#AdsorptionTechnology

Explore tagged Tumblr posts

Text

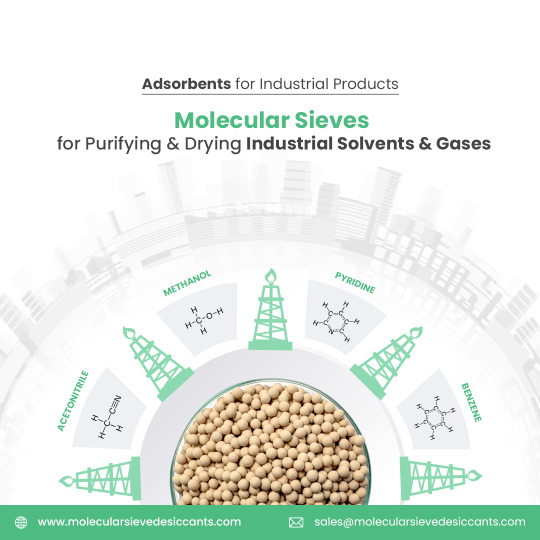

Choosing the Right Molecular Sieve for Your Drying Needs

Choose Molecular Sieve 4A for efficient adsorption tailored to your industrial needs. Its pore size ensures effective separation of target molecules, prevents blockage, and suits various conditions, such as high temperatures or low pressure. Understanding adsorption kinetics with Molecular Sieve 4A enhances performance, making it ideal for moisture removal and molecular separation.

For more information

contact us +91 9879203377,

Email us - [email protected]

Website - https://www.molecularsievedesiccants.com/blogs/different-molecular-sieve-sizes-and-their-importance-explained

#MolecularSieve4A#Zeolite4A#Desiccants#IndustrialDrying#MoistureControl#GasPurification#EthanolDrying#NaturalGasDehydration#InsulatingGlassDesiccant#AdsorptionTechnology#ChemicalProcessing#RefrigerantDrying#PaintAndPlasticDrying

1 note

·

View note

Text

Molecular Sieve for Petrochemicals Market, Global Outlook & Forecast 2025-2032

Molecular sieve for petrochemicals is an advanced adsorbent material widely used in the petrochemical industry to eliminate impurities and moisture from various petrochemical products. These sieves, often composed of zeolites, have uniform pore structures that enable selective adsorption, ensuring superior quality and stability of petrochemical products. They are crucial in processes such as dehydration, desulfurization, and gas purification.

Market Size

Download FREE Sample of this Report

The global molecular sieve for petrochemicals market was valued at USD 318 million in 2024 and is expected to reach USD 429.65 million by 2030, growing at a CAGR of 3.40% over the forecast period.

Key Statistics:

North America: USD 87.76 million in 2023, projected to grow at a CAGR of 2.91% from 2025 through 2032.

Asia-Pacific: Expected to be the fastest-growing region, driven by increasing petrochemical production and demand for high-quality fuel products.

Competitor Analysis

Key Companies

Honeywell UOP

Arkema

Tosoh

BASF

Zeochem

Market Segmentation (by Application)

Steam Cracking

Synthetic Rubber

Polymerization

Other Applications

Market Segmentation (by Type)

3A

4A

5A

TypeX

Others

Geographic Segmentation

North America: USA, Canada, Mexico

Europe: Germany, UK, France, Russia, Italy, Rest of Europe

Asia-Pacific: China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific

South America: Brazil, Argentina, Columbia, Rest of South America

Middle East & Africa: Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA

Get the Complete Report & TOC

FAQ

01. What is the current market size of the Molecular Sieve for Petrochemicals market?

The market was valued at USD 318 million in 2023 and is projected to reach USD 429.65 million by 2032.

02. Which are the key companies operating in the Molecular Sieve for Petrochemicals market?

Major players include Honeywell UOP, Arkema, Tosoh, BASF, and Zeochem.

03. What are the key growth drivers in the Molecular Sieve for Petrochemicals market?

Increasing demand for petrochemical purification, stringent environmental regulations, and technological advancements in adsorbent materials.

Key Benefits of This Market Research:

Industry drivers, restraints, and opportunities covered in the study

Neutral perspective on the market performance

Recent industry trends and developments

Competitive landscape & strategies of key players

Potential & niche segments and regions exhibiting promising growth covered

Historical, current, and projected market size, in terms of value

In-depth analysis of the Molecular Sieve for Petrochemicals Market

#MolecularSieve#PetrochemicalMarket#AdsorptionTechnology#MarketForecast#GlobalMarketTrends#IndustrialCatalysts#RefiningTechnology#MarketOutlook#GasSeparation#ZeoliteMolecularSieve#ChemicalProcessing#ExportImport#IndustryGrowth#SustainableSolutions#MarketAnalysis

0 notes

Text

Activated Alumina Market

“𝐔𝐧𝐯𝐞𝐢𝐥𝐢𝐧𝐠 𝐓𝐫𝐞𝐧𝐝𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐀𝐜𝐭𝐢𝐯𝐚𝐭𝐞𝐝 𝐀𝐥𝐮𝐦𝐢𝐧𝐚 𝐌𝐚𝐫𝐤𝐞𝐭: 𝐃𝐫𝐢𝐯𝐢𝐧𝐠 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 & 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲 🌍💡” | IndustryARC™

The Activated Alumina Market Size is forecast to reach $ 1265.4 Million by 2030, at a CAGR of 4.70% during forecast period 2024–2030.

👉 𝑫𝒐𝒘𝒏𝒍𝒐𝒂𝒅 𝑺𝒂𝒎𝒑𝒍𝒆 𝑹𝒆𝒑𝒐𝒓𝒕

The Activated Alumina Market refers to the global industry involved in the production, distribution, and application of activated alumina. Activated alumina is a highly porous material derived from aluminum hydroxide. It is widely used for its adsorption, desiccation, and catalytic properties in various industries.

𝐊𝐞𝐲 𝐂𝐡𝐚𝐫𝐚𝐜𝐭𝐞𝐫𝐢𝐬𝐭𝐢𝐜𝐬 𝐨𝐟 𝐀𝐜𝐭𝐢𝐯𝐚𝐭𝐞𝐝 𝐀𝐥𝐮𝐦𝐢𝐧𝐚:

💡 Adsorption Properties: Removes impurities like fluoride, arsenic, and moisture.

💡 Thermal Stability: Performs effectively under high-temperature conditions.

💡 Versatility: Usable as a desiccant, catalyst, or adsorbent.

𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬 𝐨𝐟 𝐀𝐜𝐭𝐢𝐯𝐚𝐭𝐞𝐝 𝐀𝐥𝐮𝐦𝐢𝐧𝐚:

🔹Water Treatment: Removes fluoride and other contaminants from drinking water.

🔹Oil & Gas: Used in gas drying and refining processes.

🔹Chemical Industry: Catalyst support in chemical reactions.

🔹Pharmaceuticals: Adsorbent for purification processes.

🔹Air Drying Systems: Dehumidification in industrial and compressed air systems.

👉 𝑭𝒐𝒓 𝑴𝒐𝒓𝒆 𝑰𝒏𝒇𝒐𝒓𝒎𝒂𝒕𝒊𝒐𝒏

𝐌𝐚𝐫𝐤𝐞𝐭 𝐃𝐫𝐢𝐯𝐞𝐫𝐬:

👉Growing Demand for Clean Water: Increasing awareness and regulatory pressure for safe drinking water.

👉Industrial Growth: Expansion in oil refining and gas processing industries.

👉Sustainability Trends: Adoption of eco-friendly materials in industrial processes.

By Now

➡️ 𝐤𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬 : BASF | Honeywell | Sumitomo Chemical | Axens | AGC Chemicals Europe | AGC Chemicals Americas Inc. | Shandong Zhongxin Hydraulic Co.,ltd | Luoyang | Shayan Fiber | Shayan Accounting Inc | HengYe® Inc. | Huber Engineered Materials | Almatis | Dynamic Adsorbents, Inc. | Porocel International | Camfil Power Systems | Adsorption Technologies LLC. | Johnson Matthey | Desotec GmbH Sondermaschinenbau | Clariant | Zeochem | Evonik | Showa Denko Carbon, Inc. | Tosoh Corporation | Tosoh Corporation |

#ActivatedAlumina#WaterTreatment#IndustrialAdsorbents#EnvironmentalSustainability#CatalystTechnology#DesiccantSolutions#CleanWaterSolutions#OilAndGasIndustry#AdvancedMaterials#GlobalMarketTrends#AdsorptionTechnology#ChemicalProcessing#EcoFriendlyMaterials#IndustrialInnovation#ActivatedAluminaMarket#GasPurification#SustainableIndustries#ActivatedAluminaApplications#MarketGrowth#IndustrialSolutions

0 notes

Text

The Science Behind Activated Aluminum Balls

Activated aluminum balls, also known as activated alumina, are composed of aluminum oxide. What sets them apart is their highly porous structure. This porosity provides an extensive surface area, allowing the balls to adsorb a variety of impurities from water. Adsorption is a process where molecules adhere to a surface, and in the case of activated aluminum balls, this surface is vast and highly effective at capturing contaminants

Discover the technology behind it Visit Website

#WaterPurification#CleanWater#ActivatedAluminumBalls#WaterTreatment#SafeDrinkingWater#EnvironmentalScience#AdsorptionTechnology#WaterQuality#SustainableWaterSolutions

0 notes

Text

Uses of 13X Molecular Sieve Zeolites for Industrial Gas and Liquid Purification

Zeolite 13X molecular sieves are critical in industrial gas and liquid purification due to their high adsorption efficiency. They effectively remove moisture and contaminants from gases such as hydrogen, oxygen, and nitrogen, and liquids like ethanol. Additionally, they purify inert gases by eliminating ammonia and remove carbon dioxide in air separation and cryogenic processes, ensuring high-purity outputs and enhancing overall process efficiency.

For more information

contact us +91 9879203377,

Email us - [email protected]

Website - https://www.molecularsievedesiccants.com/molecular-sieve-13x

#Zeolite13X#MolecularSieve13X#MolecularSieve#IndustrialAdsorbents#GasPurification#LiquidPurification#AdsorptionTechnology#CryogenicProcesses#PetroleumRefining#AirSeparation

1 note

·

View note

Text

Molecular Sieves 5A, also known as Zeolite 5A, are highly effective in gas purification processes. These sieves have a unique ability to selectively adsorb certain molecules while allowing others to pass through. This makes them ideal for removing impurities from gases.

#MolecularSieves5A#Zeolite5A#OxygenConcentrators#GasPurification#IndustrialApplications#HighPurityOxygen#HydrocarbonSeparation#AdsorptionTechnology#IndustrialEfficiency#GasDrying#PurificationProcesses#HighPerformanceMaterials

0 notes