#Manufacturing Advancements

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

i love the idea that jack is a nerd about space, why? because im a nerd about space and also that man needs hobbies and im saying it's space

#borderlands#handsome jack#trying to find hobbie hcs for him is so hard so im tossing my own in there#jack loves space!!! he loves aliens and the endless horror of the universe and space travel and has gotten emotional about the pillars#100% used to watch those “real alien sighting caught on tape (not clickbait)” grainy videos when he was a kid and get himself scared#like yes hyperion is a Gun Manufacturer i guess but also i love his interest in R&D and his knowledge of the vaults and-#-his love of the destroyer and just how invested he was in pandora#like he is a NERD and hes a nerd about the universe#plus added on my hc of his main interest in college/hyperion being immortality through technology#learned he wouldn't be around when we heard back from aliens and immediately said “alright that's my life goal now”#he'd get his hands on a guardian corpse or have one trapped in R&D and would just spend hours watching it- studying it#so in awe of something bigger then him he gets emotional over it#i like to think that hyperion has a HUGE budget for space travel advancements and universal understanding all because of him#helps that in my au his best friend is a cyborg - his daughter is magic - and his husband is an extinct species - he is living his best life

28 notes

·

View notes

Photo

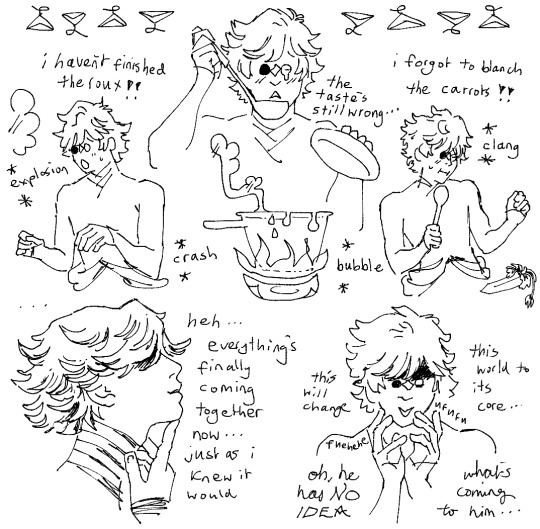

silly men

#witch hat tag#orufrey#i searched 'advanced cooking things' for this so i could find a word like 'blanch'.#lots of ppl said they want to buy my zine 😭 i have a printer now ufufu. i deleted my post of confusion even tho im still confused#i can post my ferdibert zine fic now. maybe i'll do a lil drawing for it. does anyone know what ferdibert is does anyone remember#genuinely finding it hard to call perfect-bound manufactured projects 'zines' any more.

111 notes

·

View notes

Text

A Christmas movie where instead of needing to work on a Christmas Ad campaign that in reality would have been done by October, a business woman is just too busy finalizing the Valentines Day campaign, working on the Saint Patrick’s Day campaign, and organizing the Easter campaign to worry about her family and the spirit of Christmas

#christmas#has this been said before#hallmark movie idea#I’m so tired of this trope#my parents work in manufacturing and I’ve seen this firsthand.#the Easter stuff is done like 4 months in advance#most of these dates are actually a little too early#christmas spirit#hohoho and whatnot

2 notes

·

View notes

Text

youtube

#I like davydov’s a lot and his comments are slightly more than he should cover#but there’s a thing that he’s repeating and should just give his wild guess on it#and that is why is russian high command so fixated with the same costly attacks.#and so I’m gonna give my wild guess and invite any of you to do the same and share it#like money ball in baseball I think russians are actually doing money war#russians military are dysfunctional but not aloof#russians know their military deficiencies and low iq and so they settled for the doctrine of sacrifice hits.#russians are balancing casualty rate with recruitment rate and manufacturing rate#russians know they don’t have enough infantry and enough experience to duke it in big battles#but they’ve calculated to know that they have enough to lose hundreds per day to prevent ukrainian forces from advancing#taiwantalk#ukraine#russia#Youtube

3 notes

·

View notes

Text

Three Seconds.

Rick runs his tongue across his teeth, finds a split above his left canine sluggishly oozing blood. He presses into it, the wound covering his soft pallet with liquid-iron. He used to love the taste of blood, it was exciting, made him see red. That was a long time ago, back when he was with the flesh curtains, doing mostly earth coke in the galactic equivalent of shitty truck stops. Now the taste just pisses him off, reminds him that some nameless waste of carbon actually got a hit in. He can feel a drop of spit and blood plop onto his thigh. He spits and the blood splatters a lurid pink against the concrete floor. He'd wipe his face, but his hands are tied around his back, zip ties of all things dig irritating impressions into the thin skin against his wrist. His knees ache where they're pressed against the floor below him, the cold seeping in through his pant legs and promising a good week of creaking pain if he manages to make it out of this shit hole alive. Fuck, he's too old for this shit.

Rick is pulled very sharply from his thoughts when he hears the door open behind him, followed by strong, steady foot falls and much lighter shuffling ones. He recognizes the later, and his guess is confirmed when Morty stumbles into his line of sight. He doesn't look hurt, his clothes are dirty and there's dust sticking to the tear tracks along his cheeks, but no pain graces his features. Just fear. If it weren't for Morty he'd already be out of here, fucking plastic zip ties were the last thing that would stop The Rick Sanchez. His captor knew that though, and they both knew that the ties were really more of a formality anyway. So yeah, he could've left an hour ago, but with the couple of blows to the side of his head knocking loose his augmentation controls he wasn't convinced he'd find Morty wherever they were keeping him on their ramshackle compound before they decided to take him out back and put the sorry little bastard down.

Speaking of, there's a laser gun pressed snug against the base of Morty's skull. Their kidnapper is a Melvonian, bipedal and mostly humanoid apart from their second set of arms, eyes and various other appendages. Wink. This one is male, about middle aged for his species, his skin tone an admittedly pretty shade of mauve. It's a shame, the guys hot, too bad as soon as he lets his guard down he'll be dead. "Morning Sanchez, I've brought your little buddy. Say Hi little buddy." The man grins, shaking Morty by the bruising grip on his bicep. "Ow, H-hi, grandpa Rick." he winces. "So here's the deal. We've got a really important fight coming up, and that portal tech of yours sure would come in handy." "I don't get involved in interstellar politics, and neither does my badass tech. Bite me." The guy shoves the gun harder against Morty's head, eliciting a squeak of fear and causing his knees to wobble like a new born calf. "Don't interrupt me." Rick rolls his eyes, but stays quiet. For Now.

Rick can see the twitch in one of the mans four eyes, he's still smiling, but he looks angry, a little crazed. Damn, it really is a shame this dude's gotta die. Forgive him for thinking with his dick here, but crazy is pretty much the only type that can keep up with Rick for too long, and the guys got two sets of pecs. Drool. "As I was saying, your tech would help us a lot. Someone from my group has tried and failed to get the machine from you peacefully. Clearly peaceful is not a approach you sway to. Now it's my turn. So here is my ultimatum: Give us a working portal gun and blueprints to build more, or I send a laser through your grandson's head. Simple, no?" He cocks his head to the side, tone light, like he's discussing which restaurant he wants to go to and he's not the perpetrator of a goddamn hostage situation. Morty has been so quiet, eyes trained on Rick. It unnerves him, the genuine panic on his grandson's face. He needs to focus.

Rick's been doing some mental math, trying to figure out how to get through the zip ties and the gun out of this big idiots hand before he pulls the trigger. He can see the safety is on, but he'd recognize a Fentel 16 anywhere, and you can bypass the safety by pressing down the trigger and holding for three seconds. Kinda always struck Rick as defeating the purpose of the safety, but the Fentel series is pretty much exclusively used by criminals, so the company only put a safety on the thing in the first place to get past Galactic Federation manufacturing guidelines. He's not sure he can get to Morty in 3 seconds from here. He needs to think of something, fast. "Listen muscle man, I'm telling you I'm not giving you or your little gang my portal tech. I don't care how righteous you think your cause is, there's a billion other warmongering douchebags in this star system alone who think the exact same thing. I'm not contributing to that." The guys fucking built. Rick isn't short by any means, a cool 6'4" un-slouched, but this guy has at least a foot or so on him. Plus he's pretty sure the dudes forearm is at least the size of his thigh; side note again: Drool. Anyway, he's not sure he can take him in a wrestling match for that gun, especially considering the two extra arms. If Morty reacted quick enough maybe, but the kids little wrists are bound like Ricks are, and he looks scared enough to be nauseous. Rick can't count on him on this one.

"I've been following you a long time, I can tell when you're stalling." Rick can talk a fish out of water on good days, but revolutionary types are a notoriously stubborn breed. He'd know, he was one. Still is, though its been a while since he's been in a fight over anything but his own self-interest. That thought stings just a little. Don't have time for that one, Back in the vault it goes. Rick can see Morty trembling, and can see his chest stuttering when he holds his breath to stop the shakes. It makes Rick's chest hurt a little, like something in there was knocked loose the same time his augmentations were. Rick stops looking at him. "Morty's a shit bargaining chip by the way, Broh. I've got a coupon for a new one from the citadel in my back pocket right now." Rick bares his teeth, smells his own blood on his breath. "Besides, I've been to your pitiful little planet shit for brains, I know your species has a thing about killing kids. You're all too sentimental." Their captor laughs, two of his four eyes squeezed shut in mirth, the other two still diligently trained on Rick "For The Rick Sanchez? I'm willing to make an exception." He grins, double canines glittering blue-white as he switches the safety off and the gun comes alive with a mechanical hum, neon purple lights flicking on incrementally, indicating the charge.

Fuck, there go his three seconds.

#tadaaa#rick and morty#fanfiction#rick and morty fanfiction#r&m#writing#Melvonians#alien species i made up for this fic. theyve got four arms. four eyes. a set of human-ish genitalia. skin tones range from blue to red.#will probably build a little more for them? their planet is called Milvos. theyre decently technologically advanced.#theyre under galactic federation jurisdiction obvi. but at the time of this writing theyre in the midst of a civil war abt planetary border#basically theres rlly only a few habitable portions of their planet. and theres government bodies controlling those portions. they require#certain prereqs for individuals to gain access to those places. theres a sizable group(that this guy is apart of) who believe these borders#shouldnt exist and cause unnecessary and avoidable harm.#thats why the want the portal gun tech. to infiltrate these gorvernment bodies and either demand change or execute dissenters.#the fentel series of lazer guns r manufactured by tentellis corp. mainly a weapons manufacturer#but they do some defense/security stuff too. mostly lasers tbh.#the fentel series is one of like 7 or 8 gun series theyve made. fentel series are hand-guns#theyre on of the better mid-priced hand guns. so theyre very common#anyway no one cares abt my pretend guns#G-126#dats this rick and mortys designation btw#g-126 morty is much less competent/confident then c-137#hes skittish but much more sincere and empathetic. this in part bc g-126 rick is a comparetively tender guy#like theyre still assholes dont get me wrong. but g-126 takes shit way mire seriously. he makes it clear he cares about his family.#that gives morty the room to b vulnerable more often. which in turn helps him retain at least Some of his childlike traits#uh idk i might write more about this dimension. diane didnt get like. blown up they just divorced LOL#bc rick is still rick and he was kinda too young when he got diane preggers#also rick is autistic and so is morty because i said so#they bond over it. although rick is an asshole abt it. but he does let morty info dump on him abt shit he already knows so.#uh wow writing a novel in the tags sorry

2 notes

·

View notes

Text

Leading Fiber Laser Cutting Machine Manufacturer in India

Weldark India is at the forefront of custom-made welding machine manufacturers in India, providing cutting-edge solutions to suit diverse industrial needs. As a leading fiber laser cutting machine manufacturer, Weldark India combines advanced technology with precision engineering to deliver unmatched performance and reliability. Our machines are designed to enhance productivity, ensuring high-speed, accurate cutting for a variety of materials. With a commitment to quality and innovation, Weldark India meets the emerging demands of the manufacturing sector, providing robust and efficient welding and cutting solutions that set new industry standards.

#Fiber Laser Cutting Machine#Welding Machine Manufacturer#Custom Made Welding Machines#Industrial Welding Solutions#Precision Cutting Machines#Advanced Welding Technology#Weldarc India#High-Speed Laser Cutting#Manufacturing Equipment#Indian Welding Industry

0 notes

Text

Unlocking breakthroughs with Advanced Chemical Intermediates

Discover unparalleled excellence in pharmaceutical solutions with Saurav Chemicals, a leading provider of Advanced Chemical Intermediates. Quality commitment through innovative steps aimed at generating best quality intermediates leading to development of the pharmaceutical sector.

0 notes

Text

High-Performance Liquid Lasany Chromatography – HPLC LI - 6200

Lasany International is a trusted supplier of high-performance liquid chromatography (HPLC) systems, widely used in the pharmaceutical industry. Explore our range of HPLC solutions and discover the vital role they play in pharmaceutical analysis and quality control.

Visit Our Website :- www.lasany.org

Feel Free to ContactUs :-9888911439

Follow Us On Instagram :- https://www.instagram.com/lasanyinternational/Facebook :- https://www.facebook.com/lasanyinternationals/Linkedin :- https://www.linkedin.com/in/lasanyinternational/Twitter :- https://twitter.com/LasanyInternat3

#Science Lab Equipment#Flame Atomic Absorption Spectroscopy#Blood Collection Monitor#Top Blood Bank equipment supplier in india#Digital Viscometer manufacturer in india#Best Digital Viscometer Supplier and Manufacturer in India#Spectrophotometer Supplier in Egypt#spectrophotometer supplier in brazil#Double Beam Xenon Lamps at Best Price from Manufacturers#Electronic Plasma Expressor#manufacturer Electronic Plasma Expressor#Electronic Plasma Expressor in india#Double Beam xenon lamps at best price from manufacturers in chandigarh#Double Beam Microprocessor UV-VIS Touch Screen Spectrophotometer With Software#double beam uv vis spectrophotometer#Advanced Single Beam Microprocessor UV-VIS Spectrophotometer With Scanning Software#single beam uv vis spectrophotometer 295#blood bag tube sealer manufacturers#digital rotational viscometer suppliers in india#viscometer manufacturer in india"

0 notes

Text

Semiconductor Advanced Packaging Market Global Industry Analysis, Trends and Forecast 2024-2028

From 2023 to 2028, the Semiconductor Advanced Packaging Market is projected to grow by USD 22.79 billion at an 8.72% CAGR. The market’s expansion is driven by key advancements in semiconductor IC designs, which allow for the creation of highly sophisticated chips. The development of 3D chip packaging is crucial for enhancing both performance and compactness. Furthermore, the adoption of Fan-Out Wafer-Level Packaging (FO WLP) technology is revolutionizing the industry by offering superior electrical properties and minimized package sizes.

#Semiconductor Packaging#Advanced Packaging#IC Design#3D Packaging#FO WLP Technology#Semiconductor Innovation#Electronics Manufacturing

0 notes

Text

Unitritech Leading the Way in Aerospace Machined Components Manufacturing

In the highly specialized field of aerospace manufacturing, precision and reliability are paramount. Among the key players in this industry, Unitritech stands out as the premier manufacturer of aerospace machined components. With a steadfast commitment to quality, innovation, and customer satisfaction, Unitritech has earned its reputation as the best in the business.

Unitritech's expertise in producing high-precision machined components ensures that every part meets the stringent standards required for aerospace applications. Their state-of-the-art manufacturing facilities are equipped with the latest technology, allowing for unparalleled accuracy and consistency. This dedication to excellence extends to their rigorous quality control processes, which guarantee that every component is meticulously inspected and tested before it reaches the customer.

One of the key factors that set Unitritech apart is their ability to handle complex and challenging projects. Whether it's producing intricate parts for commercial aircraft or custom components for military applications, Unitritech's skilled team of engineers and technicians possess the knowledge and experience to deliver exceptional results. Their innovative approach to problem-solving and continuous improvement ensures that they remain at the forefront of the industry.

In conclusion, Unitritech's commitment to precision, quality, and innovation makes them the best choice for aerospace machined components manufacturing. Their dedication to exceeding customer expectations and their proven track record of excellence solidify their position as industry leaders.

#High Precision Aerospace Machined Components#Advanced Aerospace Component Manufacturing#Custom Aerospace Machining Services#Leading Aerospace Machined Parts Supplier#Top Aerospace CNC Machining Company#Aerospace Precision Machining Experts#Quality Aerospace Manufacturing Solutions#Reliable Aerospace Machined Parts Manufacturer

0 notes

Text

Hydrogen Revolution: Electrolyzers Leading the Charge Towards Zero Emissions

Are you ready to delve into the future of energy? Buckle up as we explore the groundbreaking technology of electrolyzers and their pivotal role in reshaping the energy landscape. Understanding Electrolyzers: Unlocking the Power of Hydrogen In our quest for sustainable energy solutions, electrolyzers stand out as game-changers. These devices utilize an electrochemical process to split water into hydrogen and oxygen, offering a clean and efficient way to produce hydrogen gas. The Green Promise: Environmental Benefits of Electrolyzers One of the most compelling aspects of electrolyzers is their environmental friendliness. By harnessing renewable energy sources such as solar or wind power, electrolyzers can generate hydrogen with zero carbon emissions, paving the way for a greener future. Empowering Industries: Applications of Electrolyzers From transportation to manufacturing, electrolyzers have a wide range of applications across various industries. In the automotive sector, hydrogen fuel cells powered by electrolyzer-produced hydrogen offer a clean alternative to traditional fossil fuels, reducing greenhouse gas emissions and mitigating air pollution. Moreover, electrolyzers play a crucial role in industrial processes such as ammonia production and metal refining, where hydrogen serves as a key ingredient. Overcoming Challenges: Advancements in Electrolyzer Technology While electrolyzers hold immense potential, technological advancements are essential to overcome existing challenges. Improving efficiency, reducing costs, and enhancing durability are among the primary focus areas for researchers and engineers working on electrolyzer development. By addressing these challenges, we can accelerate the adoption of electrolyzer technology on a global scale. Looking Ahead: The Future of Electrolyzers As we look to the future, electrolyzers are poised to play a central role in the transition to a sustainable energy economy. With ongoing research and innovation, we can expect electrolyzer technology to become more accessible, affordable, and efficient, driving widespread adoption and facilitating the shift towards clean energy solutions. Supporting Innovation: Join the Movement Are you passionate about shaping the future of energy? Join us on this journey towards sustainability by supporting initiatives that promote innovation and development in electrolyzer technology. Together, we can create a brighter, cleaner tomorrow for generations to come. In conclusion, electrolyzers represent a paradigm shift in energy production, offering a clean, efficient, and versatile solution to meet the growing demand for sustainable energy. By harnessing the power of electrolyzers, we can pave the way towards a brighter and greener future for our planet.

#Electrolyzers#Energy Production#Hydrogen#Sustainable Energy#Environmental Benefits#Industry Applications#Technological Advancements#Clean Energy#Renewable Energy#Green Technology#Transportation#Manufacturing#Innovation#Climate Action#Zero Emissions#Energy Efficiency#Renewable Resources#Sustainability#Clean Technology#Future of Energy

0 notes

Video

youtube

greedaikin precision mold #precision #machine #cnc#injectionmold

#youtube#With the swift advancement of the manufacturing sector and the enhancement of science and technology numerous precision technologies initial

0 notes

Text

Why These Process Equipment Manufacturers are Dominating the Market?

In the highly competitive industrial landscape, certain process equipment manufacturers have risen to the top, setting benchmarks for quality, innovation, and customer satisfaction. This article explores the reasons behind their dominance in the market, shedding light on their strategies, technologies, and unwavering commitment to excellence.

Commitment to Innovation and R&D

One of the primary reasons these manufacturers lead the market is their relentless focus on innovation and research and development (R&D). Investing heavily in R&D allows them to stay ahead of the technological curve and continuously improve their products.

1. Cutting-Edge Technologies

Leading manufacturers leverage cutting-edge technologies such as automation, Internet of Things (IoT), and artificial intelligence (AI) to enhance the performance and efficiency of their equipment. For example, IoT-enabled devices provide real-time data and analytics, enabling predictive maintenance and reducing downtime.

2. Sustainable Solutions

In response to global environmental challenges, top manufacturers are also pioneering sustainable solutions. They are developing energy-efficient equipment and integrating eco-friendly practices into their production processes. Innovations like energy-efficient heat exchangers and low-emission burners are just a few examples of how they are making industrial operations greener.

Customer-Centric Approach

Dominant process equipment manufacturers put their customers at the heart of their operations. They understand that meeting and exceeding customer expectations is crucial for long-term success.

(a) Customized Solutions

By offering customized solutions, these manufacturers can address the specific needs of their clients. This flexibility ensures that customers get equipment tailored to their unique operational requirements, enhancing efficiency and productivity.

(b) Exceptional Service and Support

Outstanding customer service and after-sales support further distinguish leading manufacturers. They provide comprehensive training, maintenance services, and technical support to ensure that their equipment performs optimally throughout its lifecycle.

Quality and Reliability

Quality and reliability are non-negotiable for top process equipment manufacturers. They adhere to stringent quality control measures and industry standards to ensure their products are durable and dependable.

(i) High-Quality Materials and Manufacturing Processes

Using high-quality materials and employing advanced manufacturing processes ensures that the equipment can withstand the rigors of industrial use. Rigorous testing and quality assurance protocols help maintain high standards.

(ii) Compliance with Industry Standards

Adherence to international industry standards and certifications, such as ISO 9001 and ASME, guarantees that the equipment meets the highest quality benchmarks. This compliance not only ensures safety and reliability but also boosts customer confidence.

Strategic Partnerships and Collaborations

Forming strategic partnerships and collaborations with other industry leaders and technology providers is another strategy that sets these manufacturers apart. Such alliances enable them to integrate the latest innovations and expand their market reach.

1. Collaborative R&D Projects

Collaborative R&D projects with academic institutions and research organizations help manufacturers stay at the forefront of technological advancements. These collaborations often lead to the development of groundbreaking solutions that address emerging industry challenges.

2. Supply Chain Optimization

Strategic partnerships with suppliers ensure a robust and reliable supply chain. By working closely with their suppliers, manufacturers can maintain consistent quality and timely delivery of components and materials.

Global Reach and Market Penetration

The ability to penetrate global markets is a significant factor in the dominance of these manufacturers. They have established a strong international presence through strategic market expansion and localization efforts.

(a) Local Manufacturing and Service Centers

Setting up local manufacturing and service centers enables manufacturers to cater to regional markets more effectively. This localized approach ensures faster delivery times, better customer support, and a deeper understanding of local market dynamics.

(b) Global Distribution Networks

A robust global distribution network allows these manufacturers to reach customers worldwide. Strategic partnerships with distributors and agents ensure that their products are readily available in key markets.

Emphasis on Training and Development

Investing in the training and development of their workforce is another hallmark of leading process equipment manufacturers. A skilled and knowledgeable workforce is crucial for driving innovation and maintaining high-quality standards.

(i) Employee Training Programs

Comprehensive employee training programs keep the workforce updated on the latest technologies and best practices. These programs enhance the skills of employees, enabling them to contribute effectively to the company's success.

(ii) Talent Acquisition and Retention

Attracting and retaining top talent is a priority for these manufacturers. By offering competitive compensation, career development opportunities, and a positive work environment, they ensure that they have the best minds driving their operations.

Future Outlook and Continuous Improvement

Looking ahead, dominant process equipment manufacturers are committed to continuous improvement and staying ahead of industry trends. Their forward-thinking approach ensures they remain leaders in the market.

1. Adapting to Industry Trends

Manufacturers are closely monitoring industry trends such as digital transformation, Industry 4.0, and sustainability. By adapting to these trends, they can develop innovative solutions that meet future market demands.

2. Continuous Product Development

Ongoing product development efforts ensure that manufacturers can introduce new and improved equipment to the market. Continuous innovation helps them maintain a competitive edge and cater to evolving customer needs.

In conclusion, the dominance of leading process equipment manufacturers is the result of a multifaceted approach that includes a commitment to innovation, customer-centric strategies, uncompromising quality, strategic partnerships, global reach, and a focus on continuous improvement. By excelling in these areas, they set new standards in the industry and remain at the forefront of industrial progress.

If You Want to Discover More About Process Equipment Manufacturers then Visit the Site: Jasmino

#technology#manufacturing#manufacturing industry#manufacturer#process equipment#equipment manufacturer#industry trends#industry standards#innovative technology#technological advancements#strategicpartnerships#quality assurance#data & analytics

0 notes

Text

Whirlpool WPW10643378 Refrigerator Electronic Control Board | HnKParts

#Manufacturer Name:WHIRLPOOL#Product Number:WPW10643378#OEM Part Number:WPW10643378#The Whirlpool WPW10643378 Electronic Control Board for refrigerators is an indispensable part that regulates and manages various functions#this advanced control board monitors temperature#defrost cycles#and other vital functions in order to ensure peak performance and preserved food.#WPW10643378#Whirlpool#Refrigerator#ElectronicControlBoard#HnKParts#KitchenAppliance#HomeAppliance#700 Nicholas BLVD Suite 105 Elk Grove Village IL 60007#https://www.hnkparts.com/wpw10643378-whirlpool-cntrl-elec-corerefrig

0 notes

Text

Advanced NetSuite Manufacturing Revives Production Efficiency

Advanced Manufacturing in NetSuite delivers a single and unified business solution that replaces disparate and disconnected systems and helps modern-day Manufacturers thrive in the evolving landscape with Advanced Automated Capabilities.

For the most part, Advanced Manufacturing NetSuite is orchestrated on native NetSuite ERP. Given these points, it helps ensure that all manufacturing processes are extensively connected to financial reports, inventory management, and outstanding orders in real time.

Some of the highlighting features of Advanced Manufacturing NetSuite covers

Planning and Scheduling

Shop floor capabilities

Resource utilization

Discrete or Assembly Manufacturing Capabilities

Finite Production Scheduling

Work Order Release capabilities

Batch or Process Manufacturing capabilities

Recipe or Formulation capabilities

Raw and Bulk Lot Control

In addition, modern-day manufacturing units can make the most of Advanced Manufacturing NetSuite to gain complete control of all aspects of their manufacturing or production processes including finite capacity, scheduling, and manufacturing execution.

Advanced Inventory NetSuite

In general, the deployment of Advanced Inventory NetSuite helps modern-day production and distribution businesses drive the capability required for robust manufacturing operations management and retain customer engagement in the long run. For the most part, Advanced Inventory Management in NetSuite

Delivers inventive features such as

Demand-based Inventory Replenishment

Inventory Control

Lot Management

Bin Management

Return Merchandize Authorization

Pick, Pack, and Ship Management

In particular, the Advanced Inventory Management NetSuite is a crucial part and function of Advanced Manufacturing NetSuite.

Advanced NetSuite Support

To make the most of NetSuite capabilities, optimize ERP usage, and multiply the business benefits of Advanced Inventory NetSuite or Advanced Manufacturing NetSuite, get Advanced NetSuite Support.

At inoday, #1 ORACLE NetSuite Channel Partner, you can avail of impressive customer services, including Advanced Customer Support NetSuite.

For the most part, businesses relying on our Certified NetSuite Consultants are managing key operations under the aegis of Expertise, Exposure, and Experience.

Undeniably, by offering Advanced NetSuite Support, we help you make the best of global consulting, implementation support, and services with deep knowledge across NetSuite Solutions.

In particular, these subject-matter experts help you scale up with Advanced Customer Support in NetSuite and let you overcome critical issues, without a hitch.

At inoday, thriving manufacturing businesses can avail of Advanced Inventory Management in NetSuite or Advanced Manufacturing in NetSuite and ensure continued operations with Advanced Customer Services in NetSuite.

Explicitly, we leverage our 16+ years of experience in driving Digital Transformation via Cloud Computing Solutions and have excelled in Successful Deliveries of NetSuite Solutions.

We are globally recognized for our proven track records, innovative approach, and commitment to technology enhancements.

For more details, write to us at [email protected] Or Schedule A Demo

#netsuite erp#netsuite manufacturing#Advanced NetSuite Manufacturing#netsuite#Digital Transformation

0 notes