#AngularHead

Explore tagged Tumblr posts

Text

Specialists in CNC Rotary Tables, CNC Spindles & Angle Heads | Kuvam Technologies | Machining Solutions

Explore High-quality precision CNC rotary tables, milling spindles, water-cooled Spindles, air-cooled spindles, angular heads, and chucks at Kuvam Technologies for top-notch machining solutions.

#CNCRotaryTable#RotaryTables#spindles#AirCooledSpindle#WaterCooledSpindle#AngularHead#AngleHead#VMCSpindle#MillingSpindle#CNCSpindle

1 note

·

View note

Text

Are you facing coolant leakage from the water-cooled spindle?

1) Check and tighten the hose connection 2) Inspect hoses for damage 3) Replace seals if necessary 4) Regularly monitor coolant levels . . . Enquire now at +919560500384 or via email at [email protected] Website: https://www.kuvamtechnologies.com/water-cooled-spindle/

#coolantleak#spindlemaintenance#machinemaintenance#CoolantSystemIssues#leakdetection#machiningproblems#industrialrepairs#engineeringmaintenance#SpindleLeaks#machineshopsolutions#FluidSystemTroubles#manufacturingmaintenance#cncrepair#hosemaintenance#coolantmonitoring#kuvamtechnologies#kuvam#spindle#rotarytable#angularhead#cncspindle

0 notes

Text

Boost Your Machining Power with Heavy-Duty Angle Head

Upgrade your machining capabilities with a Heavy-Duty Angle Head. Achieve precision and power for any project with this essential tool.

Visit Now - https://www.kuvamtechnologies.com/heavy-duty-angle-head/

0 notes

Text

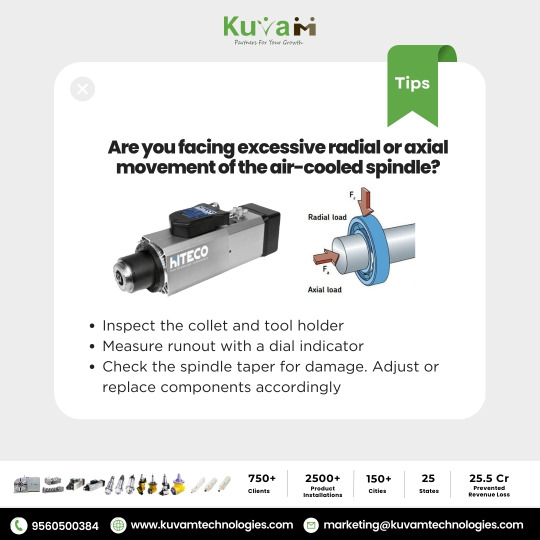

Are you facing excessive radial or axial movement of the air-cooled spindle?

1) Inspect the collet and tool holder 2) Measure runout with a dial indicator 3) Check the spindle taper for damage. Adjust or replace components accordingly . . . Enquire now at +919560500384 or via email at [email protected] Website: https://www.kuvamtechnologies.com/air-cooled-spindle/

#MachiningProblems#SpindleIssues#ToolHolderTroubles#PrecisionMachining#ManufacturingWoes#MechanicalMaintenance#IndustrialEngineering#CNCProblems#RunoutChallenge#SpindleRepair#MachineShopIssues#EngineeringSolutions#ToolingProblems#ColletInspection#MachinistTips#kuvamtechnologies#kuvam#spindle#rotarytable#angularhead#cncspindle

0 notes

Text

Hiteco Air-Cooled Spindle: Adding Value to Your Machining Needs

Achieving optimal results depends on a combination of factors, with the choice of CNC spindle being a critical one. Hiteco, a renowned name in the industry, offers a solution that not only meets but exceeds the expectations of machinists and manufacturers worldwide - the Hiteco air-cooled spindle. This article explores the value this product brings to customers, making it a must-have for anyone in the machining business.

Unmatched Performance

One of the primary reasons customers choose Hiteco's air-cooled spindle is its exceptional performance. These spindles are engineered to deliver consistent power and torque, ensuring high-speed cutting and milling operations with precision. The air-cooling system efficiently dissipates heat, allowing the spindle to operate at optimal temperatures for extended periods. This results in reduced downtime and higher productivity, ultimately adding tremendous value to the customer's operations.

Durability and Reliability

Hiteco understands that in the machining industry, downtime is a costly affair. Their air-cooled spindles are designed to withstand the rigors of industrial use. Built with high-quality materials and precision engineering, these spindles exhibit excellent durability and reliability. Customers can count on their Hiteco spindle to perform consistently day in and day out, minimizing maintenance and replacement costs.

Customization Options

No two machining applications are the same, and Hiteco recognizes this. They offer a range of customization options to tailor their air-cooled spindle to specific customer needs. Whether it's the spindle size, speed, or tooling compatibility, Hiteco provides flexibility to ensure their product aligns perfectly with your machining requirements.

Energy Efficiency

Hiteco spindle are not only powerful but also energy-efficient. The advanced cooling system reduces power consumption, making them an environmentally friendly choice. Customers can reduce their carbon footprint while saving on energy costs, a significant added value in the long run.

Expert Support and Service

Kuvam technologies pvt ltd is not just about selling a product; they are committed to building lasting relationships with their customers. Their dedicated support and service teams are always ready to assist with technical queries, maintenance, and repairs. This level of customer support ensures that customers can rely on Hiteco for a seamless machining experience.

Competitive Pricing

While Hiteco offers top-notch quality and performance, they are also mindful of their pricing. Their air-cooled spindles are competitively priced, ensuring that customers get exceptional value for their investment. The combination of performance, reliability, and affordability makes a smart choice for both small-scale workshops and large-scale manufacturing facilities.

Conclusion

where quality, performance, and reliability are paramount, the with Hiteco air-cooled spindle stands out as a product that adds significant value to customers. With its unmatched performance, durability, customization options, energy efficiency, expert support, and competitive pricing, spindle is a valuable asset for machinists and manufacturers seeking to optimize their operations. When it comes to machining excellence, kuvam technologies pvt ltd delivers, making them a trusted partner for businesses around the globe.

#spindles#kuvamtechnologies#water cooled spindle#beltdrivenspindle#rotarytable#angularhead#cnc spindle motor#angleheadforvmc

0 notes

Text

"Mastering Precision: Unveiling the Pinnacle of CNC Technology - CNC Rotary Tables, CNC Spindles, and Angle Heads for VMC"

In the ever-evolving world of manufacturing, precision and efficiency are paramount. Whether you're producing complex aerospace components or intricate medical devices, the right CNC (Computer Numerical Control) equipment can make all the difference. If you're on the lookout for top-notch CNC solutions, you've come to the right place. KUVAM TECHNOLOGIES PVT LTD Welcome to our world, where we specialize in CNC Rotary Tables, CNC Spindles, and Angle Heads for VMC (Vertical Machining Centers).

The CNC Revolution

CNC technology has revolutionized manufacturing by automating and streamlining the production process. It allows for unparalleled accuracy and consistency, ultimately leading to higher productivity and reduced costs. At the heart of this revolution are CNC Rotary Tables, CNC Spindles, and Angle Heads, which play a pivotal role in achieving precision machining results.

CNC Rotary Tables: The Pivot of Precision

CNC Rotary Table are indispensable when it comes to positioning workpieces with the utmost accuracy. These rotary tables offer a 4th or 5th axis of motion, enabling multi-axis machining that is essential for creating complex and intricate parts. They are the perfect solution for applications such as contouring, engraving, and drilling, ensuring that every angle is approached with precision.

Our CNC Rotary Tables are built to last and designed for seamless integration into your machining setup. They are engineered to meet the highest industry standards, promising reliability and accuracy for years to come.

CNC Spindles: Power and Precision

CNC Spindles are the workhorses of any machining center. They determine the speed, power, and precision of your machining operations. Our CNC Spindles are engineered to deliver exceptional performance, with options that cater to a wide range of machining needs.

Whether you require high-speed spindles for rapid material removal or high-torque spindles for heavy-duty applications, our CNC Spindles are designed to meet your specific requirements. We understand that each project is unique, and our spindles can be customized to suit your needs perfectly.

Angle Heads for VMC: The Secret to Versatility

Angle Heads for VMC are a game-changer for manufacturers seeking versatility in their machining operations. These compact attachments allow for machining at various angles and positions, greatly expanding the capabilities of your VMC. With our Angle Heads, you can easily access hard-to-reach areas of your workpiece, ensuring that every detail is precisely machined.

Why Choose Us?

Choosing the right CNC equipment supplier is crucial to the success of your machining operations. Here's why we stand out:

Expertise

We are specialists in CNC Rotary Tables, CNC Spindles, and Angle Heads for VMC. Our team consists of industry experts with years of experience in CNC technology. We have installed 2155+ items, helped 595+ clients, prevented a loss of 25.5+ crore, and generated 255+ crore in revenue across 140 cities and 25 states.

Quality

We believe in providing only the highest-quality products to our customers. Our CNC equipment is built to withstand rigorous manufacturing environments and deliver consistent precision.

Customization

We understand that one size doesn't fit all. That's why we offer customization options to tailor our CNC solutions to your unique needs.

Support

Our commitment to customer satisfaction doesn't end with the sale. We offer comprehensive support and maintenance services to keep your CNC equipment running smoothly.

Innovation

We stay at the forefront of CNC technology, constantly innovating and updating our products to meet the evolving needs of the industry.

Conclusion

In the world of manufacturing, precision and efficiency are the keys to success. Our CNC Rotary Tables, CNC Spindles, and Angle Heads for VMC are designed to help you achieve the highest levels of precision in your machining operations. With our expertise, quality products, and commitment to customer satisfaction, we are your trusted partner in mastering precision. Contact us today to learn more about how we can elevate your machining capabilities to the next level.

#kuvamtechnologies#cnc spindle motor#spindles#beltdrivenspindle#water cooled spindle#angleheadforvmc#angularhead#machinery

0 notes

Text

13 Things about CNC Rotary Table for Vertical Machine Center you may not have known

CNC rotary tables for Vertical Machine Center are precision devices used in manufacturing to rotate workpieces at precise angles.

They can be used for a wide range of machining operations, including milling, drilling, and grinding.

Rotary tables can be indexable, meaning they have detents that allow them to rotate to specific angles, or continuous, which can rotate to any angle.

They can be integrated into milling machines, and machining centers, or used as standalone devices.

The size and capacity of rotary tables can vary greatly, with some able to handle workpieces weighing several tons.

They are often used in conjunction with other precision tools, such as CNC dividing heads, to create complex, multi-sided parts.

Rotary tables can be powered by hydraulic, pneumatic, or electric motors.

They can be controlled using CNC (computer numerical control) systems for precise positioning and repeatability.

Some rotary tables can be used in a vertical orientation, allowing for the machining of vertically-oriented surfaces.

They can be used in various fields such as aerospace, automotive, medical, and many more.

Rotary tables can be programmed to rotate at various speeds, allowing for optimal machining conditions.

Many rotary tables come with built-in sensors that detect and compensate for thermal expansion, ensuring accurate positioning.

Rotary tables are used in many industries that require precision, and they can be used to make parts for a wide range of products, including aircraft, medical equipment, and consumer electronics.

#kuvamtechnologies#spindles#cnc spindle motor#angularhead#beltdrivenspindle#machinery#angleheadforvmc#rotarytable#water cooled spindle

0 notes

Text

Kuvam Technologies pvt ltd with 4th axis rotary table or CNC Rotary table 4th axis rotary table or CNC Rotary Table to your VMC, allowing for multi-sided machining, contouring, and complex part indexing. It enables you to tackle intricate tasks that were previously challenging or impossible.Our dedicated customer support team ensures prompt assistance, while our competitive pricing guarantees unbeatable value. Elevate your CNC machining capabilities with our top-of-the-line spindle motor, and experience enhanced productivity and precision like never before.

#kuvamtechnologies#rotarytable#machinery#spindles#water cooled spindle#beltdrivenspindle#angleheadforvmc#cnc spindle motor#angularhead#rotary

0 notes

Text

Are You Facing a Spindle Problem? We identify a solution for your tool machine's spindle.

We work hard to keep your machinery running smoothly and correctly. We specialize in CNC Rotary tables, CNC Spindles & Angular Head motor spindles and offer repairs, optimizations, and replacements. We're quick, competent, and have reasonable prices. We have more than 15 years of experience, repair more than 1,000 spindles each year, and are always looking for ways to improve our services.

Spindle issues? Do we find a solution?

At Kuvam Technologies Pvt Ltd, we focus on repairing all spindles, from belt-driven to high-frequency spindles. We specialize in CNC Rotary tables, CNC Spindles & Angular Heads motor spindles and offer repairs, water-cooled spindle Air cooled spindle belt driven Spindle and hiteco spindles like ATC MTC, etc. optimizations, and replacements. In the last 5 years, we have helped 595+ clients, installed 2155+ products across 140 cities and 25 states, and prevented 25.5 cr. loss and generate 255+ Crore revenue.

We're quick, competent, and have reasonable prices. We have more than 15 years of experience, repair more than 1,000 spindles each year, and are always looking for ways to improve our services.

If it is to Enhance, Fix Problems, Upkeep, and Optimization

In addition to spindle repair, we also undertake maintenance, specifically optimization. We carefully evaluate, evaluate and act to your most significant advantage, and offer insightful solutions to improve your motor spindle. In this connection, we deliver solutions designed in-house, such as expanded rotational important pathways, and are capable of grinding the spindle wheel with perfection in the -range.

Repair Spindles - Various Manufacturers

You will receive a quick reply if it is applicable. We provide such a 24-hour service, of course. You may find exchange spindles from each and every manufacturer in our spindle pool, each of which is ready for use and installation. To ensure that there is almost never a deadlock at your device, you call, then we install.

Stay safe with such a 12-month Warranty

You take the safe route with the Spindle. Our service is valid for 12 months. As an outcome, you can assume a first-rate machine that runs constantly.

Process four - the 90-day Repayment Period

With us, you benefit from a 90-day payment term and a cooperative relationship between our clients and us. The benefit is in flawless cost control, which is now much more significant. We were reasonable and constantly available.

Contact us or come visit our website at www.kuvamtechnologies.com. Whatever your request may still be, get in touch with all of us.

#spindles#angularhead#angleheadforvmc#rotarytable#beltdrivenspindle#water cooled spindle#kuvamtechnologies

1 note

·

View note

Text

Heavy duty angle head or an angular head

Heavy duty angle head or angular head for VMC provides the clients a lot of value-added benefits. Its multi-axis capabilities allow for complicated machining processes, which improve precision and broaden the range of possible applications for VMC Machine

0 notes

Text

Heavy duty angle head or an angular head for the VMC | Kuvam Technologies Heavy duty angle head or angular head for VMC provides the clients a lot of value-added benefits. Its multi-axis capabilities allow for complicated machining processes, which improve precision and broaden the range of possible applications for VMC Machine

0 notes

Text

Angular head for a VMC or Heavy duty angle head| Kuvam Technologies

Angular head for a VMC Or Heavy duty angle Head provides significant value additions to the customers. Its multi-axis capabilities enable complex machining operations, leading to enhanced precision and expanded application possibilities.

The reduction in setup time and increased productivity

contribute to cost savings and quicker project completion.

Moreover, the ability to calculate losses

empowers the customer to optimize their processes,

improving efficiency and minimizing waste.

0 notes

Text

Heavy-Duty Angle Head for High-Precision Machining | Achieve Exceptional Results

Our Heavy-Duty Angle Head is the perfect solution for high-precision machining. Achieve exceptional results and boost your productivity with our reliable and efficient equipment. Get the job done with ease and precision.

Visit Now - https://www.kuvamtechnologies.com/heavy-duty-angle-head/

0 notes

Text

6 Compelling Reasons Why You Need Angular Head for VMC

Some advantages of using an angle head include:

An Angle head, also known as a Angular Head, is a tool attachment that attaches to the end of a machine tool, such as a mill or drill, and allows the tool to operate at a 90-degree angle head to the machine's spindle.

Increased versatility: An Angle head allows for drilling, milling, and tapping in tight spaces and at difficult angles, which can greatly increase the range of work that can be done with a single machine.

Improved precision: An Angle head can help to improve the precision of cuts by allowing the cutting tool to be positioned exactly where it needs to be.

Increased productivity: An Angle head can help to increase the productivity of a machine by allowing multiple operations to be performed in one setup, reducing the need for multiple setups or multiple machines.

Improved efficiency: An Angle head can help to improve the efficiency of a machine by reducing the need for manual repositioning of the workpiece, thereby reducing the time and labor required to complete a job.

Reduced costs: An Angle head for VMC can help to reduce costs by increasing the range of work that can be done with a single machine and reducing the need for multiple setups or multiple machines.

0 notes

Text

Revolutionize Your Machining with Heavy-Duty Angular Heads

Achieve maximum efficiency in machining with our heavy-duty angle heads. Optimize your production process with angular head technology.

Visit Now - https://www.kuvamtechnologies.com/heavy-duty-angle-head/

0 notes

Text

Upgrade Your Machining with Heavy-Duty Angle Heads

Boost your machining capabilities with our Heavy-Duty Angle Heads. Achieve precision and durability for your manufacturing needs.

Visit Now - https://www.kuvamtechnologies.com/heavy-duty-angle-head/

0 notes