#Analytical laboratory testing is important for the quality control of drugs. This testing ensures that any patient will not face any side-ef

Text

Crafting Clear Skin: The Precision of Salicylic Acid Manufacturing

Salicylic acid has long been a cornerstone in skincare and pharmaceutical formulations, celebrated for its remarkable efficacy in treating acne, exfoliating the skin, and managing various dermatological conditions. As a leading ingredient in numerous products, the demand for high-quality salicylic acid is unwavering. Salicylic acid manufacturers play a crucial role in meeting this demand, employing advanced technologies, stringent quality control measures, and innovative processes to produce this essential compound. In this blog, we explore the world of salicylic acid manufacturing, highlighting its significance, processes, benefits, and why it’s a cornerstone of modern skincare and pharmaceutical solutions.

The Importance of Salicylic Acid

Salicylic acid is a beta-hydroxy acid (BHA) derived from natural sources like willow bark and wintergreen leaves or synthesized in laboratories. It is renowned for its ability to penetrate pores, exfoliate dead skin cells, and reduce inflammation, making it a powerful ingredient in acne treatments, chemical peels, and dandruff shampoos. Its keratolytic properties help to soften and shed the outer layer of skin, promoting cell turnover and revealing a smoother, clearer complexion.

For more information salicylic acid manufacturer

Advanced Manufacturing Processes

Manufacturing salicylic acid involves sophisticated chemical processes to ensure purity, potency, and safety. The most common method is the Kolbe-Schmitt reaction, which synthesizes salicylic acid from sodium phenoxide and carbon dioxide under high pressure and temperature. This method yields high-purity salicylic acid, suitable for both pharmaceutical and cosmetic applications. Manufacturers utilize advanced equipment and precise control systems to maintain optimal reaction conditions, ensuring consistent quality and yield.

Quality Control and Assurance

Quality control is paramount in salicylic acid manufacturing. Rigorous testing protocols are implemented at every stage of production, from raw material selection to final product packaging. Analytical techniques such as high-performance liquid chromatography (HPLC), gas chromatography (GC), and mass spectrometry (MS) are used to verify the purity, potency, and stability of salicylic acid. These tests ensure that the final product meets stringent industry standards and regulatory requirements, guaranteeing safety and efficacy for consumers.

Customization and Innovation

Salicylic acid manufacturers often work closely with cosmetic and pharmaceutical companies to develop customized formulations tailored to specific product needs. Whether creating a potent acne treatment, a gentle exfoliating cleanser, or an effective dandruff shampoo, manufacturers provide expertise in optimizing salicylic acid concentrations and formulations for maximum benefit. This collaborative approach fosters innovation, resulting in new and improved products that address evolving consumer demands and dermatological advancements.

Sustainability and Ethical Practices

In response to growing environmental concerns, many salicylic acid manufacturers are adopting sustainable and ethical practices. This includes sourcing raw materials from renewable resources, minimizing waste and emissions, and implementing energy-efficient technologies. Some manufacturers are also exploring greener synthesis methods that reduce environmental impact while maintaining high-quality production standards. These efforts align with the broader industry trend toward sustainability and responsible manufacturing.

Meeting Regulatory Standards

Compliance with regulatory standards is a critical aspect of salicylic acid manufacturing. Regulatory bodies such as the FDA (Food and Drug Administration) and EMA (European Medicines Agency) set stringent guidelines for the production and use of salicylic acid in cosmetic and pharmaceutical products. Manufacturers must adhere to Good Manufacturing Practices (GMP) and ensure their products are free from contaminants, properly labeled, and safe for consumer use. Regular audits and inspections by regulatory authorities help maintain compliance and uphold product integrity.

Future Trends and Innovations

The future of salicylic acid manufacturing is marked by continuous innovation and adaptation to emerging trends. Advances in green chemistry, biotechnology, and nanotechnology are poised to revolutionize production methods, enhancing efficiency and sustainability. Additionally, research into new applications and formulations of salicylic acid promises to expand its role in skincare and healthcare, offering consumers even more effective and versatile solutions.

Conclusion

Salicylic acid manufacturers are at the forefront of producing one of the most versatile and effective ingredients in skincare and pharmaceuticals. Through advanced manufacturing processes, stringent quality control, and a commitment to innovation and sustainability, these manufacturers ensure the consistent supply of high-quality salicylic acid. As consumer demand for effective skincare solutions continues to grow, the role of salicylic acid manufacturers remains vital, driving the development of products that promote healthier, clearer skin and improved well-being. Embrace the power of precision and discover the transformative benefits of expertly crafted salicylic acid.

2 notes

·

View notes

Text

Shriram Pharmacy College: Best Pharmacy Education In India

Shriram Pharmacy College, Bankner, stands out as one of India’s premier institutions for pharmacy education. With a strong focus on practical learning, experienced faculty, and state-of-the-art facilities, Shriram Pharmacy College has become synonymous with excellence in pharmacy education. The college offers a comprehensive Bachelor’s program in Pharmacy, covering diverse aspects of the pharmaceutical industry. This blog will explore the key highlights of studying at Shriram Pharmacy College, including career paths, curriculum details, and the unique benefits of choosing this institution.

### 1. **Bachelor’s Program in Pharmacy: A Four-Year Journey to Excellence**

The Bachelor’s program in Pharmacy at Shriram Pharmacy College is a four-year degree program designed to provide students with an in-depth understanding of pharmaceutical sciences. The curriculum is meticulously structured to include theoretical knowledge and practical training, ensuring that students are well-equipped to meet the challenges of the pharmaceutical industry. With a focus on developing technical skills, critical thinking, and ethical practices, the program ensures that graduates are not just academically proficient but also industry-ready professionals.

### 2. **Extensive Training Across Eight Semesters**

The Bachelor of Pharmacy program at Shriram Pharmacy College is spread across eight semesters, each designed to build a strong foundation in core subjects and introduce advanced concepts in pharmaceutical sciences. From pharmacology, medicinal chemistry, and pharmacognosy to biopharmaceutics and clinical pharmacy, the curriculum encompasses all essential topics. Students gain hands-on experience through laboratory sessions, internships, and industry visits, allowing them to apply theoretical knowledge to real-world scenarios and develop critical skills for their future careers.

### 3. **Pharmacy Business: Focus on Customer Service**

One of the critical aspects of pharmacy education at Shriram Pharmacy College is the focus on the pharmacy business and customer service. Students are trained to provide excellent customer service in community and hospital pharmacies, ensuring that they understand the importance of patient care, ethical practices, and communication skills. Courses cover topics such as patient counseling, prescription handling, and customer relationship management, preparing students to excel in pharmacy operations and maintain high standards of care.

### 4. **Hospital Pharmacist: Ensure Accurate Medication Dispensing**

Shriram Pharmacy College places a strong emphasis on training students to become hospital pharmacists, where accuracy in medication dispensing is crucial. The curriculum includes in-depth knowledge of pharmacotherapy, drug interactions, and patient safety protocols. Students learn to work closely with healthcare professionals to ensure patients receive the correct medications and dosages. The practical experience gained through hospital internships and simulation labs helps them understand the complexities of hospital pharmacy and prepares them for a career in healthcare settings.

### 5. **Chemical Technician: Maintain Strict Safety Protocols**

A significant part of the pharmacy education at Shriram Pharmacy College is dedicated to training students as chemical technicians who can work in laboratories and research facilities. The program emphasizes maintaining strict safety protocols, handling chemicals, and using advanced laboratory equipment. Students learn the importance of quality control, analytical testing, and standard operating procedures (SOPs). The hands-on training in state-of-the-art labs ensures that graduates are well-prepared to contribute to the pharmaceutical and chemical industries.

### 6. **Drug Inspector: Conduct Thorough Compliance Checks**

Shriram Pharmacy College prepares its students to pursue careers as drug inspectors, where they are responsible for ensuring that pharmaceutical products meet regulatory standards. The program covers various aspects of drug laws, quality assurance, and regulatory affairs, providing students with the knowledge needed to conduct compliance checks thoroughly. By understanding the regulatory frameworks and industry standards, graduates are equipped to play a vital role in maintaining the quality and safety of pharmaceuticals in the market.

### 7. **Medical Writer: Communicate Complex Information Clearly**

Another career path for graduates of Shriram Pharmacy College is that of a medical writer. The program emphasizes the importance of clear communication, allowing students to convey complex scientific and medical information to various audiences. Courses in technical writing, medical journalism, and content development are integral parts of the curriculum. The training enables graduates to work in research organizations, pharmaceutical companies, and healthcare institutions where effective communication of medical information is essential.

### 8. **Medical Representative: Build Strong Client Relationships**

The Bachelor of Pharmacy program at Shriram Pharmacy College also prepares students to become successful medical representatives who play a crucial role in the pharmaceutical industry. Training focuses on building strong client relationships, understanding product portfolios, and effectively communicating product benefits to healthcare professionals. Students learn the skills needed to thrive in sales and marketing roles, such as persuasive communication, negotiation, and product knowledge, which are vital for success as a medical representative.

### 9. **Unique Benefits of Choosing Shriram Pharmacy College**

Choosing Shriram Pharmacy College for your pharmacy education comes with several unique benefits. The college offers an integrated approach to learning that combines classroom instruction, practical training, and real-world experience. The faculty comprises industry experts and seasoned academicians who provide mentorship and guidance to students. The college also has strong ties with leading pharmaceutical companies and healthcare institutions, facilitating excellent placement opportunities for graduates.

/media/eb0cb48ed6146db932072f4aa2538013

### FAQs

**Q1: What is the duration of the Bachelor of Pharmacy program at Shriram Pharmacy College?**

The Bachelor of Pharmacy program at Shriram Pharmacy College is a four-year degree program, divided into eight semesters. Each semester covers different aspects of pharmaceutical sciences, from fundamental subjects like pharmacology and medicinal chemistry to advanced topics such as clinical pharmacy and drug regulations. The program also includes practical training through lab work, internships, and industry visits, which helps students gain hands-on experience and prepares them for various career opportunities in the pharmaceutical industry.

**Q2: What career opportunities are available after completing a B.Pharm from Shriram Pharmacy College?**

Graduates from Shriram Pharmacy College have a wide range of career opportunities in the pharmaceutical sector. They can work as hospital pharmacists, community pharmacists, drug inspectors, medical writers, chemical technicians, or medical representatives. The comprehensive education provided by the college ensures that students are well-prepared for roles in both clinical and non-clinical settings, research and development, regulatory affairs, and pharmaceutical marketing, among others. The college’s strong industry ties also help in securing placements for graduates.

**Q3: How does Shriram Pharmacy College ensure practical training for its students?**

Shriram Pharmacy College emphasizes practical training through its state-of-the-art laboratories, hands-on workshops, and internships. The college has collaborations with leading pharmaceutical companies and healthcare institutions where students gain real-world experience. Additionally, regular industry visits, guest lectures by professionals, and simulation-based learning modules are integrated into the curriculum. This approach ensures that students are well-equipped with the skills and experience needed to excel in various pharmacy-related roles upon graduation.

**Q4: What makes Shriram Pharmacy College stand out among other pharmacy colleges in India?**

Shriram Pharmacy College stands out due to its commitment to providing a well-rounded pharmacy education. The college offers a robust curriculum that combines theoretical learning with practical application, guided by a team of experienced faculty members. The state-of-the-art facilities, strong focus on research, and industry-oriented training modules further distinguish it from other institutions. Moreover, the college provides excellent placement support and has a track record of producing highly skilled pharmacy professionals who excel in their careers.

**Q5: Are there any research opportunities available for students at Shriram Pharmacy College?**

Yes, Shriram Pharmacy College encourages students to participate in research activities. The college provides opportunities for research in various fields such as pharmacology, medicinal chemistry, and clinical pharmacy. Students can work on innovative projects under the guidance of experienced faculty members, participate in seminars and conferences, and collaborate with industry professionals. These research opportunities not only enhance their learning experience but also prepare them for careers in academia, research, and development sectors.

### **Conclusion**

Shriram Pharmacy College, Bankner, offers a comprehensive and industry-relevant Bachelor of Pharmacy program that equips students with the skills and knowledge needed to excel in the pharmaceutical field. With a curriculum designed to provide both theoretical and practical knowledge, coupled with excellent career support, the college stands as a leading choice for pharmacy education in India. Whether you’re looking to become a pharmacist, a medical writer, or a drug inspector, Shriram Pharmacy College provides the foundation for a successful and rewarding career.

### Stay Connected with Shriram Pharmacy College!

For the latest updates, educational content, and insights into the dynamic field of pharmacy, don’t miss out on the Shriram Pharmacy College YouTube channel. By liking, sharing, and subscribing, you’ll gain access to expert lectures, student testimonials, campus events, and much more. Stay informed about advancements in pharmaceutical sciences and become a part of our vibrant community. Your support helps us grow and continue providing valuable resources to students and professionals alike. Join us today and never miss an update!

#pharmacy#public health#pharmacist#youtube#hospital#shriram medical college#online pharmacy#shriram nursing college#medicine#shriram pharmacy college

0 notes

Text

Ibuprofen Manufacturing Plant Project Report 2024: Setup and Cost

Introduction

Ibuprofen is a widely used nonsteroidal anti-inflammatory drug (NSAID) that provides relief from pain, inflammation, and fever. Its applications range from over-the-counter medications for headaches and arthritis to prescription drugs for more severe conditions. Establishing an ibuprofen manufacturing plant involves a meticulous approach to ensure high-quality production, regulatory compliance, and efficient operations. This article provides a detailed overview of a Ibuprofen Manufacturing Plant Project Report for setting up an ibuprofen manufacturing plant, focusing on key aspects such as site selection, plant design, production processes, quality control, and regulatory considerations. A frequently asked questions (FAQs) section further clarifies common inquiries related to the project.

Project Overview

1. Objective

The main objective of the Ibuprofen Manufacturing Plant Project is to establish a facility that produces high-quality ibuprofen efficiently while meeting stringent pharmaceutical standards. The plant aims to cater to the growing demand for this essential medication by leveraging advanced technology and adhering to best practices in production and quality control.

Get a Free Sample Report with Table of Contents @

https://www.expertmarketresearch.com/prefeasibility-reports/ibuprofen-manufacturing-plant-project-report/requestsample

2. Site Selection

Selecting the optimal location for the ibuprofen manufacturing plant is critical for operational success. Key factors to consider include:

Proximity to Raw Material Suppliers: Ibuprofen production requires specific raw materials, including intermediates and active pharmaceutical ingredients (APIs). Being close to suppliers can reduce transportation costs and ensure a steady supply of necessary materials.

Infrastructure: The site should have access to essential infrastructure such as reliable power, water, transportation networks for shipping products, and communication systems.

Regulatory Environment: The location should offer a favorable regulatory environment with ease of obtaining necessary permits and compliance with environmental and health regulations.

Labor Availability: Access to a skilled workforce is important for operating and maintaining advanced manufacturing equipment and ensuring adherence to Good Manufacturing Practices (GMP).

3. Plant Design and Layout

The design and layout of the ibuprofen manufacturing plant play a crucial role in ensuring operational efficiency and safety. Key areas of the plant include:

Raw Material Storage: Secure storage areas for incoming raw materials and intermediates, with proper inventory management systems to track usage and ensure quality.

Production Areas: Dedicated spaces for various stages of ibuprofen production, including synthesis, formulation, and packaging. The layout should facilitate a smooth workflow and minimize the risk of contamination.

Quality Control Laboratories: Equipped with advanced analytical instruments for testing raw materials, in-process samples, and finished ibuprofen to ensure they meet quality standards.

Packaging and Distribution: Areas for packaging ibuprofen tablets, capsules, or other dosage forms, and preparing them for shipment to customers.

Utilities and Waste Management: Facilities for managing power, water, and waste in an environmentally responsible manner, ensuring compliance with regulatory requirements.

4. Production Process

The production process for ibuprofen involves several key stages:

Raw Material Preparation: The raw materials, including intermediates and APIs, are prepared and pre-treated for the synthesis process.

Synthesis: The core of ibuprofen production involves a chemical reaction where intermediates are processed to produce ibuprofen. This step requires precise control over reaction conditions and reagent handling.

Purification: After synthesis, the ibuprofen product undergoes purification to remove impurities and ensure it meets required specifications.

Formulation: The purified ibuprofen is formulated into tablets, capsules, or other dosage forms, with precise control over dosage and consistency.

Packaging: The finished ibuprofen is packaged into various formats and prepared for distribution to ensure product protection and compliance with labeling regulations.

5. Quality Control

Ensuring the quality of ibuprofen is essential for its safety and efficacy. Key quality control measures include:

Raw Material Testing: Verifying the quality and suitability of raw materials and intermediates before they enter the production process.

In-Process Monitoring: Regular checks during synthesis, purification, and formulation to ensure adherence to established specifications and prevent deviations.

Finished Product Testing: Comprehensive analysis of the final ibuprofen to ensure it meets required specifications for potency, purity, and stability.

6. Regulatory Compliance

Compliance with regulatory standards is critical for operating an ibuprofen manufacturing plant. This includes:

Good Manufacturing Practices (GMP): Adhering to GMP guidelines to ensure that the manufacturing process is consistent and controlled, resulting in high-quality products.

Environmental Regulations: Managing waste, emissions, and resource use in compliance with local and international environmental regulations.

Health and Safety Standards: Ensuring that the plant meets health and safety regulations to protect workers and maintain safe operating conditions.

7. Economic and Environmental Considerations

The economic aspects of setting up an ibuprofen manufacturing plant involve significant capital investment in infrastructure, equipment, and operational costs. However, the potential for substantial returns through product sales and market expansion makes it a viable investment. Environmentally, implementing sustainable practices such as energy-efficient technologies and effective waste management can help minimize the plant’s ecological footprint and enhance its sustainability.

FAQs

1. What is ibuprofen used for?

Ibuprofen is used to relieve pain, reduce inflammation, and lower fever. It is commonly used for conditions such as headaches, arthritis, menstrual cramps, and muscle pain.

2. What are the main stages of ibuprofen production?

The main stages of ibuprofen production include raw material preparation, synthesis, purification, formulation, and packaging.

3. How do I choose the right location for an ibuprofen manufacturing plant?

Choosing the right location involves factors such as proximity to raw material suppliers, availability of infrastructure and skilled labor, favorable regulatory environment, and environmental impact considerations.

4. What are Good Manufacturing Practices (GMP) in ibuprofen production?

Good Manufacturing Practices (GMP) are guidelines that ensure the manufacturing process is consistent and controlled, resulting in high-quality products. GMP includes equipment maintenance, process control, and employee training.

5. What quality control measures are necessary for ibuprofen production?

Quality control measures include testing raw materials, monitoring in-process production, and conducting comprehensive tests on the finished ibuprofen to ensure it meets required specifications for potency, purity, and stability.

6. How can an ibuprofen manufacturing plant minimize its environmental impact?

An ibuprofen manufacturing plant can minimize its environmental impact by implementing energy-efficient technologies, reducing waste, controlling emissions, and adhering to environmental regulations.

7. What is the typical timeline for setting up an ibuprofen manufacturing plant?

The timeline generally includes phases for planning and design, construction and equipment installation, validation and commissioning, and production start-up, spanning approximately 18-24 months.

8. What are the economic benefits of an ibuprofen manufacturing plant?

Economic benefits include job creation, increased industrial output, and potential revenue from product sales. A well-managed plant can significantly contribute to the local economy and provide a strong return on investment.

Related Reports

https://www.expertmarketresearch.com/reports/immersion-cooling-market

https://www.expertmarketresearch.com/reports/automotive-fabric-market

https://www.expertmarketresearch.com/reports/buy-now-pay-later-market

Media Contact:

Company Name: Claight Corporation

Contact Person: Lewis Fernandas, Corporate Sales Specialist — U.S.A.

Email: [email protected]

Toll Free Number: +1–415–325–5166 | +44–702–402–5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au

0 notes

Text

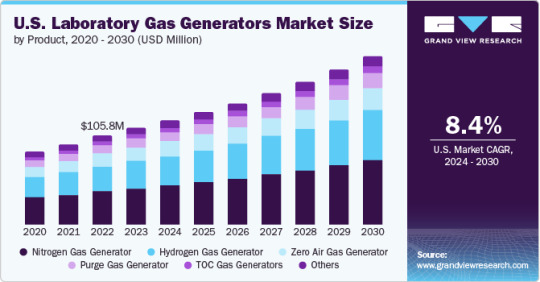

Laboratory Gas Generators Market To Reach $777.4 Million By 2030

The global laboratory gas generators market size is anticipated to reach USD 777.4 million by 2030 and is expected to expand at a CAGR of 8.3% during the forecast period, according to a new report by Grand View Research, Inc. The growth of the market is attributed to the growing importance of analytical techniques in drug and food safety testing, growing safety concerns related to the use of conventional gas cylinders, and increasing R&D spending in the life science sector.

Laboratory gas generators operate across diverse applications, including chromatography and mass spectrometry, wherein they provide high-purity gas essential for accurately identifying various substances within samples, contributing to drug development and quality control. Further in drug detection and analysis, gas supplied from generators ensures efficient and accurate analysis of drug composition, purity, and potential contaminants.

In pharmaceutical packaging, nitrogen gas generators create an inert environment, shielding products from oxidation and degradation during transport and storage, ultimately preserving their integrity and efficacy. However, their role goes beyond mere protection. The nitrogen blanketing facilitated by generators also helps improve the quality of pharmaceutical products. Oxygen exposure can degrade various medications, affecting their potency and shelf life. By creating an oxygen-free environment, generators maintain product quality and extend their usable window.

The laboratory gas generators industry is characterized by intense competition, with numerous manufacturers and suppliers vying for market share. Some of the key players operating in the market include Peak Scientific Instruments, PerkinElmer Inc., Linde plc., VICI DBS, Dürr Technik GmbH & Co. KG, Erre Due S.p.a., and CLAIND srl. Companies are focusing on product innovation, technological advancements, and strategic collaborations to differentiate their offerings and gain a competitive edge. In addition, the growing trend towards customization and modularization in gas generation systems allows end-users to tailor solutions to their specific requirements, further driving market growth and adoption.

Request a free sample copy or view report summary: Laboratory Gas Generators Market Report

Laboratory Gas Generators Market Report Highlights

The nitrogen gas generator segment led the market and accounted for 38% in 2023. The adoption of nitrogen gas generators is driven by their ability to provide high-purity nitrogen on-demand, eliminating the need for gas cylinder handling and storage.

Growing Liquid Chromatography-Mass Spectrometry (LC-MS) field, crucial for drug discovery and metabolomics, drives the need for high-purity nitrogen and helium gas generators for nebulization and collision gas.

The life science sector represents a significant end-user segment for laboratory gas generators, driven by the increasing demand for analytical instruments in drug discovery, development, and quality control processes.

North America dominated the market owing to the increasing investments in the life science, food & beverage, and chemical sectors in the region.

In July 2023, Peak Scientific Instruments introduced nitrogen gas generation solutions with the release of the Corona 1010A. This innovative solution delivers high-purity, filtered nitrogen gas, empowering various applications with a reliable and potent source. Capable of delivering flows up to 5 liters per minute at pressures reaching 80psi.

Laboratory Gas Generators Market Segmentation

Grand View Research has segmented the global laboratory gas generators market based on product, application, end-use, and region:

Laboratory Gas Generators Product Outlook (Revenue, USD Million, 2018 - 2030)

Nitrogen Gas Generator

Hydrogen Gas Generator

Zero Air Gas Generator

Purge Gas Generator

TOC Gas Generators

Others

Laboratory Gas Generators Application Outlook (Revenue, USD Million, 2018 - 2030)

Gas Chromatography

Liquid Chromatography-mass Spectrometry (LC-MS)

Gas Analyzers

Others

Laboratory Gas Generators End Use Outlook (Revenue, USD Million, 2018 - 2030)

Life Science

Chemical & Petrochemical

Food & Beverage

Others

Laboratory Gas Generators Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

U.S.

Canada

Mexico

Europe

UK

Germany

France

Spain

Italy

Asia Pacific

China

India

Japan

South Korea

Australia

Central & South America

Brazil

Argentina

Middle East & Africa

Saudi Arabia

UAE

South Africa

List of Key Players in the Laboratory Gas Generators Market

Peak Scientific Instruments

PerkinElmer Inc.

Linde plc.

VICI DBS

Dürr Technik GmbH & Co. KG

Erre Due S.p.a.

Tisch Environmental, Inc.

CLAIND srl

Isolcell

OXYMAT

0 notes

Text

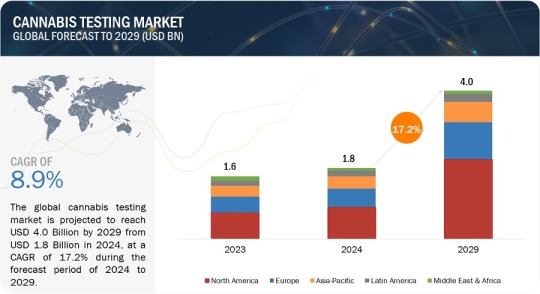

Cannabis Testing Market worth $4.0 billion by 2029

Cannabis Testing Market in terms of revenue was estimated to be worth $1.8 billion in 2024 and is poised to reach $4.0 billion by 2029, growing at a CAGR of 17.2% from 2024 to 2029 according to a new report by MarketsandMarkets™.

The important factors impacting market growth are legalization trends and rising medical applications for cannabis. Rising approvals for medical and recreational cannabis drive the regulations requiring product safety testing which in turn fuel the need for cannabis testing services. Additionally, the rise in the number of cannabis testing labs due to legalization is propelling the demand for analytical instruments is likely to uplift market growth in coming years.

Cannabis Testing Market Trends

Download an Illustrative overview:

Browse in-depth TOC on "Cannabis Testing Market"

439 - Tables

52 - Figures

378 – Pages

Products segment held the highest estimated share of the cannabis testing market.

Based on product & software, the cannabis testing market is segmented into products (analytical instruments {chromatography instruments [liquid chromatography, gas chromatography & other chromatography instruments], spectroscopy instruments [mass spectrometry instruments & atomic spectroscopy instruments] & other analytical instruments} and consumables {chromatography columns, standards and CRMS, sample preparation products and other consumables) and software. The product segment accounted for the largest share of the cannabis testing market in 2023. Market growth is driven by technological advancements providing sophisticated tools for precise analysis, ensuring compliance and quality control, and the expanding legalization of cannabis products. Additionally, increasing requirements for potency labeling and pesticide screening fuel the demand for specialized consumables, further propelling growth in the cannabis testing market. For example, Thermo Fisher Scientific Inc. launched the Thermo Scientific SureSTART consumables portfolio consisting of vials, well plates, caps, inserts, kits, and mats to improve analytical performance and sample security for chromatography and mass spectrometry users in routine and research labs in clinical, food, pharma, biopharma, environmental, and academic sectors.

High growth of services segment attributed to potency testing services.

Based on service, the cannabis testing market is broadly segmented into terpene profiling, microbial analysis, residual solvent analysis, potency testing, heavy metal testing, pesticide screening, and other services. In 2023, potency testing accounted for the largest share of the cannabis testing services market. The high growth of this segment is due to stringent regulatory requirements ensuring accurate THC and CBD levels. This is crucial for product labeling, consumer safety, and compliance, driving demand from producers and dispensaries seeking to meet legal standards and provide reliable, high-quality products.

Services take away the largest estimated share of the end-user segment.

Based on end users, the cannabis testing market is classified into segmented into product & software end users (cannabis testing laboratories {small-scale laboratories, medium-scale laboratories, large-scale laboratories} and research institutes) and service end users (cannabis drug manufacturers & dispensaries, cannabis cultivators/growers). In 2023, the service end users' segment was predicted to account for the highest share of the global cannabis testing market. The large share of this end user segment is due to the rising consumer awareness of quality and safety, rising legalization of cannabis, stringent regulatory standards, and technological advancements in cannabis testing.

During the forecast period, North America displayed lucrative market growth.

North America accounted for the largest share of 65.5% of the cannabis testing market in 2023. The North American market is projected to reach a value of USD 2.6 billion by 2029 from an estimated value of USD 1.2 million in 2024, at a CAGR of 17.3% during the forecast period. The region leads the cannabis testing market due to stringent regulatory standards, robust infrastructure, and widespread legalization of cannabis for medical and recreational purposes. Additionally, North America's advanced R&D capabilities and evolving consumer demand for quality assurance drive its prominence in this growing sector.

Request Sample Pages:

Cannabis Testing Market Dynamics:

Drivers:

Increasing legalization of medical and recreational cannabis

Increasing use of cannabis for medicinal applications

Technological advancements in testing technologies

Restraints:

Lack of standardization

Investment risks due to regularization

Opportunities:

Untapped markets in emerging economies

Research collaborations

Challenge:

High setup costs

Key Market Players of Cannabis Testing Industry:

The global cannabis testing market comprises many key market players competing for markets shares like Agilent Technologies, Inc. (US), Shimadzu Corporation (Japan), Thermo Fisher Scientific Inc. (US), Danaher Corporation (US), Waters Corporation (US), Restek Corporation (US), SGS SA (Switzerland), Merck KGaA (Germany), PerkinElmer, Inc. (US), Hamilton Company (US), Sigma Analytical Services (Canada), SC Labs (US), PharmLabs LLC (US), MCS, Inc. (US), ProVerde Laboratories (US), and Eurofins Scientific (Luxembourg).

The primary interviews conducted for this report can be categorized as follows:

By Respondent: Supply Side- 70%, and Demand Side - 30%

By Designation (Supply Side): Managers - 45%, CXOs & Directors - 30%, Executives- 25%

By Region: North America -40%, Europe -25%, Asia-Pacific -20%, Latin America -10%, MEA- 5%

Recent Developments:

In September 2023, Shimadzu Corporation launched the Brevis GC-2050 gas chromatograph used in various applications including cannabis testing.

In April 2023, SC Labs, one of the leading cannabis testing companies, acquired C4 Laboratories, one of the first Arizona cannabis labs, thus allowing it to be licensed and accredited in five states: California, Colorado, Michigan, Oregon, and Arizona.

In June 2022, Shimadzu Corporation launched the AA-7800 series atomic absorption spectrophotometers. The AA-7800 series is used for quality control in the raw material, food, and for inspecting water quality and hazardous substances in soil thus presenting an advantage in heavy metal testing of cannabis.

Get 10% Free Customization on this Report:

Cannabis Testing Market - Key Benefits of Buying the Report:

The report will help market leaders/new entrants by providing them with the closest approximations of the revenue numbers for the overall cannabis testing market and its subsegments. It will also help stakeholders better understand the competitive landscape and gain more insights to better position their business and make suitable go-to-market strategies. This report will enable stakeholders to understand the market's pulse and provide them with information on the key market drivers, restraints, opportunities, and challenges.

The report provides insights on the following pointers:

Analysis of key drivers (increasing legalization of medical and recreational cannabis, increasing use of cannabis for medicinal applications and technological advancements in testing technologies), restraints (lack of standardization and investment risks due to regularization), opportunities (untapped markets in emerging economies and research collaborations) and challenges (high setup costs) are influencing the growth of cannabis testing market.

Product Development/Innovation: Detailed insights on newly launched products of the cannabis testing market.

Market Development: Comprehensive information about lucrative markets – the report analyses the cannabis testing market across varied regions.

Market Diversification: Exhaustive information about new products, untapped geographies, recent developments, and investments in the cannabis testing market.

Competitive Assessment: In-depth assessment of market shares, growth strategies, and product offerings of leading players include Agilent Technologies, Inc. (US), Shimadzu Corporation (Japan), Thermo Fisher Scientific Inc. (US), Danaher Corporation (US), Waters Corporation (US), Restek Corporation (US), SGS SA (Switzerland), Merck KGaA (Germany), PerkinElmer, Inc. (US), Hamilton Company (US), Sigma Analytical Services (Canada), SC Labs (US), PharmLabs LLC (US), MCS, Inc. (US), ProVerde Laboratories (US), and Eurofins Scientific (Luxembourg) among others in the cannabis testing market.

Get access to the latest updates on Cannabis Testing Companies and Cannabis Testing Industry Growth

#Cannabis Testing Market#Cannabis Testing Industry Size#Cannabis Testing Market Share#Cannabis Testing Market Growth

0 notes

Text

The Importance of Quality Assurance in the Pharmaceutical Industry

https://jpcdn.it/img/051eb779158d87d0dd880a012d758bd3.jpg

Quality assurance (QA) in the pharmaceutical industry is critical to ensuring the safety, efficacy, and quality of drugs and medical products. It encompasses all aspects of the manufacturing process, from the initial research and development stages to the final distribution of the product. A robust QA system ensures that products meet the stringent regulatory standards set by health authorities worldwide.

Key Elements of Pharmaceutical Quality Assurance

1. Regulatory Compliance

Pharmaceutical companies must comply with various national and international regulations, including Good Manufacturing Practices (GMP), Good Laboratory Practices (GLP), and Good Clinical Practices (GCP). Regulatory bodies such as the FDA (Food and Drug Administration) in the United States, EMA (European Medicines Agency) in Europe, and other similar organizations globally, set these standards. Compliance ensures that pharmaceutical products are consistently produced and controlled to quality standards.

2. Quality Management Systems (QMS)

A Quality Management System is a structured system that documents processes, procedures, and responsibilities for achieving quality policies and objectives. It helps in coordinating and directing an organization’s activities to meet customer and regulatory requirements and improve its effectiveness and efficiency on a continuous basis.

3. Risk Management

Risk management is an essential part of QA, involving the identification, assessment, and control of risks throughout the product lifecycle. This includes evaluating potential hazards in the manufacturing process and implementing control measures to mitigate these risks. Techniques such as Failure Mode and Effects Analysis (FMEA) and Hazard Analysis and Critical Control Points (HACCP) are commonly used in risk management.

4. Validation and Verification

Validation ensures that manufacturing processes, equipment, and software perform as intended and produce consistent results. This includes process validation, cleaning validation, and analytical method validation. Verification involves checking and testing to confirm that processes and products meet predefined specifications and standards.

5. Documentation and Record-Keeping

Proper documentation is a cornerstone of QA. It provides evidence that manufacturing processes are performed according to approved procedures and that products meet their quality attributes. This includes batch records, Standard Operating Procedures (SOPs), deviation reports, and audit trails. Accurate and comprehensive documentation is crucial for regulatory inspections and audits.

6. Training and Competency

Ensuring that personnel are adequately trained and competent is vital for maintaining quality standards. Regular training programs and assessments help keep staff updated on current best practices, regulatory requirements, and technological advancements.

7. Continuous Improvement

Continuous improvement is a proactive approach to enhancing quality and efficiency. By analyzing data from audits, inspections, and performance metrics, companies can identify areas for improvement and implement corrective and preventive actions (CAPA). This ongoing process helps in maintaining high standards and adapting to new challenges and opportunities.

Challenges in Pharmaceutical Quality Assurance

Despite the comprehensive systems in place, QA in the pharmaceutical industry faces several challenges:

Complex Supply Chains: With many raw materials and components sourced globally, ensuring quality and compliance throughout the supply chain can be challenging.

Regulatory Changes: Keeping up with evolving regulations and guidelines across different markets requires constant vigilance and adaptation.

Technological Advancements: Integrating new technologies, such as automation and data analytics, into existing QA processes can be complex and resource-intensive.

Counterfeit Drugs: The proliferation of counterfeit drugs poses significant risks to patient safety and requires robust QA measures to detect and prevent them.

Conclusion

Quality assurance in the pharmaceutical industry is a multifaceted and dynamic field that plays a crucial role in safeguarding public health. By adhering to regulatory standards, implementing robust quality management systems, and continuously striving for improvement, pharmaceutical companies can ensure the production of safe, effective, and high-quality products. The commitment to quality assurance not only protects consumers but also enhances the reputation and success of pharmaceutical organizations in a highly competitive market.

0 notes

Text

The Vital Role Of FARE Labs In Pharmaceutical Testing.

Introduction:

In the pharmaceutical industry, where human health is at stake, ensuring the safety and efficacy of drugs is paramount. FARE Labs, a trusted name in testing and calibration, plays a pivotal role in upholding these standards through its comprehensive pharmaceutical testing services. This article explores the critical importance of pharmaceutical testing and highlights how FARE Labs contributes to safeguarding public health and fostering innovation in the pharmaceutical sector.

Comprehensive Pharma Testing Services by FARE Labs:

FARE Labs stands as a beacon of quality and reliability in the realm of pharma testing, offering a wide range of services tailored to meet the stringent requirements of the industry. With accreditation as per ISO/IEC 17025:2017 by NABL and its recognition by esteemed regulatory bodies like the Food Safety & Standards Authority of India (FSSAI), Agricultural & Processed Food Products Export Development Authority (APEDA), Export Inspection Council (EIC), Bureau of Indian Standards (BIS), and MOEF & CC attest to its credibility and adherence to stringent quality standards, FARE Labs employs cutting-edge technologies and adheres to international pharmacopeial standards to conduct meticulous analyses.

The major capabilities and competencies of FARE Labs are as follows:

Raw Material Analysis:

The quality of raw materials used in pharmaceutical formulations directly impacts the safety and efficacy of drugs. FARE Labs specializes in raw material analysis, conducting tests to assess purity, identity, and potency. This ensures that pharmaceutical labs have access to high-quality raw materials, laying the foundation for the production of safe and effective drugs.

Drug Formulation Testing:

Before drugs are released to the market, they undergo rigorous testing to ensure their safety, efficacy, and stability. FARE Labs conducts comprehensive drug formulation testing, examining factors such as dissolution rate, bioavailability, and shelf life. This testing is crucial for pharmaceutical companies to fine-tune formulations and meet regulatory requirements.

Quality Control and Batch Testing:

Maintaining consistent quality across batches is essential in pharmaceutical labs. FARE Labs provides quality control and batch testing services, ensuring that each batch of drugs meets established specifications. This meticulous testing helps pharmaceutical companies identify and address deviations early, maintaining product integrity and compliance with regulatory standards.

Stability Studies:

The stability of drugs over time is a critical aspect of pharmaceutical testing. FARE Labs conducts stability studies to assess how drugs degrade under various conditions such as temperature, humidity, and light exposure. This testing provides valuable data to pharmaceutical companies for establishing expiration dates and storage recommendations.

Regulatory Compliance:

Compliance with regulatory requirements is non-negotiable in the pharmaceutical testing labs. FARE Labs assists pharmaceutical companies in navigating complex regulatory landscapes by ensuring regulatory compliance through thorough testing and documentation. This ensures that drugs meet the stringent standards set forth by regulatory authorities.

Conclusion:

FARE Labs, through its unwavering commitment to pharmaceutical testing, emerges as a trusted partner in the quest for safe and effective drugs. By conducting comprehensive analyses and adhering to regulatory standards, the laboratory ensures that pharmaceutical companies can bring high-quality products to market with confidence. As the pharmaceutical industry continues to evolve, FARE Labs stands ready to provide the analytical expertise and support needed to navigate the complexities of drug development and testing with precision and excellence.

SOURCE- https://farelabs.com/the-vital-role-of-fare-labs-in-pharmaceutical-testing/

#Pharma Testing Labs#PharmaceuticalTesting#Pharmaceuticaltestinglabs#Pharmaceuticaltestingservices#PharmacyLabTesting

0 notes

Text

Maximizing Efficiency with Medical Records Software

In the fast-paced world of healthcare, efficiency is paramount. Medical records software, also known as Electronic Medical Records (EMR) or Electronic Health Records (EHR) systems, plays a crucial role in streamlining operations, enhancing patient care, and reducing administrative burdens. This article explores how healthcare providers can maximize efficiency with medical records software, highlighting its key benefits, features, and best practices for implementation.

The Importance of Efficiency in Healthcare

Efficiency in healthcare is not just about speed; it’s about optimizing resources, reducing errors, and improving patient outcomes. Inefficient processes can lead to long wait times, increased costs, and suboptimal patient care. Medical records software addresses these challenges by digitizing patient records, automating administrative tasks, and facilitating seamless communication between healthcare providers.

Key Benefits of Medical Records Software

Improved Patient Care and Safety:

Medical records software ensures that patient information is accurate, up-to-date, and easily accessible. This reduces the risk of medical errors, such as incorrect prescriptions or missed diagnoses. Additionally, EMR systems can provide clinical decision support, alerting providers to potential drug interactions or recommending evidence-based treatment options.

Enhanced Coordination and Communication:

Efficient communication between healthcare providers is crucial for coordinated care. Medical records software allows for the seamless sharing of patient information across different departments and specialists. This integrated approach ensures that all providers involved in a patient’s care have access to the same information, reducing duplication of tests and procedures and improving overall care coordination.

Streamlined Administrative Processes:

Manual administrative tasks, such as scheduling appointments, billing, and coding, can be time-consuming and prone to errors. Medical records software automates these processes, freeing up staff to focus on patient care. Features like automated appointment reminders, electronic billing, and coding assistance improve accuracy and reduce administrative workload.

Data Analytics and Reporting:

Medical records software provides robust data analytics and reporting capabilities. Healthcare providers can track key performance indicators, monitor patient outcomes, and identify trends. This data-driven approach enables providers to make informed decisions, improve operational efficiency, and enhance the quality of care.

Key Features to Maximize Efficiency

To maximize efficiency with medical records software, it’s essential to choose a system with the right features. Here are some key features to look for:

User-Friendly Interface:

A user-friendly interface is critical for ensuring that staff can quickly and easily navigate the system. Intuitive design reduces the learning curve and minimizes the risk of user errors.

Interoperability:

The ability to integrate with other healthcare systems, such as laboratory information systems and pharmacy management software, is essential for seamless information exchange. Interoperability ensures that all relevant patient data is available in one place.

Mobile Access:

Mobile access allows healthcare providers to view and update patient records on the go. This is particularly useful for providers who work in multiple locations or make home visits.

Customization:

Every healthcare practice has unique needs. Customizable templates and workflows ensure that the medical records software can be tailored to fit the specific requirements of the practice.

Security and Compliance:

Ensuring the security of patient data is paramount. Look for software that complies with industry standards and regulations, such as HIPAA. Features like encryption, access controls, and audit trails help protect sensitive information.

Best Practices for Implementation

Implementing medical records software effectively requires careful planning and execution. Here are some best practices to ensure a smooth transition:

Involve Stakeholders:

Engage all stakeholders, including physicians, nurses, administrative staff, and IT personnel, in the selection and implementation process. Their input is valuable in choosing a system that meets the needs of the entire practice.

Training and Support:

Provide comprehensive training to ensure that all users are comfortable with the new system. Ongoing support and resources should be available to address any issues that arise.

Data Migration:

Plan for the secure and accurate migration of existing patient records to the new system. This may involve data cleaning and validation to ensure the integrity of the data.

Monitor and Optimize:

After implementation, continuously monitor the system’s performance and gather feedback from users. Use this information to make necessary adjustments and optimize workflows.

Conclusion

Maximizing efficiency with medical records software is a multifaceted process that involves selecting the right system, implementing it effectively, and continuously optimizing its use. By leveraging the benefits and features of medical records software, healthcare providers can streamline operations, enhance patient care, and ultimately improve the overall efficiency of their practice. As technology continues to evolve, staying up-to-date with the latest advancements in medical records software will be essential for maintaining a high standard of care and operational excellence.

0 notes

Text

Pharmaceutical distributor | importer | Exporter supplier in india

Contract manufacturing pharma organization

In contract manufacturing, one organization engages an outside party/ parties to handle some of its operations and activities under the contract. Contract manufacturing acts as a helping hand to the manufacturer and the organization (such as hospitals, pharmaceutical companies, etc.), and it is beneficial for both parties. Usually, an agreement is signed by owners (manufacturers and clients) and contract facilities in contract manufacturing.

In the pharmaceutical industry, contract facilities provide various services, operations, and activities, e.g., analytical testing and other laboratory services, packaging and labeling, sterilization or terminal sterilization, cold chain storage and transportation services, and many more.

Ikris Pharma Network is a globally trusted contract manufacturing in the pharmaceutical industry in India. Ikris works according to the FDA’s guidelines of CGMP ( current good manufacturing practice), which includes the implementation of oversight and controls over the manufacture of medicines to ensure quality. It also includes managing the risk of and establishing the safety of raw materials, materials used to manufacture drugs and finished drug products. Ikris have expertise in contract manufacturing and providing such facilities for more than 5 years. It has not limited its services to only contract manufacturing but has mastery in providing other services too.

Global contract manufacturing company

Contract manufacturing in pharma refers to outsourcing the packaging and many more services related to drugs or medicines. An agreement is made between the manufacturers, contract manufacturer and the client regarding operations and activities of the medicine. Operations and activities include packaging and labelling, storage and transportation, cold chain storage, etc.

Contract manufacturers provide facilities to the manufacturing organization so that manufacturers can focus on their core competencies. Contracting can enhance speed and efficiency, provide technological expertise, and expand capacity. This facility is favourable for both manufacturers and clients. Contract manufacturers and manufacturers should adhere to the FDA guidelines always.

Ikris Pharma Network is an India based pharmaceutical contract manufacturing company providing its services worldwide. Ikris strictly adhere to the FDA guidelines and work accordingly. Following these guidelines can benefit the patients who take the drugs manufactured under these arrangements in many ways and avoid the adulteration of drugs. Ikris have expertise in this business, and it works under professionals who have experience from ages. Apart from this, Ikris has excelled in providing other pharmaceutical services too.

Best third party pharmaceutical manufacturer in India

Third-party manufacturing in the pharma industry refers to the organizations which act as a linkage between manufacturers and clients. In third-party manufacturing, pharmaceutical products are outsourced or manufactured from other manufacturing units with your brand name. There is an agreement between the three parties (the manufacturer, the third-party manufacturer, and the client organization). This quality agreement defines the expectations among the three parties regarding the quality of the product, duration of time required, etc.

There are numerous responsibilities of a third-party manufacturer in pharmaceuticals which include: finalizing quantity and composition of the required product, packaging of medicine, delivery of the product, checking of the quality of the product, storage of certain drugs under controlled temperature, etc.

Ikris is one such worldwide trusted third-party pharmaceutical manufacturer in India. Ikris have mastery in this field of third-party manufacturers of medical products. Ikris takes care that FDA guidelines are strictly followed in this process. Based on the FDA standards, Ikris makes the product qualitative and non-adulterated to make it safe for potential patients. Moreover, Ikris provides other major facilities other than third-party pharmaceutical manufacturing. It has been providing services in India and overseas for more than 5 years.

Contract Manufacturing for Pharma products

Contract manufacturing for pharmaceutical products is when a pharmaceutical company engages with other outsourcing organizations to manufacture the products under their brand.

Contract manufacturing is beneficial for both manufacturers and clients (pharmaceutical organizations or hospitals). Usually, an agreement is signed among owners (manufacturers and clients) and contract facilities in contract manufacturing.

Ikris Pharma is an India based pharmaceutical company that deals in contract manufacturing of pharma products. India is known as the largest generic medicine manufacturer in the World, and Ikris works with only certified manufacturers of such medicines. The services of pharmaceutical contract manufacturing companies are not limited to manufacturing only. Ikris provide a host of services which also include: Drug Stability studies, Manufacturing, Development of compliance documents as per FDA regulatory requirement, Developing late-stage clinical trial material, Providing scale-up and registration batches and Pre formulation. Ikris adhere to the FDA regulations and work according to these guidelines benefits the potential patient to have quality medicines with zero adulteration.

Contract manufacturing has become the essential service that a pharmaceutical organization needs. Ikris Pharma provides contract manufacturing of various medicines such as nutraceutical products, generic medicines, etc. Ikris Pharma has been in this industry for more than 7 years supplying drugs and products in India and around the World.

Top Third Party Pharma Manufacturers in India

Here we are talking about third party pharmaceutical manufacturer India, known for the largest generic medicine manufacturing in the World. Third-party manufacturers set up a business association among manufacturers and the clients (hospitals/organizations). When clients search for quality products at reasonable prices and manufacturers want their medicine to reach potential customers, then comes the role of third party manufacturer, quenching the thirst of both parties. Third-party manufacturers make a pact among manufacturers and clients. According to the pact, manufacturers produce products as per the requirements of the client.

Third-party pharma manufacturing is also known as contract manufacturing. A vast number of pharmaceutical organizations use this process for outsourcing manufactured pharma products. Some key factors burden the manufacturers to carry out several activities in-house. Third-party manufacturers decrease their (manufacturers) burden by doing jobs such as packaging and testing before transporting goods to a distribution centre. The involvement of third parties is not only limited to manufacturing and packaging. Product development, specialized processing, such as radiation sterilization, testing, logistics, and medicine transportation at appropriate temperatures.

Ikris Pharma Network is one of the best third party pharmaceutical manufacturers at the international level. Ikris provides this service to hospitals and pharmaceutical organizations, and we work with manufacturers only. There is a list of favours one gets if working with Ikris, a third party manufacturer:

We connect buyers with manufacturing companies. We have more than a hundred manufacturing companies in our Network.

We transport temperature-sensitive medication in cold chain transportation facilities under the required temperature of the medicines.

We always transport the product to the medical sites on time or ahead of time.

One will find 100 % transparency during the whole process.

We work only with approved manufacturers.

Pharmaceutical wholesalers and distributors

The pharmaceutical market is changing rapidly. Due to increasing chronic diseases and after the Covid-19 outbreak, there came a massive boom in the pharma industry. Thus the pharmaceutical organizations and manufacturers began to manufacture and supply medicines and medical equipment faster to meet the requirements of the patients. Pharmaceutical distributors work more than an intermediary and ease the tasks of manufacturers and clients.

Pharma distributors purchase and take legal ownership of pharmaceuticals and manage inventory and credit risk; this allows manufacturers to focus on their core drug development and manufacturing competencies. They are critical players in the healthcare ecosystem. Ninety-two percent of prescription pharmaceuticals flow through a complex, secure ecosystem composed of patients, providers, pharmacies, distributors, group purchasing organizations (GPOs), manufacturers, pharmacy services administration organizations (PSAOs), pharmacy benefit managers (PBMs).

Pharmaceutical distributors continue to evolve beyond their flagship offering of core services to enlarge services to ecosystem stakeholders while optimizing costs. In addition to enabling a secure, transparent, and efficient pharmaceutical supply chain that safeguards patient safety, distributors offer value-added services such as independent pharmacy support, generic sourcing programs, hub services, and innovative partnerships.

Distributors provide services and distribution facilities such as packaging and testing before transporting goods to a required site. Ikris Pharma Network is one of the trusted distributors and wholesalers in the Indian market, exporting medical products and medicines globally. Ikris is a GDP-certified company having licenses for both wholesale and retail drugs. There are temperature-sensitive drugs that require appropriate storage and transportation under the required temperature, and we are best at catering cold-chain supplies of medicines.

We have professionals, sophisticated processes, and impeccable reliability. Our aspiration and liability are to keep up to ensure our clients’ supply chains and businesses both succeed and keep flourishing. We believe in completing the assigned task before or on time. That’s why we are emerging as a top pharmaceutical distributor in India and at the global level.

India: Largest pharmaceutical distributors and manufacturers

A pharmaceutical distributor works as a link between manufacturers, healthcare providers, and eventually the patients. Pharma distributors are the backbone of the healthcare ecosystem. India is known as the largest generic medicine manufacturer and distributor in the World. Distributors manage a complex supply chain, harnessing innovative technologies to ensure safe, secure, and efficient delivery every time.

During Covid-19, distributors played a crucial role by supplying medicines and medical aids on time. Pharmaceutical distributors continuously keep in check the appropriate storage conditions, secure handling of the drugs, and medication delivery under required circumstances. Distributors facilitate the manufacturers to concentrate on their core responsibility by taking care of the distribution system, which is a complex job in a pharmaceutical ecosystem. With passing time, chronic diseases are increasing, and after Covid-19, there is a massive demand for medicines in the pharma sector. And to meet the need of the medication, manufacturers are manufacturing the products at a double rate and delivering the products on time; manufacturers need distributors to do the further job of supplying the client's requirements on time at the required site.

Ikris Pharma Network is known as the trusted pharmaceutical distributor from India. We deal in high-quality drug supply at the global level. Ikris is a certified supplier of generic medicines in India as well as in the World. We have certification from the highest authorities like ISO 9001:2008, GMP, WHO, GDP, etc. Ikris being a pharma distributor, provides services and distribution facilities such as cold chain shipping, packaging, and testing before transporting goods to a required site.

Ikris Pharma Network distributes medicines and medical products in bulk to organizations/hospitals and directly to patients. Our dedicated team and professional leaders make this distribution organization outstanding in the pharmaceutical sector in the World. We have excelled in distributing rare medicines which are not available easily in the market, such as cancer medications, heart disease medications, HIV-related medication, etc. We have served 50000+ patients, supplied more than 5000 products across 150+ countries such as Africa, United States, UK, Gulf countries, Vietnam, Sri Lanka, South East Asia, Philippines, Cambodia, Poland, and many more.

Ikris Pharma Network is a fast-growing global pharmaceutical consultancy and service company whose motto is "access is a right, not a privilege." It is dedicated to delivering hard-to-access medicines to needy patients to improve their quality of life. With Ikris, geographical boundaries are no more constraints for needy patients in getting otherwise unavailable medication.

Top-grade third-party pharmaceutical manufacturer

The third-party pharmaceutical manufacturer refers to when one firm gets medications produced by a manufacturing firm with its brand name. Third-party manufacturers help in making higher quality medicines available to the potential customers manufactured by the manufacturer. Both manufacturer and the third-party manufacturer sign the legal document according to which manufacturer will manufacture the products as per the customers' requirements.

Ikris Pharma Network (IPN) is the best emerging third-party pharmaceutical manufacturer in India, and is a known largest generic medicine manufacturer. IPN comes with a lot of perks as a third-party manufacturer, such as

The entire process becomes cost-effective.

Increase in the efficacy in the core competencies of a pharma firm.

Product development, specialized processing, such as radiation sterilization, testing, logistics, and medicine transportation at appropriate temperatures.

100% transparency in the entire process.

Selects the best manufacturer according to the customers' requirements.

IPN has an established vast network of USFDA-approved manufacturers.

Licensed Private Label Manufacturer

Private label manufacturing refers to the contract or third-party manufacturing in which a private label product is manufactured by another firm on a contract basis and sold under the retailer’s brand. Outsourced products are manufactured according to the demand and requirements of the retailers or the customers. The outsourcing process is not limited to manufacturing and packaging, but private label manufacturers provide facilities such as Drug Stability studies, Manufacturing, Development of compliance documents as per FDA regulatory requirements, Developing late-stage clinical trial material, Providing scale-up and registration batches and Pre formulation.

Ikris Pharma Network or IPN is one of the best private label pharmaceutical manufacturers firm for outsourcing the manufacturing of pharma products and medicines. IPN is already exporting products to more than 150 countries worldwide. It is run by professionals who have had expertise in this industry for more than 20 years. Ikris works with USFDA approved manufacturers only.

Pharmaceutical distributor

India is known for generic medicines manufacturing in large quantities. India is one of the top suppliers and distributors in the World. With increasing cases of chronic or long term diseases, the demand for medicines is also growing. To meet the requirements of the patients' manufacturers manufacture the drugs at twice the previous rate of manufacturing. Distributors help in connecting the manufacturers and health providers. Distribution is a vital stage in the complex supply chain of products in the pharmaceutical industry.

Ikris Pharma Network is a top-level wholesale pharmaceutical distributor from India. In addition, to allow a secure, transparent, and efficient pharmaceutical supply chain that safeguards patient safety, IPN offers value-added services such as independent pharmacy support, generic sourcing programs, hub services, and innovative partnerships. It also has expertise in cold-chain transportation for temperature-sensitive drugs, supplying in India and overseas.

A Pharmaceutical Supplier in Brazil

During the Covid-19 crisis, many countries ran out of rare medicines for patients suffering from chronic diseases like cancers, HIV, etc. India came forward to help such countries by supplying rare drugs to different countries worldwide. India is known as the largest generic medicine. Ikris Pharma Network is a fast-growing global pharmaceutical consultancy and service company dedicated to delivering hard-to-access drugs to needy patients to save their lives. Ikris is also emerging as the best pharmaceutical supplier in Brazil, mainly after it supplied medicines during the pandemic, and IPN is continuously supplying drugs in the Brazilian pharmaceutical sector. It has already provided more than 150 products to Brazil. IPN is a GDP-certified pharmaceutical organization for wholesale as well as retail drugs. We supply to pharmacies, hospitals, pharmacy organizations and many more. It is a reliable brand Worldwide for providing the best quality pharma products. It only works through legal channels in delivering products and works as per the FDA guidelines.

Private label manufacturers in India

Private label manufacturing is similar to contract manufacturing or third-party manufacturing.

This process is beneficial for pharmaceutical manufacturers and customers (hospitals, pharmacies, etc.). In private label manufacturing, the products are outsourced to manufactured by some other pharmaceutical firm under another firm's brand. To meet the increasing demand for medicines and medical equipment, pharmaceutical organizations outsource the in-house operations and activities to other firms to lessen their burden and focus on their core business.

Ikris Pharma Network is one of the best known private label pharmaceutical manufacturers India. Being a certified private label manufacturer, IPN provides the best services, including Drug Stability studies, Manufacturing, Development of compliance documents as per FDA regulatory requirements, Developing late-stage clinical trial material, Providing scale-up and registration batches and Pre formulation. IPN has been supplying internationally in more than 150 countries for more than seven years. It is run by professionals and has a vast network with FDA-approved manufacturers.

Contract Manufacturing Pharma Companies in India

Contract manufacturing refers to the manufacturers who serve other pharmaceutical organizations on a contractual basis to provide services from drug development through drug manufacturing. Contract manufacturing helps pharmaceutical firms focus on drug discovery, drug marketing, etc., reducing their in-house activities. The contract manufacturer and the customer and the manufacturer enter into a written agreement to ensure that the customer’s operations do not face any obstacles during the whole process to have an uninterrupted quality supply of the product within the appropriate time.

Ikris Pharma Network is on top in listed contract manufacturing Pharma companies in India. Do you know what qualities make IPN best? Here are the following benefits of IPN as a contract manufacturer:

Cost optimization

Fast track drug products and speed time delivery to the required site

Meeting current and projected growth trends for drug products

Helps pharmaceutical companies in the cost optimization and ease of burden of hiring and training workers during periods of labour shortage

Services offered by IPN include but are not limited to pre-formulation, formulation development, stability studies, method development, clinical trial materials, formal stability, scale-up, registration batches and commercial production.

Best Third-Party Manufacturing Pharma Companies

Third-party manufacturers mean one firm outsources the products to manufacture by another firm under the brand name of retailers. The complex supply chain in the pharmaceutical ecosystem leads pharmaceutical organizations to opt for third-party manufacturing. An assignment is signed among the manufacturers and third-party manufacturers according to which manufacturer will manufacture the products based on the customers’ requirements.

The need for third-party manufacturers comes when an organization is burdened with many in-house activities and concentrates on its core business. The involvement of third parties is also not limited to manufacturing and packaging: product development, specialized processing, such as radiation sterilization, testing, and logistics.

Ikris Pharma Network is an internationally acclaimed pharmaceutical organization. It is a GDP-certified organization having licenses in both wholesale and retail drugs. IPN is on top of the list of third-party manufacturing pharma companies in India. It provides 100% transparency in the whole process. It has been exporting products across the globe for more than 7 years.

Contract manufacturing pharmaceutical company

Contract manufacturing is a term that defines a process in which a firm produces products for a pharmaceutical firm but does not own the inventory. This kind of partnership benefits the pharma firm, the contract manufacturer, and the customers. The lack of facilities for in-house activities or the burden of many in-house activities leads to the need for a contract manufacturer. Contract manufacturers also provide advanced technologies and high containment capabilities and manufacturing and other operations and activities (Drug Stability studies, Manufacturing, Development of compliance documents as per FDA regulatory requirement, Developing late-stage clinical trial material, etc.).

Ikris Pharma Network is an internationally acclaimed and GDP-certified pharmaceutical organization blooming as among the best pharma contract manufacturing companies in India and globally. They have been in this industry for more than a decade and can find a tailor-made solution according to the needs of the clients. IPN only works with the FDA-approved manufacturers and believes in 100 percent transparency during the whole process.

Third-party manufacturers in Pharmaceutical

Third-party manufacturing is also termed contract manufacturing. Third-party manufacturing is a partnership in which two parties agree to manufacture the products according to the customers' demand within an appropriate time period.

Ikris Pharma Network (IPN) is emerging as the best third-party manufacturing pharma.IPN is run by professionals having years of experience in this industry. Apart from manufacturing and packaging, IPN facilitates many services such as product development, specialized processing, such as radiation sterilization, testing, logistics, and medicine transportation at appropriate temperatures. Outsourcing the products to third-party manufacturers reduces the burden of the pharmaceutical organization in many ways, which results in the concentration of a pharma organization in their core business. IPN as a third-party manufacturer proves to be a good agreement because it adheres to FDA guidelines, ensures the security of the supply, has specialist capabilities, has a license, provides product lifecycle management, has market access, and provides cost optimization.

Need for Contract Manufacturing in the Pharmaceutical Industry