#AluminumProfiles

Text

Forge Ahead with Virat’s H13!

Virat Special Steels takes pride in offering high-quality Aluminium Extrusion Die Steel H13 – a true pinnacle of durability and performance in every extrusion process.

Application Areas:

Die Casting: H13 is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Moulds: H13 is used in injection molding with high polishability.

Quality Assurance:

Virat Special Steels ensures that H13 steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory:

With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more!

https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📬 [email protected] ☎+91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#ExtrusionDies#AluminumProfiles#AluminumIndustry#ExtrusionProcess#ManufacturingSolutions

2 notes

·

View notes

Text

Aluminum Extrusion: Shaping the Future of Manufacturing

Introduction

Aluminum extrusion involves the shaping of aluminum profiles through a process called extrusion. The process begins with a solid cylindrical aluminum billet, which is heated and pushed through a die to form the desired shape. Aluminum extrusions find wide use in industries such as construction, transportation, electronics, and more.

What is aluminum extrusion?

Aluminum extrusion is a manufacturing process in which aluminum billets are forced through a shaped opening in a die, thereby creating a continuous profile. These profiles can have complex cross-sectional shapes and are produced with high accuracy. Extruded aluminum profiles are then cut to the desired length and used in a variety of applications.

Aluminum extrusion process

The aluminum extrusion process involves several steps to convert a raw aluminum billet into a finished profile. Let's look at each stage in detail:

Billet preparation

The first step in the extrusion process is the billet preparation. Aluminum billets are generally manufactured from high-quality aluminum alloy, selected based on the specific application requirements. These billets are preheated to ease the extrusion process and ensure uniform temperature distribution.

Heating and homogenization

Once the billets are prepared, they are heated to a specific temperature to increase their ductility. Heating is very important to reduce the strength of the material and increase its ductility, making it easier to extrude. The billets then undergo a process called homogenization, which ensures a uniform chemical composition throughout the material.

Extrusion Process

Heated billets are loaded into a chamber and pressed against a specially designed die. The die determines the shape and size of the final extruded profile. Pressure is applied to force the softened aluminum through the die, resulting in the desired shape. This continuous extrusion process allows long profiles with consistent dimensions to be produced.

Cool and Subdued

After the extrusion process, the newly formed aluminum profile cools and quenches. Cooling is essential to stabilize the structure of the profile and prevent deformation. Rapid cooling is quenched to further enhance material properties like strength and hardness. A variety of cooling methods can be used, including air or water discharge, depending on the specific requirements.

Advantages of Aluminum Extrusion

Aluminum extrusion offers many advantages that make it a preferred choice in various industries. Let's know some of its key benefits:

Design Flexibility

One of the primary benefits of aluminum extrusions is its exceptional design flexibility. The process allows complex cross-sectional shapes to be created, enabling designers to bring their innovative ideas to life. From intricate profiles to customized geometries, aluminum extrusions offer endless possibilities for creative and unique designs.

Lightweight and Powerful

Aluminum is famous for its lightweight properties without compromising on strength. Extruded aluminum profiles exhibit a high strength-to-weight ratio, making them ideal for applications where weight reduction is critical. This benefit is especially beneficial in industries such as automotive and aerospace, where lightweight materials contribute to fuel efficiency and improved performance.

Cost Effective

Aluminum extrusion offers cost-effective manufacturing solutions. The process allows the production of complex shapes in a single operation, reducing the need for additional machining or assembly processes. This streamlined manufacturing process leads to cost savings in terms of materials, labor, and overall production time.

Corrosion Resistance

Aluminum extrusions have inherent corrosion resistance. A natural oxide layer forming on the surface provides a protective barrier against environmental elements, making them resistant to rust and corrosion. This feature makes aluminum extrusions well suited for outdoor applications, where exposure to moisture and harsh weather is a concern.

Durability

Aluminum extrusion aligns with sustainable practices because of its recyclability. Aluminum is 100% recyclable with no loss in its physical properties. Recycling aluminum requires significantly less energy than primary production, making it an environmentally friendly choice. The recyclability of aluminum extrusion contributes to reducing carbon emissions and conserving natural resources.

Future Trends in Aluminum Extrusion

The field of aluminum extrusion is constantly evolving, driven by technological advancements and changing industry demands. Let's explore some of the future trends in aluminum extrusion:

Advanced Alloys

The development of advanced aluminum alloys with enhanced properties is an ongoing area of research. These alloys offer improved strength, corrosion resistance, and other desirable characteristics. By utilizing advanced alloys in the extrusion process, manufacturers can expand the application range of aluminum extrusions and meet the evolving needs of industries.

Energy Efficiency

Energy efficiency is a key focus in various industries. Aluminum extrusion processes are being optimized to reduce energy consumption, waste, and carbon emissions. Advanced heating and cooling techniques, as well as process control systems, are being implemented to achieve higher energy efficiency and sustainability.

3D Printing and Additive Manufacturing

The integration of 3D printing and additive manufacturing technologies with aluminum extrusion holds great potential. This combination allows for the creation of complex and customized profiles with intricate internal structures. By leveraging these technologies, manufacturers can further enhance design freedom, reduce material waste, and optimize resource utilization.

Conclusion

Aluminum extrusion is a versatile manufacturing process that offers exceptional design flexibility, lightweight properties, cost-effectiveness, and corrosion resistance. Its applications span across various industries, including architecture, automotive, aerospace, electronics, and consumer goods. With customization options and surface finishing techniques, aluminum extrusions can be tailored to specific requirements. While challenges exist, advancements in alloys, energy efficiency, and additive manufacturing are paving the way for future innovations in the field. Aluminum extrusion continues to shape the future of manufacturing with its unique combination of properties and endless possibilities.

#AluminumExtrusion#ExtrusionTechniques#AluminumFabrication#DIYProjects#AluminumProfiles#Metalworking

0 notes

Text

Aluminum Profile Powder Coating Line

The aluminum profile powder coating line adopts fully automatic conveying, with a speed of up to 8m/min and high production efficiency. A multi-pass dust removal process is used before spraying to ensure that the product surface is 100% free of dust larger than 0.1mm. The overall surface coating of the product is uniform and high in precision, and the product qualification rate is over 95%. The service life of the entire line is over 15 years, with less maintenance and high safety. #aluminumprofile #powdercoatingline #automaticspraying

0 notes

Text

#abelehardware#aluminium#aluminiumdoor#aluminiumwindows#eurostarladder#business#autos#cars#concept car#home & lifestyle#aluminiumladder#aluminumprofile#aluminum#Aluminiumwindows#aluminiumcoils#aluminumsheet#sheets#coils#sheetsandcoils#Abele#ladders#ceilingmaterial#abelewpc#wpcdoors#wpcdoorframes

0 notes

Text

#cookware#cookwareset#COOKWARECLEANER#Anodized#anodizedaluminum#anodized#anodizedjewelry#aluminum#aluminumfree#aluminumprofile#aluminumtrailer#cleaninghacks#cleaning#cleaningservice#cleaners#kitchen#kitchengoals#kitchenideas#kitcheninspo#kitchentools#kitchendecor

0 notes

Text

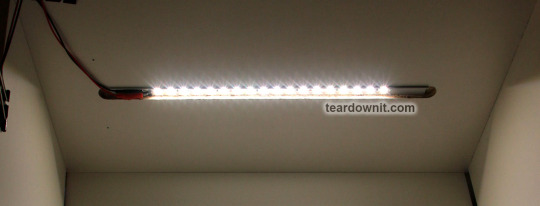

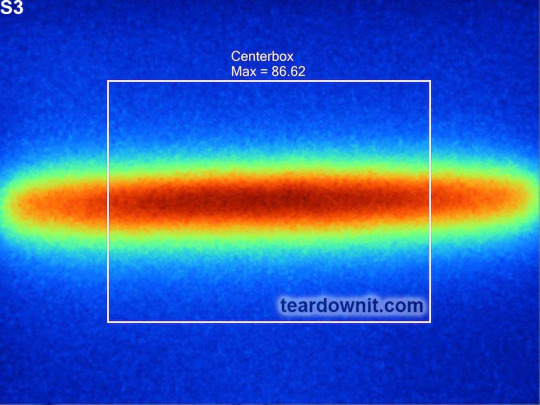

Heating LED strips on aluminum profile in chipboard

How hot are the LED strips on the aluminum profile?

How hot are the LED strips on an aluminum profile in the chipboard?

I continue to measure the temperature of LED strips under different conditions.

(Learn more about previous results)

1. Measurement description

I want to explore the effects of the heat sink commonly used with LED strips this time around. A simple 15" x 1" x 1/25" + 1/2" x 1/25" L-shaped aluminum profile was at hand. I glued the LED strips alternately to this profile.

2. Test bench and measuring instruments

I measure the temperature in a room with an air temperature of 73 deg F using a professional Fluke TiS65 thermal imager. I also use our past test bench, a simulated cabinet. (Learn more about previous results)

I added mounts to this bench to hang the profile and LED strips in the air.

3. Types of our measurements

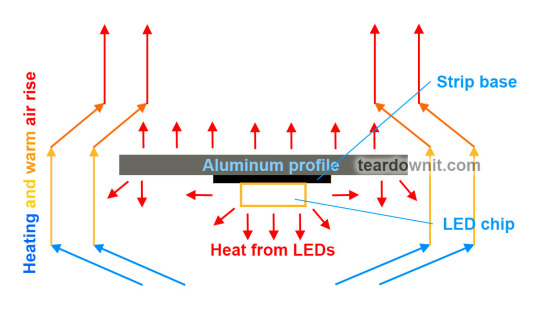

LED strip on the aluminum profile in the air. I measure the temperature of the LED chips and the heating of the aluminum profile backside (heat transfer from the base of the LED strip to the profile).

2. LED strip on the aluminum profile in the air. I measure the temperature of the LED chips and the heating of the aluminum profile backside (heat transfer from the base of the LED strip to the profile).

LED strip, covered with a diffuser, on an aluminum strip in a chipboard groove. I measure the temperature of the LED chips and the chipboard heating on the backside.

This type of measurement completely simulates conventional LED fixtures sold in stores. The heat from the LED chips is removed mainly by the strip base and the heat sink. Air convection is negligible. The plastic diffuser creates a fixed air layer near the LED chips.

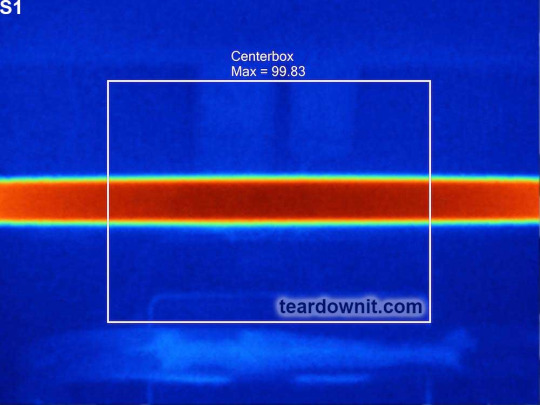

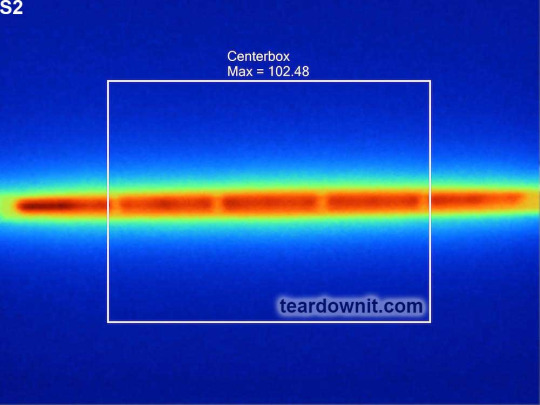

4. Results of chip temperature measurements.

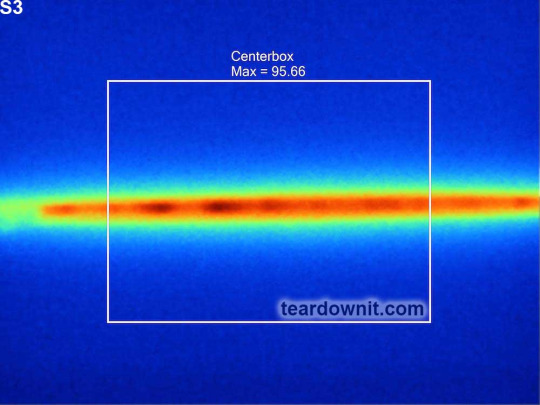

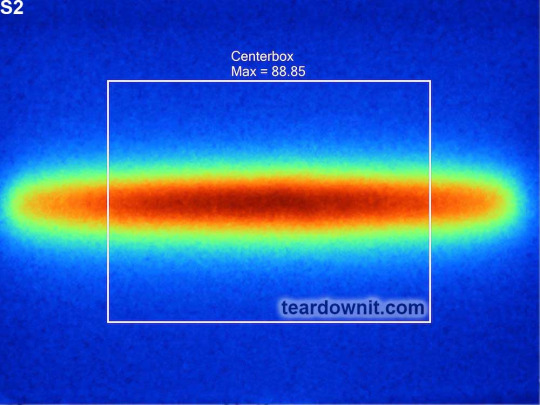

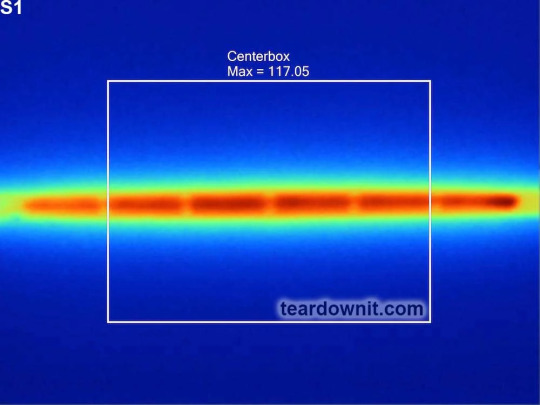

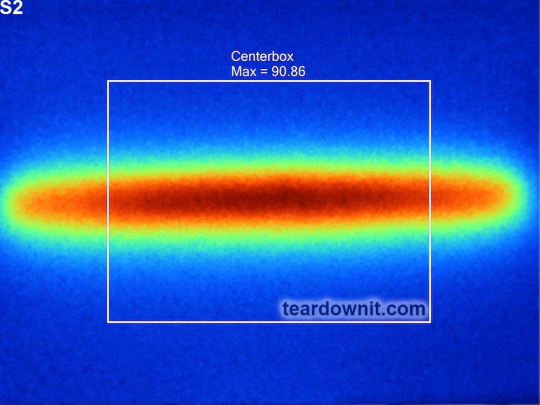

LED strips on aluminum profile in chipboard

Thermal images. LED chips on Al profile in air

Thermal images. Al profile backside in air

Thermal images. LED chips on Al profile in chipboard without diffuser

Thermal images. Chipboard backside with LED strip on Al profile without diffuser

Thermal images. LED chips on Al profile in chipboard with diffuser

Thermal images. Chipboard backside with LED strip on Al profile with diffuser

5. What's coming up in the next posts?

Samples of LED tapes on Extruded polystyrene foam (you are wondering why?)

Summary

What was in previous posts?

Real power consumption of LED strips and heating without heat sink

Heating of different types of LED strips on chipboard

Know more: https://teardownit.com/

0 notes

Video

youtube

FOEN safety meeting

Recently, Fenan Aluminium held a production safety work and fourth quarter production safety work conference, which conveyed the spirit of production safety work and fourth quarter production safety work conference, and made specific arrangements for production safety and fire safety work in the fourth quarter, so as to create a good atmosphere for production safety.

The meeting requested:

All departments should seriously and earnestly grasp the work of production safety.

It is necessary to draw lessons from recent safety accidents, make every effort to guard against major security risks, and resolutely curb the occurrence of all kinds of major accidents.

All departments should comprehensively analyze and judge the current situation and tasks, further arrange the safety and prevention work during this period, ensure the life and property safety of the broad masses of employees and the stability of the company's overall development, and take practical actions to ensure production safety.

Security check after the meeting.

After the meeting, the staff of our safety office organized the safety inspection of the gas station and the production workshop.

The convening of this meeting has played an important role in summing up experience and defining objectives for our production safety work. All the staff of our company will take the initiative to carry out the responsibility of production safety, build a solid red line of production safety, keep the bottom line of maintaining stability, and create a good company safety environment with finer, more solid and more thorough work drive, so as to ensure stable and safe production and ensure the safety of workers.

https://www.foenalu.com/

#safety #aluminumextrusion #aluminumprofile #aluminiumdoor #alumino #perfildealuminio #tslot #aluminumtube #fenanaluminum #FOENaluminum #fenan #FOEN

#youtube#safety#aluminumextrusion#aluminumprofile#aluminiumdoor#alumino#perfildealuminio#tslot#aluminumtube#fenanaluminum#FOENaluminum#fenan#FOEN

0 notes

Video

undefined

tumblr

Welcome you to visit our factory,we are in Jinan City,Shangdong Province.#window #windowmachine #pvc

Welcome you to visit our factory,we are in Jinan City,Shangdong Province.#window #windowmachine #pvcwindows #aluminumwindows #windowmaking #windowfactory #cuttingsaw #productionline #insulatingglass #windowmanufacturer #saw #aluminumprofile

0 notes

Video

undefined

tumblr

Welcome you to visit our factory,we are in Jinan City,Shangdong Province.#window #windowmachine #pvc

Welcome you to visit our factory,we are in Jinan City,Shangdong Province.#window #windowmachine #pvcwindows #aluminumwindows #windowmaking #windowfactory #cuttingsaw #productionline #insulatingglass #windowmanufacturer #saw #aluminumprofile

0 notes

Text

Forge Ahead with Virat’s H13!

Virat Special Steels takes pride in offering high-quality Aluminium Extrusion Die Steel H13 – a true pinnacle of durability and performance in every extrusion process.

Application Areas:

Die Casting: H13 is highly recommended for aluminum pressure die casting due to its exceptional performance under high working temperatures and pressure.

Forging Dies: It withstands rapid cooling and early heat testing, making it suitable for forging applications.

Plastic Moulds: H13 is used in injection molding with high polishability.

Quality Assurance:

Virat Special Steels ensures that H13 steel is fully ultrasonic inspected with 100% positive results as per NDT standards. It meets the requirements for safety and reliability.

Expertise and Inventory:

With over five decades of experience, Virat Special Steels has a reputation for providing accurate and timely service. We maintain ready stock in their steel yards, offering immediate availability.

Choose VIRAT SPECIAL STEELS PVT. LIMITED , INDIA for your Aluminium Extrusion Die Steel needs, and experience quality and reliability!

Contact us today to learn more!

https://www.viratsteel.in/materials/aluminium-extrusion-die-steel-supplier-in-india/

Any further queries feel free to contact us:

🌐https://www.viratsteels.com 📬[email protected] ☎+91 98140-21775

#ludhiana#viratsteels#india#viratspecialsteels#toolsteelsupplier#gurugram#steel#pune#gurgaon#ExtrusionDies#AluminumProfiles#DieCasting#AluminumIndustry#ExtrusionProcess

2 notes

·

View notes

Video

youtube

#SolarPanel #RenewableEnergy #CleanEnergy #Sustainability #SolarPower #GreenTechnology #SolarEnergy #SolarPV #SolarIndustry #cleantechnology #AluminumProfile #AluminumExtrusion #AluminumIndustry #AluminumProducts #AluminumFabrication #AluminumSolutions #AluminumDesign #ExtrudedProfiles #AluminumSystems #AluminumArchitecture

#youtube#SolarPanel RenewableEnergy CleanEnergy Sustainability SolarPower GreenTechnology SolarEnergy SolarPV SolarIn

0 notes

Video

vimeo

Aluminum Profile Sheet Metal Parts Powder Coating Line from Attractivechina on Vimeo.

"Aluminum profile sheet metal parts powder coating production line" is a production line equipment used for surface coating of aluminum profiles and sheet metal parts. This production line uses powder coating technology to evenly spray the powder coating on the surface of aluminum profiles and sheet metal parts, and then solidifies it through baking to form a strong and durable coating. This coating method can improve the corrosion resistance, wear resistance and aesthetics of the product, and is widely used in construction, furniture, automobile and other industries. #AluminumProfiles #PowderCoating #MetalDecoration

Phone: +86 13580616025(WeChat&WhatsApp)

Email: [email protected]

0 notes

Text

#abelehardware#aluminium#aluminiumdoor#aluminiumwindows#eurostarladder#autos#business#cars#concept car#home & lifestyle#aluminiumladder#aluminumprofile#aluminum#Aluminiumwindows#aluminiumcoils#aluminumsheet#sheets#coils#sheetsandcoils#Abele#ladders

0 notes

Text

Aluminum Profiles manufacturers & suppliers

https://www.bikudo.com/category/aluminum-profiles-13204.html

#aluminumprofiles

0 notes

Video

youtube

Fenan aluminum FOENvertical powder coating production facility

Fenan Aluminum Co., Ltd. is the largest production base of aluminum alloy building profiles and industrial profiles in Fujian Province,ranking Top Five in China.Its products have the characteristics of light weight, high strength, strong corrosion resistance, novel and beautiful shape, saving materials, durability and so on. Fenan aluminum profiles processed into doors and windows and curtain wall products have good air tightness, waterproof and sound insulation, energy-saving effect.

In order to create high-quality aluminum alloy profiles, solar photovoltaic frames and brackets, Fenan aluminum(FOEN) has introduced the latest high-efficiency and high-quality vertical powder coating production lines ( 4 powder coating production lines,seeing the video and one wood grain vertical powder coating line). It can produce 3D, 4D simulation wood grain.In addition,there is a vertical oxidation electrophoresis line with monthly output of 5000 tons(The whole process is controlled by computer automation with excellent quality) and other related facilities.

The most advanced production equipment makes Fenan(FOEN) become the largest construction aluminum profile production enterprise in Fujian Province.

It can produce at least 400,000 tons of aluminum profiles and the volume is increasing year on year.

Then let us know something about FOEN’s culture and concept.

FOEN stands for

F——Future

O——Opportunity

E——Energy

N——Nicety

Mission: Make the World More Colorful and green with Excellent Quality

Development strategy: be an industry leader rather than a follower.

Vision: Where There is a Building, There is FOEN Aluminum

Business Philosophy: Hardworking, Stability, Honesty, Trustworthiness

Management Philosophy: Seek Truth from Facts and Solve Problems Quickly

Employment philosophy: Talent First,cherish talents, love talents and cultivate talents

The concept of innovation: being faster than others.

The concept of security: to guard against micro and gradually guard against it.

Team concept: each perform his or her duties with one heart and one mind,cooperating with others at one goal.

#aluminiummanufacturing #aluminiumprofilesupplier #fenanaluminum #foenaluminum #producttalk#aluminum#aluminumprofiles#alumino#perfilesdealuminio

1 note

·

View note