#Helium Leak Detector

Text

#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System#Vacuum Furnace#Single Stage Vane Pump

0 notes

Text

A certificate of calibration that details the standards to which the leak was tested and the tolerance range for which that leak is certified should be attached to every calibrated helium leak. PTI's Helium Leak provides both external and internal leak standards with certificates of calibration.

0 notes

Text

Tekman's Helium Leak Detector: Precision and Reliability in Leak Detection Solutions

Tekman is a leading innovator in precision testing equipment, renowned for its Helium Leak Detector. This advanced device ensures the highest level of accuracy in detecting leaks, making it essential for industries requiring stringent quality control. Tekman's commitment to cutting-edge technology and reliability has established them as a trusted name in leak detection solutions. The Helium Leak Detector from Tekman exemplifies their dedication to excellence and customer satisfaction.

0 notes

Text

Tekman India is one of the best manufacturer and supplier of premium quality range of Vacuum Pumps and Helium Leak Detector machines across India. Contact us today @ +91 (22) 25838174.

0 notes

Text

Helium Leak Detection Service provides a professional solution for identifying and addressing leaks in diverse industrial systems. Utilizing specialized equipment and expertise, this service employs helium as a tracer gas to precisely locate and quantify leaks, ensuring the integrity and efficiency of equipment in applications such as manufacturing, energy, and research.

0 notes

Text

Project Mogul/Spy balloons

Project Mogul (sometimes referred to as Operation Mogul) was a top secret project by the US Army Air Forces involving microphones flown on high-altitude balloons, whose primary purpose was long-distance detection of sound waves generated by Soviet atomic bomb tests. The project was carried out from 1947 until early 1949. It was a classified portion of an unclassified project by New York University (NYU) atmospheric researchers.[1] The project was moderately successful, but was very expensive and was superseded by a network of seismic detectors and air sampling for fallout, which were cheaper, more reliable, and easier to deploy and operate.

Project Mogul was conceived by Maurice Ewing who had earlier researched the deep sound channel in the oceans and theorized that a similar sound channel existed in the upper atmosphere: a certain height where the air pressure and temperature result in minimal speed of sound, so that sound waves would propagate and stay in that channel due to refraction. The project involved arrays of balloons carrying disc microphones and radio transmitters to relay the signals to the ground. It was supervised by James Peoples, who was assisted by Albert P. Crary.

One of the requirements of the balloons was that they maintain a relatively constant altitude over a prolonged period of time. Thus instrumentation had to be developed to maintain such constant altitudes, such as pressure sensors controlling the release of ballast.

The early Mogul balloons consisted of large clusters of rubber meteorological balloons, however, these were quickly replaced by enormous balloons made of polyethylene plastic. These were more durable, leaked less helium, and also were better at maintaining a constant altitude than the early rubber balloons. Constant-altitude-control and polyethylene balloons were the two major innovations of Project Mogul.

https://en.wikipedia.org/wiki/Project_Mogul

#project mogul#spy balloon#roswell#mogul#popular mechanics#Mechanix Illustrated#popular science#modern mechanics

15 notes

·

View notes

Text

0 notes

Text

0 notes

Text

0 notes

Text

Why Tekman Is the Preferred Choice for Industrial Vacuum Pumps

When it comes to industrial vacuum pumps, choosing the right manufacturer is essential for ensuring reliable and efficient operations. Tekman has established itself as a leader in the vacuum pump industry, offering a wide range of products that meet the specific needs of various sectors. From innovative technology to high-performance machinery, Tekman has earned the reputation of being the preferred choice for industrial vacuum pumps. This article explores the reasons behind Tekman’s success, highlighting some of their standout products, including the Helium Leak Detector, Helium Leak Testing Machine, Helium Recovery System, Vacuum Furnace, and the Single Stage Vane Pump.

Commitment to Quality and Innovation

One of the main things that makes Tekman stand out in the market for industrial vacuum pumps is its dedication to quality. The business makes significant R&D investments to make sure that its goods are at the forefront of technology. Because of its commitment to innovation, Tekman can offer cutting-edge vacuum solutions that frequently surpass industry standards. The needs of the customer are taken into consideration in the design of Tekman's vacuum pumps, whether they are meant to increase operational precision or energy efficiency.

Helium Leak Detector: Precision in Leak Detection

The Helium Leak Detector, one of Tekman's most notable products, is an essential instrument for sectors requiring extremely precise leak detection. Since helium is the second-smallest molecule, it can readily escape through microscopic leaks, which makes it the perfect gas for leak detection in a variety of industrial applications. Because of its exceptional sensitivity, the Tekman Helium Leak Detector enables users to locate even the tiniest leaks in a variety of systems, including vacuum chambers and refrigeration units. This detector's accuracy and dependability guarantee that your systems stay leak-free, reducing downtime and guaranteeing operational safety.

Helium Leak Testing Machine: Ensuring Leak-Free Systems

Tekman offers the Helium Leak Testing Machine in addition to the Helium Leak Detector. By automating the leak detection process, this equipment increases efficiency and lowers the possibility of human error. In sectors where even a small leak can cause serious issues, such as aerospace, electronics, and the automobile industry, the Helium Leak Testing Machine is extensively utilized. Helium is used by the device as the tracer gas, guaranteeing that any possible leaks are found and fixed. Because of its exceptional precision, speed, and dependability, Tekman's leak testing equipment is a vital instrument for quality assurance and control procedures.

Helium Recovery System: Sustainability and Cost Efficiency

Tekman prioritizes sustainability in addition to efficiency. The company's dedication to environmental responsibility is demonstrated by its Helium Recovery System. Since helium is a non-renewable resource, recovering and recycling this priceless gas is essential given its rising demand. By collecting and reusing helium, businesses may lower operating expenses and the environmental effect of gas use thanks to Tekman's Helium Recovery System. This technique is very helpful for helium-intensive industries including electronics, aerospace, and medical device manufacture. Businesses can lower costs and improve sustainability efforts by purchasing Tekman's Helium Recovery System.

Vacuum Furnace: High-Temperature Processing Excellence

The Vacuum Furnace, another important item in Tekman's portfolio, is made for high-temperature processing applications. In fields where exact control over the thermal environment is essential, such as metallurgy, aircraft, and electronics manufacture, this equipment is commonly employed. By enabling heat treatment procedures in a regulated vacuum setting, Tekman's Vacuum Furnace keeps materials from oxidizing or being contaminated. This guarantees the creation of premium parts with enhanced mechanical capabilities. Because of their reputation for dependability, accuracy, and energy efficiency, Tekman's vacuum furnaces are a top option for businesses looking for dependable high-temperature processing solutions.

Single Stage Vane Pump: Efficiency in Motion

One more item that distinguishes Tekman from its rivals is the Single Stage Vane Pump. This kind of vacuum pump finds extensive application in sectors including food processing, packaging, and chemical processing that demand low to medium vacuum levels. The single-stage vane pump from Tekman is made with excellent efficiency in mind, using the least amount of energy possible to provide consistent vacuum pressure. Businesses that value cost savings and operational efficiency will find its small design and ease of maintenance appealing. Tekman's reputation for providing dependable and long-lasting vacuum solutions is further reinforced by the pump's capacity to withstand continuous operation in challenging settings.

Exceptional Customer Support and Service

Outstanding customer service is one of the main reasons Tekman is the go-to option for industrial vacuum pumps. Knowing that every sector has different needs, Tekman tailors its services to each industry's specifications. Tekman's team of professionals can help customers with anything from choosing the best vacuum pump to offering technical assistance and maintenance. They are always accessible to help. Additionally, the business provides after-sale assistance and training to make sure its customers get the most out of their vacuum equipment. Tekman's business philosophy is based on a strong emphasis on client satisfaction, which has played a vital role in building a devoted customer base.

Customization for Diverse Industrial Needs

Tekman's preference in the vacuum pump industry can also be attributed to its ability to tailor its products to the unique requirements of various sectors. Tekman offers a range of vacuum pump systems that may be customized to meet specific operating needs, be it food processing, metallurgy, or pharmaceuticals. The company makes sure that companies of all sizes discover the ideal vacuum pump for their needs by providing a broad selection of models and configurations. This adaptability is especially crucial in sectors of the economy where some applications call for specialized machinery.

Global Reach and Industry Reputation

The Tekman brand is well-known much beyond its immediate vicinity. The company has become a reliable name in industrial vacuum technology and has a global presence. Industries all over the world, including those in North America, Asia, and Europe, use Tekman's products, demonstrating the company's capacity to meet high performance and quality criteria set by international organizations. No matter where they are situated, clients will always receive prompt support and service because of the company's robust global network. The fact that Tekman has become successful internationally is a testament to both its dependability and the trust that companies have in its vacuum solutions.

#Helium Leak Detector#Helium Leak Testing Machine#Helium Recovery System#Vacuum Furnace#Single Stage Vane Pump

0 notes

Text

Over the past few decades, the pharmaceutical industry has experienced tremendous growth on a global scale. Assuring the quality of the packaging is of utmost importance to every manufacturer since any defect in the packaging of pharmaceuticals can have major consequences. Pharmaceutical products must be free from microbiological contamination and safe to use from the time of manufacturing until the end of their shelf life. Through contamination in the form of oxygen, humidity, or microbial entry, the stability of the drug may be negatively impacted. Container closure integrity tests with great sensitivity are needed to reduce these risks. Hence, manufacturers choose helium leak detection technology.

#helium leak testing#helium leak detection#helium leak detector#container closure integrity testing#container closure integrity

0 notes

Text

#Helium Leak Testing#Helium Recovery System#Helium Leak Detector#Helium Leak Detection Service#Helium Leak Testing Machine#Helium Leak Testing System#Helium Leak Testing Service#Rotary vane vacuum pump manufacturers#Dry Screw Vacuum Pump

0 notes

Text

Tekman India is the best helium leak detector manufacturers In India. Check out a range of products like Inficon leak detector, Adixen leak detector. Visit Now!

0 notes

Text

Benchtop Helium Leak Detector, Global Market Size Forecast, Top 10 Players Rank and Market Share

Benchtop Helium Leak Detector Market Summary

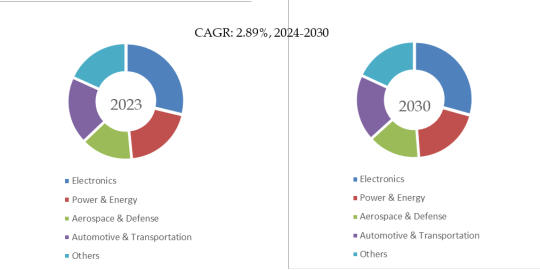

According to the new market research report “Global Benchtop Helium Leak Detector Market Report 2024-2030”, published by QYResearch, the global Benchtop Helium Leak Detector market size is projected to reach USD 0.17 billion by 2030, at a CAGR of 2.9% during the forecast period.

Figure. Global Benchtop Helium Leak Detector Market Size (US$ Million), 2019-2030

Above data is based on report from QYResearch: Global Benchtop Helium Leak Detector Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

Figure. Global Benchtop Helium Leak Detector Top 10 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Above data is based on report from QYResearch: Global Benchtop Helium Leak Detector Market Report 2024-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of Benchtop Helium Leak Detector include INFICON, Agilent, etc. In 2023, the global top three players had a share approximately 48.0% in terms of revenue.

Figure. Benchtop Helium Leak Detector, Global Market Size, Split by Product Segment

Figure. Benchtop Helium Leak Detector, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global Benchtop Helium Leak Detector Market Report 2024-2030.

In terms of product application, currently Electronics is the largest segment, hold a share of 28.7%.

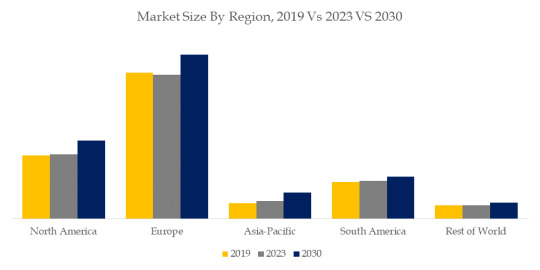

Figure. Benchtop Helium Leak Detector, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global Benchtop Helium Leak Detector Market Report 2024-2030.

Market Drivers:

Technological progress and performance improvement: With the continuous development of science and technology, helium leak detection technology has been significantly improved and improved. The new desktop helium leak detector adopts more advanced detection technology and measurement system to improve detection accuracy and efficiency. This technological advancement enables helium leak detectors to more accurately locate and measure gas leaks, meeting the needs of various industries for high-quality detection.

Growth in industry application demands: With the continuous development of the industrial field, various industries have increasingly higher requirements for product quality and safety. Gas leakage may lead to problems such as product performance degradation and increased safety hazards. Therefore, the demand for gas leakage detection in various industries continues to grow. Desktop helium leak detectors are widely used as an efficient and accurate detection tool.

Policy support and regulatory requirements: Some countries and regions have implemented strict regulatory policies on gas leaks in specific industries, requiring companies to adopt high-precision and efficient leak detection equipment. This kind of policy support and regulatory requirements have promoted the development of the desktop helium leak detector market and provided enterprises with more business opportunities.

Cost reduction and market competition: As helium leak detection technology continues to mature and the market scale expands, the production cost of desktop helium leak detectors gradually decreases, allowing more companies to purchase and use this equipment. At the same time, intensified market competition has also prompted companies to continuously launch products with better performance and more reasonable prices to meet the needs of different users.

Challenge:

Technical challenges: Although helium leak detection technology has made significant progress, there are still technical challenges in some specific application scenarios. For example, the detection of small leaks requires higher sensitivity and accuracy, which places higher requirements on the design and manufacturing of helium leak detectors. In addition, with the continuous emergence of new materials and new processes, how to adapt to and effectively detect leakage problems in these new materials and new processes is also a technical problem currently faced.

Market competition: The helium leak detector market is highly competitive, and products of different brands and models differ in performance, price, service, etc. In order to stand out in the market, companies need to continuously innovate and improve product quality to meet customer needs. At the same time, with the rise of domestic brands and the implementation of import substitution policies, market competition will further intensify, and companies need to strengthen brand building and market promotion to increase market share.

Difficulty in operation and maintenance: Although the desktop helium leak detector has the advantages of high accuracy and high efficiency, its operation and maintenance are also difficult. Operators need to have certain professional knowledge and skills to operate and maintain the equipment correctly. In addition, regular calibration and maintenance of equipment are also important links to ensure detection accuracy and stability, which require the investment of certain human and material resources.

Industry standards and regulatory norms: At present, the helium leak detector industry has not yet formed unified standards and regulatory norms, which has affected the healthy development of the market to a certain extent. Different companies have differences in product design and manufacturing, resulting in uneven product quality and performance. At the same time, the lack of clear regulatory norms also puts some companies at risk of violating regulations, which has a certain impact on fair competition in the market and the protection of consumer rights and interests.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Ensuring Freshness: The Role of Modified Atmosphere Packaging Leak Testers

Introduction: Modified atmosphere packaging (MAP) is a popular method used in the food industry to extend the shelf life of perishable products by altering the atmosphere within the packaging. However, ensuring the integrity of MAP is crucial to prevent spoilage and maintain product freshness. In this blog post, we'll explore the importance of modified atmosphere packaging leak testers, their working principles, applications in the food industry, and the benefits they offer in preserving product quality.

Understanding Modified Atmosphere Packaging Leak Testers:

Modified atmosphere packaging leak testers are specialized devices designed to detect and quantify leaks in MAP systems. These testers utilize various methods, such as pressure decay, vacuum decay, or tracer gas detection, to identify any leaks that may compromise the integrity of the packaging and allow the entry of oxygen or other gases.

Working Principles of Modified Atmosphere Packaging Leak Testers:

Pressure Decay: Pressure decay testers measure the change in pressure within the packaging over a specified period. Any decrease in pressure indicates the presence of a leak, as gas molecules escape from the packaging.

Vacuum Decay: Vacuum decay testers create a vacuum inside the packaging and monitor any changes in pressure. Similar to pressure decay testers, a decrease in pressure indicates the presence of a leak.

Tracer Gas Detection: Tracer gas testers inject a small amount of tracer gas, such as helium or carbon dioxide, into the packaging. A sensitive detector then analyzes the surrounding atmosphere for traces of the tracer gas, allowing the detection of even tiny leaks.

Applications of Modified Atmosphere Packaging Leak Testers:

Modified atmosphere packaging leak testers are widely used in the food industry to ensure the quality and safety of packaged products. Common applications include:

Fresh Produce: MAP is commonly used to package fruits, vegetables, and salads. Leak testers help ensure that the packaging maintains the desired atmosphere to extend the shelf life of these perishable products.

Meat and Poultry: MAP is used to package meat and poultry products to prevent spoilage and maintain freshness. Leak testers ensure that the packaging remains airtight, preserving the quality and flavor of the meat.

Dairy Products: MAP is employed for packaging dairy products such as cheese, yogurt, and butter. Leak testers help prevent the entry of oxygen, which can cause oxidation and spoilage of these products.

Benefits of Modified Atmosphere Packaging Leak Testers:

Quality Assurance: Leak testers ensure the integrity of MAP systems, preventing leaks that could compromise the freshness and safety of packaged products.

Extended Shelf Life: By detecting and repairing leaks, modified atmosphere packaging leak testers help extend the shelf life of perishable products, reducing waste and maximizing product availability.

Compliance: Leak testers help food manufacturers comply with regulatory requirements and industry standards for food packaging safety and quality.

Cost Savings: By minimizing product spoilage and waste, modified atmosphere packaging leak testers help reduce costs associated with product recalls and replacements.

Brand Reputation: Ensuring the freshness and quality of packaged products enhances consumer trust and loyalty, strengthening the brand reputation of food manufacturers and retailers.

Conclusion: Modified atmosphere packaging leak testers play a vital role in ensuring the freshness, safety, and quality of packaged food products. By detecting and repairing leaks in MAP systems, these testers help extend the shelf life of perishable products, minimize waste, and enhance brand reputation. With their ability to provide accurate and reliable leak detection, modified atmosphere packaging leak testers are essential tools for food manufacturers seeking to deliver superior-quality products to consumers.

0 notes