#Astm A193 grade b16

Text

Astm A193 b16 Fasteners | Roll Fast

Roll Fast is a manufacturer, supplier, and exporter of alloy steel ASTM A193 grade B16 full-threaded stud bolts and hex bolts. It includes details of high tensile, stainless, or alloy steel fasteners. ASTM A193 B16 stud bolts are high-strength fasteners manufactured from heat-treated Chromium-Molybdenum-Vanadium steel, quenched and tempered. Added Vanadium allows for operating temperatures higher than that of B7 stud bolts. It is extensively used in high-pressure and high-temperature services like valves, fittings, pressure valves, flanges, and chemical and petroleum construction applications. It covers the requirements for high-temperature and high-pressure bolting. A193 B16 all thread studs having diameters above 1" are most common in thread pitches.

visit source URL : https://www.roll-fast.com/astm-a193-grade-b16.html

0 notes

Text

Grade B16 Bolt, Nuts, Washers: Manufacturer & Supplier Overview

What is Grade B16 Bolt and Why It Is Important?

The Grade B16 bolts are used in many heavy-duty industries because of their heat resistance and high tensile strength. These bolts, which are designed to withstand environments of high pressure and temperature, are part the ASTM A193 standard. They are important because they can secure critical components in extreme conditions. This is especially true in applications like power plants, refineries and the automotive industry.

Specifications and requirements for ASTM A193 Grade B16 Bolts

ASTM A193 specifies alloy steel and stainless bolting materials primarily for high-temperature, high-pressure applications. The Grade B16 is made of alloy steel, specifically chrome-molybdenum. Bolts must have specific mechanical properties.

Minimum Tensile Strength: 860 MPa

Minimum yield strength 725 MPa

Temperature resistance: suitable for temperatures up to 45 degC

The bolts are tested for their chemical composition, hardness and performance when stressed to make sure they meet the required requirements.

Use Grade B16 Bolts for Various Industries

The Grade B16 bolts are highly valued in multiple industries because they offer many benefits.

Heat Resistant: Grade B16 bolts are made of a chromium and molybdenum alloy that is ideal for high temperature applications.

Corrosion Resistant: These products resist corrosion and oxidation to ensure longevity, even in harsh environments.

Durability Grade B16 bolts are resistant to repeated use, heavy loads and can be used for long-term installations.

Cost Effective: Due to their long life expectancy, these bolts offer a high return on investment.

Types of Grade-B16 Bolts

Grade B16 bolts are available in different types for various applications.

Hex Bolts Widely used to secure components in construction and machinery.

Carriage Bolts: Known for their smooth, rounded head, which provides a cleaner finish and is often used in woodworking or metal applications.

Flange bolts: This type of bolt has a washer-like flange built in that helps to distribute pressure and provide a stronger connection.

Stud Bolts : Used for flanged pipes and other critical joints that require superior strength.

Each type is designed to meet specific requirements based on application strength, environmental conditions, and mechanical requirements.

Different types of nuts and washers used with grade B16 bolts

Grade B16 bolts are often used with various types of nuts and washers to create secure and stable assemblies. Common combinations include:

Hex Nuts : Designed to be used with hex bolts.

Lock Nuts : Used to prevent loosening when vibration or stress occurs.

Flat Washers : Distributes the load and protects surfaces against damage.

Spring Washers : Maintain tension in dynamic environments to prevent loosening.

These combinations will ensure that the bolting assembly is able to withstand vibrations, thermal expansion and mechanical stress.

Production Process of Grade B16 Bolts - From Raw Materials to the Finished Product

The manufacturing process of Grade B16 bolts begins with the selection of high-quality alloy steel (usually chromium-molybdenum). These steps include:

Raw Materials Selection High-quality alloy is used to ensure durability.

Forming and Cutting: Steel is cut to the required lengths and bolts are shaped into the desired shape by forging or cold-heading.

Threading : Bolts threaded with precision dies ensure compatibility between nuts and bolts.

Heat Treatment Bolts are heat treated to increase strength and heat resistance.

Finishing : Bolts have a coating or treatment to prevent corrosion, usually with zinc or phosphate.

Inspection : The product is tested for quality, such as hardness, tensile and chemical analysis.

Quality Measures for Grade B16 bolts: Ensuring strength and durability

In order to maintain the integrity of Grade B16 Bolts, there are strict quality control measures in place.

Material Test: Verifies that the alloy composition is in accordance with ASTM A193 specifications.

Dimensional checks: Checks that bolts are threaded and meet exact measurements.

Mechanical Test: Verifies the tensile strength and yield strength of materials.

Non Destructive Testing includes methods such as ultrasound testing to detect internal faults.

Verification of Heat Treatment: This ensures that the bolt has been heat treated properly to increase strength and resistance.

These rigorous quality control processes ensure that bolts are fit and reliable for demanding applications.

Uses of grade B16 bolts in different industries

The Grade B16 bolt is used in many industries, especially those that need heat-resistant and durable fasteners.

Construction : Used to secure heavy steel structures such as bridges or high-rise building.

Automotive : Engine components, especially in high-performance cars where pressure and heat are high.

Oil & Gas : For pipelines and refineries as well as other equipment that is subjected extreme temperatures and pressures.

Power Generation : Used for turbines, nuclear reactors and boilers where reliability is critical.

Petrochemical : High-pressure valves and pumps.

These bolts are designed to provide the reliability necessary to prevent costly failures in mission critical environments.

Factors to consider when choosing the right supplier for grade B16 bolts

It's important to take into consideration the following when choosing a supplier of Grade B16 bolts:

Certifications: Ensure the supplier adheres to ASTM A193 standards and has proper certifications.

Quality control: Check that the supplier has a strict quality control process and can provide test results.

Experience : Select a supplier who has a proven track record in the manufacture and supply of high-quality bolts.

Customization The supplier must be able meet certain requirements, such as size, quantity, and coating.

Customer Service: Reliable vendors offer strong after-sales and technical support.

By choosing a reputable supplier, you can be assured that the bolts are manufactured to the specifications required for your application. This will minimize risks and improve performance.

Conclusion

Bolts of Grade B16 are essential in industries that require strength, heat resistance and durability. Knowing the ASTM A193 standard, the types of bolts and nuts used, the manufacturing process, and the quality control measures will help you choose the right bolts. It is important to partner with a trusted supplier in order to get high-quality products which perform well under even the most difficult conditions.

FAQ

1. What do the Grade B16 bolts for?

Bolts in Grade B16 can be mostly employed in high-temperature and high-pressure locations, including nuclear, petrochemical as well as power generation.

2. What are the specifications that B16 bolts of grade B16 bolts meet?

Grade B16 bolts are in compliance with ASTM A193 requirements, making sure they comply with strict standards in high tensile strength as well as heat resistance.

3. Do B16 bolts of grade B16 bolts stand up to wear and tear?

Although the Grade B16 bolts have excellent tensile strength as well as heat resistance However, they might require further treatments or coatings in order to increase their resistance to corrosion.

4. Are washers and nuts available in B16 grade material?

We do offer washers and nuts made of suitable materials that meet the specifications of B16 bolts of Grade B16 bolts.

5. What size bolts in Grade B16 do you produce?

We offer a range of sizes suitable for Grade B16 bolts that can be used for various industrial needs. Sizes that are custom-designed can be made on request.

6. What can I do to assure compatibility between my components making use of B16 grade fasteners? B16 fasteners?

Our technical staff can provide guidance in selecting the right washers and nuts that are compatible with the specifications of your project using grade B16 bolts.

7. Do you issue certificates to your grade B16 items?

All of our Grade B16 items come with a complete certification that confirms compliance with the ASTM A193 specification.

8. What is the time frame for a order from Grade B16 Fasteners?

Time frames for delivery vary according to the size of your order and any customization needs We strive to get standard orders out on time and maintain top-quality production standard.

0 notes

Text

The world of high-performance clasp: imperativeness and precision.

High-performance fasteners are extremely vital in production and business programs. These important additives maintain systems together, ensuring their protection, toughness, and dependability. Understanding the diverse grades and sorts of fasteners, together with A193 Grade B7, ASTM A193 B8, and ASTM A193 Grade B16, aids in choosing the precise one for the project. Here, we take a look at the ones fasteners and employ them, similarly to precise critical additives, which includes stainless-steel fasteners, threaded rods, flanges, and bars.

High-tensile fasteners are amazing for their outstanding electricity and potential to live on harsh occasions. A193 Review B7, a prevalent elective, has a tall pliable quality and uncommon flexibility to tall temperatures and stretch. These characteristics make A193 Grade B7 suitable for use within the oil and fuel zone, chemical industries, and power production centres.

ASTM A193 B8 clasp made of chrome steel has fabulous erosion resistance and solid malleable electricity. These fasteners perform well in severe situations, making them ideal for marine applications, food processing, and different sectors that often stumble upon corrosive chemicals.

ASTM A193 Grade B16 fasteners are important in conditions desiring even higher temperature tolerance. Their amazing tensile energy and capability to undergo immoderate temperatures make them ideal for steam generators and different excessive-temperature programs.

Stainless metallic fasteners combine sturdiness and corrosion resistance.

The stainless steel clasp offers a completely one-of-a-kind add-up to control and disintegration resistance. Stainless metal fasteners, which encompass the ones made via SS threaded rod manufacturers in India, are lengthy-lasting and reliable. These threaded rods serve an important characteristic in constructing, supplying strong guides for diverse structures.

SS flange manufacturers in India offer high-quality SS 304 flanges that provide a steady connection among pipes, valves, and specific gadgets. The SS 304 flange, truly noted for its immoderate corrosion resistance and power, is widely utilized in chemical processing, water treatment, and the food and beverage industries.

Duplex ribs and latches give predominant quality and erosion resistance.

Duplex spines give an exceptional level of quality and erosion resistance. These flanges are made of duplex stainless steel, which can handle hostile conditions and tremendous tension. Duplex flanges have better mechanical characteristics, making them perfect to be used in the oil and gasoline area, chemical processing, and maritime settings.

Duplex clasp, which envelops jolts, nuts, and screws, give comparable gifts. Their brilliant energy and resistance to strain corrosion cracking guarantee that constructions remain stable and last even below the maximum excessive situations.

Stainless steel bars are accessible in loads of bureaucracy and sizes, along with round bars and hex bars. Stainless steel round bar is utilized in commercial, construction, and ornamental motives. Its flexibility and resistance to corrosion make it a perfect desire for a huge variety of programs.

A chrome steel hex bar has excessive machinability and power. It is broadly utilized in the fabrication of clasps, gears, and other exactness additives. Stainless metal hex bolts made out of hex bars provide dependable fastening solutions for loads of applications, making certain a stable shape and resistance to environmental variables.

SS 304 circular bar is still a well-known choice because of its tall erosion resistance and straightforward fabrication. It is commonly utilized in nourishment preparation, chemical fabricating, and building ventures.

Specialty fasteners: precision and reliability

SS attachment head cap screws offer a secure and precise securing option. Their design enables simple installation and removal, making them perfect for applications that require regular maintenance. These screws have extremely good tensile strength and corrosion resistance, ensuring long-term performance.

ASTM A453 Review 660 clasp, cited for their over-the-top vitality and magnificent erosion resistance, are used in excessive-temperature conditions. These fasteners are important in sectors like planes, energy technology, and petrochemicals, wherein dependability beneath harsh situations is important.

Flange Weight Calculator Simplifies the Selection Process

A flange weight calculator makes the decision and design process easier for engineers and designers. This tool guarantees that the selected flanges satisfy the application's unique requirements by giving correct weight estimates, lowering the danger of overloading or underperformance.

Understanding each type's qualities and uses is critical in the wide world of fasteners and stainless steel components. From high-tensile clasps like A193 Review B7 and ASTM A193 B16 to stainless steel latches and strength things like duplex ribs and ASTM A453 Review 660 latches, each component is essential to guaranteeing the assistant adroitness and faithfulness of moved applications. Manufacturers and engineers may design stronger, more lasting buildings that survive the test of time and tough environments by selecting the appropriate fasteners and components.

0 notes

Text

Understanding the Different Grades and Materials of Stud Bolts

Delta Fitt Inc., a leading name among stud bolts manufacturers in India, we pride ourselves on offering a wide range of high-quality stud bolts to meet diverse industry needs.Stud bolts are essential components in many industrial applications, particularly in construction, oil & gas, and petrochemicals. Understanding the various grades and materials of stud bolts is critical to guaranteeing the integrity and safety of any structure or apparatus.

What Are Stud Bolts?

Stud bolts are threaded rods with two hefty hexagonal nuts that are used in a number of applications to connect pieces. They are intended to endure high pressures and harsh temperatures, making them excellent for important technical applications.

Grades of Stud Bolts

Stud bolts are categorised into different grades based on their material composition and mechanical properties. Here are some of the most commonly used grades:

B7 Stud Bolts

Material: ASTM A193 B7 stud bolts are made from alloy steel, specifically chromium-molybdenum steel.

Applications: These bolts are widely used in the petrochemical industry, oil refineries, and power plants due to their excellent strength and ability to withstand high temperatures and pressures.

Manufacturers: Delta Fitt Inc. is a renowned name among B7 stud bolts manufacturers in India, providing reliable and durable products.

B8 Stud Bolts

Material: ASTM A193 B8 stud bolts are manufactured from austenitic stainless steel, typically grade 304 or 316.

Applications: These bolts are used in environments where corrosion resistance is crucial, such as in chemical plants and marine applications.

Manufacturers: As one of the leading B8 stud bolts manufacturers in India, Delta Fitt Inc. ensures top-notch quality and performance.

B16 Stud Bolts

Material: These stud bolts are made from chromium-molybdenum-vanadium steel.

Applications: B16 stud bolts are used in high-pressure and high-temperature environments, such as in power generation and turbine manufacturing.

Materials of Stud Bolts

The material composition of stud bolts significantly influences their performance and suitability for different applications. Here are some common materials used in the manufacturing of stud bolts:

Carbon Steel: Carbon steel stud bolts are known for their strength and durability. They are suitable for applications requiring high tensile strength.

Stainless Steel: Stainless steel stud bolts offer excellent corrosion resistance and are ideal for use in harsh environments. Grades such as 304 and 316 are popular choices.

Alloy Steel: Alloy steel stud bolts, such as those made from chromium-molybdenum, provide superior strength and resistance to high temperatures and pressures.

Nickel Alloys: Nickel alloy stud bolts are used in extremely corrosive environments and high-temperature applications. They offer exceptional resistance to oxidation and corrosion.

Why Choose Delta Fitt Inc.?

As one of the leading stud bolts manufacturers in India, Delta Fitt Inc. stands out for its commitment to quality, precision, and customer satisfaction. Our products undergo stringent quality checks to ensure they meet international standards. We offer a comprehensive range of stud bolts, including B7 and B8 grades, to cater to various industrial needs.

Our dedication to innovation and excellence has made us a trusted name among stud bolts suppliers in India. Whether you need high-strength carbon steel stud bolts or corrosion-resistant stainless steel options, Delta Fitt Inc. has the perfect solution for your requirements.

To summarise, understanding the various grades and materials of stud bolts is critical for choosing the best product for your unique application. Delta Fitt Inc. guarantees high-quality stud bolts that operate, reliably, and safely in the most challenging settings. Choose Delta Fitt Inc. for all of your stud bolt requirements and discover the difference that quality makes.

Website: deltafitt.com

0 notes

Text

Purpose of choosing ASTM A193 grade strength

Alloy steel bolting materials meeting ASTM A193 Grade B16 criteria are the norm for strain vessels, valves, flanges, and fittings meant to face up to excessive temperatures and pressures. The maximum frequent users of these applications are the petrochemical, oil & gas, and power generation fields.

The chemical make-up of grade B16 bolts is as follows: silicon (0.15-zero.35%), chromium, manganese, phosphorus, sulfur, vanadium, and carbon. Grade B16 bolts are the maximum broadly used sort of alloy metal amongst numerous versions. These bolts' precise composition offers them with exquisite resistance to oxidation and sulfidation in addition to excessive temperature power.

To make certain that Grade B16 bolts are suitable and reliable for use in excessive-temperature and high-strain settings, the ASTM A193 widespread specifies necessities for his or her manufacturing, warmth treatment, and testing.

Could you explain the differences between B16 and B7 bolts?

While B7 and B16 bolts have similar features, what sincerely distinguishes them are their mechanical houses and material composition.

Enterprises coping with accelerated temperatures and pressures regularly make use of bolts with the B7 and B16 classifications. This is specially actual for the petrochemical, power era, and oil and gasoline sectors.

In order to achieve the required hardness and electricity, the medium carbon alloy metallic (4140) used to create B7 bolts and ASTM A193 B8 Bolts is often heated to the best temperature and then tempered. They have minimal yield and tensile strengths of 105 ksi and 125 ksi, respectively.

But the metal used to make B16 bolts is a higher alloy metal with molybdenum, chromium, and vanadium combined collectively. B16 bolts are stronger and extra proof against oxidation and sulfidation in warm conditions way to those additives. Moreover, B16 bolts have minimal yield and tensile strengths which can be corresponding to B7 bolts.

Use B7 bolts for packages desiring high energy and mild temperature resistance; use B16 bolts for packages requiring better energy and stronger resistance to oxidation and sulfidation at immoderate temperatures. B7 bolts are the endorsed desire while some diploma of heat resistance is vital.

Materials that are comparable to ASTM A193 Grade B16 consist of:

DIN EN 10269 1.4980:

European standard addresses bolts composed of a robust and heat-resistant chromium-molybdenum alloy steel.

ISO 898-1 class 10.9:

For bolts composed of alloy steels comparable to ASTM A193 Grade B16, International Standard ISO 898-1 class 10.9 provides mechanical criteria.

BS 1501-640B:

One can use British standard BS 1501-640B to fabricate fastening materials with characteristics comparable to ASTM A193 B8C bolts and ASTM A193 Grade B16. This general applies to high-power steel plates which have gone through heat remedy.

JIS SCM 4:

This Japanese business well-known specifies what to do with low-alloyed steels which have mechanical characteristics and chemical compositions equivalent to ASTM A193 Grade B16 and ASTM A193 B8M Stud Bolt.

It's vital to hold in mind that at the same time as the chemical composition and mechanical traits of numerous materials may be equal, their manufacturing methods, warmth remedy methods, and trying out requirements may additionally range. These variations may have an impact on the materials' performance for particular applications. It is advisable to study the pertinent material requirements and get advice from an experienced engineer or metallurgist when selecting bolting materials for applications involving high temperatures and pressures.

0 notes

Text

ASTM A193/A193M Grade B7/B7M/B16 Threaded Rods https://www.bikudo.com/product/921351.html #threaded #rods

0 notes

Text

Studs, Nuts & Bolting Products- ARTG

A.R. Thomson Group offers a full line of studs, nuts and bolting products. All of our industrial studs and nuts complement the bolted joint assembly and are manufactured in accordance to the latest editions of ASTM and ASME.

Quality

A.R. Thomson Group maintains an ISO 9001:2015 Quality Management System. Full traceability with heat codes and lot numbers ensures 100% compliance. Positive material identification, NACE, ASTM, and hardness certification are all available upon request.

Products & Materials

All Thread Studs: ASTM A193 Grade B7, B7M, B8, B8M, B16; ASTM A-320 Grade L7 and L7M Heavy Hex Nuts: ASTM A194 Grade 2H, 2HM, 4, 7L, 7LM, 8 and 8M Custom Coatings: Xylan, Teflon®, Cadmium, Zinc Washers: ASTM F436 Hardened Steel Flat Washers, Stainless Steel and Belleville Washers Specialty Fabricated and Machined Studs: Carbon Steel and Stainless Steel (specialty alloys available upon request) Thread Lubricant: CANFLEX® Approved – Helps control friction and ensures uniform compression of the gasket in the bolted joint assembly

0 notes

Text

All the significant advantages of stainless steel fasteners.

Stainless steel seems to be corrosion resistant in all grades, making it an excellent metal for use in just about anything. Not just that, but stainless steel seems to have an outstanding life span, is eco safe, is 100 percent recyclable, and therefore is resistant to excessive heat as well as cold. So it is no surprise that when we think about the stainless steel fasteners, the very first thing that comes to one's mind is their longevity. The below are the top benefits of using these extremely useful and robust fasteners as well as bolts:

* Resistant to Corrosion

Stainless steel is indeed a low carbon steel with 10.5 percent and perhaps more chromium, which forms a transparent chromium-oxide layer on the metal; that’s what makes stainless steel fasteners their corrosion resistance. When there is available oxygen, except in limited amounts, this layer will self-repair whether it is mechanically or otherwise chemically compromised. Grade 12.9 Bolts are very popular.

* Attractive on the outside

Since stainless steel ASTM A193 B8 fasteners don't really rust or otherwise tarnish, they have a smoother appearance (as well as last longer), that's why they are frequently used specifically in manufacturing and building.

* Strength

Stainless steel ASTM A193 B6 fasteners are durable and can withstand extreme corrosive conditions.

* Long Life Cycle

Stainless steel B7 Bolts would outlast any fasteners.

* Temperature Resistance

Stainless steel Astm A320 Grade L7 Bolts can withstand intense cold and heat.

*Reasonably Low-Cost

Stainless steel fasteners can be somewhat more expensive at first, but they have longer-term value, making them very inexpensive in the longer run. SS hex bolt manufacturers has been doing an excellent work.

* Mostly Non-Magnetic

Although each of the stainless steel A193 B16 alloy has varying degrees of magnetism, austenitic steels are specifically non-magnetic.

* Easy to maintain

Stainless steel SS 316 Bolts need minimal care, are resistant to cracks, and are simple to clean.

They are widely available throughout the market and can also be purchased online.

Stainless steel fasteners as well as bolts are the preferred material for nearly any application due to their reliability and additional benefits. Hex head fasteners Grades 2, 5, as well as 8 are among the most commonly used grades. Grade 2 steel is indeed a popular hardware-grade steel. This has been the most popular as well as least costly steel fastener grade. Grade 2 bolts have been commonly used in applications where the high strength isn't really needed, like handrail assembly as well as pipe clamps and otherwise hangers.

Grade 5 bolts are perhaps the most popular bolts used in vehicle industries which are reinforced to improve reliability. Bolts of grade 8 have been reinforced rather than bolts of grade 5. As a result, they are safer and are specifically used in high-stress applications like vehicle suspensions and machinery assembly.

Alloy steel is commonly used for the socket head bolts. Alloy steel bolts are particularly heat treated after being manufactured from a high quality steel alloy. Steel bolts are normally not plated, leaving them with a rusty black finish. Steel bolts are incredibly solid, but they are still very brittle.

0 notes

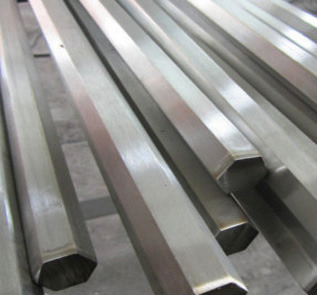

Photo

astm a193 b16

Manifold Pipe Solution Inc. is India's largest stockist and supplier of ASTM A193 B16 Bolts with an extensive inventory for industrial and commercial applications. You can also acquire different types of Astm A193 Grade B16 Bolts including A193 B16 Stud Bolts, ASTM A193 B16 Threaded Rod, ASTM A193 B16 Bolts, ASTM A193 B16 Nuts. For trusted doorstep shipping reach us at https://www.fastenersonline.co.in/

0 notes

Photo

astm a193 b16 bolts

We maintain stock & supply astm a193 b16 bolts to more than 60 locations worldwide.in our warehouse you’ll find a large inventory of astm a193 grade b16 bolts including b16 head bolts, b16 transmission bolts more than 100 types of b16 bolts.

0 notes

Text

ASTM A193 Grade B16 - Boltport Fasteners

ASTM A193 Grade B16 is a material specification for Bolts, Screws, Studs, Stud Bolts, Threaded Rods, Threaded Fasteners and Round Bars for use in high temperature or high pressure service. A193 Gr B16 bolts are primarily used for high tensile bolting applications in power generation industry, high temperature pipeline bolting, offshore and marine engineering platforms

#astm a193 grade b16 bolts#astm a193 grade b16 bar stock#astm a193 grade b16 chemical composition#astm a193 grade b16 equivalent#astm a193 grade b16 hardness#astm a193 grade b16 mechanical properties#astm a193 grade b16 material#astm a193 grade b16 properties#astm a193 grade b16 steel#astm a193 grade b16 thermal expansion#astm a193 gr b16 composition#astm a193 gr b16 steel#chemical composition of astm a193 grade b16#astm a193 b16#a193 gr b16#a193 grade b16#a193 grade b16 studs#a193 grade b16 hex bolts#a193 grade b16 bolts#a193 b16 bolts#a193grb16#astm a193#boltport fasteners#bpf

0 notes

Text

ASTM A193 grade B16 manufacturer and exporter | roll fast

The specification of ASTM A193 grade B16 includes details of high tensile, stainless, or alloy steel fasteners. The extensive use of these bolting arrangements is in administrations related to high pressure and temperatures like services like valves, fittings, pressure valves, flanges, and chemical and petroleum construction applications. Roll fast is the manufacturer and exporter of alloy steel ASTM A193 grade full threaded stud bolts and hex bolts.

visit source URL: https://www.roll-fast.com/astm-a193-grade-b16.html

0 notes

Text

New AD/CVD Petitions – Carbon and Alloy Steel Threaded Rod from China, Thailand, India, and Taiwan

Vulcan Steel Products Inc. (Petitioner) on February 19, 2019, filed antidumping (AD) and countervailing duty (CVD) petitions against Carbon and Alloy Steel Threaded Rod (“Steel Threaded Rod”) from China, India, Taiwan and Thailand.

Under U.S. trade laws, a domestic industry can petition the U.S. Department of Commerce (“DOC”) and U.S. International Trade Commission (“ITC”) to investigate whether the named subject imports are being sold to the United States at less than fair value (“dumping”) or benefit from unfair government subsidies. For AD/CVD duties to be imposed, the U.S. government must determine not only that dumping or subsidization is occurring, but also that the subject imports are causing “material injury” or “threat of material injury” to the domestic industry.

— Scope

The proposed scope definition in the petition identifies the merchandise to be covered by these AD investigations as:

The merchandise covered by the scope of these investigations is carbon and alloy steel threaded rod. Steel threaded rod is certain threaded rod, bar, or studs, of carbon or alloy steel, having a solid, circular cross section of any diameter, in any straight length. Steel threaded rod is normally drawn, cold-rolled, threaded, and straightened, or it may be hot-rolled. In addition, the steel threaded rod, bar, or studs subject to these investigations are non-headed and threaded along greater than 25 percent of their total actual length. A variety of finishes or coatings, such as plain oil finish as a temporary rust protectant, zinc coating (i.e., galvanized, whether by electroplating or hot-dipping), paint, and other similar finishes and coatings, may be applied to the merchandise.

Steel threaded rod is normally produced to American Society for Testing and Materials (“ASTM”) specifications ASTM A36, ASTM A193 B7/B7m, ASTM A193 B16, ASTM A307, ASTM A320 L7/L7M, ASTM A320 L43, ASTM A354 BC and BD, ASTM A449, ASTM F1554-36, ASTM F1554-55, ASTM F1554 Grade 105, American Society of Mechanical Engineers (“ASME”) specification ASME B18.31.3, and American Petroleum Institute (“API”) specification API 20E. All steel threaded rod meeting the physical description set forth above is covered by the scope of these investigations, whether or not produced according to a particular standard.

Subject merchandise includes material matching the above description that has been finished, assembled, or packaged in a third country, including by cutting, chamfering, coating, or painting the threaded rod, by attaching the threaded rod to, or packaging it with, another product, or any other finishing, assembly, or packaging operation that would not otherwise remove the merchandise from the scope of the investigation if performed in the country of manufacture of the threaded rod.

Carbon and alloy steel threaded rod are also included in the scope of this investigation whether or not imported attached to, or in conjunction with, other parts and accessories such as nuts and washers. If carbon and alloy steel threaded rod are imported attached to, or in conjunction with, such non-subject merchandise, only the threaded rod is included in the scope.

Excluded from the scope of these investigations are: (1) threaded rod, bar, or studs which are threaded only on one or both ends and the threading covers 25 percent or less of the total actual length; and (2) stainless steel threaded rod, defined as steel threaded rod containing, by weight,1.2 percent or less of carbon and 10.5 percent or more of chromium, with or without other elements.

Excluded from the scope of the antidumping investigation on steel threaded rod from the People’s Republic of China is any merchandise covered by the existing antidumping order on Certain Steel Threaded Rod from the People’s Republic of China. See Certain Steel Threaded Rod from the People’s Republic of China: Notice of Antidumping Duty Order, 74 Fed. Reg. 17,154 (Dep’t Commerce Apr. 14, 2009).

Steel threaded rod is currently classifiable under subheadings 7318.15.5051, 7318.15.5056, and 7318.15.5090 of the Harmonized Tariff Schedule of the United States (“HTSUS”). Subject merchandise may also enter under subheading 7318.15.2095 and 7318.19.0000 of the HTSUS. The HTSUS subheadings are provided for convenience and U.S. Customs purposes only. The written description of the scope is dispositive.

— Alleged AD Margins.

Petitioner calculated estimated dumping margins of:

China: 53.57% to 55.60%

India: 25.43% to 28.34%

Taiwan: 32.10%

Thailand: Not Yet Available

— Named Exporters/ Producers

Petitioner included a list of companies that it believes are producers and exporters of the subject merchandise. See attached list here.

— Named U.S. Importers

Petitioner included a list of companies that it believes are U.S. importers of the subject merchandise. See attached list here.

— Estimated Schedule of Investigations.

February 21, 2019 – Petitions filed

March 13, 2019 – DOC initiates investigation

March 14, 2019 – ITC Staff Conference

April 7, 2019 – ITC preliminary determination

July 21, 2019 – DOC CVD preliminary determination (assuming extended deadline)

September 19, 2019 – DOC AD preliminary determination (assuming extended deadline)

February 1, 2020 – DOC AD/CVD final determination (assuming extended deadlines)

March 17, 2020 – ITC final determination (extended)

March 24, 2020 – DOC AD/CVD orders issued (extended)

This product has previously been subject to other AD/CVD investigations. In 2009, AD/CVD orders were imposed on carbon steel threaded rod from China. In 2013, although Petitioner tried to get AD/CVD orders imposed on carbon steel threaded rod from India and Thailand, the ITC made a negative determination (i.e, no injury or threat of injury caused by the subject imports). This Petitioner appears to be a serial user of US trade laws repeatedly trying to get the US government to issue protective duties against subject imports. Given that the Petitioner’s most recent attempt to get AD/CVD duties imposed was unsuccessful, foreign exporters or US importers of this product may be able to use similar arguments to explain why these new AD/CVD actions should also be rejected.

New AD/CVD Petitions – Carbon and Alloy Steel Threaded Rod from China, Thailand, India, and Taiwan syndicated from https://immigrationattorneyto.wordpress.com/

0 notes

Link

0 notes

Text

Importance of Material Grade in Heavy Hex Bolts | Roll Fast

Roll Fast is a renowned manufacturer and exporter of heavy hex bolts for the construction of petrochemical industries. Heavy Hex Bolts are designed for use in a variety of high-temperature, high-strength industrial applications, such as steel fabrication and general construction. We also offer heavy hex bolts to structural grade ASTM a307, a325, and a490 specifications. They feature a thicker head than standard or regular hex bolts and offer a greater bearing surface that distributes the clamping load over a wider area. Heavy hex bolts are heavy profile hexagon bolts with large widths across flats and high head height. Also known as heavy hex head bolts or heavy hex structural bolts, these heavy hex bolts are commonly manufactured in high tensile grade 5, 8, 8.8, 10.9, 12.9, a193 grade b7, b7m, b8, b8m, b16, a320 grade l7, l7m, stainless steel, and other material.

visit source url : https://www.roll-fast.com/industries-served/petrochemical-industries/heavy-hex-bolts.html

0 notes

Text

Distinct steel alloys found across the globe.

Steel alloys are extremely important to makers of metal. These objects were particularly valuable in the fabrication and feedstock sectors since the production procedure that produced them allowed for a broad variety of forms and sizes to be produced. The production of these goods involves a wide variety of operations, some of which include machining, forging, casting, assembly, and spinning.

Round, hollow, and coil stocks can all be made from steel alloys. The specifics of these industrial products may be better grasped with an awareness of the many types of alloys. The ASTM A193 B8 Threaded Rod have been performing for quite some time.

The Austenitic Alloys

The first step in the production of austenite is the reaction that takes place when an iron solution is combined with an alloy. As it cools, it undergoes a phase transition, changing into other phases such as ferrite and cementite. It is probable that pearlite will also be produced in this process. This steel alloy is a popular option due to its resistance to corrosion as well as the improved strength it achieves during cold working. ASTM A193 B8 Class 2 Bolts are simple to track down.

There are two distinct categories of austenitic alloys. The first is the 200 series, which includes manganese, nickel, and chromium. The 300 series is the second kind, and it consists of only nickel and chromium. Quenching, annealing, and other forms of tempering have an effect on the mechanical properties of austenite. India is home to some of the world's finest ASTM A193 B8M Bolts.

Iron-Based Materials

These 400-series alloys are a subset of stainless steel. Commonly referred to simply as "iron," ferrite is the same element that gives both cast iron and steel their magnetic properties. Duplex Steel Hex Bolts manufacturers in India are always willing to lend a hand. They do not harden in response to heat or other treatments. However, they can be significantly strengthened with cold working. The resistance to corrosion, ductility, and oxidation of ferritic alloys are their finest qualities. ASTM A193 B16 Bolts has been excellent.

Alloys with a martensitic structure

It is possible for a tough structure known as martensite to emerge whenever the crystalline structure of steel passes through a displacive transition. Quenching an austenitic alloy at extremely low temperatures results in the production of this type of steel. It is ductile and possesses magnetic qualities, but the only protection it would have against corrosion is at very low temperatures. India has a number of reliable sources for ASTM A453 Grade 660 Bolts.

Varieties of steel alloys

There are two additional categories of steel alloys beyond the three already discussed. A320 L7 Bolts manufacturers in India are plentiful in many states.

It's possible that aluminum or nickel is the component of this alloy that makes up this metal. They are open to having techniques of hardening and strengthening applied to them. Because they include both austenitic and ferritic metal alloys, other types of stainless steel are classified as duplex stainless steels. India is home to several providers who produces ASTM A320 L7 Stud Bolts.

0 notes