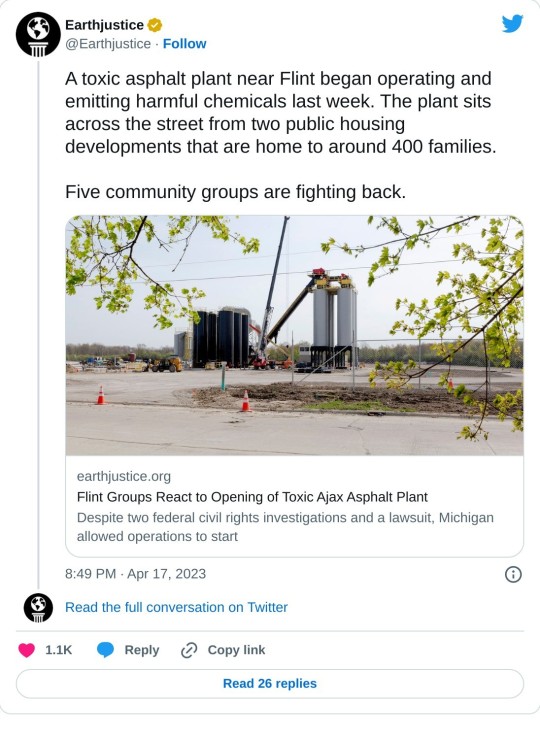

#Asphalt plant

Text

Asphalt Plant | Bitumen Sprayer Manufacturer in India - S.P. Enterprise

S.P. Enterprise is a manufacturer of road construction machinery like asphalt plant, hot mix plant, asphalt drum mix plant, bitumen sprayer in India. We are exporter and supplier of road construction equipments. Call us on +91-9712583240.

#asphalt plant#bitumen sprayer#mobile asphalt plant#asphalt drum mix plant#asphalt mixing plant#asphalt hot mix plant#bitumen pressure distributor

2 notes

·

View notes

Text

youtube

#flint mich#asphalt plant#toxic waste#ajax toxic asphalt plant#remove the toxic plants from the community#racism#systemic racism#foundational racism#chemical pollution#minority communities subjected to chemical pollution more often in america#Youtube

3 notes

·

View notes

Text

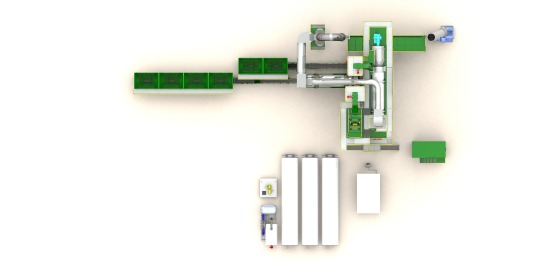

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

Industrial Gas Burner, Industrial Light Oil Burners Manufacturer | Narayan Burner

Established in 1992, NARAYAN OIL & GAS BURNERS CO. is one of the leading manufacturers & exporters of Industrial gas burners in India.

We have a wide range of manufacturing and exporting the brilliant quality assortment of Industrial Burner, Industrial Oil Burner, Industrial Gas Burner, Dual Fuel Burners, Monoblock Gas Burner, industrial boiler burner, boiler gas burner, Diesel Oil Burners, Bitumen Tank Burners, Oil Fire Burners, Natural Gas Fired Burners, etc. Our product range is manufactured using the best quality raw material as per the global standards.

Applications for industrial gas burners

Industrial Light Oil Burners

Industrial LPG Burners

Industrial Biogas Burner

Industrial Biogas Burner

High Temperature Burner

Dryer Burners

Powder Coating Oven Gas Burner

Powder Coating Oven Burner

Hot Water Generator Burner

Hot Water Generator Gas Burner

Bakery Oven Burner

Bakery Oven Gas Burner

Tea Dryer Burner

Pharmaceutical Dryer Burner

Pharmaceutical Dryer Gas Burner

Tray Dryer Burner

Tray Dryer Gas Burner

High Temperature Gas Burners

Commercial Gas Burners

Light Oil Burners

Sand Dryer Burner

Sand Dryer Gas Burner

Gas Burners for commercial application

Gas Burners for fryers

Gas Burners for Hot air generator

Gas Burners for Foundry

Gas burners for Metal industry

Gas burner for Aluminium Melting

Gas Burner for Metal Melting

Gas Burner for Furnace application

Gas Burners for Boilers

Gas Burner for thermic fluid heater

Gas Burner for Non-IBR boiler

Gas Burner for Incinerator

Gas Burner for Kiln

Gas Burners for Tin printing Dryer

Burners for Lead Melting Furnace

Paper Printing Dryer Burner

Roto Mould Oven Burner

Asphalt Plant Burners

Aluminium Curring Oven Burners

Ceramic Furnace Burners

Rotary Kiln Furnace Burners

Batch Oven Burners

Tumble Dryer Burners

Vertical Boiler Burner

Teflon Coating Oven Burner

Dual Fuel Burner for Boilers

Dual Fuel Burner for Hot Air Generators

Dual fuel burner for Thermic Fluid Heater

Industrial Burner for Powder Coating Oven

Dual Fuel Burners for Incinerator

Industrial Burners for Furnace

Industrial Burner for Bakery Oven

Industrial Burner for Hot Air Generator

Industiral Burner for Klin

Industrial Burner for Thermic Fluid Heater

Industrial Burner for Aluminium Melting Furnace

Industrial Burner for Metal Melting Furnace

Industrial Burner for Incinerator

Industrial Burner for Heat Treatment

Industrial Burner for Asphalt Plant

Industrial Burner for Glass Industry

For More Details

Click here : https://www.narayanburners.com/

0 notes

Text

How Advanced Filtration Systems Improve Asphalt Plant Efficiency

Industry Challenges

The asphalt industry faces numerous challenges, particularly concerning environmental regulations, operational efficiency, and the longevity of equipment. As demand for asphalt continues to rise, manufacturers and plant operators are under pressure to deliver high-quality products while minimizing their carbon footprint. One significant area of concern is managing emissions and waste generated during production. This is where advanced filtration systems come into play. These systems not only help in adhering to environmental norms but also enhance the overall efficiency of asphalt plants.

Filtration Systems: Definition

Filtration systems in asphalt plants are designed to capture and remove particulate matter, dust, and other contaminants from exhaust gases and air streams. These systems play a critical role in ensuring that the air released into the atmosphere meets environmental standards. By effectively filtering out pollutants, they contribute to a cleaner production process, which is crucial for both the environment and the long-term operation of the plant.

Types of Filtration Systems Commonly Used in Asphalt Plants

Several types of filtration systems are used in asphalt plants, each with unique benefits and applications:

Baghouse Filters: These are among the most common filtration systems used in asphalt plants. Baghouse filters use a series of fabric bags to capture dust and particulate matter. They are highly efficient, with some models capable of capturing up to 99.9% of airborne particles.

Cyclone Separators: Cyclone separators use a vortex to separate heavier particles from the air stream before they reach the filtration system. They are often used as a pre-filtering mechanism to reduce the load on the primary filtration system.

Wet Scrubbers: These systems use a liquid to remove contaminants from the air stream. They are particularly effective at capturing gaseous pollutants and fine particles that are difficult to filter using dry methods.

Electrostatic Precipitators (ESPs): ESPs use an electric charge to remove particles from exhaust gases. They are highly effective at capturing very fine particles and are often used in conjunction with other filtration systems to enhance overall efficiency.

Key Components of Advanced Filtration Systems

Advanced filtration systems are composed of several critical components that work together to ensure optimal performance:

Filter Media: The filter media is the material that captures the contaminants. The choice of media is crucial as it determines the efficiency and longevity of the filtration system.

Fans and Blowers: These components ensure that the air stream passes through the filtration system at the correct velocity, ensuring optimal filtration performance.

Dust Collection Hoppers: These are used to collect and store the filtered dust and particulate matter. Proper design and maintenance of dust hoppers are essential to prevent blockages and ensure smooth operation.

Control Systems: Advanced control systems monitor and adjust the operation of the filtration system to ensure optimal performance under varying operating conditions.

How These Components Work Together to Enhance Efficiency

The efficiency of an asphalt plant's filtration system depends on how well its components work together. For instance, the filter media must be matched to the specific contaminants being captured. The fans and blowers must maintain the correct airflow to ensure that the air stream is adequately filtered without causing excessive wear on the system. The dust collection hoppers must be regularly emptied and maintained to prevent blockages that could reduce system efficiency. Finally, the control systems must be properly calibrated to monitor and adjust the system's operation in real-time, ensuring that it operates at peak efficiency.

Technological Innovations

Recent technological innovations have significantly enhanced the efficiency of filtration systems in asphalt plants. One of the most notable advancements is the development of intelligent control systems. These systems use sensors and data analytics to monitor the operation of the filtration system in real-time, allowing for predictive maintenance and automatic adjustments to optimize performance.

Another innovation is the use of hybrid filtration systems that combine different types of filtration methods, such as baghouse filters and ESPs, to capture a wider range of contaminants more efficiently.

Advanced Materials Used in Filter Media

The performance of a filtration system largely depends on the quality and type of filter media used. Advanced materials, such as PTFE (Polytetrafluoroethylene) and ceramic fibers, have been developed to withstand higher temperatures and resist chemical degradation. These materials not only improve the filtration efficiency but also extend the lifespan of the filters, reducing maintenance costs and downtime.

Environmental Benefits

Integrating advanced filtration systems into asphalt plants has significant environmental benefits. By capturing a higher percentage of airborne pollutants, these systems reduce the amount of harmful emissions released into the atmosphere. This contributes to cleaner air, reduces the impact on the surrounding environment, and helps asphalt plants comply with increasingly stringent environmental regulations.

Moreover, by improving the efficiency of the production process, advanced filtration systems can reduce energy consumption and lower the overall carbon footprint of the plant.

Maintenance and Optimisation

Regular maintenance is crucial for ensuring the continued efficiency of filtration systems. This includes cleaning or replacing filter media, checking and maintaining fans and blowers, and ensuring that control systems are correctly calibrated. Advanced filtration systems often come with monitoring tools that provide real-time data on system performance, enabling plant operators to perform predictive maintenance and avoid unexpected downtime.

Performance Monitoring and Optimisation Strategies

To ensure optimal performance, it is essential to regularly monitor the performance of the filtration system. This can be done through data analytics and sensor technology that provide insights into how well the system is operating. By identifying trends and potential issues early, operators can make adjustments to optimize performance and prevent costly failures.

Optimization strategies may include adjusting airflow rates, changing filter media types, or upgrading control systems to incorporate the latest technology.

Common Issues and Troubleshooting Tips

Even the most advanced filtration systems can experience issues, such as reduced efficiency due to clogged filters or mechanical failures in fans and blowers. Troubleshooting tips include:

Regularly inspect and clean filters to prevent blockages that can reduce airflow and filtration efficiency.

Check fan and blower performance to ensure they are operating within their specified parameters.

Monitor system performance using control systems to detect issues before they become critical.

Get Tailored Solutions From a Reputed Asphalt Plant Supplier

Choosing the right filtration system for your asphalt plant is crucial for achieving optimal efficiency and environmental compliance. Working with a reputable supplier who can provide tailored solutions that meet the specific needs of your plant is essential. By investing in advanced filtration technology, you can ensure the long-term success of your operation while minimizing its environmental impact.

Visit at: How Advanced Filtration Systems Improve Asphalt Plant Efficiency

0 notes

Text

Asphalt Plant PDF

This asphalt plant pdf is the brief introduction of asphalt batching plant including components, working process, types, capacity, models and characteristics. Asphalt mixing plant is a kind of equipment specialized in producing asphalt concrete mixture. It mainly consists of asphalt mixer, aggregate bin, powder bin, control system and so on. Asphalt batch mix plant is usually used in the construction of roads, bridges, tunnels and other projects for the production of asphalt concrete of various specifications to meet the needs of engineering construction.

The working principle of asphalt mixing plant is to add aggregate, asphalt, powder and other raw materials into the mixer according to a certain proportion for mixing, after a certain time of mixing, the mixture reaches a certain degree of homogeneity, and then the mixture will be transported to trucks for transportation. Asphalt mixing plant has the advantages of high production efficiency, stable production quality and easy operation, so it is widely used in engineering construction.

Equipment classification of asphalt mixing plant:

Classified according to production capacity:

Small: the production rate is below 40t/h.

Medium-sized: production rate of 40-400t/h.

Large-scale: production rate above 400t/h.

Classified by handling method:

Mobile type: silo and mixing pot with its own tires, can be transferred with the construction site, suitable for county and township roads and low-grade highway projects.

Semi-fixed: the equipment is installed on several trailers and assembled at the construction site, mostly used in highway construction.

Fixed type: the equipment operating location is fixed, also known as stationary asphalt mixing plant, applicable to the project is concentrated, urban road construction.

Classified according to the mixing method:

Continuous drum type: the continuous uninterrupted mixing mode of production, heating and drying of aggregate and mixing the mixture in the same drum continuously.

Forced intermittent: the heating and drying of the aggregate and mixing of the mixture is forced cyclical, the equipment is mixed separately in one pot, each pot is mixed for 45 to 60 seconds, the output depends on the model of the equipment.

In summary, as an important road construction equipment, asphalt mixing plant play an important role in guaranteeing the quality of the road, improve construction efficiency.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/asphalt-plant-pdf.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

youtube

260 tph batch asphalt mixing plant video - Atlas Technologies

The plant is heavy and designed to produce quality hot mix asphalt with less maintenance.We are Indian manufacturers and exporters of asphalt mixing plant in different capacities ranging from 60 tph to 260 tph.

0 notes

Text

Top-Tier Asphalt Plant Services in India

Unlock the epitome of asphalt plant excellence with Fabhind. Our Asphalt plant stands tall as one of India's finest. Crafted for efficiency and durability, it ensures seamless road construction. Experience the pinnacle of quality and reliability with Fabhind's industry-leading solutions. Visit us at fabhind.com.

0 notes

Text

Vulcan plant on Highland Ave and Pepper in San Bernardino

0 notes

Text

Asphalt mixing plant video - Atlas Technologies

Atlas asphalt plant working near Ahmedabad, India. Plant is of 160 tph and is fitted with natural gas burner.

0 notes

Text

Asphalt batch mix plant - Atlas Industries

Find our video gallery of our wide range of road and civil construction machineries and we are leading manufacturers of construction machineries.

0 notes

Text

Tile adhesive plant | tile adhesive production line supplier manufacturer

asphalt plant manufacturer

A better low-cost and high-performance asphalt plant for asphalt contractors and construction company. As a professional asphalt mixing plant manufacturer, we produce asphalt plants match all the technical standard of high,airport,national roads and super-highway projects.

1 note

·

View note

Text

What's the Functions of Asphalt Plant Dryer Drum?

The asphalt plant dryer drum is to preheat the cold aggregate, dry and heat it up to ensure that discharge temperature meets the requirements.

Drying drum is one of the core components of asphalt mixing plant. The performance of drying drum directly determine the production of a complete set of asphalt mixing plant.

The Advantages of Drying Drum:

Long service life

Energy saving

Low emission

Low fuel cost

ZOOMLINE provide stationary and mobile type drying drums for choice.

#dryer drum#drying drum#asphalt plant dryer#asphalt dryer drum#asphalt drum mix plant#asphalt mixing plant#road construction#asphalt plant#construction#asphaltplant#mobile asphalt drum mix plant#heavy equipment#concrete#bitumen#dryer#dryer drum mix

2 notes

·

View notes

Text

https://www.powerasphalt.com/

We are at your service with our World Class Top Quality Machines.

1 note

·

View note

Text

What famous Mobile games have you played

Here is the mobile games I played

#angry birds#bad piggies#plant vs zombies#PVZ#Clash of the clans#Cut the rope#Candy crush#Fruit ninja#Brawl stars#Dan the man#Dumb ways to die#Sub way Surfers#temple run#Pixel run 3D#Wheres my water#mobile legends#crossy road#asphalt#Sonic dash#geometry dash#Doddle Jump#Hill climb racing#Minion rush#Hey day#Flappy bird#POU

23 notes

·

View notes

Text

feral michaelmas daisy - montgomery st, jc, nj - yashica mg-1 - developed at eliz digital & scanned with minolta dimage dual iii

#35mm#flowers#pink flowers#botany#daisy#aster#horticulture#plants#gardens#city street#35mm photography#film photography#35mm color photography#city photography#grunge#urban landscape#green#purple#asphalt#plantlife

16 notes

·

View notes