#Automotive Ball and Roller Bearings market

Text

Latest Automotive Ball and Roller Bearings market research report examines the potential growth opportunities and trends and forecasts for the period from 2023 to 2030.

0 notes

Text

Bearing Market Size is Projected to Reach USD 297.62 Billion, with a CAGR of 8.50% by 2030 – Report by Market Research Future (MRFR)

According to a Comprehensive Research Report by Market Research Future (MRFR), “Bearing Market Information by Product Type, Application, and Region - Forecast till 2030”, Bearing Market could thrive at a rate of 8.50% between 2021 and 2030. The market size will be reaching around USD 297.62 Billion by the end of the year 2030

Bearing Market Overview

Bearing is a mechanical component that supports rotating or moving parts to reduce friction and enable smooth motion. They are widely used in various industries such as automotive, aerospace, construction, and others. Bearings come in various types, including ball bearings, roller bearings, plain bearings, and others. They are essential in maintaining the efficiency, durability, and reliability of machines and equipment.

0 notes

Text

Increasing Demand for Vehicles in Emerging Economies Driving Demand for Automotive Bearings

The affordability of vehicles has increased significantly over the past few years. Technological advancements have paved the way for cheaper vehicles, along with which, the increasing disposable income of people has made it easier for them to buy private vehicles. Owing to these factors, the global automotive industry has been registering considerable growth over the past few years. Developing countries, including China, Indonesia, India, and Thailand are majorly contributing to the growth of the automotive industry.

Bearings are majorly of three types, namely plain bearing, roller bearing, and ball bearing, among which, the demand for ball bearings has been the highest up till now. These bearings are utilized widely in two-wheelers and passenger cars. Ball bearings are further of different types, namely self-aligning, deep-grove ball bearing, angular contact ball bearing, and thrust ball bearing. In the coming years, however, the demand for roller bearings is projected to grow significantly.

This is due to the increasing sales of heavy-duty vehicles. In addition to this, the latest enhancements in heat generation and reducing friction by these bearings is also predicted to create their high demand for off-road vehicles and commercial vehicles. Thrust roller bearing, needle roller bearing, spherical roller bearing, cylindrical roller bearing, and tapered roller bearing are the different types of roller bearings. Among all these, the demand for tapered roller bearings is expected to be significantly high in the years to come.

Bearings are made of different kinds of materials, such as fiber-reinforced composite, solid polymer, and metal polymer. Out of these, the demand for metal polymer bearings has been the highest in the past, owing to the various advantages of this material, including long-lasting nature, cost-effectiveness, dimensional stability, and negligible stick-slip. Among the different vehicle types, the demand for automotive bearings is predicted to rise significantly for electric vehicles in the years to come.

The increasing acceptance of electric vehicles and government policies for encouraging their adoption are projected to drive the demand for automotive bearings in the years to come. The Asia-Pacific region emerged as the major automotive bearing market in the past and the situation is likely to remain the same in the years to come as well. The regional domain is being led by China, as the demand for automobiles in the country is on a rise. In addition to this, the exports of small-sized and low-end sized bearings are leading to the expansion of the domain in the country.

In conclusion, the market is growing due to the rapid expansion of the automotive industry in developing countries.

#Automotive Bearing Market Share#Automotive Bearing Market Size#Automotive Bearing Market Growth#Automotive Bearing Market Applications#Automotive Bearing Market Trends

1 note

·

View note

Text

Bearing Cost-Effectiveness in India: A Guide for Manufacturers and Buyers

https://glidexbearings.com/

In India's dynamic manufacturing landscape, cost-effectiveness is paramount. From sourcing raw materials to optimizing production processes, every decision significantly impacts a company's bottom line. And when it comes to critical components like bearings, the equation becomes even more crucial.

Why are Bearings Important?

Bearings play an indispensable role in various industries, including automotive, agriculture, construction, and more. They reduce friction, enabling smooth operation of machinery and extending equipment life. However, with a diverse range of bearing types and materials available, choosing the most cost-effective option can be a challenge.

https://glidexbearings.com/about-us-1/

Factors Affecting Bearing Cost-Effectiveness in India:

Type of Bearing: Different bearing types (ball bearings, roller bearings, etc.) cater to specific applications and load requirements. Understanding your application's needs is crucial for selecting the most economical option.

Material Selection: Bearing materials like stainless steel, chrome steel, and ceramic each offer unique advantages and cost considerations. Consider factors like corrosion resistance, temperature tolerance, and load capacity when making your choice.

Local vs. Imported Bearings: The cost of bearings can vary significantly depending on whether they are manufactured locally or imported. While locally-made bearings may seem cheaper initially, factors like quality, durability, and warranty should also be considered.

Supplier Reputation: Choosing a reliable supplier with a proven track record of quality and competitive pricing is essential. Look for suppliers who offer expert advice, timely delivery, and efficient after-sales service.

https://glidexbearings.com/category/bearings/

Optimizing Bearing Cost-Effectiveness in India:

Conduct a thorough needs assessment: Clearly define your application's requirements and operating conditions. This will help you narrow down your bearing choices and identify the most cost-effective option.

Compare prices from multiple suppliers: Get quotes from various suppliers to compare pricing and negotiate for the best deal.

Consider total cost of ownership (TCO): Don't just focus on the initial purchase price. Factor in maintenance costs, replacement costs, and potential downtime due to bearing failure when making your decision.

Partner with a reliable bearing expert: Collaborate with a knowledgeable supplier who can guide you towards the most cost-effective bearing solutions for your specific needs.

https://glidexbearings.com/contact-us/

Additional Tips for Indian Buyers:

Leverage government initiatives: The Indian government offers various schemes and subsidies to support domestic bearing manufacturers. Explore these options to potentially reduce your bearing costs.

Stay informed about market trends: Regularly research market trends to stay updated on fluctuating bearing prices and identify new, cost-effective bearing technologies.

https://glidexbearings.com/faq/

By following these strategies, manufacturers and buyers in India can make informed decisions about bearing selection, ensuring optimal cost-effectiveness without compromising on quality or performance. Remember, the most cost-effective bearing is not always the cheapest one. Choose the option that delivers the best value for your specific application and business needs.

https://glidexbearings.com/faq/

0 notes

Text

Wind Turbines to Radar: Examining the Varied Applications of Slewing Bearings

Slewing bearings, essential components in machines requiring robust handling, enable both to-and-fro and rotational movements. They find applications ranging from winches to complex machinery like drilling rigs and excavators. Notably, slewing bearings can support both horizontal and vertical arrangements, providing versatility not found in traditional bearings. The Asia-Pacific (APAC) region, particularly in countries such as Japan, South Korea, and China, exhibits a significant market for slewing bearings. In China, the market has seen rapid growth, attributed to government investments in solar projects and the expanding medical sector. However, challenges such as higher costs and limited resources impede further market growth.

𝐑𝐞𝐪𝐮𝐞𝐬𝐭 𝐒𝐚𝐦𝐩𝐥𝐞 𝐏𝐃𝐅 𝐁𝐫𝐨𝐜𝐡𝐮𝐫𝐞 : https://www.alliedmarketresearch.com/request-toc-and-sample/16356

COVID-19 Impact Analysis

The global impact of the COVID-19 pandemic has been substantial, affecting various industries, including slewing bearings in 2020. With the World Health Organization declaring a public health emergency, the virus has disrupted international trade, manufacturing, tourism, and financial sectors, amplifying the downward pressure on the global economy. Import and export restrictions have significantly impacted the slewing bearings market, reflecting changes in consumer consumption patterns amid the pandemic.

Top Impacting Factors

Currently, slewing bearings are experiencing increased demand, driven by their expanding applications in infrastructure and renewable energy. Governments globally are investing significantly in these sectors, with slewing bearings playing a crucial role in windmill turbines. The importance of the infrastructure industry is recognized worldwide, further boosting the market. Additionally, the automotive industry's need for material handling equipment, including cranes and forklifts with slewing bearings, contributes to market growth.

Market Trends

The cost-effectiveness and versatile applications of slewing bearings are expected to propel the global market, particularly in the infrastructure industry. The bearings' ability to carry heavy loads, coupled with their cost-effectiveness, makes them integral to various applications, including factory automation, renewable energy, and healthcare. The application of slewing bearings in forest machinery projects, where robust design and optimized components are essential, creates significant opportunities. Urbanization and industrialization further drive market growth, with increased demand from end-user industries like healthcare and solar energy.

𝐄𝐧𝐪𝐮𝐢𝐫𝐲 𝐁𝐞𝐟𝐨𝐫𝐞 𝐁𝐮𝐲𝐢𝐧𝐠 : https://www.alliedmarketresearch.com/purchase-enquiry/16356

Key Benefits of Report

The report offers an analytical depiction of the slewing bearings industry, presenting current trends and future estimations for potential investment opportunities. It provides insights into key drivers, restraints, and opportunities, along with a quantitative analysis of market growth. Porter's five forces analysis illustrates the market's competitive landscape, guiding strategic decision-making.

By Type:

Internal Tooth

External Tooth

Without Tooth

By Design:

Cross Roller Slewing Ring Bearing

Bi-angular Roller or Taper

Single-row Four Point Contact Ball Slewing Ring Bearing

Four- and Eight-point Contact Ball

Three-row Roller Slewing Ring Bearings

Double-row Ball Slewing Ring Bearings

Others

𝐆𝐞𝐭 𝐚 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐞𝐝 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭 : https://www.alliedmarketresearch.com/request-for-customization/16356

By Application:

Radar

Mining

Construction

Wind Turbines

Onshore

Offshore

Others

By Region:

North America (U.S., CANADA, MEXICO)

Europe (FRANCE, GERMANY, ITALY, SPAIN, UK, Rest of Europe)

Asia-Pacific (CHINA, JAPAN, INDIA, SOUTH KOREA, Rest of Asia-Pacific)

LAMEA (Brazil, Saudi Arabia, South Africa, Rest of Lamea)

Key Market Players:

ThyssenKrupp Group

Rotis

NTN Corporation

IMO Group

Timken Company

SKF

Schaeffler Group

NSK Ltd.

Kinematics Manufacturing Inc.

Fortigal Group S.p.a

0 notes

Video

youtube

Elevate Your Machinery with MARC Bearings Pvt. Ltd's Premium Offerings.

MARC Bearings Pvt. Ltd is one of the leading bearing companies in India that manufactures and exports Automotive and Industrial bearings as per international standard specifications. MARC stands with courage, knowledge and an eye to innovation to produce technologically advanced bearings that reach perfection when it comes to seamless performance.

Since its inception in 1995, it has been manufacturing, supplying and exporting a plethora of bearings including Tapered roller bearings, Spherical roller bearings, Cylindrical roller bearings, and Ball bearings. Meeting high level of excellence and international standard specifications, these bearings effectively used in manufacturing of automobiles, agricultural, Industrial, power motors, appliances and a host of other applications. Efficiency never takes a back seat whether radial or thrust loads and even with high speed rotation. This certainly becomes one of the core strengths of the MARC.

Quality is one of the core strength of MARC, which has developed by adopting and implementing ISO 9001 quality management system. The entire operation right from the procurement of Raw material, SAE 52100 Steel verified by a Test Certificate of Chemical & Physical analysis and ends at thorough inspection of the manufactured bearings just before the packing stage. A well equipped laboratory, years of experience, engineers’ hands on talent and competence of quality check experts all conjure to meet the stringent quality requirements that bearings need in terms of efficiency and performance.

MARC also deals in customized bearings in accordance to customer’s needs, samples or designs. It also holds high level of flexibility so as to attune itself to the changing needs and requirements of the domestic as well as international market. With this, MARC strives to create a reliable and innovative environment to provide the most cost effective and high-quality bearings on a global scale.

#youtube#MARCbearings BearingExcellence IndustrialBearings AutomotiveBearings PrecisionEngineering QualityPerformance InnovationInBearings Internatio

0 notes

Text

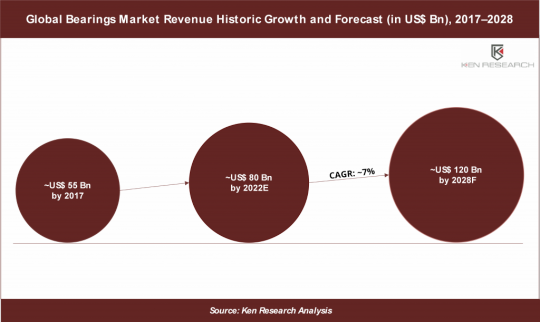

Global Bearings Market is forecasted to grow further into US$ 120 billion Opportunity by 2028: Ken Research

Buy Now

What is the Size of Global BEARING INDUSTRY?

Global Bearing market is growing at a CAGR of ~% in 2017-2022P and is expected to reach ~USD Bn by 2028F.

The Bearing Market is largely driven by continuous upgradation in the product from multiple players, and growing usage of bearings.

New product launches by players and collaboration among the industry is one of the driving factors of the Global Bearing Market. For instance, In June 2022, The Timken Company announced that it is designing and supplying main shaft bearings for GE Renewable Energy Haliade-X, the world’s most powerful offshore wind turbine. Furthermore, In December 2020, The Timken Company acquired the assets of Aurora Bearing Company.

Aurora manufactures rod ends and spherical plain bearings, which serve a diverse range of defense sector.

Interested to Know More about this Report, Request for a sample report

Counterfeit products are posing one of the major challenges for the Bearings Market. Leading companies in bearings product manufacturing are more open to this threat. Manufacturing fake products lead to machine damage and injuries. For instance, In October 2019, JTEKT cooperated with World Bearing Association (WBA) and its efforts against counterfeiting globally by developing a new WBA Check App (WBA Bearing Authenticator) to protect its customers and dealers from property damage risk, injuries, and other events.

GLOBAL BEARING MARKET BY PRODUCT TYPE

The Global Bearing market is segmented by Product type into Plain Bearing, Ball Bearing, Roller Bearing and Others.

Rolling bearing segment held the largest market share of the Global Bearings Market in 2022P. Rolling bearings are used in multiple industries such as automotive, capital equipment, aerospace, home appliances, and others

Roller bearing is a type of rolling-element bearing that used a cylinder instead of a ball. Roller bearings are used in all main shaft and auxiliary drive shaft applications to support the pure radical load.

In July 2021, NTN Bearing Corporation announced the latest innovation, the KIZEI spherical roller bearing. Spherical roller bearings are manufactured with metallic shields that protect the bearing from solid contamination such as dust, pebbles, and other debris.

GLOBAL BEARING MARKET BY APPLICATION TYPE

The Global Bearing Market is segmented by Application into Automotive, Application Transmission, Aerospace & Defense, Construction and Others.

The automotive segment accounted for the largest market share in 2022P, owing to the surging automobile production worldwide.

Visit this Link :- Request for custom report

The increasing demand for vehicles is leading the automotive segment and is forecasted to be the fastest-growing segment in the forecast period.

In September 2022, SKF and NIO, a leading premium smart electric vehicle manufacturer, have strengthen the strategic corporation. As part of the agreement, SKF will be the preferred supplier of ceramic ball bearings.

GLOBAL BEARING MARKET BY GEOGRAPHY

The Global Bearing market is segmented by geography into North America, Europe, Asia- pacific and LAMEA.

Asia Pacific accounted for the largest market share within the Global Bearings Market in 2022P, owing to surging machinery and motor vehicle production.

The increasing demand for aftermarket products for industrial equipment and motor vehicle repair. The surging construction and mining industry requires efficient industrial tools to operate, which further propels the growth of this region. Presence of leading companies manufacturing bearings products, like JTEKT Corporation, NSK Ltd., NTN Corporation, HKT Bearings Ltd., and others, are expected to further boost the expansion of this market.

For More Insights On Market Intelligence, Refer to the Link Below: –

Global Bearings Market

#Africa Bearings Market Forecast#Asia Pacific Bearings Market#Automotive Bearings Supplying Companies#Ball Bearings Market#Bearings Material Suppliers Globally#Bearings Products Market#Bearings Raw Material Suppliers#Challenges in Growth of Bearings Market#Competitors in Bearings Market#Demand for Bearing in Consumer Sector#Distributors of Bearings Globally#Emerging Companies in Bearing Market#Europe Bearings Market Forecast#Global Ball Bearing Market#Global Ball Screw Market#Global Bearing Distributors#Global Bearings Industry#Global Bearings Industry Outlook#Global Bearings Market#Global Bearings Market Trends#Global Flexure Bearings Market#Global Magnetic Bearings Market#HKT Linear Bearings Market#India Bearings Market#Investment in Bearing Manufacturing Start-ups#JTEKT Deep Groove Ball Bearings Market#Latin America Bearings Market Forecast#Leading Players in Bearing Market#Major Players in Bearings Market#Middle East Bearings Market Revenue

0 notes

Text

0 notes

Text

Quality and Precision Bearing by Paramount Bearing Company in Delhi's Bearing Market

Welcome to the world of bearings, where efficiency, performance, and reliability all come together. One name stands out in the bearing sector in the busy city of Delhi, and that is Paramount Bearing Company. Paramount Bearing Company has become a reputable Bearing Supplier in Delhi thanks to its reputation for excellence and dedication to providing top-notch goods and services. Come along as we go into the intriguing world of bearings, examine the several kinds that are available, and learn about the first-rate services provided by Paramount Bearing Company.

Regarding Bearings

By providing effective rotational or linear motion, bearings are essential in a variety of sectors. Bearings come in many different types,

Ball Bearings: These popular bearings feature rolling elements in the form of steel balls. They are widely used in applications that require low friction, high speed, and precise rotation, such as electric motors, automotive components, and machinery.

Roller Bearings: Roller bearings utilize cylindrical or tapered rolling elements instead of balls. They excel in handling heavy radial or axial loads and are commonly used in industries like mining, construction, and heavy machinery.

Thrust Bearings: Thrust bearings are specifically designed to support axial loads and facilitate rotational movement in one direction. They find application in automotive transmissions, aerospace systems, and industrial machinery.

Needle Bearings: Needle bearings are compact and lightweight, featuring long, thin rollers. They are suitable for applications with limited space and high load requirements, such as automotive engines, gearboxes, and printing machinery.

Services Offered in Delhi

High-Quality Bearings: Paramount Bearing Company sources bearings from recognized producers with an emphasis on quality, ensuring genuine and dependable products that adhere to exacting industry standards.

Technical Support: The business offers knowledgeable technical support and consulting to assist customers in selecting the best bearings for their unique needs. The highly qualified team at Paramount Bearing Company helps with bearing-related problems and performance optimization.

Logistics and on-time delivery: Paramount Bearing Company is aware of the value of on-time delivery. To ensure fast and dependable distribution of bearings throughout Delhi, they have effective logistical systems in place.

Our Objective:-

As a dependable source of bearings in Delhi, Paramount Bearing Company shows a dedication to quality and client satisfaction. Go on a path of improved performance, efficiency, and dependability by placing your trust in their knowledge.

For more details Contact us:-

Paramount Bearing Company

Address: 674/75, 2nd Floor, Asha Bhawan

Behind G. B. Road, Delhi, 110006

Phone: +91-6291607327

Email: [email protected]

Website:www.paramountbearing.com

#Bearing Supplier in Delhi#Bearing Supplier in Kolkata#Bearing Supplier in Mumbai#Bearing Supplier in Chennai#Bearing Supplier in Ahmedabad#Bearing Supplier in Pune#Bearing Supplier in Ludhiana#Bearing Supplier in Chandigarh#Bearing Supplier in Punjab#Bearing Supplier in Jammu & Kashmir

0 notes

Text

Automotive Wheel Bearing Aftermarket Future Scenario, Key Insights, Top Companies 2032

The global automotive wheel bearing aftermarket is set to witness an impressive growth rate of 4% over the forecasted years of 2022 to 2032. The contact market size is anticipated to reach a valuation of around US$ 58.8 Billion by the end of year 2032 from the current valuation of US$ 39.75 Billion in 2022.

The worldwide growth of the automobile sector can be regarded as the major factor having a strong positive impact on the aftermarket for automotive wheel bearings. The manufacturing of passenger, luxury, commercial, and other types of cars is also increasing, which is causing a significant increase in demand for automobile wheel bearings across all nations.

Ball bearings and taper roller bearings are the two bearing types often used in passenger automobiles. Additionally, they change based on the application and load. The heavy demands placed on a wheel hubs car are growing due to expanding transit volumes, improved performance, and altered driving habits.

On a different dimension, as automated driving systems are entirely controlled by sensors, there is a strong demand for automotive wheel bearing in this industry as well. As ball thrust bearings are often employed for low speed, non-precision applications, they are needed for mostly in agriculture and transport vehicles as typically these run comparatively at low speeds in the fields.

This type of automotive ball bearings support axial stresses in both directions when used in back-to-back pairs. The need for tapered roller bearings is also anticipated to increase more in the next years as the automotive sector is anticipated to expand.

For more information: https://www.futuremarketinsights.com/reports/automotive-wheel-bearing-aftermarket

Key Takeaways from Automotive Wheel Bearing Aftermarket Study

The overall growth of the global automotive wheel bearing aftermarket is estimated to be around US$ 19 Billion over next ten forecast years ending in 2032, by following the global CAGR of 4%.

According to the different end use applications of automotive wheel bearing, the segment with the fastest-growing vehicle type by far is the passenger automobile.

As in automobile industry, there has been an impressive growth in demand for thrust bearings in last couple of years.

On the basis of components, the automotive wheel bearing aftermarket is now led by tapered roller bearing, and this position is expected to hold during the projected period.

South Asia and Pacific countries are the dominating markets for the sales of automotive wheel bearing with growing volume of automobile market.

Competitive Landscape for the Global Automotive Wheel Bearing Aftermarket

Some of the well-known contact automotive wheel bearing aftermarket players are Federal – Mogul Corporation (Tennenco Inc.), Schaeffler AG, Mahle GmbH, Continental AG, The Timken Company, NSK Ltd., JTEKT Corp, NTN Corporation, Rheinmetall AG, NRB Bearings Ltd., Nachi – Fujikoshi Corp., MinebeaMitsumi Inc., and Wafangdian Bearing Group Corporation among others.

As the automotive market is well developed in almost all parts of the world so the automotive wheel bearing market is highly fragmented. Thus mergers and acquisitions are a very common feature in this sector. For instance, Drake Manufacturing Services. Co. LLC was bought by CW Bearings USA, Inc. in the year 2017. The business was able to join the Machine Tools sector thanks to the purchase.

Shortly after, the global market saw the acquisition of ABC Bearings Ltd., an Indian manufacturer of conical or tappered, circular or round roller bearings as well as slewing rings, by Timken India Ltd, which is a division of The Timken Company.

0 notes

Link

0 notes

Text

The latest report on the Worldwide Automotive Ball and Roller Bearings Market Report is the more professional in-depth of this Industry is providers the status and forecast, categorizes, market size (value & volume) by type, application, region and Forecast 2023 - 2030.

0 notes

Text

Automotive Bearing Market Demand, Scope and Future Estimation until 2026

The Automotive Bearing Market is a highly competitive and rapidly growing market, driven by the increasing demand for automobiles and the need for efficient and durable bearings. Automotive bearings are used in a variety of applications, including wheel bearings, transmission bearings, and engine bearings, and are critical components in ensuring the smooth operation of vehicles.

The market for automotive bearings is segmented by product type, application, and geography. By product type, the market is segmented into ball bearings, roller bearings, and others. Ball bearings are the most widely used type of automotive bearings and are expected to dominate the market due to their high load-carrying capacity and low cost.

By application, the market is segmented into passenger cars, commercial vehicles, and two-wheelers. The passenger car segment is expected to dominate the market due to the increasing demand for cars in emerging economies and the growing use of advanced technologies in these vehicles.

Geographically, the market is segmented into North America, Europe, Asia Pacific, and Rest of the World. Asia Pacific is expected to dominate the market due to the presence of major automotive manufacturers in the region and the increasing demand for cars in countries such as China and India.

For More Info @ https://www.persistencemarketresearch.com/market-research/automotive-bearing-market.asp

Key players in the automotive bearing market include SKF, NTN Corporation, NSK Ltd., Timken, JTEKT Corporation, Schaeffler AG, and others. These companies are focusing on strategic collaborations, partnerships, and acquisitions to expand their market presence and enhance their product offerings.

In conclusion, the Automotive Bearing Market is expected to grow at a steady rate during the forecast period due to the increasing demand for automobiles and the need for efficient and durable bearings. The market will be driven by the increasing demand for cars in emerging economies, the growing use of advanced technologies in vehicles, and the efforts of key players to expand their market presence through strategic collaborations and acquisitions.

0 notes

Text

Reason for Using Ball Bearings

When a ball bearing rolls over the hard surface of its races, it creates a minute elastic groove that recovers after the ball passes. They use separate two "races," or bearing rings, to reduce surface contact and friction across moving planes. The rotating motion of the balls reduces the coefficient of friction when compared to flat surfaces that rub against each other. Ball bearings are made up of four major components: two rings/races, the balls (the rolling elements), and the retainer (the ball separator).

PRECISION

One of the best aspects of mechanics in general is unquestionably precision. Precision ball bearings, however, rank first among watchmakers, machine tool manufacturers, and aerospace manufacturers. Ball bearing manufacturers frequently use tolerances of less than one micron (one millimetre divided by 1,000, or 0.001 mm), demonstrating the high level of precision required and the necessity of keeping up with technological advancements to meet customer expectations.

VARIETIES

ball bearings suppliers provides different types such as ball, roller, needle, ceramic, titanium, stainless steel, radial, axial, angular contact, twin ball races, to 4 points of contact bearings, etc.

This subject is appealing and fascinating due to the enormous variety, particularly given the diverse bearing applications in the industry and the demand for innovations among end users.

FUNCTIONALITY

In actuality, the ball bearing allows for more than just circular motion. Additionally, it is the part that supports axial and radial stresses, including those from speed sensors, absorbs alignment mistakes in systems, or thermally and electrically isolates the parts to lower maintenance. So for thrust bearings include transferring thrust loads applied on the shaft and preventing the shaft from drifting in the axial direction. Typically, thrust ball bearing suppliers inform you or can guide you all about why you choose this type for your application.

ADAPTABILITY

Standard ball bearings come in a wide variety of varieties, however their unique requirements may not always be met by these dimensions. To address the most cutting-edge and outlandish requirements of many industries, including healthcare, building technology, automotive, and consumer products, small and medium-sized manufacturers of customised ball bearing solutions have emerged. Here, engineers can benefit from imagination, which frequently yields helpful solutions to problems. Ball bearing design is crucial, but some manufacturers go one step further by providing steel bearings with a plastic covering for even more performance options and component weight savings.

ECONOMY

In 2010, the global market for ball bearings company was valued at more than 40 billion dollars. This is important information. The ball bearing has significant economic value because it supports thousands of employment globally, and this fact demands some respect. The bearings also help to the green movement by offering yet less friction and hence less energy usage.

#ball bearing#ball bearing company#ball bearings suppliers#thrust ball bearing suppliers#industrial ball bearings#ball bearing manufacturers

0 notes

Text

Best Self-aligning Bearing Manufacturers in India

Self-aligning Bearing is a type of bearing designed and utilized to accommodate misalignment between the housing and shaft is referred to as a self-aligning bearing. Self-aligning ball bearings, spherical roller bearings, toroidal roller bearings, and self-aligning thrust bearings are examples of self-aligning bearings. Self-aligning ball bearing designs include the following: open, sealed, tapered bore with adapter sleeve and extended inner ring version with unique bore tolerances for commercial ground shafting applications

Features and Benefits Allows for Misalignment Extremely low friction and heat generation Environmentally friendly High-speed performance Low lubricant usage Low noise and vibration levels High-speed performance Increases productivity Applications Cereal Mills Staple machines for magazines Process pumps for refineries and power plants Luggage conveyor systems Shredders for fruit farms Industrial Fans Carton Boards Ring spinning machines for the production of yarn Twisting machines for the production of thread Centrifugal separators.

Best Self-aligning Bearing Manufacturers in India-igus

It should come as no surprise that there are so many different bearing names and types that bearing manufacturing companies in India are in high demand. Over the past ten years, there have been industry scandals, a growing market for counterfeit bearings, and the global economic crisis of 2008. Following the market crash, ripples surged through all industries, particularly automotive, which, according to Global Industry Analysts (GIA), accounts for approximately a quarter of international bearing sales. The shaft's angular misalignment with the housing has no effect on the bearings.

Double-row, self-retaining self-aligning ball bearings have solid outer rings with concave raceways, solid inner rings with cylindrical or tapered bores, and ball and cage assemblies. Both open and sealed versions of the bearings are available.

The best Online shop for plain bearings: The fundamental idea and goal of all iglidur® polymer plain bearings is to reduce costs while also increasing service life. There is no need for lubrication, there is less work to do on maintenance, and everything is delivered right away from stock.

Best Self-aligning Bearing Manufacturers in India-igus

At igus, you get Sleeve bearings, flange bearings, thrust washers, piston rings, clip-on plain bearings, and numerous other designs are available in the igus® plain bearings collection. Iglidur® plain bearings always provide a solution, either as a standard product from the catalog or as a custom-made special solution for plain bearings. No minimum order!

Iglidur® bearings are suitable for all moving applications, including underwater applications, special mechanical engineering, automotive mass production, the food or tobacco industries, and simple sheet-metal bushings due to their resistance to extreme temperatures and chemicals.

Best Self-aligning Bearing Manufacturers in India-igus

iglidur® GLW, sleeve bearing with flange, mm Resistant to shocks and impacts Resistant to dirt and dust Resistant to high loads (>60N/mm2) Fogging behavior in accordance with DIN 75201-B Low-cost material for high-volume production beginning at 78.40 INR/Pc

9.18 INR/Pc. from 1,000 units

23 items are ready to ship, including:

4 in 2 weeks RoHS compliant Iglidur® SG03, flanged sleeve bearing and felt seal, mm Clean bearings even with dirt and dust, thanks to the felt seal. In laboratory tests, a service life that was up to 50 times longer was achieved.

Visit the website to know more.

0 notes

Text

How high speed ball bearings can help in handling the high speeds achieved on the transmission input shaft?

Several new types of transmissions have been developed in the last few years to enhance the driving experience and reduce fuel consumption. The evolution of this technology is providing drivers utmost comfort and is playing an instrumental role in the growth of electric vehicles. While buying a car or a commercial vehicle consumers want an improved transmission system that can offer ease in driving, comfort and an enhanced experience.

Various components help in improving the transmission system. One among them is high-speed ball bearings. Schaeffler’s high speed cylindrical rolling bearings contribute greatly to this improvement. They are used in the electrified drive systems. They help in handling the high speed achieved on the transmission shaft and attaining greater efficiency and service life for powertrains.

What are the benefits of using high speed cylindrical rolling bearings?

The cylindrical roller bearings are very adaptable and have a wide range of uses such as in road rollers, compressors, pumps, industrial fans, etc. They are used in different industries to reduce friction among different parts of the machine. Hence, in the market, numerous varieties of cylindrical roller bearings are available, in different shapes and sizes. They differ depending on the cages and the number of rows of rollers (often one, two, or four).

These bearings have a high radial load capacity and they are suitable for high speeds. The vehicles can achieve high speed. They remain in linear contact with the raceways. They are designed to be reliable and a good fit for the environment.

Cylindrical roller bearings support a load by inserting rolling components like balls or rollers between two bearing rings known as races. The relative motion of the races reduces rolling resistance and supports rolling elements to roll freely.

The performance and design of high precision cylindrical roller bearings make them suitable for different applications. In comparison to a ball bearing, these bearings have a high resistance to shock and fatigue. Also, they can easily be mounted and dismounted on a shaft. Their unique design makes this possible. Due to their special design, they can take the radial load (N and NU type) and thrust load (NJ and NUP type) simultaneously.

Most importantly, cylindrical roller bearings don’t require too much lubrication care. A very low quantity of lubricating oil can keep them functioning well for a longer period of time. This gives vehicle owners and drivers respite in maintenance work.

Why you should choose it?

Primarily, it improves vehicles’ capacity to achieve and maintain high speed on the transmission input shaft. It improves components’ movement in the machine by reducing fiction. So, ultimately, it offers you a great driving experience.

Also, cylindrical roller bearings are easy to install bearing solutions. While installing, you cannot inflict any damage on the other parts of the machine. At the same time, as it doesn’t require heavy lubrication and maintenance, it saves money and time.

Schaeffler, a leading industrial and automotive supplier, offers the best bearing solutions to meet the evolving needs and requirements of the automotive industry. You can reap the benefits of the solutions provided by the company. The super-precision cylindrical roller bearings resolve your worries related to managing the high speed achieved on the transmission input shaft. It will improve your driving experience significantly.

0 notes