#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market

Explore tagged Tumblr posts

Text

Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market - Forecast(2024 - 2030)

AI in Cobots Market Overview

The global AI in cobots market in 2021 reached $118.2 million and is estimated to grow at a CAGR of 34.22% during the forecast period to reach $616.3 million by 2027. The entire robotics industry is witnessing the effects of Covid-19 pandemic, with strain felt on the supply chain restricting parts of imports and equipment exports in H1 2021 especially. The overall economic uncertainty also pushed majority of customers to defer purchases in order to conserve capital. Recent advancements in Machine Learning and human robot interaction have enabled collaborative robots to precisely execute tasks in dynamically changing workspaces, enabling operations and material handling to run more smoothly, efficiently and productively. AI is now intelligently powering cobots by leveraging billions of hours of iterative machine learned practices in manufacturing, production and engineering. Collaborative robots (cobots) represent a variant of industrial robots and is currently considered to be one of the fastest growing segments in industrial automation driven by improved technology such as virtual assistants, cloud computing, internet of things. A cobot is a type of robot that is designed to operate alongside humans in shared workspaces. These machines are easy to program and deploy, can increase productivity manifold, and offer high returns on investment.

Report Coverage

The report: “AI in Cobots Market – Forecast (2022-2027)”, by IndustryARC covers an in-depth analysis of the following segments of the AI in Cobots market

By Payload: Up to 5 Kg, 5 to 10 Kg, Above 10 Kg. By Application: Handling, Assembling/Disassembling, Welding and Soldering, Dispensing, Packaging and Others. By End User: Automotive, Electronics, Semiconductor, Plastics and Polymer, Food and Beverage, Healthcare, Metals and Machining and others. By Geography: North America (U.S, Canada, Mexico), South America (Brazil, Argentina and others), Europe (Germany, UK, France, Italy, Spain, Russia and Others), APAC (China, Japan India, SK, Aus and Others), and RoW (Middle east and Africa).

Request Sample

Key Takeaways

Group PSA’s Sochaux plant in France has chosen Universal Robots UR10 for its "Plant of the Future" Project. Two UR10 cobots have been implemented at the Sochaux plant in screw driving applications on body-in-white assembly lines to increase performance and reduce production costs at the factory.

In 2019, Walmart has planned to invest $2.7 billion to add new robots totaling almost 4,000 robots in its stores and facilities in order to shift human workforce to customer service roles. The robots are majorly used for scanning, sorting goods from delivery trucks. This is set to create opportunities for AI in cobots in retail sector.

AI in Cobots Market Segment Analysis – By Application

Material Handling had a major share in the AI in Cobots Market with a value share of approximately 22.3% in 2021. Material handling is one of the major applications of industrial robots. Robots in material handling segment are used in applications such as movement of goods, protection, storage and control of products throughout manufacturing as well as warehousing of the products. Any industries that need to store, receive, dispatch or ship its products always entail industrial robot. Manufacturing and Warehouse operations involving handling of goods becomes complex when it takes place at a larger scale. This is made easy and efficient with the aid of industrial robots. Material handling robots are majorly used in warehousing applications as compared to its counterpart. Material handling applications that benefit from the incorporation of AI cobots encompass picking, packing, palletizing, sorting, and more. The wide-ranging use of these applications makes them a more site-specific solution for safety implementation. Operators and other workers are often moving or transporting other materials around the AI cobot, requiring additional planning to avoid hazardous contact. Safety-rated grippers are rare in the market at the present time. Currently, manufacturers typically use pneumatic grippers, which require safety considerations for impacts and the loss of power or suction. Uses of bar code, RFID, voice-activated receiving and packaging, pick-to-light technology, transportation management system is some of the drifts observed by material handling robots. Cycle counting, annual, physical and perpetual are few approaches of keeping a track of inventory.

Inquiry Before Buying

AI in Cobots Market Segment Analysis – By End User

Among industries, automotive held the largest share in 2021 at 23.2%. The industry development of AI cobots is ongoing in several different areas. Faster reaction time, more exact movement patterns, orientation capabilities, capabilities in imitating humans – all these aspects contribute to advancements in AI driven cobot development. In addition, brain-computer interfaces is an exciting area that has made significant progress recently. In recent developments in technologies such as linked data, parallel processing, edge computing and distributed artificial intelligence allow for efficient decision making by cobots, making execution robust and efficient. A challenge with the market deployment of AI cobots is that insufficient technology maturity hinders the market deployment of cobots. AI Cobot technology includes hardware design, sensors and actuators, efficient information processing, video processing, planning and multiple of fields from artificial intelligence landscapes, along with technologies that ensure safety, predictability and security of the solution. There is currently a need for high amount of signaling, bandwidth, low latency, and fast decision-making capabilities through efficient computing for AI driven cobots in safety-critical environments, wherein the facilities do not need human intervention. While the automation industry was affected during the pandemic, the longterm outlook for automation is positive, as end users evaluate their reliance on overseas supply chains and reevaluate their operations in a world where a pandemic can stop production cold. Automation is hence being looked upon as a valuable bulwark against the risks laid bare during the pandemic, and this can act as a strong growth driver for AI driven cobots and robots in industrial automation end user verticals.

AI in Cobots Market Segment Analysis – By Geography

Geographically, APAC held major share of 37% of AI in cobots market share in 2021, owing to high adoption of automation technologies in industrial and automotive warehouses and increasing investments and funding. North America is the next largest market with 33% revenue share in 2021. South America is witnessing the fastest growth rate with a CAGR of around 46.6% during the forecast period 2022 – 2027 owing to high investments and growing deployment of automation technology mainly in the countries such as Brazil, Argentina and Colombia. Portuguese company MOV.AI has announced in October, 2020 that it has raised $4m in funding. The company has designed its ROS for manufacturers of cobots, as well as academics and automation integrators. It also contributes to the ROS community. Some of the robots with AI enabled are YuMi from ABB, Franka Emika Panda, APAS from Bosch, Aura, Aubo, NEXTAGE and CORO etc.

Schedule a Call

AI in Cobots Market Drivers

Growing demand for automation and technological advancements set to drive the AI In Collaborative Robotics Market

There has been significant growth in AI driven collaborative robotics market owing to the increased demand for automation, high competition in the e-commerce industry, and the advancement in technologies such as Internet of Things (IoT) and Artificial Intelligence (AI). The use of robots reduces the risk of injury to workforce has also witnessed growth. Integration of robots with artificial intelligence (AI) and machine vision technology has been assisting companies in obstacle detection, navigation, movement of the goods. This has been attracting vendors in automating the warehouses and installing the robots in warehouse, thereby driving the collaborative robotics market. In 2019, Geek Plus Robotics, an intelligent logistics robot solution provider had launched the world’s first interweaving sorting robot, which could be an alternative to conveyor systems. Mobile Industrial Robots (MiR), a leading manufacturer of collaborative mobile robots launched a new warehouse robot to automate the transportation of pallets and heavy goods across warehouses. Development of new robots for various applications of warehouses set to boost the demand of collaborative robotics market.

Growth in E-Commerce Sector

E-Commerce industry is rising at global level of retail and logistics. As a result, growing number of e-commerce companies look forward to automate warehouses. Warehouse robots play a key role in e-commerce industry for various applications such as automated storage and retrieval, picking and placing, order fulfillment operations and many others. Adoption of warehouse cobots by e-commerce companies helps in reducing operational and logistical costs and save on delivery time. This has been increasing automation in warehouses in order to deliver goods to shoppers in faster and more efficient ways by increasing productivity of supply chain. In developed countries such as the U.S., and Canada, Grocery retailers are focusing on deploying robots that bring the shelf stacks to human workers, who pick out the right products and package them up to be sent out. These robots travel with high speed, faster than humans, thereby increasing efficiency of the work. In 2019, Amazon had introduced new warehouse cobots in several of its U.S. warehouses that scan and pack items to be sent to customers. It has started using robots in warehouses, which scans goods coming down a conveyor belt raising the scope of adoption. In 2020 Covariant.ai launched its AI robots and solutions through its warehouse bin-picking robots which is being used by companies such as Knapp, a warehouse logistics company and Obeta, a German electronics retailer. As per estimates, around 2,000 AI powered robots have been deployed across warehouses globally.

AI in Cobots Market Challenges

High Initial Investment

The initial cost of AI driven collaborative robots that are used in factories are high as the cost of automation is much higher in comparison with labor costs. This prevents most companies from completely automating their operations with robots. The average selling prices of cobots vary from $25,000 to $50,000 and does not include the installation costs. In addition to this, there is a training cost associated with the robots that further restricts the operators’ likeability for integrating robots into their operating lines. Slow deployment of collaborative robotic systems by smaller and medium enterprises hampers the robotics market. However, high labor costs are set to drive the collaborative robot market during forecast period.

Buy Now

AI in Cobots Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the AI in Cobots market. In 2021, the market of AI in Cobots market has been consolidated by the top players

Fanuc

Techman Robots

Rethink Robots

AUBA Robots

ABB

Kawasaki

KUKA

Yaskawa

Staubli

Universal Robots

Recent Developments

In May 2019, the government of Saudi Arabia announced an investment of $30 billion to upgrade warehousing facilities by adoption of the advanced autonomous robots in the newly built warehouses across Saudi Arabia, thereby contributing towards the growth of the cobots market during forecast period in this region.

In October 2019, the South Korean government announced an investment $150 million to develop the intelligent robots for various industrial application which includes warehousing and logistics, thereby enhancing the growth of the cobots market.

#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market size#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Industry#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market share#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems top 10 companies#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Market Report#Artificial Intelligence (AI) in Collaborative Robotic (Cobots) Systems Industry outlook

0 notes

Text

Flexible Automation Needs Drive Strong Demand for Collaborative Robots

The global collaborative robot (cobot) market was valued at USD 1.2 billion in 2023 and is projected to expand at a remarkable CAGR of 26.1% from 2024 to 2034, reaching a market size of USD 15.3 billion by the end of 2034, according to the latest industry research. This exponential growth is primarily driven by the growing demand for workplace automation, enhanced safety standards, and advancements in robotics technology.

Market Overview: Collaborative robots designed to work safely alongside humans are transforming industries by combining precision, productivity, and adaptability. Unlike traditional industrial robots, cobots feature integrated safety mechanisms, including force-limiting sensors and intelligent programming, enabling them to perform tasks in dynamic environments shared with human workers.

These robots are increasingly adopted across industries including automotive, electronics & semiconductors, healthcare, food & beverage, and logistics, owing to their flexibility, efficiency, and cost-effectiveness.

Market Drivers & Trends

1. Surging Demand for Automation

Industries worldwide are facing escalating labor costs and demand for consistent output. Cobots are bridging the gap by enhancing productivity without replacing human labor, enabling businesses to stay competitive in fast-evolving global markets.

2. Focus on Workplace Safety & Ergonomics

Companies are investing heavily in solutions that enhance worker safety and comfort. Cobots, designed with built-in torque and speed control features, address these concerns effectively—significantly reducing workplace injuries and enhancing job satisfaction.

3. Flexibility and Reusability

Cobots can be easily programmed, re-deployed, and adapted for various tasks. This makes them invaluable in dynamic production settings, especially in consumer electronics and automotive manufacturing, where production lines often change.

Latest Market Trends

Integration of AI Capabilities: The latest cobots incorporate artificial intelligence and machine learning, enabling smarter task execution, predictive maintenance, and real-time decision-making.

Human-Robot Collaboration Enhancements: Next-gen cobots are now equipped with advanced vision systems, touch sensitivity, and voice commands, allowing seamless interaction with human co-workers.

Compact and Lightweight Designs: Smaller cobots are gaining traction among SMEs that require affordable automation with minimal footprint.

Key Players and Industry Leaders

The collaborative robot market is moderately consolidated, with leading players holding around 55–60% market share. Major companies include:

ABB Group

FANUC CORPORATION

KUKA AG

Kawasaki Heavy Industries Ltd.

Mitsubishi Electric Corporation

Yaskawa Electric Corporation

OMRON Corporation

Schneider Electric SE

These companies are investing aggressively in R&D, product portfolio expansion, and strategic acquisitions.

Access an overview of significant conclusions from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=15536

Recent Developments

Universal Robots launched the UR20 in April 2023, the company’s most powerful cobot, featuring a 20 kg payload and a 1750 mm reach—ideal for heavy-duty applications.

In March 2023, Fanuc upgraded its CRX series with enhanced AI features, simplifying programming and improving adaptability for diverse manufacturing tasks.

ABB introduced the GoFa cobot, combining high payload capacity with safety-focused operations for assembly and material handling.

Market Opportunities

As cobot technologies evolve, new applications are emerging in healthcare, pharmaceuticals, logistics, and 3PL operations. These sectors are expected to witness substantial adoption due to labor shortages and increasing demand for precision, hygiene, and continuous operations.

The electronics & semiconductors sector, in particular, is anticipated to remain a dominant force, holding a 26.5% market share in 2023 and forecast to grow at a 30.9% CAGR, driven by increasing complexity in microelectronic assemblies.

Future Outlook

Analysts forecast a bright future for the collaborative robot industry, with wider integration across small and medium-sized enterprises, AI-embedded robotics, and scalable solutions becoming the norm. Governments supporting smart manufacturing and Industry 4.0 are further fueling demand.

Companies that adopt cobot solutions early stand to benefit from:

Increased output

Enhanced safety

Greater operational flexibility

Reduced downtime

Stronger return on investment (ROI)

Market Segmentation

By Type:

Power and Force Limiting Cobots

Hand Guiding Cobots

Safety Monitored Stop Cobots

Speed and Separation Cobots

By Component:

Hardware (End Effectors, Robot Arm, Controllers, Sensors)

Software

Services

By Payload:

<5 Kg

5–10 Kg

10–20 Kg

Above 20 Kg

By Application:

Material Handling

Assembly

Inspection & Quality Testing

Painting

Others

By End-use Industry:

Automotive

Electronics & Semiconductors

Healthcare

Food & Beverage

Aerospace & Defense

3PL

Others

Regional Insights

Asia Pacific led the global collaborative robot market in 2023 with a 34.2% share and is expected to grow at 28.9% CAGR. The region houses the world’s top manufacturing economies—China, Japan, South Korea, and India—driven by:

Large-scale manufacturing units

Government incentives for automation

Growing SMEs looking for cost-effective automation solutions

North America and Europe are also growing steadily due to technological maturity and early adoption of automation solutions.

Why Buy This Report?

Comprehensive market sizing and forecasts (2024–2034)

Detailed segmentation by type, payload, component, application, and region

Strategic analysis of key players and market shares

Coverage of recent innovations and technological developments

Insights into growth opportunities and investment areas

Regional performance analysis across North America, Europe, Asia Pacific, and more

In-depth industry dynamics: drivers, restraints, and future prospects

Explore Latest Research Reports by Transparency Market Research:

Surface Acoustic Wave (SAW) Devices Market: https://www.transparencymarketresearch.com/surface-acoustic-wave-sensors.html

Rugged Power Supply Market: https://www.transparencymarketresearch.com/rugged-power-supply-market.html

Ceramified Cable Market: https://www.transparencymarketresearch.com/ceramified-cable-market.html

Gantry (Cartesian) Robot Market: https://www.transparencymarketresearch.com/gantry-robot-market.htmlAbout Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes

Text

AI’s Global Impact: Building a More Inclusive Economic Future

Artificial Intelligence (AI) has evolved from a breakthrough technology to a defining force of modern civilization. As it transitions from algorithmic models into fully integrated systems of productivity, its next frontier is no longer just technical—it’s economic, structural, and deeply human.

In 2025, we stand on the cusp of a global economic revolution, where AI isn't merely automating tasks but actively reshaping how we work, build, and live. On behalf of Businessinfopro, this report explores how the transformative power of AI is unlocking inclusive growth, rearchitecting industries, and redefining human potential on a global scale.

From Productivity Gains to Economic Multipliers

The earliest promises of AI focused on automation and productivity. Today, its impact is broader and more systemic. AI is now seen as an economic multiplier, with the potential to contribute over $15 trillion to global GDP by 2030, according to estimates by PwC and McKinsey.

What differentiates this wave from prior industrial revolutions is speed, scalability, and universality. Unlike electricity or the internet, AI’s applications cut across every sector—from agriculture and healthcare to logistics and financial systems—reaching both mature economies and emerging markets simultaneously.

In regions like Southeast Asia, Latin America, and Sub-Saharan Africa, AI is not just an enhancement but an equalizer, helping leapfrog traditional barriers to infrastructure, capital, and expertise.

AI in Emerging Markets: Accelerating Financial Inclusion

One of AI’s most significant economic contributions is expanding financial access. In markets with low banking penetration, AI-driven platforms are enabling alternative credit scoring, digital lending, and mobile-first financial services.

Fintech innovators are leveraging machine learning models trained on behavioral data—such as mobile usage patterns, transaction histories, and social media activity—to underwrite loans for the unbanked. This has opened credit lines for millions of microentrepreneurs and small businesses that traditional banks often overlook.

Countries like Kenya, India, and Brazil are leading the way with AI-powered financial ecosystems that blend inclusion with efficiency. The knock-on effects—entrepreneurship, job creation, and local economic resilience—are profound and accelerating.

Smart Agriculture: Feeding a Growing Planet Sustainably

With global populations soaring and climate volatility increasing, food security is a pressing economic concern. AI is now at the heart of precision agriculture—optimizing water usage, monitoring crop health via computer vision, and forecasting yields with meteorological models.

Startups and agritech platforms are using drone imagery, satellite data, and real-time sensors to guide farmers in resource allocation and pest control, improving both productivity and sustainability. In developing nations, where agriculture is still a major employment sector, AI is raising incomes and lowering risk, creating more resilient rural economies.

Importantly, these innovations are being made accessible through low-cost, mobile-enabled solutions that don’t require large-scale capital investment—bringing technological equity to even the smallest farms.

Redefining Human Capital: The Rise of Augmented Workforces

Rather than displacing humans, AI is augmenting them. In healthcare, AI systems are helping radiologists detect diseases faster, assisting surgeons in precision procedures, and enabling rural clinics to access expert diagnostics through telemedicine.

In manufacturing, collaborative robots—or “cobots”—work alongside humans on assembly lines, improving safety, accuracy, and output. Across service sectors, AI assistants manage logistics, recommend inventory levels, and streamline workflows.

The result is not just productivity, but a redefinition of human roles. Jobs are shifting from repetitive execution to creative problem-solving, strategy, and oversight—elevating the value of human judgment and empathy in the workplace.

Governments and enterprises are investing in AI literacy, with national upskilling programs in countries like Singapore, the UAE, and Germany preparing citizens for the future of work. This educational pivot is essential to ensuring the economic dividends of AI are shared widely and not concentrated among technical elites.

Enabling Scalable Innovation in Small Businesses

AI is democratizing innovation. Small businesses, once limited by access to capital and talent, can now tap into AI tools for marketing, operations, and customer engagement.

Through generative AI platforms, local entrepreneurs can design logos, write product descriptions, and generate business plans—all in minutes. Natural language interfaces make it possible for non-technical users to access insights, forecast demand, or even build basic applications.

AI marketplaces and APIs have lowered the barrier to entry for advanced capabilities such as computer vision, voice synthesis, and personalization. As a result, small enterprises are becoming more competitive, agile, and customer-centric—fueling a new wave of digitally empowered entrepreneurship.

This micro-level transformation scales up to macroeconomic impact, particularly in economies where MSMEs (Micro, Small & Medium Enterprises) form the backbone of employment and GDP.

AI Governance and Equitable Value Distribution

With great potential comes great responsibility. As AI becomes deeply embedded in economic frameworks, equitable governance is imperative. Who benefits, and who gets left behind?

The global conversation is shifting toward AI ethics, transparency, and accountability. Organizations like the OECD, UNESCO, and the World Economic Forum are working with governments and private entities to develop inclusive AI frameworks that prevent algorithmic bias, ensure data privacy, and promote shared prosperity.

Multilateral initiatives are also exploring data trusts, AI-sharing platforms, and interoperability standards to avoid monopolization and promote open innovation. AI's economic revolution must not become a race to the bottom—it must be a collective ascent to better outcomes for all.

Public-private partnerships, regulatory sandboxes, and civic engagement will play key roles in shaping policies that align technological advancement with social equity.

Infrastructure and Ecosystem Readiness

To unlock the full economic potential of AI, nations must also invest in digital infrastructure: cloud computing, high-speed internet, reliable data centers, and local innovation hubs.

Cloud-native AI is enabling resource-light models where businesses and governments can rent rather than build infrastructure. Edge AI is allowing low-latency computation for industries like logistics and healthcare even in connectivity-constrained environments.

In Africa, pan-regional data exchanges and open-source AI platforms are being established to ensure that local context and languages are embedded into models. In South America, innovation hubs are fostering partnerships between academia, startups, and government to localize AI development.

Building a sustainable AI economy requires more than tools—it demands an ecosystem that balances innovation with resilience, inclusion with scalability, and local relevance with global ambition.

The Human-Centered AI Economy

The ultimate promise of AI is not efficiency—it is empowerment. In its next frontier, AI is helping humanity solve its most complex challenges: climate adaptation, public health, economic inequality, and education at scale.

It is doing so not by replacing people, but by enhancing our ability to think, act, and build better. Whether it’s an entrepreneur in Lagos, a rice farmer in Vietnam, a healthcare worker in Bolivia, or a logistics analyst in Munich—AI’s true value lies in how it uplifts people, not just profits.

As this revolution unfolds, one principle must remain at the core: AI should work for everyone. And when it does, it doesn’t just transform markets—it transforms lives.

Read Full Article : https://businessinfopro.com/ais-next-frontier-a-global-economic-revolution-for-people/

About Us: Businessinfopro is a trusted platform delivering insightful, up-to-date content on business innovation, digital transformation, and enterprise technology trends. We empower decision-makers, professionals, and industry leaders with expertly curated articles, strategic analyses, and real-world success stories across sectors. From marketing and operations to AI, cloud, and automation, our mission is to decode complexity and spotlight opportunities driving modern business growth. At Businessinfopro, we go beyond news—we provide perspective, helping businesses stay agile, informed, and competitive in a rapidly evolving digital landscape. Whether you're a startup or a Fortune 500 company, our insights are designed to fuel smarter strategies and meaningful outcomes.

0 notes

Text

Collaborative Robots Market Overview: Growth Drivers and Future Prospects

Introduction

The global collaborative robots market, commonly referred to as the cobots market, is witnessing unprecedented growth as industries shift toward more efficient, flexible, and human-friendly automation solutions. Unlike traditional industrial robots, collaborative robots are designed to work safely alongside human operators, making them ideal for diverse industries ranging from manufacturing to healthcare. This article offers an overview of the market, highlighting the major growth drivers and projecting its future prospects.

1. Understanding Collaborative Robots

Collaborative robots are designed with sensors, safety mechanisms, and smart software that allow them to interact with humans without the need for protective barriers. They can be easily programmed and redeployed, making them particularly appealing for small and medium enterprises (SMEs). These robots typically assist with repetitive or ergonomically challenging tasks, improving workforce productivity and safety.

2. Key Market Drivers

a. Rising Demand for Automation

One of the major forces behind cobot adoption is the growing demand for automation. Companies are seeking to reduce labor costs, increase efficiency, and minimize human error. Collaborative robots provide a flexible, cost-effective solution that doesn't require the significant infrastructure changes associated with traditional robotics.

b. Labor Shortages and Workforce Augmentation

With an aging population in many industrialized nations and ongoing labor shortages in skilled trades, cobots offer a solution that augments human labor rather than replacing it outright. Their ability to take over repetitive, tedious tasks allows human workers to focus on more complex responsibilities.

c. Cost Efficiency and ROI

Compared to traditional industrial robots, cobots are often more affordable, with quicker return on investment (ROI). Their plug-and-play nature and ease of programming further reduce implementation costs and time, making them ideal for businesses without dedicated robotics teams.

d. Improved Safety Standards

Enhanced safety features in cobots, such as force limiting and real-time sensing, have made them increasingly viable in open production environments. Compliance with international safety standards (like ISO/TS 15066) has further boosted user confidence and market adoption.

3. Emerging Applications

Cobots are no longer limited to large manufacturing firms. Industries across the board are integrating collaborative robots into their operations:

Automotive: Assisting in assembly, painting, and quality inspection.

Electronics: Handling delicate components and performing precision tasks.

Healthcare: Supporting surgical procedures and laboratory automation.

Food & Beverage: Managing packaging and repetitive processes.

Logistics: Sorting, packing, and handling inventory in warehouses.

The growing scope of applications is rapidly expanding the collaborative robots market.

4. Technological Advancements Fueling Growth

New technological integrations are transforming cobots from simple task performers to intelligent collaborators. Key innovations include:

Artificial Intelligence (AI) for adaptive behavior and predictive maintenance.

Machine Vision Systems for complex inspection and quality assurance.

Natural Language Processing (NLP) for intuitive human-machine communication.

Cloud-Based Connectivity for centralized monitoring and updates.

These advancements are making cobots smarter, safer, and more versatile, boosting their value across diverse sectors.

5. Market Size and Growth Forecast

As of the mid-2020s, the global collaborative robots market is valued in the multi-billion-dollar range and is projected to expand at a compound annual growth rate (CAGR) exceeding 25% through 2030. Asia-Pacific is expected to dominate market share, driven by rapid industrialization and automation in countries like China, Japan, and South Korea. North America and Europe follow closely due to strong innovation ecosystems and high labor costs.

6. Opportunities and Future Outlook

The future of the collaborative robots market appears bright, with several growth avenues:

SME Adoption: As cobots become more affordable and easier to integrate, small businesses will increasingly deploy them to remain competitive.

Healthcare Sector: The use of cobots in surgery, diagnostics, and rehabilitation presents a significant opportunity.

Remote Operation and Telepresence: Cobots may evolve to support remote work scenarios and virtual human-machine collaboration.

Educational Integration: Universities and vocational institutes are beginning to use cobots to train the future workforce, boosting long-term market adoption.

As the technology matures, collaborative robots will become even more autonomous and integrated into smart factory ecosystems.

Conclusion

The collaborative robots market is at the forefront of the next wave of industrial automation. With benefits like cost savings, ease of use, and the ability to work alongside humans, cobots are well-positioned to revolutionize both manufacturing and non-manufacturing sectors. Continued innovation, combined with expanding awareness and regulatory support, will ensure that cobots play a central role in the future of work across the globe.

0 notes

Text

Robotic Platform Market driven by Automation Demand

The Robotic Platform Market encompasses a suite of advanced robotic systems designed to execute tasks ranging from material handling and assembly to inspection and packaging across diverse industries. These platforms integrate cutting-edge hardware components—such as robotic arms, end effectors, and vision systems—with sophisticated software for motion planning, simulation and real-time control. Key advantages include enhanced operational efficiency, improved precision, reduced human error and heightened workplace safety. As industries confront labor shortages and rising production costs, the need for scalable robotic platforms has soared, fueling demand for customizable and modular solutions.

In manufacturing, these systems optimize throughput and facilitate Industry 4.0 initiatives, while in healthcare, they support surgical assistance, telepresence and laboratory automation. Additionally, the ongoing trend toward collaborative robots (cobots) underlines the market’s focus on human-machine interaction and adaptive intelligence. Market research indicates that small and medium enterprises are increasingly adopting robotic solutions to maintain competitive cost structures. Robust market insights point to the pharmaceutical and food & beverage sectors as emerging segments for growth, driven by stringent quality standards and consumer expectations. Overall, continuous innovations in artificial intelligence and machine learning are expected to expand the Robotic Platform Market scope, enabling predictive maintenance and advanced analytics.

The Global Robotic Platform Market is estimated to be valued at USD 11.37 Bn in 2025 and is expected to reach USD 18.62 Bn by 2032, growing at a compound annual growth rate (CAGR) of 7.3% from 2025 to 2032. Key Takeaways Key players operating in the Robotic Platform Market are:

-ABB LTD.

-Amazon.com, Inc.

-Google LLC

-IBM Corporation

-KUKA AG

These market players dominate the industry size and contribute significantly to collectively over 40% of market share, leveraging robust market growth strategies such as strategic partnerships, acquisitions and extensive R&D spending. ABB LTD. continues to enhance its robotics portfolio through modular platforms, focusing on collaborative robots for light-duty tasks. Amazon.com, Inc. integrates robotic platforms in its fulfillment centers for automated order processing, boosting business growth and reducing operational costs. Google LLC and IBM Corporation invest heavily in AI-driven automation, offering cloud-based robotic solutions with advanced analytics and machine vision. Meanwhile, KUKA AG differentiates through high-precision industrial robots tailored for automotive and aerospace segments. Collectively, these leading companies drive market competition, develop new applications and influence market dynamics across global regions.

‣ Get More Insights On: Robotic Platform Market

‣ Get this Report in Japanese Language: ロボットプラットフォーム市場

‣ Get this Report in Korean Language: 로봇플랫폼시장

0 notes

Text

Robotic Arms Market Future Trends Highlighting Automation, Industry 4.0, and Evolving Manufacturing Demands

The robotic arms market is undergoing a profound transformation, driven by automation, smart manufacturing, and the rising adoption of Industry 4.0 technologies. Once confined to heavy manufacturing plants, robotic arms are now expanding into new sectors and redefining how industries approach production, assembly, logistics, and even healthcare. As businesses prioritize efficiency and flexibility, the future of robotic arms lies in smarter, faster, and more collaborative systems designed to work seamlessly alongside humans.

Smart Manufacturing and Industrial Evolution

The integration of robotic arms into modern manufacturing systems is no longer a futuristic concept but a growing necessity. With smart factories becoming the new standard, robotic arms are at the center of digital transformation. Manufacturers are investing in robotics to improve accuracy, reduce downtime, and enhance productivity. This shift is also supported by a growing demand for high-quality, customized products with faster turnaround times.

Robotic arms, equipped with AI-powered sensors and machine learning algorithms, are enabling predictive maintenance, real-time process optimization, and autonomous decision-making. These innovations reduce operational costs and minimize human error, pushing the market toward increased adoption in sectors like automotive, electronics, and aerospace.

Collaborative Robots (Cobots) Gaining Traction

One of the key future trends shaping the robotic arms market is the rapid rise of collaborative robots, or "cobots." These systems are designed to safely operate alongside human workers, eliminating the need for safety cages and enabling direct interaction in shared workspaces. Their flexibility, affordability, and ease of programming make them ideal for small and medium enterprises (SMEs) seeking to automate without investing heavily in traditional industrial robots.

As cobots evolve, their applications are expanding into areas such as medical device assembly, packaging, inspection, and even food processing. Their ability to learn from human input and adapt to changing environments is setting the stage for a more inclusive and human-centered approach to industrial automation.

Miniaturization and Precision in Robotics

In addition to collaboration, the miniaturization of robotic arms is opening new possibilities in sectors that require precision and delicacy. Medical robotics, in particular, is benefiting from compact robotic arms that assist in minimally invasive surgeries, diagnostics, and rehabilitation. The increasing demand for medical automation and telehealth solutions is expected to boost the use of robotic arms in hospitals and clinics globally.

Similarly, in the electronics and semiconductor industries, micro-robotic arms are revolutionizing component placement, soldering, and quality control. The combination of speed and microscopic precision is allowing manufacturers to meet the growing demand for smaller, more powerful consumer electronics.

AI and Machine Learning Integration

Another transformative trend in the robotic arms market is the integration of artificial intelligence and machine learning. These technologies enable robotic arms to perform complex tasks without pre-programmed instructions, learning from their environment and improving over time. AI-powered vision systems, speech recognition, and decision-making capabilities are making robotic arms smarter and more autonomous.

This is especially relevant in sectors like logistics, where robotic arms are now capable of sorting, packing, and delivering goods with little human intervention. As e-commerce continues to boom, logistics firms are turning to robotics to enhance efficiency and meet rising consumer expectations.

Sustainability and Energy Efficiency

The future of the robotic arms market is also tied to global sustainability goals. Manufacturers are increasingly looking for energy-efficient solutions that reduce carbon footprints and lower waste. Robotic arms designed with lightweight materials, low-energy consumption motors, and smart power management systems are aligning with the green manufacturing movement.

Additionally, robotic arms are being used in recycling, waste management, and renewable energy industries. From sorting recyclable materials to assembling solar panels, these applications underscore the broader environmental role robotics can play in the future.

Challenges and Opportunities Ahead

While the robotic arms market is set for significant growth, it also faces challenges such as high upfront costs, cybersecurity concerns, and the need for skilled workers. However, advancements in plug-and-play robotics, cloud-based control systems, and remote diagnostics are gradually lowering these barriers.

Governments and private sectors are also investing in robotics training programs to address the skills gap and ensure a smooth transition toward automation. These initiatives will play a crucial role in shaping a workforce that’s ready to embrace and thrive alongside robotic technologies.

Conclusion

The robotic arms market is entering an era defined by smart automation, human-machine collaboration, and sector-wide innovation. From manufacturing floors to operating rooms, robotic arms are transforming how tasks are performed, enhancing productivity, and opening doors to new opportunities. As technology continues to evolve, businesses that adopt and adapt to these trends will lead the future of industry.

0 notes

Text

AI in Manufacturing: Real-World Case Studies That Prove Artificial Intelligence Is Transforming Production

Artificial Intelligence (AI) is no longer a futuristic concept — it's here, and it's redefining the way manufacturing operates. From optimizing supply chains to predictive maintenance, AI is becoming a powerful enabler of efficiency, agility, and innovation in the manufacturing sector.

In this blog, we’ll explore real-world case studies that showcase how AI is being used to transform production environments, reduce costs, improve quality, and future-proof factories in an increasingly competitive global market.

1. Predictive Maintenance at General Electric (GE)

Challenge: Downtime in industrial equipment leads to massive financial losses. GE needed a solution to anticipate equipment failures before they occurred.

AI Solution: GE implemented AI-powered predictive maintenance tools across its factories and in the field. Using sensors, machine learning models analyzed data from turbines, engines, and other equipment to predict wear-and-tear.

Results:

20% reduction in unplanned downtime

Savings of millions of dollars in maintenance costs

Extended equipment life and increased safety

Takeaway: Predictive maintenance driven by AI ensures better resource utilization and minimizes costly disruptions.

2. Quality Control with Computer Vision at BMW

Challenge: Manual inspection of components often led to inconsistent quality checks and missed defects.

AI Solution: BMW adopted computer vision systems powered by AI to inspect parts on the production line in real time. These systems could detect micro-defects in paint, welds, and assembly far better than the human eye.

Results:

100% visual inspection coverage

Defect detection accuracy improved by over 95%

Reduced return rates and warranty claims

Takeaway: AI-powered visual inspection ensures consistency and enhances brand reputation through better product quality.

3. Smart Manufacturing at Siemens with Digital Twins

Challenge: Siemens wanted to simulate and optimize production processes digitally before implementing physical changes.

AI Solution: Using AI and digital twin technology, Siemens created virtual models of its manufacturing lines. These models were used to test different production scenarios, identify inefficiencies, and simulate new workflows.

Results:

30% faster implementation of production changes

20% increase in productivity

Lower energy consumption

Takeaway: AI-driven simulation tools help companies innovate and iterate rapidly without disrupting physical operations.

4. Inventory Optimization at Foxconn

Challenge: Foxconn, a major electronics manufacturer, needed to reduce excess inventory and avoid stockouts during production peaks.

AI Solution: They implemented AI-based inventory forecasting models that analyzed historical data, real-time demand, and external factors like market trends and weather patterns.

Results:

Inventory holding costs dropped by 15%

Production delays reduced by 20%

Improved alignment between supply and demand

Takeaway: AI helps manufacturers better manage materials and resources through smarter forecasting.

5. Collaborative Robots (Cobots) at Bosch

Challenge: Bosch sought to improve labor productivity and safety on the assembly line without replacing human workers.

AI Solution: Bosch introduced AI-powered collaborative robots that work alongside humans. These cobots learn from human movements, adapt to real-time situations, and can safely assist with repetitive or ergonomically challenging tasks.

Results:

25% increase in productivity

Fewer workplace injuries

Enhanced worker satisfaction

Takeaway: AI-driven automation doesn’t replace workers — it enhances their capabilities and creates safer environments.

Final Thoughts: The Future is AI-Driven

These case studies demonstrate that AI is not just a buzzword in manufacturing — it's a transformational force. By embracing AI, companies gain:

Real-time insights into operations

Higher operational efficiency

Cost reductions and increased ROI

Greater agility and competitiveness

As AI in manufacturing technologies continue to evolve, manufacturers that adopt early will be better positioned to lead the market, innovate continuously, and withstand disruption.

0 notes

Text

Top Mechanical Engineering Trends in 2025: What’s Shaping the Industry

Mechanical engineering is evolving at a breakneck pace, fueled by cutting-edge technology and a global push for efficiency and sustainability. In 2025, several trends are capturing the attention of professionals and businesses across the United States. From automation to sustainable design, these developments are reshaping the future of the industry. Below, we dive into the most sought-after mechanical engineering topics, optimized for readers searching for the latest innovations.

1. Automation and Robotics in Manufacturing

Automation remains a cornerstone of modern mechanical engineering. Robotics, integrated with artificial intelligence (AI), is revolutionizing manufacturing by enhancing precision, reducing costs, and boosting productivity. Automated systems are now capable of handling complex tasks, from assembly lines to quality control. In the U.S., industries like automotive and aerospace are heavily investing in collaborative robots (cobots) that work alongside humans, improving efficiency without compromising safety.

For cutting-edge automation solutions, companies like An Thanh Tech provide advanced tools and expertise to optimize manufacturing processes.

2. 3D Printing and Additive Manufacturing

Additive manufacturing, particularly 3D printing, is transforming how mechanical engineers design and produce components. This technology allows for rapid prototyping, customization, and the creation of complex geometries that traditional methods can’t achieve. In 2025, 3D printing is widely adopted in industries such as healthcare, aerospace, and automotive, where lightweight, durable parts are in high demand. The ability to print metal alloys and composites has further expanded its applications.

3. Sustainable Design and Green Engineering

Sustainability is no longer optional—it’s a priority. Mechanical engineers are focusing on eco-friendly designs to reduce energy consumption and environmental impact. Innovations like energy-efficient HVAC systems, biodegradable materials, and renewable energy integration are gaining traction. In the U.S., government incentives and consumer demand for green solutions are driving companies to adopt sustainable practices, making this a top concern for engineers.

4. Industry 4.0 and Smart Manufacturing

Industry 4.0, the fourth industrial revolution, is all about connectivity and data-driven decision-making. Mechanical engineers are leveraging the Internet of Things (IoT), big data, and machine learning to create smart factories. These facilities use real-time data to optimize production, predict maintenance needs, and minimize downtime. In 2025, U.S. manufacturers are prioritizing smart technologies to stay competitive in a global market.

For high-quality mechanical engineering solutions tailored to Industry 4.0, check out An Thanh Tech for innovative tools and services.

5. CNC Machining Advancements

Computer Numerical Control (CNC) machining remains a critical technology in mechanical engineering. Recent advancements, such as multi-axis machining and AI-driven precision, have made CNC systems faster and more accurate. These improvements are vital for industries requiring high-precision components, like aerospace and medical device manufacturing. In the U.S., the demand for skilled CNC machinists and advanced equipment continues to grow.

Why These Trends Matter

These trends—automation, 3D printing, sustainable design, Industry 4.0, and CNC machining—are not just buzzwords; they represent the future of mechanical engineering. They address the U.S. market’s need for innovation, cost-efficiency, and environmental responsibility. By staying ahead of these trends, engineers and businesses can remain competitive in a rapidly changing landscape.

For those looking to implement these technologies, partnering with experts like An Thanh Tech can provide the tools and support needed to succeed. Stay informed, stay innovative, and shape the future of mechanical engineering in 2025 and beyond.

1 note

·

View note

Text

🤖 AI Robots Market to Skyrocket to $126.8B by 2034 | Massive 23.6% CAGR

Artificial Intelligence (AI) Robots Market is experiencing explosive growth, with the global market expected to skyrocket from $15.2 billion in 2024 to $126.8 billion by 2034. This impressive CAGR of 23.6% is fueled by rapid advancements in AI technologies, increasing automation needs, and the demand for higher productivity across industries. AI robots — powered by machine learning, computer vision, and natural language processing — are redefining how businesses operate. Whether it’s in manufacturing, healthcare, logistics, or personal assistance, these intelligent systems are becoming critical enablers of innovation and operational efficiency.

Market Dynamics

A key driver in this market is the widespread adoption of AI-powered automation. Industries are increasingly leaning on smart robots to improve precision, reduce human error, and cut costs. Industrial robots currently lead the market, accounting for 45% of the global share, particularly in manufacturing and logistics. Service robots, with a 35% share, are rapidly rising in sectors like healthcare and hospitality. However, the market is not without challenges. High initial costs, integration complexity, and regulatory compliance are significant hurdles. Moreover, ethical concerns surrounding AI autonomy and data privacy are prompting stricter frameworks that could influence future deployments.

Click to Request a Sample of this Report for Additional Market Insights: https://www.globalinsightservices.com/request-sample/?id=GIS20118

Key Players Analysis

The market is highly competitive, featuring both established names and disruptive newcomers. Key players like Ubtech Robotics, SoftBank Robotics, Rethink Robotics, and Kuka Robotics dominate due to their robust R&D and established global presence. Meanwhile, emerging players such as Cognite Robotics, AI Mechanica, and Future Bots are bringing fresh innovations to the table, particularly in niche markets like agriculture and defense. Strategic partnerships, mergers, and product launches are common strategies used by these companies to maintain and expand market share. As AI capabilities continue to evolve, these players are expected to push boundaries further, making robots smarter and more intuitive.

Regional Analysis

North America currently holds the lion’s share of the market, largely due to strong infrastructure, investment in AI, and a culture of early adoption. The U.S. is the clear leader, with Canada trailing but catching up through strategic government initiatives. Europe is another major player, with Germany and France leveraging their strengths in industrial automation and sustainability-focused innovation. Asia-Pacific is rapidly emerging as a key market, with China and Japan leading thanks to massive investments in robotics and favorable government policies. Meanwhile, Latin America and the Middle East are developing steadily, propelled by technological adoption and economic diversification.

Recent News & Developments

The AI robots landscape is buzzing with activity. Significant advancements in machine learning and robotics have made robots more autonomous, efficient, and cost-effective. A noteworthy trend is the rise of collaborative robots (cobots) that work alongside humans, enhancing both safety and productivity. The healthcare sector, in particular, has seen a surge in robotic adoption for surgical assistance and patient care. Furthermore, integration with IoT is creating smarter systems capable of predictive analytics and real-time decision-making. On the regulatory front, governments worldwide are establishing clearer frameworks to ensure safe, ethical use — an essential move for market stabilization and trust.

Browse Full Report :https://www.globalinsightservices.com/reports/artificial-intelligence-ai-robots-market/

Scope of the Report

This report delivers an in-depth analysis of the Artificial Intelligence (AI) Robots Market across multiple dimensions. It covers various robot types, including humanoid, collaborative, and autonomous mobile robots. Applications span across manufacturing, healthcare, retail, agriculture, logistics, and more. We assess deployment methods, from cloud-based to hybrid systems, and analyze end-user segments from industrial to residential. The report also provides market forecasts, SWOT analysis, PESTLE insights, competitive landscapes, and regional profiles. Our research supports strategic decision-making by identifying opportunities, forecasting trends, and highlighting regulatory and market challenges that can shape future growth trajectories.

Discover Additional Market Insights from Global Insight Services:

Machine Control System Market : https://www.globalinsightservices.com/reports/machine-control-system-market/

Wires And Cables Market : https://www.globalinsightservices.com/reports/wires-and-cables-market/

Asset Integrity Management Market : https://www.globalinsightservices.com/reports/asset-integrity-management-market/

GPS Tracking Device Market : https://www.globalinsightservices.com/reports/gps-tracking-device-market/

Gallium Nitride (GaN) Power Devices Market : https://www.globalinsightservices.com/reports/gallium-nitride-gan-power-devices-market/

#ai #robotics #artificialintelligence #aitechnology #roboticsindustry #automation #roboticsengineering #smartrobots #industrialautomation #roboticsmarket #airobots #machinelearning #futureofwork #intelligentautomation #servicerobots #cobots #roboticsinnovation #roboticsnews #roboticsupdate #aidevelopment #autonomousrobots #smartmanufacturing #healthcarerobots #logisticsrobots #roboticsresearch #aifuture #roboticsintegration #nextgenrobots #cloudrobotics #humanoidrobots #manufacturingautomation #roboticstechnology #aihealthcare #aiinmanufacturing #roboticsapplications #techtrends2025 #roboticsasia #roboticsnorthamerica #roboticsstartup #roboticsbusiness #airobotsmarket

About Us:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC 16192, Coastal Highway, Lewes DE 19958 E-mail: [email protected] Phone: +1–833–761–1700 Website: https://www.globalinsightservices.com/

0 notes

Text

Navigating the Future of Industrial Efficiency: Industrial Automation Market Outlook 2025–2035

Industrial Automation Market Size & Forecast

The industrial automation market is undergoing a rapid transformation, driven by a wave of technological innovations and economic factors. The integration of Industry 4.0 elements—such as the Internet of Things (IoT), Artificial Intelligence (AI), and robotics—has dramatically improved operational efficiencies across industries by reducing reliance on manual labor and increasing real-time control of manufacturing processes. A pressing shortage of skilled labor and rising wage costs are further nudging manufacturers toward automated solutions to sustain their productivity levels.

Government initiatives around the world, including tax incentives and policy support for smart manufacturing, are fueling this transition. Sectors like automotive, oil & gas, and pharmaceuticals are experiencing a significant boost in automation demand due to the rising need for predictive maintenance and energy-efficient systems. However, high initial investment costs remain a notable barrier, especially for small and medium-sized enterprises (SMEs). Cybersecurity challenges and the complexities of integrating new systems with existing legacy infrastructure also present growth restraints.

Key trends propelling the market include the rise of collaborative robots (cobots), the implementation of 5G-enabled smart factories, and AI-driven predictive maintenance. The growing popularity of digital twins for real-time simulation and optimization, along with a shift toward sustainable automation, is reshaping operational strategies. Opportunities are abundant in emerging economies such as those in Asia-Pacific and Latin America, where industrial growth and favorable government policies are accelerating automation adoption. Technologies like cloud-based SCADA systems and Autonomous Mobile Robots (AMRs) are offering new areas for growth, while the emergence of hyperautomation—an approach that blends RPA, AI, and IoT—is revolutionizing manufacturing end-to-end.

Get Sample Copy @ https://www.meticulousresearch.com/download-sample-report/cp_id=5172?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=28-05-2025

Key Findings

By Offering: The solutions segment is anticipated to lead the industrial automation market by 2025.

By Mode of Automation: Semi-automatic systems are projected to dominate in 2025.

By End-use Industry: The oil & gas sector is expected to take the lead.

By Geography: Asia-Pacific will be the dominant region in 2025.

Industrial Automation Market Drivers

Industry 4.0 & Smart Manufacturing

One of the primary forces shaping the industrial automation market is the widespread adoption of Industry 4.0 and smart manufacturing. These advancements facilitate integration between IoT, AI, and big data analytics, enabling real-time monitoring, optimized workflows, and predictive maintenance. Smart factories, equipped with self-correcting machinery, digital twins, and automated quality control systems, reduce both waste and downtime. This translates to increased productivity, lower operational costs, and agile supply chain management.

As companies strive to remain competitive, particularly in sectors like electronics, automotive, and pharmaceuticals, the demand for edge computing solutions and cobots continues to grow. The digital transformation enabled by Industry 4.0 is helping businesses move from traditional manufacturing practices to data-driven and automated environments.

Government Initiatives & Incentives

Governmental support through financial aid and policy reforms is a major catalyst in driving industrial automation. Initiatives such as Germany’s Industrie 4.0, China’s Made in China 2025, and the U.S. Advanced Manufacturing Partnership aim to enhance manufacturing competitiveness. These programs provide critical support in the form of tax incentives, R&D funding, and automation subsidies.

Developing economies like India and Vietnam are also taking steps to foster smart manufacturing by subsidizing digital upgrades to attract foreign direct investment. These policies significantly lower entry barriers for manufacturers transitioning to automated systems, paving the way for market expansion and technological innovation.

Industrial Automation Market Trends

AI and Machine Learning Integration in Industrial Automation

Artificial Intelligence and Machine Learning are playing pivotal roles in redefining the industrial automation landscape. These technologies enable predictive maintenance by analyzing sensor-generated data to predict equipment failures before they happen, thus minimizing downtime and costly interruptions.

Machine learning is also improving operational efficiencies by adjusting real-time production variables, identifying inefficiencies, and lowering energy consumption. In quality control, deep learning-driven computer vision systems are outperforming human operators in defect detection. Robotics and supply chain decisions are increasingly being made autonomously, thanks to advancements in AI.

Edge AI is also gaining momentum, allowing for faster on-site data processing, which is critical for time-sensitive applications. The rising implementation of digital twins and generative AI for design and operational optimization is reinforcing AI and ML’s central role in shaping the future of manufacturing across various industries.

Industrial Automation Market Opportunities

Emerging Markets (Asia-Pacific, Latin America)

Asia-Pacific and Latin America are proving to be hotspots for industrial automation growth. These regions are characterized by swift industrialization, increasing labor costs, and growing government interest in smart manufacturing. Nations like China, India, Brazil, Mexico, and Vietnam are significantly investing in automation technologies to stay competitive globally and attract international investments.

The boom in automotive, electronics, and textile sectors in these regions is creating a robust demand for advanced robotics, IoT-enabled machinery, and AI-based systems. Favorable policies, such as tax breaks and improved infrastructure, are also encouraging businesses to adopt automation, thus opening new avenues for automation vendors to expand their market reach.

Get Full Report @ https://www.meticulousresearch.com/product/industrial-automation-market-5172?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=28-05-2025

Industrial Automation Market Analysis: Segmental Highlights

Market By Offering

The market is segmented into solutions and services. The solutions segment is expected to hold the largest share in 2025. These include plant instrumentation, plant-level controls, and enterprise-level controls. The dominance of this segment is largely attributed to the increasing integration of systems like ERP, SCADA, DCS, and PLM that optimize manufacturing operations. Predictive maintenance, resource utilization, and operational cost reduction are driving the adoption of these technologies as part of Industry 4.0 transformations.

Market By Mode of Automation

Industrial automation is categorized into semi-automatic and fully automatic systems. In 2025, semi-automatic systems are anticipated to command the largest market share due to their lower implementation cost and the flexibility they offer in blending manual oversight with automation. This mode allows human operators to intervene when necessary, helping to prevent operational downtime or product defects. Nevertheless, the fully automatic systems segment is forecasted to experience a higher growth rate during the projection period.

Market By End-use Industry

The market spans several industries, including automotive, oil & gas, food & beverage, chemicals & materials, pharmaceuticals & biotech, consumer goods, electronics, and more. The oil & gas industry is poised to hold the largest share by 2025. This is driven by its growing reliance on automation for process efficiency, regulatory compliance, remote monitoring, and cost reduction.

Simultaneously, the automotive sector is expected to be the fastest-growing due to the adoption of robotics, AI, and smart factory initiatives. The increasing demand for electric vehicles (EVs), autonomous driving technologies, and flexible manufacturing lines is propelling the sector’s automation needs.

Geographical Analysis

Asia-Pacific (APAC) Dominates the Industrial Automation Market in 2025

Asia-Pacific will remain the most dominant and fastest-growing market for industrial automation by 2025. Factors such as robust industrialization, large-scale investment in automotive and electronics sectors, and government-led policies like China’s Made in China 2025 and India’s Production-Linked Incentive (PLI) scheme are driving this growth.

The region’s manufacturing capacity, combined with affordable labor transitioning to automation, creates fertile ground for technological adoption. North America also holds a substantial market share thanks to its advanced technological base, but Asia-Pacific is witnessing the fastest growth trajectory, supported by favorable regulations, increased foreign direct investment, and rapid digital transformation.

Key Companies

The global industrial automation market is shaped by key players like ABB Ltd (Switzerland), Rockwell Automation Inc. (U.S.), Siemens AG (Germany), Yaskawa Electric Corporation (Japan), Schneider Electric SE (France), Yokogawa Electric Corporation (Japan), KUKA AG (Germany), Emerson Electric Co. (U.S.), FANUC CORPORATION (Japan), Honeywell International Inc. (U.S.), Mitsubishi Electric Corporation (Japan), OMRON Corporation (Japan), Advantech Co., Ltd. (Taiwan), Hitachi Ltd. (Japan), and General Electric Company (U.S.).

Industrial Automation Industry Overview: Latest Developments from Key Industry Players

In May 2025, Siemens introduced the Simatic AX AI Controller, designed for real-time machine learning applications in production environments. This AI controller is integrated into the Siemens Totally Integrated Automation (TIA) platform for tailored automation solutions.

In February 2025, Mitsubishi Electric joined forces with NVIDIA to co-develop AI-powered robotic systems using the NVIDIA Omniverse platform. This partnership aims to enhance next-generation robotics for industrial applications.Get Sample Copy @https://www.meticulousresearch.com/download-sample-report/cp_id=5172?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=28-05-2025

0 notes

Text

Artificial Intelligence in Manufacturing Market – Size, Share, Analysis, Forecast, and Growth Trends to 2032 Unveil Technological Innovations Transforming US Factories

The Artificial Intelligence in Manufacturing Market was valued at USD 3.4 billion in 2023 and is expected to reach USD 103.3 billion by 2032, growing at a CAGR of 46.08% from 2024-2032.

Artificial Intelligence in Manufacturing Market is witnessing rapid transformation as U.S. manufacturers increasingly deploy AI technologies to optimize operations, reduce downtime, and boost productivity. From predictive maintenance to real-time quality control, AI is becoming integral to modern factory systems, aligning with Industry 4.0 goals and the national push for smart manufacturing.

U.S. AI in Manufacturing Industry Trends: Robotics, Predictive Maintenance, and Edge AI Lead the Way

Artificial Intelligence in Manufacturing Market continues to evolve as companies embrace intelligent automation, robotics, and machine learning. With high-tech hubs across the U.S. driving innovation, the adoption of AI is no longer optional—it's a competitive imperative for manufacturing sectors including automotive, electronics, aerospace, and consumer goods.

Get Sample Copy of This Report:https://www.snsinsider.com/sample-request/6587

Market Keyplayers:

IBM Corporation – Watson IoT for Manufacturing

Siemens AG – Industrial Edge

Microsoft Corporation – Azure AI

Alphabet Inc. (Google Cloud) – Vertex AI

Amazon Web Services (AWS) – AWS IoT SiteWise

General Electric Company (GE Digital) – Predix Platform

SAP SE – SAP Digital Manufacturing Cloud

Oracle Corporation – Oracle AI for Manufacturing

Rockwell Automation, Inc. – FactoryTalk Analytics

NVIDIA Corporation – NVIDIA Metropolis for Factories

Intel Corporation – Intel Edge AI Software

Schneider Electric SE – EcoStruxure Machine Advisor

PTC Inc. – ThingWorx Industrial IoT Platform

Fanuc Corporation – FIELD system (Fanuc Intelligent Edge Link and Drive)

ABB Ltd. – ABB Ability™ Genix Industrial Analytics and AI Suite

Market Analysis

The integration of artificial intelligence in manufacturing is shifting from experimentation to execution. Manufacturers are leveraging AI to enhance operational efficiency, cut costs, and make data-driven decisions in real time. Smart factories are becoming a reality, with AI at the core of predictive analytics, process automation, and quality assurance.

In the U.S., the market is accelerated by federal incentives, robust digital infrastructure, and a skilled workforce. AI-enabled solutions are empowering manufacturers to navigate labor shortages, manage supply chain volatility, and maintain continuous production under evolving market demands.

Market Trends

Surge in predictive maintenance solutions to reduce equipment failure

AI-powered computer vision for automated defect detection

Increased use of digital twins for real-time system monitoring

Integration of machine learning in supply chain forecasting

Collaborative robots (cobots) enhancing human-machine synergy

AI-driven energy efficiency and sustainability programs

Cloud-based AI platforms enabling remote factory management

Market Scope

The U.S. market is embracing AI as a transformative tool in reshaping the manufacturing value chain. From production floors to executive dashboards, AI is enabling smarter decisions, faster workflows, and agile responses to market dynamics.

Intelligent process automation across manufacturing units

Data-driven quality control and error reduction

Real-time decision-making enabled by AI analytics

Workforce augmentation through human-AI collaboration

Smart robotics improving production precision

AI-integrated ERP and MES systems for seamless coordination

Forecast Outlook

The outlook for the Artificial Intelligence in Manufacturing Market is highly optimistic, with U.S. manufacturers positioned at the forefront of global innovation. Continuous investment in AI R&D, coupled with government and private sector collaboration, is expected to drive next-generation capabilities. Future growth will be shaped by scalable platforms, adaptive machine learning models, and tighter integration with IoT and 5G technologies. The focus will shift from pilot projects to enterprise-wide AI deployment, delivering real impact across production ecosystems.

Intelligent process automation across manufacturing units

Data-driven quality control and error reduction

Real-time decision-making enabled by AI analytics

Workforce augmentation through human-AI collaboration

Smart robotics improving production precision

AI-integrated ERP and MES systems for seamless coordination

Access Complete Report: https://www.snsinsider.com/reports/artificial-intelligence-in-manufacturing-market-6587

Conclusion

AI is no longer a futuristic concept—it's the new reality for U.S. manufacturing. As companies strive for agility, efficiency, and resilience, artificial intelligence is emerging as the critical engine behind their transformation. From streamlining supply chains to revolutionizing shop floors, AI is redefining what's possible.

Related Reports:

Discover top Trade Management Software solutions used across the U.S

Explore U.S. factoring companies to boost your cash flow

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#Artificial Intelligence in Manufacturing Market#Artificial Intelligence in Manufacturing Market Scope

0 notes

Text

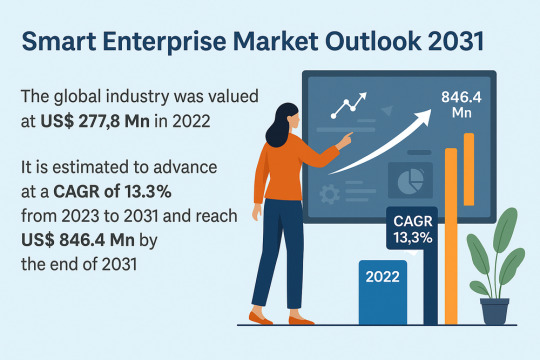

Global Smart Enterprise Sector to Grow at 13.3% CAGR as Intelligent Solutions Rise

The global smart enterprise market is witnessing a rapid evolution, with the industry projected to grow from USD 277.8 Mn in 2022 to USD 846.4 Mn by 2031. The market is expected to expand at an impressive CAGR of 13.3% from 2023 to 2031, according to new research highlighting major drivers, developments, and future opportunities.

Market Overview: Smart enterprise systems represent the convergence of operational technology (OT) and information technology (IT) to enhance real-time data-driven decision-making, streamline production, and boost productivity. By integrating technologies such as IoT, AI, machine learning, big data analytics, and cloud computing, manufacturers are transforming traditional operations into connected, intelligent ecosystems.

Market Drivers & Trends

Digital Transformation: The increasing need to stay competitive in a fast-paced, interconnected market has driven manufacturers to embrace smart technologies. Digitization not only facilitates greater operational efficiency but also enables predictive maintenance, real-time monitoring, and autonomous process control.

Customized Manufacturing: Consumers now expect tailored products, which has compelled manufacturers to move away from large-scale production towards flexible, smaller batch manufacturing. Smart enterprise solutions make this shift possible through agile and automated systems.

Rise of Robotics and Automation: Robotic Process Automation (RPA), collaborative robots (cobots), and autonomous mobile robots (AMRs) are revolutionizing traditional factories. These technologies reduce errors, improve worker safety, and ensure higher consistency in product quality.

Latest Market Trends

Integration of Digital Twin Technology: Digital twins, or virtual replicas of physical systems, are enabling manufacturers to simulate operations, predict failures, and manage assets remotely. These innovations enhance predictive maintenance, reduce downtime, and increase system responsiveness.