#BOD and COD Reduction

Explore tagged Tumblr posts

Text

Why Bioculture Is Key in Modern Wastewater Treatment

Wastewater management has come a long way from traditional chemical-heavy methods. Today, with growing environmental concerns and the push for sustainable solutions, bioculture in wastewater treatment is gaining serious traction. But what exactly is bioculture, and why is it becoming the go-to solution in modern wastewater systems? Let’s break it down in simple, practical terms.

What Is Bioculture?

Bioculture refers to a concentrated mix of beneficial microorganisms—think bacteria, fungi, and enzymes—that are specifically designed to digest organic waste present in wastewater. These microbes feed on the pollutants, breaking them down into simpler, non-toxic compounds. It’s nature doing the dirty work—literally.

How Bioculture Works in Wastewater Treatment

When bioculture is introduced into a sewage treatment plant or an effluent treatment plant, it kickstarts a natural biological process. The microbes begin breaking down:

Organic matter

Fats, oils, and grease (FOG)

Sludge

Harmful pathogens

The process not only accelerates the breakdown of waste but also significantly reduces foul odors and improves water clarity.

Benefits of Using Bioculture in Wastewater Treatment

Let’s be real—why should industries, municipalities, or even residential complexes care about using bioculture? Here’s why:

1. Eco-Friendly and Sustainable

Bioculture-based systems use naturally occurring organisms, making them an environmentally friendly alternative to harsh chemicals that often harm aquatic ecosystems.

2. Cost-Effective

Using bioculture can actually cut operational costs. How? It reduces the need for frequent desludging, minimizes chemical usage, and lowers energy consumption.

3. Improves Efficiency

Bioculture boosts the efficiency of the treatment process. It enhances Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) removal, making treated water safer for discharge or reuse.

4. Reduces Sludge Volume

One major headache for wastewater facilities is dealing with excess sludge. Bioculture helps reduce the volume of sludge generated, making disposal easier and cheaper.

5. Faster Recovery from Shock Loads

Industrial plants often face “shock loads”—a sudden influx of high-strength waste. Bioculture helps treatment systems bounce back faster without major operational hiccups.

Common Applications of Bioculture

Bioculture in wastewater treatment isn’t just for large-scale operations. It finds applications across various sectors:

Sewage Treatment Plants (STPs)

Effluent Treatment Plants (ETPs)

Dairy, textile, and food processing industries

Hotels and residential complexes

Septic tanks and community toilets

Things to Consider Before Using Bioculture

While bioculture is a game-changer, a few things need to be in place for it to work effectively:

Maintain the right pH, temperature, and oxygen levels

Avoid using toxic cleaning agents that can harm microbes

Regular monitoring to ensure microbial health

Working with an experienced wastewater treatment consultant can help tailor the solution to your specific needs.

Final Thoughts

As environmental regulations tighten and the demand for cleaner processes rises, bioculture in wastewater treatment is not just an option—it’s quickly becoming a necessity. It's a smart, sustainable, and scalable solution that leverages nature to solve one of modern society's most pressing problems.

If you're exploring ways to upgrade your wastewater management practices, integrating bioculture is a step in the right direction. It’s time to trust the microbes—they’ve got this!

#Bioculture in Wastewater Treatment#Wastewater Treatment Solutions#Sustainable Wastewater Management#Eco-Friendly Wastewater Treatment#Biological Treatment of Wastewater#Sewage Treatment Using Bioculture#Wastewater Microbial Solutions#Effluent Treatment Plants#Organic Waste Breakdown#Modern Wastewater Technology#Sludge Reduction Methods#Wastewater Treatment for Industries#Bioculture for STP and ETP#Environmental Wastewater Solutions#BOD and COD Reduction#waste water treatment

0 notes

Text

Super Nutrients – Advanced Micro & Macro Nutrient Booster for Wastewater

Super Nutrients is a powerful blend of essential vitamins, amino acids, and trace minerals designed to support healthy microbial growth in wastewater systems. It enhances the breakdown of organic waste, improves floc structure, and boosts COD/BOD reduction. Ideal for ETPs, STPs, lagoons, ponds, and bioremediation, it fills nutrient gaps and helps maintain efficient treatment even under low oxygen conditions.

0 notes

Text

Aerobic Wastewater Treatment for Industrial Effluents: Compliance and Efficiency

Industrial sectors ranging from food processing to pharmaceuticals, textiles, and chemicals all generate large volumes of wastewater during their operations. Managing these effluents is both an environmental responsibility and a legal requirement, especially as regulatory bodies enforce stricter discharge norms. Among the various treatment methodologies available, Aerobic Wastewater Treatment has proven to be one of the most efficient and compliant solutions for treating industrial wastewater with high levels of organic pollutants.

Understanding Aerobic Wastewater Treatment

Aerobic Wastewater Treatment is a biological process that uses oxygen to stimulate the growth of microorganisms that degrade organic pollutants in wastewater. These microorganisms convert organic matter into carbon dioxide, water, and biomass (sludge), allowing for effective removal of biochemical oxygen demand (BOD), chemical oxygen demand (COD), and suspended solids.

The treatment is widely used across industries due to its reliability, ease of integration, and ability to consistently meet regulatory discharge limits.

Industrial Effluents: Challenges and Characteristics

Industrial effluents differ significantly from domestic sewage in terms of volume, variability, and the presence of complex contaminants. Key challenges include:

High organic loads (especially in food, dairy, and beverage industries)

Toxic chemicals and heavy metals (common in pharmaceuticals, textiles, and chemical manufacturing)

Fats, oils, and grease (FOG) that inhibit microbial activity

pH fluctuations from cleaning agents or batch processes

High temperatures or flow variability due to operational shifts

To manage these challenges, treatment systems must be robust, adaptable, and efficient — all qualities associated with aerobic processes.

Benefits of Aerobic Wastewater Treatment for Industrial Use

1. Regulatory Compliance

One of the strongest advantages of Aerobic Wastewater Treatment is its ability to meet stringent discharge standards. Most government and environmental agencies, including the U.S. Environmental Protection Agency (EPA) and equivalent bodies worldwide, require treated industrial effluents to maintain low levels of BOD, COD, and TSS. Aerobic systems can reliably achieve these benchmarks with proper design and operation.

2. Efficiency in Organic Load Reduction

Aerobic systems are particularly well-suited to industries with high levels of biodegradable organic matter. With proper aeration and microbial population control, these systems can achieve over 90% removal efficiency of BOD and COD.

3. Faster Treatment Cycles

Compared to anaerobic systems, aerobic processes have shorter hydraulic retention times (HRT), making them suitable for facilities needing quicker treatment turnaround. This allows industries to operate at higher flow rates with consistent performance.

4. Lower Odor Emissions

Aerobic environments suppress the formation of hydrogen sulfide and other malodorous compounds. This is essential in industrial settings where odor control is a critical aspect of community relations and workplace conditions.

5. Technology Integration and Automation

Modern aerobic systems are compatible with digital monitoring tools and SCADA systems. This enables real-time tracking of pH, oxygen levels, flow rates, and microbial health, allowing operators to make timely adjustments to maintain treatment quality and efficiency.

Common Aerobic Treatment Technologies in Industry

Several types of Aerobic Wastewater Treatment technologies are suited for industrial applications, including:

Activated Sludge Process (ASP): A conventional system ideal for high-load wastewater, involving aeration tanks and clarifiers.

Sequencing Batch Reactors (SBR): Compact and flexible batch systems that combine aeration, settling, and decanting in a single tank.

Membrane Bioreactors (MBR): Combine biological treatment with membrane filtration for high-quality effluent, ideal for water reuse.

Moving Bed Biofilm Reactors (MBBR): Utilize biofilm carriers to support microbial growth, and are resistant to shock loads.

Trickling Filters: Utilize fixed media for microbial colonization, often used in smaller-scale industrial settings.

The choice of system depends on the wastewater characteristics, available space, budget, and long-term operational goals.

Integration with Industrial Operations

1. Pretreatment Requirements

Many industries need to install pretreatment units such as screens, oil-water separators, pH balancing tanks, and equalization tanks before aerobic treatment. These help in removing harmful substances that could inhibit microbial activity or damage equipment.

2. Energy Consumption

Aeration, the core of aerobic treatment, requires a significant amount of energy. However, advances in blower design, aeration diffusers, and variable frequency drives (VFDs) have made systems more energy-efficient. Integrating renewable energy sources, such as solar or biogas, can also offset operational costs.

3. Sludge Management

Aerobic treatment generates biological sludge that must be periodically removed, treated, and either disposed of or used for composting or energy generation. Proper sludge handling is crucial to prevent secondary pollution and maintain system efficiency.

4. Monitoring and Maintenance

Modern aerobic systems require ongoing monitoring to manage oxygen levels, microbial balance, and load variations. Automation, remote sensors, and machine learning tools are now being used to optimize performance in real-time.

Environmental and Economic Impact

Implementing Aerobic Wastewater Treatment contributes positively to both environmental protection and economic efficiency:

Reduces environmental footprint by ensuring safe effluent discharge

Lowers water procurement costs through opportunities for effluent recycling and reuse

Improves brand reputation among environmentally conscious consumers and regulators

Qualifies for green certifications and potential government incentives

Additionally, some systems allow for nutrient recovery or biomass utilization as energy sources, aligning with circular economy principles.

Challenges and Considerations

Despite its advantages, aerobic treatment comes with some considerations:

Higher energy costs for aeration compared to anaerobic systems

Sensitivity to toxic substances in certain industrial effluents

Sludge production and disposal requirements

Need for skilled operators and routine system maintenance

Therefore, feasibility studies, pilot testing, and expert consultation are essential before selecting and implementing a treatment system.

Conclusion

For industrial operations aiming to balance environmental compliance with cost-effective wastewater management, Aerobic Wastewater Treatment offers a dependable and scalable solution. Its ability to handle high organic loads, deliver consistent performance, and support water reuse initiatives makes it an ideal choice across diverse industrial sectors.

As industries move toward more sustainable and automated operations, aerobic treatment systems will play a crucial role in helping them meet regulatory obligations, reduce environmental impact, and improve overall efficiency.

1 note

·

View note

Text

Membrane Based Condensate Polishing Unit

Membrane-Based Condensate Polishing: A Game-Changer for Sustainable Distilleries ♻️💧 As distilleries face stricter Zero Liquid Discharge (ZLD) norms and water scarcity challenges, reusing condensate (a byproduct of evaporation) is no longer optional—it’s essential. Enter Membrane-Based Condensate Polishing Units (CPUs), leveraging Ultrafiltration (UF) + Reverse Osmosis (RO) to turn wastewater into reusable high-purity water. Why Membrane Tech? Traditional methods fall short in removing: ✔ Trace organics ✔ Volatile acids ✔ BOD/COD & dissolved solids

Membrane CPUs ensure: • UF → Removes particles, colloids, bacteria • RO → Eliminates TDS, color, odors • Reuse-ready water (TDS <50 mg/L) for boilers, cooling towers, or processes. Key Benefits • 90% water recovery (vs. freshwater intake) • Compact footprint (beats biological systems) • ZLD compliance + lower operational costs • 30% reduction in freshwater demand Challenges? • Membrane fouling → Needs CIP monitoring • RO reject → Requires MEE/ZLD integration • Energy use → Still lower than thermal methods Sustainability Impact A 100 KLPD distillery can recover 150–200 m³/day of water, slashing: ➞ Freshwater dependency ➞ Effluent load on ETPs ➞ Overall water footprint The Bottom Line Membrane CPUs are no longer a luxury—they’re a must-have for distilleries aiming for cost efficiency, compliance, and circular water economies. 💬 Thoughts? How’s your industry tackling water reuse? #WaterSustainability #DistilleryTech #ZLD #CircularEconomy

1 note

·

View note

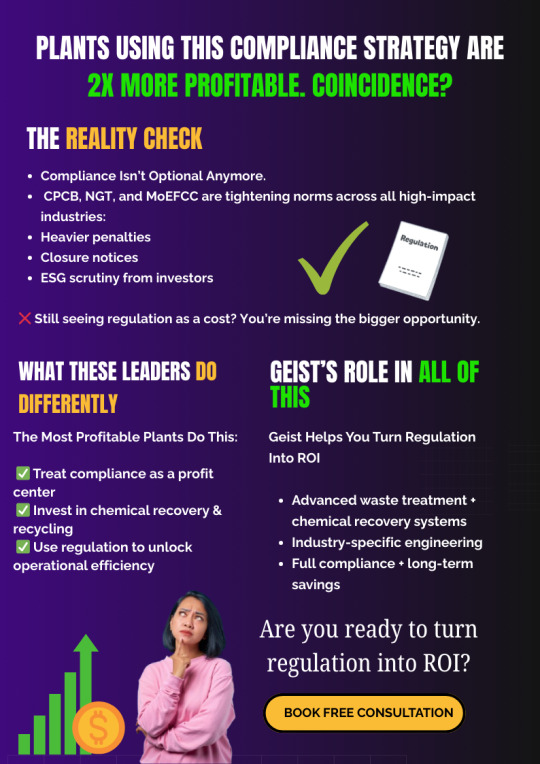

Text

Did you know that some of India’s most regulated industries — pharma, chemicals, textiles — are also seeing the highest operational margins?

What’s their edge? They’re turning environmental compliance into competitive advantage.

At Geist, we help industries like yours not just meet the latest CPCB, NGT, and MoEFCC mandates — but go beyond, by implementing:

💧 Zero Liquid Discharge (ZLD) systems

♻️ Chemical and solvent recovery technologies

🔁 Water recycling for non-potable use

📉 Drastic reductions in BOD, COD, and TDS levels

Result? ✔ Lower input costs ✔ No unplanned shutdowns ✔ Better ESG ratings ✔ Peace of mind

👉 Are you ready to turn regulation into ROI?

Let’s schedule a quick call to explore where your current system stands — and how much more value it can deliver.

1 note

·

View note

Text

Bio culture for ETP (Effluent Treatment Plant) and STP (Sewage Treatment Plant) plays a pivotal role in enhancing the biological treatment of wastewater. These bio cultures, also referred to as bioculture for ETP and bioculture for STP, consist of selected strains of microorganisms specifically formulated to break down organic pollutants, reduce sludge volume, and control odour. Used widely in industrial and municipal applications, bio culture for wastewater treatment accelerates the degradation process, improves BOD/COD reduction, and boosts overall system efficiency. Regular dosing of bio culture ensures a healthy microbial population, leading to consistent and environmentally safe wastewater discharge.

Frequently Asked Questions (FAQs)

1. What is bio culture for ETP and how does it work? Bio culture for ETP consists of beneficial microorganisms that help degrade organic waste in effluent water, improving the efficiency of the treatment plant.

2. Can bio culture be used in both ETP and STP systems? Yes, bio cultures are suitable for both ETP and STP, where they support the breakdown of contaminants in industrial and domestic sewage, respectively.

3. What are the benefits of using bioculture in wastewater treatment? Benefits include faster degradation of pollutants, improved BOD/COD levels, odour control, reduced sludge production, and cost-effective operation.

4. How often should bio culture be dosed in STP or ETP systems? Dosing frequency depends on plant load and design, but typically it is done daily or as per the recommendation of the bio culture supplier.

#bioculture for etp#bio culture for etp#bioculture for stp#bio culture for wastewater treatment#watertreatment

0 notes

Text

Bengaluru, often referred to as the Silicon Valley of India, is witnessing rapid urbanization, which brings along increasing demand for efficient water and wastewater management. In this growing metropolitan hub, Aquamech Engineering Corporation stands out as a reliable and trusted name, offering the best water treatment in Bengaluru with a focus on innovation, efficiency, and sustainability.

Delivering Complete Water & Wastewater Solutions

Aquamech Engineering Corporation provides comprehensive and tailor-made solutions for water and wastewater treatment challenges. From disinfection and filtration to advanced systems like Ultrafiltration, Reverse Osmosis, and Zero Liquid Discharge, our technologies are engineered to meet both environmental and industrial needs with maximum effectiveness.

Our offerings include:

Effluent Treatment Plants (ETP)

Sewage Treatment Plants (STP)

Disinfection systems using chlorine dioxide generators, ozonators, and Sodium Hypochlorite dosing units

Hi-Purity Water Systems

Custom Resin Bed Technologies

These solutions help industries and communities across Bengaluru to purify, recycle, and optimize water usage—making Aquamech the go-to choice for the best water treatment in Bengaluru.

Why Choose Aquamech?

With a reputation built over years of delivering top-tier service, Aquamech Engineering Corporation is an ISO 9001:2015 certified company known for reliability and results. Our facilities in Navi Mumbai support innovation and precision manufacturing, ensuring that every solution we deliver is up to global standards.

Our technology not only tackles high COD/BOD levels but also ensures compliance with evolving environmental regulations. Whether it's for residential complexes, commercial buildings, or large industrial units, our systems are scalable and customized to every client's need.

Serving Bengaluru with Commitment

Bengaluru’s growing industries—from IT and biotech to manufacturing—require dependable water management systems. Aquamech understands the local demands and offers prompt service, expert guidance, and lasting solutions. Our team of professionals ensures seamless project execution and after-sales support, helping us earn the trust of clients throughout the region.

Trusted by Many, Built for the Future

At Aquamech, we believe in long-term environmental stewardship. Our vision aligns with Bengaluru’s smart city mission, promoting sustainable water use and pollution reduction through innovative engineering.

When you're looking for the best water treatment in Bengaluru, Aquamech Engineering Corporation is your ideal partner.

Contact Us 📧 [email protected] 📞 (+91) 9833318254, 22-404-90800 📍 A 132, Industrial Area, MIDC Pawane, Navi Mumbai 400710, Maharashtra, India 🔗 Connect with us on LinkedIn

0 notes

Text

The Ultimate Guide to Bio STP Installation in India: A Sustainable Solution for Wastewater Management

With water scarcity on the rise and environmental regulations tightening, wastewater management is no longer a back-end utility — it’s a frontline sustainability strategy. In India, where urbanization is exploding and infrastructure is evolving rapidly, Bio Sewage Treatment Plants (Bio STPs) are fast becoming the gold standard for eco-friendly and cost-efficient sewage solutions.

If you’re a builder, industrial operator, facility manager, or residential society representative, this guide will walk you through everything you need to know about Bio STP installation, its benefits, applications, and how to choose the right service provider.

What is a Bio STP?

A Bio STP (Biological Sewage Treatment Plant) is a type of wastewater treatment system that uses naturally occurring microorganisms and biological processes to break down organic matter and pollutants in sewage water.

Unlike traditional STPs that depend heavily on chemicals, Bio STPs promote the growth of beneficial bacteria in an oxygen-rich environment, offering a cleaner, greener, and more sustainable solution.

Learn more about this process through our detailed Bio STP Installation Services page.

Why India Needs Bio STPs Now More Than Ever

1. Rapid Urbanization

With India's urban population projected to reach over 600 million by 2030, the need for advanced wastewater treatment is critical. Residential complexes, commercial towers, malls, and hospitals are all generating increasing volumes of sewage that need to be responsibly managed.

2. Government Regulations

Authorities such as the Central Pollution Control Board (CPCB) and State Pollution Control Boards (SPCBs) now mandate the installation of STPs in most large-scale construction projects. Non-compliance can lead to heavy penalties or even the suspension of operations.

3. Water Reuse & Recycling

Water reuse is no longer just a sustainability trend—it’s an economic necessity. With Bio STPs, the treated water can be reused for:

Gardening and landscaping

Toilet flushing

HVAC systems and cooling towers

Construction purposes

This reduces the dependence on freshwater sources and helps cut down on water bills significantly.

Benefits of Bio STP Installation

✅ Eco-Friendly Operation

Bio STPs reduce the use of harsh chemicals, helping to preserve groundwater quality and the environment.

✅ Cost-Effective Over Time

Although the initial investment might seem higher than conventional systems, the low power consumption, minimal manpower, and low maintenance costs make Bio STPs more economical in the long run.

✅ Compact and Scalable

Modern Bio STPs are modular and compact, making them perfect for urban spaces with limited room. Whether you need a system for a small apartment complex or a large industrial park, solutions can be tailored to your needs.

✅ Higher Efficiency

Bio STPs offer better BOD (Biochemical Oxygen Demand) and COD (Chemical Oxygen Demand) reduction rates compared to conventional systems, meaning cleaner output water and better compliance.

Ready to see how you can implement one? Visit our Bio STP services for project-specific guidance.

Applications: Who Can Benefit from Bio STPs?

Residential Apartment Complexes & Gated Communities

Commercial Offices & IT Parks

Hospitals & Healthcare Facilities

Hotels, Resorts & Restaurants

Educational Institutions & Campuses

Factories & Industrial Units

Shopping Malls & Multiplexes

If your facility generates sewage, installing a Bio STP isn’t just an environmental choice — it’s a strategic asset.

The Bio STP Installation Process

At BioSTP.co.in, we offer a streamlined and end-to-end service that includes:

Site Survey & Load Analysis We assess your sewage generation levels and space availability to recommend the right system capacity.

Design & Engineering Our team creates custom STP layouts based on space, flow rate, inlet water characteristics, and reusability goals.

Installation & Commissioning From excavation to plumbing, tank setup, and electrical fittings — we take care of everything.

Trial Run & Testing We test all components and parameters to ensure output meets CPCB/SPCB norms.

Post-Installation Support We offer Annual Maintenance Contracts (AMC), monitoring support, and system optimization.

For more information or a site assessment, contact us via our Bio STP Installation Services page.

Why Choose BioSTP.co.in?

We’re not just service providers—we're your wastewater management partners. Here’s what sets us apart:

✅ Decade-long experience in Bio STP design and implementation

✅ 100+ successful installations across India

✅ Use of energy-efficient technologies

✅ Trained technicians and environmental engineers

✅ Transparent pricing and clear documentation

✅ Full compliance with local and national environmental norms

Final Thoughts: Build Sustainably with Bio STP Systems

Whether you’re building a new facility or retrofitting an old one, a Bio STP installation is one of the smartest and most responsible decisions you can make. It protects the environment, complies with regulations, and creates long-term savings for your business or community.

At BioSTP.co.in, we help you make that decision easy. Reach out to our team today for expert guidance, competitive pricing, and dependable support.

👉 Click here to learn more or get a custom quote

0 notes

Text

Understanding Sewage Water Treatment Plants: How They Work and Why They're Essential

Sewage water treatment plants (STPs) are critical infrastructure that ensure the safe disposal or reuse of wastewater, protecting both public health and the environment. In rapidly urbanizing societies, managing the growing volume of wastewater is becoming an increasingly complex challenge. These plants are designed to treat water from households, industries, and businesses, removing harmful contaminants before releasing it back into natural water bodies or reusing it for non-potable purposes. In this article, we will explore how sewage water treatment plants work and why they are essential for maintaining a clean and healthy environment.

1. The Importance of Sewage Water Treatment

Sewage water contains a mixture of organic waste, chemicals, heavy metals, pathogens, and other harmful substances that, if left untreated, can severely degrade water quality, pose health risks, and harm aquatic ecosystems. Sewage is generated from a wide variety of sources, including:

Household waste (bathroom waste, kitchen effluent, etc.)

Industrial effluent (manufacturing plants, factories)

Commercial waste (from restaurants, hotels, etc.)

Stormwater runoff (which can carry pollutants into the sewage system)

If untreated sewage is allowed to flow into rivers, lakes, or oceans, it can result in waterborne diseases, ecosystem destruction, and a significant reduction in water quality for drinking, agriculture, and recreation. Sewage water treatment plants are essential for protecting public health and ensuring environmental sustainability by treating and recycling wastewater before it enters natural systems.

2. The Process of Sewage Water Treatment

Sewage treatment is a multi-step process that involves physical, biological, and chemical methods to remove pollutants. The process typically consists of the following stages:

Preliminary Treatment

In the first stage of treatment, large debris such as sticks, rags, and plastic are removed from the sewage through screening. This is followed by the grit removal process, where sand, gravel, and other inorganic materials are separated from the water. This step helps prevent damage to the equipment in subsequent stages of treatment.

Primary Treatment

The primary treatment focuses on removing solid waste and suspended solids from the wastewater. This is done through sedimentation. In large sedimentation tanks, the sewage is allowed to settle, causing heavier particles like sludge to sink to the bottom, while lighter waste materials float to the surface. These materials are then removed, and the partially treated water moves on to the next phase.

Secondary Treatment

This is the most critical stage of sewage treatment, involving the breakdown of organic matter by biological processes. In secondary treatment, bacteria and other microorganisms are introduced to the wastewater. These organisms feed on the organic matter, breaking it down into simpler compounds. The treatment can be carried out in two main ways:

Activated Sludge Process: In this method, air or oxygen is bubbled into aeration tanks where bacteria thrive and break down organic pollutants. The mixture is then allowed to settle, and the clean water is separated from the sludge.

Trickling Filter: In this system, wastewater is passed over a bed of microorganisms that treat the water biologically.

Secondary treatment effectively reduces the biochemical oxygen demand (BOD) and chemical oxygen demand (COD), making the water safer for discharge or further treatment.

Tertiary Treatment

In some cases, tertiary treatment is applied as the final step to ensure the water is safe for reuse or discharge into the environment. This process involves advanced filtration techniques, such as membrane filtration, ultraviolet (UV) disinfection, or chlorination, to remove remaining pollutants, bacteria, and pathogens. Tertiary treatment can help reduce nitrogen and phosphorus levels, which are nutrients that can contribute to eutrophication (excessive algae growth) in water bodies.

Sludge Treatment

During the treatment process, sludge (the solid waste removed during primary and secondary treatment) accumulates. Sludge treatment involves processes like dewatering, compaction, and sometimes digestion, where microorganisms break down organic material in the sludge. In some cases, the treated sludge can be used as fertilizer, while in others, it is disposed of in landfills or incinerated.

3. Why Sewage Water Treatment Plants Are Essential

Environmental Protection

One of the main reasons sewage treatment plants are essential is their role in protecting the environment. Without proper treatment, sewage can contaminate water sources, harming aquatic life and polluting ecosystems. The toxic chemicals, heavy metals, and pathogens in untreated sewage can also harm wildlife and disrupt local ecosystems, leading to biodiversity loss. By treating wastewater, STPs help preserve the quality of rivers, lakes, and oceans, ensuring a healthy environment for both humans and wildlife.

Public Health and Safety

Sewage treatment plants also play a crucial role in protecting public health. Untreated sewage contains harmful pathogens like bacteria, viruses, and parasites, which can cause waterborne diseases such as cholera, dysentery, and typhoid. By removing these pathogens and ensuring that water is safe for human contact, STPs reduce the risk of disease outbreaks, particularly in densely populated urban areas where sanitation is critical.

Water Recycling and Reuse

As freshwater resources become scarcer due to population growth, climate change, and overconsumption, treating and recycling sewage water has become a viable solution to address water scarcity. Treated sewage water can be reused for various non-potable purposes, such as:

Agricultural irrigation

Industrial processes

Landscape irrigation

Cooling systems in power plants

This reduces the demand for fresh water from natural sources, conserving precious resources and helping ensure that water is available for essential uses like drinking and sanitation.

Compliance with Regulations

Most countries have strict environmental regulations and discharge standards to protect water quality. Sewage water treatment plants help industries, municipalities, and commercial enterprises comply with these regulations, preventing pollution and avoiding legal penalties. Proper sewage treatment ensures that wastewater is treated to meet specific quality standards before being released into the environment, thereby minimizing the risk of environmental damage and public health hazards.

4. The Future of Sewage Water Treatment

As cities grow and industries expand, the demand for efficient sewage treatment systems will continue to increase. The future of sewage water treatment will likely see innovations in:

Energy-efficient treatment methods that reduce the energy footprint of treatment plants.

Advanced filtration technologies, such as reverse osmosis and membrane bioreactors, for higher-quality treated water.

Decentralized treatment solutions, where smaller, localized treatment plants treat sewage closer to the source, reducing the strain on centralized infrastructure.

Additionally, as the need for water recycling becomes more urgent, the use of treated sewage for potable water (after advanced purification) may become more common, especially in water-scarce regions.

Conclusion

Sewage water treatment plants are an essential component of modern waste management, protecting the environment, public health, and ensuring sustainable water usage. Through a multi-step process that removes pollutants and pathogens, these plants turn wastewater into a resource that can be safely returned to nature or reused for non-potable purposes. As urbanization and water scarcity continue to rise, sewage treatment will remain a cornerstone of efforts to protect our planet’s most valuable resource: water.

0 notes

Text

Effluent Treatment Plants: Essential Processes, Types, and Environmental Benefits

Effluent Treatment Plants (ETPs) are vital for managing industrial wastewater, ensuring that harmful pollutants are removed before discharge into the environment. With industrial activities producing a diverse array of waste contaminants, effective treatment of effluent water is essential for safeguarding ecosystems, human health, and compliance with environmental regulations. This comprehensive guide explores the processes, types, and benefits of ETPs, highlighting their role in sustainable industrial practices.

What is an Effluent Treatment Plant?

An Effluent Treatment Plant (ETP) is a facility designed specifically to treat wastewater produced by industries. Unlike domestic sewage, industrial effluent contains a wide variety of contaminants, including heavy metals, toxic chemicals, organic pollutants, and high concentrations of suspended solids. These contaminants are often harmful and, if untreated, can cause significant environmental damage.

ETPs are structured to remove pollutants through various chemical, physical, and biological processes, producing water that meets regulatory standards for safe discharge or reuse. ETPs play a critical role in industrial sectors such as pharmaceuticals, textiles, chemicals, leather, food processing, and many others where wastewater characteristics are complex and vary widely.

Key Processes in Effluent Treatment

ETPs typically follow a multi-stage treatment process, each stage designed to target specific types of pollutants in the wastewater. The four main stages are preliminary, primary, secondary, and tertiary treatments.

Preliminary Treatment

Screening: This initial stage removes large particles and debris, such as plastics, rags, and other solids, to protect downstream equipment from clogging and damage.

Grit Removal: Grit and small sand particles are settled and removed to prevent abrasive damage to equipment.

Primary Treatment

Sedimentation: The effluent is allowed to settle in large tanks, where suspended solids form sludge and settle at the bottom.

Coagulation and Flocculation: Coagulants are added to neutralize charges on fine particles, helping them to clump together. The larger aggregates, or “flocs,” settle more easily, further removing suspended particles.

Secondary Treatment

Biological Treatment: Biological processes target dissolved organic pollutants. Activated sludge systems or trickling filters introduce aerobic microorganisms that break down organic substances.

Aeration: Oxygen is introduced to enhance the activity of aerobic microorganisms, aiding in the reduction of Biological Oxygen Demand (BOD) and Chemical Oxygen Demand (COD).

Tertiary Treatment

Filtration: Fine particles that remain after secondary treatment are removed using filters such as sand, activated carbon, or membrane filters.

Disinfection: The treated water is disinfected using chlorine, UV light, or ozone to eliminate any remaining pathogens, making it safe for discharge or reuse.

Advanced Treatment (Optional): For industries with high levels of heavy metals or toxic chemicals, additional treatment may be necessary. Processes like reverse osmosis (RO), ion exchange, or adsorption are employed to achieve stricter effluent standards.

Types of Effluent Treatment Plants

ETPs can be categorized based on the technology and processes they use, allowing industries to choose the best option for their specific effluent characteristics.

Activated Sludge Process (ASP)

The ASP method is commonly used in industries to treat wastewater with high organic loads. It uses aeration tanks and activates sludge to break down organic contaminants effectively.

Membrane Bioreactor (MBR)

MBR combines biological treatment with membrane filtration, producing high-quality treated water. It’s suitable for industries requiring compact ETPs with high-efficiency water treatment, such as food processing or pharmaceuticals.

Sequencing Batch Reactor (SBR)

The SBR operates in a batch mode, where treatment occurs in cycles within a single tank. It is ideal for industries with variable flow rates, such as textile or leather industries, where production volumes may fluctuate.

Moving Bed Biofilm Reactor (MBBR)

MBBR systems use plastic carriers within the reactor to support microbial growth. This system provides a large surface area for microorganisms, making it efficient and compact, suitable for industries with moderate organic loads.

Zero Liquid Discharge (ZLD) Systems

ZLD is designed to eliminate all liquid discharge from industrial processes. It employs processes like RO, evaporation, and crystallization to recover water and concentrate waste. ZLD is increasingly popular in industries with strict environmental regulations, such as power plants and petrochemicals.

Constructed Wetlands

For industries focused on sustainable wastewater treatment, constructed wetlands offer a natural solution. Using vegetation, soil, and microorganisms, these systems provide effective treatment with minimal environmental impact, suitable for certain agricultural or food processing industries.

Benefits of Effluent Treatment Plants

Environmental Protection

ETPs prevent the release of hazardous chemicals, heavy metals, and other toxic pollutants into natural water bodies, safeguarding ecosystems and biodiversity. By treating effluent properly, industries help preserve clean water sources.

Regulatory Compliance

Governments and environmental agencies mandate strict effluent discharge standards to prevent water pollution. ETPs enable industries to comply with these regulations, avoiding potential fines, penalties, or legal issues.

Water Conservation

Treated water from ETPs can be reused for non-potable applications, such as irrigation, cleaning, or cooling processes, reducing overall water consumption. In water-scarce regions, this practice is crucial for conserving valuable freshwater resources.

Reduction in Toxicity and Health Risks

Untreated effluent can be harmful to both human and animal health. ETPs minimize exposure to hazardous pollutants by removing toxins and pathogens, ensuring that wastewater is safe for the environment and reducing health risks.

Improved Industry Reputation and Community Relations

Industries that actively implement and maintain ETPs demonstrate responsibility and commitment to environmental protection, improving their public image and relations with local communities and stakeholders.

Resource Recovery

Modern ETPs can recover valuable resources from wastewater, such as biogas from organic sludge. Biogas can be used as an energy source, helping reduce operational costs and providing an additional benefit from waste.

Conclusion

Effluent Treatment Plants are indispensable for industries seeking to manage their wastewater responsibly, mitigate environmental impact, and comply with strict regulatory standards. By implementing effective ETPs, industries contribute to environmental protection, water conservation, and public health.

The selection of an ETP type depends on the nature of the industry and specific wastewater characteristics. Regardless of the chosen technology, the benefits of ETPs extend beyond compliance, helping industries improve resource efficiency, reduce costs, and foster better relationships with the public and regulatory bodies. As environmental awareness grows, ETPs will continue to play a central role in sustainable industrial practices, paving the way for a cleaner and more sustainable future.

0 notes

Text

Are You Looking For The Best Sewage Treatments Plant Manufacturer In Gurgaon?

The process of storing & pre-treating sewage that is produced by factories & various other industrial firms before it can be utilized in agriculture & various other applications or purposes is referred to as wastewater treatment. The wastewater hygiene for the surroundings is very crucial for Netsol Water to maintain, a stable as well as an efficient Sewage Treatment Plant Manufacturer In Gurgaon. Three essential elements are utilized by the STP process:

High-density pollutants are removed from the sewage by filtering employing wire cloth, wire mesh, & mechanical separators.

O2(oxygen) is supplied while maintaining the crucial chemistry-based configuration that allows water molecules to transit the sewage via aerators. Furthermore, the degree of water pollution dictates how much chlorine is supplied.

In the final step of the treatment phase, trickling filters are implemented to filter the contaminated water. This procedure isn't typically utilized very often.

Nearly all regions of Gurgaon, Netsol Water provides Sewage Treatment Plant for a variety of activities that separate pollutants & repurpose chemical compounds along with wastewater.

When it comes about Wastewater Treatment Plant facilities, Netsol Water's technological know-how is unmatched. It incorporates cutting-edge trending developing technology in combination with cutting-edge refining techniques to produce low-cost STP for that particular industry.

Modern technology-based therapy techniques are implemented in an STP.

Wastewater accumulates & its properties as well as flow are balanced in a waste balancing tank. Through the utilization of air-blowing aerators, the contents are kept in an interdependent environment. Coarse bar-screens filter the Sewage before it gets through the equilibrium maintaining tank. After the wastewater has equalized, it is pumped to a quick flash mixing tank & then transported to a flocculation tank.

In the rapid blending tank, chemical-dosing of lime along with alum is applied to promote coagulation. To help the particles clustered, an ionic poly-electrolyte is introduced & fused in the flocculation tank. The flocs are eliminated by the lamella-clarifier, tube-settler, or subsequent up-flow filtering.

Following the first stage of the Sewage treatment, the sewage wastewater is fed into a biological reactor by gravity, where aerobic BOD-COD reduction takes place. Using the bubble-diffusion method ensures an adequate supply of air.

The produced biological solids are removed from then fed secondary settlement tank, also known as the lamella clarifier or tube-settlers. Salt hypochlorite is administered in the chlorine contact tank & serves to polish, rectify, clarify, & disinfect the cleansed sewage water. After being sterilized, the water was filtered utilizing an activated carbon filter & a pressurized sand filter. Discarding the disinfected wastewater is permissible. Alternatively, collect them & place them in a pond where they will ultimately evaporate.

Netsol Water in Gurgaon uniquely utilizes top-notch equipment; they don't use any cheap or subpar electro-mechanical equipment.

Chemical Procedures Applied in Sewage Treatment Plant Facilities

Chemical techniques for treating wastewater from factories, or sewage produced by the companies, malls or any restaurants, employ two sorts of distinctive features:

The pollutants' chemical properties, including how they operate or react with the chemicals that are utilized for treatment.

The ineffectiveness of the products to stay as suspended or aqueous solutions is related to their ability to dissipate, changing unstable matter, or other qualities that result from the combined response of pollutants with treatment chemicals.

Conclusion

While reviewing, leading in wastewater treatment plant systems including Sewage Treatment Plant Manufacturer In Gurgaon is Netsol Water. This business provides a wide range of advantages, such as innovative, fashionable technology & specialist services that include environmentally friendly methods. These producers are essential to maintaining the effective as well as durable wastewater treatment of Gurgaon as the city expands.

0 notes

Text

Superweld Eco-Solutions provides sustainable, bio-based wastewater treatment services for industries like hospitality, textiles, and pharmaceuticals. Their solutions focus on BOD/COD reduction, odor control, and sludge management using herbal, enzyme, and microbial technologies.

0 notes

Text

The Multifaceted Advantages of Deep Water Jet Aerators in Wastewater Treatment Applications

In the realm of wastewater treatment, the quest for efficient and sustainable solutions is an ongoing endeavor. Among the various technologies employed, the Deep Water Jet Aerator stands out as a versatile and effective tool. This article explores the numerous advantages that Deep Water Jet Aerators offer in the context of wastewater treatment, highlighting their role in enhancing the overall process.

One of the primary benefits of Deep Water Jet Aerators is their ability to efficiently oxygenate water bodies. By injecting air or oxygen directly into the water, these aerators facilitate the dissolution of gases, which is crucial for the biological processes involved in wastewater treatment. The enhanced oxygen levels support the growth of aerobic microorganisms, which are essential for breaking down organic matter and reducing the biochemical oxygen demand (BOD) and chemical oxygen demand (COD) of the wastewater.

The design of Deep Water Jet Aerators allows for a uniform distribution of oxygen throughout the water column, which is particularly beneficial in deep-water bodies where traditional surface aeration methods may be less effective. This uniform distribution ensures that all areas of the water body receive adequate aeration, promoting a more balanced and efficient treatment process.

Another advantage of Deep Water Jet Aerators is their adaptability to various water conditions. Whether the wastewater is characterized by high turbidity, strong odors, or a high concentration of pollutants, these aerators can be adjusted to meet the specific needs of the treatment process. Their robust construction and resistance to corrosion make them suitable for use in harsh environments, ensuring a long service life with minimal maintenance requirements.

The energy efficiency of Deep Water Jet Aerators is another significant advantage. Compared to traditional aeration methods, these devices consume less power while providing the same or better oxygen transfer efficiency. This not only reduces operational costs but also contributes to a smaller environmental footprint, aligning with the goals of sustainable wastewater management.

In terms of installation and operation, Deep Water Jet Aerators offer simplicity and flexibility. They can be easily integrated into existing wastewater treatment systems, requiring modifications to the infrastructure. Additionally, the operation of these aerators can be automated, allowing for remote monitoring and control, which further reduces the labor and time involved in the treatment process.

The use of Deep Water Jet Aerators also contributes to the reduction of greenhouse gas emissions. By promoting aerobic conditions, these devices help to decrease the production of methane and other harmful gases that are associated with anaerobic digestion. This not only improves the quality of the treated water but also helps to mitigate the impact of wastewater treatment on climate change.

Furthermore, Deep Water Jet Aerators can play a role in odor control within wastewater treatment facilities. By effectively aerating the water and promoting the breakdown of organic matter, these devices help to reduce the production of malodorous compounds, thereby improving the overall working environment and reducing the impact on neighboring communities.

In conclusion, the advantages of Deep Water Jet Aerators in wastewater treatment are manifold. Their ability to efficiently oxygenate water, adapt to various conditions, and operate with energy efficiency makes them a valuable asset in the pursuit of sustainable and effective wastewater management solutions. As the demand for cleaner water and more eco-friendly treatment processes continues to grow, the role of Deep Water Jet Aerators is likely to become increasingly significant in the future of wastewater treatment.

0 notes

Text

ETP Chemicals To Meet Water Quality Parameters

> pH Neutralization

> Reduction in Turbidity

> Reduction in TSS, COD and BOD

> In-house Laboratory Quality Testing

> Better Quality and Economical Solution

> More Effective Environmental Compliance > Reduces Odour and Colour in Treated Water

#wastewatertreatmentproduct#bioscience#watertreatmentproduct#wastewatertreatment#watertreatmentchemical

0 notes

Text

What Is An Effluent Treatment Plant Manufacturer ?

Depending on the kind of effluent, different effluents require different treatments. Wastewater enters the effluent or sewage treatment facility and through many processing steps before being released into the environment. But the question arises, what is an effluent treatment plant and is there any requirement for effluent treatment?

Let’s understand what is effluent treatment!

It is possible to treat wastewater and adhere to pollution board disposal guidelines by using an effluent treatment plant (WWTP).

Wastewater treatment is used in ETP plants to handle contaminants such as suspended particles, oil and grease, heavy metals, organic and inorganic debris, and more. It is possible to treat using a batch technique or continuous flow process. Chemical treatment, biological treatment, a combination of chemical and biological treatment, and heat treatment are the different types of wastewater treatment facilities.

Why there is a requirement for effluent treatment?

Globally, the industrialisation process is damaging the environment. Due to ineffective industrial wastewater treatment, India also has serious environmental issues, which is especially concerning considering the country's burgeoning small-scale manufacturing sector. As a remedy for industrial pollution discharge, the employment of cleaner production methods and waste reduction techniques is growing in popularity. Effluent Treatment Plants (ETPs) are one of the viable options for effective wastewater treatment for small and medium-sized industries.

An Effluent Treatment Plant (ETP) is a critical component of the production process when it comes to wastewater, the site's sewer/drainage system, and the contaminants with their corresponding limit values that must be attained. Also, the ETP aids environmental regulatory authorities in more successfully enforcing pollution reduction and environmental improvements by minimizing the number of disposal points in an industrial estate. A sanitary sewer or surface water may be used to dispose of the cleaned industrial wastewater (or effluent).

Best effluent treatment plant manufacturer: Netsol

The Netsol effluent treatment plant is a system that can treat effluent and make it environmentally safe. Effluent is defined as effluent that has been released by industries into the environment. This effluent may include hazardous compounds, which infiltrate our ecosystem via rivers, oceans, and so forth. People who consume contaminated water risk becoming very sick. Through effluent treatment, effluent is treated and all the harmful elements and toxins are eliminated so that discharge won’t be harmful to the environment.

Furthermore, organic debris is present in effluent, which is broken down by organisms in effluent treatment facilities. Once all of the contaminants have been consumed by these microscopic creatures, the cleaned effluent may be released back into nature.

Working on Effluent Treatment Plant

Pre-treatment: This is a physical procedure that involves screening or a grit chamber to eliminate floatable solids in raw effluent before they harm the plant's pumps and other equipment. It also has an oil and grease trap for eliminating floatable oil and grease from the industrial effluent.

Primary Treatment: Pre-treated wastewater is now introduced into the primary tank, where a chemical procedure is carried out (which involves coagulation, flocculation, and neutralization). Heavy sediments sink to the bottom, while oil, grease, and other lighter solids float to the surface and are skimmed. The settled particles are referred to as primary sludge, and the residual liquid wastewater is treated at the next step.

Secondary Treatment: This treatment comprises a biological process that eliminates approximately 90% of the BOD and COD. Depending on the quality of the effluent, the biological process might be aerobic or anaerobic. However, the majority of ETPs employ the aerated sludge process to effectively treat wastewater. It eliminates biological stuff that has been dissolved or suspended.

Tertiary Treatment: This treatment is critical in ETPs. Because chlorine, ozone, and UV radiation are used to disinfect treated wastewater here. It also eliminates leftover suspended particles left behind from prior treatment stages. Finally, the treated effluent from the vehicle industry is of acceptable quality and ready for release.

Conclusion

Netsol is an excellent investment for all manufacturing industries, with the lowest operating costs and the longest emptying intervals in the market. Therefore, it is rightly said that, before taking a decision, always think first!

Contact Netsol Water Solutions at +91 9650608473 or [email protected] for water treatment professionals.

0 notes

Text

Bio culture for ETP (Effluent Treatment Plant) and STP (Sewage Treatment Plant) plays a pivotal role in enhancing the biological treatment of wastewater. These bio cultures, also referred to as bioculture for ETP and bioculture for STP, consist of selected strains of microorganisms specifically formulated to break down organic pollutants, reduce sludge volume, and control odour. Used widely in industrial and municipal applications, bio culture for wastewater treatment accelerates the degradation process, improves BOD/COD reduction, and boosts overall system efficiency. Regular dosing of bio culture ensures a healthy microbial population, leading to consistent and environmentally safe wastewater discharge.

Frequently Asked Questions (FAQs)

1. What is bio culture for ETP and how does it work? Bio culture for ETP consists of beneficial microorganisms that help degrade organic waste in effluent water, improving the efficiency of the treatment plant.

2. Can bio culture be used in both ETP and STP systems? Yes, bio cultures are suitable for both ETP and STP, where they support the breakdown of contaminants in industrial and domestic sewage, respectively.

3. What are the benefits of using bioculture in wastewater treatment? Benefits include faster degradation of pollutants, improved BOD/COD levels, odour control, reduced sludge production, and cost-effective operation.

4. How often should bio culture be dosed in STP or ETP systems? Dosing frequency depends on plant load and design, but typically it is done daily or as per the recommendation of the bio culture supplier.

5. Is bio culture environmentally friendly and safe to use? Yes, bio cultures are eco-friendly and composed of non-pathogenic bacteria, making them safe for the environment and human health.

#odour control spray#bioculture for etp#bio culture for etp#bioculture for stp#chemicals used for wastewater treatment

0 notes