective method for linear position feedback.

UNIMEASURE ROTARY POSITION TRANSDUCERS

Position Sensor

UniMeasure rotary position transducers provide an analog output signal that is directly proportional to the angle of rotation of the shaft of the device. With a voltage or 4 to 20 mA analog electrical output, UniMeasure rotary position transducers are also known as angle sensors, analog rotary shaft encoders and analog multiturn analog shaft encoders and absolute angle encoders. These position sensor devices are commonly used in applications where an absolute output signal is a must. Typical use occurs in closed loop process control and in testing applications where oscillatory rotary motion occurs. UniMeasure absolute analog rotary position transducers have proven to be an extremely cost effective alternative for measuring rotational positioning.

CONTACT US

UniMeasure Inc https://unimeasure.com/ ADDRESS: 4175 SW Research Way Corvallis, OR 97333 PHONE: (541) 757-3158

Facebook

1 note

·

View note

Text

Non-Contact Sensing: Benefits of Optical Encoder Technology

An Optical Encoder is a critical component in various industrial and consumer applications, used to convert rotary or linear motion into electrical signals.

This technology utilizes light beams to detect position, speed, and direction with high precision and reliability. Optical Encoders are widely employed in robotics, CNC machines, printers, and aerospace systems, where accurate motion control is essential. They offer advantages such as non-contact operation, immunity to electromagnetic interference, and high resolution, making them suitable for demanding environments. Optical Encoders can be incremental or absolute, providing either relative position changes or exact position information, respectively. They contribute to enhanced automation and efficiency by providing real-time feedback for closed-loop control systems, ensuring precise movement and positioning of equipment. As industries continue to advance towards automation and digitalization, Optical Encoders play a crucial role in improving operational accuracy, reducing downtime, and enhancing overall productivity.

#OpticalEncoder #IndustrialAutomation #MotionControl #PrecisionEngineering #Robotics #CNCMachines #PositionSensing #HighResolution #AutomationTechnology #Digitalization #Manufacturing #AerospaceEngineering #SensorTechnology #EncoderTechnology #NonContactSensing #ClosedLoopControl #IoTDevices #SmartManufacturing #IndustrialRobotics #MachineTools

0 notes

Text

Future Trends: The Advancement of Encoders in Industrial Automation

Industrial automation has come a long way since its commencement, with technology playing a critical role in enhancing efficiency, productivity, and precision in manufacturing and other industrial processes. One key component dynamic these improvements is the encoder. Encoders, which convert motion into an electrical signal that can be read by a control device, are fundamental in ensuring precise movement and positioning of machinery. As we look to the future, the advancement of encoders in industrial automation is set to bring about significant changes and improvements. This blog explores the future trends in encoder technology and their impact on industrial automation.

What Are Encoders?

Before diving into future trends, it’s essential to understand what encoders are and how they function. Encoders are sensors that provide feedback on position, speed, and direction of a rotating shaft or linear movement. They are crucial in applications where precise control of motion is required. There are two main types of encoders:

Rotary Encoders: These encoders measure the rotational position and speed of a shaft. They can be either incremental or absolute.

Linear Encoders: These measure the linear position and speed of an object, providing feedback for precise control in linear motion applications.

Future Trends in Encoder Technology

As technology continues to progress, several trends are influential the future of encoders in industrial automation. These trends promise to enhance the capabilities of encoders, making them more accurate, reliable, and versatile.

1. Higher Resolution and Accuracy

One of the most significant trends is the push for higher resolution and accuracy in encoders. As industries demand greater precision, manufacturers are developing encoders with finer resolution capabilities. Higher resolution encoders provide more detailed feedback, allowing for better control and accuracy in applications such as semiconductor manufacturing and precision machining.

2. Integration of Advanced Communication Protocols

Modern industrial automation systems rely heavily on communication networks to exchange data between various components. The integration of advanced communication protocols such as Ethernet/IP, PROFINET, and EtherCAT into encoders is becoming increasingly common. These protocols enable faster and more reliable data transmission, improving the overall efficiency and performance of automation systems.

3. Miniaturization and Compact Designs

With the trend towards smaller and more compact machinery, there is a growing demand for miniaturized encoders. Advances in micro-electromechanical systems (MEMS) technology have made it possible to develop compact encoders without compromising performance. These smaller encoders are ideal for applications with limited space, such as medical devices and compact robotic systems.

4. Enhanced Durability and Environmental Resistance

Industrial environments can be harsh, with factors such as dust, moisture, and extreme temperatures posing challenges to encoder performance. Future encoders are being designed with enhanced durability and environmental resistance. Encoders with IP67 or higher ratings, for example, can withstand exposure to water and dust, ensuring reliable performance in demanding conditions.

5. Development of Wireless Encoders

Wireless technology is making its way into industrial automation, and encoders are no exception. Wireless encoders eliminate the need for cables, reducing installation complexity and maintenance requirements. They are particularly useful in applications where wired connections are impractical or hazardous. Advances in wireless communication protocols are ensuring that wireless encoders provide reliable and secure data transmission.

6. Increased Customization and Flexibility

Industries are increasingly seeking customized solutions to meet specific application requirements. Encoder manufacturers are responding by offering more customizable and flexible products. This trend includes the ability to configure encoders with different output signals, mounting options, and communication interfaces. Customizable encoders allow for tailored solutions that optimize performance in specific applications.

7. Integration with Advanced Sensors

Encoders are being integrated with other advanced sensors to provide more comprehensive feedback and control. For example, combining encoders with gyroscopes and accelerometers can enhance the precision and stability of motion control systems. This integration is particularly valuable in applications such as autonomous vehicles and advanced robotics.

8. Energy Efficiency and Power Management

As industries strive to reduce their carbon footprint and energy consumption, the energy efficiency of automation components is becoming increasingly important. Future encoders are being designed with energy-efficient components and power management features. Low-power encoders are particularly beneficial in battery-powered applications, such as portable devices and remote monitoring systems.

9. Enhanced Safety Features

Safety is a top priority in industrial automation, and encoders are playing a crucial role in enhancing safety measures. Encoders with built-in safety features, such as redundant sensing elements and self-diagnostics, provide additional layers of protection. These safety features help prevent accidents and ensure the reliable operation of machinery in critical applications.

Impact of Future Encoder Trends on Industrial Automation

The advancements in encoder technology are set to have a profound impact on industrial automation. Here are some key ways these trends will shape the future of industrial processes:

Improved Precision and Quality

Higher resolution and accuracy in encoders will lead to improved precision and quality in manufacturing processes. This is particularly important in industries such as aerospace, automotive, and electronics, where even minor deviations can have significant consequences. Enhanced precision will result in higher-quality products and reduced waste.

Increased Efficiency and Productivity

The integration of advanced communication protocols, IoT capabilities, and wireless technology will streamline data exchange and improve the efficiency of automation systems. Real-time data collection and analysis will enable predictive maintenance, reducing downtime and increasing productivity. Automation systems will be able to operate more smoothly and efficiently, leading to cost savings and higher output.

Greater Flexibility and Customization

The trend towards customization and flexibility in encoder design will allow industries to implement customized solutions that meet specific requirements. This flexibility will enable manufacturers to optimize their processes and achieve better performance. Customizable encoders will also make it easier to adapt to changing production needs and technological advancements.

Enhanced Safety and Reliability

The incorporation of advanced safety features and durable designs will enhance the reliability and safety of industrial automation systems. This is crucial in applications where safety is paramount, such as in the chemical, pharmaceutical, and food industries. Reliable encoders with robust safety features will help prevent accidents and ensure consistent performance.

Adoption of Smart Manufacturing Practices

The integration of IoT and Industry 4.0 capabilities into encoders will drive the adoption of smart manufacturing practices. Smart factories, equipped with connected and intelligent components, will be able to optimize operations, reduce energy consumption, and improve overall efficiency. The data generated by smart encoders will provide valuable insights for continuous improvement and innovation.

Expansion of Automation into New Areas

Advancements in encoder technology will enable the expansion of automation into new areas and applications. For example, miniaturized and wireless encoders will make it possible to automate processes in confined spaces and remote locations. This expansion will open up new opportunities for automation in industries such as agriculture, healthcare, and logistics.

Conclusion

The future of encoders in industrial automation is bright, with numerous advancements set to enhance their capabilities and impact. Higher resolution, advanced communication protocols, miniaturization, durability, IoT integration, wireless technology, customization, advanced sensors, energy efficiency, and enhanced safety features are some of the key trends shaping the future of encoder technology. These advancements will lead to improved precision, efficiency, flexibility, safety, and the adoption of smart manufacturing practices.

#industrial automation#auto2mation#industrial equipment#industrial spare parts#industrial and marine automation equipment#industrial and marine automation#industrial automation equipment#automation#industrial encoder

0 notes

Text

Global Position Transducers Market growth, trend, opportunity and forecast 2023-2030

Position Transducers Market

The Position Transducers Market is expected to grow from USD 1.70 Billion in 2022 to USD 2.60 Billion by 2030, at a CAGR of 5.30% during the forecast period.

Get the sample report: https://www.reliablebusinessinsights.com/global-position-transducers-market-r1297260

Position Transducers Market Size

Position transducers are devices used to measure linear or rotary positions of objects accurately. The global position transducers market research report categorizes the market based on type, including draw wire linear position transducers, incremental encoder, absolute position encoders, inductive proximity sensors, LVDT transducer, linear potentiometer, magnetostrictive transducer, and non-contact or laser linear position sensors. The report also segments the market by application, including metal processing industries, geotechnics, rubber and plastic injection presses, earth-moving and agricultural machines, blowing machines, renewable energies, machines in the automotive sector, pneumatic and hydraulic sensors, and the food industry, and by region, including North America, Asia Pacific, Middle East, Africa, Australia, and Europe. Leading market players include TE Connectivity, Honeywell, Gerfan, Rota Engineering, Novotechnik, Allergo Microsystems, Panasonic, and Qualcomm Technologies. Regulatory and legal factors specific to market conditions are also analyzed in the report.

Position Transducers Market Key Players

TE Connectivity

Honeywell

Gerfan

Rota Engineering

Novotechnik

Position Transducers Market Segment Analysis

One of the latest trends in the Position Transducers market is the integration of sensors with advanced technologies such as IoT and AI. The sensors are designed to capture position, acceleration, and temperature data, which is then analyzed using advanced data analytics tools to provide valuable insights to manufacturers and service providers. Moreover, the miniaturization of Position Transducers is also a major trend in the market, enabling its installation in small and confined spaces.

In conclusion, the Position Transducers market presents various growth opportunities with its wide target market and increasing demand for automation and motion control systems. However, challenges such as high costs and regular maintenance and calibration requirements need to be addressed to ensure a sustainable revenue growth path. By integrating advanced technologies, manufacturers can enhance their product offerings, which could lead to increased market adoption and revenue growth.

This report covers impact on COVID-19 and Russia-Ukraine wars in detail.

KEY PRODUCT APPLICATION COVERED

Metal Processing Industries

Geotechnics

Rubber and Plastic Injection Presses

Earth-Moving and Agricultural Machines

Blowing Machines

KEY PRODUCT TYPES COVERED

Draw Wire Linear Position Transducers

Incremental Encoder

Absolute Position Encoders

Inductive Proximity Sensors

Contact Info:

Krishna Sharma

US:- +1 507 500 7209Email:- [email protected]

0 notes

Text

Global Absolute Rotary Encoders Market 2017- HENGSTLER, Baumer Group, Pepperl+Fuchs

Global Absolute Rotary Encoders Market 2017- HENGSTLER, Baumer Group, Pepperl+Fuchs

Worldwide Absolute Rotary Encoders Market 2017 Research report is an in-depth analysis of 2017 global Absolute Rotary Encoders market on the current state.

First of all, the report (2017 Absolute Rotary Encoders Market) provides a basic overview of the Absolute Rotary Encoders industry 2017 including – definitions, classifications, Absolute Rotary Encoders market by applications and Absolute…

View On WordPress

#Absolute Rotary Encoders#Absolute Rotary Encoders Industry#Absolute Rotary Encoders Market#Absolute Rotary Encoders Market 2017#Absolute Rotary Encoders Market Share

0 notes

Text

High-Performance Rotary Encoders for Industrial Automation

Discover a wide range of high-performance rotary encoders for industrial automation at Briter Encoder. Our absolute encoders offer precision and reliability, ensuring accurate data acquisition in various industrial fields. From single-turn to multi-turn encoders, waterproof to explosion-proof options, we provide innovative solutions tailored to your specific needs. Backed by a decade of sensor technology expertise, our encoders come with professional after-sales support and a two-year warranty. Enhance your motion control systems with the industry-leading rotary encoders from Briter Encoder. Visit our website now!

0 notes

Text

Why Absolute Rotary Encoders with High Resolution Matter in Robotics

Robotics is one of the most technically sophisticated fields in modern engineering, where precise motion control is essential. From surgical robots to industrial automation arms and autonomous vehicles, robotics relies on accurate positioning to function safely and efficiently. At the heart of these systems are sensors that provide essential feedback to controllers, enabling machines to perform tasks with pinpoint accuracy. Among these sensors, rotary encoders play a pivotal role by translating rotational motion into digital signals. However, not all encoders are created equal. The combination of absolute rotary encoders and high resolution technology represents a major step forward in achieving the precision robotics requires.

This article explores the critical importance of high resolution absolute rotary encoders in the field of robotics. It addresses the fundamental principles behind these components, their advantages over alternative technologies, and their applications in various robotic systems. As the demand for smarter, more responsive, and safer robots grows, understanding the technical underpinnings and strategic value of advanced encoder technologies becomes increasingly important.

The Basics of Rotary Encoders in Robotics

Rotary encoders are electromechanical devices that convert the angular position or motion of a shaft into digital output signals. They are essential in systems that require continuous or absolute positioning, speed control, and feedback for motion correction. In robotics, these devices serve as the sensory bridge between mechanical motion and electronic control systems. Without encoders, robotic systems would lack the spatial awareness necessary for tasks requiring high accuracy.

There are two main types of rotary encoders: incremental and absolute. Incremental encoders measure relative movement and require an initial calibration or homing procedure to determine position. In contrast, absolute encoders provide a unique digital code for each shaft position, offering real-time positional data without the need for recalibration after power cycles. This distinction becomes particularly crucial in robotic systems that demand reliability and consistency.

High resolution in this context refers to the encoder's ability to distinguish very fine increments of movement. For example, an encoder with 16-bit resolution can detect 65,536 distinct positions per revolution. Such granularity is essential for robots operating in complex environments or performing intricate tasks such as assembly, surgery, or micro-manipulation.

Why Precision Matters in Robotics

Precision is the foundation upon which successful robotic applications are built. Every robot must know its position, orientation, and the configuration of its joints and appendages at all times. This awareness is critical for effective task execution, especially in dynamic or sensitive environments. A lack of precision can result in errors, reduced efficiency, or even hazardous outcomes.

For example, in surgical robotics, even a millimeter of deviation can mean the difference between a successful operation and a serious medical error. In manufacturing, imprecise positioning can lead to defective products, material waste, or downtime due to repeated calibration. The more accurate the encoder, the finer the control that can be exerted over the robot’s movements.

High resolution absolute rotary encoders provide the necessary data fidelity to meet these demands. They enable controllers to make better-informed decisions about movement, adjusting trajectory in real time based on highly detailed positional feedback. This leads to smoother operation, faster responses, and higher confidence in the robot's performance, even under unpredictable conditions.

Advantages of Absolute Rotary Encoders

The primary advantage of absolute rotary encoders lies in their ability to retain positional information even when power is lost. Unlike incremental encoders, which lose their positional data during a shutdown and require re-homing on startup, absolute encoders provide immediate feedback without any additional movement. This is a game-changer in robotics, where startup speed and reliability are critical.

Another benefit is the elimination of cumulative errors. Incremental systems can drift over time or become misaligned due to missed pulses or electrical noise. Absolute encoders, on the other hand, assign a unique code to each position on the shaft, ensuring consistent and repeatable readings. This makes them ideal for closed-loop systems where ongoing positional accuracy is paramount.

In addition, absolute encoders can be designed with multiple turns of resolution, enabling them to track both position and rotation count over several revolutions. This feature is particularly valuable in robotic joints, where angular position across multiple turns may need to be monitored accurately to maintain kinematic integrity.

The Role of High Resolution in Robotics

High resolution adds a layer of detail that significantly enhances the capability of absolute rotary encoders. The finer the resolution, the more granular the control over a robot’s movements. This is especially important in applications that involve complex trajectories, variable speeds, or force-sensitive operations.

Consider a robotic arm assembling micro-electronic components. Such tasks require the end effector to move with sub-millimeter accuracy, which is only possible with extremely detailed feedback from high resolution encoders. Even in larger-scale applications, like autonomous mobile robots navigating through dynamic environments, high resolution allows for smoother path planning and more responsive collision avoidance.

Moreover, high resolution data enables better interpolation and smoother acceleration and deceleration profiles, which reduces mechanical stress and prolongs the system’s lifespan. It also facilitates advanced control algorithms such as model predictive control, which depend on precise state estimation to function effectively.

Integration Challenges and Solutions

While the benefits are clear, integrating high resolution absolute rotary encoders into robotic systems does pose some challenges. These include increased data throughput requirements, more complex signal processing, and potential electromagnetic interference issues. In compact robotic designs, space constraints can also limit the size and placement of encoder components.

However, modern advancements in encoder design have mitigated many of these challenges. Miniaturization technologies have enabled the production of compact encoders with high resolution capabilities, making them suitable even for small-scale or articulated robots. Signal processing chips have become more powerful and efficient, capable of handling high-resolution feedback without latency.

Additionally, robust shielding techniques and differential signal transmission have made encoders more resistant to electrical noise. Many contemporary encoders also offer digital communication interfaces like SSI, BiSS, and EtherCAT, which support high-speed data transmission and facilitate integration into complex control architectures.

Real-World Applications in Robotics

The use of high resolution absolute rotary encoders spans a broad spectrum of robotic applications. In collaborative robots, or cobots, these encoders provide the precise joint feedback needed to safely interact with human coworkers. Their ability to detect minute positional changes enhances safety features such as force limiting and emergency stop mechanisms.

In humanoid robots, which often require dozens of degrees of freedom, high resolution feedback ensures lifelike motion and balance control. These encoders are also critical in robotic exoskeletons used for medical rehabilitation or human augmentation, where precise alignment with human movement is essential.

Agricultural robotics, used for tasks like harvesting and spraying, benefit from accurate GPS and wheel rotation data provided by encoders, allowing them to navigate fields efficiently. Similarly, in logistics, warehouse robots use encoder feedback to align with shelves and conveyors with high precision, optimizing throughput and minimizing human intervention.

The Growing Demand for High Resolution Encoder Solutions

As the robotics industry continues to evolve, the demand for high-performance sensing technologies is increasing. The proliferation of autonomous systems in consumer, industrial, and military sectors has elevated the requirements for precision, reliability, and real-time control. Encoder manufacturers are responding by developing solutions that combine high resolution with absolute positioning in compact, rugged designs.

Emerging trends such as soft robotics and bio-inspired mechanisms further underline the importance of nuanced motion control. These systems often operate in unpredictable environments or interact closely with humans, necessitating advanced feedback mechanisms. A high resolution encoder can meet these needs by delivering accurate feedback without sacrificing response time or increasing system complexity.

Cost considerations are also influencing the adoption of these technologies. As production scales and design innovations reduce component costs, high resolution absolute encoders are becoming viable for mid-range and even entry-level robotic systems. This democratization of precision sensing could accelerate the development of smarter, more capable robots across industries.

Selecting the Right Encoder for Robotic Applications

Choosing the appropriate encoder involves evaluating several factors, including resolution, form factor, communication interface, and environmental tolerance. Engineers must balance the need for precision with constraints such as space, weight, and cost. For high-performance robots, especially those requiring multi-axis synchronization and fine control, absolute encoders with high resolution are often the optimal choice.

It is also important to consider the mechanical interface—whether the encoder will be mounted directly on a motor shaft, integrated into a gear assembly, or placed on an auxiliary axis. Each configuration imposes different demands on encoder performance and durability. In some cases, magnetic or capacitive encoding technologies offer advantages over optical systems, particularly in harsh environments.

Support for real-time diagnostics and health monitoring is another factor to consider. Some advanced encoders can report temperature, vibration, or signal integrity metrics, enabling predictive maintenance and reducing downtime. These capabilities enhance overall system reliability, a critical requirement for mission-critical robotic applications.

Conclusion

The evolution of robotic systems has underscored the indispensable role of sensing technologies, particularly in motion control. Absolute rotary encoders with high resolution are among the most vital components in achieving the precision, reliability, and intelligence modern robots demand. By combining the persistent positional awareness of absolute encoding with the fine granularity of high resolution, these devices provide the backbone for advanced robotic performance.

As robots continue to expand into new industries and applications, the capabilities enabled by high-end encoders will become even more essential. Whether ensuring the delicate touch of a surgical instrument or the agile navigation of an autonomous vehicle, these technologies bridge the gap between mechanical movement and digital control. The growing adoption of the absolute rotary encoder is a testament to its value in enabling the next generation of robotics innovations.

0 notes

Text

Basic features of the Elcis Absolute Encoders

Absolute position input for a rotating shaft or object is provided by rotating encoders of the Elcis Absolute Encoder type.

The following are some reasons why Elcis Absolute Encoders are important:

Absolute position feedback: In contrast to incremental encoders, which only provide relative position data, absolute encoders can precisely pinpoint the location of a shaft or object even in the case of a power failure.

High resolution: Because Elcis Absolute Encoders are available in high resolutions, they are suitable for applications needing precise position input.

The availability of multiple output ports for Elcis Absolute Encoders makes it simple to integrate them into current systems. Fieldbus, parallel, and serial are some of these output interfaces.

Elcis Absolute Encoders, a specific class of rotary encoders, provide absolute position input for a spinning shaft or object. You should be aware of the following, Elcis Absolute Encoders:

Unlike incremental encoders, which only provide relative position data, absolute encoders can determine the exact location of a shaft or item, even in the event of a power failure.

High-resolution Elcis Absolute Encoders are available, which makes them perfect for applications requiring precise position feedback.

Multiple output interfaces are available on Elcis Absolute Encoders, making it simple to integrate them into existing systems. These output interfaces include fieldbus, parallel, and serial. Elcis Absolute Encoders can establish a shaft's position across several revolutions or inside a single revolution.

Elcis Absolute Encoders are capable of determining a shaft's position throughout several revolutions or within a single revolution. Both multiturn and single-turn versions of these encoders are available.

Elcis Absolute Encoders are designed to withstand the harsh environments seen in industrial settings, making them dependable over time.

Installing is easy: Due to their ease of installation and integration into existing systems, Elcis Absolute Encoders are a preferred choice for numerous industrial applications.

Conclusion

On the website http://iscglobal.co.in, there are several justifications for employing a specific algorithm. Consider the conclusion for further information, which can be obtained by calling +91-33-23577460 or emailing [email protected].

0 notes

Text

Revolutionizing Motion Control: The Power of Optical Encoders

Optical encoders are devices used to convert physical motion into digital signals. They consist of a rotating disc, which has evenly spaced lines or slots etched into it. As the disc rotates, a light source shines on the disc, and a sensor detects the changes in light intensity caused by the lines or slots passing by. These changes in light intensity are then converted into digital signals, which can be used to determine the position, speed, and direction of the rotating disc.

One of the primary benefits of optical encoders is their high accuracy and precision. They can detect even small changes in position or speed, making them ideal for use in a wide range of applications, from robotics to precision manufacturing. Additionally, they are highly reliable, with a long lifespan and minimal maintenance requirements.

Optical encoders come in various forms, including linear and rotary encoders. Linear encoders are used to measure linear motion, such as the movement of a linear stage or conveyor belt, while rotary encoders are used to measure rotational motion, such as the speed and position of a motor shaft. They can also be absolute or incremental, with absolute encoders providing a unique position code for every point in a rotation, and incremental encoders providing a signal that indicates the amount and direction of rotation since the last signal.

Overall, optical encoders are a versatile and essential component in many applications requiring precise position or motion control. Their high accuracy, reliability, and variety of forms make them a popular choice among engineers and manufacturers in a wide range of industries.

Read More: https://thetechnologynews-24.blogspot.com/2023/04/precision-tracking-benefits-of-optical.html

0 notes

Text

Absolute Rotary Encoders

Hubner's Absolute Rotary Encoders provide precise angular position feedback with high accuracy and reliability. Designed for industrial applications, they feature robust construction, advanced signal processing, and long-lasting performance, ensuring seamless integration into automation and motion control systems.

Visit at: https://hubner.au/product/absolute-rotary-encoders-singleturn/

0 notes