#Advanced Sintering Technologies Market Forecast

Explore tagged Tumblr posts

Text

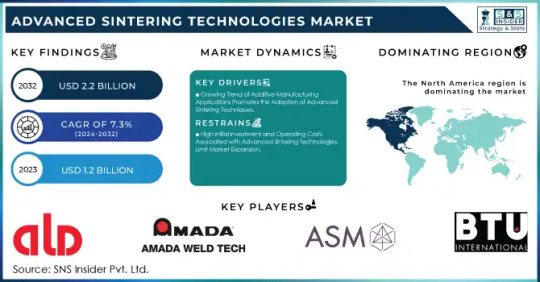

Advanced Sintering Technologies Market Analysis: Key Players and Competitive Landscape

Rising Demand for High-Performance Materials in Aerospace and Electronics Drives Growth in the Advanced Sintering Technologies Market.

The Advanced Sintering Technologies Market Size was valued at USD 1.2 billion in 2023 and is expected to reach USD 2.2 billion by 2032 and grow at a CAGR of 7.3% over the forecast period 2024-2032.

The Advanced Sintering Technologies Market is driven by increasing demand for high-performance materials in industries such as aerospace, automotive, electronics, and healthcare. Advanced sintering technologies, including spark plasma sintering (SPS), microwave sintering, and hot isostatic pressing (HIP), are revolutionizing the manufacturing process by enhancing material strength, density, and efficiency. The shift toward lightweight, high-strength, and energy-efficient materials is fueling innovation in powder metallurgy, ceramics, and additive manufacturing.

Key Players

ALD Vacuum Technologies

AMADA Weld Tech

ASM International N.V.

BTU International

Carpenter Technology Corporation

ChinaSavvy

DSB Technologies

EOS

FCT Systeme

GKN Powder Metallurgy

Future Scope

The advanced sintering technologies market is expected to expand rapidly due to growing applications in high-performance ceramics, powder metallurgy, and additive manufacturing. The automotive industry is increasingly using sintered components for lightweight and fuel-efficient vehicles, while the electronics sector is integrating sintered materials into high-density circuit boards and semiconductor packaging. Additionally, advancements in nanostructured materials and 3D printing sintering methods are expected to enhance precision and reduce production costs.

Emerging Trends

The market is experiencing a transition towards energy-efficient and cost-effective sintering processes. Microwave sintering is gaining popularity due to its rapid processing times and lower energy consumption, making it an attractive alternative to conventional methods. Spark plasma sintering (SPS) is revolutionizing material fabrication by allowing high-speed densification with minimal grain growth, leading to stronger and more durable components. Furthermore, additive manufacturing combined with sintering processes is paving the way for customized, high-performance parts in sectors like biomedical implants, aerospace, and defense.

Key Points

Rising demand for high-performance sintered materials in aerospace, automotive, and electronics.

Innovations in sintering methods, including spark plasma sintering (SPS) and microwave sintering.

Growing adoption of sintering in additive manufacturing for customized and high-precision components.

Advancements in nanostructured materials improving strength and durability.

Increasing focus on energy-efficient sintering techniques to reduce production costs.

Conclusion

The Advanced Sintering Technologies Market is poised for strong growth, driven by technological advancements, increasing industrial applications, and the push for energy-efficient manufacturing. As industries continue to demand stronger, lighter, and more durable materials, advanced sintering technologies will play a critical role in shaping the future of manufacturing and material science.

Read Full Report: https://www.snsinsider.com/reports/advanced-sintering-technologies-market-2459

Contact Us:

Jagney Dave — Vice President of Client Engagement

Phone: +1–315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Advanced Sintering Technologies Market#Advanced Sintering Technologies Market Size#Advanced Sintering Technologies Market Share#Advanced Sintering Technologies Market Report#Advanced Sintering Technologies Market Forecast

0 notes

Text

Neodymium-Iron-Boron Permanent Magnet Market Size, Share & Global Insights 2021–2031

The global neodymium iron boron (NdFeB) permanent magnet market is projected to grow significantly, reaching US$ 29,129.11 million by 2031, up from US$ 15,204.23 million in 2024. This growth reflects a robust CAGR of 10.3% during the forecast period from 2025 to 2031.

Executive Summary & Global Market Analysis

The NdFeB magnet market is witnessing strong momentum, fueled by increasing adoption of high-performance, energy-efficient technologies across diverse industries. These magnets are known for their exceptional magnetic strength, compact size, and versatility—attributes that make them indispensable in electric vehicles (EVs), wind turbines, consumer electronics, and medical devices.

Key growth drivers include:

The global transition to renewable energy sources

Rapid electrification in automotive and industrial sectors

Miniaturization and automation of electronic devices

Emerging trends such as recycling of rare earth elements, supply chain resilience, and environmental sustainability are reshaping the competitive landscape. Market players are also heavily investing in advanced manufacturing technologies and collaborative R&D to enhance performance and sustainability.

Despite the market’s dominance by established Asian manufacturers, new opportunities are opening for companies that can deliver differentiated value such as higher magnet quality, local supply chains, and lower carbon footprints.

📥 Click Here to Download Sample Report

Market Segmentation Analysis

By Type:

Sintered NdFeB Magnets (Dominant in 2024)

Bonded NdFeB Magnets

By End-User:

Automotive (Leading segment)

Consumer Electronics

Power Generators (Wind Turbines)

Industrial Automation & Robotics

Medical Devices

Others

By Geography:

North America

Europe

Asia-Pacific (Leading region)

Middle East & Africa

South & Central America

Key Market Drivers and Opportunities

Electrification of Transportation

The increasing adoption of electric vehicles globally is one of the strongest drivers of NdFeB magnet demand. These magnets are critical components in EV motors, offering unmatched energy efficiency and magnetic strength. Regulatory mandates, consumer preferences for cleaner mobility, and infrastructure investments are further fueling this trend.

Industrial Automation and Energy Sector Growth

The global shift toward automation, smart manufacturing, and wind energy generation also significantly contributes to the demand for high-performance NdFeB magnets.

Type-Based Market Insights

Sintered NdFeB magnets held the largest market share in 2024. These magnets are produced using powder metallurgy, providing superior temperature stability, demagnetization resistance, and magnetic performance—ideal for demanding applications in EVs, renewable energy, and robotics.

Key Players in the NdFeB Magnet Market

Hitachi Metals, Ltd.

Shin-Etsu Chemical Co., Ltd.

TDK Corporation

Ningbo Yunsheng Co., Ltd.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Vacuumschmelze GmbH & Co. KG

Neo Performance Materials Inc.

About Us

Business Market Insights provides data-rich intelligence across industries like healthcare, electronics, automotive, aerospace, and chemicals. Our actionable insights help global stakeholders make informed strategic decisions.

#NeodymiumMagnets#NdFeB#PermanentMagnets#ElectricVehicles#WindTurbines#RareEarthMagnets#MagnetTechnology#GreenEnergy#IndustrialAutomation#EVComponents#MagnetMarket#MagnetManufacturing#SinteredMagnets#MagneticMaterials#CleanTech#MagnetIndustry#AdvancedMaterials#Electrification#RenewableEnergy#ConsumerElectronics

0 notes

Text

Ferrite Permanent Magnet Market- Expert Analysis Report

Business Market Insights recently announced the release of the market research titled Ferrite Permanent Magnet Market Outlook to 2031 | Share, Size, and Growth. The report is a stop solution for companies operating in the Ferrite Permanent Magnet market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. Ferrite Permanent Magnet Market report allows business to reduce their risks by offering a closer picture of consumer behaviour, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, Business Market Insights is helping brands unlock revenue opportunities in the Ferrite Permanent Magnet market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated Ferrite Permanent Magnet market research has all that you need.

What are Key Offerings Under this Ferrite Permanent Magnet Market Research?

Global Ferrite Permanent Magnet market summary, current and future Ferrite Permanent Magnet market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global Ferrite Permanent Magnet Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the Ferrite Permanent Magnet Market?

Ferrite Permanent Magnet market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. Ferrite Permanent Magnet market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their Ferrite Permanent Magnet market share.

Report Attributes

Details

Segmental Coverage

Type

Sintered Magnets

Bonded Magnets

Product Type

Strontium Ferrite Magnets

Barium Ferrite Magnets

End-users

Automotive

Consumer Electronics

Power Tools

Others

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Proterial, Ltd

TDK Corporation

Shin-Etsu Chemical Co., Ltd

Ningbo Yunsheng Co., Ltd.

Beijing Zhong Ke San Huan High-Tech Co., Ltd.

Hangzhou Permanent Magnet Group., Ltd.

FE Ferrite Co., Ltd.

Anhui Long Magnetic Technology Co., Ltd.

Guangdong LingYI Co., Ltd.

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective Ferrite Permanent Magnet market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The Business Market Insights offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The Ferrite Permanent Magnet market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

Business Market Insights is a market research platform that provides subscription services for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductors, Aerospace & Defense, Automotive & Transportation, Energy & Power, Healthcare, Manufacturing & Construction, Food & Beverages, Chemicals & Materials, and Technology, Media & Telecommunications.

Contact Us:

If you have any questions about this report or would like further information, please contact us:

Contact person: Ankit Mathur

Email: [email protected]

Phone: +16467917070

#Ferrite Permanent Magnet Market#Ferrite Permanent Magnet Market Size#Ferrite Permanent Magnet Market Trends#Ferrite Permanent Magnet Market Shares#Ferrite Permanent Magnet Market Growth

0 notes

Text

Alnico Permanent Magnet Market Outlook Opportunities, Statistics, Size, Share, Competitive Landscape with Forecast (2021-2031)

The alnico permanent magnet market size is expected to reach US$ 1,137.02 million by 2031 from US$ 612.49 million in 2024. The market is estimated to record a CAGR of 9.1% from 2025 to 2031.

Executive Summary and Global Market Analysis

The global alnico permanent magnet market is experiencing steady growth, fueled by the unique blend of high-temperature stability, durability, and robust magnetic properties that alnico magnets provide. These magnets, composed of aluminum, nickel, cobalt, and iron, are extensively used across various sectors, including electronics, automotive, aerospace, wind energy, and medical devices. The market is invigorated by the escalating demand for dependable and efficient magnetic solutions in advanced technologies, as well as the ongoing emphasis on energy efficiency and sustainability in manufacturing and industrial processes.

The alnico magnet market stands out for its wide-ranging applicability and resilience in challenging environments. The electronics sector is a significant driving force, with alnico magnets finding use in sensors, actuators, and various electronic components that necessitate stable magnetic performance over a broad temperature range. The proliferation of consumer electronics, smart devices, and Internet of Things (IoT) technologies is further boosting demand, as these applications increasingly rely on high-performance magnetic materials.

Alnico Permanent Magnet Market Segmentation Analysis

Key segments that contributed to the derivation of the alnico permanent magnet market analysis include drive type, propulsion, sales channel, and geography.

By type, the alnico permanent magnet market is segmented into Cast Alnico, Sintered Alnico, and Others. Cast alnico magnets held the largest market share in 2024.

By application, the alnico permanent magnet market is segmented into Electronics, Automotive, Aerospace, Energy, and Others. The automotive application held the largest market share in 2024.

By geography, the alnico permanent magnet market is segmented into North America, Europe, Asia-Pacific, Middle East & Africa, and South & Central America. The Asia-Pacific region held the largest market share in 2024.

Alnico Permanent Magnet Market Drivers and Opportunities

The automotive industry is a primary driver for the alnico permanent magnet market, especially with the rapid adoption of electric vehicles (EVs) and hybrid vehicles. Alnico magnets are highly valued for their exceptional thermal stability and resistance to demagnetization, making them perfectly suited for use in electric motors, sensors, and actuators within EVs. As governments and consumers increasingly prioritize sustainable transportation, the demand for reliable and efficient magnetic materials is soaring. The automotive sector’s focus on energy efficiency and performance is further accelerating the integration of alnico magnets into advanced powertrain and electronic systems, supporting robust market expansion.

Alnico Permanent Magnet Market Size and Share Analysis

By type, the cast alnico segment maintained its dominance in the alnico permanent magnet market. This leadership is attributed to the superior magnetic properties and higher energy product that cast alnico magnets offer compared to sintered alnico and other variants. The casting process facilitates the production of magnets with an optimized microstructure and stability, resulting in stronger and more reliable magnetic performance, particularly in demanding, high-temperature environments.

Download our Sample PDF Report

@ https://www.businessmarketinsights.com/sample/BMIPUB00031699

About Us:

Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Defense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications

0 notes

Text

Iron Ore Pellets Market, Global Outlook & Forecast 2025-2032

Iron ore pellets are small, spherical agglomerations of iron ore fines combined with binders such as bentonite clay and fired at high temperatures to create a hardened product. These pellets serve as a primary raw material in steel manufacturing, enhancing efficiency in blast furnaces and direct reduction processes. Compared to sinter and lump ore, iron ore pellets offer higher iron content (typically 65-70%), resulting in energy savings and improved steel production performance.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/661/global-iron-ore-pellets-

Market Size

The global Iron Ore Pellets market was valued at US$ 51,517.04 million in 2024 and is projected to reach US$ 66,640.92 million by 2030, growing at a CAGR of 3.79% during the forecast period from 2024 to 2030.

Total Industry Sales: The total volume sold by all manufacturers amounted to 224,287.45 K TON, indicating a dynamic and robust market.

U.S. Market Size: The U.S. market was valued at $10,449.15 million in 2023, showcasing strong demand in North America.

Segment Growth: The Blast Furnace Pellets segment alone is expected to reach $149,533.29 million by 2030.

Market Dynamics

Drivers

Growing Steel Production: The increasing demand for steel in construction, automotive, and infrastructure projects fuels the demand for iron ore pellets.

Higher Efficiency & Energy Savings: Iron ore pellets provide higher iron content (65-70%), reducing energy consumption in steel manufacturing.

Environmental Benefits: The use of pellets results in lower emissions of sulfur dioxide and other pollutants, making them an environmentally friendly alternative.

Technological Advancements: Innovations in pelletizing processes are improving production efficiency and reducing costs.

Restraints

Volatility in Iron Ore Prices: Fluctuations in raw material costs can impact profitability.

Stringent Environmental Regulations: Government policies aimed at reducing carbon footprints may impose additional costs on manufacturers.

High Initial Investment Costs: Setting up pelletizing plants requires significant capital expenditure.

Opportunities

Rising Adoption of Direct Reduced Iron (DRI): Increasing use of DRI plants provides new opportunities for iron ore pellet manufacturers.

Expansion in Emerging Markets: Rapid industrialization in Asia-Pacific and Latin America is expected to drive demand.

Sustainability Trends: The growing emphasis on eco-friendly and energy-efficient steel production methods can enhance market adoption.

Challenges

Logistical Issues: Transporting iron ore pellets over long distances can be expensive and logistically complex.

Competition from Scrap Steel Recycling: The growth of recycled steel may pose a competitive threat to the iron ore pellet industry.

Regional Analysis

North America

The U.S. is a key market, driven by robust steel demand.

Adoption of cleaner steel production methods boosts iron ore pellet consumption.

Europe

Germany, UK, and France lead in industrial demand.

Stringent environmental regulations promote the use of iron ore pellets over traditional sinter.

Asia-Pacific

China, Japan, and India are the top consumers due to their high steel production capacities.

Rapid urbanization and infrastructure growth fuel demand.

South America

Brazil is both a key producer and consumer, with major companies like Vale dominating the region.

Middle East & Africa

Increasing investments in steel plants, particularly in Saudi Arabia and South Africa, drive demand.

Competitor Analysis

Major Players

Vale (Brazil)

Rio Tinto (Australia)

BHP (Australia)

Fortescue Metals (Australia)

ArcelorMittal (Luxembourg)

Anglo American (UK)

HBIS Group (China)

Cleveland-Cliffs (USA)

LKAB Group (Sweden)

Market Segmentation (by Type)

Blast Furnace Pellets

Direct Reduction Pellets

Market Segmentation (by Application)

Magnetite

Hematite

Others

Geographic Segmentation

North America: USA, Canada, Mexico

Europe: Germany, UK, France, Russia, Italy, Rest of Europe

Asia-Pacific: China, Japan, South Korea, India, Southeast Asia, Rest of Asia-Pacific

South America: Brazil, Argentina, Colombia, Rest of South America

Middle East and Africa: Saudi Arabia, UAE, Egypt, Nigeria, South Africa, Rest of MEA

FAQ :

1. What is the current market size of the Iron Ore Pellets market?

The market was valued at US$ 51,517.04 million in 2024 and is projected to reach US$ 66,640.92 million by 2030, growing at a CAGR of 3.79%.

2. Which companies dominate the Iron Ore Pellets market?

Key players include Vale, Rio Tinto, BHP, Fortescue Metals, ArcelorMittal, Anglo American, HBIS Group, and Cleveland-Cliffs.

3. What are the main growth drivers in the Iron Ore Pellets market?

Growing steel production

Higher efficiency and energy savings

Environmental benefits

Advancements in pelletizing technology

4. Which regions lead the Iron Ore Pellets market?

Asia-Pacific dominates due to high steel production in China, India, and Japan, followed by North America and Europe.

5. What are the emerging trends in the Iron Ore Pellets market?

Increased use of Direct Reduced Iron (DRI)

Focus on sustainability and carbon reduction

Expansion in emerging markets

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/661/global-iron-ore-pellets-

0 notes

Text

Powder Magnetic Cores Market Growth 2025

The global Powder Magnetic Cores market was valued at US$ 708.85 million in 2023 and is anticipated to reach US$ 2,048.76 million by 2030, witnessing a CAGR of 16.82% during the forecast period 2024-2030.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/372/powder-magnetic-cores-market

Powder Magnetic Cores are a type of magnetic component that is used in various electronic devices and systems.These cores are made from a mixture of fine iron particles, called "iron powder," that is molded into a specific shape and size. The iron powder is then sintered, which involves heating the particles to a high temperature to bind them together and create a solid material.

The major global manufacturers of Powder Magnetic Cores include POCO Magnetic, ZheJiang NBTM KeDa (KDM), CSC (Changsung Corp.), MAGNETICS, Micrometals, Proterial, Ltd. (Formerly Hitachi Metals), Dongbu Electronic Materials, Samwha Electronics, and Qingdao Yunlu Advanced Materials, etc. in 2023, the world's top three vendors accounted for approximately 48% of the revenue.

This report aims to provide a comprehensive presentation of the global market for Powder Magnetic Cores, with both quantitative and qualitative analysis, to help readers develop business/growth strategies, assess the market competitive situation, analyze their position in the current marketplace, and make informed business decisions regarding Powder Magnetic Cores.

The Powder Magnetic Cores market size, estimations, and forecasts are provided in terms of output/shipments (Tons) and revenue ($ millions), considering 2023 as the base year, with history and forecast data for the period from 2019 to 2030. This report segments the global Powder Magnetic Cores market comprehensively. Regional market sizes, concerning products by Type, by Application, and by players, are also provided.

For a more in-depth understanding of the market, the report provides profiles of the competitive landscape, key competitors, and their respective market ranks. The report also discusses technological trends and new product developments.

The report will help the Powder Magnetic Cores manufacturers, new entrants, and industry chain related companies in this market with information on the revenues, production, and average price for the overall market and the sub-segments across the different segments, by company, by Type, by Application, and by regions.

Market Segmentation By Company

POCO Magnetic

ZheJiang NBTM KeDa (KDM)

CSC (Changsung Corp.)

MAGNETICS

Micrometals

Proterial, Ltd. (Formerly Hitachi Metals)

Dongbu Electronic Materials

Samwha Electronics

Qingdao Yunlu Advanced Materials

TDG

DMEGC

CMSS Technology

Nanjing New Conda Magnetic

Sinomag Technology

Amogreentech

Segment by Type

MPP

Sendust

High Flux

Fe-Si

Others

Segment by Application

Photovoltaics and Energy Storage

Electric Vehicles and Charging Piles

Household Appliances

UPS

Telecommunication

Others

Production by Region

North America

Europe

China

Japan

South Korea

Asia Other

Consumption by Region

North America

U.S.

Canada

Asia-Pacific

China

Japan

South Korea

Southeast Asia

India

Europe

Germany

France

U.K.

Italy

Russia

Rest of Europe

Latin America, Middle East & Africa

Brazil

Mexico

Turkey

Israel

GCC Countries

Drivers

Rising Demand for High-Efficiency Power Electronics

The growing adoption of high-efficiency power electronics in renewable energy systems, electric vehicles (EVs), and industrial automation is driving the demand for powder magnetic cores. These cores enhance energy conversion efficiency by reducing energy loss during magnetic flux changes.

Growth in Electric Vehicle Production

The rapid expansion of the EV market has significantly increased the need for lightweight, high-performance magnetic components. Powder magnetic cores are essential for the transformers and inductors used in EV powertrains and charging systems, contributing to their rising demand.

Advancements in Renewable Energy Systems

The global push for renewable energy has led to increased installations of solar and wind power systems, where powder magnetic cores are used in inverters and energy storage systems to improve performance and reliability.

Expansion of Smart Grids and IoT

The proliferation of smart grids and IoT devices has boosted the demand for high-frequency inductors and transformers. Powder magnetic cores offer superior magnetic properties, making them ideal for these applications.

Superior Properties of Powder Magnetic Cores

Powder magnetic cores exhibit low eddy current losses, high saturation flux density, and excellent thermal stability. These properties make them indispensable for high-frequency and high-power applications, ensuring their adoption across industries.

Restraints

High Cost of Raw Materials

The production of powder magnetic cores requires high-purity raw materials such as iron, nickel, and cobalt alloys. Fluctuating prices of these materials can increase production costs, limiting market growth.

Complex Manufacturing Processes

The fabrication of powder magnetic cores involves advanced processes like compaction, sintering, and heat treatment, which require specialized equipment and expertise, potentially hindering adoption by smaller manufacturers.

Competition from Alternative Magnetic Materials

Conventional magnetic cores, such as ferrites and laminated cores, remain widely used in some applications due to their cost-effectiveness and established manufacturing processes, posing a challenge to powder cores.

Performance Limitations in Extreme Environments

Despite their advantages, powder magnetic cores may face performance issues under extreme temperatures or in highly corrosive environments, limiting their application range.

Opportunities

Increased Adoption in 5G Technology

The rollout of 5G infrastructure has created new opportunities for powder magnetic cores, which are used in base stations, power amplifiers, and signal processing equipment to improve efficiency and performance.

Emergence of Electric Aviation and Autonomous Vehicles

The growth of electric aviation and autonomous vehicles is driving the demand for advanced power management systems. Powder magnetic cores, with their lightweight and efficient energy conversion properties, are well-suited for these applications.

Development of Advanced Alloys and Coatings

Innovations in alloy composition and surface coatings are enhancing the performance of powder magnetic cores, opening up opportunities in high-demand applications such as data centers, medical devices, and high-frequency transformers.

Expansion in Emerging Markets

The rapid industrialization and urbanization in regions like Asia-Pacific, Latin America, and the Middle East present significant opportunities for market growth. Increased investments in infrastructure, automotive, and renewable energy sectors are driving demand for magnetic cores.

Focus on Energy Efficiency and Sustainability

Governments and industries are prioritizing energy-efficient technologies to meet sustainability goals. Powder magnetic cores, which contribute to reduced energy loss, align with these trends, encouraging their adoption.

Challenges

Technical Barriers in Miniaturization

As electronic devices continue to shrink, developing powder magnetic cores with high performance in compact sizes is a technical challenge for manufacturers, requiring extensive R&D investment.

Economic Slowdowns Impacting Capital Investments

Economic downturns or geopolitical instability can reduce investments in industries such as automotive, renewable energy, and electronics, negatively affecting the demand for powder magnetic cores.

Lack of Awareness Among End-Users

Limited awareness about the advantages of powder magnetic cores in certain regions or industries may restrict market penetration, especially in developing markets.

Environmental Regulations on Raw Material Extraction

Stringent regulations on the mining and processing of raw materials used in magnetic cores may pose supply chain challenges and increase production costs.

Get free sample of this report at : https://www.intelmarketresearch.com/download-free-sample/372/powder-magnetic-cores-market

0 notes

Text

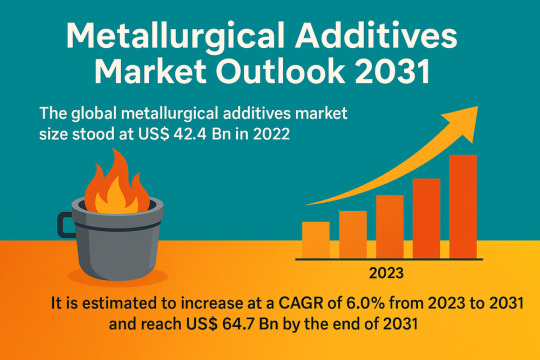

Robust Growth Ahead for Metallurgical Additives Market Through 2031

The global metallurgical additives market is poised for robust expansion, driven by increasing demand from steel, automotive, aerospace, and construction sectors. According to the latest industry research, the global metallurgical additives market size, which stood at US$ 42.4 billion in 2022, is projected to grow at a CAGR of 6.0% from 2023 to 2031, reaching a valuation of US$ 64.7 billion by the end of the forecast period.

Market Overview: Metallurgical additives are vital components in metal manufacturing processes, enhancing the mechanical, chemical, and thermal properties of base metals. These additives are used extensively in steelmaking, casting, and smelting to produce high-performance alloys suited for demanding industrial applications. Their usage is imperative in producing corrosion-resistant, high-strength materials required across the construction, automotive, and aerospace industries.

Market Drivers & Trends

The surge in demand for lightweight and durable components, especially in transportation and infrastructure development, has increased the reliance on enhanced alloys. This trend, coupled with the rapid pace of urbanization and industrialization, is bolstering the need for metallurgical additives.

Key drivers include:

The rise in global construction activity.

Increased demand for structural components in automotive and machinery manufacturing.

Technological advancements in metal refining and alloy development.

Shift toward high-efficiency, precision-engineered metal components.

Manufacturers are prioritizing cost-effective processes like sintering and thermal processing to enhance production efficiency, further fueling demand for quality metallurgical additives.

Latest Market Trends

Growth of additive manufacturing: Though still a niche within the metals industry, additive manufacturing is gaining traction due to its flexibility and efficiency. This technique, supported by metallurgical additives, enables rapid prototyping and complex design implementation.

Sustainability and green metallurgy: With increasing regulatory pressure and environmental concerns, the industry is adopting additives that promote eco-friendly steel and alloy production processes.

Customization and specialty alloys: Rising customization in metal compositions to meet specific performance criteria is driving R&D investment in innovative metallurgical additives.

Key Players and Industry Leaders

The global metallurgical additives market is highly consolidated, with key players accounting for over 80% of the total market share. These companies continue to lead in innovation, regional expansion, and sustainability initiatives.

Prominent players include:

Kerneos S.A.

Imerys Aluminates

Calucem GmbH

Almatis

Harsco Corporation

RHI Magnesita

Grecian Magnesite

Premier Periclase Ltd.

Magnesitas Navarras S.A.

Nedmag Industries Mining & Manufacturing B.V.

Others

These companies are enhancing their capabilities through acquisitions, R&D initiatives, and investments in manufacturing capacities across high-growth regions.

Recent Developments

RHI Magnesita announced in January 2023 the acquisition of a majority stake in Jinan New Emei Industries Co. Ltd. The deal is aimed at strengthening its steel flow control product portfolio and expanding its footprint in China and East Asia.

Imerys inaugurated a new manufacturing plant in Atchutapuram, India, in October 2022 with an annual capacity of 30,000 tons of calcium aluminate binders for the refractory and construction industries.

These developments signal a strong focus on regional expansion and product innovation to meet evolving customer needs.

Market Opportunities

Significant opportunities exist in:

Emerging economies: Rapid infrastructure development and increasing industrialization in Asia Pacific, Latin America, and parts of Africa present vast growth prospects.

High-performance alloy segments: Growing demand for specialized alloys in aerospace and defense sectors.

Eco-friendly metallurgy: Rising preference for additives that reduce environmental impact and energy consumption in metal processing.

Explore pivotal insights and conclusions from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85845

Future Outlook

Analysts foresee the metallurgical additives market evolving in alignment with industrial trends such as lightweighting in automotive, smart infrastructure, and sustainable manufacturing. The demand for performance-driven and application-specific additives will keep rising, pushing companies to innovate faster and expand regionally.

As industrial sectors aim for higher efficiency and precision, metallurgical additives will remain indispensable in achieving desired material characteristics across diverse end-use applications.

Market Segmentation

By Type:

Calcium Aluminate

Aluminum Silica Based Slag

Magnesia

Lime

Others

By Category:

Ferrous

Non-Ferrous

By End-use Industry:

Automotive

Aerospace

Electronics

Medical

Energy

Building & Construction

Others

Ferrous additives dominate the category segment, thanks to their widespread use in iron and steel manufacturing. Meanwhile, automotive and construction sectors lead among end-users due to their high volume consumption of refined steel and alloy products.

Regional Insights

Asia Pacific emerged as the dominant region in 2022, led by countries like China, India, and Japan. The region benefits from large-scale urbanization, growing population, and heavy investments in infrastructure.

China and India are experiencing increased per capita consumption of metallurgical additives due to rapid industrial expansion and growing steel production capacities.

North America and Europe remain key regions with strong demand in aerospace, automotive, and advanced manufacturing sectors. These regions are also pioneers in sustainable metallurgical practices, boosting demand for eco-friendly additives.

Emerging economies in Latin America and Africa offer untapped potential due to increasing construction activities and the presence of untapped mineral resources.

Why Buy This Report?

Comprehensive analysis of market trends, drivers, and growth forecasts

In-depth segmentation and regional outlook

Competitive landscape featuring leading global players

Insights into recent developments and future market strategies

Frequently asked questions and actionable recommendations for investors and stakeholders

Frequently Asked Questions

1. What is the market size of the metallurgical additives industry in 2022? The global market was valued at US$ 42.4 billion in 2022.

2. What is the projected market value by 2031? It is expected to reach US$ 64.7 billion by 2031, growing at a CAGR of 6.0%.

3. Which segment dominates the market? Ferrous additives dominate, primarily due to their widespread application in steelmaking.

4. Which region holds the largest market share? Asia Pacific, driven by demand from China, India, and Japan.

5. Who are the top players in the market? Major players include Kerneos S.A., Imerys Aluminates, Calucem GmbH, RHI Magnesita, and Harsco Corporation.

6. What are the key growth opportunities? Emerging markets, sustainable metallurgy, and additive manufacturing represent significant growth avenues.

7. Why are metallurgical additives important? They enhance the performance of base metals, making them more suitable for high-stress, high-performance applications in construction, automotive, and aerospace.

Explore Latest Research Reports by Transparency Market Research: Feed Intermediate Chemicals Market: https://www.transparencymarketresearch.com/feed-intermediate-chemicals-market.html

Automatic Plastic Recycling Market: https://www.transparencymarketresearch.com/automatic-plastic-recycling-market.html

Lipophilic Dyes Market: https://www.transparencymarketresearch.com/lipophilic-dyes-market.html

Low-carbon Monocrystalline Silicon Ingots Market: https://www.transparencymarketresearch.com/low-carbon-monocrystalline-silicon-ingots-market.html

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

Europe Aluminium Magnesium Spinel Market Industry Trends, Competition Strategies, Revenue Analysis and Forecast to 2025-2033

The Reports and Insights, a leading market research company, has recently releases report titled “Europe Aluminium Magnesium Spinel Market: Industry Trends, Share, Size, Growth, Opportunity and Forecast 2025-2033.” The study provides a detailed analysis of the industry, including the Europe Aluminium Magnesium Spinel Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Europe Aluminium Magnesium Spinel Market?

Europe aluminium magnesium spinel market was valued at US$ 173.8 Million in 2024 and is expected to register a CAGR of 4.5% over the forecast period and reach US$ 258.3 Million in 2033.

What are Europe Aluminium Magnesium Spinel?

Aluminium Magnesium Spinel in Europe is a high-performance ceramic known for its outstanding thermal and mechanical properties. Made from aluminum oxide (Al₂O₃) and magnesium oxide (MgO), it offers excellent resistance to thermal shock, corrosion, and mechanical wear. This material is widely used in industrial applications including refractory linings in furnaces and reactors, as well as in aerospace components and advanced ceramic products. Its exceptional combination of high melting point, hardness, and chemical stability makes it ideal for demanding environments where durability and reliability are essential.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/2351

What are the growth prospects and trends in the Europe Aluminium Magnesium Spinel industry?

The Europe aluminium magnesium spinel market growth is driven by various factors and trends. The Aluminium Magnesium Spinel market in Europe is experiencing growth, fueled by its widespread adoption in multiple industries due to its strong thermal and mechanical properties. This high-performance ceramic, comprised of aluminum oxide (Al₂O₃) and magnesium oxide (MgO), is prized for its resilience against thermal shock, corrosion, and mechanical wear. It is utilized extensively in industrial refractories, aerospace components, and advanced ceramics, leveraging its high melting point, hardness, and chemical stability. Market expansion is driven by rising demand for durable materials in industrial applications and continuous advancements in technology to enhance its effectiveness across various uses. Hence, all these factors contribute to Europe aluminium magnesium spinel market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type

Fused Spinel

Reaction Bonded Spinel

Sintered Spinel

Others

By Composition

Al2O3 (76/78%)

MgO (24/22%)

By Form

Powder

Granules

Bricks

Others

By Production Method

Sol-Gel Process

Conventional Solid-State-Reaction

Spray Drying (Atomization)

Chemical Vapor Deposition (CVD)

Electrical Fusion Process

Wet Synthesis Techniques

Mechano-Chemical Alloying

Molten Salt Synthesis

Others

By Purity

99%

Above 99%

By Packaging

Steel Drum

Container

By Application

Refractory Materials

Metal Casting

Electrical Insulators

Iron And Steel Smelting

Glass Furnace

Calcined Lime Furnace Lining

Cement Rotary Kiln

Steel Ladles

Alumina-Magnesia Brick

Sliding Nozzle

Ceramics Manufacturing

HumiditySensors

Others

By End-Use Industry

Automotive

Electronics

Refractories

Cement

Iron and Steel

Glass

Water Treatment

Others

Europe

Germany

Austria

Switzerland

Italy

Spain

Portugal

Greece

Cyprus

Malta

Poland

Czech Republic

Slovakia

Hungary

Ukraine

Moldova

Balkan Countries

Rest of Europe

Who are the key players operating in the industry?

The report covers the major market players including:

Almatis

Refratechnik Group

Keralit LLC

Surmet Corporation

CeraNova Corporation

Washington Mills

Baikowski

MFE Magnesium

View Full Report: https://www.reportsandinsights.com/report/Europe Aluminium Magnesium Spinel-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Europe Aluminium Magnesium Spinel Market share#Europe Aluminium Magnesium Spinel Market size#Europe Aluminium Magnesium Spinel Market trends

0 notes

Text

Electronic Grade Copper Oxide Powder Market Report: Trends, Opportunities, and Forecast 2025-2031

Electronic Grade Copper Oxide Powder Market, Global Outlook and Forecast 2025-2032

The global Electronic Grade Copper Oxide Powder Market valuation reached USD 182.90 million in 2023, with projections indicating steady growth at a CAGR of 2.60% to reach USD 230.43 million by 2032. This specialized material—with copper oxide content exceeding 99.0%—has become indispensable for high-precision electronics manufacturing, particularly in PCB production and advanced interconnect technologies where microscopic honeycomb structures enable superior electroplating performance.

Electronic grade copper oxide powder demonstrates exceptional characteristics including uniform particle distribution, rapid dissolution rates, and plating consistency—properties critical for HDI boards and IC carrier boards. As miniaturization trends accelerate across consumer electronics and automotive applications, demand surges for materials that balance conductivity with precise deposition characteristics.

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/290264/electronic-grade-copper-oxide-powder-market

Market Overview & Regional Analysis

Asia-Pacific commands the lion's share of production, fueled by China's dominance in PCB manufacturing and Taiwan's advanced semiconductor ecosystem. The region benefits from vertically integrated electronics supply chains and aggressive R&D investment in material science. Japan maintains leadership in nanoparticle technologies, while South Korea's display industry drives specialized demand.

North America shows robust growth particularly in military/aerospace applications, where stringent reliability requirements justify premium pricing. Europe's market thrives on automotive electronics innovation, with German chemical giants pioneering eco-friendly production methods. Emerging economies in Southeast Asia demonstrate accelerating uptake as electronics manufacturing migrates from traditional hubs.

Key Market Drivers and Opportunities

Three seismic shifts propel market expansion: First, the 5G infrastructure rollout demands high-frequency PCBs requiring ultra-fine copper deposition. Second, electric vehicle adoption expands applications in power electronics and battery management systems. Third, AI hardware development necessitates advanced packaging solutions leveraging copper's superior conductivity.

Opportunity abounds in developing copper oxide formulations optimized for: - Additive manufacturing of electronic components - Low-temperature sintering processes - Hybrid conductive pastes These innovations could unlock new applications in flexible electronics and IoT devices, potentially adding USD 15-20 million to the addressable market by 2028.

Challenges & Restraints

The market faces headwinds from: - Copper price volatility impacting production costs - Tightening REACH and RoHS regulations on heavy metal content - Emergence of conductive polymer alternatives - Technical hurdles in achieving sub-20nm particle consistency

Supply chain vulnerabilities surfaced during recent semiconductor shortages, prompting manufacturers to diversify sourcing strategies. Meanwhile, environmental concerns drive investment in closed-loop recycling systems for copper recovery.

Market Segmentation by Type

Below 20nm

20-50nm

50-100nm

Above 100nm

Download FREE Sample Report: https://www.24chemicalresearch.com/download-sample/290264/electronic-grade-copper-oxide-powder-market

Market Segmentation by Application

PCB Manufacturing Industry

HDI Board

IC Carrier Board

Others

Market Segmentation and Key Players

Strem Chemicals

Nanoshel

American Elements

SkySpring Nanomaterials

SAT Nano Technology Material

NGimat

Jiangxi Jiangnan New Material

Report Scope

This comprehensive analysis covers the global electronic grade copper oxide powder market from 2024-2032, featuring:

Market size projections with 8-year forecasts

Application-specific demand analysis across electronics verticals

Particle size segmentation and growth potential

The report delivers actionable intelligence through:

Competitive benchmarking of 15+ manufacturers

Production capacity assessments by region

Emerging application pipeline analysis

Regulatory impact assessment

Get Full Report Here: https://www.24chemicalresearch.com/reports/290264/electronic-grade-copper-oxide-powder-market

About 24chemicalresearch

Founded in 2015, 24chemicalresearch has rapidly established itself as a leader in chemical market intelligence, serving clients including over 30 Fortune 500 companies. We provide data-driven insights through rigorous research methodologies, addressing key industry factors such as government policy, emerging technologies, and competitive landscapes.

Plant-level capacity tracking

Real-time price monitoring

Techno-economic feasibility studies

With a dedicated team of researchers possessing over a decade of experience, we focus on delivering actionable, timely, and high-quality reports to help clients achieve their strategic goals. Our mission is to be the most trusted resource for market insights in the chemical and materials industries.

International: +1(332) 2424 294 | Asia: +91 9169162030

Website: https://www.24chemicalresearch.com/

Follow us on LinkedIn: https://www.linkedin.com/company/24chemicalresearch

0 notes

Text

Healthcare 3D Printing Market Opportunities, Growth Potential & Regional Analysis 2033

The integration of 3D printing in the healthcare sector is ushering in a new era of personalized medicine, surgical precision, and cost-effective manufacturing. Once seen as an emerging technology, 3D printing has firmly rooted itself as a transformative force across various medical applications—from custom prosthetics and implants to bioprinted tissues and surgical tools. The healthcare 3D printing market is not only evolving rapidly but also opening doors to innovations that were once confined to science fiction.

Market Overview and Growth Trajectory

As of 2024, the global healthcare 3D printing market is valued at approximately USD XXX billion and is expected to grow significantly in the coming years. Forecasts suggest the market will reach around USD XXX billion by 2033, reflecting a CAGR of over XX% during the 2025–2033 period. The growing need for patient-specific medical solutions, improvements in additive manufacturing technologies, and cost efficiencies are among the leading drivers of this explosive growth.

North America currently dominates the global market, accounting for about 45% of total revenue, due to its robust healthcare infrastructure, technological leadership, and strong regulatory support. However, the Asia-Pacific region is catching up fast, driven by growing healthcare expenditures, rising awareness, and supportive government initiatives.

Download a Free Sample Report: - https://tinyurl.com/4jdvj2th

Key Drivers Fueling Market Growth

1. Personalized Medicine and Patient-Specific Solutions

3D printing enables the customization of medical devices to suit individual patient anatomies, especially in orthopedics, dentistry, and reconstructive surgery. Prosthetics, implants, and dental aligners are now being tailored with unmatched precision, resulting in improved patient outcomes and comfort.

2. Technological Advancements

The introduction of new biocompatible materials, faster printers, and multi-material printing capabilities has significantly expanded the range of possible applications. Technologies such as stereolithography (SLA), fused deposition modeling (FDM), and selective laser sintering (SLS) are being widely adopted in healthcare for their reliability and precision.

3. Cost-Effective Production

3D printing minimizes material wastage and reduces production times, which is particularly beneficial for low-volume, high-complexity medical devices. Hospitals and research institutions are now setting up in-house 3D printing labs to fabricate instruments, anatomical models, and surgical guides on demand.

4. Rising Use in Surgical Planning

Pre-surgical planning using patient-specific 3D printed anatomical models is gaining popularity among surgeons. These models allow for better visualization of complex anatomy, enabling more accurate and efficient surgeries, especially in cardiology, neurology, and orthopedics.

Applications Across the Healthcare Ecosystem

1. Prosthetics and Implants

Custom-made 3D-printed prosthetics have revolutionized mobility aids by providing affordable, adaptable, and accessible solutions. In the field of orthopedics, 3D-printed implants offer better fit, function, and longevity. Cranial and spinal implants, for instance, are now being developed using titanium and bioceramics through additive manufacturing.

2. Dental Applications

The dental segment accounts for a substantial share of the healthcare 3D printing market. Aligners, crowns, bridges, and even dentures are being 3D-printed with micron-level accuracy. Companies like 3D Systems and Align Technology have capitalized on this trend by delivering clear dental aligners using proprietary 3D printing processes.

3. Bioprinting and Tissue Engineering

One of the most groundbreaking areas is bioprinting, where living cells are used as “inks” to build tissue-like structures layer by layer. Although still in the experimental phase, successful trials in printing skin, cartilage, and even small blood vessels offer promising solutions for regenerative medicine and organ transplantation.

4. Surgical Instruments and Tools

Sterile, durable, and customizable surgical instruments are being 3D-printed for specific operations. These include forceps, retractors, hemostats, and more. The ability to produce these tools on-site allows hospitals to reduce costs and streamline inventory management.

5. Educational and Training Models

Medical schools and hospitals are using life-sized 3D printed models for teaching anatomy, practicing surgical procedures, and training in complex interventions. These models are more cost-effective and realistic than traditional cadavers or simulations.

Leading Players in the Market

Several companies are pioneering healthcare 3D printing technologies. Key players include:

3D Systems Corporation – A market leader offering 3D printing solutions for dental and surgical planning. Recently secured a $250 million contract for clear dental aligner production.

Stratasys Ltd. – Known for its FDM and PolyJet technologies used in surgical tools and anatomical modeling.

Materialise NV – Provides software and 3D printing services for medical imaging and orthopedics.

EnvisionTEC – Specializes in high-precision DLP 3D printing systems used in audiology and dental sectors.

Organovo Holdings Inc. – A leader in bioprinting technologies, focusing on developing functional human tissues for drug discovery and regenerative medicine.

Regulatory Landscape

The increasing involvement of regulatory agencies such as the U.S. FDA and the European Medicines Agency (EMA) is helping standardize and validate the use of 3D printed devices in healthcare. As of recent years, over 100 3D-printed medical devices have received FDA approval, including orthopedic implants, cranial plates, and dental devices.

Additionally, agencies are now working on developing frameworks for bioprinted tissues and organ substitutes, although this segment still faces significant ethical, technical, and regulatory hurdles.

Challenges and Limitations

Despite its numerous advantages, the healthcare 3D printing market is not without challenges:

High Initial Investment: Setting up 3D printing labs requires significant capital outlay in terms of equipment, software, and skilled personnel.

Material Constraints: Limited availability of biocompatible and sterilizable materials can restrict certain applications.

Regulatory Hurdles: Standardization of processes and validation of products for mass production remain complex, especially for bioprinted tissues.

Data Security: Handling of patient-specific digital files raises concerns about data privacy and cyber threats.

Future Outlook and Trends

Looking ahead, several trends are expected to shape the future of the healthcare 3D printing market:

AI Integration: Artificial intelligence will optimize design processes, error detection, and real-time quality control during printing.

Point-of-Care Manufacturing: Hospitals and clinics will increasingly install 3D printers to produce patient-specific models and tools on-site.

Advancements in Bioprinting: Ongoing research into organ printing could eventually address donor shortages and revolutionize organ transplantation.

Sustainable Printing Practices: New eco-friendly materials and energy-efficient processes will make 3D printing more sustainable.

Conclusion

The healthcare 3D printing market is not merely a technological innovation—it represents a fundamental shift in how medical devices are designed, produced, and utilized. From restoring mobility to reshaping organ transplantation, 3D printing is enabling outcomes that are faster, cheaper, and more precise. With continuous advancements and growing regulatory clarity, the market is poised for unprecedented growth and deeper integration into mainstream healthcare.

Read Full Report: - https://www.uniprismmarketresearch.com/verticals/healthcare/healthcare-3d-printing

0 notes

Text

3D and 4D Printing Technology Market - Strategic Developments

Business Market Insights recently announced the release of the market research titled 3D and 4D Printing Technology Market Outlook to 2031 | Share, Size, and Growth. The report is a stop solution for companies operating in the 3D and 4D Printing Technology market. The report involves details on key segments, market players, precise market revenue statistics, and a roadmap that assists companies in advancing their offerings and preparing for the upcoming decade. Listing out the opportunities in the market, this report intends to prepare businesses for the market dynamics in an estimated period.

Is Investing in the Market Research Worth It?

Some businesses are just lucky to manage their performance without opting for market research, but these incidences are rare. Having information on longer sample sizes helps companies to eliminate bias and assumptions. As a result, entrepreneurs can make better decisions from the outset. 3D and 4D Printing Technology Market report allows business to reduce their risks by offering a closer picture of consumer behavior, competition landscape, leading tactics, and risk management.

A trusted market researcher can guide you to not only avoid pitfalls but also help you devise production, marketing, and distribution tactics. With the right research methodologies, Business Market Insights is helping brands unlock revenue opportunities in the 3D and 4D Printing Technology market.

If your business falls under any of these categories – Manufacturer, Supplier, Retailer, or Distributor, this syndicated 3D and 4D Printing Technology market research has all that you need.

What are Key Offerings Under this 3D and 4D Printing Technology Market Research?

Global 3D and 4D Printing Technology market summary, current and future 3D and 4D Printing Technology market size

Market Competition in Terms of Key Market Players, their Revenue, and their Share

Economic Impact on the Industry

Production, Revenue (value), Price Trend

Cost Investigation and Consumer Insights

Industrial Chain, Raw Material Sourcing Strategy, and Downstream Buyers

Production, Revenue (Value) by Geographical Segmentation

Marketing Strategy Comprehension, Distributors and Traders

Global 3D and 4D Printing Technology Market Forecast

Study on Market Research Factors

Who are the Major Market Players in the 3D and 4D Printing Technology Market?

3D and 4D Printing Technology market is all set to accommodate more companies and is foreseen to intensify market competition in coming years. Companies focus on consistent new launches and regional expansion can be outlined as dominant tactics. 3D and 4D Printing Technology market giants have widespread reach which has favored them with a wide consumer base and subsequently increased their 3D and 4D Printing Technology market share.

Report Attributes

Details

Segmental Coverage

Technology

Stereolithography

Fused Deposition Modelling

Selective Laser Sintering

Direct Metal Laser Sintering

Polyjet/Multijet Printing

Electron Beam Melting

Digital Light Processing

Material

Plastics

Metal

Ceramics

Composites

Resins

Bio-Metals

Hybrid Metals

Application

Prototyping

Manufacturing

Research & Development

End Use Industry

Aerospace & Defence

Automotive

Healthcare

Consumer Goods

Construction

Education & Research

Electronics

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

Stratasys Ltd.

3D Systems Corporation

Materialise NV

Autodesk, Inc.

Hewlett Packard Enterprise (HP)

EOS GmbH

Desktop Metal, Inc.

Organovo Holdings, Inc.

Dassault Syst?mes SE

Nano Dimension Ltd.

Other key companies

What are Perks for Buyers?

The research will guide you in decisions and technology trends to adopt in the projected period.

Take effective 3D and 4D Printing Technology market growth decisions and stay ahead of competitors

Improve product/services and marketing strategies.

Unlock suitable market entry tactics and ways to sustain in the market

Knowing market players can help you in planning future mergers and acquisitions

Visual representation of data by our team makes it easier to interpret and present the data further to investors, and your other stakeholders.

Do We Offer Customized Insights? Yes, We Do!

The Business Market Insights offer customized insights based on the client’s requirements. The following are some customizations our clients frequently ask for:

The 3D and 4D Printing Technology market report can be customized based on specific regions/countries as per the intention of the business

The report production was facilitated as per the need and following the expected time frame

Insights and chapters tailored as per your requirements.

Depending on the preferences we may also accommodate changes in the current scope.

About Us:

Business Market Insights is a market research platform that provides subscription services for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductors, Aerospace & Defense, Automotive & Transportation, Energy & Power, Healthcare, Manufacturing & Construction, Food & Beverages, Chemicals & Materials, and Technology, Media & Telecommunications.

Contact Us:

If you have any questions about this report or would like further information, please contact us:

Contact person: Ankit Mathur

Email: [email protected]

Phone: +16467917070

#3D and 4D Printing Technology Market#3D and 4D Printing Technology Market Size#3D and 4D Printing Technology Market Trends#3D and 4D Printing Technology Market Shares#3D and 4D Printing Technology Market Growth

0 notes

Text

More Than Just Models: The Real-World Applications of the Dental 3D Printing Market

Dental 3D Printing Industry Overview

The global Dental 3D Printing Market, estimated at $3.1 billion in 2023, is projected to experience substantial expansion, growing at a compound annual growth rate (CAGR) of 26.4% from 2024 to 2030. The integration of cutting-edge technology with significant potential has firmly established 3D printing in modern dental product manufacturing. Factors such as the design and development of sophisticated products like invisible aligners, advanced fabrication techniques for enhanced aesthetics, and precise delivery positioning are driving increased demand and adoption of dental 3D printers. The user-friendly nature and ease of 3D printing procedures are encouraging the dental industry to produce customized solutions that meet the diverse dental needs of individuals. These printers are expected to boost production output while simultaneously reducing fabrication time. Furthermore, the digitalized workflow promises to minimize procedural discomfort and enhance overall customer satisfaction.

This market is currently experiencing robust growth, with further expansion anticipated in emerging economies. According to the American College of Prosthodontists, approximately 15% of the edentulous population receives dentures annually. Edentulism disproportionately affects vulnerable groups, including economically disadvantaged and aging individuals. In the U.S. alone, around 120 million people are missing at least one tooth, and over 36 million Americans are completely edentulous. These figures are expected to rise in the coming decades, indicating a growing need for tooth replacement solutions among the aging population. Moreover, both partially toothless individuals, regardless of age, are increasingly opting for dental procedures, viewing dental implants as a practical and appealing option.

Detailed Segmentation:

End-use Insights

The dental laboratories segment dominated the market and accounted for the largest revenue share of 55.6% in 2023. The segment is likely to show the highest CAGR of 26.7% over the forecast period. The rising adoption of advanced technologies in laboratories is supplementing the growth of the segment. Moreover, the increasing number of dental laboratories, rising outsourcing of various manufacturing functions to dental laboratories, and increasing demand for fabricated/customized dental framing solutions required for several applications are fueling the demand for dental 3D printing technologies.

Application Insights

The orthodontics segment held the largest revenue share of 39.0% in 2023 and is expected to grow at a significant rate of 26.5% during the forecast period. The growth can be attributed to the rising number of cases of misalignment and gaps in the teeth. Furthermore, it is observed that approximately 3 million Canadian and American teens have braces, with the number of adults beginning orthodontic treatment rising at a steady rate.

Technology Insights

The selective laser sintering segment dominated the market with the largest share of 37.8% in 2023 and is likely to maintain its position throughout the forecast period, owing to its advantages over other technologies such as good chemical resistance, biocompatibility, and excellent surface finishing. The other technological segment is expected to show the highest CAGR of 27.5% during the forecast period, due to the rising investments in R&D related to material jetting, electron beam melting, and binder jetting techniques. The popularity of fused deposition modeling is rising due to the availability of a wide range of strong, biocompatible, and sterilizable thermoplastics. FDM is very cost-effective and is the most widely used technique to produce complicated shapes and designs. This is due to the growing cases of edentulism and tooth decay that are contributing to the growth of the segment.

Regional Insights

Asia Pacific is anticipated to witness the most lucrative growth of 27.1% over the forecast period. The growth of the market can be attributed to the rising commercial activities by major industry manufacturers, expanding the number of patients undergoing tooth replacement surgeries, and improving healthcare infrastructure in emerging economies. The rising geriatric population, flourishing dental tourism, growing per capita income, and favorable government policies are some of the factors that are driving the growth of the regional market. India and China are projected to spearhead the growth in the Asia Pacific and market players are looking forward to investing in these countries.

Gather more insights about the market drivers, restraints, and growth of the Dental 3D Printing Market

Key Companies & Market Share Insights

Players in the market could face two restrains- a lack of skilled dental professionals and the high cost of dental 3D printers which can hamper their growth pace. The dental 3D printing sector is a highly competitive market with the presence of large and medium-sized organizations. The growing demand for advanced technologies in the field of dentistry is encouraging the manufacturers in the dental 3D printing industry to enhance their existing scope of R&D activities by allocating high funds to incorporate advanced technologies.

These manufacturers also focus on various growth strategies such as mergers & acquisitions and launch of the new products. For instance, In February 2022, 3D Systems and Saremco Dental AG entered into partnership to advance the digital dentistry innovation. Combining 3D Systems' NextDent with Saremco's materials science expertise, the collaboration aims to empower dental laboratories and clinics with enhanced accuracy, repeatability, productivity, and cost-effectiveness across various indications. In February 2023, Stratasys Ltd. has unveiled TrueDent, a groundbreaking full-color 3D printed permanent dentures solution. TrueDent resin allows dental labs to produce natural-looking gums and accurate tooth structure with the desired shade and translucency, all in a single continuous print.

Key Dental 3D Printing Companies:

3D Systems

Stratasys Ltd.

Renishaw

Roland DG

SLM Solutions

EnvisionTec

DentsPly Sirona

Straumann

Form Labs

Prodways

Planmeca

Order a free sample PDF of the Market Intelligence Study, published by Grand View Research.

0 notes

Text

Automotive 3D Printing Market Size, Analyzing Trends and Projected Outlook for 2025-2032

Fortune Business Insights released the Global Automotive 3D Printing Market Trends Study, a comprehensive analysis of the market that spans more than 150+ pages and describes the product and industry scope as well as the market prognosis and status for 2025-2032. The marketization process is being accelerated by the market study's segmentation by important regions. The market is currently expanding its reach.

The Automotive 3D Printing Market is experiencing robust growth driven by the expanding globally. The Automotive 3D Printing Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive 3D Printing Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive 3D Printing Market Size, Share & Industry Analysis, By Technology Type (Electronic Beam Melting (EBM), Selective Laser Sintering (SLS), Digital Light Processing (DLP), Fused Disposition Modelling (FDP)), By Material Type (Ceramic, Metal, Polymer), By Application Type (Production, Innovation and R&D, Prototyping) and Regional Forecast 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/103613

Dominating Region:

North America

Fastest-Growing Region:

Asia-Pacific

Major Automotive 3D Printing Market Manufacturers covered in the market report include:

The major companies in the global 3D printing market include 3D Systems Corporation, Stratasys Ltd., Arcam AB, EnvisionTEC, Ponoko Limited, The ExOne Company, Autodesk Inc., Hoganas AB, Optomec, Inc., Voxeljet AG among others.

Globally, the rise in urbanization, high standard of living, and increased demand of customers are leading to an increase in the automotive industry. Furthermore, the adoption of advanced technology, less time required to manufacture intricate designs, low cost of raw materials, innovation in printing methods an also investment of government to develop new technology is driving the growth of the market. However, the lack of skilled laborers and high printing costs may hamper the growth of the market.

Geographically, the detailed analysis of consumption, revenue, market share, and growth rate of the following regions:

The Middle East and Africa (South Africa, Saudi Arabia, UAE, Israel, Egypt, etc.)

North America (United States, Mexico & Canada)

South America (Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, etc.)

Europe (Turkey, Spain, Turkey, Netherlands Denmark, Belgium, Switzerland, Germany, Russia UK, Italy, France, etc.)

Asia-Pacific (Taiwan, Hong Kong, Singapore, Vietnam, China, Malaysia, Japan, Philippines, Korea, Thailand, India, Indonesia, and Australia).

Automotive 3D Printing Market Research Objectives:

- Focuses on the key manufacturers, to define, pronounce and examine the value, sales volume, market share, market competition landscape, SWOT analysis, and development plans in the next few years.

- To share comprehensive information about the key factors influencing the growth of the market (opportunities, drivers, growth potential, industry-specific challenges and risks).

- To analyze the with respect to individual future prospects, growth trends and their involvement to the total market.