Ananka Group is a leading fasteners manufacturer, supplier, exporter & stockist in India

Don't wanna be here? Send us removal request.

Text

Hex Flange Bolts Manufacturer, Supplier & Exporter

Introduction

Ananka Group is a leading global manufacturer, supplier, and exporter of industrial fasteners, known for delivering precision-engineered solutions to a wide range of sectors including oil & gas, petrochemical, aerospace, marine, construction, and heavy engineering.

With a state-of-the-art manufacturing facility based in Vasai, Maharashtra (India) and fully operational offices in the USA and UK, Ananka Group is strategically positioned to serve clients worldwide with superior quality, timely delivery, and technical support.

We specialize in standard and non-standard fasteners, made from high-performance materials such as stainless steel, duplex, and super duplex, Inconel, Monel, Hastelloy, Titanium, and other specialty alloys. Our commitment to ISO-certified quality management, innovation in design, and customization capabilities makes us a preferred partner for mission-critical applications.

Key Strengths:

In-house design, prototyping, and rapid manufacturing

Wide range of coating and plating solutions

Custom fastener solutions in both metric and imperial sizes

Global exports with full compliance to ASTM, DIN, ISO, and BS standards

A dedicated R&D division focused on aerospace and API-certified components

Hex flange bolts are among the most versatile and widely used fasteners in the industrial world, known for their built-in washer-like flange that distributes load efficiently and eliminates the need for a separate washer. As a trusted manufacturer and supplier of hex flange bolts, we deliver high-performance, corrosion-resistant, and precision-engineered fasteners tailored to suit diverse applications across global industries.

What Are Hex Flange Bolts?

Hex flange bolts are hexagonal head bolts with an integrated flange at the base of the head. This flange acts as a washer, spreading the clamping load over a larger surface area. It reduces the risk of damage to the fastening material and enhances bolt retention, especially in high-vibration environments.

These bolts are frequently used in the automotive, aerospace, oil & gas, heavy machinery, and construction sectors for their strength and reliability.

Design & Prototyping

Whether you need a bolt designed for extreme environments or specialized machinery, our engineering team can prototype the fastener to your exact specifications, including:

Flange diameter customization

Thread pitch variation (coarse/fine)

Head height and drive type

Unique surface treatments or alloy choices

Our focus is on innovative fastening solutions to meet modern engineering demands.

Rapid Manufacturing Capabilities

Thanks to our state-of-the-art CNC machines, forging units, and automated plating lines, we support rapid manufacturing of hex flange bolts, from small-batch custom orders to bulk production runs.

We maintain large inventories of standard sizes and provide just-in-time delivery across various industries and countries. Our agile manufacturing approach ensures minimal lead times and consistent quality.

Custom Coating & Plating Options

Corrosion resistance and environmental compatibility are crucial for bolt longevity.

Zinc and yellow zinc plating

PTFE (Teflon) coating

Hot-dip galvanizing

Black oxide finish

Dacromet and Geomet coatings

Nickel, chrome, and copper plating

These coatings enhance performance in aggressive conditions like marine, chemical, offshore, and automotive applications.

Product Types Offered

High-Performance Hex Flange Bolts

Designed for critical applications like aerospace, nuclear, and motorsports, where reliability and durability are essential.

Custom Fastener Solutions

Our team creates bespoke fasteners that align with your blueprints or technical requirements, including unique dimensions, threading, and materials.

Precision-Engineered Fasteners

Manufactured to tight tolerances, ensuring optimal performance in applications that demand high accuracy.

Specialty Alloy Hex Flange Bolts

Manufactured from premium materials like Inconel, Monel, Hastelloy, Titanium, Duplex, Super Duplex, and others, engineered to perform reliably in the most demanding and corrosive environments.

Corrosion-Resistant Fasteners

Manufactured using stainless steel grades like SS 304, SS 316, and SS 316L or coated with advanced finishes to withstand harsh conditions.

Non-Standard Hex Flange Bolts

Custom dimensions, threading types, and geometries that don't conform to conventional fastener norms.

Metric & Imperial Sizes

Available in a wide range of thread sizes and lengths in both metric (M6 to M80) and imperial (¼” to 3”) standards.

Applications of Hex Flange Bolts

Automotive Industry: Engine components, transmissions, and chassis

Construction: Steel frameworks, bridges, and heavy structures

Oil & Gas: Offshore rigs, refineries, and chemical plants

Aerospace: Airframe structures and engine assemblies

Heavy Equipment: Cranes, bulldozers, and mining machinery

Railways: Track assemblies and locomotive parts

Why Choose Us?

As an ISO-certified manufacturer, supplier, and exporter of hex flange bolts, we ensure:

Superior material selection & quality control

Compliance with international standards: DIN, ASTM, ISO, BS, JIS

Bulk availability and global shipping

In-house R&D for developing advanced fastening systems

Offices & supply chains in India, USA, UK, Europe, and the Middle East

Conclusion

Whether you require standard, non-standard, or custom-engineered hex flange bolts, we have the manufacturing expertise, design capability, and international reach to deliver what you need fast and reliably. With a focus on quality, innovation, and performance, we are your ideal partner for all your fastener requirements.

FAQs

What materials are hex flange bolts made from?

They are typically manufactured from stainless steel, alloy steel, titanium, and specialty alloys like Inconel and Monel.

Are hex flange bolts reusable?

Yes, if not overtightened or damaged, they can be reused. However, it depends on the application and environmental conditions.

Do I need a washer with a hex flange bolt?

No, the integrated flange serves the same purpose as a washer, distributing the load and preventing loosening.

#HexFlangeBolts#FlangeBolt#CustomFasteners#CorrosionResistantBolts#SpecialtyAlloyFasteners#NonStandardFasteners#CustomBoltSolutions#RapidManufacturing#CoatedFasteners#AnankaGroup#HexBoltsSupplier#FastenersExporter#BoltsAndNuts#FlangeBoltSupplier#Anankafasteners#Blog#Articles#tumblr#ananka#tumblr blog

0 notes

Text

Heavy Hex Bolts Manufacturer, Supplier & Custom Fastener Solutions

Heavy Hex Bolts are a fundamental component in industrial fastening applications, widely used in construction, heavy machinery, power plants, oil & gas, marine, and structural steel sectors. With a larger head size than standard hex bolts, these fasteners provide superior clamping force, enhanced load distribution, and better resistance to loosening under vibration.

At Ananka Group, we specialize in custom-engineered Heavy Hex Bolts that are precision-crafted, high-performance, and suited for the most demanding environments.

What Are Heavy Hex Bolts?

Heavy Hex Bolts are externally threaded fasteners with a hexagonal head, featuring a larger head and thicker body compared to regular hex bolts. The larger head design offers enhanced bearing surface, making it ideal for handling high-load and high-stress applications.

Key Characteristics:

Larger head size for better load distribution

High tensile strength

Available in coarse and fine thread types

Designed for structural and critical connections

Typically used alongside heavy hex nuts and hardened washers to ensure superior joint integrity and long-term durability.

Applications of Heavy Hex Bolts

Heavy Hex Bolts are vital in:

Steel Fabrication

Bridges and Flyovers

Oil and Gas Pipelines

Power Generation Plants

Marine and Offshore Equipment

Wind Turbines

Mining and Heavy Equipment

Their ability to withstand extreme mechanical stress makes them a preferred choice in both onshore and offshore industrial settings.

Design & Prototyping Capabilities

We offer complete design and prototyping services for Heavy Hex Bolts based on your technical drawings, performance requirements, and industry-specific needs. Our engineering team uses advanced 3D modeling and simulation tools to ensure that the fastener meets all structural and mechanical benchmarks before it goes into production.

Prototyping Highlights:

CAD-assisted design validation

Custom geometries for specialized fittings

Performance simulation and stress analysis

Rapid Manufacturing Process

With an agile production system and lean manufacturing processes, we ensure rapid manufacturing of Heavy Hex Bolts without compromising on quality. Whether you need a small prototype batch or a high-volume production run, our facility is equipped to deliver fast and efficiently.

Reduced lead times

Precision CNC machining

Heat treatment and forging for strength enhancement

Fast turnaround on urgent custom orders

Custom Coating & Plating Options

To improve durability and corrosion resistance, our Heavy Hex Bolts come with a wide range of custom coatings and platings, tailored to the service environment. This includes both decorative and protective finishes.

Available Coatings:

Hot-Dip Galvanized (HDG)

Zinc Nickel

PTFE (Teflon)

Xylan

Black Oxide

Cadmium

Phosphate

Epoxy & Ceramic Coatings

These coatings help extend the bolt's life in corrosive, marine, and chemical environments.

Available Product Types

We manufacture and supply a wide array of Heavy Hex Bolts that meet diverse industrial specifications:

High-Performance Bolts

Made from advanced alloys and heat-treated for maximum tensile strength, ideal for high-pressure, high-temperature applications.

Custom Fastener Solutions

Tailored to your drawings or engineering requirements, suitable for critical structural applications.

Precision-Engineered

Machined to tight tolerances with consistent thread forms, ensuring secure and durable fastening.

Specialty Alloy Options

Offered in specialty alloys such as Inconel, Monel, Hastelloy, Duplex, Super Duplex, Titanium, and others perfectly suited for demanding sectors like petrochemical, marine, and aerospace industries.

Corrosion-Resistant Fasteners

Designed with anti-rust coatings and materials like stainless steel (304, 316) for use in humid or saline environments.

Non-Standard Heavy Hex Bolts

We produce non-standard sizes, head styles, and threads that are not commonly available in the market.

Metric & Imperial Sizes

Offered in both metric (M12–M100) and imperial (1/2" to 4") sizes as per ISO, DIN, ASTM, and ANSI standards.

Global Reach & Quality Assurance

As a trusted global manufacturer and supplier, Ananka Group exports Heavy Hex Bolts to over 70 countries, meeting international standards such as ASTM, ASME, DIN, BS, and ISO. Each fastener is subjected to comprehensive quality control inspections, which include:

Material testing

Dimensional inspection

Hardness and tensile testing

Coating thickness evaluation

Third-party inspections on request

Conclusion

Heavy Hex Bolts are the backbone of heavy-duty industrial connections. At Ananka Group, we combine engineering expertise, advanced manufacturing, and innovative surface treatment solutions to offer fasteners that perform under pressure. Whether you need standard sizes or complex custom designs, our fasteners are built for strength, durability, and precision.

Frequently Asked Questions (FAQ)

Q1: What materials are used to manufacture Heavy Hex Bolts?Common materials include Carbon Steel, Alloy Steel, Stainless Steel (304, 316), Inconel, Monel, Duplex, and more.

Q2. What is the difference between hex bolts and heavy hex bolts?A standard hex bolt has a smaller head and width across flats, while a heavy hex bolt has a larger head and thicker body for enhanced strength and torque application.

Q3: Can I order custom-designed Heavy Hex Bolts?Absolutely, we offer custom fastener solutions backed by in-house design expertise and rapid prototyping capabilities.

Q4: What finishes are available for corrosion protection?Finishes include Hot-Dip Galvanizing, PTFE, Zinc, Xylan, and other specialized coatings.

Q5: Are both metric and imperial sizes available?Yes, we supply both metric (M sizes) and imperial (inch-based) Heavy Hex Bolts.

Q6: Do you offer testing and quality documentation?Absolutely, we provide full inspection reports, material test certificates, and third-party inspection if required.

#HeavyHexBolts#HexBoltManufacturer#HexHeadBolts#ASTMA193#CustomBolts#BoltSupplierIndia#FastenersManufacturer#HeavyHexNutsAndBolts#AnankaFasteners#BoltsAndNuts#HexBoltExporters#Anankafasteners#Ananka#Blog#Articles#manufacturer#fasteners#tumblr#tumblr blog

0 notes

Text

12 Point Flange Bolt Manufacturer in India | Exporter & Stockist

Ananka Fasteners is a top-tier 12 Point Flange Bolt Manufacturer in India, specializing in precision-engineered fastener solutions for demanding industrial applications. Our 12-point flange bolts are widely used across aerospace, automotive, oil & gas, power generation, defense, and heavy machinery sectors due to their high strength, durability, and performance under extreme conditions.

We offer standard and non-standard sizes, custom dimensions, and a variety of specialty coatings and materials to meet our clients’ specific requirements. As a reliable exporter and stockist of 12 point flange bolts, we supply to countries like the USA, UK, Germany, UAE, Singapore, and more.

What is a 12 Point Flange Bolt?

A 12 point flange bolt is a type of fastener featuring a twelve-point head (double hex) and an integrated washer-like flange beneath the head. This design offers enhanced torque capacity, improved load distribution, and eliminates the requirement for a separate washer.

Key Features:

12-point head allows for tighter torque and fits a bi-hex socket or wrench.

Flange base ensures more load distribution and helps prevent loosening under stress or vibration.

Compact design makes them suitable for tight or hard-to-reach assemblies.

High-strength versions are typically manufactured using alloy steel or various grades of stainless steel.

12 Point Flange Bolt Specifications

Applications of 12 Point Flange Bolts

12 point flange bolts are engineered for high-stress, vibration-prone environments.

Aerospace and Aircraft Engines

Automotive Racing and Performance Vehicles

Power Plants and Turbines

Oil and Gas Pressure Vessels

Marine and Offshore Platforms

Heavy Equipment and Machinery

Why Choose Ananka Fasteners?

In-House Manufacturing

With cutting-edge CNC and forging machinery, Ananka Fasteners manufactures 12 point flange bolts with tight tolerances and superior quality control.

Material Traceability & Certifications

We supply products with complete documentation – Material Test Certificates (MTC), Third-Party Inspection Reports, and compliance with ASTM, DIN, ISO standards.

Global Exporter

We export to over 50 countries. Our logistics team ensures on-time delivery with secure packaging suitable for sea and air freight.

Custom Solutions

We offer non-standard sizes, exotic alloys, and custom-coated 12-point flange bolts for corrosive and critical environments.

12 Point Flange Bolt Supplier – Global Reach

Ananka Fasteners is a trusted supplier and stockist of 12-point flange bolts in:

USA: Houston, Texas | Chicago, Illinois

UK: Birmingham | Manchester

Germany: Hamburg | Frankfurt

UAE: Dubai | Abu Dhabi

Singapore, South Africa, Australia, and more.

Packing & Delivery

Packaging: HDPE Bags, Wooden Boxes, Export-Grade Pallets

Delivery Time: 2–4 weeks (Standard), 1 week (Urgent Orders)

Shipping: Sea, Air, and Express

Certifications

ISO 9001:2015

PED 2014/68/EU

CE Marking

RoHS Compliance

IBR Approved (India)

FAQs

Q1. What is the benefit of a 12-point bolt over a hex bolt?A 12-point bolt allows more torque and fits in tighter spaces due to its smaller head size and multiple drive angles.

Q2. Are 12 point bolts reusable?Yes, provided they haven’t been overstressed or damaged during previous use. Always inspect before reuse.

Q3. Can I get 12 point flange bolts with PTFE coating?Absolutely. We offer multiple coating options including PTFE, zinc, hot-dip galvanizing, and others to suit corrosive or high-temperature applications.

Q4. What is the difference between a 12 point bolt and a hex bolt?The key difference is the head design. A 12 point bolt has a double-hex head (allows more contact points for the wrench) and often includes a built-in flange, whereas a hex bolt has six contact points.

Conclusion

Ananka Fasteners stands out as a premier 12 Point Flange Bolt Manufacturer, delivering excellence through material integrity, customization, and reliable supply chains.

In mission-critical applications where ordinary fasteners fall short, 12 Point Flange Bolts offer unmatched performance, durability, and precision. At our facility, we combine advanced manufacturing technology with engineering excellence to deliver bolts that perform under the most demanding conditions. From subsea pipelines to medical devices, we’re your trusted partner for non-standard, corrosion-resistant, and high-performance fastening solutions.

#12PointFlangeBolt#FlangeBolt#BoltManufacturer#IndustrialFasteners#PrecisionFasteners#HeavyDutyBolts#CustomBolts#AerospaceFasteners#AutomotiveFasteners#OilAndGasFasteners#MarineFasteners#AnankaFasteners#BoltExporters#Blog#Articles#ananka#tumblr blog#tumblr#manufacturer#fasteners

0 notes

Text

🔩 Titanium Grade 5 Allen Bolts – Engineered for Excellence

Proudly manufactured by Ananka Fasteners, these precision-engineered bolts represent the next generation of fastening solutions.

✅ Titanium Grade 5 – unmatched strength-to-weight ratio ✅ ISO Certified – ensuring top-tier quality standards ✅ Now advancing into the Aerospace and API sectors ✅ New offices launched in the USA 🇺🇸 and UK 🇬🇧

At Ananka Fasteners, we’re not just expanding globally — we’re pushing the boundaries of performance and reliability.

📞 Connect with us for high-performance fasteners that meet the most demanding industrial and aerospace applications.

Ananka Fasteners – Where Quality Meets Innovation

#AnankaFasteners#TitaniumBolts#Grade5Titanium#ISOcertified#AerospaceFasteners#API#USA#UK#EngineeringExcellence#PrecisionManufacturing#FastenersIndustry#ananka#manufacturer#fasteners#supplier#Ananka#Tumblr#my post#viral#viral post

0 notes

Text

Flange Head Bolt Manufacturer, Supplier & Global Exporter

Introduction

Flange head bolts are an essential component in a wide range of industrial applications, known for their built-in washer-like flange that helps distribute the load evenly and enhances clamping performance. These bolts eliminate the need for a separate washer, making installations faster and more efficient. As a trusted flange head bolt manufacturer, Ananka Group delivers top-quality fasteners that meet international standards and serve various industries across the globe.

What is a Flange Head Bolt?

A flange head bolt features a circular flange under the head, which acts like a washer to distribute the load more uniformly. This design offers several advantages:

Improved load distribution

Enhanced grip and holding strength

Reduced risk of loosening due to vibrations

Faster assembly with fewer components

These bolts are commonly used in automotive, construction, machinery, and heavy engineering sectors.

Flange Head Bolt Manufacturer – Ananka Group

Ananka Group is a trusted name in the fasteners manufacturing industry, known for delivering consistent quality and customized flange bolt solutions. Our advanced manufacturing setup, skilled workforce, and commitment to quality make us one of the top choices for flange head bolts in India and overseas markets.

Key Highlights:

Precision engineering and adherence to global standards

Available in metric and imperial sizes

Options for full or partial threading

Wide material selection, including corrosion-resistant alloys

Surface-treated bolts for enhanced performance and durability

Flange Head Bolt Specifications

Types of Flange Head Bolts We Manufacture

Hex Flange Bolts

Serrated Flange Bolts

12-Point Flange Head Bolts

Metric Flange Bolts

Custom-designed flange Bolts as per Client Requirements

Industries We Serve

Flange bolts are widely used in industries such as:

Oil & Gas Pipelines

Refineries

Offshore Platforms

Pressure Vessels

Marine Shipbuilding

Underwater Structures

Why Choose Ananka Group?

Global Exporter – We export flange head bolts to the USA, UK, UAE, Germany, Canada, Australia, Singapore, South Africa, and more.

Custom Manufacturing – Tailor-made solutions as per drawing, specification, or international standards.

Wide Material Range – From stainless steel to exotic alloys, we cover a broad spectrum of material grades.

Certifications – ISO 9001:2015 certified manufacturing, with full traceability and compliance with ASTM, DIN, BS, ISO standards.

Fast Delivery – With a robust supply chain, we ensure timely delivery to both domestic and overseas clients.

Global Presence

India Office (Head Office & Factory):

USA Office:

Ananka Group LLC8003 S Breaswood Blvd, Houston TX 77071

UK Office:

Ananka Fasteners Ltd 23 Ash Grove Stanley WF3 4JY

Export Destinations

Ananka Group is a renowned flange head bolt exporter in countries such as:

USA

UK

Germany

France

Canada

Mexico

UAE

Oman

Singapore

Malaysia

Australia

South Africa

Conclusion

If you're looking for a reliable flange head bolt manufacturer, Ananka Group delivers exceptional quality fasteners with international certifications, timely delivery, and custom manufacturing support. We aim to offer solutions that meet both general and critical application requirements with precision and performance.

Frequently Asked Questions (FAQ)

Q1. Are flange bolts suitable for high-vibration environments?

Ans: Yes, especially serrated flange bolts, which provide better grip and resist loosening due to vibrations.

Q2. What industries typically use flange head bolts?

Ans: Automotive, construction, oil & gas, marine, power generation, and heavy engineering industries.

Q3. What materials are flange head bolts available in?

A: We manufacture them in stainless steel, carbon steel, alloy steel, brass, titanium, and duplex/super duplex alloys.

Q4. Can flange bolts be customized?

A: Yes, we offer custom bolt manufacturing based on client specifications, including size, thread, and coating.

Q5. Are flange bolts suitable for marine or offshore use?

A: Yes, especially when manufactured from stainless steel 316, duplex, or other corrosion-resistant alloys.

Q6. Do you export to the USA and UK?

A: Absolutely! We have operational offices in both the United States and the United Kingdom to better support our clients.

#FlangeHeadBolt#HexFlangeBolt#FlangeBolts#MarineFasteners#OilAndGasFasteners#OffshoreFasteners#SubseaFasteners#AerospaceFasteners#APIFasteners#CustomCoating#RapidManufacturing#Anankafasteners#Articles#Blog#ananka#blog tumblr#tumblr blog#tumblr

1 note

·

View note

Text

304 Stainless Steel Machine Screws for Marine Equipment

Introduction

In maritime engineering and marine fabrication, selecting the appropriate fastening components is paramount to ensuring structural integrity, corrosion resistance, and long-term performance. Among the vast array of fastening solutions available, 304 stainless steel machine screws stand out as a versatile and cost-effective choice. Their widespread use in marine environments stems from their reliable mechanical properties, resistance to environmental degradation, and adaptability across various marine assemblies.

This article explores the metallurgical characteristics, performance attributes, and application suitability of 304 stainless steel machine screws in marine-grade equipment.

What Are 304 Stainless Steel Machine Screws?

Machine screws are precision-threaded fasteners engineered to engage with pre-tapped holes or mating nuts. They are utilized in applications demanding controlled torque and uniform clamping pressure, particularly in metal-to-metal assemblies. When fabricated from 304 stainless steel, these screws exhibit an optimal combination of corrosion resistance and tensile strength, making them suitable for semi-corrosive marine environments, especially in topside or splash zone installations.

Material Profile: Composition & Properties of 304 Stainless Steel

304 stainless steel is a member of the austenitic AISI 300-series and is chiefly alloyed with the following elements:

Iron (Fe) – Base metal

Chromium (Cr) – approximately 18%, which promotes passivation and enhances corrosion resistance.

Nickel (Ni) – ~8% (for ductility and enhanced corrosion resistance)

Key Metallurgical and Mechanical Properties:

Corrosion Resistance: Exhibits excellent resistance to atmospheric and mildly saline conditions due to the formation of a stable chromium oxide (Cr₂O₃) passive layer.

Mechanical Strength: Ultimate tensile strength typically ranges between 515–750 MPa, providing robust fastening under mechanical loading.

Ductility and Toughness: High elongation at break (≥40%), enabling resistance to shock and vibration.

Non-Magnetic Behavior: Non-ferromagnetic in the annealed state; however, slight magnetism may develop post-cold-working.

Thermal Stability: Performs well up to moderately elevated temperatures (~870°C intermittent service), making it ideal for engine and electrical enclosures.

Why Choose 304 Stainless Steel Screws for Marine Applications?

Although 304 SS does not match the chloride pitting resistance of 316 SS (which includes 2–3% Molybdenum), it is widely specified in non-submerged or intermittently wet marine environments due to its:

Advantages:

Cost Efficiency: Lower alloying content makes it more economical than molybdenum-bearing grades like 316 or duplex stainless steels.

Extensive Availability: Compliant with global standards such as ASTM A193, DIN, and ISO, and offered in a wide range of head types, thread configurations, and dimensional specifications.

Adequate Marine Corrosion Resistance: Suitable for above-deck hardware, coastal installations, and indoor marine compartments.

Fabrication Versatility: Compatible with welding, machining, and forming processes without loss of corrosion resistance.

Marine Applications of 304 Stainless Steel Machine Screws

304 SS machine screws are integrated across numerous marine subsystems and hardware components:

1. Deck and Superstructure Hardware

Used to fasten cleats, railings, winch plates, and deck-mounted brackets.

2. Marine Engine and Machinery Assemblies

Ideal for fastening control housings, engine shrouds, pump casings, and protective equipment covers.

3. Electrical and Navigation Panels

Ensures conductive-free fastening in switchboards, marine lighting systems, and navigation control units.

4. Marina and Dock Fixtures

Suitable for weather-exposed components like dock brackets, signage plates, and structural guards.

5. Yacht and Boat Interiors

Commonly used in cabinetry, seat frame assemblies, and stainless fixtures for corrosion-free aesthetics.

Limitations in Saltwater Environments

While 304 SS offers reliable performance in aerial and splash zones, it lacks the pitting and crevice corrosion resistance required for continuous saltwater immersion or high-chloride concentrations.

For submerged applications or chemical exposure zones, opt for:

316 Stainless Steel (A4)

Duplex Stainless Steel (e.g., UNS S31803/S32205)

Super Duplex (UNS S32750/S32760)

Maintenance Recommendations for Marine Durability

Even corrosion-resistant materials benefit from basic care in marine environments:

Routine Cleaning: Rinse with fresh water post-exposure to salt spray to remove chloride residues.

Insulate from Carbon Steel: Prevents galvanic coupling that accelerates corrosion.

Apply Anti-Seize Lubricants: Especially in high-humidity zones to prevent thread galling and facilitate removal.

Periodic Inspection: Check for discoloration or early signs of corrosion and replace if necessary.

Conclusion

304 stainless steel machine screws provide an optimal balance of performance, availability, and cost for a broad spectrum of marine-grade assemblies, particularly those not subject to full immersion or harsh saline exposure. When used with appropriate design practices and maintenance schedules, they serve as reliable fasteners for both recreational and commercial maritime applications.

Whether you're engineering a yacht interior, outfitting a coastal dock, or installing deck-mounted hardware, 304 stainless steel screws remain a proven and trusted solution.

Frequently Asked Questions (FAQ)

1. Are 304 stainless steel screws appropriate for continuous submersion in marine environments?

Not recommended. While 304 SS is corrosion-resistant, continuous immersion in seawater may cause localized corrosion. 316 SS or duplex grades should be used instead.

2. Is 304 stainless steel magnetic?

In its annealed form, it is non-magnetic. However, cold working processes like forming or machining can impart slight magnetic properties.

3. How can corrosion be mitigated on 304 SS screws in marine use?

Rinse with fresh water after saltwater exposure

Avoid contact with dissimilar metals

Use protective coatings or anti-seize compounds

4. What head types and threads are available in 304 SS machine screws?

Available in multiple configurations such as:

Head Types: Pan, Flat, Round, Hex, Truss

Threads: UNC, UNF, Metric Coarse/Fine

Standards: ASTM, ISO, DIN

5. Where to source marine-grade 304 SS machine screws?

You can purchase them from specialized marine hardware suppliers, industrial fastener distributors, or directly from manufacturers like Ananka Fasteners, who offer high-quality stainless steel fasteners tailored for marine and industrial use.

#FlangeHeadBolt#HexFlangeBolt#FlangeBolts#CustomFasteners#AnankaFasteners#AerospaceFasteners#APIFasteners#CustomCoating#RapidManufacturing#MadeInIndia#USAFastenerSupplier#UKFastenerSupplier#GlobalFastenerManufacturer#AnankaGroup#Anankafasteners#ananka#manufacturer#fasteners#Tumblr#blog tumblr#supplier

0 notes

Text

Super Duplex Threaded Studs for Subsea Pipelines – Corrosion-Resistant Strength Beneath the Surface

Introduction

In the demanding world of subsea pipeline systems, where extreme pressures and aggressive corrosive environments dominate, selecting the right fasteners is not just a choice it’s a necessity. Among the most reliable options available today are Super Duplex Threaded Studs, known for their exceptional mechanical strength and corrosion resistance. These threaded studs play a critical role in bolted joints in subsea manifolds, pipeline end terminations (PLETs), flanges, and other underwater assemblies.

This blog delves into the properties, advantages, applications, and manufacturing considerations of Super Duplex Threaded Studs in the context of subsea pipeline operations.

What are Super Duplex Threaded Studs?

Threaded studs are long rods with threads on both ends (or the entire length), designed to be tightened with nuts to secure components. When made from Super Duplex Stainless Steel a material combining the best features of austenitic and ferritic stainless steels they become ideal for high-performance applications, especially in subsea environments.

Properties of Super Duplex Stainless Steel (UNS S32750 / S32760)

These characteristics make Super Duplex stainless steel a preferred choice for subsea fasteners, delivering the necessary strength, corrosion resistance, and long-term reliability essential for harsh underwater conditions.

Why Use Threaded Studs in Subsea Pipelines?

Threaded studs are preferred in underwater applications due to:

Full engagement with nuts on both sides provides uniform load distribution.

Ease of maintenance and disassembly, especially for bolted flange connections.

Superior clamping force, ensuring long-term joint integrity under fluctuating pressure and thermal cycles.

Advantages of Super Duplex Threaded Studs in Subsea Applications

Exceptional Corrosion ResistanceWith a high chromium (24-26%), molybdenum (3-5%), and nitrogen content, Super Duplex studs resist chloride-induced pitting, stress corrosion cracking (SCC), and crevice corrosion, especially in warm seawater.

High Mechanical StrengthTheir strength is roughly twice that of 300 series stainless steels, allowing for smaller diameters and weight savings in subsea structures.

Long Service LifeIn harsh subsea environments, they significantly reduce the risk of premature failure, minimizing maintenance costs and downtime.

Cost-Effective in the Long RunWhile the upfront cost is higher than conventional alloys, their durability and corrosion resistance lead to reduced replacement frequency and long-term savings.

Common Applications in Subsea Pipelines

Subsea Christmas trees and manifolds

Pipeline end terminations (PLETs, PLEMs)

Flange connections in high-pressure pipelines

Risers and jumpers

Underwater valve bodies and bolted joints

ROV-compatible bolted assemblies

Manufacturing Considerations

Manufacturing Super Duplex threaded studs demands meticulous attention to the following aspects:

1. Material Certification

Use of certified Super Duplex grades (S32750 / S32760), with full traceability and compliance to NORSOK M-650, ASTM A1082, or ASTM A479.

2. Threading

Precision threading (UNC/UNF or metric) per ASME B1.1 or ISO standards, often cold-rolled to improve fatigue resistance.

3. Heat Treatment

Proper solution annealing and controlled cooling to maintain a balanced duplex microstructure and avoid phase segregation.

4. Surface Finish

Passivation or pickling is performed to eliminate surface iron contamination and significantly improve corrosion resistance.

5. Testing & Inspection

NDT (like ultrasonic or MPI), hardness, PMI, and corrosion testing to ensure quality compliance.

Standards and Specifications

Super Duplex Threaded Studs are typically manufactured to these standards:

ASTM A1082 – For forged or rolled UNS S32750/S32760 fasteners

ASTM A479 – Specification for stainless steel bars used in pressure vessels and related components

NACE MR0175 / ISO 15156 – Defines material requirements for safe use in environments containing hydrogen sulfide (H₂S), ensuring resistance to sulfide stress cracking and other sour service conditions.

API 6A / API 6D – Standards that specify technical requirements for components such as valves, flanges, and connectors used in oil and gas wellhead, pipeline, and pressure control systems.

ASME B1.1 / B1.13M – Threading standards

Challenges in Subsea Use (and How Super Duplex Overcomes Them)

Ananka Group – Trusted Supplier of Super Duplex Fasteners

At Ananka Fasteners, we specialize in manufacturing and supplying precision-engineered Super Duplex Threaded Studs for subsea oil & gas and offshore infrastructure. Our threaded studs are:

Made from certified S32750 / S32760 material

Machined to tight tolerances

Tested for mechanical and corrosion performance

Supplied with full EN 10204 3.1 / 3.2 certification

We understand the critical nature of fasteners in subsea projects, and we deliver accordingly.

Conclusion

In subsea pipeline systems, every component must endure the toughest environmental conditions while delivering uncompromised performance. Super Duplex Threaded Studs meet this challenge head-on with unmatched strength, corrosion resistance, and reliability. Whether it’s for a deepwater oil rig or a subsea valve, these studs form the backbone of bolted connections that must not fail.

As industries continue to push the boundaries of offshore exploration, the demand for high-performance fasteners like Super Duplex Threaded Studs will only grow, and Ananka Fasteners is at the forefront of that supply chain.

FAQs

Q1. What is the difference between Duplex and Super Duplex threaded studs?

Super Duplex has a higher alloy content (more Cr, Mo, and N), offering better corrosion resistance and higher mechanical strength than standard Duplex grades.

Q2. Are Super Duplex studs suitable for use in sour gas environments?

Yes, Super Duplex studs can be used in sour gas environments, provided they comply with NACE MR0175 / ISO 15156 standards. Proper material selection, heat treatment, and manufacturing practices are essential to ensure resistance to hydrogen sulfide (H₂S)-induced cracking and sulfide stress corrosion in these harsh conditions.

Q3. What thread types are available for Super Duplex studs?

Super Duplex studs are available in a variety of thread types, including UNC (Unified Coarse Thread), UNF (Unified Fine Thread), and metric threads (coarse and fine), manufactured in accordance with standards such as ASME B1.1, ASME B1.13M, and ISO metric thread profiles to suit diverse industrial applications.

Q4. Are these studs magnetic?

Super Duplex materials have partial ferritic content and may exhibit slight magnetic properties, unlike fully austenitic stainless steels.

Q5. How do I ensure the quality of Super Duplex threaded studs?

Opt for a trusted manufacturer like Ananka Fasteners that provides:

Full material traceability

Third-party testing

Certificates like EN 10204 3.1 / 3.2

As Ananka Group, we continue to set global benchmarks in the fasteners industry. With our headquarters in India (Ananka Fasteners Pvt. Ltd.), and now with newly established offices in:

USA – Ananka Group LLC

📍 8003 S Braeswood Blvd, Houston, TX 77071

UK – Ananka Fasteners Ltd

📍 23 Ash Grove, Stanley WF3 4JY

#SuperDuplexStuds#SubseaPipelineFasteners#ThreadedStuds#OilAndGasFasteners#S32750#S32760#SubseaBolting#CorrosionResistantFasteners#AnankaFasteners#DuplexFasteners#MarineGradeStuds#Ananka#Marketing#Articles#Blog#manufacturer#fasteners#supplier#tumblr#blog tumblr#tumblr blog

0 notes

Text

Reliable Duplex Steel Anchor Bolts for Chemical Processing Plants

Chemical processing plants require fasteners that can handle extreme conditions—corrosive chemicals, high temperatures, and heavy loads. Duplex Steel Anchor Bolts are engineered for just that. Known for their exceptional strength and resistance to corrosion, these bolts provide secure anchoring of equipment and structures in demanding industrial settings.

Made from a unique blend of austenitic and ferritic stainless steels, duplex anchor bolts offer twice the strength of regular stainless steel and unmatched durability in chemical-rich environments. They're the ideal solution for maintaining structural integrity and safety in chemical plants, even under constant exposure to aggressive substances.

Introduction

In chemical processing plants, machinery and structures face harsh chemicals, high temperatures, and constant moisture. To keep everything safe and secure, you need strong, corrosion-resistant fasteners. This is where Duplex Steel Anchor Bolts come in.

These special bolts are made from duplex stainless steel — a material that is stronger than regular stainless steel and can resist chemical corrosion much better. Whether you’re anchoring heavy equipment or structural supports to concrete, duplex steel anchor bolts provide long-lasting performance in tough industrial environments.

What Are Duplex Steel Anchor Bolts?

Anchor bolts are used to securely attach machinery, equipment, or structural elements to concrete foundations, ensuring stability and safety. They make sure machinery stays in place, even when exposed to heavy loads or vibrations.

When these bolts are made from duplex stainless steel, they become even more powerful. Duplex stainless steel features a dual-phase microstructure of ferritic and austenitic stainless steels, offering superior mechanical and corrosion-resistant properties. This combination gives duplex steel:

Very high strength

Excellent corrosion resistance

Good durability in extreme environments

Common Grades of Duplex Steel Used:

UNS S31803 and S32205 – These are standard duplex stainless steel grades known for their good balance of strength and corrosion resistance.

UNS S32750 and S32760 – These are super duplex grades offering higher strength and enhanced corrosion resistance, ideal for more demanding or aggressive environments.

Why Are They Ideal for Chemical Processing Plants?

Chemical plants often deal with:

Corrosive substances like acids, alkalis, and solvents

High moisture and chloride exposure

High pressure and temperature

Duplex steel anchor bolts are a perfect choice for these settings because they:

Resist chemical attack and rust

Can handle high mechanical loads

Work well in wet, salty, or acidic environments

Last much longer than regular carbon steel or even some stainless steels

Benefits of Duplex Steel Anchor Bolts

1. High Resistance to Corrosion

Duplex steel is known for its ability to fight corrosion from chemicals and salt, making it perfect for chemical plants.

2. Very Strong and Tough

These bolts are nearly twice as strong as standard stainless steel bolts. This means you can use smaller bolts to handle the same loads.

3. Good for Harsh Conditions

They can handle shocks, vibrations, and repeated loading without cracking or failing.

4. Cost-Efficient in the Long Run

Even though they cost more upfront, their long life and low maintenance make them a smart investment.

Where Are Duplex Anchor Bolts Used in Chemical Plants?

Applications of duplex steel anchor bolts include:

Mounting heavy machines to the floor

Holding down pressure vessels, storage tanks, and reactors

Securing pumps, agitators, and pipe supports

Supporting steel structures, instrument panels, and control systems

Anywhere that needs a strong, secure, and corrosion-proof fastening system — duplex bolts are ideal.

Types of Anchor Bolts Available

Duplex anchor bolts are manufactured in a range of configurations to meet specific structural and installation requirements.

Straight bolts with nuts and washers – Easy to install and remove

Headed anchor bolts – Have a head that locks into concrete

Sleeve anchor bolts are designed to expand within pre-drilled holes, ensuring firm anchorage in concrete or masonry.

Stud bolts – Threaded on both ends, used with nuts

Each type has a specific purpose based on how and where it’s used.

Standards and Specifications

To ensure quality, duplex steel anchor bolts are made according to international standards, including:

ASTM A1082 – For duplex stainless steel fasteners

ASTM F3125 – Structural bolt specification

ISO 898-1 – For mechanical properties

DIN / EN standards – For global compatibility

Installation and Maintenance Tips

Use the correct torque during installation to avoid breaking or loosening the bolt.

Clean the surface before installation to prevent contamination or rust spots.

Use anti-seize compounds on threads to stop galling or thread damage.

Store bolts in a dry, clean area before use.

Conclusion

Duplex Steel Anchor Bolts are a powerful and reliable solution for the demanding needs of chemical processing plants. They offer high strength, long life, and excellent corrosion resistance, even in the most challenging environments. By choosing duplex steel fasteners, plant engineers and operators can avoid costly failures, reduce maintenance, and ensure safe, stable operation.

Whether it’s holding down a reactor or anchoring a large pump, duplex anchor bolts provide the strength and performance that chemical plants can count on.

Frequently Asked Questions (FAQs)

Q1. What’s the difference between Duplex and Super Duplex Anchor Bolts?

Duplex bolts (like S31803) offer strong resistance to corrosion and good strength. Super Duplex bolts, such as S32750, provide superior strength and corrosion resistance, making them perfect for highly corrosive chemical or marine environments.

Q2. Can Duplex Anchor Bolts handle high temperatures?

Yes, they can typically handle temperatures up to 250°C (480°F). For temperatures higher than this, a specialized alloy may be better.

Q3. Are these bolts good for marine or coastal chemical plants?

Absolutely. Duplex steel resists salt and moisture, making it ideal for coastal and offshore environments.

Q4. How are these bolts installed in concrete?

They can be either:

Set into wet concrete during construction, or

Inserted into holes in existing concrete using epoxy adhesives or mechanical expansion systems.

Q5. Are Duplex Steel Anchor Bolts cost-effective?

Yes. Although they may cost more initially, their long lifespan, low maintenance, and reliability make them more economical over time.

#DuplexSteelAnchorBolts#ChemicalPlantFasteners#CorrosionResistantBolts#AnchorBolts#DuplexStainlessSteel#IndustrialFasteners#SuperDuplexBolts#ChemicalIndustryFasteners#AnankaFasteners#FastenersManufacturer#Ananka#manufacturer#fasteners#supplier#tumblr#blog tumblr#tumblr blog

0 notes

Text

Inconel Stud Bolts for High-Temperature Environments

Traditional materials often fall short under such demanding conditions. This is where Inconel stud bolts come into play engineered to thrive in environments that push most metals to their limits.

Renowned for their exceptional resistance to heat, oxidation, and corrosion, Inconel stud bolts are the go-to solution for critical applications in oil & gas, aerospace, power generation, marine, and chemical processing industries. These fasteners not only ensure joint integrity but also contribute to longer operational life and reduced maintenance in harsh service environments.

In this comprehensive guide, we’ll delve into what makes Inconel stud bolts uniquely reliable, covering their properties, grades, standards, benefits, and industry-specific applications.

This blog explores Inconel stud bolts in detail, focusing on their composition, properties, advantages, applications, and why they are ideal for extreme environments.

What is Inconel?

Inconel is a high-performance nickel-chromium superalloy renowned for its exceptional resistance to extreme heat and highly corrosive environments. The most commonly used Inconel grades in fastener manufacturing are Inconel 600, Inconel 625, and Inconel 718.

These alloys maintain their mechanical strength and resist oxidation, corrosion, and carburization at temperatures exceeding 1000°C (1832°F).

What are Inconel Stud Bolts?

Inconel stud bolts are threaded rods made from Inconel alloy, used primarily in flanged piping connections. This design offers flexibility, especially in high-pressure and high-temperature flange joints, allowing easier maintenance and torque control.

Grades of Inconel Used in Stud Bolts

Inconel 600

Nickel (72%), Chromium, and Iron

Good oxidation and corrosion resistance

Used in furnace components, chemical industries, and heat exchangers

Inconel 625

Nickel (58%), Chromium, Molybdenum, Niobium

Excellent strength, fatigue resistance, and weldability

Suitable for marine, nuclear, and chemical processing

Inconel 718

Nickel-Chromium alloy with niobium, molybdenum, titanium, and aluminum

High yield strength and creep resistance

Ideal for aerospace and turbine engine components

Key Properties of Inconel Stud Bolts

Applications of Inconel Stud Bolts

Due to their robust nature, Inconel stud bolts are used across industries that demand maximum reliability:

1. Petrochemical & Refinery

Flanged joints in high-pressure and sour gas systems

Heat exchangers, reactors, and furnaces

2. Aerospace Industry

Jet engines, rocket motors, and turbine components

Fasteners in high-speed airframes

3. Nuclear Power Plants

Reactor core components and steam generators

Ideal for high-radiation, high-heat zones

4. Marine Engineering

Subsea oil and gas extraction systems

Saltwater-resistant bolting solutions

5. Chemical Processing

Acid handling equipment and autoclaves

High-pressure chemical injection systems

Manufacturing Standards and Specifications

Inconel stud bolts are manufactured in accordance with the following standards:

ASTM B446 – Standard for Inconel 625 bar and rod

ASTM B637 – For precipitation-hardened Inconel 718

ASME B16.5 / B16.47 – Flange compatibility

Advantages of Using Inconel Stud Bolts

Unmatched Temperature Stability: Unlike stainless steel, Inconel retains strength at red-hot temperatures.

Superior Corrosion Resistance: Performs in environments where even stainless steel fails.

Longevity: Reduces the frequency of replacements and maintenance.

Stress and Fatigue Resistance: Ideal for cyclic loads and vibration-heavy equipment.

Weldability: Easy to fabricate and integrate into systems.

Inconel vs. Other High-Temperature Materials

Tips for Selecting Inconel Stud Bolts

Check Operating Conditions: Select the grade that suits the temperature and corrosive conditions.

Ensure Certification: Look for ASTM/ASME compliance and mill test reports (MTRs).

Choose Right Threads: Consider UNC/UNF or metric threading depending on the assembly.

Consider Coatings: For added protection or galvanic isolation, consider PTFE or Xylan coatings.

Why Choose Ananka Fasteners for Inconel Stud Bolts?

Ananka Fasteners, a division of Ananka Group, is a leading manufacturer and supplier of Inconel stud bolts globally. We offer:

Precision-engineered Inconel 600, 625, and 718 stud bolts

Full traceability with test certificates

Custom sizes and coatings

Fast worldwide shipping and expert technical support

We serve major clients in oil & gas, petrochemicals, nuclear, marine, and defense industries.

Conclusion

Inconel stud bolts are the backbone of many high-temperature, high-pressure systems. Their unique combination of strength, corrosion resistance, and durability ensures long-lasting and safe connections in the most demanding environments. Whether you're securing turbine casings or reactor vessels, choosing Inconel stud bolts is a long-term investment in performance and safety.

FAQs: Inconel Stud Bolts

Q1. What makes Inconel stud bolts suitable for high-temperature environments?

Inconel stud bolts retain their strength, resist oxidation, and maintain structural integrity at temperatures exceeding 1000°C. Their unique nickel-chromium composition provides excellent thermal stability and corrosion resistance, making them ideal for extreme heat applications.

Q2. Which industries commonly use Inconel stud bolts?

Inconel stud bolts are widely used in the aerospace, petrochemical, marine, power generation, and chemical processing industries, especially in environments involving high pressure, corrosive substances, or fluctuating thermal conditions.

Q3. How do Inconel stud bolts compare to stainless steel bolts?

While stainless steel bolts perform well in many environments, Inconel bolts offer superior strength and corrosion resistance at much higher temperatures. Inconel also resists chloride-induced stress corrosion cracking, which stainless steels are vulnerable to.

Q5. Can Inconel stud bolts be customized?

Absolutely. Inconel stud bolts can be customized in terms of thread type (UNC/UNF/Metric), length, coating (such as PTFE, Xylan), and size according to specific application needs.

Q6. What standards are used to manufacture Inconel stud bolts?

Inconel stud bolts are typically manufactured to ASTM B166, ASTM B446, or ASTM B637, depending on the grade. They also adhere to industrial standards such as ASME, DIN, ISO, and API, based on application requirements.

Q7. Are Inconel stud bolts non-magnetic?

Yes, Inconel is generally non-magnetic, which is beneficial for applications involving sensitive instrumentation or electromagnetic environments.

#InconelStudBolts#InconelBolts#NickelAlloyFasteners#HeatResistantBolts#IndustrialFasteners#Inconel625#Inconel718#SuperalloyBolts#BoltingSolutions#AerospaceFasteners#StudBolts#AnankaFasteners#Ananka#Articles#Blog#tumblr#blog tumblr#tumblr blog

1 note

·

View note

Text

📦 Precision Meets Presentation | Washer Packing Excellence

📍 Ananka Fasteners Pvt. Ltd.

Here’s a look at our latest Hot Dip Galvanized (HDG) washers — expertly packed for optimal protection, organization, and transit-readiness.

Why does packaging matter? Because quality doesn’t end at production — it’s reflected in how we deliver it. Every washer in this shipment reflects our commitment to durability and detail, from factory to field.

🛡️ Type: Flat Washers

🧰 Finish: Hot Dip Galvanized (HDG)

📦 Packing: Industrial-grade corrugated boxes + poly-wrap to prevent oxidation and preserve coating integrity

🏢 Ananka Fasteners Pvt. Ltd. — ISO Certified & advancing toward Aerospace and API certifications.

Proudly India-based, with a global footprint in the USA & UK 🌍

💼 Industries We Serve:

* Oil & Gas

* Marine

* Offshore

* Subsea

* Chemical

* Nuclear

* Medical

🔧 Our Capabilities:

* Custom Fastener Development

* Precision CNC Machining

* Advanced Surface Coating

* Non-standard Material Handling

🛠️ Product Line Includes:

* High-tensile & Non-standard fasteners

* Alloy & Corrosion-resistant solutions

* Imperial & Metric series

* Bolts | Nuts | Washers | Studs | Special parts

We engineer not just fasteners — but reliability at scale.

#AnankaFasteners#HotDipGalvanized#HDGWashers#WasherPacking#PrecisionPacking#FastenerSolutions#ISOcertified#CNCThreading#OilAndGas#AerospaceGrade#IndiaManufacturing#GlobalReach#EngineeringExcellence#USA#UK#APIStandards#Linkedin#Ananka

0 notes

Text

Fasteners for Oilfield Equipment: Ensuring Safety and Performance in Harsh Environments

Introduction

In the oil and gas industry, equipment is routinely exposed to some of the harshest and most demanding environments on Earth. From high pressures and extreme temperatures to corrosive chemicals and abrasive materials, oilfield operations present unique engineering challenges. At the heart of this critical infrastructure are fasteners, small components that play a vital role in maintaining the integrity, safety, and reliability of oilfield equipment.

This blog explores the importance of fasteners in oilfield applications, the types commonly used, their material requirements, and why choosing the right fastener is essential for operational success.

Importance of Fasteners in Oilfield Operations

Fasteners are used to assemble, secure, and maintain oilfield equipment such as drilling rigs, wellheads, pressure vessels, pipelines, pumps, compressors, and offshore platforms. These components must perform flawlessly under:

High-pressure environments

Corrosive exposure (e.g., H₂S, saltwater, CO₂)

Dynamic loads and vibrations

High thermal stress

A single failure in a fastener can lead to leaks, equipment malfunction, downtime, or even catastrophic failure, making it imperative to use high-performance, certified fasteners in every application.

Common Oilfield Equipment Requiring Fasteners

1. Drilling Equipment

Fasteners in rotary drilling systems, drill strings, and derricks must withstand constant vibration, rotation, and torque. High-strength bolts, nuts, and studs play a crucial role in maintaining structural integrity and delivering dependable performance in challenging and demanding environments.

2. Wellheads and Christmas Trees

These systems are exposed to extreme pressure and require corrosion-resistant fasteners for sealing and securing critical components. Stud bolts paired with heavy hex nuts are commonly used in flange assemblies to ensure secure and leak-proof connections.

3. Pressure Vessels and Separators

Fasteners are required to meet specified pressure ratings and adhere to industry codes such as those set by ASME. Bolts used here often need to endure both pressure containment and chemical resistance.

4. Subsea Equipment

Located deep underwater, subsea tools and equipment are bolted with super duplex, Inconel, or titanium fasteners that resist saltwater corrosion and high pressure.

5. Offshore Platforms

Structural bolts secure walkways, support beams, pipe racks, and equipment foundations. These bolts are required to comply with marine-grade standards and offer exceptional resistance to corrosion.

Types of Fasteners Used in Oilfield Equipment

Stud bolts and nuts – Commonly used for securing flange joints in high-pressure applications.

Hex Head Bolts – Used where high clamping force is needed

Socket Head Screws – For compact or precision applications

Anchor Bolts – To secure equipment to concrete foundations

U-Bolts and Clamp Bolts – For securing pipework and supports

Each type of fastener is selected based on load-bearing requirements, accessibility, maintenance, and operating conditions.

Material Considerations

Due to harsh operating environments, materials used for oilfield fasteners must offer:

High tensile and yield strength

Excellent corrosion resistance

Temperature resilience

Common Materials Include:

Material

Properties

ASTM A193 Grade B7

High strength, used in non-corrosive high-temperature applications

316 Stainless Steel

Good corrosion resistance, general use

Inconel 718 / 625

Extreme strength and corrosion resistance in sour wells

Monel 400 / K500

Excellent resistance to seawater and hydrofluoric acid

Duplex & Super Duplex

Ideal for offshore and subsea conditions

Hastelloy

Outstanding chemical resistance in acidic environments

Coatings like PTFE, Xylan, or Zinc plating are also applied to further improve corrosion resistance and reduce galling.

Standards and Certifications

Fasteners for oilfield applications must comply with international standards to ensure safety and compatibility. Some key standards include:

ASTM A193 / A194 – Standards that define bolting materials engineered to perform reliably under high-temperature and high-pressure environments.

ASME Section VIII – Pressure vessel codes

Always verify that the fasteners used are certified and tested in accordance with relevant standards.

Conclusion

In the complex and demanding world of oil and gas extraction, fasteners play a mission critical role in the functionality and safety of oilfield equipment. From drilling platforms to deep-sea pipelines, the performance of these small but essential components directly affects the efficiency and reliability of the entire operation.

Ananka Group offers a wide range of high-strength, corrosion-resistant, and certified fasteners tailored for the oil and gas industry. Our products meet global standards and are trusted by operators worldwide for performance in the most extreme environments.

FAQs

Q1: What is the most commonly used fastener material in oilfields?ASTM A193 Grade B7 is commonly chosen for its excellent strength and ability to withstand high-pressure and high-temperature conditions.

Q2: Why is NACE certification important for oilfield fasteners?It provides protection against hydrogen sulfide (H₂S) corrosion, making it suitable for sour service environments.

Q3: What fasteners are suitable for subsea oilfield equipment?Materials like Inconel, Super Duplex, and Monel are preferred for subsea applications due to their superior corrosion resistance.

Q4: Are coated fasteners used in oilfields?Yes, PTFE or Xylan coatings are commonly used to improve corrosion resistance and reduce galling during assembly.

Q5: How do you choose the right fastener for oilfield equipment? By considering pressure, temperature, chemical exposure, and mechanical load, along with compliance to relevant industry standards.

#OilfieldFasteners#CorrosionResistantFasteners#OilAndGasIndustry#HeavyDutyBolts#FastenersForPipelines#PetrochemicalFasteners#OffshoreBoltingSolutions#HighStrengthBolts#AnankaFasteners#BoltsAndNuts#OilGasSupplyChain#Articles#Blog#ananka#tumblr#tumblr blog

0 notes

Text

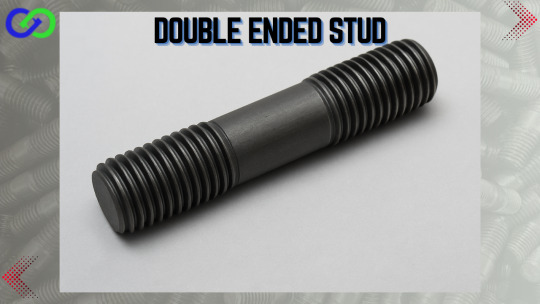

🔩 Threading in Process | Performance in Every Piece 📍 Ananka Fasteners Pvt. Ltd. In focus: Double-ended studs (Size: 1/2" x 61mm) 📏 Material Grade: B8 Class 2 🛠️ Ready for Roll Threading — a process that enhances strength, accuracy, and surface finish. This is not just a stud — it’s a symbol of our precision-engineered excellence. At Ananka Fasteners, we combine advanced manufacturing with global quality benchmarks. ✅ ISO Certified | Progressing towards Aerospace and API Certifications 🌐 We're not just in India anymore — now proudly operating in the USA and UK. (Details on our profile.) 🎯 Headquartered in India. https://anankafasteners.com/contact-us/

💼 Industries We Serve: * Marine * Oil & Gas * Offshore * Chemical Processing * Subsea * Nuclear * Medical Devices 🔧 Our Capabilities: * Design & Prototyping * Rapid Manufacturing * Custom Coating & Plating 🔩 Our Product Range Includes: * High-performance fasteners * Custom fastener solutions * Precision-engineered components * Specialty alloy products * Corrosion-resistant and non-standard parts * Metric and Imperial sizes We engineer with intent. We manufacture with excellence.

#AnankaFasteners#StudBolts#ThreadRolling#B8Class2#PrecisionMachining hashtag#ISOcertified hashtag#AerospaceFasteners hashtag#OilAndGas hashtag#RollThreading hashtag#CustomFasteners hashtag#ManufacturingIndia hashtag#USA hashtag#UK hashtag#GlobalEngineering#MetricImperial#EngineeringExcellence

1 note

·

View note

Text

Uses of Bolts for Oil & Gas Pipelines

Introduction

In the oil and gas industry, pipelines serve as the lifelines for transporting crude oil, natural gas, and refined products over long distances. These critical infrastructures demand components that ensure safety, durability, and performance under extreme conditions. Bolts, though small in size, play a vital role in the assembly, integrity, and maintenance of oil & gas pipeline systems.

This blog delves into the importance, various types, and specific applications of bolts in oil and gas pipeline systems.

Importance of Bolts in Oil & Gas Pipelines

Bolts are critical mechanical fasteners that securely connect two or more components. In oil and gas pipeline systems, they serve to:

Secure flange connections

Support valve assemblies

Withstand high pressure and temperature

Resist corrosion from harsh chemicals and environmental conditions

Enable easy maintenance and disassembly

Any failure in bolted joints could result in leaks, production downtime, or safety hazards, making bolt selection and installation critical to pipeline integrity.

Key Applications of Bolts in Oil & Gas Pipelines

1. Flanged Connections

Used to bolt two pipe ends together using gaskets.

Ensure tight sealing in high-pressure, high-temperature environments.

They typically use high-strength stud bolts and nuts in accordance with ASME B16.5 or B16.47 standards.

2. Valve Installation

Bolts attach valves to pipelines, allowing for effective regulation of flow and pressure within the system.

They must withstand frequent operation and significant mechanical stress.

3. Compressor & Pump Stations

They anchor rotating machinery like pumps and compressors to the pipeline system, ensuring stable and reliable operation.

Require vibration-resistant bolts with high tensile strength.

4. Manifolds & Headers

Bolts connect complex pipe networks for distributing or collecting fluids.

Used in both upstream and downstream systems.

5. Pipeline Supports and Anchors

Anchor bolts fix supports that carry the pipeline’s weight and thermal expansion.

Must withstand static and dynamic loads.

Types of Bolts Used in Oil & Gas Pipelines

Stud Bolts

Common in flange connections; used with two nuts

Hex Head Bolts

Used in areas requiring easy access for tightening

Anchor Bolts

Secure pipelines and equipment to concrete foundations

U-Bolts

Support pipes in hangers or saddle mounts

Heavy Hex Bolts

Provide additional contact surface for high-load applications

Material Considerations for Oil & Gas Pipeline Bolts

Pipelines are often exposed to corrosive environments, including:

Sour gas (H₂S presence)

Saline offshore environments

High-temperature fluids

Acids and hydrocarbons

Common Materials Used:

Carbon Steel (B7)

High tensile strength; cost-effective; used in non-corrosive environments

Stainless Steel (316, 304)

Good corrosion resistance; suitable for moderate environments

Duplex / Super Duplex

Excellent corrosion resistance and strength; ideal for offshore use

Inconel / Monel / Hastelloy

For extreme conditions involving acids, heat, or seawater

PTFE or Xylan Coated Bolts

Enhanced resistance against galling and corrosion

Industry Standards for Pipeline Bolts

Bolts used in oil & gas pipelines must meet stringent international standards, such as:

ASTM A193 / A194 – For high-temperature and pressure service

ASME B16.5 / B16.47 – Flange dimensions and bolting

API Standards – For pipeline construction and pressure testing

Conclusion

Though often overlooked, bolts are critical components in the oil and gas pipeline infrastructure. Their correct selection, installation, and maintenance ensure the safety, reliability, and longevity of pipeline systems in some of the world’s harshest environments. From securing flange joints to supporting heavy equipment, bolts must be engineered to withstand extreme mechanical and chemical stresses.

Ananka Group offers a wide range of high-performance bolts that meet the demanding specifications of the oil and gas industry. With precision manufacturing, premium materials, and adherence to international standards, our fasteners are trusted in pipeline projects around the world.

FAQ

Q1: What are the different types of bolts used in oil and gas pipeline systems?The most commonly used bolts include stud bolts with heavy hex nuts, hex head bolts, and anchor bolts, particularly for flange connections, valve installations, and structural support.

Q2: Why is material selection important for pipeline bolts?Pipeline environments involve high pressure, extreme temperatures, and corrosive media like H₂S or saltwater. Material selection ensures the bolts can withstand these conditions without failure, enhancing safety and reliability.

Q3: What standards govern bolts for oil & gas pipeline applications?Key standards include ASTM A193 / A194 for high-pressure and high-temperature bolting, ASME B16.5/B16.47 for flanges, and NACE MR0175/ISO 15156 for sour gas corrosion resistance.

Q4: Are stainless steel bolts suitable for all oil and gas pipeline environments?Not necessarily. While stainless steel offers good corrosion resistance, environments with sour gas or extreme salinity often require more specialized materials like Inconel, Monel, or Super Duplex.

Q5: What types of coatings are applied to pipeline bolts to enhance corrosion resistance?Common protective coatings include PTFE (Teflon), Xylan, hot-dip galvanizing, and zinc plating, which enhance corrosion resistance and ease of installation.

Q6: How are bolt failures prevented in pipeline systems?By using the correct material grade, applying proper torque during installation, following maintenance schedules, and ensuring compliance with relevant engineering standards and certifications.

Q7: What is the role of stud bolts in pipeline flange assemblies?Stud bolts provide even clamping force across the flange face when used with heavy hex nuts, ensuring a leak-proof and secure connection in high-pressure pipeline systems.

Q8: Can coated bolts be used in subsea pipeline systems? Yes, but the coating and base material must be selected carefully. In subsea applications, corrosion-resistant alloys like Super Duplex or Inconel, often coated with PTFE or Xylan, are preferred for longevity and performance.

#OilAndGas#PipelineBolts#IndustrialFasteners#HighStrengthBolts#PipelineConstruction#StudBolts#ASMEBolts#ASTMA193#HeavyHexNuts#AnankaFasteners#BoltsAndNuts#OilAndGasEngineering#Ananka#Articles#Blog#tumblr blog#tumblr

1 note

·

View note

Text

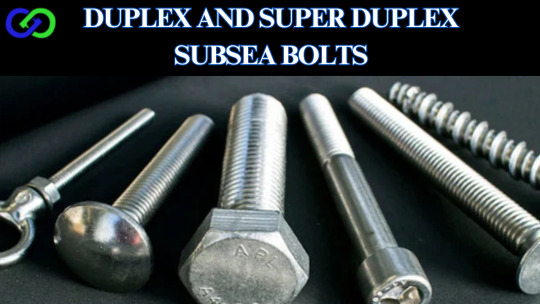

Duplex and Super Duplex Subsea Bolts: High-Performance Fasteners for Extreme Environments

Equipment used in these environments must withstand intense pressure, corrosive saltwater exposure, and extreme temperature variations. In such extreme situations, Duplex and Super Duplex Subsea Bolts play a critical role in ensuring structural integrity and long-term performance of underwater infrastructure.

In this blog, we will explore what makes these fasteners ideal for subsea applications, their unique material properties, key applications, and how they contribute to the safety and longevity of marine structures.

What Are Duplex and Super Duplex Subsea Bolts?

Duplex stainless steel bolts are crafted from a class of stainless steels that feature a dual-phase microstructure, composed of both austenite and ferrite. This combination results in higher strength and excellent corrosion resistance compared to standard stainless steel.

Super Duplex stainless steel bolts take these advantages further by offering even higher levels of strength and corrosion resistance. These bolts are specifically engineered for environments with extreme chemical exposure, such as deep-sea installations, oil rigs, and underwater pipelines.

Chemical Composition

Typical Duplex (e.g., UNS S31803 / 2205):

Chromium: 21–23%

Nickel: 4.5–6.5%

Molybdenum: 2.5–3.5%

Nitrogen: 0.14–0.2%

Balance: Iron

Typical Super Duplex (e.g., UNS S32750 / 2507):

Chromium: 24–26%

Nickel: 6–8%

Molybdenum: 3–5%

Nitrogen: 0.24–0.32%

Balance: Iron

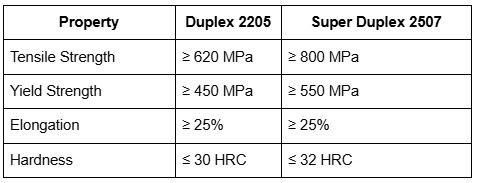

Mechanical Properties

These properties ensure the bolts can withstand high-stress environments, particularly in subsea applications where pressure and corrosion are constant threats.

Corrosion Resistance

Subsea bolts must resist:

Pitting and crevice corrosion caused by stagnant seawater

General corrosion due to long-term exposure to seawater and harsh chemicals

With elevated levels of molybdenum and nitrogen, Super Duplex bolts provide exceptional corrosion resistance, making them perfectly suited for highly aggressive subsea environments.

Uses of Duplex and Super Duplex Subsea Bolts

Subsea Oil and Gas InstallationsRiser systems, manifolds, BOPs (Blowout Preventers), and wellhead systems Underwater PipelinesFor flanged joints, pipe supports, and brackets in offshore pipelines Offshore Wind TurbinesBolt connections exposed to splash and tidal zones Underwater InfrastructureBridges, tunnels, and seabed constructions requiring corrosion-resistant fasteners

Benefits of Using Duplex and Super Duplex Subsea Bolts

Enhanced Mechanical Strength: Provides significantly higher yield and tensile strength than conventional stainless steel fasteners

Outstanding Corrosion Resistance: Perfect for chloride-heavy environments such as seawater

Excellent Fatigue Resistance: Designed to endure high pressures and repeated stress cycles

Cost Efficiency: Extended service life minimizes maintenance and replacement costs

Wide Temperature Range: Maintains reliable performance under varying temperature extremes

Standards and Specifications

ASTM A182 / A479 – For forged or rolled duplex/super duplex materials

ASTM A276 – For stainless steel bars used in bolts

NORSOK M-630 – For materials used in oil & gas subsea systems

Why Choose Duplex or Super Duplex for Subsea Fasteners?

When choosing fasteners for subsea installations, material performance over time is crucial. Duplex and Super Duplex bolts offer a superior blend of strength and corrosion resistance, outperforming most traditional alloy fasteners in demanding environments. While initial costs may be higher than regular carbon steel fasteners, their long-term benefits less maintenance, fewer replacements, and improved safety, far outweigh the investment.

Conclusion

In subsea engineering, the reliability of every component counts. Duplex and Super Duplex Subsea Bolts are high-strength, with superior corrosion resistance and long life, making them the first choice for offshore oil rigs, pipelines, naval systems, and underwater structures.

For any organization working in subsea environments, investing in the right fasteners is not just a technical decision; it's a strategic one. Choose duplex and super duplex bolts for safer, stronger, and longer-lasting underwater infrastructure.

FAQs

Q1. Difference between Duplex and Super Duplex bolts?

Duplex bolts deliver excellent strength and corrosion resistance, whereas Super Duplex bolts enhance these properties further with superior mechanical strength and exceptional durability in extremely corrosive environments.

Q2. Can Super Duplex bolts be used in sour gas environments?

Yes. Super Duplex bolts like UNS S32750 meet NACE MR0175 standards and are suitable for sour service environments.

Q3. Can I use duplex bolts in submerged saltwater applications?

Yes. Duplex bolts are well-suited for continuous exposure to saltwater but Super Duplex is recommended for the most aggressive conditions.

Q4. Do duplex and super duplex bolts require special coatings?

Often, they don’t need additional coatings due to their inherent corrosion resistance, but some applications may use passivation or other surface treatments for added protection.

#DuplexBolts#SuperDuplexBolts#SubseaFasteners#MarineBolts#CorrosionResistantBolts#OffshoreBolts#DuplexStainlessSteel#SuperDuplexStainlessSteel#OilAndGasFasteners#HighStrengthBolts#AnankaFasteners#FastenersManufacturer#IndustrialFasteners#MarineEngineering#DuplexFasteners#SuperDuplexFasteners#Ananka#tumblr blog#tumblr

1 note

·

View note

Text

The Ultimate Guide to Saltwater Resistant Fasteners for Marine Applications

Marine environments pose some of the toughest conditions for fasteners due to continuous exposure to saltwater, high humidity, and fluctuating temperatures. Select the right fastener is essential to ensure long-term durability, safety, and reliable performance. In this guide, we cover everything you need to know about marine-grade fasteners, saltwater-resistant options, and anti-corrosion marine bolts.

What Are Marine Grade Fasteners?

Marine-grade fasteners are specifically engineered to resist the harsh and corrosive conditions found in marine and coastal environments. These fasteners are manufactured using specialized materials and protective coatings designed to withstand:

Constant exposure to saltwater

UV rays

High humidity

Temperature extremes

Physical stress from waves and vibrations

Their corrosion-resistant properties make them ideal for use in boats, docks, offshore rigs, naval structures, and coastal construction.

Why Standard Fasteners Fail in Marine Environments

Regular carbon steel or even mild steel fasteners corrode quickly in marine settings due to:

Saltwater exposure, which accelerates oxidation

Electrochemical reactions between different metals (galvanic corrosion)

Crevice corrosion, especially in tight joints

Pitting corrosion, common in chloride-rich environments

Top Materials Used in Marine Grade Fasteners

1. Stainless Steel (304, 316, 316L)

316 and 316L Stainless Steel

The most commonly used stainless steel fasteners for marine applications are made from 316 and 316L stainless steel.

These alloys contain molybdenum, which greatly enhances resistance to chlorides and saltwater corrosion.

304 Stainless Steel

Less corrosion-resistant than 316 but still suitable for mildly marine environments

Not recommended for full immersion or high-salinity conditions

2. Silicon Bronze

Excellent resistance to saltwater corrosion

Commonly used in boat building, especially below the waterline