#Automotive Vacuum Pump Market Size

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Why Tekman is the Leading Dry Vacuum Pump Manufacturer

In the competitive world of vacuum technology, Tekman has established itself as a leader in the manufacturing of dry vacuum pumps. Known for its commitment to innovation, quality, and customer satisfaction, Tekman offers a range of advanced solutions, including dry vacuum pumps, helium leak detectors, helium leak testing machines, and helium recovery systems. This article explores why Tekman stands out as the premier choice for these critical industrial tools.

Unmatched Quality in Dry Vacuum Pumps

The foundation of Tekman's standing as a top producer of dry vacuum pumps is its consistent commitment to quality. The company's dry vacuum pumps are made to operate with exceptional efficiency, dependability, and performance. Because these pumps don't use oil, there is no chance of contamination, and maintenance expenses are lower. Through the application of cutting-edge innovation and premium materials, Tekman guarantees that our pumps provide remarkable endurance and durability.

The dry vacuum pumps made by Tekman are designed to work in a variety of environments, including industrial and laboratory settings. They are perfect for jobs needing high vacuum levels because of their precise engineering, which enables maximum vacuum performance. Because of the company's dedication to quality control, every pump is put through a thorough testing process to make sure it satisfies the highest requirements before being delivered to the customer.

Advanced Helium Leak Detectors

To find and quantify leaks in systems and components, helium leak detectors are indispensable instruments. Helium leak detectors made by Tekman are well known for their precision, sensitivity, and dependability. Because of its small atomic size and high permeability, helium is used as a tracer gas in these detectors to detect even the smallest leakage.

Modern technology powers Tekman's helium leak detectors, enabling accurate and quick leak detection. Operators can quickly and easily locate leaks because of their extensive features and user-friendly UI. Maintaining the integrity of expensive machinery and guaranteeing operational effectiveness across a range of sectors, such as industrial, automotive, and aerospace, depend heavily on this skill.

Precision in Helium Leak Testing Machines

To guarantee the dependability and security of goods and systems that function under pressure or vacuum, a helium leak testing Machine is essential. The helium leak testing apparatuses from Tekman are an essential tool for quality control because of their ability to produce reliable and consistent results.

These testing devices use cutting-edge technology to carry out exacting leak tests. They can find even the smallest breaches that could jeopardize the functionality of vital systems. Because of Tekman's dedication to precise engineering, their helium leak testing equipment produces accurate data that enables producers to uphold strict quality and safety standards.

Efficient Helium Recovery Systems

Because helium is a scarce and precious resource, cost containment and environmental sustainability depend on its recovery and reuse. The helium recovery systems from Tekman are made to effectively recover and recycle helium, which lowers waste and operating expenses.

The recovery systems made by Tekman are designed to handle helium in huge quantities very effectively. They use cutting-edge compression and filtering techniques to guarantee that recovered helium is cleaned and fit for reuse. This promotes a more economical and sustainable operation in addition to helping to conserve a valuable resource.

Innovation Driving Tekman’s Success

Tekman's dedication to innovation is the main factor behind its leadership in the dry vacuum pump market. To keep abreast of market trends and technological breakthroughs, the organization makes significant investments in research and development. Tekman's emphasis on innovation enables it to consistently enhance its range of products and present novel approaches that cater to the changing demands of its clientele.

Tekman has achieved new performance and efficiency benchmarks by utilizing vacuum engineering know-how and combining state-of-the-art technologies. The company's creative methodology guarantees that, in addition to being dependable, its products offer exceptional performance over a broad spectrum of applications.

Customer-Centric Approach

Tekman's success can also be attributed to its customer-centric strategy. The business places a high priority on comprehending and meeting each customer's wants. To guarantee that its products perform and give value as promised, Tekman provides extensive support and service.

From first advice to after-sale assistance, Tekman's team of professionals is committed to providing top-notch support. Because of its dedication to client satisfaction, Tekman has established a solid name in the sector for dependability and credibility.

Comprehensive Product Portfolio

In addition to dry vacuum pumps, Tekman offers a variety of cutting-edge products, including helium leak detectors, helium leak testing equipment, and helium recovery systems. With this extensive portfolio, Tekman can cater to a wide range of applications and industries, offering integrated solutions that are tailored to each sector's unique requirements.

Tekman's solutions are engineered to yield remarkable outcomes, be it for dependable vacuum performance, effective helium recovery, or high-precision testing. Customers can find the ideal solution for their unique needs thanks to the company's ability to provide a full array of products.

Tekman's steadfast dedication to quality, innovation, and client happiness has earned it the title of top dry vacuum pump manufacturer. With a wide selection of products, such as helium recovery systems, dry vacuum pumps, helium leak detectors, and helium leak testing equipment, Tekman provides complete solutions that satisfy the demands of different industries.

The company's emphasis on sustainability, cutting-edge technology, and precision engineering guarantees that its products offer remarkable performance and value. Tekman is the best option for companies looking for dependable and effective vacuum and leak detection systems because of its commitment to quality and customer-centric business model.

#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System#Dry Vacuum Pump Manufacturer#Dry Vacuum Pump

0 notes

Link

0 notes

Text

Air Compressor Equipment & Services in Los Angeles, California

OUR COMMITMENT

YOUR TRUSTED COMPRESSED AIR SOLUTIONS PROVIDER IN LOS ANGELES, CALIFORNIA

At Pattons CA, we take pride in being your premier partner for all your compressed air needs in Los Angeles, CA. With years of experience in the air compressor industry, we offer a comprehensive range of top-quality air compressor products, unrivaled services, and OEM and after-market parts to ensure your operations run seamlessly and efficiently.

Based in Cerritos, California, the Pattons CA team provides compressed air solutions and services to all of Southern California. Our team members are experts in identifying cost saving opportunities for your compressed air system. So, whether you need a routine service or looking to upgrade your compressed air system, Pattons CA is here for you.

CONTACT US

OUR COMPRESSED AIR PRODUCTS

Discover a diverse selection of quality air compressors, vacuum & blowers, compressed air dryers, condensate management equipment, and more! Pattons of California offers compressed air system products that are engineered to deliver unparalleled performance. Our compressed air products are designed to meet the demands of various industries such as food and beverage, aerospace, automotive, textile, and electronics.

Compressed air is vital to the operations of facilities. That is why Pattons CA partners with CAGI certified brands such as ELGi Air Compressors, Champion Air Compressors, BEKO Compressed Air Dyers to ensure our customers can purchase with confidence and have reliable and trusted compressed air solutions.

Explore our offerings of air compressors, compressed air dryers, compressed air piping, vacuum pumps, filtration, nitrogen generators and more!

Air Compressor Products

PCA has a wide range of reliable, high quality, energy-efficient & low maintenance air compressors. You can count on us for all your compressed air needs.READ MORE

Compressed Air Dryers

When it comes to keeping your compressed air system free from contamination, You'll need Air dryers. At PCA, we can recommend best dryer products that meet your unique specifications.READ MORE

Compressed Air Piping

PCA offers compressed air piping for all applications including stainless steel, aluminum and more! We can install your new pipes on-site in a fast and professional manner.READ MORE

When it comes to selecting the compressed air equipment there are many factors to consider. There are many different air compressor technologies including rotary screw, reciprocating/piston, centrifugal. Size and application of compressed air is also important to consider. Our team works closely with you to determine the right equipment for your specific needs. Reach out to the Pattons of California team to help you make the best decision for your operation. We offer complimentary system assessments to help you determine the best air compressor equipment for your business.Request Free Assessment

PROVIDING QUALITY AIR COMPRESSOR SERVICES IN LOS ANGELES, CA

At Pattons CA, we specialize in providing top-notch air compressor services in Los Angeles, CA, and the surrounding areas. With over 70 years of experience in the industry, we are dedicated to delivering prompt and cost-effective compressed air services

Pattons of California services all major brand compressors including ELGi, Atlas Copco, Ingersoll Rand, Kaeser, Gardner Denver, and Quincy compressors! We keep OEM and aftermarket parts and equipment in stock at our Cerritos, CA warehouse so we can quickly address your needs.

Don't let air compressor problems disrupt your business.Contact Pattons of California for reliable air compressor services in Los Angeles, CA. Our team is ready to assist you.

CONTACT ADDRESS

Pattons of California LLC

16312 Bloomfield Ave,

Cerritos, CA 90703

EMAIL

CALL US

562 229 0955

Read More

#elgi air compressor dealers#Air compressor distributor los angeles#Air compressor parts in los angeles#Air compressor distributor california#Elgi air compressor dealers in los angeles#Air compressor dealers in los angeles#Air compressor dealers in california#zeks air dryer

0 notes

Text

Global Top 14 Companies Accounted for 94% of total Semiconductor Dry Vacuum Pump market (QYResearch, 2021)

A vacuum pump is a device used to generate, improve and maintain a vacuum environment according to a certain working principle. It is an indispensable product that directly affects the performance and quality of vacuum complete equipment. Dry vacuum pumps are non-contact vacuum pumps that do not use oil or seals.

In order to control the manufacturing process to smaller dimensions, it is increasingly necessary to perform more semiconductor manufacturing process steps with greater precision and uniformity. To achieve this, semiconductor processes must operate in an extremely controlled vacuum environment. At present, vacuum pumps have been widely used in many process links of semiconductor manufacturing, including etching, coating, diffusion and so on.

According to the new market research report “Global Semiconductor Dry Vacuum Pump Market Report 2023-2029”, published by QYResearch, the global Semiconductor Dry Vacuum Pump market size is projected to reach USD 2.24 billion by 2029, at a CAGR of 8.9% during the forecast period.

Figure. Global Semiconductor Dry Vacuum Pump Market Size (US$ Million), 2018-2029

Figure. Global Semiconductor Dry Vacuum Pump Top 14 Players Ranking and Market Share (Ranking is based on the revenue of 2022, continually updated)

The global key manufacturers of Semiconductor Dry Vacuum Pump include Atlas Copco (Edwards Vacuum), Ebara Corporation, Pfeiffer Vacuum GmbH, LOTVACUUM, Kashiyama Industries, Hanbell Precise Machinery, Busch Vacuum, SKY Technology Development, ULVAC, Inc, Osaka Vacuum, Ltd, etc. In 2022, the global top five players had a share approximately 94.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Vacuum Sucker Market Size, Trends, Growth and Forecast to 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Vacuum Sucker Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Vacuum Sucker Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Vacuum Sucker?

The global vacuum sucker market size reached US$ 730.8 million in 2023. Looking forward, Reports and Insights expects the market to reach US$ 1,245.2 million in 2032, exhibiting a growth rate (CAGR) of 6.1% during 2024-2032.

What are Vacuum Sucker Market?

A vacuum sucker, or vacuum suction cup, is a device designed to lift and handle objects using vacuum pressure. It typically features a flexible cup made from materials like rubber or silicone, which is connected to a vacuum pump. When air is removed from the cup, a vacuum is formed, causing the cup to adhere securely to the surface of the object. This technology enables the efficient handling, lifting, and movement of items without manual gripping or complex machinery, making it useful in various fields such as manufacturing, packaging, and robotics.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1901

What are the growth prospects and trends in the Vacuum Sucker Market industry?

The vacuum sucker market growth is driven by various factors and trends. The vacuum sucker market is experiencing notable growth, driven by the increasing adoption of automation in industries such as manufacturing, logistics, packaging, and robotics. These devices are crucial for the efficient and safe handling of materials, reducing manual labor and boosting productivity. Innovations in suction technology, along with advancements in materials and design, are broadening their application across various sectors. The demand is also rising due to the need for precision and reliability in automated systems, as well as a focus on workplace safety and ergonomic solutions. With the continued shift towards automation, the vacuum sucker market is set for ongoing expansion. Hence, all these factors contribute to vacuum sucker market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Type:

Electric Vacuum Suckers

Pneumatic Vacuum Suckers

Hybrid Vacuum Suckers

By End-Use Industry:

Automotive

Electronics

Food & Beverage

Packaging

Pharmaceutical

Logistics & Warehousing

Others

By Application:

Material Handling

Assembly & Robotics

Pick & Place

Packaging & Palletizing

Inspection & Testing

Others

By Sales Channel:

Direct Sales

Distributors/Wholesalers

E-commerce

Global Market Segmentation by Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europ

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

Piab AB

Schmalz Inc.

Festo AG & Co. KG

SMC Corporation

Aventics GmbH

VACUUBRAND GMBH + CO KG

Vaccon Company, Inc.

SMC Corporation of America

Pneumadyne, Inc.

Schmalz GmbH

Vuototecnica S.p.A.

DESTACO, a Dover Company

ANVER Corporation

AERO-LIFT Vakuumtechnik GmbH

VMECA Co., Ltd.

Discover more: https://www.reportsandinsights.com/report/Vacuum Sucker-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

#Vacuum Sucker Market Size#Vacuum Sucker Market Share#Vacuum Sucker Market Demand#Vacuum Sucker Market Analysis

0 notes

Text

Powder Coatings Market - Forecast(2024 - 2030)

Powder Coatings Market Overview

The Powder Coatings Market size is forecasted to reach US$18.2 billion by 2027 after growing at a CAGR of 6.1% during the forecast period 2022-2027. Powder coating is a dry finishing process in which free-flowing, thermoplastic or thermoset powder material is applied to a surface, melted and then allowed to dry and harden into a protective coating. Powder coating based on thermoplastic polymers is derived from polyolefins, polyvinyl chloride, polyvinyl fluoride, polyester and so on whereas thermoset-based powder coatings are derived from epoxy, polyester, acrylic, polyurethanes and so on. Powder coating imparts a high-quality, durable finish, that allows for improved efficiency and is eco-friendly. Powder coatings are based on polymer resin systems. The environmental advantages offered by powder coatings compared to liquid coating methods drives the powder coatings market. The pandemic resulted in shortages of raw materials and supply chain disruptions. According to Echemi, a chemical industry B2B website, there were shortages of neopentyl glycol that is used in many of the resins for powder coatings and triglycidyl isocyanurate which is a curing agent used in polyester powder coatings. This resulted in price hikes of over 60% in the Powder Coatings industry.

Powder Coatings Market Report Coverage

The “Powder Coatings Market Report – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments of the Powder Coatings industry.

By Resin Type: Thermoset (Epoxy, Polyester, Acrylic, Fluoropolymer, Polyurethanes and Others) and Thermoplastic (Polyamide, Polyolefin, Polyethylene, Polyvinyl Chloride, Polypropylene and Others).

By Coating Method: Fluidized Spray, Electrostatic Fluidized Bed, Electrostatic Spray and Others.

By Substrate: Metal (Steel, Aluminum and Others) and Non-Metal (Plastic, Wood, Ceramics, Glass and Others).

By End-Use Industry: Automotive [Two-wheelers (Scooters and Bikes) and Three/Four-wheelers (Passenger Cars, Heavy Commercial Vehicles and Light Commercial Vehicles)], Construction (Outdoor Construction and Indoor Construction), Appliances (Refrigerator, Water Coolers, Vending Machines, Washing Machines, Air Conditioners/Coolers, Electrical Fans, Kitchen Blenders/Mixers, Vacuum Cleaners, Water Heaters, Ovens & Chimneys, LPG Cylinders and Others), Electrical & Electronics (Transformers, Generators, ATM Machines, Industrial/Commercial Systems, Electrical Motor Stators/Rotors, Electric Meters & Connectors, Computer Room Floor System and Others), General Industrial (Industrial Carts & Power Tools, Storage & Racking, Escalators & Elevators, Lockers, Walls & Fittings, Water Pumps, Steel Drums, Pipes & Rebars and Others), Furniture (Outdoor Metal Furniture, Beds & Chairs, Benches and Others), Medical, Transportation & Equipment (Railways, Industrial Transportation, Construction Equipment, Agricultural Equipment, Marine, Aerospace) and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Denmark, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and Rest of South America), Rest of the World (the Middle East and Africa)

Request Sample

Key Takeaways

The Asia-Pacific region dominates the powder coatings market on account of the increasing construction activities and the recovering automotive industry. According to Invest India, the construction industry in India is expected to reach $1.4 trillion by 2025.

There are two types of powder coatings, thermoplastic and thermoset. Thermoplastic powders are commonly derived from polyolefins, polyvinyl chloride and polyvinyl fluoride while thermosetting powders are derived from acrylic, epoxy and polyester resins.

Thermoplastic powder coating melts and flows when heat is applied but continues to have the same chemical composition once it cools and solidifies. On the other hand, thermoset powder coatings will not melt when heated after curing.

The major opportunity for this market is developing thin-film coatings.

A detailed analysis of strengths, weaknesses, opportunities and threats will be provided in the powder coatings market report.

Powder Coatings Market Segment Analysis – by Resin Type

The thermoset segment held a dominant Powder Coatings Market share in 2021 and is expected to grow at a CAGR of 7.2% during the forecast period of 2022-2027. In the powder coating process, as the powder heats and melts it flows around the surface of the object and undergoes a chemical change called cross-linking which forms a hard and durable coating. Thermosetting coatings do not re-melt when they are cooled after heat is re-applied. In its powdered state, thermoset material tends to have a much lower molecular weight than other coating materials, usually requiring less heat to melt, making it more energy efficient. Thermoset powders are commonly derived from epoxy, acrylic, polyester and polyurethane groups. The most frequently employed are epoxy and polyester-based resins. Epoxy resin-based thermoset powders form a tough impact-resistant coating that has excellent corrosion resistance, so they are used for internal applications. Polyester-based coatings have the added advantage of being highly UV resistant, making them an ideal choice for outdoor applications. Thus, the thermoset segment is anticipated to dominate the powder coatings market.

Inquiry Before Buying

Powder Coatings Market Segment Analysis – by Application

The construction segment held a dominant Powder Coatings Market share in 2021 and is expected to grow at a CAGR of 8.3% during the forecast period of 2022-2027. Powder coating can be used for metal components such as door frames, railings, window frames, fencing, shelters, storefronts, façade or other areas of buildings. According to WSP, around 25% of the overall construction cost is the façade, with the metal contributing a major part of the cost. Powder coating can prevent corrosion and minimize re-coating as it imparts a long-lasting coating. The powder coat is more resistant to scratching, fading, erosion or other types of damage that can ruin the aesthetic appeal of a building The latest trend in the construction industry is low-emitting products and sustainable buildings. According to the U.S. Green Building Council (USGBC), 1,105 projects have been certified with LEED certification for green buildings in the U.S. in 2021. Powder coatings are solvent and VOC-free and produce less waste than other coating methods, making them a clear choice for green buildings. Thus, the construction industry is expected to dominate the market.

Powder Coatings Market Segment Analysis – by Geography

The Asia-Pacific region held the dominant Powder Coatings Market share up to 60% in 2021 owing to the rising consumption of powder coatings from the automotive, construction and appliances sector. The construction activities in the region rebounded after the initial lockdown in 2020. The government of India has made several investments in construction and infrastructure to aid in development. As per a report by the Indian Construction Equipment Manufacturers Association (ICEMA), the construction equipment industry recorded a 47% growth in the second quarter of FY2021-22. According to a news report in Reuters, in FY22-23, US$529.7 billion will be invested to further drive economic growth across the country. China’s construction sector is expanding rapidly. according to the National Bureau of Statistics, China’s construction output is estimated to be worth approximately US$4.3 trillion in 2021. China plans to invest US$1.43 trillion in key construction projects as part of its 14th five-year plan. As per the National Development and Reform Commission (NDRC), the Shanghai plans call for a total investment of US$38.7 billion over the next three years. The Japanese construction industry is expected to boom as the World Expo will be hosted in Osaka, Japan in 2025. Therefore, this region is set to dominate the Powder Coatings market.

Schedule a Call

Powder Coatings Market Drivers

Environmental Advantages of Using Powder Coatings

Powder coating is the green process of choice for finishing operations. It produces less waste than other finishing processes such as liquid coating. The use of powder coating aids in eliminating waste because, after application, the powder coating overspray can be reclaimed and reused. These types of reclamation practices keep overhead costs low while minimizing environmental impacts. Solvents contain volatile organic compounds (VOCs) which are detrimental to the environment. In liquid coatings, the average VOC content is between 3.5 to 5.5 pounds per gallon, which is approximately one-third to one-half of each gallon of the liquid coating being emitted into the environment during the application process. Since powder coating lines do not require the use of solvents, they do not emit VOCs and can operate with reduced energy, faster curing and lower temperatures. This makes powder coatings highly attractive from an environmental perspective. Innovations in the powder coatings industry strive to make it even better. For instance, in early 2020, Sherwin-Williams General Industrial Coatings division launched the Powdura ECO line made from a resin that uses pre-consumer recycled polyethylene terephthalate (rPET). Thus, the environmental advantages offered by using powder coatings drive the market.

Growing Usage of Powder Coatings in Electric Vehicles

The growth of electric vehicles (EVs) can be attributed to increasing oil prices and growing awareness regarding climate change. According to the International Energy Agency (IEA), in 2021, sales of electric cars (including fully electric and plug-in hybrids) doubled to a new record of 6.6 million. Sales kept rising in 2022 as well, with 2 million electric cars sold worldwide in Q1 2022, up almost 75% compared to Q1 2021. To keep EV motors and batteries operating efficiently, it’s important to maintain an optimum temperature range. Sometimes EV motors can generate operating temperatures that may exceed 200°C. Powder coatings are used to insulate battery boxes and isolate thermal activity. To take advantage of the growing EV market, powder coating manufacturers are launching products that cater to EVs. For instance, in January 2022, Arkema announced high-voltage coating solutions for electric vehicles. The two new polyamide 11 powder coating grades with UL certification were introduced for use in electric vehicle battery systems and other applications. Thus, the growing usage of powder coatings for EVs drives the market.

Powder Coatings Market Challenge

High Initial Investment

The major restraint in the Powder Coatings market is the high initial investment required to set up the powder coating equipment. Liquid coating applications only require a spray gun and a spray area. Comparatively, a powder coating workshop needs a spray gun, spray booth and curing oven. The addition of the curing oven adds significantly to the initial start-up costs for powder coating. The size of the curing oven purchased needs to take into account the maximum part size that can effectively be handled. Larger, thicker and heavier parts require a larger and more powerful oven, which further adds to the overall equipment costs. While metals can be powder coated using electrostatic spray deposition, non-metals require a fluidized bed powder coating application. The need for a fluidized bed also increases the overall equipment costs for the establishment of a complete powder coating facility. This can prove to be a challenge for the powder coatings market.

Buy Now

Powder Coatings Industry Outlook

Product launches, acquisitions and R&D activities are key strategies adopted by players in the Powder Coatings market. The top 10 companies in the Powder Coatings Market are:

PPG Industries

AkzoNobel Powder Coatings

BASF SE

Axalta Coating Systems

The Sherwin Williams Company

Jotun

Valspar Corporation

Nippon Paint Holdings Co. Ltd.

Kansai Nerolac Paints Limited

Tiger Coatings

Recent Developments

In June 2022, Polychem launched a new powder coating collection called the Effects Collection. The collection features powder special effects, such as speckles, translucents, metallics, sparkle translucent, veins, patina effects, river textures, fine textures and dramatic illusion colors, available in a variety of colors.

In May 2022, AkzoNobel Powder Coatings launched a comprehensive range of ready-to-ship powder coatings ranges specifically for the North American market. The range comprises approximately 500 unique powder coatings, with a broad variety of premium quality colors, textures and finishes.

In February 2022, PPG announced that it has entered into an agreement to acquire the powder coatings business of Arsonsisi, an industrial coatings company based in Milan, Italy. The acquisition will enable PPG to expand its powder coatings offering in the Europe, Middle East and Africa (EMEA) region.

#Powder Coatings Market#Powder Coatings Market Share#Powder Coatings Market Size#Powder Coatings Market Forecast#Powder Coatings Market Report#Powder Coatings Market Growth

0 notes

Text

Fruit Puree Market Developments, Trends & Opportunities till 2032

Fruit Puree Market provides in-depth analysis of the market state of Fruit Puree manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Fruit Puree in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Fruit Puree Market Report:

The report offers a comprehensive and broad perspective on the global Fruit Puree Market.

The market statistics represented in different Fruit Puree segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Fruit Puree are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Fruit Puree.

Major stakeholders, key companies Fruit Puree, investment feasibility and new market entrants study is offered.

Development scope of Fruit Puree in each market segment is covered in this report. The macro and micro-economic factors affecting the Fruit Puree Market

Advancement is elaborated in this report. The upstream and downstream components of Fruit Puree and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/fruit-puree-market-101464

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Fruit Puree Market Forecast

Global Smart Doorbell Camera Market Share

Passenger Boarding Bridge Market Growth Rate

Live Streaming Video Platform Market Size

Data Center Backup and Recovery Solutions Market Share

Vacuum Insulation Panels Market Analysis

Lateral Flow Immunoassay Based Rapid Tests Market

Automotive Battery Testing Market Growth

Global Point-Of-Use Water Treatment Systems Market Growth

Global Industrial Wastewater Treatment Plant Market Size

Global In-Memory Computing Market Share

LNG As A Bunker Fuel Market Forecast

Portable Solar Charger Market Size

Ketamine Treatment Market Growth Rate

Quartz Monitor Crystals Market Analysis

Electric Heater Market Share

Structural Heart Devices Market Growth

Fluid Viscous Dampers (FVD) Market

Global MEMS Microphone Market Size

Global Thyristor Market Growth

Food Robotics Market Forecast

Global Medical Billing Outsourcing Market Share

Voice Communication Equipment Market Growth Rate

Demand Side Platforms (DSP) for Programmatic Advertising from the Mobile Side Market Size

Transcatheter Heart Valves Market Share

Baseball Cap Market Analysis

Anc Headset Market

6-amino-nicotinic Acid Methyl Ester (Cas#36052-24-1) Market Growth

Global Digital Logistics Market Growth

Global Architectural Acoustic Panels Market Size

Global Down Jacket Market Share

Work Stress Management Market Forecast

Energy Management V2H (Vehicle-To-Home) Power Supply Systems Market Size

Carbonyl Iron Powder and Ultra Fine Iron Powder Market Growth Rate

Music Streaming Subscription Service Market Analysis

Healthcare-associated Infectious Disease Diagnostics Market Share

Bone Conduction Headphones Market Growth

Seawater Desalination Pump Market

Global Basketball Equipment Market Size

Global Human Microbiome Therapeutics Market Growth

#Fruit Puree Market Size#Fruit Puree Market Share#Fruit Puree Market Trends#Fruit Puree Market Industry#Fruit Puree Market Growth

0 notes

Text

0 notes

Text

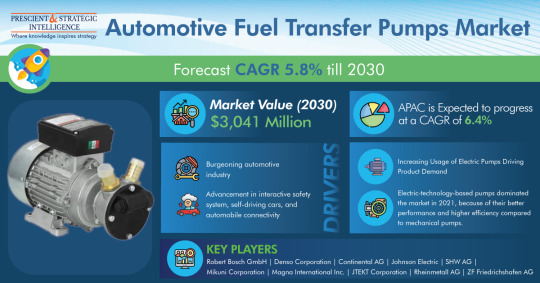

Automotive Fuel Transfer Pumps Market: Trends, Innovations, and Global Growth Insights

The size of the automotive fuel transfer pumps market was USD 1,831 million in 2021, and it will grow at a rate of 5.8% in the years to come, to reach USD 3,041 million by 2030, according to a report of P&S Intelligence.

Electric-technology-based pumps led the industry in the recent past, due to their improved performance and higher efficiency in comparison to mechanical pumps.

Furthermore, electric pumps offer numerous benefits, including improved pressure regulation, a lower wear and tear risk, and high strength. These devices are capable in operating at pressures between 30 and 40 pounds per square inch.

Vehicles featuring advanced injection systems make use of such pumps as these components are relatively safe and supply fuel to the engine proficiently, with a low loss of power. Electric vacuum fuel transfer pumps too help in the lessening of emissions of carbon dioxide from engines.

So, the acceptance of electricity-based injecting machines is relatively high, ensuing an increase in the price of an automobile. With the increasing awareness around the benefits, consumers are requiring automobiles fortified with electric pumps for transfer of gasoline.

The automobile fuel transfer pumps market was dominated by APAC and it will register the highest CAGR, of above 6.4%, in the years to come. The development of the automotive industry in China has grabbed the attention of numerous international automakers. Home to the major auto sector globally, the nation experiences a boom in the integration of components, transferring fuel from the tank to the engine.

Furthermore, the nation’s rapid embrace of hybrid vehicles has formed an increase in the sales of car, which bids a lot potential to auto component makers in the Peoples Republic.

#Automotive Fuel Transfer Pumps#Market Trends#Innovations#Global Growth Insights#Automotive Sector#Fuel Distribution#Market Players#Competitive Landscape#Pump Technology Advancements#Smart Fuel Transfer Systems

0 notes

Text

Global vacuum pumps market size was valued at $5.4 billion in 2021, and is projected to reach $9.3 billion by 2031, growing at a CAGR of 5.5% from 2022 to 2031.

0 notes

Text

Features and applications of automatic blister packaging machine

Automatic blister packaging machine (also known as thermoplastic molding machine) is used to absorb heat-plasticized PVC, PE, PP, PET, HIPS and other thermoplastic coils into various shapes of advanced packaging and decoration boxes, frames and other products. machine. Using the vacuum suction generated by the vacuum pump, the heated and softened thermoplastic sheets such as PVC and PET are molded into various shapes of vacuum covers, blister trays, blisters, etc. through molds.

1. Principle of blister forming machine

Blister molding is also called thermoplastic molding. This molding process mainly uses the vacuum suction generated by the vacuum pump to heat and soften PVC, PET, PETG, APTT, PP, PE, PS and other thermoplastic sheets through molds. Vacuum covers of various shapes, or attached to the surface of products of various shapes. According to the thickness of the sheet, blister is divided into thin sheet blister and thick sheet blister.

At present, the common product sheet blisters on the market include: daily necessities blister packaging, hardware blister packaging, automotive supplies blister packaging, electronic products blister packaging, food blister packaging, cosmetics blister packaging, computer peripheral equipment blister packaging, Blister packaging for toys, blister packaging for sporting goods, blister packaging for stationery, etc.

The main structure of the machine is composed of feeding, pulling, upper and lower electric heating furnaces, lower gate, multi-functional adjustable size, lower mold plate, upper mold, upper gate, knife gate, slicing, releasing and equipped with vacuum devices, etc. ;Pneumatic device is the main power source, and the pulling and feeding of the film adopts electric, reducer, time relay, intermediate relay, travel switch and other electrical appliances to form a fully automatic control system.

The common products of thick sheet blister include: household appliances liner shell, luggage, display rack accessories, decoration, car interior, bumper, fender, beauty equipment, light box shell, toy car shell, industrial panel, advertising light box, Plastic LOGO, bathroom products, refrigerator liner, etc.

2. Main application of blister machine

Plastic packaging industry (blister packaging, plastic, batteries, toys, gifts, hardware, home appliances, electronics, stationery, decoration); food packaging industry (fast food boxes, fruit trays, biscuit boxes); pharmaceutical industry (pill packaging, tablet packaging) ; Industrial cooling tower cooling water deflectors, etc.; three-dimensional relief patterns for decoration, plastic ceilings, wall panels, automotive materials, sanitary equipment and other manufacturing industries.

Suitable for the production of various color sheets: polyethylene PS, polyvinyl chloride PVC, plexiglass, abs, polymethyl methacrylate; flocking sheets; environmentally friendly sheets APET, PET, PP, etc.; photodegradable materials; biodegradable Materials and other plastic products.

3. Main features of blister machine

Strong product specification adaptability Blister molding method can be used to manufacture various products of extra large, extra small, extra thick, and extra thin. The sheet can be as thin as 1~2MM, or even thinner. A few square millimeters, the wall thickness can be as large as 20mm, as small as 0.1mm;

Blister packaging for daily necessities, plastic packaging for small hardware, plastic packaging for automotive supplies, plastic packaging for electronic products, plastic packaging for food, plastic packaging for cosmetics, plastic packaging for computer peripheral equipment, plastic packaging for toys, sporting goods Blister packaging, stationery blister packaging, etc.;

Less equipment investment; convenient mold manufacturing (plaster mold, copper mold, aluminum mold); high production efficiency. Saving raw and auxiliary materials, light weight, convenient transportation, good sealing performance, in line with the requirements of environmentally friendly green packaging; can pack any special-shaped products, without additional cushioning materials for packing; the packaged products are transparent and visible, beautiful in appearance, easy to sell, and suitable for Mechanized and automated packaging facilitates modern management, saves manpower and improves efficiency.

Commonly used thermoforming plastics and performance plastics can be divided into two categories: thermoplastics and thermosetting plastics according to their heating behavior. Most of the materials used for thermoforming are thermoplastic materials. Regardless of single-layer or multi-layer composite plastic sheet (board) used for thermoforming processing, it must have the following technological properties: plastic memory; thermal stretching; thermal strength; forming temperature.

0 notes

Text

IE4 Permanent Magnet Synchronous Motors Forecast to 2031 with Key Companies Profile, Supply, Demand and SWOT Analysis

IE4 Permanent Magnet Synchronous Motors Market Outlook — 2025

The global IE4 permanent magnet synchronous motors market size was valued at $85,153 thousand in 2013, and is projected to reach $206,623 thousand by 2025, growing at a CAGR of 9.8% from 2018 to 2025. IE4 permanent magnet synchronous motors is a super-premium efficiency class motor, which is designed and manufactured according to the energy efficiency motors program to encourage end users to use higher efficiency motors. The aim of utilization of IE4 permanent magnet synchronous motors is to reduce energy consumption and minimize CO2 emissions. These motors are further used to drive industrial fans, pumps, compressors, and other mechanical applications, which fuel their adoption.

In addition, IE4 motors find their application in numerous robotic processes. Factors such as speed, acceleration, torque requirements, control, and angular movements make IE4 motors an ideal choice for robotic system manufacturers. Efficiency and performance have increased owing to rising demand for superior machine control, thereby improving the performance of equipment where IE4 motors are installed. Efficiency and performance have increased owing to rising demand for superior machine control.

Upsurge in adoption of green technologies is gaining popularity across the world. The benefits energy-efficient IE4 motors offer over standard motors include low fan losses and high-quality insulation & lamination. Such factors have a prominent impact on the demand for energy-efficient IE4 motors across various end-use industries. In addition, implementation of stringent regulations and laws related to the environment, such the EP Act and Minimum Energy Performance Standards (MEPS), drives the demand for these motors across the globe. Industries such as material handling systems, compressed air, HVAC, refrigerators, pumps, and ventilation serve as the key consumers of energy-efficient IE4 motors, thus fueling their demand across the globe. In addition, the blowers and the wind power sectors are anticipated to exhibit high demand for these motors in the coming years.

On the basis of application, the market is classified into material handling, liquid pumps, fans & ventilation, cooling compressors, air compressors & vacuum pumps, blowers, and coolers. In 2017, the air compressors & vacuum pumps segment held the largest share, due to increase in demand for compressors systems in manufacturing and automotive industries.

Region wise, the market is analyzed across North America, Europe, Asia-Pacific, and LAMEA. In 2017, Asia-Pacific accounted for the highest share, and is anticipated to secure the leading position during the forecast period. This is attributed to industrial growth in the developing countries such as India and China. China is a pioneer in the IE4 permanent magnet synchronous motors market. Therefore, IE4 permanent magnet synchronous motors market share is highest among the Asia-Pacific countries.

Competition Analysis

The major players operating in the global IE4 permanent magnet synchronous motors market include ABB, Altra Industrial Motion Corp, Anhui Wannan Electric Machine Co., Ltd., Bharat Bijlee, CG global, Danfoss, Fuji Electric Co., Ltd., Hitachi Ltd., Kaeser Kompressoren, Kienle + Spiess GmbH, KSB SE & Co. KGaA, Lafert, Merkes GmbH, Nidec, NORD Drive systems, O.M.E. Motori Elettrici s.r.l., OEMER, Siemens AG, Toshiba Corporation, Weg S.A., and VEM Group. Key players adopted product launch and partnership as its key developmental strategy to sustain the intense competition and improve its product portfolio. For instance, in December 2017, Nord Drivesystems expanded its portfolio of smooth-surface permanent-magnet synchronous motor by launching IE4 or Super Premium Efficiency synchronous motors for applications in food, beverage, and pharmaceutical industries. similarly, in January 2019, WEG S.A, established partnership with Iberian pork producer located in Badajoz, Spain. According to the partnership agreement WEG S.A has provided a W22 Magnet IE4 electric motors for compressors operation of its new refrigeration unit at the Mafresa facilities for cold production.

Many competitors in IE4 permanent magnet synchronous motors market adopted product launch and partnership as its key developmental strategies to sustain the intense competition and improve their product portfolio. For instance, Kaeser established partnership with a renowned motor manufacturer to develop IE4 motors for next-generation compressor packages. Moreover, in December 2017, Nord Drive Systems expanded its portfolio of smooth-surface permanent-magnet synchronous motor by launching IE4 or super-premium efficiency synchronous motors for applications in food, beverage, and pharmaceutical industries.

Full Report With TOC:-https://www.alliedmarketresearch.com/ie4-permanent-magnet-synchronous-motors-market

0 notes

Text

Best Mobile Air Compressor Repair and Cost in Los Angeles California |Aone Mobile Mechanics In Los Angeles

more information is at: https://mobilemechanicsinlosangeles.com/mobile-air-compressor-repair-near-me/

Mobile Air Compressor Repair near Los Angeles California: Are you looking for the Best Mobile Air Compressor Repair near Los Angeles California ? Aone Mobile Mechanics In Los Angeles, is a well-established auto repair shop. Our company offers car maintenance to major repairs. We are a company that has built its reputation on reliable services for all times of vehicles. Cost? Free estimates! Send us a message or call us today. Best Services around Los Angeles California. We serve Los Angeles California and other areas. Get a Free Quote Now!

MOBILE AIR COMPRESSOR REPAIR LOS ANGELES, CALIFORNIA

Compressor uptime is critical to your manufacturing and process requirements. Aone Mobile Mechanics Los Angeles prioritizes your urgency and values our customer needs very seriously. We recognize that our “Service” commitment is important to your customers as well. Our goal is to maximize your productivity and eliminate any risk of down-time associated with compressed air. Our employees understand time is of the essence and schedules are ever changing, this is why Aone Mobile Mechanics Los Angeles Compressor is your best choice for immediate compressor service, repairs, and rentals.

In effort to support all of your facility and application needs, Aone Mobile Mechanics Los Angeles provides engineering and design support for a broad range of product and solutions for the Food, Medical, Commercial and Industrial Manufacturing, Construction & Automotive Markets. Offering products made in the US equipment and full system of various sizes. Our channel partners offer technical support, sales and service of Assembly Tools, Impacts, Grinders, Construction Tools, ARO Diaphragm Pumps, Medical Grade Air Compressors, Breathing Air packages and certification, Nitrogen Generation Systems, Diesel Compressors, Vacuum Systems, Smart Compressor Sequence Controllers, Innovative and Industry leading Automation Controls and a full range of service and repair support.

MOBILE LOS ANGELES, CALIFORNIA AIR COMPRESSORS REPAIRS DONE RIGHT

Aone Mobile Mechanics Los Angeles is committed to helping you and your organization with your air compressor and vacuum production needs. Whatever you’re short or long term compressed air requirements are, we can help you secure the equipment you need – when you need it with a smart and cost effective financial arrangement that works best for your current situation.

Lower your operating, production and capital equipment acquisition costs by renting from Aone Mobile Mechanics Los Angeles. With 20 years of experience in providing organizations with compressed air and vacuum systems and services… you can trust us with your critical short-term equipment needs…

Aone Mobile Mechanics Los Angeles provides the best in Mobile Air Compressor Repairs in Los Angeles, California. Our service saves you from loading and transporting your machine to a local shop and most often, reduces the equipment’s down time! Service shops generally have on hand your lawn or small engine equipment for a minimum of 2 weeks before they even begin to assess or perform repairs to it.

WHY US?

Finding a reliable source for equipment repair doesn’t have to be complicated! Every customer is unique, every situation is different and without a doubt, we get that. We work hard to provide the best possible experience for each of our customers. Trust in our experience. We know outdoor equipment; from lawn mowers to generators, we can fix it. Make the right step, toward choosing us:

Aone Mobile Mechanics Los Angeles is professionally licensed and insured

Convenient, at home service

Quality over quantity

We use parts made in the USA, whenever possible

98% customer retention year after year

We come to you at no extra charge!

When you need it, you need it fast and want it done right the first time. At Aone Mobile Mechanics Los Angeles, we understand service. Aone Mobile Mechanics Los Angeles offers experienced service technicians capable of troubleshooting a variety of compressed air equipment problems with a support structure and specialized tools to assist them.

Compressor uptime is critical to your manufacturing and process requirements. Aone Mobile Mechanics Los Angeles prioritizes your urgency and values our customer needs very seriously. We recognize that our “Service” commitment is important to your customers as well. Our goal is to maximize your productivity and eliminate any risk of down-time associated with compressed air. Our employees understand time is of the essence and schedules are ever changing, this is why Aone Mobile Mechanics Los Angeles Compressor is your best choice for immediate compressor service, repairs, and rentals

CALL FOR US:

Mobile Farm Tractor Repair Near Me

Mobile Air Compressor Repair Near Me

Farm Tractor Repair Shops Near Me

Mobile Tractor Mechanic Near Me

Tractor Repair Service Near Me

Mobile Farm Equipment Repair Near Me

Mobile Tractor Service Near Me

Mobile Lawn Mower Repair Near Me

Service Area

Valley LA, Mobile Air Compressor Repair Near Me

The Verdugos LA, Mobile Air Compressor Repair Near Me

Los Angeles LA, Mobile Air Compressor Repair Near Me

Long Beach LA, Mobile Air Compressor Repair Near Me

Glendale LA, Mobile Air Compressor Repair Near Me

Santa Clarita LA, Mobile Air Compressor Repair Near Me

Lancaster LA, Mobile Air Compressor Repair Near Me

Palmdale LA, Mobile Air Compressor Repair Near Me

Pomona LA, Mobile Air Compressor Repair Near Me

Torrance LA, Mobile Air Compressor Repair Near Me

El Monte LA, Mobile Air Compressor Repair Near Me

Downey LA, Mobile Air Compressor Repair Near Me

Inglewood LA, Mobile Air Compressor Repair Near Me

West Covina LA, Mobile Air Compressor Repair Near Me

Norwalk LA, Mobile Air Compressor Repair Near Me

Burbank LA, Mobile Air Compressor Repair Near Me

Compton LA, Mobile Air Compressor Repair Near Me

South Gate LA, Mobile Air Compressor Repair Near Me

Carson LA, Mobile Air Compressor Repair Near Me

Santa Monica LA, Mobile Air Compressor Repair Near Me

Whittier LA, Mobile Air Compressor Repair Near Me

Hawthorne LA, Mobile Air Compressor Repair Near Me

Alhambra LA, Mobile Air Compressor Repair Near Me

Lakewood LA, Mobile Air Compressor Repair Near Me

Bellflower LA, Mobile Air Compressor Repair Near Me

Baldwin Park LA, Mobile Air Compressor Repair Near Me

Lynwood LA, Mobile Air Compressor Repair Near Me

Beach LA, Mobile Air Compressor Repair Near Me

Pico Rivera LA, Mobile Air Compressor Repair Near Me

Monterey Park LA, Mobile Air Compressor Repair Near Me

Arcadia LA, Mobile Air Compressor Repair Near Me

Paramount LA, Mobile Air Compressor Repair Near Me

Rosemead LA, Mobile Air Compressor Repair Near Me

Glendora LA, Mobile Air Compressor Repair Near Me

BEST MOBILE AIR COMPRESSOR REPAIR COMPANY IN LOS ANGELES

AONE MOBILE MECHANICS LOS ANGELES

REQUEST MORE INFORMATION. CONTACT US NOW!

SERVICE AREA

Valley, The Verdugos, Los Angeles, Long Beach, Glendale, Santa Clarita , Lancaster , Palmdale , Pomona , Torrance, El Monte, Downey, Inglewood, West Covina , Norwalk , Burbank , Compton , South Gate , Carson , Santa Monica , Whittier, Hawthorne, Alhambra , Lakewood, Bellflower, Baldwin Park ,Lynwood, Beach ,Pico Rivera , Monterey Park ,Arcadia ,Paramount, Rosemead, Glendora

Angelino Heights, Echo Park, Elysian Heights, Elysian Park, Elysian Valley, Historic Filipino town, Los Feliz, Pico-Union, Silver Lake, Solano Canyon, Sunset Junction, Westlake, Franklin Hills, Lake Elizabeth, Antelope Acres, Leona Valley, Rosamond, Littlerock, Quartz Hill, Mojave, Tehachapi, Lancaster, Palmdale, Lake Los Angeles, Aqua Dulce, Acton, Arleta, Canoga Park, Chatsworth, Encino, Granada Hills, Lake Balboa| Lake View Terrace| Mission Hills |NoHo Arts District |North Hills | North Hollywood |Northridge | Pacoima| Panorama City| Porter Ranch |Reseda| Shadow Hills| Sherman Oaks| Sherwood Forest| Studio City| Sun Valley| Sylmar| Tarzana| Toluca Lake| Toluca Terrace| Toluca Woods| Valley Glen| Valley Village| Van Nuys| Warner Center| West Hills| Winnetka| Woodland Hills| Altadena| Glendale | La Crescenta| La Cañada Flintridge| Pasadena| Sunland |Tujunga California

0 notes

Text

0 notes

Text

Painting Tools Market Predicted to Witness Steady Growth by 2028

The painting tools market is expected to register notable gains by 2028 due to the expanding automotive industry across the globe.

Painting and coatings make products visually appealing and provide an added layer of protection and durability to products without adding any significant weight. Prevalent use of painting and coatings in varied applications has bolstered product uptake in recent years. Additionally, increasing adoption of flexible packaging solutions that utilize coated barrier systems, which enhance the recyclability and reusability of the packaging, has propelled market expansion.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/1843

The painting tools market has been segmented based on application, product, and region. With respect to product, the market has further been bifurcated into masking tapes, brushes, spray gun, rollers, trays, scrapers, knives, and others (extension poles, sanding tools, trowels).

The brushes sub-segment is projected to grow at a CAGR of around 5.4% in terms of revenue over the assessment period. Paint brushes are one of the most fundamental and oldest tools that are used for painting. Brushes are utilized to paint corners, walls, and ceilings, which is not possible with rollers and spray guns. Paint brushes are classified on the basis of types of bristles, shapes, and sizes. Surging demand for paint brushes with high-quality natural or synthetic bristles that deliver a smooth finish and provide a comfortable grip is likely to drive segmental growth in the forthcoming years.

From the application perspective, the painting tools market has been divided into packaging, construction, industrial machineries & equipment, residential, furniture, commercial, appliances, industrial, and automotive.

The packaging sub-segment is slated to reach a substantial valuation by 2028, expanding at a CAGR of approximately 3% through the review timeline. Paints and coatings provide all the features required for primary and secondary packing, including high performance, lightweight, low contamination, and airtightness. Packaging items use about 70% less plastic as well as take up lesser space than rigid packaging options. In addition, the use of improved paints and coatings on these packaging helps in protecting the goods from outside influences, which is estimated to boost product demand over the forthcoming years.

Request for customization @ https://www.gminsights.com/roc/1843

On the regional front, the Middle East & Africa painting tools market is poised to see robust expansion at a CAGR of more than 4.5% over the forecast period owing to high infrastructure spending and widespread post-war construction activities. The MEA painting tools market is dominated by Saudi Arabia and South Africa in terms of market share, with Saudi Arabia emerging as the fastest expanding market in the region. Notably, the booming domestic construction industry would bolster paint consumption, which is likely to drive regional market growth. Moreover, economic diversification and the growing tourism sector in the region are set to augment industry uptake over the upcoming years.

Table of Contents (ToC) of the report:

Chapter 1 Methodology and Scope

1.1 Market definitions

1.2 Base estimation & working

1.2.1 North America

1.2.2 Europe

1.2.3 Asia Pacific (APAC)

1.2.4 Latin America (LATAM)

1.2.5 Middle East & Africa (MEA)

1.3 Forecast calculations

1.3.1 COVID-19 impact calculations on industry forecast

1.4 Data Sources

1.4.1 Primary

1.4.2 Secondary

Chapter 2 Executive Summary

2.1 Global Painting Tools industry 360° synopsis, 2018 – 2028

2.1.1 Business trends

2.1.2 Product trends

2.1.3 Application trends

2.1.4 Regional trends

Browse complete Table of Contents (ToC) of this research report @ https://www.gminsights.com/toc/detail/painting-tools-market

HVAC & Construction Research Reports

Vacuum Pumps Market

Positive Displacement Blowers Market

Centrifugal Blower Market

About Global Market Insights:

Global Market Insights, Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider; offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy and biotechnology.

Contact Us:

Aashit Tiwari

Corporate Sales, USA

Global Market Insights Inc.

Toll Free: 1-888-689-0688

USA: +1-302-846-7766

Europe: +44-742-759-8484

APAC: +65-3129-7718

Email: [email protected]

#Painting Tools Market Analysis#Painting Tools Market by Type#Painting Tools Market Share#Painting Tools Market Development

0 notes