#BatteryTestingSolutions

Explore tagged Tumblr posts

Text

Battery Testing Equipment Market Witnesses Strong Growth Due to Increasing Electric Vehicle Adoption Worldwide

The global battery testing equipment market is experiencing significant growth, driven by the accelerating demand for batteries across multiple industries, including automotive, electronics, energy storage, and renewable energy. As the world shifts toward electrification and clean energy solutions, battery performance, safety, and reliability have become paramount creating robust demand for advanced battery testing solutions. This article explores the current market scenario, key drivers, technological trends, and future prospects of the battery testing equipment industry.

Market Overview

Battery testing equipment encompasses devices and systems used to evaluate various parameters of batteries, such as voltage, current, temperature, resistance, and overall capacity. These tests are essential during research and development, manufacturing, and maintenance phases to ensure battery efficiency, performance, and safety standards are met. In 2024, the global market for battery testing equipment was valued at over USD 500 million and is projected to grow at a compound annual growth rate (CAGR) exceeding 6% through 2030.

Key Market Drivers

1. Surging Electric Vehicle (EV) Demand

The rapid expansion of the electric vehicle sector has become the primary catalyst for the battery testing equipment market. Governments worldwide are offering incentives and implementing regulations to reduce carbon emissions, leading to increased EV adoption. As EVs rely heavily on high-performance lithium-ion batteries, rigorous testing is crucial to ensure longevity, safety, and optimal performance.

2. Energy Storage System (ESS) Integration

The integration of energy storage systems in grid infrastructure and renewable energy installations is fueling demand for battery testing solutions. ESS applications require consistent battery health monitoring and diagnostics to prevent failure and maximize energy efficiency, particularly in solar and wind power projects.

3. Technological Advancements in Batteries

With ongoing advancements in battery chemistry ranging from lithium-sulfur and solid-state to sodium-ion batteries manufacturers are increasingly investing in sophisticated testing protocols to validate new materials and configurations. These innovations necessitate specialized equipment capable of handling diverse testing parameters and extreme conditions.

4. Consumer Electronics Growth

The consumer electronics market, including smartphones, laptops, and wearable devices, continues to expand, necessitating highly reliable batteries. Quality assurance through battery testing is crucial to minimize the risk of overheating, swelling, or short-circuiting, which can lead to safety hazards.

Technological Trends

Battery testing equipment is evolving rapidly, incorporating automation, IoT, and artificial intelligence to enhance precision and reduce human intervention. Some key trends include:

AI-Driven Predictive Testing: Leveraging AI algorithms to predict battery degradation and potential failures before they occur.

Remote and Cloud-Based Monitoring: Real-time data collection and remote diagnostics are gaining traction, particularly for large-scale installations.

Modular and Scalable Systems: Manufacturers are focusing on modular systems that can be scaled up or down based on testing needs and battery type.

Regional Insights

Asia-Pacific holds the largest market share, driven by the presence of major battery manufacturers in China, South Korea, and Japan. The region is a global hub for lithium-ion battery production and R&D, leading to strong demand for advanced testing solutions.

North America and Europe are also significant contributors, supported by strong EV adoption, stringent environmental regulations, and active renewable energy initiatives. Countries like the United States, Germany, and Norway are witnessing increased investments in battery testing facilities and pilot manufacturing lines.

Challenges in the Market

Despite strong growth prospects, the battery testing equipment market faces several challenges:

High Initial Costs: Advanced testing systems with precision sensors and data analytics capabilities can be expensive, creating barriers for small and medium enterprises.

Complex Testing Protocols: The wide variety of battery chemistries and use cases requires customized testing protocols, increasing operational complexity.

Lack of Standardization: Differing regional standards and testing requirements can hinder international collaboration and market scalability.

Future Outlook

The future of the battery testing equipment market looks promising, shaped by sustainability goals, electrification of transportation, and technological innovations in energy storage. The market is expected to benefit from:

Expansion in gigafactories and battery manufacturing capacities.

Strategic partnerships among OEMs, testing equipment vendors, and research institutions.

Growing emphasis on second-life battery applications, which will require extensive diagnostics and testing before reuse.

In conclusion, as the global economy transitions to low-carbon and digital solutions, battery testing equipment will play a vital role in enabling safer, more reliable, and higher-performing energy storage systems. Market players that invest in automation, innovation, and global compliance will be well-positioned to capitalize on this evolving and dynamic landscape.

0 notes

Text

youtube

Ensure airtight performance in every battery with Semco Infratech’s SI-SQ 80L & SI-SQ 80 Air Leak Testers! This product demo showcases the precision leak detection system that applies controlled air pressure to identify even micro-leaks using high-sensitivity sensors.

📌 Ideal for battery cells, modules, and packs 🎯 Boost reliability and reduce recalls 🎥 Watch the full video to see it in action!

📞 +91-8920681227 📧 [email protected] 🌐 www.semcoinfratech.com

#BatteryAirLeakTester#BatteryManufacturing#BatteryTestingSolutions#SemcoInfratech#EVBatteryTech#LeakTesting#BatteryAssembly#BatterySafety#Youtube

0 notes

Text

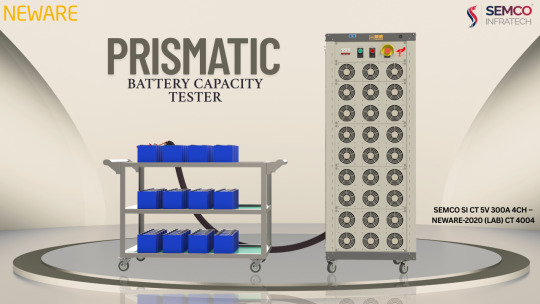

Tune in to learn how the Semco SI CT 5V 300A 4CH is transforming lithium-ion battery testing. Discover its key features, industrial use cases, and benefits for EVs, energy storage, and R&D.

📧 Email: [email protected] | 🌐 www.semcoinfratech.com

#BatteryPodcast#EVBatteryTech#BatteryTestingSolutions#SemcoInfratech#CleanEnergyTools#BatteryInnovation#NewareBatteryCycler

0 notes

Text

Reliable Lithium-Ion Battery Testing with Semco SI CT 5V 300A 4CH – The Ultimate Lab Solution

The Semco SI CT 5V 300A 4CH – Neware-2020 (LAB) CT 4004 is an advanced battery testing solution engineered for modern lithium-ion battery assembly labs and R&D centres.

Ideal for both academic institutions and industrial facilities, this high-performance equipment ensures precision, flexibility, and robust functionality required for cutting-edge battery cell making machine environments.

High-Precision Electrical Performance

This four-channel battery testing system delivers power via a 380V AC input and a total output of 6000W. Each of its four independent channels features:

Voltage Range: 0.025V to 5V with ±0.1% FS accuracy

Current Range: 1.5A to 300A with ±0.1% FS accuracy

Output Per Channel: 1500W

Stable CV and CC modes

This makes it perfect for validating cells used in any lithium-ion battery assembly process.

Flexible Charging & Discharging Modes

The CT 4004 offers versatile testing for various battery-making equipment applications:

Charging: CC, CV, CCCV, Constant Power

Discharging: CC, CP, Constant Resistance

Pulse Testing: Up to 32 cycles, 500ms minimum pulse width

DCIR Testing: Direct Current Internal Resistance

Data Management & Protection

Featuring 16-bit AD/DA resolution and a minimum data record interval of 100ms, it ensures accurate monitoring.

Voltage Change Detection: 10 mV

Current Change Detection: 600mA

Data Export: XLS, PDF, TXT

Supports MySQL Databases

Its robust software and hardware protections are vital for safe lithium battery pack assembly testing.

Programmable Cycles and Steps

Support for up to 65,535 cycles and 254 steps with 3-level nested loops makes it adaptable for complex battery-making machine test scenarios. Independent channel control and Kelvin connections ensure accuracy.

Auxiliary Channel Integration

Up to 248 temperature and voltage auxiliary inputs

Temp Range: -25°C to 110°C (±1°C)

Voltage: -5V to 5V (±0.1%)

Configurable ΔV triggers and safety settings

(Not compatible with soft-reset battery protection boards.)

User-Friendly & Lab-Ready

With Ethernet communication, Windows 7/10 support, and a 30U rack form (600×600×1520 mm), it’s easy to install in professional battery cell making machine labs.

Noise: <85 dB

Storage: 500GB HDD required

IP20-rated housing

Environmental Compatibility

Operating Temp: 0°C to 40°C

Storage Temp: -10°C to 50°C

Humidity Tolerance: Up to 70% operational, 80% storage (no condensation)

Conclusion

The Semco SI CT 4004 is a powerful, lab-grade battery testing platform engineered to support the growing demands of lithium-ion battery assembly, battery-making machines, and lithium battery pack assembly validation.

#SemcoSICT4004#BatteryTesting#AdvancedBatteryTesting#LithiumIonBatteryTesting#BatteryTestEquipment#BatteryTestingMachine#BatteryAssemblyLine#LithiumIonBatteryAssembly#BatteryManufacturing#BatteryTestingSolutions#BatteryQualityCheck#BatteryInspection#BatteryPerformanceTesting#SemcoInfratech#EVBatteryTesting

0 notes

Text

The SEMCO SI BCDS 60V 20A 40CH Battery Aging Machine offers precise lifecycle testing for lithium-ion batteries, ensuring accurate performance assessments for R&D and manufacturing applications.

#BatteryTesting#BatteryAging#LithiumIon#BatteryLife#BatteryPerformance#BatteryResearch#BatteryTechnology#BatteryTestingEquipment#BatteryTest#BatteryAnalyzer#BatteryTesters#BatteryTestingSystem#BatteryTestingMachine#BatteryTestingLab#BatteryTestingSolutions

0 notes

Text

Explore the Semco SI CT 5V 120A 16CH-BK—an advanced, reliable battery testing solution designed for precision and efficiency in lithium-ion battery testing.

#BatteryTesting#LithiumIonTesting#BatteryTester#SemcoInfratech#SemcoSICT5V120A#BatteryPerformance#EnergySolutions#AdvancedTesting#BatteryTestingEquipment#PrecisionTesting#EVBatteryTesting#LithiumIonTechnology#BatteryTestingSolutions

0 notes

Text

"Efficiently sort prismatic cells with the OCV Intelligent Sorting Machine, offering precise voltage and resistance testing, automated code scanning, and seamless MES integration for streamlined battery manufacturing."

#PrismaticCellSorting#BatteryManufacturing#OCVTesting#BatteryQualityControl#PrismaticBatteryTechnology#SortingMachineAutomation#BatteryTestingSolutions#MESIntegration#BatteryProductionEfficiency#LithiumBatterySorting

0 notes

Text

Uncover the power behind lithium-ion batteries that are revolutionizing two-wheeler electric vehicles (EVs). In this video, SEMCO Infratech explains the science of battery cell composition, charging processes, and the role of these efficient, long-lasting batteries in powering your 2-wheeler rides.

Learn how SEMCO Infratech provides innovative battery testing solutions and top-quality battery assembly equipment to support the growing EV industry.

#ElectricVehicles#EVBattery#LithiumIonBattery#BatteryTechnology#EVRevolution#EnergyStorage#TwoWheelerEV#SustainableEnergy#FutureOfMobility#BatteryInnovation#EVCharging#SemcoInfratech#BatteryTestingSolutions#BatteryManufacturing#CleanEnergy#GreenTechnology#SmartMobility#EVCommunity

0 notes

Text

Discover the SEMCO SI CT 5V 10A 8CH – an efficient and accurate battery testing machine built for lithium-ion cell formation and performance analysis. Ideal for R&D and production lines.

#BatteryTesting#LithiumIonBattery#BatteryTestingMachine#SemcoInfratech#BatteryTech#EnergyStorage#EVBattery#BatteryManufacturing#BatteryTestingEquipment#ElectronicsTesting#RDEquipment#BatteryInnovation#8CHBatteryTester#SemcoBatteryTester#BatteryTestingSolution

0 notes