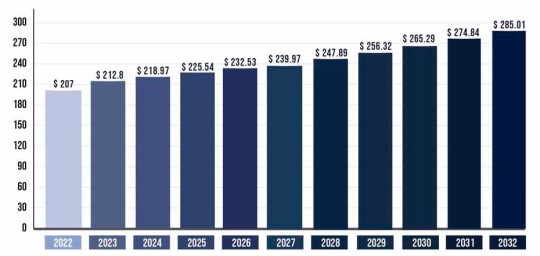

#Ammonium Phosphates Market Growth

Text

Assessing the Competitive Landscape of the Ammonium Phosphates Market

Ammonium phosphates are essential chemical compounds used in various industries due to their versatile properties and applications. This market encompasses a wide array of products and plays a crucial role in sectors like agriculture, food processing, and industrial processes. In this article, we will delve into the definition, market overview, scope, growth factors, industry landscape, and emerging trends within the ammonium phosphates market.

Definition: Ammonium phosphates refer to a group of inorganic salts that contain both ammonium and phosphate ions. These compounds are highly valued for their use as fertilizers and flame retardants. They typically include substances like monoammonium phosphate (MAP) and diammonium phosphate (DAP), each of which has distinct properties and applications.

Market Overview & Scope: The ammonium phosphates market is a significant segment of the global chemical industry. Its scope extends across various sectors, primarily driven by the agricultural and chemical industries. In agriculture, ammonium phosphates are widely used as fertilizers to enhance crop yields and improve soil quality. In the chemical sector, they find application in flame retardants for materials like textiles and plastics. The market scope also includes use in food processing, where ammonium phosphates are utilized as food additives and leavening agents.

Market Growth: The ammonium phosphates market has witnessed substantial growth in recent years. This growth can be attributed to the increasing demand for fertilizers to support global food production and the growing emphasis on sustainable agriculture practices. Furthermore, the need for fire-resistant materials in construction and other industries has led to a surge in the use of ammonium phosphates as flame retardants.

Market Industry: The ammonium phosphates market industry surrounding is multifaceted and consists of several key players, including chemical manufacturers, agribusinesses, and food processing companies. Chemical manufacturers are involved in the production and distribution of ammonium phosphates, catering to the diverse needs of the agricultural and industrial sectors. Agribusinesses utilize these compounds to boost crop yields, while food processing companies incorporate them into various products to enhance quality and texture.

Trends: Several noteworthy trends have emerged in the ammonium phosphates market. One significant trend is the increasing emphasis on sustainable agriculture and environmentally friendly fertilizers. This has driven the development of more eco-friendly ammonium phosphate formulations. Additionally, as regulations regarding flame retardants become more stringent, there is a growing focus on developing safer and more effective flame retardant materials, which often include ammonium phosphates as key components.

In conclusion, the ammonium phosphates market is a dynamic sector with diverse applications, ranging from agriculture to fire safety. Its sustained growth is driven by the evolving needs of these industries and the development of innovative products to meet them. As we move forward, the market is likely to continue evolving in response to environmental and regulatory pressures, ensuring a fascinating trajectory for this essential chemical segment.

0 notes

Text

IFFCO Fertilizer Franchise: Your Gateway to a Lucrative Business Opportunity

Are you interested in joining a reputed brand in the agricultural sector? The Indian Farmers Fertiliser Cooperative Limited (IFFCO) is a leader in providing high-quality fertilizers to farmers across India. Opting for an IFFCO fertilizer franchise can be a lucrative business opportunity, offering high demand, a trusted brand, and strong industry support. This comprehensive guide will tell you everything you need to know about securing an IFFCO fertilizer franchise.

Why Choose an IFFCO Fertilizer Franchise?

Established Reputation

IFFCO is one of the largest cooperative societies globally, making its products highly trusted by farmers. Partnering with such a reputable brand ensures a steady stream of business and growth opportunities.

High-Quality Fertilizer Products

IFFCO offers a range of fertilizers, including urea, DAP (Di-Ammonium Phosphate), NPK complexes, and specialized fertilizers. Their high-quality products are manufactured using state-of-the-art technology, ensuring superior crop nutrition and yield improvement.

Extensive Distribution Network

Joining the IFFCO fertilizer franchise means becoming part of an extensive distribution network. This ensures timely delivery and consistent support, helping you maintain a smooth and efficient business operation.

Steps to Secure an IFFCO Fertilizer Franchise

Conduct Market Research

Understanding the local market is crucial before you venture into the franchise business. Conduct thorough market research to identify the demand for fertilizers in your area, pinpoint your target customer base, and analyze your competitors. This information will help you tailor your business strategy effectively.

Fulfill Eligibility Criteria

IFFCO has laid down specific eligibility criteria for potential franchisees:

Financial Stability: Ensure you have the financial capability to support initial setup costs and ongoing operations.

Adequate Infrastructure: Secure a suitable location with sufficient storage space to accommodate your inventory.

Relevant Experience: Prior experience in the agricultural or fertilizer industry is beneficial but not mandatory.

Compile Required Documents

Gather all necessary documents before starting your application process. These usually include:

Identity proof (Aadhaar Card, PAN Card)

Address proof

Financial statements

GST registration

Bank reference letter

Photographs of your business premises

Submit Your Application

To apply for an IFFCO fertilizer franchise, fill out an application form and submit it to the nearest IFFCO office or through their official website. Ensure that all information provided is accurate and complete, and attach all required documents.

Verification and Approval

Upon receiving your application, IFFCO will conduct a thorough verification process. They may inspect your business premises and evaluate your financial stability, infrastructure, and market potential. If your application meets their standards, you will receive approval for the franchise.

Execute the Franchise Agreement

Once approved, you will need to sign a franchise agreement with IFFCO. This agreement outlines the terms and conditions of the franchise, including supply terms, payment processes, and other essential clauses.

Establish Your Business Setup

After securing the IFFCO fertilizer franchise, focus on setting up your business. Ensure that your storage facility is well-organized and meets safety standards. Develop a marketing and sales strategy to attract customers and establish your presence in the local market.

Access Training and Support

IFFCO provides comprehensive training and ongoing support to its franchisees. Attend training sessions to familiarize yourself with their products and best business practices. Utilize the support services to resolve any issues and optimize your operations.

Tips for Running a Successful IFFCO Fertilizer Franchise

Prioritize Customer Relationships

Building strong relationships with your customers is key to a successful franchise. Offer excellent customer service, provide valuable agricultural advice, and ensure timely delivery of products. Trust and loyalty from customers can lead to repeat business and referrals.

Maintain Efficient Inventory Management

Effective inventory management ensures that you have the required stock available at all times. Keep track of your inventory levels and place orders with IFFCO in advance to avoid stockouts.

Educate Farmers

Organize workshops and seminars to educate farmers about the benefits of using IFFCO fertilizers. Demonstrating the positive impact on crop yield and quality can significantly boost your sales.

Embrace Digital Marketing

Utilize digital marketing strategies to promote your franchise. Create a website, engage with customers on social media platforms, and use online advertising to increase your reach and visibility.

Conclusion

Securing an IFFCO fertilizer franchise is an excellent business opportunity for those looking to enter the agricultural sector. By following the steps outlined in this guide and meeting the eligibility criteria, you can successfully become part of this esteemed organization. Fertilizer Dealerships, especially those affiliated with reputable brands like IFFCO, offer significant growth and profitability potential.

0 notes

Text

Di Ammonium Phosphate (DAP) Prices | Pricing | Trend | News | Database | Chart | Forecast

Di-Ammonium Phosphate (DAP) prices is a critical component in global agricultural practices, particularly in the production of fertilizers. The fluctuation of DAP prices significantly impacts farmers, agricultural industries, and the overall food supply chain. In recent years, the price of DAP has been on a volatile trend due to several contributing factors. This has resulted in significant interest in understanding the dynamics behind its pricing, its impact on various stakeholders, and how future trends might evolve.

One of the primary factors influencing the price of Di-Ammonium Phosphate is the cost of raw materials. DAP is primarily composed of phosphoric acid and ammonia, both of which are subject to global market fluctuations. Any increase in the price of these raw materials directly affects the production cost of DAP, thereby increasing its market price. Additionally, the availability of these raw materials is influenced by global political and economic conditions, such as trade policies and supply chain disruptions, further complicating the price stability of DAP.

Another key factor in determining DAP prices is the demand from the agricultural sector. As global food demand rises due to population growth, the need for fertilizers like DAP also increases. Countries that are heavily reliant on agriculture, especially developing nations, drive much of the demand for DAP. However, while demand increases, supply often struggles to keep up due to production constraints and environmental factors, pushing prices higher. Seasonal demand patterns also play a role, as certain times of the year see higher usage of fertilizers, leading to temporary price spikes.

Get Real Time Prices for Di-Ammonium Phosphate (DAP): https://www.chemanalyst.com/Pricing-data/diammonium-phosphate-dap-1179

Global trade policies and tariffs are also crucial in determining the price of Di-Ammonium Phosphate. Countries that are major producers of DAP, such as China and the United States, often impose export restrictions or tariffs that affect the global supply chain. These trade policies can result in price increases, especially when key exporting nations decide to limit their output or impose tariffs to protect their domestic industries. On the other hand, favorable trade agreements or reductions in tariffs can help to stabilize or reduce prices. The geopolitical relationships between major fertilizer-producing countries and those with large agricultural sectors are therefore significant in shaping DAP prices.

Environmental regulations and sustainability concerns are increasingly affecting the production and pricing of Di-Ammonium Phosphate. The production of DAP, especially the mining of phosphate rock and the synthesis of ammonia, has been criticized for its environmental impact, including pollution and greenhouse gas emissions. As a result, governments and international bodies have imposed stricter environmental regulations on producers, which often leads to increased production costs. These additional costs are passed down to consumers in the form of higher DAP prices. In the future, we may see more emphasis on sustainable production methods, which could either increase or decrease prices depending on technological advancements and regulatory changes.

Currency exchange rates also play a role in the pricing of DAP, particularly for countries that rely on imports. Fertilizer prices are often quoted in US dollars, and any fluctuations in the exchange rate can lead to higher or lower costs for importing countries. When the local currency depreciates against the dollar, the cost of importing DAP rises, leading to higher prices for farmers and agricultural industries in those countries. On the other hand, a strong local currency can help to offset some of the price increases caused by global factors.

In terms of future trends, the price of Di-Ammonium Phosphate is expected to remain volatile due to the ongoing challenges in the global supply chain, fluctuating raw material costs, and the increasing demand for food production. However, technological advancements in fertilizer production, such as more efficient methods for synthesizing ammonia or extracting phosphate, could help to stabilize prices in the long term. Additionally, the growing interest in sustainable agriculture practices may lead to innovations in how fertilizers are produced and used, potentially reducing the environmental impact and cost of DAP.

There is also growing competition from alternative fertilizers, which could impact the demand and pricing of Di-Ammonium Phosphate. For instance, organic fertilizers, slow-release fertilizers, and precision agriculture techniques are becoming more popular as farmers look for ways to reduce costs and increase efficiency. While DAP remains one of the most widely used fertilizers globally, shifts in agricultural practices and the adoption of new technologies could alter the demand dynamics in the coming years.

To sum up, the price of Di-Ammonium Phosphate is influenced by a wide range of factors, including raw material costs, agricultural demand, trade policies, environmental regulations, and supply chain disruptions. As global food demand continues to rise, the need for fertilizers like DAP remains critical, ensuring that its pricing will remain a key concern for farmers, industries, and governments. Understanding these factors is essential for anyone involved in agriculture or the fertilizer industry, as it allows for better planning and risk management in the face of price volatility. Looking ahead, technological innovations and sustainable practices could provide some relief from the current price challenges, but the complex interplay of global factors will continue to make DAP prices a subject of significant interest and importance.

Get Real Time Prices for Di-Ammonium Phosphate (DAP): https://www.chemanalyst.com/Pricing-data/diammonium-phosphate-dap-1179

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#DAP Price#DAP Price Monitor#DAP Pricing#Di Ammonium Phosphate#Di Ammonium Phosphate Price#Di Ammonium Phosphate Prices

0 notes

Text

In modern agricultural production, fertilizer granulator is one of the key equipment for the production of high-quality fertilizer. Choosing the right fertilizer machine can not only improve production efficiency, but also ensure the quality and effect of fertilizer. This article will introduce how to choose the suitable fertilizer granulator according to the production needs.

1. Understand the requirements of fertilizer production line

First, you need to identify the specific needs of your Fertilizer Granulating Production Line. Different production lines are suitable for different types of fertilizer production. For example, the NPK Fertilizer Production Line is suitable for the production of Complex Fertilizer containing nitrogen, phosphorus and potassium, the three main elements necessary for plant growth. The Organic Fertilizer Production Line applies to the production of fertilizers based on organic materials.

2. Choose the right type of granulator

After determining the type of production line, the next need to choose the appropriate fertilizer granulator series. Common types of granulators on the market include Fertilizer Granules Compaction Machine, Flat-Die Pellet Machine, Rotary Drum Granulator, and Disc Granulator. Each granulator has its own unique advantages and application scenarios. For example, the Fertilizer Granules Compaction Machine is suitable for producing high density fertilizer pellets, while the Rotary Drum Granulator is suitable for producing larger scale fertilizer pellets.

3. Consider the raw material characteristics of the fertilizer

When choosing a fertilizer granulator, it is also necessary to consider the characteristics of fertilizer raw materials. For example, If the raw material is nitrogen fertilizer (such as Urea, Ammonium Sulfate, Ammonium Chloride), Phosphate fertilizer (such as Ammonium Dihydrogen Phosphate, Ammonium Phosphate Dibasic, Ground Phosphate Rock) or potash (such as Potassium Chloride, Potassium Sulphate), you need to choose a granulator that can adapt to the characteristics of these raw materials.

4. Consider production scale and efficiency

Finally, when choosing a fertilizer granulator, you also need to consider your production scale and efficiency needs. If your production is larger, you may want to choose Rotary Drum granulators that can handle large quantities of raw materials. In addition, factors such as the degree of automation, energy consumption and maintenance costs of the pelletizer need to be considered to ensure an efficient and economical production process.

Through the above four aspects of consideration, you can more scientifically choose the granulator suitable for your fertilizer production line. The right choice can not only improve production efficiency, but also ensure the quality and effect of fertilizers, providing strong support for agricultural production.

0 notes

Text

The Indian agriculture sector relies heavily on fertilizers to boost crop yield and ensure food security. With the burgeoning population and increasing demand for food, fertilizer companies play a crucial role in enhancing agricultural productivity. Among the many players in this industry, a few companies stand out due to their scale, technological advancements, and market reach. In this blog, we will explore the top 10 largest fertilizer companies in India, shedding light on their contributions and impact on the agricultural landscape.

top 10 largest fertilizer companies in india

1. Indian Farmers Fertiliser Cooperative Limited (IFFCO)

IFFCO is a leading fertilizer cooperative in India, known for its vast production capacity and extensive distribution network. Established in 1967, IFFCO operates several manufacturing units across the country, producing a range of fertilizers including urea, DAP (Diammonium Phosphate), and complex fertilizers. The cooperative’s emphasis on quality and its significant role in the cooperative sector make it a cornerstone of India’s fertilizer industry.

2. National Fertilizers Limited (NFL)

NFL, a public sector enterprise, is another major player in the Indian fertilizer sector. Founded in 1974, NFL is known for its large-scale production of urea and other nitrogenous fertilizers. The company operates multiple production plants and has a robust distribution network, ensuring that its products reach farmers across India. NFL’s commitment to innovation and sustainability has helped it maintain a strong market position.

3. Rashtriya Chemicals and Fertilizers Limited (RCF)

RCF, established in 1978, is a prominent manufacturer of fertilizers and chemicals. The company produces a variety of products, including urea, DAP, and complex fertilizers. With a focus on technological advancements and operational efficiency, RCF has grown to become one of the largest fertilizer companies in India. Its comprehensive distribution network ensures that its products are widely available to the farming community.

4. Coromandel International Limited

Coromandel International, a subsidiary of the Murugappa Group, is a major player in the Indian fertilizer industry. The company produces a range of fertilizers, including urea, phosphate-based fertilizers, and micro-nutrients. Established in 1961, Coromandel International has a significant presence in both the production and distribution sectors, making it a key contributor to India’s agricultural growth.

5. Tata Chemicals Limited

Tata Chemicals, a part of the Tata Group, is a renowned name in the Indian fertilizer market. The company produces a variety of fertilizers, including urea and complex fertilizers. Founded in 1939, Tata Chemicals has a long history of innovation and excellence. Its commitment to sustainable practices and its focus on research and development have helped it maintain a competitive edge in the industry.

6. GSFC (Gujarat State Fertilizers & Chemicals)

GSFC, established in 1962, is a leading fertilizer and chemicals manufacturer in India. The company produces a wide range of fertilizers, including urea, DAP, and NPK (Nitrogen, Phosphorus, and Potassium) fertilizers. With a strong focus on technological advancements and operational efficiency, GSFC has become a major player in the Indian fertilizer sector.

7. Bharat Petroleum Corporation Limited (BPCL)

While primarily known as an oil and gas company, BPCL also has a significant presence in the fertilizer industry. The company’s fertilizer division produces urea and other nitrogenous fertilizers. Established in 1976, BPCL has leveraged its expertise in the chemical industry to become a notable player in the fertilizer sector.

8. Fertilizer Corporation of India Limited (FCI)

FCI, founded in 1961, is a public sector enterprise that plays a crucial role in the Indian fertilizer market. The company produces a range of fertilizers, including urea, ammonium sulphate, and complex fertilizers. With a focus on expanding its production capacity and improving its distribution network, FCI continues to be an important player in the industry.

9. Shree Pushkar Chemicals & Fertilizers Limited

Shree Pushkar Chemicals & Fertilizers Limited, established in 1993, is a significant player in the production of specialty fertilizers and chemicals. The company’s focus on innovation and product quality has helped it establish a strong presence in the market. Shree Pushkar’s range of products includes complex fertilizers and specialty chemicals, catering to the diverse needs of farmers.

10. Deepak Fertilisers and Petrochemicals Corporation Limited (DFPCL)

DFPCL, founded in 1979, is a major manufacturer of fertilizers and petrochemicals. The company’s product portfolio includes urea, ammonium nitrate, and other nitrogenous fertilizers. With a commitment to quality and sustainability, DFPCL has become a prominent name in the Indian fertilizer industry.

Conclusion

The Indian fertilizer industry is characterized by its diversity and scale, with several major players contributing to its growth and development. These top 10 largest fertilizer companies in india, including IFFCO, NFL, RCF, and others, play a pivotal role in supporting Indian agriculture and ensuring food security. Their commitment to innovation, quality, and sustainability continues to drive progress in the sector, benefiting farmers and the broader agricultural community.

Aradhaya, as an observer of this dynamic industry, recognizes the contributions of these leading companies and their impact on India’s agricultural landscape. Their continued efforts in improving fertilizer production and distribution are crucial for the country’s food security and agricultural sustainability.

0 notes

Text

Nitrogen, phosphorus and potassium compound fertilizer, referred to as NPK Compound Fertilizer, as a key nutrient recharge station in agricultural production, its importance is self-evident. This set of nitrogen (N), phosphorus (P), potassium (K) in one of the chemical fertilizer, through modern scientific and technological means to accurately match, to meet the diversified needs of plant growth. When it comes to the production and processing of fertilizer, it is necessary to mention the efficient and accurate fertilizer granulator, which plays a crucial role in the fertilizer production line.

First, the integration of main characteristics and granulation technology

The comprehensive characteristics of nutrient elements of NPK compound fertilizer benefit from the selection of raw materials with scientific ratio. In the process of converting these raw materials into granular Fertilizer, the precision work of the Fertilizer Granules Compaction Machine is indispensable. The machine extrudes the powdered fertilizer into a compact and uniform particle through double roller compression, which not only improves the physical properties of the fertilizer, but also facilitates storage and transportation.

Second, the adaptation of various types and granulation equipment

There are a wide variety of NPK Compound Fertilizer on the market, from mono-ammonium phosphate to potassium dihydrogen phosphate, and then to various ratios of compound fertilizers, each fertilizer has its own specific application scenarios. In order to adapt to the production needs of different fertilizers, a variety of granulation equipment such as Disc Granulator and Rotary Drum granulator came into being. The Disc Granulator uses the high-speed rotation and tilt Angle of the disk to make the fertilizer raw materials naturally form balls under the combined action of centrifugal force and gravity, and the particles are uniform and the surface is smooth, which is conducive to the absorption of crop roots. The Rotary Drum Granulator is the first choice for large-scale fertilizer production lines with its high efficiency and wide adaptability.

Third.Optimization of application method and granulation process

Whether it is used as base fertilizer, topdressing fertilizer or foliar fertilizer, the application effect of NPK Compound Fertilizer is closely related to its particle shape and quality. High-quality fertilizer particles can be better dispersed in the soil, improving the utilization of nutrients. Through the precise control of fertilizer granulator, fertilizer particles suitable for different application methods can be produced, such as large particles for base fertilizer and small particles for foliar fertilizer, and the fertilization effect is further optimized.

Fourth, precautions and auxiliary role of granulation equipment

In the application of nitrogen, phosphorus and potassium compound fertilizer, reasonable proportion and appropriate application is the basic principle. In order to ensure the precise ratio of fertilizer and particle quality, fertilizer granulator plays an important role in raw material mixing, particle size adjustment and quality control. In addition, when it is necessary to mix with other fertilizers or pesticides, the granulator can also help reduce the risk of reactions between different substances, ensuring the safety and effectiveness of the mixed fertilizer.

Fifth. Market trends and innovations in granulation technology

With the continuous development of agricultural technology and the improvement of environmental awareness, the NPK Compound Fertilizer market is developing in the direction of high efficiency, environmental protection and sustainable development. At the same time, fertilizer granulators are constantly innovating and upgrading, using more environmentally friendly materials and production processes to reduce energy consumption and emissions. In the future, we have reason to believe that with the help of fertilizer granulator,NPK Compound Fertilizer will bring more significant benefits and broader application prospects for agricultural production.

#Fertilizer Granules Compaction Machine#Disc Granulator#Rotary Drum Granulator#NPK Compound Fertilizer

0 notes

Text

Nitrogen, phosphorus and potassium compound fertilizer, referred to as NPK Compound Fertilizer, as a key nutrient recharge station in agricultural production, its importance is self-evident. This set of nitrogen (N), phosphorus (P), potassium (K) in one of the chemical fertilizer, through modern scientific and technological means to accurately match, to meet the diversified needs of plant growth. When it comes to the production and processing of fertilizer, it is necessary to mention the efficient and accurate fertilizer granulator, which plays a crucial role in the fertilizer production line.

First, the integration of main characteristics and granulation technology

The comprehensive characteristics of nutrient elements of NPK compound fertilizer benefit from the selection of raw materials with scientific ratio. In the process of converting these raw materials into granular Fertilizer, the precision work of the Fertilizer Granules Compaction Machine is indispensable. The machine extrudes the powdered fertilizer into a compact and uniform particle through double roller compression, which not only improves the physical properties of the fertilizer, but also facilitates storage and transportation.

Second, the adaptation of various types and granulation equipment

There are a wide variety of NPK Compound Fertilizer on the market, from mono-ammonium phosphate to potassium dihydrogen phosphate, and then to various ratios of compound fertilizers, each fertilizer has its own specific application scenarios. In order to adapt to the production needs of different fertilizers, a variety of granulation equipment such as Disc Granulator and Rotary Drum granulator came into being. The Disc Granulator uses the high-speed rotation and tilt Angle of the disk to make the fertilizer raw materials naturally form balls under the combined action of centrifugal force and gravity, and the particles are uniform and the surface is smooth, which is conducive to the absorption of crop roots. The Rotary Drum Granulator is the first choice for large-scale fertilizer production lines with its high efficiency and wide adaptability.

Third.Optimization of application method and granulation process

Whether it is used as base fertilizer, topdressing fertilizer or foliar fertilizer, the application effect of NPK Compound Fertilizer is closely related to its particle shape and quality. High-quality fertilizer particles can be better dispersed in the soil, improving the utilization of nutrients. Through the precise control of fertilizer granulator, fertilizer particles suitable for different application methods can be produced, such as large particles for base fertilizer and small particles for foliar fertilizer, and the fertilization effect is further optimized.

Fourth, precautions and auxiliary role of granulation equipment

In the application of nitrogen, phosphorus and potassium compound fertilizer, reasonable proportion and appropriate application is the basic principle. In order to ensure the precise ratio of fertilizer and particle quality, fertilizer granulator plays an important role in raw material mixing, particle size adjustment and quality control. In addition, when it is necessary to mix with other fertilizers or pesticides, the granulator can also help reduce the risk of reactions between different substances, ensuring the safety and effectiveness of the mixed fertilizer.

Fifth. Market trends and innovations in granulation technology

With the continuous development of agricultural technology and the improvement of environmental awareness, the NPK Compound Fertilizer market is developing in the direction of high efficiency, environmental protection and sustainable development. At the same time, fertilizer granulators are constantly innovating and upgrading, using more environmentally friendly materials and production processes to reduce energy consumption and emissions. In the future, we have reason to believe that with the help of fertilizer granulator,NPK Compound Fertilizer will bring more significant benefits and broader application prospects for agricultural production.

#Fertilizer Granules Compaction Machine#Disc Granulator#Rotary Drum Granulator#NPK Compound Fertilizer

0 notes

Text

List of Top 10 Iron Syrup in India

Iron syrup, the most vital part of all anaemia patients and people with a little low iron level, is now coming with so many varieties in the market. Even one iron syrup supplier in India is supplying a huge variety of iron syrups from different brands, so think how many more syrups are available in the entire pharma market! And among this plethora of options, it would be really a daunting task for anyone to find the best syrup which is perfect for all aspects. That’s why we have searched and listed out top 10 iron syrup in India for your ease. Scroll down to know their names.

Which Are the Best Iron Syrup in India?

Earlier, there was only a few options available in iron syrups. But these days, Iron syrup manufacturer manufacturs iron syrup in various formulations. So, it’s necessary to check the formulation, ingredients, other nutrition availability, and the probable side effects before buying one from an iron syrup supplier. Now you can find best iron syrup for adults, and best iron syrup for child also. Here are the names of top 10 iron syrups in India that are bets from every aspect.

1. Dexotone Iron Tonic

Dexotone iron tonic is a very nutritious iron syrup in India for both adults and children. ferric ammonium citrate, a bioavailable form of iron, vitamin B12, B9, C and zinc. Along with treating iron deficiency, it increases the production of red blood cells, improves brain functioning and boost up energy levels.

2. Hapro Bloodo Vita Syrup

Hapro Bloodo Vita syrup is best for adults and it contains iron, folic acid, magnesium phosphate, Ferrum phosphate and more nutrients. It helps create healthy red blood cells, better blood circulation all-over the body, and manage weight loss.

3. Livogen Syrup

Livogen syrup treats iron deficiency in pregnant women and made of folic acid, iron etc.

4. Dexorange Hematinic Syrup

Dexorange Hematinic Syrup comes with folic acid, vitamin b12 and iron. It addresses and treats iron deficiency in pregnant ladies.

5. Hemfer Syrup

Hemfer Syrup is rich in ferrous glycine sulphate, folic acid, vitamin b12, D-biotin, and zinc sulphate. It is effective for managing anaemia and also improves hair growth.

6. Sangobion Syrup

Sangobion syrup contains so many ingredients like Vitamin C , Copper sulfate and manganese sulfate, Folic acid and Vitamin B12. It elevates the low red blood cells level. It is available in delicious vanilla and strawberry-scented flavours, especially for kids. However, pregnant women and people with more serious illnesses can also take it if they lack iron.

7. Ferrous Iron Syrup

8. Ferium XT Syrup

9. Orofer XT Iron Tonic

10. Wilsoplex Herbal Syrup

Conclusion

We have made this list after lots of searching and checking people’s opinions about these syrups to give you just a basic information. There are more iron syrups available in India that might have the best ingredients and work very efficiently for iron deficiency. It’s totally up to you which brand and which syrup you will choose.

If you are looking for a leading iron syrup manufacturer in India to collect most effective and good quality iron syrups, then come to Sapphire HealthCare. This is a well-reputed iron syrup manufacturer and supplier in this country selling iron syrups made of best and genuine ingredients only. Get low-price but highest-quality iron syup from Sapphire healthcare.

0 notes

Text

Ammonia Market Analysis: Assessing Growth Opportunities

Ammonia stands as a fundamental chemical compound with diverse applications across industries such as agriculture, chemicals, pharmaceuticals, and more. This blog aims to delve into the dynamics of the global ammonia market, examining key drivers, applications, emerging trends, and future growth prospects.

Understanding the Ammonia Market:

Ammonia (NH3) is a colorless gas with a pungent odor and is highly soluble in water. It serves as a vital precursor in the production of fertilizers, chemicals, pharmaceuticals, and various industrial applications due to its nitrogen-rich properties.

Market Dynamics:

Fertilizer Production: The largest application of ammonia is in the manufacturing of nitrogen-based fertilizers such as urea, ammonium nitrate, and ammonium phosphate, contributing significantly to global food production and agriculture.

Chemical Industry: Ammonia is a key raw material in the production of chemicals such as ammonium sulfate, ammonium nitrate, nitric acid, and various organic nitrogen compounds used in pharmaceuticals, plastics, explosives, and cleaning agents.

Environmental Applications: Ammonia is used in environmental control technologies such as selective catalytic reduction (SCR) systems in power plants and vehicles to reduce nitrogen oxide (NOx) emissions, contributing to air quality improvement.

Industrial Refrigeration: Ammonia's properties as a refrigerant make it suitable for industrial refrigeration systems, cold storage facilities, and food processing industries due to its low environmental impact and energy efficiency.

Applications Across Industries:

Agriculture: Fertilizers, soil amendments.

Chemicals: Nitrogen compounds, cleaning agents.

Environmental Control: NOx reduction, wastewater treatment.

Refrigeration: Industrial refrigeration, cold storage.

Market Trends:

Sustainable Agriculture: Growing emphasis on sustainable agriculture practices drives demand for ammonia-based fertilizers due to their high nitrogen content, improved crop yields, and reduced environmental impact compared to traditional fertilizers.

Green Ammonia Production: Innovations in green and renewable ammonia production methods, including electrolysis of water and nitrogen, hydrogen-based processes, and carbon capture utilization (CCU), align with sustainability goals and carbon footprint reduction.

Industrial Safety and Efficiency: Advancements in ammonia production technologies focus on safety enhancements, energy efficiency improvements, and process optimization to meet regulatory standards and reduce operational costs.

Future Prospects:

The global ammonia market is poised for steady growth, driven by rising agricultural demands, environmental regulations promoting clean technologies, and innovations in production processes. Investments in green and sustainable ammonia production, coupled with expanding industrial applications, present significant growth opportunities in the coming years.

Conclusion:

Ammonia remains a cornerstone chemical with critical roles in agriculture, chemicals, environmental control, and refrigeration industries worldwide. Navigating the ammonia market requires a deep understanding of industry trends, regulatory landscapes, and technological advancements. With a focus on sustainability, innovation, and application diversification, the ammonia market is primed for continued growth and contributions to various sectors addressing global challenges and opportunities.

0 notes

Text

Exploring the Vibrant World of the Fertilizer Market: Growth and Outlook

Exploring Fertilizer Market Research Reports

The Fertilizer Industry is a cornerstone of global agriculture, playing a pivotal role in ensuring food security and sustainable crop production. With an ever-increasing demand for agricultural products to feed a growing population, understanding the intricacies of the fertilizer market is essential. Let's delve deeper into this vital sector with comprehensive data and insightful analysis.

Assessing Fertilizer Market Outlook

The outlook for the fertilizer market is shaped by a multitude of factors, including technological advancements, regulatory frameworks, and shifting consumer preferences. Industry experts offer valuable insights into future market trends and developments, aiding stakeholders in making informed decisions:

Technological Innovations: Advancements in fertilizer manufacturing processes, such as controlled-release formulations and precision agriculture techniques, are driving market growth by enhancing efficiency and sustainability.

Environmental Considerations: Increasing awareness of environmental sustainability and concerns about nutrient runoff and soil degradation are driving demand for eco-friendly fertilizers and organic alternatives.

Market Disruptions: External factors such as geopolitical tensions, trade disputes, and climate change can significantly impact fertilizer markets, leading to supply chain disruptions and price volatility.

Understanding Fertilizer Market Size and Growth

The fertilizer market is vast and continues to expand to meet the needs of farmers worldwide. Statistical data provides valuable insights into the market's size and growth trajectory. The Fertilizer Market was valued at approximately USD 170 billion in 2021 and is projected to exceed USD 230 billion by 2026, with a compound annual growth rate (CAGR) of around 5% during the forecast period. Market dynamics vary across regions, influenced by factors such as agricultural practices, government policies, and climatic conditions. While emerging economies show promising growth potential, mature markets exhibit steady but moderate expansion.

Click here – To Know more about Crop Protection market

Challenges in Fertilizer Marketing

Fertilizer marketing faces numerous challenges, requiring industry players to navigate complex market dynamics and regulatory landscapes:

Price Volatility: Fluctuations in raw material prices, currency exchange rates, and energy costs can affect fertilizer production costs and profit margins, necessitating risk management strategies.

Regulatory Compliance: Adherence to stringent environmental regulations and quality standards poses compliance challenges, particularly for multinational companies operating in diverse regulatory environments.

Market Competition: Intense competition among fertilizer manufacturers and suppliers compels companies to differentiate their products through branding, product innovation, and value-added services.

Analyzing Market Share of Different Fertilizers

The fertilizer market comprises various types of fertilizers, each with its unique properties and market dynamics:

Nitrogen Fertilizers: Nitrogen-based fertilizers, such as urea, ammonium nitrate, and ammonium sulfate, account for the largest market share due to their essential role in promoting plant growth and protein synthesis.

Phosphorus Fertilizers: Phosphorus-based fertilizers, including diammonium phosphate (DAP) and triple superphosphate (TSP), are vital for enhancing root development, flowering, and fruiting in crops.

Potassium Fertilizers: Potassium-based fertilizers, such as potassium chloride (MOP) and potassium sulfate (SOP), contribute to plant stress tolerance, water regulation, and fruit quality improvement.

Exploring Fertilizer Market Trends

Fertilizer market trends reflect evolving consumer preferences, technological advancements, and sustainability initiatives:

Shift Towards Sustainable Agriculture: Growing environmental concerns and regulatory pressures are driving the adoption of sustainable fertilizer practices, such as precision farming, organic fertilizers, and soil health management.

Digitalization and Precision Agriculture: Integration of digital technologies, such as drones, sensors, and data analytics, is revolutionizing fertilizer application techniques, enabling farmers to optimize nutrient use efficiency and minimize environmental impact.

Rise of Specialty Fertilizers: Increasing demand for high-value crops, such as fruits, vegetables, and cash crops, is fueling the adoption of specialty fertilizers tailored to specific crop needs and soil conditions.

Fertilizer Additives Market: Enhancing Fertilizer Performance

Fertilizer Additives play a crucial role in improving fertilizer efficacy, nutrient uptake, and crop yields. Key trends in the fertilizer additives market include:

Adoption of Micronutrient Additives: Micronutrient additives, such as zinc, boron, and manganese, are gaining traction for addressing soil deficiencies and enhancing plant nutrition.

Bio-stimulants and Soil Conditioners: Bio-stimulants and soil conditioners, derived from natural sources such as seaweed extracts and humic substances, are increasingly used to promote plant growth, stress tolerance, and soil health.

Innovations in Coating Technologies: Coating technologies, such as polymer coatings and encapsulation, are being employed to improve fertilizer release kinetics, reduce nutrient losses, and prolong nutrient availability in the soil.

Conclusion: Navigating Opportunities in the Fertilizer Market

The fertilizer market presents a dynamic landscape with numerous opportunities and challenges for industry stakeholders. By leveraging market insights, embracing technological innovations, and adopting sustainable practices, companies can navigate market uncertainties, capitalize on emerging trends, and contribute to global food security and agricultural sustainability. Continued investment in research and development, strategic partnerships, and market diversification will be essential for long-term success in the evolving fertilizer market.

#Fertilizer Industry#Fertilizer Market Size#Fertilizer Market Analysis#Fertilizer Market Demand#Fertilizer Market Forecast#Fertilizer Market Growth#Fertilizer Market Outlook#Fertilizer Market Revenue#Fertilizer Market Trends#Fertilizer Industry Research Reports#Fertilizer Market Research Reports#Fertilizer Market Major Players#Fertilizer Market#Fertility Supplements Market#Fertilizer Production Machinery Market in India#Trends in Global Fertilizer Market#Fertilizer Additives Market#Challenges in Fertilizer Marketing#Market Share of Different Fertilizers#Fertilizer Market in India

0 notes

Text

Australia Ammonia Market Insights: Trends, Challenges, and Future Outlook

Market Overview:

Ammonia is an important nitrogen source used to produce nitrogen-containing fertilizers such as urea, ammonium nitrate and ammonium phosphate. It is also used in fibers, plastics, explosives and cleaning products.

Market Dynamics:

Ammonia is mostly used in Australia for nitrogen fertilizers production due to the high demand from agricultural industry. According to recent reports, Australian agricultural sector has seen significant growth over past few years and is estimated to grow at over 3% annually during forecast period owing to rising food demand from growing population and demand for Australian agricultural exports globally. This rise in agricultural outputs will positively influence the demand for nitrogen fertilizers and subsequently ammonia market in Australia. In addition, growing demand for industrial use of ammonia like cleaning products manufacturing will also drive its market. However, stringent environmental regulations around CO2 emissions from ammonia production plants may slightly hamper the market growth during forecast period.

Major Drivers of the Australia Ammonia Market: Increased Fertilizer Demand Boosting Ammonia Consumption

The agricultural sector in Australia has been expanding significantly over the past few years. As the nation seeks to boost its agricultural output and meet the growing global food demand, the consumption of fertilizers has increased substantially. Ammonia is a key ingredient that is used in the production of nitrogen-based fertilizers such as urea, ammonium nitrate, and ammonium sulfate. With the rise in fertilizer usage, the demand for ammonia from the fertilizer industry has surged as well.

Stringent Regulations on Nitrogen Oxide Emissions Favoring Ammonia Production Shift

The Australian government has introduced stringent regulations to curb nitrogen oxide emissions from industries including power generation and waste incineration. As ammonia production and processing contributes significantly lower NOx emissions compared to other sources, many companies are shifting towards ammonia. The favorable policy environment is encouraging investments in ammonia facilities and infrastructure to replace conventional technologies. This transition is expected to boost ammonia consumption volumes in the coming years.

Major Restraint of the Australia Ammonia Market: Transportation Issues Hindering Market Expansion

While ammonia demand is rising steadily across various end-use sectors, transportation of ammonia poses unique safety challenges due to its corrosive and toxic nature. There is a lack of dedicated pipeline infrastructure for long-distance ammonia transportation within Australia. Reliance on road and sea shipments makes distribution difficult and cost-intensive. Remote locations witness supply disruptions as setting up storage and handling facilities is a major undertaking. These transportation barriers restrict the market from reaching its true potential and expanding across all geographical regions.

Major Opportunity for the Australia Ammonia Market: Green Ammonia Production Opening New Growth Avenues

With the world accelerating energy transition, green ammonia is emerging as a promising carbon-free solution. Australia is well-positioned to tap the vast potential of green ammonia due to its abundance of renewable energy resources like solar and wind. Several projects are being planned and established to produce green ammonia through electrolysis using renewable power. This provides an opportunity for Australia to export green ammonia to high demand markets in Asia and become a globally significant supplier. It can also facilitate the decarbonization of domestic shipping, fertilizer manufacturing and other industries.

Major Trend in the Australia Ammonia Market: Rising Investments in Large-Scale Import Terminals

To cater to the increasing fertilizer demand and ensure steady ammonia supply, major players in the Australian market are investing heavily in setting up import terminals with large capacities. For instance, Incitec Pivot recently completed expansion of its ammonia import facility at Kwinana, Perth to achieve a handling capacity of 1 million tonnes per year. Yara is constructing a new ammonia import terminal near Brisbane which is expected to receive 800,000 tonnes annually once completed in 2024. These import hubs will strengthen Australia's position as a key ammonia importing and distribution center to support the agricultural growth momentum.

#Australia Ammonia Market Share#Australia Ammonia Market Growth#Australia Ammonia Market Demand#Australia Ammonia Market Trend#Australia Ammonia Market Analysis

0 notes

Text

Ammonium Phosphates Market Growth Dynamics 2023 Emerging Technologies and Supply Chain Analysis

The ammonium phosphates market refers to the global industry involved in the production, distribution, and consumption of ammonium phosphate fertilizers and other related products. Ammonium phosphates are important fertilizers widely used in the agricultural sector to enhance crop productivity. They provide essential nutrients, such as nitrogen and phosphorus, which are crucial for plant growth and development.

Here is some full information about the ammonium phosphates market:

Market Overview: The global ammonium phosphates market has been experiencing steady growth due to the increasing demand for food, population growth, and the need for higher agricultural productivity. Ammonium phosphates are widely used in various crops, including cereals, fruits, vegetables, and oilseeds.

Types of Ammonium Phosphates: The market offers different types of ammonium phosphates, including monoammonium phosphate (MAP) and diammonium phosphate (DAP). MAP has a higher phosphorus content, while DAP contains equal amounts of nitrogen and phosphorus.

Application Areas: Ammonium phosphates find applications primarily in the agricultural sector as fertilizers. They are also used in the production of fire retardants, animal feed supplements, and various industrial processes.

Regional Market: The market for ammonium phosphates is globally distributed, with key regions including North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa. The demand for these fertilizers varies across regions based on factors such as agricultural practices, crop patterns, and government policies.

Factors Driving the Market: The growth of the ammonium phosphates market is driven by several factors, including the increasing global population, rising food demand, shrinking arable land, and the need to improve agricultural productivity. Additionally, the adoption of modern farming techniques and the growing trend of organic farming are boosting the demand for ammonium phosphates.

Market Challenges: The market faces challenges such as stringent government regulations on fertilizer usage, environmental concerns related to nutrient runoff, and the availability of alternative fertilizers. These challenges have led to the development of innovative and eco-friendly fertilizers in recent years.

Key Players: The market is highly competitive, with several prominent players operating globally. Some of the key players in the ammonium phosphates market include OCP Group, Mosaic Company, Yara International ASA, CF Industries Holdings, Inc., and EuroChem Group AG, among others.

Future Outlook: The future of the ammonium phosphates market looks promising, driven by the increasing global population, the need for sustainable agriculture practices, and the introduction of advanced fertilizers. The market is expected to witness technological advancements, product innovations, and strategic collaborations to meet the evolving demands of farmers and regulatory requirements.

It's important to note that the information provided here is a general overview, and specific market dynamics, trends, and statistics may change over time. For the most up-to-date and detailed information, it is recommended to refer to market reports, industry publications, and consult with experts in the field.

0 notes

Text

0 notes

Text

DAP Price, Prices, Trend, Demand, Market Analysis | ChemAnalyst

The Di Ammonium Phosphate (DAP) prices have been a focal point for stakeholders in the global agricultural and fertilizer industries. DAP, a highly water-soluble fertilizer containing phosphorous and nitrogen, plays a crucial role in enhancing crop yields. The fluctuation in DAP prices is influenced by several factors, including raw material costs, geopolitical events, and global demand-supply dynamics.

One key determinant of DAP prices is the cost of phosphoric acid and ammonia, the primary ingredients used in its production. Fluctuations in prices of these raw materials, often driven by market conditions, weather-related disruptions, or geopolitical tensions, directly impact the overall production cost of DAP. Additionally, energy prices, given their role in the production process, contribute significantly to the final price of DAP in the market.

Geopolitical events and trade relations among major producing and consuming nations also exert a notable influence on DAP market prices. Tariffs, trade agreements, and diplomatic tensions can disrupt the supply chain, leading to uncertainties and price volatility. The global nature of the fertilizer market means that decisions made in one part of the world can have ripple effects on prices elsewhere, creating a complex web of interconnected factors.

Get Real Time Prices of DAP: https://www.chemanalyst.com/Pricing-data/diammonium-phosphate-dap-1179

Moreover, the agricultural sector's demand for fertilizers, including DAP, is subject to seasonal variations. Planting seasons and harvesting cycles in different regions can lead to fluctuations in demand, affecting prices accordingly. Unpredictable weather conditions, such as droughts or floods, further amplify the uncertainty in agricultural output, influencing the need for fertilizers like DAP.

Global economic conditions also play a pivotal role in determining DAP prices. Economic downturns can lead to reduced purchasing power, affecting farmers' ability to invest in fertilizers and impacting overall market demand. Conversely, periods of economic growth can stimulate agricultural activities, driving demand for fertilizers and subsequently influencing DAP prices.

The DAP market is also shaped by regulatory developments and environmental concerns. Increasing awareness of sustainable farming practices and environmental regulations aimed at reducing nutrient runoff may impact the production and use of fertilizers, including DAP. Manufacturers adapting to these changing norms might face additional costs, potentially affecting the final market prices of DAP.

In conclusion, the Di Ammonium Phosphate market prices are intricately linked to a multitude of factors ranging from raw material costs and geopolitical events to seasonal demand variations and regulatory changes. Industry stakeholders must closely monitor these dynamic influences to make informed decisions and navigate the complex landscape of the global fertilizer market. As the world continues to grapple with challenges related to climate change, food security, and sustainable agriculture, the DAP market will likely remain subject to ongoing shifts in supply and demand dynamics, making it crucial for market participants to stay agile and adaptive in their strategies.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

0 notes

Text

Mono Ammonium Phosphate Fertilizers Market Expanding at a Healthy Rate of 6.9% in the Forecast Period

The mono ammonium phosphate fertilizers market is expand at a compound annual growth rate of 6.9% over the forecast period of 2021 to 2028 and is likely to reach a value of USD 0.51 billion by 2028. The rapid growth in greenhouse vegetable production and the rise in environmental concerns are the factor for the mono ammonium phosphate fertilizers market in the forecast period of 2021 to…

View On WordPress

0 notes