#Ampoule Washing Machine

Explore tagged Tumblr posts

Text

Ampoule Vial Combi Washing Machine

Ampoule Vial Combi Washing Machine, also known as the rotary ampoule washing machine, is a particularly made washing machine that cleans ampoules and vials while minimizing machine part contact and adhering to cGMP regulations. Positive ampoule and vial washing is ensured by a machine with a specially developed Gripper system that grabs the ampoule from the neck and inverts it until the washing process is finished. The ampoule is then released on the outfeed feedworm system in a vertical position after washing. With the use of replacement parts, the machine can wash ampoules and vials ranging from 1 to 20 milliliters.

When filling and packing pharmaceuticals, complete sanitation and hygienic conditions are crucial. This is especially true when injectables are placed within glass ampoules. Before an ampoule is placed in the sterile filling chamber, it must be completely sterile. The industry leader in high-tech pharmaceutical equipment, Adinath, provides a highly accurate ampoule washing machine that satisfies the strict sterility and hygiene requirements of today.

A specifically made Gripper holds the ampoule from its neck, inverts it, and moves it further on a rotating moving system for the cleaning process. The ampoule feeds through feedworm to infeed Star Wheel. When a needle enters an ampoule neck, it travels in a neck-down position above the cleaning needles and moves with the needle bar to ensure that the greatest amount of washing time is achieved. Machine with six standard washing stations, each with six needles for optimal cleaning; the order can be altered to suit the needs of the customer. For the best possible Ampoule and vial washing, the machine also has an exterior wash. In this machine, we have two distinct models. While the AVRW-240 High Speed Ampoule Washing Machine could produce up to 200 ampoules per minute, the AVRW-120 Automatic Ampoule Washing Machine could only produce up to 100 ampoules per minute. One milliliter to twenty milliliter ampoules and vials can be cleaned by either the automatic ampoule and vial washer or the high-speed ampoule and vial washer. For ampoule vial combi washing machine validation and replacement components, we offer extended support.

0 notes

Text

Multijet Ampoule Washing Machine - Lodha Machine

Lodha Machine is a renowned manufacturer and exporter of the Multijet Ampoule Washing Machine in India. Our multijet ampoule washing machines are designed to provide efficient and thorough cleaning for ampoules, ensuring the highest standards of hygiene and quality. These machines uses multiple jets to ensure comprehensive cleaning, making them ideal for the pharmaceutical industry. With advanced technology and durable construction, our multijet ampoule washing machines deliver reliable and consistent performance. Lodha Machine's commitment to quality, innovation, and customer satisfaction has made us a trusted name in the industry. Visit our site - https://www.lodhamachines.com/multijet-ampoule-washing-machine

#ampoule washing machine#multijet ampoule washing machine#multijet ampoule washing machine manufacturer#ampoule washing machine exporter#multi jet ampoule washing machine manufacturer#multijet ampoule washing machine price#ampoule washing machine manufacturer in gujarat#automatic multiJet vial washing machine in india#ampoule washing machine manufacturer in india#multijet ampoule washing machine manufacturer in india#manufacturer of multijet ampoule and vial washing machine

0 notes

Text

If you work in the pharmaceutical industry, you know how important it is to have clean and sterile equipment. One crucial piece of equipment that needs is the external ampoule washing machine. With so many options on the market, it's overwhelming to choose the best one for your needs. That's why we've created the ultimate guide to choosing the best external ampoule washing machine. From understanding the different machines available to features to look for, we'll walk you through everything you need to know to make an informed decision. With our guide, you can feel confident in your choice and ensure that your equipment is always clean and ready to use. So, let's dive in and discover the best external ampoule washing machine for your business.

0 notes

Text

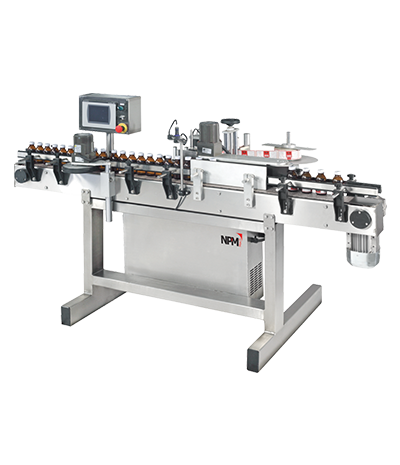

Revolutionizing Pharma Production: The Role of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Introduction

In the dynamic world of pharmaceuticals, precision, hygiene, speed, and compliance are non-negotiable. As the demand for high-quality medicines continues to rise globally, the pharmaceutical industry must meet rigorous standards in both production and packaging. This is where Pharma Packaging Machines come into play—ensuring products are safely, efficiently, and accurately packed before reaching the end-user.

At NPM Machinery Pvt. Ltd., we understand the critical importance of packaging in the pharma value chain. As a leading manufacturer of pharma packaging machines, our mission is to empower pharmaceutical companies with robust, automated, and intelligent machinery that supports regulatory compliance while improving productivity and product integrity.

In this blog, we will delve into the importance of pharma packaging machines, the types available, their benefits, and why NPM Machinery Pvt. Ltd. is your ideal partner in pharmaceutical automation.

Why Pharma Packaging Machines Matter

Pharmaceutical packaging is far more than just enclosing a product in a container. It is a protective barrier, a compliance requirement, a branding tool, and an enabler of global logistics. A well-packaged pharmaceutical product ensures:

Product integrity during transport and storage

Accurate dosage and ease of administration

Protection against contamination and tampering

Compliance with FDA and other global regulatory norms

Efficient serialization and tracking

Manual packaging simply cannot keep up with the high-volume, high-precision demands of modern pharmaceutical production. That’s where automated packaging solutions step in—offering speed, consistency, and compliance.

Core Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

At NPM Machinery Pvt. Ltd., we design and manufacture a full spectrum of advanced pharma packaging machines tailored to the needs of small-scale manufacturers as well as large pharmaceutical giants. Here are the most common types and their applications:

📦 1. Blister Packaging Machines

Ideal for packing tablets and capsules in pre-formed plastic blisters sealed with aluminum foil

Ensures tamper-proof packaging and extended shelf life

Used widely in retail and hospital pharmacy sectors

💊 2. Strip Packaging Machines

Designed to wrap tablets and capsules between aluminum or plastic strip foils

Compact, precise, and perfect for heat-sensitive medicines

Offers high output and minimal material wastage

🧪 3. Bottle Filling and Capping Machines

Automates filling of syrups, suspensions, and other liquids into bottles with accurate volume control

Integrates seamlessly with capping units for secure sealing

Customizable for different bottle sizes and materials

🏷️ 4. Labeling Machines

Applies labels accurately on bottles, ampoules, vials, or boxes

Supports serialization and barcoding for traceability

Compatible with multiple label shapes and sizes

🧼 5. Washing & Sterilizing Machines

Cleans vials, ampoules, and bottles before filling to ensure zero contamination

Uses air and water jets with complete automation

Essential for injectable and parenteral products

🧴 6. Cartoning Machines

Automates the packing of blister packs, bottles, or tubes into cartons

Integrates leaflet insertion and batch coding

Enhances product presentation and traceability

🎯 7. Inspection Machines

Detects broken tablets, missing capsules, misprinted labels, and other defects

Ensures every packaged product meets quality control standards

Reduces human error and improves customer trust

Benefits of Pharma Packaging Machines by NPM Machinery Pvt. Ltd.

Choosing the right packaging solution is not just about machinery—it’s about performance, reliability, and long-term value. NPM Machinery's pharma packaging machines offer:

✅ 1. High-Speed Automation

Boost production rates with minimal human intervention

Ideal for mass manufacturing and 24/7 operations

✅ 2. Unmatched Accuracy

Delivers exact filling, sealing, and labeling

Reduces product loss and ensures dosage consistency

✅ 3. Compliance & Validation

Built with GMP, FDA, and CE compliance in mind

Supports 21 CFR Part 11 for electronic data integrity

✅ 4. Flexibility & Customization

Machines tailored to your product specifications

Modular designs allow for future scalability

✅ 5. Advanced Technology Integration

Equipped with PLC-based controls, SCADA systems, and IoT capabilities

Enables remote monitoring, real-time alerts, and preventive maintenance

✅ 6. Superior Build Quality

Made with stainless steel and corrosion-resistant materials

Long machine life, low maintenance, and robust performance

✅ 7. Global Support & Service

On-site training, remote diagnostics, and spare parts availability

Dedicated support teams for installation, validation, and upgrades

Industries We Serve

While our core strength lies in pharmaceutical packaging, our machines are versatile enough for other regulated industries such as:

Nutraceuticals

Ayurveda and Herbal

Cosmetics

Food & Beverage

Veterinary Medicine

Why Choose NPM Machinery Pvt. Ltd.?

With decades of experience, NPM Machinery Pvt. Ltd. has built a reputation for engineering excellence and customer-centric innovation. Here's what sets us apart:

✔️ 150+ skilled professionals including engineers, technologists, and validation experts

✔️ ISO-certified manufacturing with a focus on precision and safety

✔️ Custom turnkey packaging lines from design to commissioning

✔️ Strong domestic and global footprint with clients across Asia, Africa, Europe, and South America

✔️ Client-first approach—we adapt our solutions to your needs, not the other way around

Our goal is not just to sell machines—but to build long-term partnerships that add value to your production process, protect your brand, and ensure regulatory peace of mind.

Conclusion

The future of pharmaceutical manufacturing lies in smart, integrated, and efficient packaging systems. With increasing global demand, strict compliance requirements, and growing competition, investing in high-performance pharma packaging machines is no longer optional—it's essential.

At NPM Machinery Pvt. Ltd., we don’t just provide machines—we deliver confidence, quality, and peace of mind. Whether you're launching a new production line or upgrading your existing setup, we are here to guide you every step of the way with reliable, cutting-edge, and compliant solutions.

✅ Call to Action

Ready to upgrade your pharma packaging line? Partner with NPM Machinery Pvt. Ltd. and experience unmatched quality, service, and innovation. 📩 Contact us today for a free consultation or demo customized to your packaging needs! 🌐 Visit us at www.npmmachinery.com | 📞 +91-XXXXXXXXXX

0 notes

Text

Leading Manufacturer of Pharmaceutical Machinery in China: Comprehensive Solutions for Vial and Ampoules Packaging Line

As a trusted manufacturer of pharmaceutical machinery and equipment, we specialize in delivering complete solutions designed for the production of tablets, liquids, capsules, powders, granules, and especially Vial and Ampoules Packaging Line. Our robust manufacturing capabilities, advanced R&D, and unwavering commitment to quality position us at the forefront of the pharmaceutical equipment industry in China and globally.

Why Choose Our Pharmaceutical Machinery Solutions

Unmatched Expertise in Pharmaceutical Engineering

We bring decades of experience in pharmaceutical engineering, offering high-precision machinery tailored for all production stages. Our pharmaceutical equipment is designed to comply with international standards such as GMP, CE, and ISO, ensuring safe, efficient, and compliant pharmaceutical production.

End-to-End Production Capabilities

From tablet compression machines to granule processing units, our product lineup covers every essential stage of pharmaceutical manufacturing:

Tablet Press Machines

Capsule Filling Machines

Liquid Filling and Sealing Machines

Powder Mixing & Blending Systems

Granulation Lines

Vial and Ampoules Packaging Line

Our integrated solutions streamline production processes, reduce downtime, and increase yield, which directly translates into higher profitability for pharmaceutical manufacturers.

Vial and Ampoules Packaging Line – Precision and Performance

Fully-Automated Packaging Line for Sterile Injectables

Our Vial and Ampoules Packaging Line offers high-speed, fully automated systems suitable for sterile environments. These lines are designed to handle delicate ampoules and glass vials with pinpoint precision, ensuring integrity, sterility, and consistent quality across batches.

Key features of our vial and ampoule packaging lines include:

Washing, Sterilizing & Drying Units

Liquid Filling Systems (Peristaltic or Piston Pump Based)

Rubber Stoppering and Capping Machines

Ampoule Sealing & Vial Crimping

Visual Inspection Systems

Labeling & Serialization Modules

Integrated PLC and SCADA Control Systems

Each component is designed to maintain aseptic conditions, protect product integrity, and deliver consistent performance.

Core Components of Vial and Ampoules Packaging Line

1. Automatic Vial and Ampoule Washing Machines

These machines are engineered to remove particulates and contaminants from containers using multi-stage ultrasonic and pressure-based washing with WFI (Water for Injection) and clean compressed air. Features include:

In-feed and out-feed automation

Multiple needle spray systems

Customizable formats for different vial sizes

2. High-Temperature Sterilization Tunnels

Utilizing dry heat sterilization, our tunnels eliminate microbial contamination and maintain the sterility of containers post-wash. They feature:

HEPA filtration

Conveyor system with variable speed

Temperature monitoring and validation systems

3. Liquid Filling and Stoppering Machines

These are precision filling machines with servo-driven pistons or peristaltic pumps, ensuring accurate filling volumes for even the smallest doses.

Filling range flexibility (0.1 ml to 100 ml)

In-line or rotary stoppering mechanisms

Laminar airflow units integrated for Class 100 environments

4. Sealing and Capping Units

For ampoules, flame-sealing systems provide hermetic closures, while for vials, aluminum caps are crimped tightly for maximum security.

Flame annealing systems for ampoules

Rotary or linear vial crimping systems

Cap feeding and sorting automation

5. Visual Inspection Systems

High-speed cameras and AI-powered software ensure every ampoule or vial is visually inspected for foreign particles, fill volume, seal integrity, and cosmetic defects.

360-degree inspection

Rejection systems for non-conforming units

Batch reporting and traceability

6. Labeling, Serialization, and Track & Trace

Incorporating advanced serialization technology, our labeling systems help comply with global traceability regulations including 21 CFR Part 11, EU FMD, and DSCSA.

Inkjet and thermal transfer printing

Tamper-evident labels

QR code and barcode support

Made in China, Trusted Worldwide

Our pharmaceutical machinery, proudly made in China, is exported to over 70 countries, including markets in Europe, the Americas, Middle East, Southeast Asia, and Africa. We offer turnkey projects and full support, from design consultation to post-installation training and after-sales service.

Custom-engineered solutions are our specialty. Whether you need a small-scale line for clinical trials or a full commercial production system, we provide flexible configurations tailored to your needs.

Innovation and Compliance – Our Manufacturing Promise

Research-Driven Development

Our dedicated R&D center is continuously innovating to enhance performance, reduce footprint, and integrate AI, IoT, and smart automation into our systems.

Digital twin modeling

Predictive maintenance systems

Cloud-connected data analytics

Regulatory Compliance

Our equipment complies with international regulatory frameworks, including:

GMP (Good Manufacturing Practices)

FDA 21 CFR Part 11

EU Annex 1 Guidelines

WHO and PIC/S Recommendations

Each machine undergoes rigorous FAT (Factory Acceptance Testing) and SAT (Site Acceptance Testing) to ensure seamless compliance during audits.

Unparalleled Customer Support and Global Services

Our team of multilingual engineers and service professionals provides 24/7 remote and on-site support to ensure uptime, training, and continuous improvement. Our global network of distributors and service hubs ensures fast delivery of spare parts and preventive maintenance services.

Industries We Serve

Our solutions are ideal for:

Pharmaceutical manufacturers

Biotech companies

Veterinary drug producers

Clinical research facilities

Contract manufacturing organizations (CMOs)

Partner with Us for Advanced Pharmaceutical Machinery Solutions

As a manufacturer of pharmaceutical machinery, we are proud to set benchmarks in precision engineering, sterile manufacturing, and packaging automation. Our specialized Vial and Ampoules Packaging Line is one of the most trusted solutions for injectable drug manufacturers worldwide.

Contact us today to discuss your production needs and discover how our China-based manufacturing facility can support your end-to-end pharmaceutical production goals.

Contact us:

GRAND INTELLIGENT EQUIPMENT (GUANGZHOU) CO.,Ltd

301A, Building 5, No.333, Juhuashi Ave, Huadu District, Guangzhou City, Guangdong, China.

+86-15361285728 ; +86-020-86886090

Email [email protected]

Wenzhou Grand Machinery Technology Co.,Ltd

Floor 4, Building 2, No.116, Xinglong Road, Wanquan Town, Pingyang County, Wenzhou City, Zhejiang Province, China

+86-15323319612 ; +86-577-65565288

Also available on

On Whatsapp

On Facebook

On Twitter

On Pinterest

On Youtube

On Tumblr

0 notes

Text

0 notes

Text

At Shree Bhagwati Machtech (India) Pvt. Ltd., we take pride in delivering top-tier Bottle and Vial Washing Machines designed to meet the demanding needs of the pharmaceutical industry. Our state-of-the-art machines ensure thorough cleaning of bottles, vials, and ampoules, offering unmatched efficiency and precision. From offline rotary models to high-speed airjet cleaners, our products cater to various industry requirements, ensuring flawless results every time.

For more details, visit - https://www.bhagwatipharma.com/product-category/washing-machinery/

#bhagwatilabeling#vialwashingmachine#washingmachinery#BottleWashingMachine#AmpouleWashingmachine#vialbottlewashingmachine

0 notes

Text

Eugia Steriles Private Limited, part of the Aurobindo Pharma group, is hiring for multiple roles in their Production Department at their manufacturing facility in Visakhapatnam. This is a fantastic opportunity for candidates with expertise in sterile injectables to join a leading global pharmaceutical company. Whether you're an experienced Technical Assistant or a skilled Executive, Eugia Steriles has vacancies that match your skills and experience. Read on to find out more about the available roles, qualifications, and job location. Vacancy Details and Key Responsibilities 1. Technical Assistant / Sr. Technical Assistant Experience Required: 2-7 years in sterile injectables Qualification: Diploma or B.Sc. in a relevant field Job Function: Production of sterile injectables (ampoule, vial, cartridge) Key Responsibilities: Operation of ampoule, vial, and cartridge washing machines, filling machines, and sealing machines Tunnel operations and handling of Autoclave & TS equipment Batch records preparation, compounding, and filling processes Candidates with hands-on experience in sterile injectable manufacturing and knowledge of machine operations are preferred for this role. Your technical expertise will play a crucial part in ensuring smooth production processes. 2. Executive / Sr. Executive Experience Required: 2-8 years Qualification: B. Pharmacy Job Function: Production with a focus on aseptic filling and quality management Key Responsibilities: Qualification activities related to sterile production Knowledge of lyophilization processes Handling QMS elements such as deviations, change controls, and CAPA implementation Active involvement in aseptic filling activities This role is perfect for professionals with exposure to quality management systems (QMS) and a deep understanding of production operations in a sterile environment. Your role will ensure compliance with industry standards and maintain product quality at every stage. Job Location and Interview Details The job location is at Eugia Steriles Private Limited's state-of-the-art facility in Visakhapatnam, Andhra Pradesh. The production unit is located at: Venue: APIIC Industrial Park, Parawada, Anakapalli - 531021 Interview Date: 05th October 2024 Interview Time: 9:00 AM to 3:30 PM To apply, please send your CV to: Email: [email protected], [email protected] How to Apply If you meet the qualifications and are excited about working in sterile production, don't miss this opportunity! Ensure you send your updated CV before the interview date.

0 notes

Text

Rotary Ampoule Washing Machine

Rotary Ampoule Washing Machine, also known as the rotary ampoule washer, is a particularly made washing machine that cleans ampoules while minimizing machine part contact and adhering to cGMP regulations. Positive ampoule washing is ensured by a machine with a specially developed Gripper system that grabs the ampoule from the neck and inverts it until the washing process is finished. The ampoule is then released on the outfeed feedworm system in a vertical position after washing. With the use of replacement parts, the machine can wash ampoules ranging from 1 to 20 milliliters.

When filling and packing pharmaceuticals, complete sanitation and hygienic conditions are crucial. This is especially true when injectables are placed within glass ampoules. Before an ampoule is placed in the sterile filling chamber, it must be completely sterile. The industry leader in high-tech pharmaceutical equipment, Adinath, provides a highly accurate rotary ampoule washing machine that satisfies the strict sterility and hygiene requirements of today.

A specifically made Gripper holds the ampoule from its neck, inverts it, and moves it further on a rotating moving system for the cleaning process. The ampoule feeds through feedworm to infeed Star Wheel. When a needle enters an ampoule neck, it travels in a neck-down position above the cleaning needles and moves with the needle bar to ensure that the greatest amount of washing time is achieved. Machine with six standard washing stations, each with six needles for optimal cleaning; the order can be altered to suit the needs of the customer. For the best possible Ampoule washing, the machine also has an exterior wash. In this machine, we have two distinct models. While the AVRW-240 High Speed Ampoule Washing Machine could produce up to 200 ampoules per minute, the AVRW-120 Automatic Ampoule Washing Machine could only produce up to 100 ampoules per minute. One milliliter to twenty milliliter ampoules can be cleaned by either the automatic ampoule washer or the high-speed ampoule washer. For rotary ampoule washing machine validation and replacement components, we offer extended support.

0 notes

Text

Multijet Vial Washing Machine - Lodha Machine

Lodha Machine is manufacturer and exporter of the Multijet Vial Washing Machine in India. Our multijet vial washing machines are engineered to provide exceptional cleaning for vials used in the pharmaceutical industry. Utilizing multiple jets, these machines ensure thorough and efficient cleaning, maintaining the highest standards of hygiene and quality. With advanced technology and strong construction, our multijet vial washing machines offer reliable and consistent performance. Lodha Machine's dedication to quality, innovation, and customer satisfaction makes us the preferred choice for businesses seeking effective vial washing solutions. Visit our site - https://www.lodhamachines.com/multijet-vial-washing-machine

#vial washing machine#multijet vial washing machine#multijet vial washing machine manufacturer#multijet vial washing machine exporter#vial washing machine price#multijet vial washing machine manufacturer in gujarat#multijet vial washing machine manufacturer in india#manufacturer of multijet ampoule and vial washing machine

0 notes

Text

We are a leading provider of top-of-the-line Ampoule Filling & Sealing solutions and take great pride in delivering high-quality machinery that meets the needs of pharmaceutical companies and guarantees the integrity of their products. Our Ampoule Filling & Sealing Machine Line features a variety of highly efficient and versatile equipment, including Automatic Rotary Ampoule Washing Machines, Automatic Ampoule Filling & Sealing Machines, and Automatic Ampoule Sticker Labeling Machines. For detailed information visit;

https://www.parthec.com/product/category/ampoule-filling-sealing-machine

0 notes

Text

Pharmaceutical Packaging Machine - lodhapharma

We are one of the premier pharmaceutical company in India engaged in manufacturing & exporting of Pharmaceutical Turnkey Projects.

LODHA International LLP is Indian based company owned and operated since 2008. LODHA focus on their customer’s requirements to drive and develop the Lodha range of Packaging Machinery & Process Equipment’s for Pharmaceutical, Healthcare, Veterinary, Cosmetic, Chemical and Biotech Industry.

We, Lodha International LLP, is a leading manufacturer of Pharmaceutical Packaging Machine & Process Equipment for the healthcare, veterinary, cosmetic, chemical and pharmaceutical biotech industry. As a result of wide industry experience and continuous research and development, we have developed an extensive product range of highly reliable and advanced Pharmaceutical Packaging Machinery & Process Equipment.

Our cutting-edge machinery is created with the goals and specifications of all associated sectors in mind. Pharmaceutical Packaging Machine in India All of our equipment are built to last a long period with minimal maintenance thanks to their robust construction. Being a top producer of packaging machinery and process equipment, we place a lot of emphasis on quality, which is visible in the superior products we provide.

Sterilisation equipment, chemical machinery, capsule filling machines, tablet press machines, liquid filling machines, powder filling machines, sticker labelling machines, packaging machines, sterile washing machines, and other packaging machines are among the many high-quality machinery products that we offer.

Various Product Selection: At Pharmaceutical Packaging Machine, we offer a comprehensive range of conveyor solutions tailored to suit various applications. Whether you require:

STERILE WASHING MACHINES

LIQUID FILLING MACHINE

AMPOULE FILLING AND SEALING MACHINE

POWDER FILLING MACHINE

CAP SEALING MACHINE

STICKER LABELING MACHINES

PACKAGING MACHINES

CAPSULE SECTION

TABLET SECTION

PROCESS EQUIPMENTS

STERILIZATION EQUIPMENTS

CHEMICAL MACHINERY

OTHER PACKAGING MACHINES

Put it up, Green Dot BioPak is a perfect example of how biodegradable products can transform whole sectors and lessen their adverse effects on the environment. Not only are they setting the standard for environmentally sustainable production, but they are also encouraging others to adopt a more thoughtful approach to consuming with their unwavering dedication to sustainability, innovation, and responsibility. Businesses like Green Dot BioPak act as rays of light as we confront the problems of resource depletion and climate change, showing that a better, cleaner future is achievable.

Contact us today at +91 9081915912 or mailto:[email protected], or visit our website at https://www.lodhapharma.com to discuss your requirements.

#Pharmaceutical Packaging Machine#Pharmaceutical Packaging Machines manufacturers#Pharmaceutical Packaging Machinery#Pharmaceutical Packaging Machine In India

0 notes

Text

External Air Jet Bottle Cleaning and Washing Machine Manufacturer

Brothers is a leading manufacturer of Air Jet Cleaning and Washing Machines in India. We deliver all types of Ampoule Washing machine, linear vial washing, with all industrial safety and quality features. External Vial Washing Machine & Rotary Bottle Washing Multi Head Air Jet Cleaning Machine External Vial Washing Machine Automatic air jet cleaning machine Air Jet Cleaning Machine manufacturer Air Jet bottle washing machine air jet washing machine Bottle Washing and Air Jet Cleaning Machine Air jet bottle cleaning machine Air jet cleaning machine High Speed Automatic Rotary Ampoule linear tunnel bottle washing machine Air jet vacuum cleaning machine Rotary vial washing machine Rotary Bottle Washing Machine Multi head air jet cleaning machine Washing and air jet cleaning machine

For More Details Click here : https://www.brothers.in

0 notes

Text

Harsiddh Engineering: Leading Manufacturer and Supplier of Pharmaceutical Machines

Harsiddh Engineering Co. is a renowned manufacturer and exporter specializing in the production of Washing, Filling, Capping, and Labeling Machines for various industries. With a strong global presence, Harsiddh Engineering Co. has gained recognition for its exceptional products, adherence to international standards, and unwavering commitment to customer satisfaction.

Specialization in Pharmaceutical Machines: Washing, Filling, Capping, and Labeling

At Harsiddh Engineering Co., we excel in manufacturing Washing, Filling, Capping, and Labeling Machines. These machines are extensively used in the pharmaceutical, cosmetic, and agrochemical industries. By providing reliable and efficient machines, we contribute to the seamless production processes of our valued clients.

Applications in Pharmaceutical, Cosmetic, and Agrochemical Industries

Our machines at Harsiddh Engineering Co. play a vital role in the pharmaceutical, cosmetic, and agrochemical sectors. In the pharmaceutical industry, we offer a range of machines such as ampoule filling machines, liquid and powder injection machinery, and tablet capsule counting and filling lines. These machines ensure precise and hygienic packaging of medications. For the cosmetic industry, we provide cream and ointment filling machines. In the agrochemical sector, our specialized machinery facilitates the filling of agrochemical products.

Compliance with International Standards

At Harsiddh Engineering Co., maintaining stringent compliance with international standards is of utmost importance to us. Our products adhere to reputable standards such as USFDA, UKMHRA, and WHOGMP. This ensures that our machines meet the highest quality and safety requirements. Our commitment to compliance instills confidence in our clients, assuring them of the reliability and performance of the machines they invest in.

Growth and Expansion of Harsiddh Engineering

Over the years, Harsiddh Engineering Co. has experienced remarkable growth and expansion. In 2005, we underwent a restructuring process and emerged with a new name, Harsiddh Engineering Co., to strengthen our presence in the international market. This strategic move has allowed us to explore new opportunities and further establish our technical expertise in the pharmaceutical industry, both domestically and globally.

Focus on Quality and Customer Satisfaction

At Harsiddh Engineering Co., we place the highest importance on delivering products of exceptional quality to our customers. We follow rigorous quality control measures at every stage of production to ensure that each machine meets stringent industry standards. By prioritizing quality, we aim to provide reliable and durable machines that contribute to the smooth operation of our clients' manufacturing processes. Customer satisfaction is a core value for us, and we continually strive to exceed customer expectations through our unwavering commitment to quality and service.

Certifications and Awards

The dedication, efficiency, and quality of our production at Harsiddh Engineering Co. have been recognized through various certifications and awards. We have achieved ISO 9001:2015 certification, which testifies to our adherence to international quality management standards. Additionally, our products have obtained CE certification, ensuring compliance with European health, safety, and environmental protection standards. These certifications validate our commitment to delivering superior products to our customers.

Industry Memberships and Associations

To stay at the forefront of advancements and industry trends, Harsiddh Engineering Co. actively participates in industry memberships and associations. We proudly associate ourselves with the Engineering Export Promotion Council of India, a prestigious organization that promotes and supports Indian engineering exports on a global scale. By actively engaging with industry associations, Harsiddh Engineering Co. remains updated with the latest developments, standards, and regulations in the pharmaceutical machinery sector.

Global Presence and Export of Pharmaceutical Machinery

Harsiddh Engineering Co. has successfully established a strong global presence through the export of pharmaceutical machinery to various countries worldwide. Our unwavering commitment to quality, reliability, and customer satisfaction has enabled us to build long-standing relationships with international clients. By consistently delivering high-performance machines, we have gained a solid reputation as a reliable partner in the global pharmaceutical machinery market.

Product Range and Offerings

At Harsiddh Engineering Co., we offer a diverse range of machinery to cater to the specific requirements of the pharmaceutical, cosmetic, and agrochemical industries. Our product range includes Cream and Ointment Filling Machines, Dry Powder Filling Machines, Tablet Capsule Counting and Filling Lines, Bottle Washing Machines, Ampoule Filling Machines for Open Ampoules, Ampoule Filling Machines for Closed Ampoules, and many others. Each machine undergoes meticulous design and manufacturing processes to meet the highest standards of quality, efficiency, and reliability. We understand the unique needs of our clients and strive to provide tailored solutions that enhance their production processes.

In conclusion, Harsiddh Engineering Co. stands as a leading manufacturer and supplier of pharmaceutical machines. With our specialization in Washing, Filling, Capping, and Labeling Machines, we cater to the needs of various industries, including pharmaceuticals, cosmetics, and agrochemicals. Our commitment to compliance with international standards ensures that our machines meet the highest quality and safety requirements. We focus on delivering products of exceptional quality, prioritizing customer satisfaction through reliable and durable machines. With certifications, industry memberships, and a global presence, Harsiddh Engineering Co. continues to be a trusted and innovative player in the pharmaceutical machinery market.

0 notes

Text

Automatic Ampoule Sticker Labeling Machine in Egypt

Laxmi Pharma Equipment is Manufacturer, Supplier, and Exporter of Automatic Rotary Gipper Type Washing Machine in Egypt . Our Registered office and manufacturer unit is in Ahmedabad, Gujarat, India. An automatic ampoule sticker labeling machine applies labels accurately and efficiently to ampoules, small glass containers commonly used in the pharmaceutical and healthcare industries. These machines are essential for ensuring product traceability, safety, and compliance with regulatory standards. Process of Automatic Ampoule Sticker Labeling Machines: Ampoule Feeding: The machine automatically feeds the ampoules into the labeling area. Label Dispensing: The labeling machine dispenses the appropriate label from a roll. Label Application: The machine accurately applies the label to the ampoule, ensuring proper alignment and adhesion. Inspection: The machine may include an inspection system to verify that the labels are applied correctly. Product Output: The labeled ampoules are conveyed to the next stage of the production process. Features: High Speed: Capable of labeling a large number of ampoules per minute. Accuracy: Ensures precise label placement and alignment. Flexibility: Can handle various ampoule sizes and shapes. Ease of Use: User-friendly interface with touch screen controls. Durability: Built to withstand continuous operation in demanding environments. Customization: You can customize it to meet specific labeling requirements, such as different label sizes, materials, or adhesives. Laxmi Pharma Equipment is an Automatic Ampoule Sticker Labeling Machine in Egypt Including Cario, Alexandria, Giza, Shubra el-Khema, Port Said, Suez, EL mahalla el Kubra, El Mansoura, Tanta, Asyut, Fayoum, Zagazig, Ismailia, Khusus, Aswan, Damanhur, El- Minya, Damietta, Luxor, Qena, Beni Suef, Sohag, Shibin el-Kom, Hurghada, Banha, Mallawi. For more information, please feel free to contact us. View Product: Click Here Read the full article

#Alexandria#Aswan#Asyut#AutomaticAmpouleStickerLabelingMachineinEgypt#AutomaticAmpouleStickerLabellingMachine#Banha#BeniSuef#Cario#Damanhur#Damietta#Egypt#ELmahallaelKubra#ElMansoura#El-Minya#Exporter#ExporterofAutomaticAmpouleStickerLabelingMachine#ExporterofAutomaticAmpouleStickerLabelingMachineinEgypt#Fayoum#Giza#Hurghada#Ismailia#Khusus#LaxmiPharmaEquipment#Luxor#Mallawi#Manufacturer#ManufacturerofAutomaticAmpouleStickerLabelingMachine#ManufacturerofAutomaticAmpouleStickerLabelingMachineinEgypt#PortSaid#Qena

0 notes

Text

What is an automatic rotary ampoule and vial washing machine?

Automated high-speed rotary ampoules and vial washing machines wash ampoules and vials with minimal contact between machine parts. These machines are suitable for washing or cleaning various sizes of ampoules and vials with the help of interchangeable parts. Automatic rotary ampoules and vial washing machines are generally used in the pharmaceutical, veterinary, and biotech industries.

#ampoule washing machine#rotary ampoule washing machine#automatic ampoule washing machine#ampoule washing#automatic rotary ampoule washing machine#vial washing machine#rotary ampoule washing machine manufacturer#automatic ampoule washing machine exporter#rotary ampoule washing machine exporters#ampoule washing machine gujarat

1 note

·

View note