#Automated pipetting systems

Explore tagged Tumblr posts

Text

Liquid Handling in Drug Discovery: Enhancing Precision and Throughput

Liquid handling is a critical process in drug discovery, involving the accurate and efficient transfer of liquids between containers. The precision and throughput of liquid handling operations can significantly impact the success of drug discovery research. In this blog post, we will explore the importance of precision liquid handling in drug discovery and discuss some of the key technologies and techniques that are used to enhance precision and throughput.

The Importance of Liquid Handling in Drug Discovery

Liquid handling is a fundamental aspect of drug discovery research, with applications ranging from compound screening and formulation to analysis and quality control. Accurate and precise liquid handling is essential for:

Ensuring data reliability: Inconsistent liquid handling can lead to errors in experimental data, compromising the validity of research findings.

Improving efficiency: Efficient liquid handling techniques can accelerate the drug discovery process and reduce costs.

Enhancing reproducibility: Consistent liquid handling practices are crucial for ensuring reproducibility of experimental results.

Liquid Handling Technologies

A variety of liquid handling systems are available to researchers, each with its own advantages and limitations. Some of the most commonly used technologies include:

Manual pipettes: While still widely used, manual pipettes can be time-consuming and prone to human error.

Electronic pipettes: Automated pipetting systems offer improved accuracy and precision compared to manual pipettes, as well as features such as adjustable pipetting speeds and programmable protocols.

Liquid handling workstations: Automated liquid handling workstations can significantly increase throughput and reduce the risk of human error. These systems can be programmed to perform complex liquid handling tasks, such as serial dilutions, transfers, and aliquoting.

Techniques for Enhancing Precision and Throughput

In addition to selecting the appropriate liquid handling technology, researchers can also employ a number of techniques to enhance precision and throughput:

Tip calibration: Regular calibration of pipette tips is essential for ensuring accurate liquid handling.

Liquid handling robotics: Automated liquid handling robots can be used to perform repetitive tasks with high precision and speed.

Miniaturization: Reducing the volume of liquid handled can improve efficiency and reduce costs.

Microfluidics: Microfluidic devices can enable high-throughput liquid handling with minimal sample volumes.

Conclusion

Liquid handling is a critical process in drug discovery that requires precision, accuracy, and efficiency. By selecting the appropriate technologies and techniques, researchers can enhance the quality and speed of their work, ultimately accelerating the development of new drugs.

#precision liquid handling#liquid handling#liquid handling systems#Automated pipetting systems#pipette tips#pipettes#micropipette#pipette filler

0 notes

Text

Affordable Cobot Solutions: Safe, Smart, and Efficient Automation for Your Business

In today's competitive industrial landscape, businesses of all sizes are seeking smarter and more cost-effective ways to improve productivity and streamline operations. One of the most transformative innovations in recent years is the collaborative robot, or cobot. Designed to work safely alongside humans, cobots offer the benefits of industrial automation without the need for expensive safety barriers or complex programming. For businesses looking to enhance their workflows without breaking the bank, an affordable cobot is the ideal solution.

What Is a Cobot?

A cobot, short for collaborative robot, is a type of robot specifically engineered to interact directly and safely with humans in a shared workspace. Unlike traditional industrial robots that require isolation due to safety concerns, cobots are equipped with advanced sensors, force limitations, and user-friendly interfaces. These features make them ideal for applications in manufacturing, logistics, packaging, inspection, and even healthcare.

Cobots are not only safer but also more flexible and easier to deploy than traditional robots. Whether it's repetitive assembly tasks, material handling, or precision testing, cobots offer intelligent automation with minimal setup time.

Why Choose an Affordable Cobot?

The term affordable cobot is becoming increasingly relevant as businesses search for practical automation solutions without the high costs typically associated with robotic systems. In the past, automation was considered a luxury, accessible only to large manufacturers with deep pockets. Today, however, advancements in technology and increased market competition have driven down costs, making high-quality cobots more accessible than ever.

Here are some key reasons to choose an affordable cobot:

Lower Upfront Investment Compared to traditional robotic systems, cobots require less initial capital. Many affordable cobot models are designed with small to medium-sized businesses in mind, providing excellent ROI (return on investment) even with limited budgets.

Ease of Use Most cobots come with intuitive programming interfaces, including drag-and-drop features or hand-guided teaching. This allows non-technical staff to set up and operate cobots without needing advanced engineering skills.

Rapid Deployment Unlike conventional robots that may take weeks to install and configure, cobots can be set up and integrated into your production line in just a few hours. This minimizes downtime and ensures you start seeing productivity gains quickly.

Flexibility Across Tasks A single cobot can perform multiple tasks. With quick tool changes and easy reprogramming, your team can adapt a cobot for different functions, maximizing its value and utilization.

Enhanced Safety Cobots are built with built-in safety protocols that allow them to detect collisions and reduce force upon impact. This means they can safely work side-by-side with human operators without compromising workplace safety.

Top Applications of Affordable Cobots

Affordable cobots can be deployed across a variety of industries and applications, including:

Assembly: Speed up repetitive assembly processes while maintaining precision and consistency.

Pick and Place: Reduce labor costs in material handling and packaging operations.

Machine Tending: Automate the loading and unloading of CNC machines, reducing human fatigue and improving productivity.

Quality Inspection: Use vision systems to automate inspection processes and ensure product quality.

Lab Automation: Perform repetitive lab tasks like pipetting and sample handling in pharmaceutical or research environments.

How to Select the Right Affordable Cobot

Choosing the right cobot for your business starts with understanding your specific needs. Consider these factors:

Payload and Reach: Match the cobot's payload and reach with your application requirements.

Precision and Speed: Depending on your task, select a cobot that delivers the right balance of speed and accuracy.

Compatibility: Ensure the cobot integrates well with your existing systems and machinery.

Support and Training: Opt for a vendor that offers reliable customer support, training, and resources to help your team succeed.

Where to Find the Best Deals on Affordable Cobots

As the demand for collaborative robots increases, more vendors are offering competitive pricing, financing options, and bundled packages that include software, end-effectors, and support. When exploring your options, look for providers that offer:

Transparent pricing with no hidden fees

Comprehensive warranties and service plans

Online configurators to tailor cobot packages to your needs

Real customer reviews and case studies

At [Your Website Name], we specialize in connecting businesses with top-rated affordable cobots from leading manufacturers. Our curated selection ensures safety, reliability, and performance at unbeatable prices. Whether you're automating a single workstation or upgrading your entire production line, our team is here to help you choose the best cobot solution for your business.

Final Thoughts

affordable cobot are revolutionizing the way businesses approach automation. No longer confined to large corporations, cobots are now accessible, practical, and safe for small and mid-sized enterprises. With the right cobot, you can enhance operational efficiency, reduce costs, and improve product quality — all while keeping your team safe and engaged.

If you're ready to explore the possibilities of smart automation, start by browsing our collection of affordable cobots today. Experience the future of work — collaborative, efficient, and within your reach.

0 notes

Text

0 notes

Text

Understanding Pipette Tips: Choosing the Right One for Every Lab

In modern laboratories, where precision and contamination control are non-negotiable, the right tools make all the difference—especially when it comes to liquid handling. At Accumax, we understand that pipette tips aren’t just accessories; they’re critical components of reliable lab performance. That’s why we offer a wide range of pipette tips, designed to deliver uncompromised accuracy, efficiency, and safety across a wide spectrum of applications. Whether it’s robotic tips for automated systems, LF tips for low-retention needs, our eco-conscious GreenMAX tips, or standard pipette tips for everyday use, each product is engineered for compatibility, durability, and contamination-free transfers. Trusted in research, diagnostics, and molecular biology, Accumax pipette tips are built to elevate the standards of modern laboratories—one precise drop at a time.

What Exactly is a Pipette Tip?

A pipette tip is a small, disposable, cone-shaped plastic attachment designed to fit onto a pipette—a handheld instrument used to measure and transfer small volumes of liquid. Pipette tips allow for accurate and precise aspiration and dispensing of liquids while protecting both the sample and the pipette from contamination.

What Are Pipette Tips Used For?

Pipette tips are more than just disposable plastic attachments — they are essential tools in maintaining accuracy, sterility, and efficiency in modern laboratories.

Different Types of Pipette Tips

Depending on the application and sensitivity of the experiment, different pipette tips are used.

Standard Pipette Tips

Despite innovations, standard pipette tips remain a cornerstone of most labs. Known for their cost-effectiveness and availability in various sizes, they are ideal for general laboratory tasks that don’t require ultra-low retention.

Filter Tips

When it comes to sensitive applications like PCR, microbiology, or sterile lab procedures, filter pipette tips are indispensable. These tips include an integrated filter that blocks aerosols and liquid from entering the pipette shaft, safeguarding against cross-contamination and preserving experimental integrity.

Long Tips

Long tips are ideal for reaching the bottom of tall containers, narrow tubes, or deep-well plates without risking contamination of the pipette’s shaft. Their extended length ensures that liquid can be aspirated and dispensed accurately, even in hard-to-reach vessels. Especially valuable in sterile environments, long tips help maintain cleanliness and precision — making them a reliable choice for applications where depth and accuracy matter.

Short Tips

Short pipette tips are designed with ergonomics in mind. They allow for more comfortable pipetting, especially during repetitive tasks or when working with multichannel pipettes and shallow well plates. By allowing the user to pipette closer to the work surface, short tips reduce strain on the arm and wrist — making them ideal for high-throughput work or use in automated systems.

Applications of Different Pipette Tips

1. Standard Pipette Tips

Routine liquid handling

Buffer and reagent transfers

General laboratory workflows in chemistry, biology, and clinical labs

2. Low Retention Pipette Tips

Molecular biology experiments (e.g., DNA/RNA extraction)

Pharmaceutical testing with costly reagents

Genomics and proteomics research

Handling viscous liquids or small-volume samples

3. Filter Tips

PCR and qPCR applications

Microbiology and sterile technique labs

Clinical diagnostics

Handling infectious or sensitive samples

Cross-contamination-sensitive workflows

4. Long Tips

Reaching into deepwell plates, tall flasks, or narrow centrifuge tubes

Sterile environments requiring contamination-free handling

Microbiology and media preparation in deep vessels

5. Short Tips

High-throughput screening (HTS) and automation platforms

Use with multichannel pipettes

Ergonomic pipetting tasks with shallow well plates

Automated liquid handling robots

Final Thoughts: Getting the Most Out of Your Pipette Tips

Choosing the right type of pipette tip is only part of the equation — the quality and compatibility of the tip are equally crucial. Using low-quality or poorly fitting tips can lead to inaccurate measurements, increased pipetting fatigue, and a higher risk of sample contamination. These small issues can add up quickly, compromising your experiments and overall lab productivity.

To achieve consistent and reliable results, always opt for high-quality pipette tips like those from Accumax, designed for full compatibility with most leading pipette models. A proper fit ensures a secure seal, minimizes leakage, and maintains precision across repetitive tasks.

Remember, selecting the appropriate pipette tip isn’t just about personal preference — it directly impacts the accuracy, efficiency, and success of your lab work. With Accumax Pipette Tips, you can trust in optimal liquid handling, reduced variability, and superior data integrity every time.

Blog Source -- Understanding Pipette Tips: Choosing the Right One for Every Lab

#lab equipment#pipette tips#screw cap tubes#microcentrifuge tubes#centrifuge tube#micropipettes#oem manufacturing#sustainable labware#micropipette tips

0 notes

Text

How UAE’s Accredited Laboratories Leverage Automation for Precision Testing? | +971 554747210

The UAE is rapidly advancing as a regional hub for scientific research, manufacturing, and quality assurance. At the heart of this progress are accredited laboratories in the UAE, which play a vital role in ensuring products and materials meet stringent standards. To stay ahead in a competitive global market, many of these labs are embracing automation technologies that revolutionize precision testing.

Automation is transforming how accredited laboratories operate, enabling faster, more accurate, and highly reliable test results. This blog explores how UAE’s accredited laboratories leverage automation for precision testing, the benefits of automation, and its impact on various industries.

The Growing Importance of Accredited Laboratories in the UAE

Laboratory accreditation, such as ISO/IEC 17025 certification granted by bodies like ENAS (Emirates National Accreditation System), guarantees that labs meet international quality and technical standards. These accredited labs are trusted to deliver reliable testing services essential for:

Regulatory compliance

Product certification

Quality assurance

Research and development

In sectors like oil and gas, pharmaceuticals, food safety, and manufacturing, precision testing is non-negotiable. Automation helps UAE’s accredited laboratories meet these high demands efficiently and consistently.

What Is Automation in Laboratory Testing?

Automation in laboratory testing involves using technology-driven systems, robotics, and software to perform test procedures with minimal human intervention. This includes:

Automated sample preparation and handling

Robotic liquid handling systems

Computer-controlled analytical instruments

Integrated data acquisition and management platforms

By reducing manual processes, automation minimizes human error, speeds up workflows, and enhances data accuracy.

How UAE’s Accredited Laboratories Use Automation for Precision Testing

1. Automated Sample Preparation

Sample preparation is often the most labor-intensive and error-prone part of testing. UAE labs use automated systems to:

Weigh and measure samples precisely

Perform dilution and mixing with exact proportions

Conduct sample digestion or extraction processes

Automation ensures uniformity across samples, which is critical for reproducible test results.

2. Robotic Liquid Handling

Accredited labs in the UAE implement robotic liquid handlers to transfer precise volumes of liquids during chemical analysis, molecular biology, and pharmaceutical testing. These robots offer:

High throughput processing

Reduced contamination risks

Consistent pipetting accuracy

This technology is vital for labs conducting food safety tests, water quality analysis, and drug potency assays.

3. Advanced Analytical Instruments

Automation extends to advanced instruments such as:

Chromatography systems (GC, HPLC) for separating chemical mixtures

Spectroscopy devices (UV-Vis, FTIR, Mass Spectrometry) for qualitative and quantitative analysis

Automated microscopes and imaging systems for material characterization

These instruments are often integrated with software that controls their operation, collects data, and processes results automatically.

4. Data Management and Reporting

Automated data management platforms collect, store, and analyze test data securely. Features include:

Real-time data monitoring

Automated calculation of results with statistical validation

Generation of standardized, customizable reports

Traceability and audit trails for compliance

Such platforms help UAE’s accredited laboratories maintain transparency and meet regulatory demands efficiently.

Benefits of Automation for UAE’s Accredited Laboratories

Enhanced Accuracy and Precision

Automation drastically reduces human error associated with manual handling and subjective interpretation. Precise control over sample volumes, instrument parameters, and data processing leads to more consistent and trustworthy results.

Increased Testing Throughput

Automated systems can process hundreds or thousands of samples simultaneously, dramatically increasing laboratory productivity. This is crucial in sectors like food testing or environmental monitoring where large sample volumes are routine.

Faster Turnaround Time

Automation shortens testing cycles, enabling faster delivery of results without compromising quality. This agility helps manufacturers and exporters meet tight deadlines and regulatory timelines.

Improved Safety

Handling hazardous chemicals and biological samples manually poses risks. Automated systems reduce operator exposure to dangerous substances, promoting safer laboratory environments.

Regulatory Compliance and Traceability

Automation supports compliance with international standards such as ISO/IEC 17025 by maintaining comprehensive records, reducing documentation errors, and facilitating external audits.

Impact of Automation on Key UAE Industries

Oil and Gas

Accredited labs use automated precision testing to analyze petroleum products, pipeline materials, and environmental samples. Rapid and accurate test results help companies comply with local and global standards, ensuring operational safety and efficiency.

Pharmaceuticals

Automation in pharmaceutical testing ensures drug quality, potency, and purity. Accredited labs in the UAE employ robotic systems for sample prep and automated instrumentation to meet stringent health authority requirements.

Food Safety

The UAE’s food import and manufacturing sectors depend heavily on accredited labs to test for contaminants, allergens, and nutritional content. Automation enables high-throughput screening of food samples, essential for consumer safety.

Manufacturing and Construction

Material testing labs use automated systems to assess the mechanical, chemical, and physical properties of metals, plastics, and composites. This ensures that products meet UAE’s regulatory and quality benchmarks.

Challenges and Considerations in Implementing Automation

Despite its advantages, automation implementation requires significant investment in equipment, staff training, and software integration. Accredited laboratories must:

Select compatible automated systems for their specific testing needs

Maintain rigorous calibration and validation of automated instruments

Ensure skilled personnel are trained to operate and troubleshoot automated workflows

UAE laboratories are increasingly partnering with global technology providers and investing in workforce development to overcome these challenges.

The Future of Automation in UAE’s Accredited Laboratories

With the UAE’s strategic focus on innovation and smart technologies, automation in accredited laboratories is poised for exponential growth. Emerging trends include:

Artificial Intelligence (AI) and Machine Learning: For predictive analytics and anomaly detection in test data

Internet of Things (IoT): Connected devices providing real-time monitoring of laboratory instruments

Cloud-based Data Solutions: Enhancing collaboration, storage, and remote access to lab results

Advanced Robotics: For fully autonomous lab workflows

These advancements will further improve the precision, efficiency, and scalability of testing services offered by accredited laboratories in the UAE.

Conclusion

Automation is revolutionizing the landscape of accredited laboratories in the UAE, especially in delivering precision testing critical to multiple industries. By integrating robotic systems, advanced instruments, and sophisticated data management platforms, UAE’s labs achieve unparalleled accuracy, faster throughput, and enhanced safety.

For businesses seeking reliable testing and certification, partnering with an ENAS-accredited, ISO/IEC 17025 certified laboratory that leverages automation is a smart move. It ensures compliance, quality, and operational excellence in today’s fast-paced market.

As the UAE continues to lead in technology adoption, the future of laboratory testing will undoubtedly be shaped by intelligent automation — empowering accredited labs to set new standards of precision and trust.

0 notes

Text

PCR Bottles Market Trends: Rising Usage in Molecular Diagnostics Propelling Future Market Opportunities

The PCR bottles market is witnessing a notable surge in demand, largely driven by the rapid expansion of molecular diagnostics across healthcare, biotechnology, and pharmaceutical sectors. The increasing prevalence of infectious diseases, heightened research activities in genomics, and growing global investment in diagnostic laboratories are fueling the use of polymerase chain reaction (PCR) technologies—and, by extension, the supporting consumables such as PCR bottles. As these trends continue to gain momentum, the PCR bottles market is poised for substantial growth, presenting numerous opportunities for manufacturers, suppliers, and investors.

Rising Demand in Molecular Diagnostics: A Key Growth Catalyst

Molecular diagnostics has emerged as a transformative tool in modern medicine. From early disease detection to personalized treatment strategies, PCR-based testing enables precise and rapid analysis of genetic material. This growing reliance on molecular diagnostics has intensified the need for high-quality, contamination-free lab consumables—including PCR bottles, which play a critical role in the accurate storage and handling of reagents, samples, and other sensitive biological materials.

One of the primary applications driving this demand is infectious disease testing, especially in the wake of global health crises like the COVID-19 pandemic. PCR has become the gold standard for detecting viral RNA, and laboratories worldwide have had to scale up operations. This expansion has directly translated into increased consumption of PCR-compatible containers and bottles, creating a robust growth trajectory for the market.

Material Advancements and Product Innovations

To meet evolving user requirements, manufacturers in the PCR bottles market are increasingly focused on innovation in terms of materials and bottle design. The trend is moving toward high-performance polymers that offer enhanced thermal resistance, chemical stability, and reduced leachability. Polypropylene (PP) and polyethylene (PE) continue to be the most commonly used materials, but newer variants and hybrid materials are being explored to further improve the efficacy of PCR workflows.

Another noteworthy innovation is the integration of ergonomic and automation-friendly features. As laboratory automation becomes more prevalent, PCR bottles are being engineered for compatibility with robotic arms, automated pipetting systems, and high-throughput processing. These improvements not only enhance efficiency but also reduce the risk of cross-contamination—a critical concern in molecular diagnostics.

Stringent Quality Standards Driving Premium Product Segments

PCR testing requires an ultra-clean environment with minimal chances of contamination. As a result, end-users are placing increasing importance on product certifications such as DNase/RNase-free, pyrogen-free, and non-cytotoxic labels. This trend is driving manufacturers to enhance quality assurance protocols and invest in cleanroom production facilities. Premium PCR bottles that meet these stringent criteria are finding growing demand in both research and clinical diagnostics settings.

Furthermore, regulatory compliance is a vital aspect of this market. Bottles that conform to international quality standards such as ISO 13485 and FDA regulations are more likely to be adopted by diagnostic labs and healthcare providers, thereby pushing manufacturers toward more rigorous documentation and quality control practices.

Regional Market Trends: Growth Hotspots

While North America continues to lead the global PCR bottles market—thanks to its well-established healthcare infrastructure and biotech ecosystem—emerging economies in the Asia-Pacific region are becoming significant growth drivers. Countries such as China, India, and South Korea are heavily investing in healthcare modernization and research capabilities, leading to a surge in diagnostic testing and lab setups.

Europe, too, is witnessing strong demand due to the presence of major life science companies and increasing government initiatives in disease surveillance. Meanwhile, Latin America and the Middle East are showing potential for future expansion, particularly as access to healthcare technologies improves.

Competitive Landscape and Strategic Moves

The PCR bottles market is moderately consolidated, with a mix of global giants and niche players competing for market share. Key participants such as Thermo Fisher Scientific, Corning Inc., Eppendorf AG, DWK Life Sciences, and Greiner Bio-One are leveraging their existing networks and product development capabilities to introduce advanced and reliable bottle solutions tailored for PCR applications.

Mergers, acquisitions, and strategic partnerships are common strategies used to strengthen market presence. For instance, companies are collaborating with diagnostic kit manufacturers and laboratory equipment suppliers to offer bundled solutions that include PCR instruments, reagents, and consumables. This integrated approach enhances customer loyalty and simplifies procurement for end-users.

Sustainability and Eco-Friendly Packaging

As sustainability becomes a core consideration in laboratory operations, manufacturers are exploring eco-friendly alternatives for PCR bottle production. This includes using recyclable materials, reducing packaging waste, and implementing closed-loop recycling programs. While these initiatives are still at an early stage, they are expected to gain traction as laboratories worldwide adopt greener practices.

Future Outlook

Looking ahead, the PCR bottles market is expected to maintain its upward trajectory, bolstered by sustained investments in molecular diagnostics, increased focus on public health infrastructure, and continued technological advancements. The rise of point-of-care testing, growing applications in cancer genomics, and the integration of AI and IoT in laboratory workflows will further open new frontiers for growth.

Manufacturers that can offer precision, quality, and compliance—while also innovating on materials and design—will be best positioned to capture value in this evolving market. As molecular diagnostics cements its role in modern healthcare, the humble PCR bottle is proving to be an indispensable enabler of scientific progress.

0 notes

Text

Empowering Laboratories Through AI and Automation

Laboratories are experiencing an unprecedented transformation, driven by the integration of automation and artificial intelligence. By automating routine processes and leveraging the power of AI to analyze complex data, laboratories can redirect their focus toward critical research and innovation, accelerating breakthroughs and delivering superior outcomes.

Leading this transformative wave is NextGen Invent, a leading enterprise AI software development company, dedicated to empowering laboratories with intelligent, forward-thinking software. With a deep commitment to innovation and excellence, we leverage innovative technology to address the unique challenges faced by laboratories, providing tailored AI-powered software designed to enhance productivity and decision-making.

As laboratories continue to embrace the possibilities of AI and automation, the opportunities to revolutionize scientific discovery, diagnostics, and operational efficiency are boundless. As a leader in the field, we understand the unique challenges faced by modern laboratories—from managing complex data sets to ensuring regulatory compliance and enhancing throughput. By designing and implementing medical laboratory information management system software, we enable laboratories to optimize operations, maximize efficiency, and achieve groundbreaking results that push the boundaries of what is possible in research and diagnostics.

The Role of Medical LIMS Software in Modern Laboratories

Medical laboratory information management system software serves as the backbone of efficient laboratory operations. NextGen Invent’s LIMS software development services are specifically designed to address the dynamic needs of today’s laboratories, providing:

Centralized Data Management: Our LIMS software development services consolidate all laboratory data into a single, secure platform, enabling seamless access and real-time updates. This eliminates the silos often created by disparate systems and ensures that critical information is always available when needed.

Enhanced Workflow Automation: From sample tracking to result interpretation, our LIMS software automates key processes, saving time and reducing operational costs. Automated workflows also ensure that laboratories can handle increased workloads without compromising quality or accuracy.

Regulatory Compliance: With built-in compliance features, the software helps laboratories meet industry standards and regulatory requirements effortlessly. This includes audit trails, validation protocols, and data integrity measures to ensure complete transparency and accountability.

Scalability and Flexibility: As laboratories grow and their needs evolve, the LIMS software scales to accommodate increased data volumes, new testing protocols, and additional users. This adaptability ensures long-term value and relevance.

Empowering Laboratories with AI and Automation

The integration of AI into laboratory operations is a game-changer, offering unprecedented opportunities to enhance productivity and innovation. AI-powered systems excel at identifying patterns, analyzing trends, and making predictions that would be impossible to discern manually. For instance, NextGen Invent’s AI algorithms can process years of assay data to reveal hidden correlations, enabling laboratories to fine-tune their processes and improve outcomes.

Moreover, automation driven by AI allows laboratories to achieve remarkable efficiency gains. Tasks that once required hours of manual effort—such as pipetting, data transfer, and image analysis—can now be completed in minutes with minimal human intervention. This not only accelerates turnaround times but also frees up skilled personnel to focus on high-value activities such as research design and strategic decision-making.

Real-World Impact: Transforming Laboratory Operations

The transformative power of AI and automation is evident in the real-world impact achieved by laboratories adopting NextGen Invent’s software development services. Consider the following examples:

Data Analysis Acceleration: A task that previously required multiple hours of manual computation can now be completed in seconds, because of automated workflows. This accelerates the pace of research and allows laboratories to deliver results faster.

Error Reduction: By standardizing processes and eliminating manual data entry, our LIMS software minimizes the risk of errors and ensures consistent, high-quality results.

Increased Throughput: With robotic systems handling routine tasks such as titrations and sample preparation, laboratories can significantly increase their throughput without expanding their workforce or physical infrastructure.

Improved Resource Utilization: Automation reduces the need for consumables such as pipette tips and reagents, leading to cost savings and a more sustainable approach to laboratory operations.

Shaping the Future of Laboratory Science

The future of laboratory science is undoubtedly shaped by the continued integration of AI and automation. As technologies evolve, NextGen Invent remains at the forefront, driving innovation and setting new benchmarks for efficiency and quality. Our vision is to create a world where laboratories are not constrained by manual processes or outdated systems but are instead empowered to achieve their full potential through intelligent, data-driven software.

Whether it’s accelerating breakthroughs in medical research, improving diagnostic accuracy, or optimizing resource utilization, NextGen Invent is dedicated to enabling laboratories to thrive in an increasingly competitive and complex landscape. With our expertise as an enterprise AI software development company and our commitment to innovation, we are proud to lead the way toward a brighter, more efficient future for laboratory operations.

0 notes

Text

Automated Liquid Handling Technologies Market: Key Trends and Growth Opportunities

The global automated liquid handling technologies market size was estimated at USD 4.20 billion in 2030 and is anticipated to grow at a compound annual growth rate (CAGR) of 10.5% from 2024 to 2030. Automated liquid handling technology has changed wet lab research handling by allowing substantial restructuring of the manufacturing and research facilities of the pharma and biotech companies. There is increasing acceptance of liquid handling robots to restore the conventionally reserved wet lab bench work areas. This factor is expected to drive the market.

The key aspects of maintaining the overall productivity of these companies are the efficient and accurate handling of the liquid samples. This makes biopharma companies and research laboratories rely greatly on robotics and automation. Usage of preprogrammed and customizable procedures reduces the need for management as it allows scientists to invest additional time in the analysis of data. Moreover, the buyers have a choice to select from various liquid handling technologies such as positive displacement, air displacement dispensing, acoustic, and piezoelectric. This choice to pick from a variety of automated liquid handlers impacts the power of the buyer. Significant market players are involved in manufacturing low-volume liquid handling systems owing to the increasing adoption of microplates and microfluidics in lab processing.

The COVID-19 pandemic has augmented the industry growth significantly as the demand for ALHsystem has increased with an upsurge in the need to process the specimens quicker in the laboratory for COVID-19 virus research with the examination of virus genetic makeup and study of COVID-19 virus genetic mutations. Thus, the pandemic has positively impacted the market. Moreover, new product launches accelerated the growth of the market during the pandemic. For instance, in April 2022, Novacyt introduced a novel ALH system to meet the increasing requirement for no manual pipetting in COVID-19 Polymerase Chain Reaction testing. Furthermore, in March 2020, Hamilton Company announced numerous automation-related initiatives to help healthcare researchers and workers during the coronavirus pandemic. The company launched two innovative automated assay-ready workstations, established on the company’s liquid handling workstation (Microlab STARlet), which enables rapid, research-based testing of SARS-CoV-2 and high-throughput diagnostic.

Gather more insights about the market drivers, restrains and growth of the Automated Liquid Handling Technologies Market

Automated Liquid Handling Technologies Market Report Highlights

• By product, the automated liquid handling workstations segment held the largest share in 2022. The growing competition among the pharmaceutical companies and their pursuit of new drugs to treat diseases effectively drive the adoption of automated workstations

• Multipurpose workstations are projected to witness the fastest growth during the forecast period due to their rapid adoption by the pharma and biopharma CROs. These workstations enable microplate washing, multichannel pipetting, and bulk reagent dispensing within a single unit

• By application, the drug discovery and ADME-Tox research segment dominated the market in 2022. Various applications in drug discovery and ADME Tox include stepwise serial dilution over a wide concentration range, selection and transfer of compounds for the retest, and confirmatory and further analysis

• Cancer and genomic research is expected to witness the fastest growth during the forecast period owing to the ability of these workstations to handle multiple samples of microliter to picoliter volume

• Workflow complexity and the need for the fastest target screening resulted in the increase in the installation of automated workstations by the pharmaceutical and biotechnology companies

• North America dominated the market in 2022 owing to the rapid adoption of advanced platforms, the high cost of hiring skilled professionals, and the presence of key players

• Asia Pacific is expected to expand at the fastest CAGR during the forecast period owing to the rapid progress of the pharma and biopharmaceutical companies in the region

• High economic developments in APAC countries are anticipated to increase investments in the life science, medicine, and pharmaceutical sectors. Progress in these sectors is expected to fuel the demand for automated workstations, especially those based on microfluidics

Automated Liquid Handling Technologies Market Segmentation

Grand View Research has segmented the global automated liquid handling technologies market report based on product, application, end-user, and region:

Automated Liquid Handling Technologies Product Outlook (Revenue, USD Million, 2018 - 2030)

• Automated Liquid Handling Workstations

o By Assembly

o By Type

• Reagents & Consumables

o Reagents

o Accessories

Automated Liquid Handling Technologies Application Outlook (Revenue, USD Million, 2018 - 2030)

• Drug Discovery & ADME-Tox Research

• Cancer & Genomic Research

• Bioprocessing/Biotechnology

• Others

Automated Liquid Handling Technologies End-User Outlook (Revenue, USD Million, 2018 - 2030)

• Academic & Research Institutes

• Pharmaceutical & Biotechnology Companies

• Contract Research Organizations

Automated Liquid Handling Technologies Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

o Canada

• Europe

o U.K.

o Germany

o France

o Italy

o Spain

o Denmark

o Sweden

o Norway

• Asia Pacific

o Japan

o China

o India

o South Korea

o Australia

o Thailand

• Latin America

o Brazil

o Mexico

o Argentina

• Middle East & Africa

o South Africa

o Saudi Arabia

o UAE

o Kuwait

Order a free sample PDF of the Automated Liquid Handling Technologies Market Intelligence Study, published by Grand View Research.

#Automated Liquid Handling Technologies Market#Automated Liquid Handling Technologies Market Size#Automated Liquid Handling Technologies Market Share#Automated Liquid Handling Technologies Market Analysis#Automated Liquid Handling Technologies Market Growth

0 notes

Text

Evaluating the Return on Investment (ROI) of Automated Liquid Handling Systems

In today’s fast-paced scientific research and diagnostic environments, efficiency, accuracy, and reliability are essential for laboratories aiming to meet increasing demands. One of the most impactful innovations in laboratory automation is the automated liquid handling system. These systems, designed to perform a variety of liquid dispensing tasks with precision and speed, have become indispensable in modern labs. However, like any significant capital investment, organizations must evaluate the return on investment (ROI) before integrating these systems into their workflows.

In this blog, we’ll break down the key factors to consider when assessing the ROI of automated liquid handling systems, covering how these systems influence cost savings, productivity, and long-term value for labs.

1. Direct Cost Savings

One of the most apparent aspects of ROI for automated liquid handling systems is the reduction in direct costs associated with manual pipetting and liquid handling processes. Automated systems help lower costs in several ways:

Reduced Reagent Waste: Automated systems can dispense precise volumes, minimizing reagent wastage due to human error or variability. Over time, this can result in significant savings, especially for costly reagents.

Lower Labor Costs: Replacing or supplementing manual labor with automation reduces the need for skilled personnel to spend time on repetitive tasks. This frees up technicians and scientists to focus on higher-value activities.

Fewer Errors and Reworks: Human errors in liquid handling can lead to failed experiments or inaccurate data, resulting in the need for reworks. Automated systems improve accuracy, reducing the need for costly reruns of assays or experiments.

2. Increased Productivity

Automated liquid handling systems are capable of working faster than humans, and can operate for long hours, even continuously if needed. Here’s how automation boosts productivity:

Time Efficiency: Tasks that would typically take hours for a human technician can be performed in a fraction of the time by an automated system. This significantly increases throughput, especially in high-demand settings like drug discovery or genomic testing labs.

24/7 Operation: Automated systems can work around the clock, which is a critical advantage for labs with high sample volumes. Overnight or weekend operations can further enhance output without requiring additional human resources.

Batch Processing: These systems are capable of handling multiple plates or samples simultaneously, allowing for large-scale experiments or tests to be completed much faster than manual processes.

3. Improved Accuracy and Data Quality

One of the primary advantages of using automated liquid handling systems is the high precision they offer. Human variability is a challenge in manual pipetting, which can lead to errors in volumes, dilution factors, or sample contamination. Automated systems offer:

Consistent Precision: Automated systems are designed to deliver precise volumes every time, reducing errors associated with manual liquid handling.

Reproducibility: Consistency in experimental processes leads to more reliable and reproducible results, which is critical in regulated environments or when scaling up experiments.

Reduced Contamination Risk: Many automated systems are designed with features that minimize contamination risk, further improving the quality of the results.

4. Long-Term Value and Scalability

While the initial investment in automated liquid handling systems can be significant, the long-term value they provide often justifies the cost. As laboratories grow and scale their operations, automated systems can continue to meet rising demands without the need for additional staff. Key points to consider include:

Scalability: Automated systems can be programmed to handle varying volumes and tasks, making them adaptable to changing workloads. As your lab’s requirements increase, the system can often scale without the need for additional units.

Flexible Applications: Many automated liquid handling equipment are versatile, capable of being used for multiple applications such as PCR setup, ELISA, or drug screening. This adaptability further enhances their long-term value.

5. Hidden Costs to Consider

While evaluating ROI, it's essential to account for some potential hidden costs, including:

Maintenance and Servicing: Like any machine, automated systems require regular maintenance to keep them running smoothly. The costs of service contracts, repairs, and replacement parts should be factored into the ROI analysis.

Training Costs: Training staff to operate and troubleshoot the automated system is necessary and can involve a time and financial investment. However, once trained, operators can improve system efficiency and minimize downtime.

Initial Downtime During Implementation: During the initial setup phase, there may be some downtime as the system is integrated into workflows, and staff become familiar with its operation. This temporary dip in productivity should be balanced against long-term gains.

6. Qualitative Benefits

Beyond the quantitative ROI, there are qualitative benefits of automated liquid handling systems that contribute to the overall success of a lab:

Employee Satisfaction: By automating tedious and repetitive tasks, lab staff can focus on more intellectually stimulating work. This can lead to improved job satisfaction, retention rates, and a better overall work environment.

Enhanced Lab Competitiveness: Labs that adopt automation are often more competitive, attracting more projects, clients, or funding due to their ability to handle higher volumes with greater accuracy and speed.

Conclusion: Making an Informed Decision

Evaluating the ROI of an automated liquid handling system involves looking at both direct and indirect cost savings, productivity gains, and the long-term value it brings to the laboratory. Although the upfront investment may seem steep, the substantial savings in labor, increased throughput, improved data quality, and scalability typically provide an attractive ROI in the medium to long term.

For laboratories seeking to stay ahead of the curve, especially those working in high-throughput or regulated environments, investing in automated liquid handling technology is not just about increasing efficiency; it's about staying competitive and maintaining accuracy in an ever-evolving scientific landscape. By weighing both the tangible and intangible benefits, labs can make an informed decision about whether an automated liquid handling system is the right investment for their specific needs.

0 notes

Text

Affordable Cobot Solutions: Safe, Smart, and Efficient Automation for Your Business

In today's competitive industrial landscape, businesses of all sizes are seeking smarter and more cost-effective ways to improve productivity and streamline operations. One of the most transformative innovations in recent years is the collaborative robot, or cobot. Designed to work safely alongside humans, cobots offer the benefits of industrial automation without the need for expensive safety barriers or complex programming. For businesses looking to enhance their workflows without breaking the bank, an affordable cobot is the ideal solution.

What Is a Cobot?

A cobot, short for collaborative robot, is a type of robot specifically engineered to interact directly and safely with humans in a shared workspace. Unlike traditional industrial robots that require isolation due to safety concerns, cobots are equipped with advanced sensors, force limitations, and user-friendly interfaces. These features make them ideal for applications in manufacturing, logistics, packaging, inspection, and even healthcare.

Cobots are not only safer but also more flexible and easier to deploy than traditional robots. Whether it's repetitive assembly tasks, material handling, or precision testing, cobots offer intelligent automation with minimal setup time.

Why Choose an Affordable Cobot?

The term affordable cobot is becoming increasingly relevant as businesses search for practical automation solutions without the high costs typically associated with robotic systems. In the past, automation was considered a luxury, accessible only to large manufacturers with deep pockets. Today, however, advancements in technology and increased market competition have driven down costs, making high-quality cobots more accessible than ever.

Here are some key reasons to choose an affordable cobot:

Lower Upfront Investment Compared to traditional robotic systems, cobots require less initial capital. Many affordable cobot models are designed with small to medium-sized businesses in mind, providing excellent ROI (return on investment) even with limited budgets.

Ease of Use Most cobots come with intuitive programming interfaces, including drag-and-drop features or hand-guided teaching. This allows non-technical staff to set up and operate cobots without needing advanced engineering skills.

Rapid Deployment Unlike conventional robots that may take weeks to install and configure, cobots can be set up and integrated into your production line in just a few hours. This minimizes downtime and ensures you start seeing productivity gains quickly.

Flexibility Across Tasks A single cobot can perform multiple tasks. With quick tool changes and easy reprogramming, your team can adapt a cobot for different functions, maximizing its value and utilization.

Enhanced Safety Cobots are built with built-in safety protocols that allow them to detect collisions and reduce force upon impact. This means they can safely work side-by-side with human operators without compromising workplace safety.

Top Applications of Affordable Cobots

Affordable cobots can be deployed across a variety of industries and applications, including:

Assembly: Speed up repetitive assembly processes while maintaining precision and consistency.

Pick and Place: Reduce labor costs in material handling and packaging operations.

Machine Tending: Automate the loading and unloading of CNC machines, reducing human fatigue and improving productivity.

Quality Inspection: Use vision systems to automate inspection processes and ensure product quality.

Lab Automation: Perform repetitive lab tasks like pipetting and sample handling in pharmaceutical or research environments.

How to Select the Right Affordable Cobot

Choosing the right cobot for your business starts with understanding your specific needs. Consider these factors:

Payload and Reach: Match the cobot's payload and reach with your application requirements.

Precision and Speed: Depending on your task, select a cobot that delivers the right balance of speed and accuracy.

Compatibility: Ensure the cobot integrates well with your existing systems and machinery.

Support and Training: Opt for a vendor that offers reliable customer support, training, and resources to help your team succeed.

Where to Find the Best Deals on Affordable Cobots

As the demand for collaborative robots increases, more vendors are offering competitive pricing, financing options, and bundled packages that include software, end-effectors, and support. When exploring your options, look for providers that offer:

Transparent pricing with no hidden fees

Comprehensive warranties and service plans

Online configurators to tailor cobot packages to your needs

Real customer reviews and case studies

At [Your Website Name], we specialize in connecting businesses with top-rated affordable cobots from leading manufacturers. Our curated selection ensures safety, reliability, and performance at unbeatable prices. Whether you're automating a single workstation or upgrading your entire production line, our team is here to help you choose the best cobot solution for your business.

Final Thoughts

affordable cobot are revolutionizing the way businesses approach automation. No longer confined to large corporations, cobots are now accessible, practical, and safe for small and mid-sized enterprises. With the right cobot, you can enhance operational efficiency, reduce costs, and improve product quality — all while keeping your team safe and engaged.

If you're ready to explore the possibilities of smart automation, start by browsing our collection of affordable cobots today. Experience the future of work — collaborative, efficient, and within your reach.

0 notes

Text

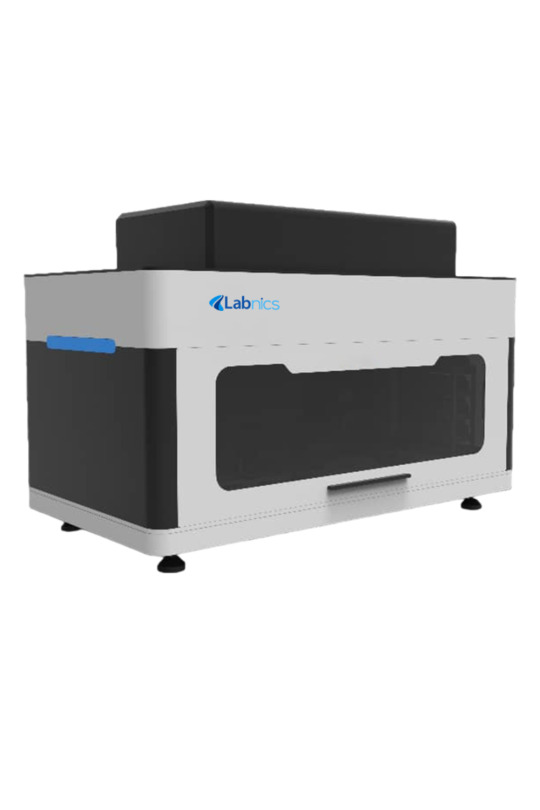

Automated NGS Library Preparation System NNGS-100

Labnics Automated NGS Library Preparation System features a 0.5–200µl pipetting range, air displacement pipetting and 8 or 96 channels for flexible sample processing. It ensures precise DNA/RNA fragment purification with magnetic beads and enhances assay sensitivity with improved fluorescence detection.

0 notes

Text

Life Sciences Laboratory Products

Categories of Life Sciences Laboratory Products

1. Consumables

Laboratory consumables are single-use items that ensure hygiene and accuracy during experiments.

Examples: Test tubes, petri dishes, pipette tips, and gloves.

2. Instruments

These high-tech devices aid in data analysis and sample processing.

Examples: Spectrophotometers, PCR machines, and centrifuges.

3. Safety Equipment

Products designed to protect researchers and maintain lab safety.

Examples: Fume hoods, safety goggles, and spill kits.

4. Chemicals and Reagents

Critical substances used in experiments for reactions, analysis, and testing.

Examples: Buffers, solvents, and assay kits.

5. Storage and Preservation Products

Used for preserving samples, reagents, and biological materials.

Examples: Cryogenic freezers, refrigerators, and incubators.

Essential Life Sciences Laboratory Products

Pipettes

Used for transferring precise liquid volumes. Adjustable and electronic pipettes are popular for reducing human error.

Centrifuges

Separate substances based on density, essential for molecular biology and biochemistry.

Microscopes

From basic optical microscopes to advanced electron microscopes, these are vital for observing minute structures.

PCR Machines

Widely used for amplifying DNA, essential in genetic research and diagnostics.

Spectrophotometers

Measure the intensity of light absorbed by a sample, crucial in quantifying proteins, nucleic acids, and other molecules.

Applications of Life Sciences Laboratory Products

1. Pharmaceutical Research

Laboratory products are integral to drug discovery, testing, and quality assurance.

2. Academic Research

Universities and institutions utilize these products to train future scientists and conduct cutting-edge research.

3. Clinical Diagnostics

Laboratories use products like ELISA kits and diagnostic instruments for disease detection and monitoring.

4. Environmental Studies

Analyzing soil, water, and air samples to study ecosystems and address environmental issues.

5. Biotechnology Development

Critical for innovations like CRISPR gene editing and biomanufacturing.

How to Choose the Right Laboratory Products

Identify Your Needs

Consider the type of experiments and research you’ll be conducting.

Assess Quality and Reliability

Choose products from trusted brands with a proven track record.

Evaluate Cost-Effectiveness

Look for durable and efficient products that provide long-term value.

Check Compliance

Ensure the products meet industry standards for safety and quality.

Leading Brands in Life Sciences Laboratory Products

Thermo Fisher Scientific Known for its wide range of lab equipment and consumables.

Sigma-Aldrich (Merck) A trusted name for chemicals and reagents.

Eppendorf Famous for its precision pipettes and centrifuges.

Bio-Rad Offers innovative products for molecular biology and clinical diagnostics.

Agilent Technologies Specializes in high-performance analytical instruments.

Emerging Trends in Life Sciences Laboratory Products

1. Automation and Robotics

Automated pipetting systems and robotic lab assistants enhance efficiency.

2. Sustainability

Eco-friendly lab consumables and energy-efficient equipment are gaining popularity.

3. IoT-Enabled Devices

Smart lab equipment connected to cloud platforms for real-time monitoring.

4. Customization

Tailored products to meet specific research needs are becoming common.

Best Practices for Maintaining Lab Products

Regular Calibration

Instruments like spectrophotometers and pipettes should be calibrated regularly for accuracy.

Routine Cleaning

Proper cleaning prevents contamination and extends the life of equipment.

Storage Guidelines

Store chemicals and sensitive equipment as per manufacturer recommendations.

Periodic Training

Train lab personnel on using and maintaining complex instruments.

Challenges in Managing Life Sciences Lab Products

High Costs

The initial investment in quality equipment can be steep.

Complex Maintenance

Sophisticated instruments require regular servicing and skilled technicians.

Supply Chain Issues

Delays in procuring essential consumables can disrupt workflows.

Rapid Technological Advancements

Keeping up with new innovations requires continuous learning and upgrades.

Conclusion

Life sciences laboratory products are the backbone of scientific discovery and innovation. From ensuring accuracy in experiments to advancing global healthcare solutions, these products make groundbreaking research possible. By investing in high-quality tools and maintaining them effectively, laboratories can achieve unparalleled success in their endeavors.

Contact Us : [email protected]

https://www.linkedin.com/company/foxxlifesciences

0 notes

Text

Liquid Handling System Market Report: A Comprehensive Analysis of the Growing Demand for Efficient Liquid Handling Solutions

Liquid Handling System Market Report: A Comprehensive Analysis of the Growing Demand for Efficient Liquid Handling Solutions

Market Definition and Latest Trends

The liquid handling system market refers to the industry that provides equipment and solutions for handling liquids in various laboratory, research, and industrial settings. The market includes manual, semi-automated, and automated liquid handling systems, which are used for pipetting, dispensing, and other liquid handling tasks. The latest trends in the market include the increasing adoption of automated liquid handling systems, the growing demand for high-throughput liquid handling solutions, and the rising importance of precision and accuracy in liquid handling applications.

Market Size and Growth Prospects

According to a recent report by Straits Research, the global liquid handling system market size was valued at USD 4.59 Billion in 2024 and is projected to reach from USD 4.81 Billion in 2025 to USD 7.00 Billion by 2033, growing at a CAGR of 4.8% during the forecast period (2025–2033).

Requset a Sample Report of Liquid Handling System Market

Market Segmentation

The liquid handling system market is segmented based on type, product, application, and end-user.

By Type

Manual Liquid Handling: Manual liquid handling systems are used for low-throughput applications and require manual operation.

Automated Liquid Handling: Automated liquid handling systems are used for high-throughput applications and offer high precision and accuracy.

Semi-automated Liquid Handling: Semi-automated liquid handling systems offer a balance between manual and automated liquid handling systems.

By Product

Automated Workstations: Automated workstations are integrated systems that offer automated liquid handling, sample preparation, and other laboratory tasks.

Pipettes: Pipettes are handheld instruments used for measuring and transferring liquids.

Dispensers: Dispensers are instruments used for dispensing liquids in precise volumes.

Burettes: Burettes are instruments used for measuring the volume of liquids.

Other Products: Other products include liquid handling accessories, consumables, and software.

By Application

Drug Discovery: Liquid handling systems are used in drug discovery applications, such as high-throughput screening and lead optimization.

Cancer and Genomics Research: Liquid handling systems are used in cancer and genomics research applications, such as next-generation sequencing and gene expression analysis.

Clinical Diagnostics: Liquid handling systems are used in clinical diagnostics applications, such as molecular diagnostics and immunoassays.

Other Applications: Other applications include food and beverage testing, environmental monitoring, and industrial research and development.

By End User

Pharmaceutical and Biotechnology Industry: The pharmaceutical and biotechnology industry is the largest end-user of liquid handling systems, using them for drug discovery, development, and manufacturing.

Contract Research Organization: Contract research organizations use liquid handling systems for research and development services, such as assay development and testing.

Academic Institutes: Academic institutes use liquid handling systems for research and education purposes, such as teaching and research laboratories.

Other End Users: Other end users include government laboratories, environmental monitoring agencies, and food and beverage companies.

Browse Full Report and TOC of Liquid Handling System Market

Key Opportunity

The increasing adoption of automated liquid handling systems is a key opportunity for the market. Automated liquid handling systems offer high precision, accuracy, and throughput, making them ideal for high-throughput applications such as drug discovery and genomics research.

Key Players

Some of the key players operating in the liquid handling system market include:

Agilent Technologies

Bio-Rad Laboratories Inc.

Corning Incorporated

Eppendorf AG

Hamilton Company

PerkinElmer Inc.

Promega Corporation

Thermo Fisher Scientific Inc.

Danaher Corporation

Tecan Trading AG

10x Genomics

These companies offer a range of liquid handling systems, including automated workstations, pipettes, dispensers, and burettes. They also provide software and services for liquid handling applications.

Buy Liquid Handling System Market Report here!

About Straits Research

Straits Research is a top provider of business intelligence, specializing in research, analytics, and advisory services, with a focus on delivering in-depth insights through comprehensive reports.

Contact Us

Email: [email protected]

Address: 825 3rd Avenue, New York, NY, USA, 10022

Phone: +1 646 905 0080 (US), +91 8087085354 (India), +44 203 695 0070 (UK)

#Liquid Handling System Market#Liquid Handling System Market Share#Liquid Handling System Market Size#Liquid Handling System Industry#Liquid Handling System Market Analysis

0 notes

Text

Cotaus® is a professional automated pipette tips manufacturer and supplier, providing customers with various specifications of automated pipette tips.

Automatic pipette tip series products suit various automatic experimental detection scenarios in the life science service industry. It is suitable for TECAN, Hamilton, Agilent, Beckman, Xantus, Apricot Designs, and other high-throughput automatic pipetting workstations, and automatic sampling systems, mainly used for liquid distribution and transfer, to achieve high-throughput operation of biological samples. The pipette tip was carefully designed and validated. We go through several strict quality controls to ensure product consistency. With excellent verticality and CV value, the pipette tips provide accurate pipetting performance.

#LabConsumables#PipetteTips#LabPlasticware#Liquid Handling Consumables#automatic pipetting workstation#High-throughput pipetting

1 note

·

View note