#CatalystTechnology

Explore tagged Tumblr posts

Text

Activated Alumina Market

“𝐔𝐧𝐯𝐞𝐢𝐥𝐢𝐧𝐠 𝐓𝐫𝐞𝐧𝐝𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐀𝐜𝐭𝐢𝐯𝐚𝐭𝐞𝐝 𝐀𝐥𝐮𝐦𝐢𝐧𝐚 𝐌𝐚𝐫𝐤𝐞𝐭: 𝐃𝐫𝐢𝐯𝐢𝐧𝐠 𝐈𝐧𝐧𝐨𝐯𝐚𝐭𝐢𝐨𝐧 & 𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲 🌍💡” | IndustryARC™

The Activated Alumina Market Size is forecast to reach $ 1265.4 Million by 2030, at a CAGR of 4.70% during forecast period 2024–2030.

👉 𝑫𝒐𝒘𝒏𝒍𝒐𝒂𝒅 𝑺𝒂𝒎𝒑𝒍𝒆 𝑹𝒆𝒑𝒐𝒓𝒕

The Activated Alumina Market refers to the global industry involved in the production, distribution, and application of activated alumina. Activated alumina is a highly porous material derived from aluminum hydroxide. It is widely used for its adsorption, desiccation, and catalytic properties in various industries.

𝐊𝐞𝐲 𝐂𝐡𝐚𝐫𝐚𝐜𝐭𝐞𝐫𝐢𝐬𝐭𝐢𝐜𝐬 𝐨𝐟 𝐀𝐜𝐭𝐢𝐯𝐚𝐭𝐞𝐝 𝐀𝐥𝐮𝐦𝐢𝐧𝐚:

💡 Adsorption Properties: Removes impurities like fluoride, arsenic, and moisture.

💡 Thermal Stability: Performs effectively under high-temperature conditions.

💡 Versatility: Usable as a desiccant, catalyst, or adsorbent.

𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬 𝐨𝐟 𝐀𝐜𝐭𝐢𝐯𝐚𝐭𝐞𝐝 𝐀𝐥𝐮𝐦𝐢𝐧𝐚:

🔹Water Treatment: Removes fluoride and other contaminants from drinking water.

🔹Oil & Gas: Used in gas drying and refining processes.

🔹Chemical Industry: Catalyst support in chemical reactions.

🔹Pharmaceuticals: Adsorbent for purification processes.

🔹Air Drying Systems: Dehumidification in industrial and compressed air systems.

👉 𝑭𝒐𝒓 𝑴𝒐𝒓𝒆 𝑰𝒏𝒇𝒐𝒓𝒎𝒂𝒕𝒊𝒐𝒏

𝐌𝐚𝐫𝐤𝐞𝐭 𝐃𝐫𝐢𝐯𝐞𝐫𝐬:

👉Growing Demand for Clean Water: Increasing awareness and regulatory pressure for safe drinking water.

👉Industrial Growth: Expansion in oil refining and gas processing industries.

👉Sustainability Trends: Adoption of eco-friendly materials in industrial processes.

By Now

➡️ 𝐤𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬 : BASF | Honeywell | Sumitomo Chemical | Axens | AGC Chemicals Europe | AGC Chemicals Americas Inc. | Shandong Zhongxin Hydraulic Co.,ltd | Luoyang | Shayan Fiber | Shayan Accounting Inc | HengYe® Inc. | Huber Engineered Materials | Almatis | Dynamic Adsorbents, Inc. | Porocel International | Camfil Power Systems | Adsorption Technologies LLC. | Johnson Matthey | Desotec GmbH Sondermaschinenbau | Clariant | Zeochem | Evonik | Showa Denko Carbon, Inc. | Tosoh Corporation | Tosoh Corporation |

#ActivatedAlumina#WaterTreatment#IndustrialAdsorbents#EnvironmentalSustainability#CatalystTechnology#DesiccantSolutions#CleanWaterSolutions#OilAndGasIndustry#AdvancedMaterials#GlobalMarketTrends#AdsorptionTechnology#ChemicalProcessing#EcoFriendlyMaterials#IndustrialInnovation#ActivatedAluminaMarket#GasPurification#SustainableIndustries#ActivatedAluminaApplications#MarketGrowth#IndustrialSolutions

0 notes

Text

Effect Of Pressure Difference Of SCR Denitration Catalyst On Denitration Efficiency

#Denitration#SCRCatalyst#PressureDifference#CatalystTechnology#EnvironmentalScience#IndustrialProcesses#CleanEnergy#EmissionControl#AirQuality#GreenTech#PollutionControl#IndustrialCatalysts#GreenTechnology#SCRTechnology#EmissionReduction#CatalystPerformance

0 notes

Text

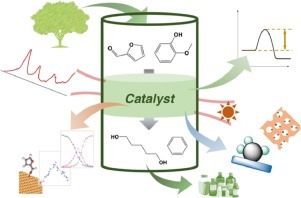

Catalyst Market: Charting New Pathways for Growth in an Evolving Market

The global catalyst market size is expected to reach USD 42.63 billion by 2030, as per the new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 4.6% from 2024 to 2030. Catalyst refers to the class of compounds or chemicals that enables a chemical reaction to proceed at a pace faster than otherwise possible. Depending on the similarity or dissimilarities of the catalyst with the reactants, a catalyst can be either homogeneous or heterogeneous. Therefore, based on product type, the market is segmented as homogeneous and heterogeneous catalysts.

Catalyst Market Report Highlights

Chemical compounds dominated the market with a volume share of 39.8% in 2023, it is used as catalyst raw materials for numerous applications in chemical, petrochemical, and polymer industries

Homogenous is predicted to witness the fastest growth, in terms of revenue, with a CAGR of 4.9% from 2023 to 2030. The growing popularity of organometallic compounds to produce polyethylene and polypropylene is further expected to fuel their demand in the near future

Asia Pacific dominated the catalyst market with a volume share of 34.8% in 2023. This can be attributed to the rapid development of the chemical industry, predominantly in the emerging economies of the region such as China and India

In June 2020, Albemarle Corporation entered into a definitive agreement with W. R. Grace & Co. for selling its polyolefin catalyst and components business for a value of around USD 416 million

With the escalating demand from applications including chemical synthesis, petroleum refining, polymers and petrochemicals, and environmental there has been an upsurge in demand for catalysts for process optimization, yield improvement, cost-saving, and energy saving amongst the manufacturers globally

For More Details or Sample Copy please visit link @: Catalyst Market Report

The raw materials used for catalyst manufacturing include acids, peroxides, and amines, which are generally classified as chemical compounds. Metals including precious metals and base metals besides zeolites are the prominent raw material market segments. A catalyst finds numerous applications in end-use industries such as chemicals (adsorbents, polyolefins); petroleum refining (alkylation, hydrotreating, hydrocracking, catalytic reforming); polymers and petrochemicals; and automotive (motorbikes, light-duty, and heavy-duty vehicles) owing to the benefits obtained by the application of a catalyst in any particular chemical reaction.

The global market has witnessed a significant growth rate over the past few years owing to the benefits it has gained from high-value product segments. For instance, the application of catalysts in an automobile reduces carbon emissions that are harmful to the environment and, thus, their application is highly promoted by governments globally. Favorable government regulations, in turn, have increased the demand for catalysts in the automotive industry across regions.

Catalysts are increasingly being used to reduce the processing time of crude oil refining along with improving refining equipment efficiency. These factors are likely to fuel the demand for catalysts over the projected forecast period. However, volatile prices of raw materials, including gold and platinum, are expected to hamper the manufacturing output of catalysts, thereby restraining the market growth. Nonetheless, the introduction of biocatalysts is expected to open new avenues for the market over the forecast period.

Key market players include BASF, Johnson Matthey, W.R. Grace, Albemarle Corporation, Evonik Industries AG, and DuPont. In July 2014, Johnson Matthey Process Technologies established a new production site in Brazil which manufactures catalyst for captive hydrogen production in the refining sector. This initiative was taken to ensure product supply to refining companies located in Latin America over the next eight years.

#Catalysts#ChemicalIndustry#CatalystMarket#CatalystTechnology#CatalystApplications#CatalystInnovation#CatalystManufacturing#CatalystSupplyChain#CatalystResearch#CatalystTrends#CatalystDemand#CatalystFuture#SustainableCatalysts#GlobalCatalystMarket#CatalystIndustry#CatalystAnalysis#CatalystDynamics#CatalystPerformance#CatalystSolutions

0 notes

Text

"Shaping the Oil Industry: Market Dynamics and Forecast for 2024-2033"

Oil refining is undergoing a transformation as the industry embraces advanced technologies and sustainable practices to meet the growing demand for cleaner fuels. Modern refineries are integrating innovations such as digitalization, advanced catalysts, and renewable feedstocks to enhance efficiency and reduce environmental impact. These efforts are not only driving operational excellence but also positioning the oil refining sector as a crucial player in the global transition towards a more sustainable energy landscape.

#OilRefining #EnergyTransition #CleanFuels #SustainableRefining #AdvancedTechnology #Digitalization #GreenEnergy #RenewableFeedstocks #EnergyEfficiency #EnvironmentalImpact #ModernRefineries #OperationalExcellence #InnovativeRefining #FutureOfEnergy #CatalystTechnology #GreenTransition #EnergyInnovation #SustainablePractices #RefineryTech #ClimateAction

0 notes