#Aluminium Extrusion

Text

Forge Ahead with Virat’s H13!

The Pinnacle of Durability and Performance in Every Extrusion!

Virat Special Steels offers high-quality Aluminium Extrusion Die Steel H13. H13 is a versatile hot work tool steel known for its excellent combination of heat resistance, hardness, and toughness.

Application Areas:

Die Casting: H13 is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Molds: H13 is used in injection molding with high polishability.

Quality Assurance:

Virat Special Steels ensures that H13 steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory:

With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose Virat Special Steels for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more!

https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬[email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#pune#gurugram#iso9001#steel#h13toolsteels#DieSteelH13#Aluminium Extrusion#Extrusion Die Steel#AluminumProfiles#MetalShaping

2 notes

·

View notes

Text

Primus Corp India Pvt Ltd Is Part of The Global Incorporate Of Primus Corp. The Company Has Been Growing In Presence In The Business Of Non Ferrous Metals.

2 notes

·

View notes

Text

Aluminium Extrusion vs. Other Methods: Advantages and Applications

When it comes to shaping and manipulating aluminium into various forms for industrial, architectural, and manufacturing purposes, several methods are at our disposal. Among these methods, aluminium extrusion stands out as a versatile and cost-effective technique. In this blog, we’ll explore the advantages of aluminium extrusion compared to other methods and delve into its diverse applications across industries.

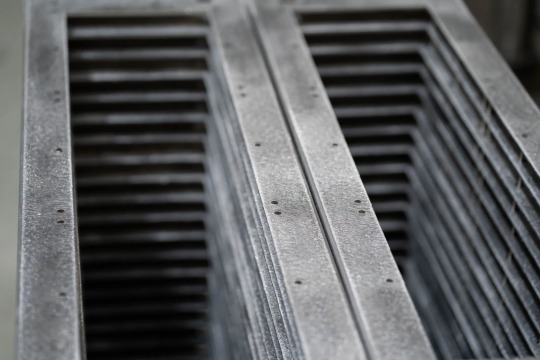

Understanding Aluminium Extrusion

Before we dive into comparisons, I’ll firstly explain what aluminium extrusion is. It’s a manufacturing process that involves forcing aluminium through a die or mould to create specific shapes or profiles. These profiles can range from simple bars and tubes to complex and intricate designs. The process begins with heating aluminium billets to a malleable state, making them suitable for extrusion.

Now, let’s examine how aluminium extrusion measures up against other common methods of shaping aluminium.

Advantages of Aluminium Extrusion

Complex Geometries: In my opinion, the most significant advantage of aluminium extrusion is it’s ability to create intricate and customised profiles. Unlike some other methods that are limited in shape and design options, extrusion allows for a wide range of complex geometries, making it suitable for diverse applications.

Cost-Effectiveness: Aluminium extrusion is cost-effective, especially when it comes to producing large quantities of parts or profiles. The process requires relatively low tooling costs and can efficiently produce consistent shapes, reducing wastage.

Precision and Consistency: Extrusion offers high precision and consistency in producing profiles. The controlled process ensures that each piece meets exact specifications, which is crucial for industries that demand tight tolerances.

Strength and Lightweight: Extruded aluminium profiles are strong and lightweight, making them ideal for applications where durability and weight savings are essential. This is particularly valuable in industries like aerospace and automotive.

Material Efficiency: Unlike some methods that generate significant material waste, aluminium extrusion minimises scrap, making it an environmentally friendly choice.

Versatility: Extrusion can produce profiles of varying sizes and complexities, making it suitable for a wide range of applications across industries.

Applications Across Industries

Construction and Architecture: Aluminium extrusion is commonly used in architectural projects for window frames, curtain walls, and structural components. It’s ability to create sleek and modern designs, combined with it’s corrosion resistance, makes it a popular choice in construction.

Transportation: In the automotive and aerospace industries, aluminium extrusion plays a pivotal role in reducing weight while maintaining structural integrity. This contributes to fuel efficiency and improved performance.

Electronics: Extruded aluminium profiles find applications in the electronics industry for heat sinks, housing components, and enclosures, thanks to their excellent thermal conductivity.

Manufacturing: The versatility and cost-effectiveness of aluminium extrusion make it a preferred choice for manufacturing various components, including conveyor systems, machinery frames, and industrial profiles.

Renewable Energy: The solar and wind energy sectors rely on aluminium extrusion for the fabrication of frames and support structures for solar panels and wind turbine component.

Conclusion

Aluminium extrusion, with it’s many advantages such as flexibility, cost-effectiveness, precision, and material efficiency, stands as a formidable method for shaping aluminium compared to other techniques. It’s applications span across many industries, from construction and transportation to electronics and renewable energy.

In a world where innovation and efficiency are essential, aluminium extrusion has earned it’s place as a go-to solution for transforming aluminium into the shapes and profiles needed to power progress and create the products of the future. It’s adaptability and cost-efficiency make it a versatile tool in the hands of designers, engineers, and manufacturers, driving innovation across a wide range of applications.

Simmal is an established provider of aluminium extrusion in it's wide range of forms. View their work here.

0 notes

Text

Maker Store is Proud to Announce the 40-Series Aluminium Extrusions

Maker Store is Proud to Announce the 40-Series Aluminium Extrusions

Maker Store is Proud to Announce the 40-Series Aluminium Extrusions

Empowering Makers with Versatile Extrusions, Plates, Brackets, Fasteners, and more, Maker Store is thrilled to announce the launch of the much-anticipated 40-Series T-Slot Hardware.

Maker Store is Proud to Announce the 40-Series Aluminium Extrusions. This versatile hardware collection includes; Extrusions, Plates, Brackets,…

View On WordPress

#3D Printers#40-Series#40-Series-Hardware#Aluminium Extrusion#Bracket#Brackets#Extrusion#Hardware#Plates

0 notes

Text

Customized Aluminium Extrusions Information

This is efficacious info for knowing an optimal press speed, and dependent on the alloy used, various exit temperatures might be optimal. Imagine Play-Doh, and how the strong ‘dough’ mass is filtered by way of shaped holes to create lengthy, thin sections. That is the end-product of extrusion, however to achieve this on an industrial scale with products of various chemical composition requires an excellent deal extra nuance in its preparation and execution. However, we know that you can't always choose which profile is for use. Sometimes clients insist on something specific, or only one design will match a construct.

These diffusers can be found in either a Clear or a frosted finish to complete the end for an additional £1.67 per metre. The extrusion is available in 1m or 2m lengths as standard, however you'll find a way to simply minimize the extrusion the size you require utilizing a hack saw. Each meter of AL-1 comes with 2 mounting clips + 2 finish caps as standard. Our group has years of consultancy experiences to advise on all aspects of any safeguard project. All our guarding systems are simple to put in whereas providing ease in relocatability if the necessity arrives. Centreline Aluminium guarding is a modular development that provides a bodily barrier for enclosed and fenced off constructions in industrial amenities.

The better the machinability of material the faster the machining time, leading to lowered cost. 6000 series alloys are essentially the most versatile and most cost-effective choice for extrusions. Blisters can form when there's trapped air or different contaminants (such as lubricants) in the aluminium extrusions extrusion process. Once again, we suggest using a trustworthy reputable producer to keep away from such points. By making certain a high-quality material enter and correct machine maintenance, blisters can be simply averted in the aluminium extrusion process.

This provides us the power to chop materials to length, 4-axis CNC machining, double mitre slicing, drilling, countersinking, riveting, and small part CNC machining. Parallel Connector are used for a gap free connection between two aluminium strut profiles parallel to the axis ,or at any angle. Occasionally, however, there are occasions when a nook interfaces with one other part and you would possibly due to this fact want a pointy corner. In these cases, we advocate including a dogbone style corner, as proven within the picture under on the best. This essentially removes a small circle of fabric from the nook to permit the mating half to interface appropriately with the extrusion. Temper is the business term given to the mixed elements of hardness and strength created by mechanical and/or thermal therapies.

By utilizing highly effective hydraulic presses able to exerting up to 15,000 tons of pressure, aluminium may be extruded into any form you would imagine. Extrusion is the process used to create lengths of aluminium of a fixed cross-sectional profile. Through extrusion, very advanced cross-sections can be created with excellent aluminium profiles energy and floor end. By working along with our clients during the design part, Simmal can introduce innovative ideas early in the growth of a component, serving to to maximise the functionality of the aluminium profiles.

Teucer UK Ltd was based in May 2012, with a vision of serving to the lighting industry to adapt to the LED lighting revolution. Their range provides LED strip for each home and commercial applications. They are committed to the surroundings and vitality effectivity by supporting corporations to reduce their vitality costs and carbon emissions. Teucer aluminium extrusions are made from a 6063 aluminium alloy; as a result of its anti-corrosive resistance, good heat retention and workable properties, it ensures a simple however sturdy installation. ABL Aluminium Components specialises within the fabrication, finishing and assembly of aluminium extrusions. With over forty five years expertise and our central Midlands location, we are completely placed to supply your aluminium extrusion requirements.

Each centre holds inventory to meet the immediate needs of consumers within the local area and this is backed up by bulk shares held at a central warehouse. Maximum pressure shall be wanted for hard alloys that require the lowest billet temperature. When the extrusion ratio is larger, greater stress shall be needed to force the steel via the smaller opening in the aluminium extrusion die, which means intense mechanical working will happen. Having worked in various roles masking gross sales and enterprise administration, Nick has worked throughout the residential and industrial sectors in manufacturing and installation. Nick now writes about all aspects of fenestration, including the impact of changing building regulations and an ever-evolving client market.

0 notes

Text

https://globalaluminium.com/about-us/

Top Aluminium Extrusion Profile Exporter to USA

Global Aluminium incorporated in year 1996 to produce excellent quality aluminium extrusion products with one extrusion press of 1000 Tons capacity.

#Top Aluminium Extrusion Profile Exporter to USA#Aluminium Extrusion#global aluminium private limited#aluminium building products#aluminium extrusion plant manufacturers in uk#aluminium extrusions in air handling units

0 notes

Text

2 notes

·

View notes

Text

Primus Corp India Pvt Ltd Is Part of The Global Incorporate Of Primus Corp. The Company Has Been Growing In Presence In The Business Of Non Ferrous Metals, Focusing On Aluminium.

0 notes

Text

0 notes

Text

Precision Plastic: Advancing Aluminium Extrusion Technology in the UAE

Sustainability is at the core of Precision Plastic's operations. We employ environmentally friendly practices throughout our manufacturing process, such as recycling scrap aluminium and using energy-efficient technologies. Our commitment to sustainability extends to our products like Aluminium Extrusion Manufacturers in UAE, ensuring that they meet the highest standards of quality and performance while minimizing environmental impact.

0 notes

Text

Exploring the Versatility of Aluminium Extrusion Profiles

In the realm of modern manufacturing and construction, aluminium extrusion profiles stand out as a beacon of versatility and innovation. From simple frameworks to intricate architectural designs, these profiles offer a myriad of benefits that make them indispensable in various industries.

What are Aluminium Extrusion Profiles

Aluminium extrusion profiles are created through the extrusion process, where a billet of aluminum is forced through a die to create a specific cross-sectional shape. This process allows for the creation of complex shapes with consistent dimensions, making them ideal for a wide range of applications.

Features and Benefits

Versatility: One of the key advantages of aluminium extrusion profiles is their versatility. They can be customized to meet the unique requirements of different projects, whether it's for automotive components, industrial machinery, or architectural structures.

Lightweight yet Durable: Aluminium is inherently lightweight, making it easy to handle and transport. However, it doesn't compromise on strength and durability, making it suitable for both structural and decorative purposes.

Corrosion Resistance: Unlike some other metals, aluminium has natural corrosion resistance. This property makes aluminium extrusion profiles ideal for outdoor applications where they may be exposed to harsh weather conditions.

Design Flexibility: With aluminium extrusion, designers have the freedom to create intricate shapes and profiles that would be challenging or impossible with other materials. This flexibility opens up a world of possibilities for creative and innovative designs.

Applications

The applications of aluminium extrusion profiles are virtually limitless. They are commonly used in:

Construction: From curtain walls and window frames to structural components, aluminium extrusion profiles play a vital role in modern construction projects.

Transportation: In the automotive and aerospace industries, aluminium extrusions are used for lightweight yet sturdy components such as chassis, frames, and interior fittings.

Industrial Machinery: Manufacturers rely on aluminium extrusion profiles for the construction of machine frames, conveyor systems, and other equipment where strength and precision are paramount.

Consumer Electronics: The sleek and modern appearance of aluminium extrusion profiles makes them a popular choice for consumer electronics such as computer frames, LED lighting fixtures, and display enclosures.

Conclusion

In conclusion, aluminium extrusion profiles represent a pinnacle of engineering and design. Their versatility, durability, and aesthetic appeal make them indispensable in a wide range of industries. Whether you're building a skyscraper, manufacturing a car, or designing the next generation of electronic gadgets, aluminium extrusion profiles offer the perfect combination of form and function.

To explore the diverse range of aluminium extrusion profiles and unleash your creativity, visit Naview Aluminium today!

0 notes

Text

The Power of Data: How ERPs Help Manufacturers Track and Reduce Environmental Impact

Manufacturers nowadays are under increasing pressure to operate sustainably. Consumers are demanding environmentally responsible practices, investors are prioritizing ESG (Environmental, Social, and Governance) factors, and regulations are becoming more stringent. However, how can manufacturers assess their environmental impact and find opportunities for improvement?

The answer lies in data, and Enterprise Resource Planning (ERP) systems are powerful tools for capturing and analyzing this data. Here at Extrusion ERP, we understand the unique needs of the extrusion industry, and our ERP solution is designed to empower you to track and reduce your environmental impact.

Unveiling the Hidden Costs: How ERPs Track Environmental Performance

Extrusion processes can be energy-intensive and generate significant waste. However, traditional methods of tracking these factors often lack accuracy and real-time insights. Here's how ERPs help:

Energy Consumption Monitoring:

ERPs integrate with energy meters and sensors to track energy usage across various production lines and equipment. This granular data allows you to identify areas for improvement and implement targeted energy-saving strategies like optimizing production schedules or investing in energy-efficient machinery. Financial Benefits: Reduced energy consumption translates to lower utility bills and a smaller carbon footprint

Material Management:

ERPs track raw material usage throughout the extrusion process. You can identify areas where waste is generated, such as inefficient cutting practices or equipment malfunctions. This data helps you optimize material utilization, explore options for using recycled materials, and ultimately reduce your environmental footprint. Financial Benefits: Minimizing material waste reduces costs and promotes efficient resource utilization.

Production Planning and Scheduling:

By optimizing production runs and minimizing downtime, ERPs can significantly reduce scrap generation and the energy consumption required to produce those wasted materials. This translates to a smaller environmental footprint and lowers waste disposal costs. Financial Benefits: Reduced scrap leads to less material being wasted, saving money and resources.

Waste Stream Management:

ERPs can track and categorize waste streams, providing valuable insights into the types and volumes of waste generated. This empowers you to explore recycling or upcycling opportunities, reducing your reliance on landfills and virgin materials. Financial Benefits: Proper waste management can lead to reduced disposal costs and potential revenue streams through recycling initiatives.

Beyond Tracking: Making Data Actionable

The real power of ERP lies in its ability to convert data into actionable insights. Here's how:

Real-time Reporting:

Access real-time reports to monitor key environmental metrics. This allows you to identify trends, track progress toward your sustainability goals, and make data-driven decisions for continuous improvement

Benchmarking:

Compare your environmental performance against industry benchmarks or your historical data. This helps you identify areas for significant improvement and prioritize your sustainability efforts

Regulatory Compliance:

ERPs can help you track and manage environmental regulations, ensuring your operations comply and avoiding costly penalties

Beyond Tracking: Making Data Actionable

“Extrusion ERP” provides the best ERP Software for extrusion companies. We're committed to empowering extrusion businesses like yours to achieve operational excellence while embracing sustainability. Our ERP solution goes beyond just tracking data; it provides the tools and insights you need to make informed decisions and take concrete steps toward a greener future.

Ready to unlock the power of data and reduce your environmental impact?

Contact Extrusion ERP today for a demo. Let's discuss how our ERP system can help you track your environmental footprint, optimize your extrusion processes, and achieve your sustainability goals.

#aluminium extrusion management erp#best erp for aluminium extrusion industry#erp development company#erp for aluminium extrusion companies#erp software for aluminium extrusion#erp software for aluminium extrusion companies#erp for aluminium extrusion industry#erp software development company#erp software development companies#erp software development services#erp#erp solution#erp systems#erp software

0 notes

Text

Taking Advantage of Innovations in Aluminium Fabrication

Innovation is the cornerstone of progress in any industry, and aluminium fabrication is no exception. In Perth's bustling industries, the applications of aluminium fabrication are expanding rapidly, driven by technological advancements and a growing demand for lightweight, durable, and sustainable materials.

From aerospace to construction, automotive to electronics, aluminium fabrication plays a pivotal role in shaping modern solutions. This article explores the latest innovations in aluminium fabrication and how businesses in Australia, particularly in Perth, can leverage these advancements to their advantage.

Innovations in Aluminium Fabrication

Before delving into the innovations, let's first understand what aluminium fabrication entails. Aluminium fabrication involves the manipulation of aluminium materials into desired shapes and forms through various processes such as cutting, bending, welding, and assembling.

Aluminium is favoured for its remarkable properties - it is lightweight, corrosion-resistant, strong, and highly conductive, making it suitable for a wide range of applications across diverse industries.

Advanced Machining Techniques

With advancements in CNC (Computer Numerical Control) machining technology, precision and efficiency in aluminium fabrication have reached unprecedented levels. CNC machines enable intricate designs and complex shapes to be achieved with utmost accuracy, reducing production time and minimising material wastage.

Perth-based fabrication companies are increasingly investing in state-of-the-art CNC machining equipment to meet the demands of modern industries.

Additive Manufacturing

Additive manufacturing, commonly known as 3D printing, has revolutionised the fabrication landscape. This technology allows for the layer-by-layer deposition of aluminium powder or wire, enabling the creation of complex geometries that would be difficult or impossible to achieve using traditional methods.

In Perth, businesses are exploring the potential of additive manufacturing in prototyping, custom part production, and even in the development of lightweight components for aerospace and automotive applications.

Composite Materials Integration

Aluminium composites, such as aluminium-lithium alloys, offer enhanced strength-to-weight ratios compared to traditional aluminium alloys. By integrating these composite materials into fabrication processes, manufacturers can produce lighter yet structurally robust components.

Perth's aerospace and marine industries are particularly interested in these innovations, as they seek to improve fuel efficiency and performance while reducing overall weight.

Surface Treatment Technologies

Surface treatment technologies, including anodizing, powder coating, and chemical etching, play a crucial role in enhancing the aesthetics, durability, and corrosion resistance of aluminium components.

Innovations in surface treatment processes have led to the development of eco-friendly and cost-effective solutions that comply with stringent environmental regulations. Perth's architectural firms and construction companies are leveraging these advancements to create visually appealing and long-lasting aluminium structures.

Digital Design and Simulation

Digital design tools and simulation software have become indispensable in the field of aluminium fabrication. These tools allow engineers and designers to visualise concepts, optimise designs, and simulate manufacturing processes before physical production begins.

By embracing digital design and simulation, Perth-based companies can streamline their product development cycles, minimise errors, and ultimately deliver superior-quality aluminium products to their clients.

Applications of Innovations in Perth's Industries

With all of those details laid out, let’s take a look at some industries where aluminium fabrication innovations truly shine:

Aerospace

In Perth's burgeoning aerospace sector, innovations in aluminium fabrication are driving the development of lightweight aircraft components, including fuselage panels, wing structures, and interior fittings.

Advanced machining techniques and additive manufacturing technologies enable aerospace manufacturers to achieve significant weight savings without compromising on strength or performance, thereby enhancing fuel efficiency and operational capabilities.

Construction

The construction industry in Perth is witnessing a surge in the use of aluminium fabrication for architectural cladding, curtain walls, roofing systems, and structural components.

The integration of composite materials and advanced surface treatments ensures durability, weather resistance, and aesthetic appeal in architectural designs. Furthermore, digital design tools facilitate the customization of aluminium profiles to suit the unique requirements of each construction project.

Automotive

In the automotive sector, aluminium fabrication innovations are driving the production of lightweight body panels, chassis components, and engine parts. The use of aluminium alloys and composites reduces vehicle weight, leading to improved fuel efficiency and lower emissions. Additive manufacturing technologies enable the rapid prototyping and customization of automotive parts, facilitating innovation and agility in product development.

Electronics

The electronics industry relies on aluminium fabrication for the production of heat sinks, enclosures, and components for electronic devices. With the miniaturisation trend in electronic design, precision and reliability are paramount.

Advanced machining techniques and surface treatment technologies ensure tight tolerances, efficient heat dissipation, and protection against environmental factors such as moisture and electromagnetic interference.

Conclusion

Innovations in aluminium fabrication are reshaping industries across Perth, offering unprecedented opportunities for businesses to enhance product performance, efficiency, and sustainability. From advanced machining techniques to additive manufacturing, and composite materials integration to digital design tools, the possibilities are endless.

By embracing these innovations and leveraging the expertise of Perth's fabrication professionals, businesses can stay ahead of the curve and thrive in today's competitive market landscape. As the demand for lightweight, durable, and sustainable solutions continues to grow, aluminium fabrication will undoubtedly remain at the forefront of innovation in Australia and beyond.

#custom aluminium#aluminium products#aluminium fabrication#aluminium#custom aluminium wa#aluminium extrusions#aluminium services

0 notes

Text

water pollution control in india

WATER POLLUTION CONTROL

#incinerator manufacturer in india#industrial waste incinerator manufacturers#force draft cooler#recuperator manufacturer in india#ladle manufacturers in india#aluminium extrusion plant manufacturers in india#turnkey projects companies in india#hot air generator manufacturers in india#plate bending machine manufacturers in india#Rotary kiln manufacturers#furnace manufacturers in india#calciner manufacturers#bag filter manufacturers in india#bag filter manufacturers#cartridge filter manufacturers in india#cyclone dust collector#Battery Cutting Machine#battery cutting machine manufacturers#battery cutting machine manufacturers in india#Battery Recycling Plant#battery recycling plant in india#battery recycling plant manufacturers#Battery Recycling Technology#battery recycling technology india#lead acid battery recycling companies in india#Disposal technology for Lead Acid Battery Waste#disposal technology for lead acid battery waste india#cyclone dust collector manufacturers#cyclone dust collector manufacturer in india#baghouse manufacturers

1 note

·

View note