#Agro Textile Testing

Explore tagged Tumblr posts

Text

Role of Accredited Labs in Verifying Agro Textiles for Crop Protection

In the world of modern agriculture, the demand for crop protection solutions that are efficient, eco-friendly, and cost-effective has never been higher. Agro textiles—such as shade nets, insect-proof screens, mulch mats, and greenhouse covers—have emerged as essential tools for improving crop yield, protecting plants from pests, regulating climate, and conserving water. However, the effectiveness of these materials depends significantly on their quality and performance under field conditions. This is where Agro Textiles Testing by accredited laboratories becomes indispensable.

This blog explores how accredited labs play a critical role in verifying agro textiles to ensure they meet crop protection requirements and comply with industry standards.

What are Agro Textiles?

Agro textiles are specially designed technical fabrics used in agriculture and horticulture for various protective and enhancement purposes. These textiles are primarily made from synthetic polymers like polypropylene (PP), polyethylene (PE), and polyester. Key applications include:

Shading crops from excessive sunlight

Preventing insect and bird intrusion

Reducing weed growth

Retaining soil moisture

Controlling temperature and humidity in greenhouses

Given their continuous exposure to sun, wind, chemicals, and mechanical stress, the performance and reliability of agro textiles must be verified through rigorous testing.

Importance of Agro Textiles Testing for Crop Protection

Agro textiles are designed to offer physical protection, microclimate control, and pest resistance. Their failure due to poor material quality or improper installation can lead to:

Reduced crop yields

Increased pest infestations

Soil degradation

Economic losses for farmers

To prevent such issues, agro textiles must be tested for:

UV stability and light filtration

Tensile and tear strength

Air and water permeability

Thermal aging and durability

Chemical resistance to fertilizers and pesticides

Only accredited labs have the infrastructure and certification to carry out these tests using standardized methodologies.

Who are Accredited Labs?

An accredited laboratory is a testing facility that meets the requirements of international quality standards, such as ISO/IEC 17025. Accreditation is granted by authorized bodies such as:

NABL (National Accreditation Board for Testing and Calibration Laboratories) – India

UKAS (United Kingdom Accreditation Service) – UK

A2LA (American Association for Laboratory Accreditation) – USA

DAkkS (German Accreditation Body) – Germany

Accredited labs ensure that their results are accurate, reproducible, and recognized globally. Their role in verifying agro textiles includes testing, certification, and sometimes, product development support.

Role of Accredited Labs in Verifying Agro Textiles

1. Conducting Standardized Tests

Accredited labs use globally accepted testing methods such as:

ISO 13934-1: Tensile strength of woven fabrics

ISO 4892-2: UV resistance through accelerated weathering

ASTM D5035: Grab test for fabric strength

IS 16008: Indian standards for shade nets and mulch mats

These standardized procedures ensure that the agro textiles are tested under controlled and repeatable conditions.

2. Evaluating Material Durability

Accredited labs simulate long-term usage of agro textiles by exposing them to:

UV light to test degradation

High and low temperatures to assess thermal aging

Mechanical stress to test wear and tear

This helps determine if a material can withstand multiple crop cycles without failing.

3. Verifying Crop-Specific Protection

Different crops have different environmental needs. For example:

Tomatoes require 30–50% shade nets

Lettuce may need insect-proof nets with specific mesh sizes

Grapes benefit from reflective ground covers for light management

Accredited labs test agro textiles for light transmission, air flow, permeability, and mesh density to match the textile’s performance to the crop’s requirements.

4. Ensuring Chemical Safety

Agro textiles may come into contact with fertilizers, pesticides, and herbicides. Accredited labs evaluate:

Resistance to chemical degradation

Leaching of harmful substances

Effect of cleaning agents and sprays

This ensures that the textiles do not degrade prematurely or harm the soil and crops.

5. Compliance with Export and Regulatory Standards

For manufacturers and exporters, accredited testing is essential for meeting:

REACH compliance in Europe

IS 16008 and BIS standards in India

OEKO-TEX certification for textiles near food products

GMP and GAP certifications for organic and high-value crops

Accredited labs issue valid certificates that are accepted by government bodies, buyers, and international markets.

6. Product Labeling and Quality Assurance

Based on the results from accredited labs, manufacturers can confidently label their products with:

Shade percentage (e.g., 50% or 75% shade net)

Lifespan (e.g., UV-stabilized for 5 years)

Mesh size (e.g., 40-mesh insect net)

Tensile and tear strength ratings

This transparency builds trust among buyers and farmers, and reduces the risk of field failure.

Benefits of Using Accredited Labs for Agro Textiles Testing

Benefit

Impact

Reliable Results

High accuracy and reproducibility in testing data

Global Recognition

Test reports accepted by international buyers and regulators

Quality Validation

Helps manufacturers differentiate their products

Reduced Crop Loss

Verified textiles reduce the risk of product failure in field

Regulatory Compliance

Ensures agro textiles meet mandatory government and export standards

Real-World Applications

✅ Greenhouses

Accredited labs test films for light transmission, thermal insulation, and anti-drip properties—ensuring optimal plant growth conditions year-round.

✅ Shade Net Houses

Shade nets undergo testing for shade factor, UV stability, and wind resistance to prevent crop burn and storm damage.

✅ Open Field Mulching

Mulch mats are tested for water permeability, weed resistance, and biodegradability to enhance soil health and moisture retention.

✅ Insect-Proof Farming

Labs test insect nets for mesh density, strength, and air circulation to safeguard crops from pests without using harmful chemicals.

How to Choose the Right Accredited Lab

When selecting a lab for agro textiles testing, consider:

ISO/IEC 17025 accreditation status

Experience with polymer and textile materials

Capability to test under national and international standards

Quick turnaround and detailed test reports

Client support and consultation services

Working with a reliable lab ensures accurate verification and adds value to your agro textile products.

Conclusion

Agro textiles are indispensable tools in modern, sustainable agriculture—but only if they perform as expected under real-world conditions. The role of accredited labs in verifying these materials is critical for ensuring crop protection, regulatory compliance, and long-term agricultural success.

By performing rigorous, standardized tests on shade nets, greenhouse films, insect screens, and mulch mats, accredited labs help manufacturers create reliable products and assist farmers in choosing the best tools for their fields. In the ever-evolving agri-tech landscape, agro textiles testing by accredited labs is the foundation of quality assurance and crop protection.

0 notes

Text

Title: Biomass vs. Solar and Wind: Choosing the Right Renewable Energy for Industrial Use

As India moves toward a cleaner and greener energy future, industries are under increasing pressure to shift from fossil fuels to renewable energy. Among the most discussed options are solar, wind, and biomass gasification. While each technology has its strengths, the right solution often depends on the industry type, location, and energy requirements.

In many cases, especially in agro-based or rural industries, biomass gasifiers offer a more practical and cost-effective solution. Veera Group, a trusted name in sustainable industrial solutions, is helping companies make this shift by providing advanced, high-efficiency biomass gasifier machines that are tailor-made for Indian industries.

Solar and Wind: Popular, But Limited

Solar and wind power are well-established renewable sources in India. They are ideal for large-scale grid feed-in or commercial campuses. However, they come with limitations for industrial use:

Intermittency: Solar only works during daylight, and wind depends on weather conditions. This inconsistency requires expensive battery backups or diesel generators.

Land Requirements: Large solar or wind farms need significant space—something not all factories or industries can spare.

Upfront Costs: While costs have dropped, the initial investment for solar or wind setups, especially with storage, can still be steep.

These challenges make solar and wind less viable for industries that need continuous power, thermal energy, or operate in semi-urban and rural areas.

Biomass Gasifiers: A Reliable Industrial Solution

Unlike solar or wind, biomass gasifiers generate energy on demand and are not reliant on weather or sunlight. These systems convert agricultural waste like wood chips, coconut shells, rice husk, and sawdust into producer gas—a clean, combustible fuel that can be used for:

Electricity generation

Thermal heating in boilers

Powering industrial machinery

Veera Group’s biomass gasifier machine is engineered for high-efficiency performance and reliability, specifically targeting industrial use cases. These machines are capable of running continuously, are easy to maintain, and utilize locally available biomass—cutting fuel costs and dependence on external suppliers.

Industrial Sectors Benefiting from Biomass

Numerous industries are now turning to biomass gasification for their daily energy needs. These include:

Textile units using it for hot water and steam.

Food processing units using it for roasting, drying, or baking.

Small manufacturing plants running machinery with electricity generated by gasifiers.

Veera Group has helped several industrial clients replace diesel generators with biomass systems—cutting both emissions and energy bills.

To explore such case studies and industry insights, check out the Veera Group Blog, where they regularly publish updates on renewable technologies and their industrial applications.

Why Industries Choose Biomass Over Other Renewables

Here’s a quick comparison table: FeatureBiomass GasifiersSolar EnergyWind EnergyReliabilityHigh (on-demand)Low (daylight only)Low (depends on wind)Industrial HeatingYesNoNoEnergy Storage NeededNoYesYesSpace RequirementLowMedium-HighHighFuel CostLow (local biomass)Free (after setup)Free (after setup)Initial InvestmentModerateHigh (with batteries)High

Clearly, for many industrial setups—especially in rural or agro-based sectors���biomass gasifiers provide a more stable and scalable energy solution.

Veera Group: Your Partner in Clean Industrial Power

With decades of experience in engineering and clean technology, Veera Group is at the forefront of India's industrial energy revolution. Their biomass gasifier machines are built with precision, tested under tough industrial conditions, and backed by expert support. Whether you're a small enterprise or a large-scale manufacturer, they offer custom solutions to help you transition smoothly to renewable energy.

Conclusion

While solar and wind are excellent renewable sources in the right context, biomass gasification stands out as the most practical choice for many industries—especially those looking for round-the-clock power and thermal energy. Thanks to Veera Group and their cutting-edge gasifier machines, Indian industries now have a reliable, sustainable, and cost-effective energy alternative.

0 notes

Text

Bluecraft Agro – Manufacturing Premium Starch Products in India

Bluecraft Agro is a distinguished leader in the starch manufacturing sector, committed to producing premium starch products that serve a wide array of industries. With years of expertise and advanced technology, Bluecraft Agro ensures high-quality output that meets the rigorous demands of food processing, textiles, pharmaceuticals, adhesives, and paper industries.

At Bluecraft Agro, the focus is on delivering starch solutions that not only enhance product performance but also contribute to sustainable and eco-friendly production practices. Our dedicated research and development team continuously innovates to develop modified starches and customized blends tailored to client needs, ensuring optimal functionality and consistency.

Equipped with modern manufacturing facilities, Bluecraft Agro adheres to stringent quality control standards. Every batch undergoes comprehensive testing to maintain purity, effectiveness, and compliance with international benchmarks. This commitment to quality has earned us a trusted reputation across domestic and global markets.

As one of the leading starch manufacturers in India, Bluecraft Agro is recognized for its customer-centric approach, reliability, and technical expertise. We pride ourselves on building lasting partnerships with clients by offering not only superior starch products but also responsive support and tailored solutions.

Bluecraft Agro stands out among starch manufacturers in India for its ability to cater to diverse industrial requirements with precision and efficiency. Our products are designed to boost productivity while adhering to environmental regulations, making us the preferred choice in the industry.

Being one of the foremost starch manufacturers in India, Bluecraft Agro’s dedication to quality, innovation, and sustainability continues to drive growth and success. Clients trust us for consistent supply and excellent service, making us a key player in India’s starch production landscape.

Choosing Bluecraft Agro means partnering with one of the best starch manufacturers in India, committed to delivering premium starch products that meet global standards and industry demands.

0 notes

Text

SMSR Gear Box manufacturer in Ahmedabad, India

In the fast-paced world of industrial operations, power transmission systems play a key role in maintaining consistent performance and productivity. One of the most widely used and efficient components in this category is the SMSR Gear Box (Shaft Mounted Speed Reducer). Known for its reliability and ease of use, the SMSR gear box is a vital part of conveyor systems and other heavy-duty equipment. Nisuka Industries, a leading Shaft mounted Gear Box manufacturer in Ahmedabad, India, is proud to offer high-performance gearboxes designed to meet demanding industrial needs.

What is an SMSR Gear Box?

An SMSR (Shaft Mounted Speed Reducer) Gear Box is a mechanical device mounted directly onto the driven shaft of a machine. It reduces speed and increases torque, providing smooth and efficient power transmission. Unlike traditional gearbox setups that require base plates and coupling alignment, SMSR gearboxes are compact and easy to install, saving both space and maintenance time.

At Nisuka Industries, we manufacture SMSR gearboxes with robust design, precision-machined components, and superior quality materials to ensure long operational life even under harsh working conditions.

Why Nisuka Industries?

With decades of experience in gearbox manufacturing, Nisuka Industries has become a trusted name for engineering excellence. We are recognized not only in Ahmedabad but throughout India for delivering performance-driven solutions that support the growth of industries such as cement, mining, steel, chemical, and agriculture.

As a reputed SMSR Gear Box supplier in Ahmedabad, India, we offer:

Precision Engineering: Each gearbox is made with accurate gear tooth profiles, ensuring low noise and smooth operation.

Heavy-Duty Construction: Made from high-grade cast iron and alloy steels, our gearboxes are built to last in rugged conditions.

Customization: We provide gearboxes tailored to customer specifications in terms of shaft size, gear ratios, and mounting preferences.

After-Sales Support: We believe in long-term partnerships, offering technical assistance, spare parts, and maintenance services.

Key Features of Nisuka SMSR Gear Boxes

Our gearboxes are engineered to deliver optimal performance, making us a reliable choice for industrial users. Key features include:

Easy installation and alignment with the driven shaft

High torque output and efficiency

Anti-corrosive body coating for long-term durability

Oil-sealed enclosures for maintenance-free operation

Available with or without torque arm and backstop arrangements

These features make Nisuka SMSR gearboxes ideal for conveyor systems, crushers, feeders, and other material-handling machinery.

Industrial Applications

As one of the most reliable SMSR Gear Box manufacturers in India, we cater to a wide range of industries, including:

Mining and Quarrying: For conveyors and crushers that demand continuous power.

Cement Plants: Supporting heavy conveyor belts in material movement.

Steel and Power Plants: Assisting in high-torque mechanical applications.

Agro Industries: Used in grain handling, fertilizer plants, and packaging units.

Textile and Chemical: Suitable for mixers, dryers, and rollers.

No matter your sector, our gearboxes are designed to operate under high load and varying temperatures with minimal breakdowns.

Quality and Manufacturing Excellence

Our facility in Ahmedabad is equipped with advanced CNC machines, gear-cutting equipment, and quality-testing systems. Every SMSR gearbox goes through rigorous checks for:

Gear accuracy and tooth strength

Shaft alignment and fitting tolerances

Noise and vibration levels

Lubrication system integrity

Heat dissipation capacity

This strict quality assurance system ensures that you receive gearboxes that perform consistently and exceed expectations.

Also a Conveyor Gearbox Manufacturer in India

At Nisuka, we also specialize as a Conveyor Gearbox Manufacturer in India, offering gearboxes specifically designed for heavy-duty material transportation. These gearboxes are used in bulk material handling systems across various industries and are known for their rugged design and reliable torque transfer.

Also a Plummer Block Manufacturer in India

We are also a trusted Plummer Block Manufacturer in India, producing high-precision blocks used to house and support bearings in rotating equipment. Our plummer blocks are machined to perfection, ensuring proper alignment and protection of shafts in demanding applications.

By manufacturing both gearboxes and essential components like plummer blocks, Nisuka provides a complete mechanical solution for industrial operations.

Location Advantage – Ahmedabad, India

Being based in Ahmedabad, a major hub for engineering and manufacturing, allows us to respond quickly to customer demands and maintain competitive pricing. With access to a skilled workforce, modern infrastructure, and reliable transportation, we serve clients across Gujarat, Maharashtra, Rajasthan, and other states efficiently.

Commitment to Customer Satisfaction

Nisuka Industries is built on values of quality, service, and trust. From product selection to technical support, we focus on offering solutions that match your operational needs. Our team of engineers and service experts work closely with clients to ensure smooth installation, optimal performance, and long-term satisfaction.

Conclusion

If you're looking for a reliable SMSR Gear Box Manufacturer in Ahmedabad, India, choose Nisuka Industries for quality that speaks for itself. Our gearboxes are known for durability, efficiency, and cost-effectiveness across a wide range of industrial applications.

Whether you need a shaft-mounted gearbox, a custom conveyor drive, or a heavy-duty plummer block, Nisuka is your one-stop destination for mechanical transmission excellence.

#SMSR Gear Box manufacturer in Ahmedabad#SMSR Gear Box supplier in Ahmedabad#SMSR Gear Box exporter in Ahmedabad

0 notes

Text

More than Agriculture: Different Uses of Phosphorous Oxychloride

Phosphorous Oxychloride is one of the active compounds which is used in various products. While the main use of the compound is in Agriculture, however, it is used in the manufacturing of optical lenses along with the usage in the textile industry. Moreover, certain products such as batter manufacturing and the Automotive industry rely on Phosphorous Oxychloride highly because of semi-conductors that are found in Electric Vehicles.

Overview Phosphorous Oxychloride is a potential compound that is used in the making of Pesticides and manures which are high-demand products for the Agricultural Industry. It is Pale yellow and is a valuable compound. Moreover, being cheap, it can be used in pesticides. While it is quite helpful in eliminating pests and small insects from the agro fields, apart from killing and eliminating small pests and insects, it also helps in binding the crops better way. Phosphorous Oxychloride, apart from being used in agriculture, is also used as an additive in engine oils and petroleum that improves engine performance and provides longevity to the engines of cars and bikes. In many cleaning agents, the use of Phosphorous Oxychloride is evident as it can take out hard stains and can clean a specific area effectively.

Different Uses of Phosphorous Oxychloride The following are different uses of Phosphorous Oxychloride

Automotive- In the production of car engine oils and petrol additives, Phosphorous Oxychloride is used which enhances the bonding between the engine and the power, it enables a sticky surface that allows the engine to work freely and smoothly. In electric vehicles, semiconductors are used which is needed for the battery of the cars. The car batteries are doped using impurities for which Phosphorous Oxychloride is also used.

Medicinal usage- The compound is often reactive for which it is highly used for medicinal purposes. Phosphorous Oxychloride is used in the creation of Anti-inflammatory drugs. Moreover, phosphate esters are needed for the development of medicines. Thus, it can be used in the production of medicines that require high-quality easters.

Textile- The use of Phosphorous Oxychloride in the textile industry is also quite common. Often clothes are designed to retard flames so that they do not catch fire easily. The compound can be added to the threads or even to the finished clothes so that they do not catch fire and can provide safety. The fabrics need to be strengthened for which the use of Phosphorous Oxychloride is quite helpful. This is one of the most effective ways by which the fabrics can be strengthened and harsh tests can be performed on the cloth.

Optical uses- In certain types of lenses, the compound is extremely helpful. Because of its refractive nature, the material can be used in the lens. Moreover, it is used in the coating's special lens which provides clear vision. The chemical is quite popular and its uses are also extended in the preparation of contact lenses.

Plastic manufacturing- The manufacturing of plastic products such as bottles and containers needs the help of Phosphorous Oxychloride for resin manufacturing. Polycarbonate products are manufactured with the help of Phosphorous Oxychloride.

0 notes

Text

Who Is The Best Sewage Treatment Plant Manufacturer In Gurgaon ?

Situated in Haryana’s Southern area, Gurgaon is a significant hub for both agriculture & commerce. Gurgaon's output of industrial & residential sewage has increased over time due to rapid industrialization & population expansion. Gurgaon has to treat these wastewater streams effectively in order to manage its water resources sustainably, reduce pollution, & allow for the reuse of treated water.

While STPs handle sewage from residential & commercial sectors including handling industrial processed effluents. An essential component of a manufacturer attempts to grow sustainably is the operation of well-planned & managed Sewage Treatment Plant Manufacturer in Gurgaon.

Gurgaon major Sewage Treatment Plants' Functions & Needs with related demands

Textile, pesticide, rubber processing, distilleries, steel rolling, & agro-processing plants are among the industries located in Gurgaon. These STP units' sewage includes organic materials, suspended particles, solvents, heavy metals, oil & grease, & a high chemical oxygen demand.

In Gurgaon, the direct release of untreated sewage into rivers, lakes, & land results in high pollution levels that endanger human health, groundwater supplies, & aquatic life.

STP plants are necessary to treat this sewages utilizing physio-chemical & biological techniques to allowable levels before ultimate disposal following discharge guidelines provided by pollution control agencies. Waterbodies are shielded from future industrial contamination by STP plants manufactured by a good Sewage Treatment Plant manufacturer in Gurgaon.

In addition to residential or industrial sewage effluents, Gurgaon’s increasing urban development & population growth have led to a rise in the amount of sewage produced by homes & businesses. Organic waste, nutrients, pathogens, & chemicals can all be found in domestic sewage.

When untreated unprocessed sewage falls into water treatment systems, it contaminates groundwater as well as the surface water. STP plants efficiently treat sewage to remove impurities while keeping it environmentally safe through the implementation of sedimentation vessels, clarification systems, screening or filtration systems, activated sludge processes, plus chlorine dosing systems.

Gurgaon’s overall growth in the industrial & municipal sectors necessitates the need for Sewage Treatment plants with the capacity to treat sewage & industrial effluents to regulations before disposal. This will enable Ratlam to expand & manage its water resources sustainably without having an adverse effect on the environment or public health. Commercial RO Plant is the best sewage treatment plant manufacturer in india at best affordable price and the quality.

Manufacturing Experience & Appropriate Knowledge of Netsol Water about STP Plants

The leading provider of end-to-end solutions for STP plant design, engineering, supply, mounting as well as installation, testing, commissioning, & operation is Netsol Water. With more than ten years of extensive industry expertize, we provide tailored STP systems that utilize world-class trending technology to meet the treatment requirements of various municipalities & companies in Haryana.

Based on sewage characteristics & specified discharge norms, we design & build complete STP facilities for industries in Gurgaon, comprising collection, equalization, primary, secondary, & tertiary treatment units.

Our expertize resides in the most economical efficient treatment of complicated residential & commercial sewage released, through the application of appropriate technologies such as filters, diffused aeration, activated carbon, & advanced oxidation.

In various sectors of a city for sewage treatment, Netsol Water provides typical advanced, world-class, & tertiary STPs. From conception to completion, we complete STP projects that include process planning, hydraulic analysis, equipment size, setup, evaluation, & operator training. Technologies including SBR, MBBR, MBR, & Activated Sludge Process are employed & utilized by our STP partners following project specifications.

Being a company that cares about sustainability, we incorporate technology like automation, solar power, & remote monitoring into our designs to improve plant performance while minimizing carbon emissions.

By utilizing process control, preventative maintenance, & constant performance monitoring, our treatment systems continuously satisfy the CPCB as well as Haryana Pollution CB specified discharge criteria. We are the most eligible Staff at Netsol Water that helps their customers get regulatory approval for their STP Plant orders very quickly.

Conclusion

Ability of this town to expand sustainably is largely dependent on itsSTP Plants designed by a reputed & good Sewage treatment plant manufacturer in Gurgaon such as Netsol Water, which treat sewage or even effluent to a pre-determined criteria before disposing of them. Most important STPplant manufacturer in Gurgaon, Netsol Water incorporates best of the advanced & modern innovative treatment technology to offer specialized end-to-end solutions from idea to commissioning.

Several companies can comply with effluent discharge requirements & maintain clean water bodies thanks to the solutions provided by Netsol Water. Gurgaon can successfully overcome its wastewater treatment issues & continue its journey of planned, environmentally responsible expansion throughout the industrial & municipal sectors thanks to its competence in developing & implementing sewage treatment projects simultaneously followed by ETPs as well.

0 notes

Text

Seeds for Softness: India's Trailblazing Cotton Seeds Manufacturers

In the heartland of Indian agriculture, where the cotton fields stretch like a sea of white, the role of cotton seeds manufacturers is crucial. This article explores the world of trailblazing cotton seeds company in India, delving into their contributions to the textile industry and the nation's cotton cultivation. From genetic advancements to sustainable practices, these manufacturers are pioneering the way for a softer and more resilient cotton industry.

The Cotton Landscape in India:

India has a rich history of cotton cultivation, and today it stands as one of the largest producers and exporters of cotton in the world. The softness and versatility of Indian cotton have made it a sought-after commodity for the textile industry globally. At the core of this success are the cotton seeds manufacturers, who continually innovate to enhance the quality and yield of cotton crops.

Pioneering Genetic Advancements:

Leading the charge in India's cotton industry are manufacturers who invest significantly in genetic advancements. These advancements result in the development of high-yielding and disease-resistant cotton varieties. By employing cutting-edge breeding techniques and biotechnology, these manufacturers contribute to the creation of cotton seeds that not only ensure a bountiful harvest but also improve the overall quality of the cotton fibers.

Quality Assurance for Premium Fibers:

Quality assurance is paramount in the production of cotton seeds, as it directly influences the quality of the cotton fibers harvested. Trailblazing cotton seeds manufacturers implement rigorous testing procedures to guarantee the purity, germination rates, and genetic traits of their seeds. This commitment to quality ensures that farmers receive seeds that lay the foundation for premium cotton fibers, meeting the stringent requirements of the textile industry.

Sustainable Practices in Cotton Farming:

As the world increasingly recognizes the importance of sustainable practices, cotton seeds manufacturers in India are taking steps to promote environmentally friendly farming. Sustainable cotton farming involves optimizing water usage, reducing pesticide and fertilizer inputs, and implementing eco-friendly cultivation methods. Manufacturers advocating for sustainable practices contribute not only to the ecological balance but also to the long-term viability of cotton farming.

Tailoring Seeds for Different Agro-climatic Zones:

India's diverse agro-climatic zones demand a tailored approach to cotton cultivation. Trailblazing cotton seeds manufacturers understand the importance of developing varieties that thrive in specific regions. Whether it's the arid landscapes of Gujarat or the humid plains of Maharashtra, these manufacturers create seeds optimized for local conditions, ensuring maximum yield and quality in each cotton-growing region.

Farmers' Empowerment through Technology:

Empowering farmers with knowledge and technology is a key focus of progressive cotton seeds manufacturers. These companies provide farmers with access to modern agricultural practices, pest management strategies, and the latest technological innovations. By organizing training sessions, workshops, and field demonstrations, manufacturers ensure that farmers have the tools and knowledge to optimize their cotton yields.

Research and Development for Cotton Innovation:

Investment in research and development is a hallmark of trailblazing cotton seeds manufacturers. These companies collaborate with agricultural research institutions, biotechnologists, and geneticists to stay at the forefront of cotton innovation. The continuous improvement of cotton varieties, including the development of genetically modified seeds, plays a pivotal role in sustaining and enhancing India's cotton industry.

Government Collaborations and Regulatory Compliance:

Collaboration with government agencies and adherence to regulatory standards are crucial for cotton seeds manufacturers. Leading manufacturers work closely with governmental bodies to align their initiatives with national agricultural goals. Compliance with seed quality and biotechnology regulations ensures that the seeds produced meet the necessary standards, fostering a robust and regulated cotton industry.

Conclusion:

In the dynamic landscape of Indian agriculture, cotton seeds manufacturers stand as trailblazers, steering the nation's cotton industry towards innovation and sustainability. Through genetic advancements, quality assurance, sustainable practices, regional customization, farmer empowerment, research and development, and collaborations with government bodies, these manufacturers play a pivotal role in ensuring the softness and success of India's cotton industry. As they continue to sow the seeds of progress, the future promises a cotton landscape that is not only softer but also more sustainable and resilient.

0 notes

Text

Elevating Textile Innovation: Madaan Engineering's Superior Electronic Jacquard Machines

In the vibrant textile landscape of India, where precision and efficiency are paramount, Madaan Engineering emerges as a beacon of excellence, especially in the realm of Electronic Jacquard Machines. While Bangalore is recognized as a tech hub, Surat is a textile powerhouse, and Madaan Engineering seamlessly bridges these worlds with its cutting-edge electronic jacquard offerings.

Madaan Engineering's Technological Marvels:

Madaan Engineering, a prominent player in the electronic jacquard manufacturing space, has carved a niche for itself by consistently delivering products of unparalleled quality. The company's electronic jacquard machines showcase a perfect amalgamation of innovation and reliability, catering to the evolving needs of the textile industry.

Precision Redefined:

Bangalore, renowned for its technological prowess, demands precision in every aspect, and Madaan Engineering rises to the occasion. The electronic jacquard machines crafted by Madaan Engineering are a testament to meticulous engineering, ensuring intricate patterns are woven with utmost accuracy. The machines provide textile manufacturers in Bangalore with the tools they need to stay at the forefront of innovation.

Surat's Textile Heritage meets Madaan's Excellence:

Surat, a city synonymous with textiles, requires machinery that can keep pace with its legacy of craftsmanship. Madaan Engineering's electronic jacquard machines cater to the city's rich textile heritage by enhancing efficiency and productivity. These machines empower manufacturers in Surat to weave intricate designs seamlessly, meeting the demands of the modern textile market.

Quality Assurance – Madaan's Forte:

Madaan Engineering's commitment to delivering superior quality is the cornerstone of its success. Each electronic jacquard machine undergoes rigorous testing to ensure it meets the highest industry standards. The company's dedication to quality not only enhances the performance of the machines but also establishes a trust factor among its clientele.

The Future of Textile Innovation:

As the textile industry in India continues to evolve, electronic jacquard machines have become indispensable for achieving intricate designs and patterns. Madaan Engineering, with its state-of-the-art technology and unwavering commitment to quality, stands poised at the forefront of this transformation, shaping the future of textile innovation in both Bangalore and Surat.

In conclusion, Madaan Engineering's electronic jacquard machines represent a perfect blend of precision, reliability, and technological innovation. With a focus on delivering top-tier products, the company remains a key player in the electronic jacquard manufacturing landscape, contributing significantly to the growth and advancement of the textile industry in India.

CONTACT US TODAY:

+91 - 9812003292, +91-8607603344, +91-9996133347 0180-3551641 [email protected] [email protected] Office / Work Madaan Engineering Works Pvt Ltd.

E-67, Old Industrial Area, Near Gole Chakker, Panipat - 132103, Haryana(INDIA)

Work - Madaan Agro Industries Kabri Road, Near TDI Bypass, Panipat 132103 Haryana INDIA

#jacquard machine price in india#disc harrow manufacturers in india#madaan jacquard panipat#agriculture implements manufacturer in india#electronic jacquard manufacturers in panipat#disc plough manufacturers in india#jacquard suppliers in panipat

0 notes

Text

Made-in-Pakistan: Improving Global Perceptions

The ‘Made-in-Pakistan’ label has the potential to become a symbol of repute, but this aspiration must be vigorously pursued. If we are to consider the increased digitization of markets in the wake of COVID-19 as an opportunity, with advanced tools and greater access to buyers, these tools must be used to address the international branding of our products, so that a label bearing our country’s name not only becomes a marker of great quality, but also a motivation to buy by choice. This would require an environment that facilitates exporting industries to focus on quality improvement through new processes, thereby developing new products and entering fresh markets.

Despite having low-tariff access to textile and apparel markets of the European Union, USA, Japan and China, Pakistan’s market share is low, which shows an inability to fully leverage our position as a textile-dominated economy, losing critical expansion opportunities to regional competitors. In addition, the EU and USA are now largely considered to be shrinking markets, and by continuing to focus on these rather than on expanding markets, our policies contradict global trends. Asian competitors have gained significant market shares from 2011-18 while Pakistan’s share decreased by 2.17%. It is not as if they possess something we don’t; rather their development of supporting policies, intelligent branding, market forecasting and diversification has helped them to excel.

Market Shares

China (33%) is the leading exporter of textiles in World followed by India (4.7%) & Bangladesh (4.6%). Pakistan’s share is only 1.7%.

When considering emerging textile markets, our best bet is to target those segments which have less market saturation by competitors. According to a report by the AfDB, Africa currently accounts for 1.9% of global trade, and trends have showcased it to be a major textile player in the near future. As stated by Hans Rosling, the African market is by far the largest potential market of the future. In order to preemptively capture this opportunity, we must enhance trade with Africa in order to secure a foothold in the fastest rising market in the world. Given that imports from China are restricted, South Africa is one country that offers ample opportunities for Pakistan to leverage. Furthermore, trade data for 2019 from Botswana, Mozambique, Lesotho, Swaziland, Namibia and South Africa has shown that despite growing demand, textile related exports from Pakistan to these countries added up to a mere $114 million. The demand for textile continues to rise in these countries, so to capture market share, the industry must focus on trade and connectivity and the Ministry of Commerce must facilitate it. Reduction in tariff and non-tariff barriers by both sides would serve as a catalyst for accelerated growth in bilateral trade.

While it is often assumed that manufacturing inputs in Pakistan come cheap, this disregards the poor productivity and very real hindrances in power and logistics that raise costs of doing business. With numerous policy setbacks, and energy and infrastructural impediments at each level, exporters have been so caught up in trying to manage day-to-day affairs and onerous bureaucratic hurdles that there is little revenue left to be competitive, let alone consider a marketing plan. There is also a shortage of skilled labor in textiles, chemicals and hosiery/bed linen. Firms regard inadequate institutional training and the low quality of education as the most important reasons for the lack of labor skills, thereby hindering competitiveness.

Pakistan’s textile industry comprises an entire value chain from cotton production to prêt-à-porter and export, although it is more concentrated in the lower value-added end of the chain. The fragmentation of the supply chain falls into two main sectors: the formal sector, which involves spinning units/textile mills, and the informal sector, where sewing, knitting, as well as clothing and towel production fall under the scope of SMEs and small cottage units. In a fast-paced global market, the primary reliance on traditional goods in Pakistan is becoming a burden rather than worth maintaining. Textiles and clothing have accounted for nearly 60 percent of Pakistan’s export basket for more than a decade, and while this allows for a significant advantage in this sector, that advantage is not being leveraged as well as it could be. Other South Asian economies have diversified their export baskets to not only capture an abundance of untapped markets, but to increasingly tap into high-value-added products that utilize advanced technologies in their production. Pakistan must mitigate its reliance on primary and traditional goods and machinery and shift towards the export of value added, nontraditional goods. Only then can the country market itself effectively as a textile supplier that meets the greatest number of needs of global consumers.

With a myopic focus on short staple fiber raw cotton, we are essentially relying on a shrinking market while neglecting the rapidly expanding market for MMF. The MMF tariff regime effectively prevents Pakistan from aligning its products in tandem with the rest of the world. More than 60% of world textile trade is in MMF materials, the demand for which has grown exponentially owing to the convenience it affords as a cheap material used in the production of the ever-relevant active-wear trend. However, the duty protection given to obsolete plants in Pakistan is denying the Pakistani industry any chance to compete in this booming market, internationally or domestically. This brings us to the issue of polyester staple fiber, a raw material of the industry upon which it would be unreasonable to apply any duties. Alarmingly, at present there is a 7% customs duty on the import of polyester staple fiber. This racks up the total import duties, which subsequently fall in the range of 20% including antidumping duty. Despite the antidumping duty on cheap Chinese materials having expired, the duty has been extended for a further year.

This highlights the need for a policy environment and a tariff structure which favors global market needs, which are likely to be linked to synthetic fibers for the foreseeable future. The goals of the industry must remain aligned with the demands of the market, and this requires the industry to equip labor with new technologies and train them in the latest skills, thus shifting them from primary to secondary and tertiary activities. Agriculture must diversify into high value-added products, reduce the loss of fertile land to real estate speculations, improve domestic marketing systems, improve water management and set up centers for agro-genomics. In addition to investment in increased capacity and technology, there is a need to improve local design capacity through new clusters for training, design and testing and better managerial practices. Furthermore, the quality of these products should not be compromised at any level, as creating more processed products that rank later in the value-chain is no objective if quality is not simultaneously improved.

When it comes to apparel and ready-made garments, brands that have made it global have some pre-existing structures that have been instrumental in their success. Firstly, they largely benefit from being rooted in a more globally appealing culture, i.e. Zara specializes in Western fast fashion and streetwear, which is largely adaptable and worn across the globe. After all, fashion is an off-shoot of culture and its transferability depends on the culture of the origin country. In comparison, our signature shalwar kurta does not have an international appeal, save for our diaspora. If Pakistani brands aim to go global they need to introduce product ranges that cater to a wider and more diverse audience. Secondly, success stories in the global space relied on the existing clusters of the origin country’s textile industries. To mimic this, siloed efforts within the private sector in Pakistan need to join hands and work towards mutual success. Thirdly, once a Pakistani brand decides to go global it will have to reconsider its existing linkages. A common theme among global success stories is the disruption or specialization of supply chain models. Apart from aiming to supply to these internationally acclaimed fashion brands, if Pakistani brands can realistically emulate their business model, it could be the impetus for a booming industry.

Pakistani brands that have adopted a similar business model and targeted international consumer include Khaadi and Rastah. Behind efforts to export more and provide the country with valuable jobs and foreign exchange, there is a lot of effort and craftsmanship that goes into creating textile products, representing local talent and skills that should be showcased to the world via effective marketing. Khaadi was launched back in 1998 by introducing hand-woven kurtas. With its launch, it gained recognition for its distinctive embroidery designs, which reflected our traditional wear with a modern look. Khaadi soon expanded to create Western cuts without compromising on the traditional patterns of Pakistani culture. Intricate embroidery and block printing represent our rich South Asian heritage in a globally appealing way, and Rastah is a brand that has managed to achieve a blend of traditional Pakistani patterns and designs with Western streetwear cuts and styles.

Product planning is a crucial marketing activity in the garments industry. However, it is contingent upon ensuring product quality, developing attractive packaging, constantly innovating, distributing through the best middlemen, and maintaining an efficient inventory management system. Pricing lower than other countries and providing discounts to buyers is essential for competitiveness. At the same time, quality certification and adherence to health, labor, and environment standards is of utmost importance for exporters. However, awareness of these standards remains limited, thereby hindering quality assurance, and the procedures to avail the facilities provided in this regard are unnecessarily complicated. Measures must be taken to raise awareness and simplify procedures so that the maximum number of products can be brought up to an international standard. Given that a number of Pakistani textile firms are domestically owned and vertically integrated, activities like designing and branding can play an instrumental role in bringing the textile sector greater acclaim. As another measure to ensure vertical integration and a more diversified product mix, international buying houses should be incentivized to open outlets in Pakistan, with supporting policies such as tax exemption and free office and warehousing space. This would enable a larger geographical spread and allow for the goal of new products, processes and markets to be streamlined.

The Textile Policy for 2020-2025 proposes certain marketing strategies that go hand-in-hand with changing consumer behavior and technological upgradation. The strategies are outlined below:

Showcasing Products: an exhibition plan is to be developed in consultation with textile stakeholders and support from the Ministry of Commerce. The Ministry of Commerce has already initiated process of holding virtual exhibitions. In addition, Pakistan’s first virtual fashion show took place in June 2020 in the midst of the COVID-19 pandemic, following a global trend of continuing the tradition safely. The plan also suggests holding the dedicated textile exhibition ‘TEXPO’ every year rather than alternate years, and expanding it to other countries.

Digital Marketing: this has already played a vital role in showcasing textile products and attracting new business. The Textile Wing, Ministry of Commerce has created a one stop E-Portal for this purpose. However, SMEs do not have ease of access to this portal, so measures are needed to make it more SME-friendly.

Market Access: The Ministry of Commerce is already in negotiation with developed and developing economies for market access. Competitor countries have taken bold steps by opening their markets, thereby securing access to major markets. Following this strategy, we must formulate a road map to increase market access, while remaining cognizant of the fact that this would be on a reciprocal basis and our market openness would also have to increase.

E-Commerce: Our first-ever e-commerce Policy is in the implementation phase, with the objective of giving open access to textile manufacturers/exporters to tap into business opportunities across the globe. Amazon has started registering Pakistan manufacturers and exporters including textiles. Ease of access must be granted to SMEs as well.

Exporters are presently allowed to retain / utilize 10% of export proceeds for marketing without requiring permission from SBP. Steps must be taken to extend this facility, allowing the establishment of development centers, design & marketing offices, near shore manufacturing, warehousing etc.

Moving forward, we must enable our textile industry to climb further up the value chain into original brand manufacturing (OBM) and original design manufacturing (ODM) categories. This will require support in development of skills eco-system around design and branding to capture higher value, and the development of fast-fashion design districts in Karachi and Lahore with strong academic linkages e.g., NCA and IVS. Furthermore, the industry must focus on the collection of relevant data. Hiring skilled graduates who can gauge emerging trends would make data collection more reliable and thereby significantly improve international marketing and branding. Finally, measures must be taken to promote private investment in the industry, contingent upon interest rate support and a reputation for never compromising on quality.

Some opportunities to attract investment and achieve expansion include the regional Textile Production-Consumption Hub, FTA 2nd phase with China, EU GSP+ until 2023 and a growing domestic market. CPEC in particular will allow the industry to leverage Chinese technology, efficiency and discipline to enhance its existing potential as well as to initiate new projects for higher value. CPEC’s improvements in infrastructure have improved trade routes, mitigated constraints to growth, and led to the establishment of Special Economic Zones (SEZs) to enable smooth supply chains, enhanced innovation and economies of scale. Remaining on this track, CPEC has the potential to significantly boost industrialization and double Pakistan’s exports in four years, while also generating around 2.3 million new jobs in the country.

It is essential to promote foreign collaborations and joint ventures to improve technology, marketing and manufacturing processes, to introduce new technology and build brands. Pakistan's export-oriented industries are 25 percent more productive than non-exporting firms, and their productivity increases as exports increase. However, inefficiencies cannot be exported, so these must be mitigated from all input materials before results can be seen. Since exports in Pakistan are labor-intensive, expansion in this industry is a way to ensure large-scale job-creation, and an increase in foreign currency to pay for required imports. With the right policies in place, a diversified set of high quality exports will provide a crucial uplift to economic activity and lead to a cycle of development and improvement in perception.

3 notes

·

View notes

Text

Top Testing Parameters in Agro Textiles: Strength, UV Resistance, and More

As the global agriculture industry rapidly adopts innovative technologies, agro textiles have emerged as a vital component for enhancing crop productivity, conserving resources, and supporting sustainable practices. From shade nets and ground covers to mulch films and insect-proof screens, agro textiles serve a wide range of agricultural applications. However, to ensure these products perform effectively in real-world conditions, they must undergo comprehensive Agro Textiles Testing.

In this blog, we’ll dive into the most critical testing parameters for agro textiles, including tensile strength, UV resistance, air and water permeability, tear resistance, and durability under environmental stress. Understanding these parameters helps manufacturers, exporters, and farmers make informed decisions about product quality and performance.

What is Agro Textiles Testing?

Agro Textiles Testing refers to a systematic evaluation of the physical, chemical, and mechanical properties of fabrics designed for agricultural use. Testing is essential to:

Ensure material suitability for specific farming conditions

Comply with national and international standards

Prove durability, safety, and efficiency

Support product certification and export documentation

The testing is usually conducted by ISO/IEC 17025-accredited laboratories, following global standards such as ISO, ASTM, and EN.

Why Testing Agro Textiles is Important

Agro textiles are used in outdoor environments where they are exposed to:

Sunlight (UV radiation)

Mechanical stress (wind, handling)

Water and chemical exposure (irrigation, pesticides)

Temperature extremes

Inadequate performance in any of these areas can lead to crop damage, wasted investment, and regulatory non-compliance. Testing ensures that agro textiles are fit for purpose, offering consistent protection and support for plants and soil.

Key Testing Parameters in Agro Textiles

1. Tensile Strength

Tensile strength measures the maximum force a fabric can withstand before breaking. It is one of the most critical parameters, especially for:

Shade nets

Crop covers

Windbreak screens

Test Standard:

ISO 13934-1

ASTM D5035 (for strip method)

Purpose:

Ensures the material can handle physical stress from wind, installation, or handling without tearing.

Verifies durability in field conditions.

2. UV Resistance

Exposure to ultraviolet (UV) radiation can degrade polymer-based textiles, leading to brittleness, color fading, and loss of structural integrity. UV resistance testing simulates prolonged exposure to sunlight.

Test Standard:

ISO 4892-2 (Xenon Arc)

ASTM G154 (Fluorescent UV)

Purpose:

Determines how long the fabric will last in outdoor use.

Validates manufacturer claims on service life (e.g., 3 years, 5 years).

Essential for agro textiles used in tropical and high-sunlight regions.

3. Tear Resistance

Tear resistance measures a fabric’s ability to resist propagation of a tear once it begins. Agro textiles often face mechanical damage during installation or from weather events.

Test Standard:

ISO 9073-4 (Elmendorf tear test)

ASTM D1424

Purpose:

Ensures textiles won’t quickly degrade from small tears.

Crucial for mulch films and greenhouse fabrics exposed to frequent wear and tear.

4. Air Permeability

Certain agro textiles, such as insect-proof nets and shade fabrics, need to allow air to pass through for ventilation while blocking pests or sunlight.

Test Standard:

ISO 9237

Purpose:

Verifies comfort and airflow for crops in greenhouse or net houses.

Balances protection and aeration, supporting plant health.

5. Water Permeability

Water permeability tests are especially important for ground covers, mulches, and erosion control mats, where water must pass through while retaining soil and nutrients.

Test Standard:

ISO 11058 (Vertical water permeability)

ASTM D4491

Purpose:

Confirms proper drainage and irrigation efficiency.

Prevents waterlogging or excessive drying of soil.

6. Puncture Resistance

Puncture resistance evaluates how well the textile can withstand sharp objects like rocks, plant stems, or machinery. This is especially relevant for soil covers and geotextiles.

Test Standard:

ASTM D4833

Purpose:

Measures the toughness of the fabric under point loads.

Enhances product longevity in rugged field conditions.

7. Weight and Thickness (GSM & mm)

The mass per unit area (GSM) and thickness of agro textiles directly impact their strength, UV resistance, and cost-effectiveness.

Test Standard:

ISO 3801 for GSM

ASTM D1777 for thickness

Purpose:

Helps standardize product specifications for manufacturers and buyers.

Assists in selecting the right material for specific applications.

8. Biodegradability and Eco-Toxicity

For biodegradable agro textiles made from natural fibers (like jute or coir) or biopolymers (like PLA), biodegradability tests are essential to prove environmental claims.

Test Standard:

ISO 14855

ASTM D5338

Purpose:

Validates whether the textile safely degrades without harming soil or water.

Important for organic and sustainable agriculture markets.

9. Color Fastness and Aging

Some agro textiles need to retain color under sun exposure, particularly for colored shade nets used in light management farming.

Test Standard:

ISO 105-B02 (Color fastness to light)

Accelerated aging simulations

Purpose:

Prevents color fading and material breakdown.

Supports branding and performance over time.

How Accredited Labs Conduct Agro Textiles Testing

To ensure reliability, agro textiles should be tested at ISO/IEC 17025-accredited laboratories. These labs provide:

Standardized procedures using calibrated equipment

Reproducible and traceable test results

Detailed technical reports for certification and compliance

Support for export documentation and regulatory submissions

By testing with an accredited lab, manufacturers and exporters can confidently market their products globally, meet regulatory requirements, and win trust from buyers.

Final Thoughts

As demand for high-performance, eco-friendly, and export-ready agro textiles increases, thorough testing becomes essential. By evaluating critical parameters such as strength, UV resistance, tear durability, and permeability, agro textiles testing helps manufacturers:

Deliver reliable products for agriculture

Meet regional and international compliance standards

Reduce product failures and customer complaints

Win new markets with certified performance

Whether you are producing shade nets for greenhouse farming, mulch films for organic crops, or insect nets for pesticide-free protection, partnering with an accredited agro textiles testing lab is the smart way to ensure quality, safety, and success.

0 notes

Text

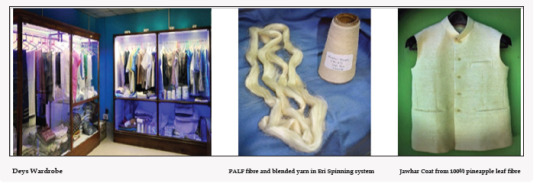

Lupine Publishers | Future Prospect for Sustainable Luxury Textiles from Pineapple Leaf Fibre - An Agro Waste

Lupine Publishers | Journal of Textile and Fashion Designing

Abstract

The treasure of Major natural fibres belongs to cotton, jute, wool, silk, flax, sisal and Manila hemp which are extensively used across the globe. Besides, a large number of fibres grown in lesser quantities throughout the world have local economic importance and are consumed locally. Utilization of underexploited, unexplored natural fibres from crop waste are not only critical issues in the international scenario but are also the need of the hour in developing countries like India to search out a suitable avenue for which separate spinning system is not widely available or established. Pine apple leaf fibre successfully tested as a base material for conveyor belts in the early eighties, could well have been the magic yarn of the day. Pineapple leaf fibre extracted from the green pineapple leaf, an agro waste reveals its immense potentiality in the field of textiles particularly due to the disposal problem after harvesting for cleaner and green environment.

PALF is well known for its silky lustre which possesses some advantageous physical and chemical properties like high tensile strength, dimensional stability, considerable resistance to heat and fire, and good dyeability while the demerits are coarseness, inextensibility. Besides, it is a low cost renewable resource and eco-friendly material. If the apparent demerits can be masked, a diverse range of products can be developed by exploiting the intrinsic properties of PALF. One of the ways of masking is blending of PALF with natural and synthetic fibres. It is felt that such binary blending will help development of textiles with better functional properties by combining positive features of the constituent fibres. Therefore, binary blending will give a wider application for production of value added diversified products which are the need of the hour.

The paper also delineates suitable processing technique for blending of PALF with different natural and synthetic fibres for conversion into textiles using existing fibre processing system since there is no specialized spinning system available for pineapple and their possible commercial utilization. The PALF blended yarn has a bright future prospect for sustainable luxury textiles like fancy apparel products (Figure 1).

Introduction

Wealth from waste is no more a slogan in 21st century but achieved successfully turning pineapple leaves into wealth which not only creates green environmental sense but also turns waste into wealth. Resource depletion and global warming have driven each industry to move toward a greener and sustainable industry. Lignocelluloses, the most abundant renewable biomass is composed of cellulose, hemicelluloses and lignin, as well as other minor components. Pine apple leaf fibre successfully tested as a base material for textiles in the early eighties, could well have been the magic yarn of the day. Research work on pineapple leaf fibre, an agro waste reveals its immense potentiality in the field textiles particularly technical textiles. Sufficient fibre will be available to arouse interest if the fibre is extracted commercially. Due to non-availability of specialized spinning system for PALF in India, it will be much easier to promote PALF in any of the existing spinning systems provided an appropriate processing technology is developed.

Major natural fibres belongs to cotton, jute, wool, silk, flax, sisal and Manila hemp which are extensively used across the globe possess suitable processing technology and developed machinery. Besides, a large number of fibres grown in lesser quantities throughout the world have local economic importance and are consumed locally The pineapple plant AnanasComosus (L) is a member of the family Bromaliaceae of the monocotyledonous, containing 1,300 species; most of which are native to tropical America. Although over nearly 90 varieties of the plants cultivated in various parts of the world, only 3 varieties, namely, Kew, Queen and Mauritius are cultivated commercially. The form of pineapple leaves varies and depends on the position of the stem and age.

According to the data available, Pineapple fibre can be profitably produced in Tripura as well as Siliguri in West Bengal, where extensive pineapple farming takes place. In India, Pineapple leaves are never cut off, and are cleared when the plants naturally shed them. As a result, fewer pineapple plants are grown in India, as the leaves cover a lot of space. In countries like Brazil where extensive pineapple farming is done the leaves are cut away to make space for more plants. "We have gone through the science of it- Interestingly, cutting away of the leaves does not harm the plant and in fact helps it grow bigger fruit, as the leaves normally draw away a lot of the nourishment” says Dr. S. K. Dey, Senior Scientist of ICAR-CIRCOT, Mumbai. Indian farmers mostly throw away the leaves. Research on plantation has established that the leaves can be cut three times a year, without harming the harvest and suitably designed industry for pineapple leaf fibre, can run the year-round on these supplies.

The philosophy of blending between two fibres depends on two basic principles which apparently appear to be a bit contradictory.

a) PALF may be blended with cheaper fibres so that a cheaper product mix becomes feasible. In this category, blending of ramie with jute, ramies, Mesta, banana, Roselle hemp appear to be worth pursuing.

b) PALF is often blended with synthetic fibres to produce diversified blended fabrics which are expected to fetch higher prices per unit weight of ramie and consequently higher profitability.

PALF is well known for its silky lustre which possesses some advantageous physical and chemical properties like high tensile strength, dimensional stability, considerable resistance to heat and fire, and good dyeability while the demerits are coarseness, inextensibility. Besides, it is a low cost renewable resource and eco- friendly material.

Normally, the fibre is as fine as the finer quality jute, although about ten times as coarse as cotton. Unlike jute, its structure is without mesh, filaments are well separated and it is two and a half times more extensible with superior bundle strength and L/B ratio. Both the flexural and torsional rigidity of pineapple leaf fibres are comparable with jute fibres of less rigid quality. An interesting characteristic was observed in the case of pineapple leaf fibre and yarn when their tensile properties were studied in wet condition. The bundle strength of pineapple leaf fibre decreases by 50% when in a wet condition but the yarn strength increases by about 13%. A detailed research reveals that the frictional property of pineapple leaf fibre is very high in the wet condition and it predominates over the fall in tensile strength of the fibre so as to increase the wet strength of the yarn.

Different Stages of Blending Process

The development of blended yarn from PALF with natural and synthetic fibres can be achieved in the three stages of processing as given below.

a) Blending at carding or drawing.

b) Blending at spinning

c) Union blending i.e. at fabric stage.

Blending at Carding or Drawing

I. Jute Spinning System: The processing technology of pineapple leaf fibre in jute, cotton, semi-worsted and flax systems as well as to compare performance, research work was undertaken at Jute Technological Research laboratories which later on renamed as National Institute of Research on Jute and Allied Fibre Technology, Kolkata.

II. Performance of jute/Pineapple Leaf Fibre on Jute Spinning System: When the golden fibre blends with pineapple, a magic yarn is born. The fibre is best used as decorative material. Firstly, the natural colour is creamy white-hence unlike jute it does not need bleaching. We have tried various combinations of the fibre at our pilot plant and blended it with jute and synthetic material. When blended with synthetic material, the product is an extra fine material. It can work wonders with jute. If pineapple fibre is blended with jute up to 20-25% fine yarn of linear density of 69 tex or less can be created. This is very difficult to achieve with Indian jute alone.

III. PALF-Ramie Blended Yarn: PALF and ramie yarns spun in dry and wet spinning systems are comparable but wet spun yarns reveal better performance than dry spun yarns due to better inter fibre friction in the wet spinning system. By gradual increase in the percentage of PALF in the blend, a gradual decrease in tenacity of the blended yarn has been observed. And this may be due to the difference of fineness of the two fibres.

IV. PALF-Viscose Blended Yarn: 100% viscose yarn spun in jute spinning system shows higher tenacity for wet spinning and lower extension compared to dry spinning. Gradual increase of PALF in the blend brings about gradual improvement in the tenacity of the blended yarns due to higher strength of PALF. The wet spun blended yarn from PALF-viscose show better performance than corresponding blended yarns spun on the dry spinning system.

V. PALF-Polypropylene Blended Yarn: Binary blending of PALF -Polypropylene for its use in sophisticated area of textiles, Polypropylene fibre of 15 denier and 120 mm length was used. Both PALF and Polypropylene fibres were processed separately in Flax Finisher card with the developed technology of processing the above fibres and a linear density of 138 tex was spun with 5.5 T.P.I in both dry and wet spinning system. Binary blending of the carded material was achieved at Mackie's First Screw Gill Drawing frame with a blend proportion of 75:25, 50:50 and 25:75. No difficulty was encountered during spinning of blended yarn and control yarn.

VI. PALF-Acrylic Blended Yarn: PALF: Acrylic: 50:50 blended yarns having linear density of 84 tex with a T.P.I of 7.5 were developed in jute spinning system in dry and wet spinning conditions. Four blended yarns were spun by blending PALF and acrylic at four different stages of Jute processing viz, carding and three drawing frames. The performance of the blended yarns was studied to evaluate the optimum stage of mechanical processing for binary blending of PALF and acrylic.

Wet Spinning Technology

Wet spinning brings about improvement in short-term weigh irregularity of the yarns resulting in better regularity of yarn diameter. This is chiefly due to better control of fibres in the drafting zone of the spinning frame during wet spinning. The diameter of wet spun PALF yarn of equivalent linear density is lower and its packing coefficient is also higher than that of the dry spun one. The tenacity of the wet spun yarn is higher than that of the dry spun one as the regularity of wet spun yarn is better and the higher packing coefficient is expected to generate transverse pressure during tensile loading. The strength C.V % of wet spun yarn was also lower compared to dry spun yarns. There was no significant difference in breaking elongation of dry and wet spun yarns.

Short staple Cotton Spinning System

Pineapple leaf fibre was first stapled to 32 mm, opened in a single opener machine, blended with Indian cotton in two proportions

A. 67% cotton: 33% Pineapple leaf fibre

B. 80% cotton: 20% pineapple leaf fibre and yarn of a coarse count 14s spun. The performance of the blended yarns showed that on increasing the proportion of pineapple leaf fibre in the blend, the count strength product and regularity deteriorated and a higher percentage of droppings of fibre was noticed in the blow room and carding machine. Spinnability of PALF improves after chemical treatment which was not achieved from cotton/raw PALF (67:33) blend composition. It is clear that the Spinnability increased from 14s to 22s with higher blend composition of PALF: Cotton:: 70:30. Yarn performance indicates that the C.S.P of the blended yarn is lower compared to cotton yarn. The cohesiveness of chemically treated PALF needed higher twist multiplier than normal cotton yarn of same count.

Semi-Worsted Spinning Systems

PALF were blended with Chokla variety of coarse Indian Wool at Central Sheep and Wool Research Institute, Avikanagar, Rajasthan, a sister concern of Indian Council of Agricultural Research. Yarns of nominal linear density of 138 tex were spun on the semi-worsted spinning system by varying the blend proportion of PALFs. Blending of PALFs by 25% could bring about a sharp drop in breaking elongation of yarns and blending by 50% results a sharp increase in tenacity of blended yarns. Besides, by blending PALF with wool at 25:75,the bulk resilience of yarn decreased only by 10% as compared to all wool yarn. The blended materials of PALF-Wool, all PALF and all wool were processed separately on the semi worsted spinning systems.

Eri Silk Spinning Systems

Latest finding reveal that pineapple leaf fibre was successfully processed and blended with red eri available in north eastern region only using Chinese silk processing facilities available at Fabric Plus, Guwahati. Red eri and softened pineapple leaf fibre were processed through the sequence as follows:

Floss Cutter - First Circular Dressing - Second Circular Dressing - Third Circular Dressing - First Spreader - Second Spreader - Slivering - First Drawing-Second drawing - Third Drawing- Roving - Ring spinning - Winding - Twisting - Conditioning - Singeing - Package.

Finer linear density of PALF: Red Eri blended yarn reveals its immense potentiality to be used in the field of Luxury textiles. Finest blended yarn could not be spun except this spinning system. The mechanical properties of the blended yarn were up to textile quality.

Conclusion

Investigation on pineapple leaf fibre clearly indicates that the agro waste can be suitably processed into useful products. Development of appropriate processing technologies for generating yarn with improved properties can widen the application ofthis agro waste.The extractor can effectively be used to extract the fibre from the agro waste of pineapple leaves and the residual sludge obtained after scratching the leaves can be used for vermicomposting successfully. Investigation on pineapple leaf fibre clearly indicates that the agro waste can be suitably processed into useful products. Development of appropriate processing technologies for generating yarn with improved properties can widen the application of this agro waste. The integrated technology for the extraction of pineapple leaf fibre and the vermicomposting altogether becomes remunerative to pineapple cultivators which can be adopted by all pineapple growers not only for additional income but also proper utilization of wastes particularly agricultural wastes which is an important factor in planning the economic progress of a developing country like India.

For more Lupine Publishers Open Access Journals Please visit our website: http://lupinepublishers.us/ For more Fashion Designing open access journals articles Please Click Here: https://lupinepublishers.com/fashion-technology-textile-engineering/

To Know More About Open Access Publishers Please Click on Lupine Publishers

51 notes

·

View notes

Text

Leading Modified Starch Manufacturers in India: Bluecraft Agro's Commitment to Quality

When it comes to the production of high-quality modified starch, Bluecraft Agro stands as one of the most trusted names among modified starch manufacturers in India. With a robust legacy and years of experience, Bluecraft Agro has earned a reputation for producing starch products that cater to diverse industrial needs. Whether it's the food industry, textiles, paper, or pharmaceuticals, Bluecraft Agro has established itself as a key player in providing solutions that drive success.

What is Modified Starch?

Modified starch is a chemically altered form of starch that has been modified to improve its functional properties. It is widely used in various industries due to its ability to enhance texture, stability, and performance. From providing a thicker texture in sauces and soups to improving the shelf life of food products, modified starch is essential in numerous applications.

Bluecraft Agro: A Trusted Name in Modified Starch Manufacturing

Bluecraft Agro is one of the premier modified starch manufacturers in India, known for its state-of-the-art production processes and stringent quality control measures. The company’s commitment to quality begins with sourcing the best raw materials. Using advanced techniques, Bluecraft Agro modifies starch to meet the specific requirements of their clients. Their product range includes food-grade starch, industrial starch, and a variety of other customized solutions that cater to industries such as food, textiles, paper, and pharmaceuticals.

Why Choose Bluecraft Agro for Modified Starch?

1. Premium Quality: Bluecraft Agro follows international standards in manufacturing modified starch. Their products are tested for consistency and performance, ensuring that they meet the highest industry standards.

2. Diverse Product Range: Whether it's for thickening, gelling, or stabilizing, Bluecraft Agro offers a variety of modified starch products that suit different industry needs. The company ensures that each product is tailor-made to deliver optimal results.