#Best Product Lifecycle Management (PLM)

Explore tagged Tumblr posts

Text

Teamcenter PLM Costing

#Siemens teamcenter price#cost reduction software#plm software#costmanagementsoftware#free plm software#plmsolutions#Siemens product lifecycle management#siemens teamcenter cost#teamcenter software#cost management software#Best PLM Software#teamcenter plm

0 notes

Text

Modern Product Lifecycle Management Isn’t Just for Tech Anymore

Product lifecycle management (PLM) is often pigeonholed into the IT world—but at 3R Technology, we've taken a broader view. We’re not just handling end-of-life laptops. We're navigating the full arc of a product's journey, from surplus to second life, across industries.

Whether you’re clearing out a lab, liquidating manufacturing equipment, or streamlining your inventory strategy, our model is built to unlock value from the unexpected.

The Engine Behind the Recovery: What Sets Us Apart

Multi-Channel Sales Reach We don’t rely on just one outlet to remarket your products. Through our established multi-channel sales platform, we cast a wide net to capture the best possible value for every item, whether it’s a server rack or a surplus microscope.

A Broker Network That Works Our extensive broker network gives us access to niche buyers and markets that typical resale channels overlook. That means more eyes on your assets and better returns at the end of the line.

Decades of Tactical Sales Expertise We bring technical sales acumen that’s been refined over decades. Our team knows how to position, price, and place your inventory for optimal results, no matter the product category.

What We Remarket

At 3R Technology, the word “remarket” isn’t limited to tech. Here’s a snapshot of what we handle:

IT equipment and electronics

Laboratory instruments

Industrial and manufacturing machinery

Surplus components and unused inventory

Return logistics materials

Office furniture and fixtures

If you can box it, pallet it, or roll it out—chances are, we can find it a buyer.

More Than Sales: A Full-Service PLM Solution

It’s not just about selling. It’s about strategy.

Our team provides a suite of services that takes the pressure off your internal operations:

Logistics Management: From pickups to drop-offs, we’ve got it covered.

Onsite Project Management: We manage removals and asset transitions with minimal disruption.

Fulfilment & Warehousing: Need space or storage while assets are staged for sale? We’ve got the infrastructure.

Why It Matters Now

In a market defined by agility, every piece of idle inventory represents lost opportunity. By partnering with 3R Technology, you transform those assets into revenue while meeting sustainability and compliance goals.

We don’t just remarket—we rethink what product lifecycle management can be.

In today’s competitive environment, assets that sit idle aren’t just collecting dust—they're collecting costs. At 3R Technology, our Product Lifecycle Management (PLM) service is engineered to recover value from equipment, inventory, and materials across every sector, not just IT.

Our model is built on decades of technical sales knowledge, a high-performing broker network, and an infrastructure that supports resale, removal, and redistribution. From electronics to office furniture, we find a second life for almost anything.

Here’s a closer look at how we make it happen.

Components

Whether brand new, unused, or removed from equipment, electronic components often retain significant value. Rather than letting these items go to waste in storage, we remarket them through targeted sales channels that reach the right buyers—engineers, refurbishers, and niche manufacturers.

From semiconductors and circuit boards to power supplies and cabling, we handle the resale process end-to-end, ensuring return value on even the smallest components.

Return Logistics

Returns are part of business, but they don’t have to be a loss. Our return logistics service manages everything from reverse shipping coordination to item processing, evaluation, and resale.

Whether you’re managing high-volume returns or dealing with one-off speciality items, we step in to streamline operations and ensure assets are re-integrated into the value chain, not discarded

Surplus Inventory

Excess stock is common across industries, especially when forecasts shift or production slows. Letting surplus sit on shelves isn’t a viable strategy and liquidation doesn’t have to mean giving it away.

We specialise in remarketing surplus inventory, from packaging materials and raw components to finished goods. Our multi-channel sales platform and broad broker reach allow us to find buyers in secondary and tertiary markets where demand still exists.

Office Furniture

Office downsizing, renovations, or closures often result in a flood of used furniture, most of which still has life left. Rather than pay for removal and disposal, organisations can turn to us to remarket these assets.

We handle everything: assessment, pickup, storage, and resale. From desks and chairs to conference tables and filing systems, office furniture is a viable resale category that too often gets overlooked.

Manufacturing Excess

Unused production equipment and over-ordered supplies tie up capital and space. We help manufacturers offload machinery, tools, and materials through proven resale channels that maximise return.

Our team understands the complexity of manufacturing environments and provides tailored support from on-site project management and equipment removal to warehousing and fulfilment.

We Handle the Rest, Too

Logistics, fulfilment, storage, resale, and reporting—we handle every phase so your team doesn’t have to. Whether you’re managing an asset disposition project or clearing out a facility, we act as a single point of contact for full-service product lifecycle management.

3R Technology, a CTL Company

8002 S 208th St Suite E105 Kent, WA 98032

(206) 582-7100

0 notes

Text

Top 5 Best CAD Software for Mechanical Design in 2025

Introduction

In the world of mechanical engineering, designing accurate, functional, and reliable components is critical. This is where CAD (Computer-Aided Design) software comes into play. CAD tools help engineers create, modify, analyze, and optimize mechanical designs with precision and efficiency.

With dozens of software options available, selecting the right CAD software can be challenging. Whether you're a student, a beginner, or a professional mechanical designer, this guide highlights the Top 5 Best CAD Software for Mechanical Design in 2024 to help you make the right choice.

1. AutoCAD

Overview:

Developed by Autodesk, AutoCAD has been a staple in the engineering and architecture industries for decades. It is widely used for 2D drafting and 3D modeling.

Key Features:

Precision drawing tools

Extensive library of mechanical components

Easy collaboration and documentation

Widely supported file formats

Best For:

Mechanical engineers and drafters who need detailed 2D/3D design capabilities.

2. SolidWorks

Overview:

SolidWorks, developed by Dassault Systèmes, is a parametric CAD tool that is highly favored for mechanical part and assembly design. It offers powerful simulation tools and an intuitive interface.

Key Features:

3D modeling with real-time simulation

Assembly modeling and motion analysis

Built-in design automation

Excellent for product development and prototyping

Best For:

Mechanical designers working with assemblies, simulations, and custom product development.

3. CATIA

Overview:

CATIA (Computer-Aided Three-dimensional Interactive Application) is another powerful tool from Dassault Systèmes, mainly used in the aerospace and automotive industries for complex product designs.

Key Features:

Advanced surface modeling and multi-disciplinary design

Seamless collaboration between teams

Integration with PLM (Product Lifecycle Management) tools

High-level system engineering support

Best For:

Large-scale industrial mechanical design, especially in high-end industries like aerospace.

4. Creo (formerly Pro/ENGINEER)

Overview:

Creo, developed by PTC, is known for its robust feature set covering everything from conceptual design to product simulation. It supports parametric and direct modeling.

Key Features:

Real-time simulation and analysis

AR (Augmented Reality) design visualization

Detailed sheet metal and plastic part design

Scalability across different stages of design

Best For:

Advanced mechanical engineering applications and enterprise-level product design.

5. Fusion 360

Overview:

Fusion 360 is a cloud-based CAD/CAM/CAE software from Autodesk. It’s beginner-friendly and widely used for product development, 3D printing, and CNC manufacturing.

Key Features:

Unified platform for CAD, CAM, and CAE

Cloud-based collaboration and file access

Free for students, startups, and hobbyists

Integrated simulation and generative design

Best For:

Startups, students, and small teams looking for a versatile and budget-friendly solution.

Conclusion

Choosing the right CAD software depends on your project requirements, industry standards, and level of expertise. Whether you're designing complex machinery or prototyping small components, these tools can transform your ideas into high-precision models.

From AutoCAD’s 2D/3D drafting to Fusion 360’s all-in-one cloud platform, each software brings unique strengths to the table. Mastering any of them can significantly boost your career in mechanical design.

#CAD Software 2025#Best CAD for Mechanical Design#3D CAD Tools#Engineering Design Software#Mechanical Design CAD#Top CAD Software 2025

0 notes

Text

Apparel Product Lifecycle Management Software: Why A2000 Software Can Help Maximize Your Fashion Business

Being ahead and having things processed in a systematized way is what helps its survival in this era of fast fashion. Apparel Product Lifecycle Management (PLM) Software is turning out to be the best way to remain in touch with fashion houses who are willing to maintain their processes at their optimal level from designing to the customer. A2000 Software offers a complete Apparel Product Lifecycle Management Software in which all and each product development process is simplified, and your business operates smoothly and competitively.

Visit Us - https://medium.com/@sanjanabrainfoster/apparel-product-lifecycle-management-software-why-a2000-software-can-help-maximize-your-fashion-d4c8335a77e3

0 notes

Text

Best Software Development Company for Manufacturing Industry

The manufacturing industry is undergoing a significant transformation with the integration of advanced technologies such as IoT, AI, and cloud computing. To stay competitive, manufacturers need robust software solutions that can streamline operations, improve productivity, and reduce costs. Choosing the right software development company for manufacturing industry can be the key to transforming your operations and enabling long-term success.

This article explores what makes a company the best software development partner for the manufacturing sector, and what specific manufacturing software development services they offer to help companies optimize their processes.

Why Manufacturing Industry Needs Specialized Software Development

Manufacturing is a complex industry with numerous processes, from procurement and production to inventory management and distribution. Standard off-the-shelf software may not address the intricacies of these workflows. Custom-built software solutions for manufacturing provide an integrated approach to handle the following:

Production Planning & Scheduling: Streamline the manufacturing process to optimize resources and ensure timely delivery.

Supply Chain Management: Maintain full control over suppliers, vendors, and distribution channels.

Inventory Control: Ensure real-time tracking of raw materials, in-progress items, and finished products.

Quality Assurance: Implement automation and monitoring tools to guarantee that products meet required standards.

Equipment Maintenance: Predictive maintenance tools can help reduce downtime and extend equipment life.

A trusted software development company with expertise in the manufacturing industry can offer tailored solutions that address all these needs.

Key Features of Software Development Company for Manufacturing Business

To determine the best software development company for manufacturing, it’s important to evaluate key factors that indicate reliability, technical expertise, and an understanding of the industry’s unique challenges. Here’s what to look for:

1. Industry-Specific Expertise

The manufacturing sector has its own set of challenges, from fluctuating supply chains to complex production schedules. The best software development company will have experience in working with manufacturing clients and possess a deep understanding of the industry’s specific requirements. They should be able to offer custom solutions that directly address issues like production efficiency, process automation, and supply chain optimization.

2. Proven Track Record

Look for companies with a proven track record of delivering successful manufacturing software projects. A portfolio of satisfied clients and case studies detailing previous work in the manufacturing domain can provide reassurance that the company can handle your unique software requirements.

3. Comprehensive Manufacturing Software Development Services

The best software development companies provide a range of services designed to meet the evolving needs of manufacturers. These include:

Enterprise Resource Planning (ERP) Systems: Fully integrated systems that help manufacturers manage everything from inventory to accounting in one place.

Manufacturing Execution Systems (MES): Software solutions that control and monitor production processes in real-time, ensuring maximum efficiency.

Supply Chain Management (SCM) Solutions: Platforms that allow manufacturers to track and manage every aspect of their supply chain, from raw materials to delivery.

Product Lifecycle Management (PLM) Software: Tools that help manufacturers manage the entire lifecycle of a product, from conception to disposal.

IoT Integration: Internet of Things (IoT) technologies that allow for real-time data collection and monitoring of manufacturing equipment.

4. Scalability and Flexibility

Manufacturing operations often change as businesses grow or enter new markets. The software development company you choose should provide scalable solutions that can adapt to your evolving needs. This means the software should be flexible enough to accommodate new processes, technologies, or increased production demands without major disruption.

5. Focus on Innovation

Technology is constantly evolving, and the manufacturing industry is no exception. The best software development companies stay up to date with the latest trends, such as Industry 4.0, AI-driven automation, and cloud-based solutions. They should be able to leverage these innovations to create cutting-edge software that gives manufacturers a competitive advantage.

Top Manufacturing Software Development Services

Leading software development companies offer a variety of services aimed at optimizing manufacturing processes and improving operational efficiency. Here are some core manufacturing software development services that are critical for modern manufacturers:

1. Custom ERP Solutions for Manufacturing

ERP systems are essential for coordinating different parts of the manufacturing process, including production, finance, human resources, and inventory. Custom ERP solutions can be tailored to meet the specific demands of each manufacturer, providing full integration across departments and improving overall efficiency.

2. Manufacturing Execution Systems (MES)

An MES tracks and documents the transformation of raw materials to finished products. These systems monitor real-time production, gather data, and analyze process performance. With an effective MES, manufacturers can reduce waste, increase production efficiency, and improve product quality.

3. Supply Chain Management Software

Supply chain visibility is crucial for manufacturers, especially in the face of global disruptions. Custom SCM solutions enable companies to optimize logistics, track inventory, predict demand, and manage suppliers in real time. With these tools, manufacturers can create more resilient supply chains and prevent bottlenecks.

4. Quality Management Systems (QMS)

Ensuring product quality is one of the most important aspects of manufacturing. A QMS helps track defects, monitor compliance, and implement corrective actions. Custom-built quality management systems ensure that products consistently meet customer and regulatory standards.

5. IoT Solutions for Smart Manufacturing

With the rise of the Internet of Things (IoT), manufacturers can now connect machines, equipment, and devices to the internet for real-time monitoring and control. IoT solutions enable predictive maintenance, remote monitoring, and data-driven insights that reduce downtime and increase productivity.

Conclusion

The best software development company for the manufacturing industry will understand the complexity of your business and offer customized solutions to meet your needs. By partnering with an experienced provider of manufacturing software development services, you can optimize your operations, reduce costs, and boost productivity. Be sure to choose a partner with a proven track record, industry expertise, and a commitment to innovation that will help take your manufacturing business to the next level.

👉 Contact Us Today for a Consultation and Turn Your Vision into Reality!

🌐 www.ebslon.com

#Manufacturing Software Development Company#Manufacturing Software Development#Software Development Company for Manufacturing Industry#Software Development for Manufacturing#Manufacturing Software Developer#Manufacturing Software Development services#Software#Software Development#Manufacture#Manufacturing

1 note

·

View note

Text

Happy New Year 2025!

Happy New Year 2025! Wishing you a year filled with new achievements, prosperity, and continued success. Thank you for being an integral part of our journey.

0 notes

Text

Upraise your Manufacturing business with Transines Solutions

Step Up Your Manufacturing Game and Embrace the Future-Ready Manufacturing Landscape

For business management, companies prefer a single software that can manage all the departments, like the accounting section, CRM management, sales and purchase section, and manufacturing field. Odoo simplifies all the different business stages and sections and integrating Odoo ERP for manufacturing will empower the business with increasing efficiency.

ERP software is the most important for a company since progress depends highly on the ERP System a company uses. the RRP System can make a business shine. So, a business should follow before choosing the Odoo Partner in UAE.

One Software for the Manufacturing processes Odoo ERP for the manufacturing business revolutionizing in the UAE market as the best manufacturing software.

Odoo Manufacturing Software Features

Odoo manufacturing ERP software is an ideal platform for production managers working in the manufacturing field. with Odoo ERP manufacturing businesses can get the Maximum retail price, execution systems (MES), Product lifecycle management (PLM), ERP Maintenance, and everything you need. the manufacturing ERP Simulates business operations in real-time, Manufacturing orders, capacity planning, components availability, and cost control. Odoo has barcode scanning for lots or serial numbers.

SCHEDULE YOUR ODOO CONSULTATION WITH TRANSINES SOLUTIONS

Business Scheduling with Odoo

Businesses must have experienced the pressure of hitting a deadline. Odoo ERP allows you to plan schedules with MRP Scheduler, multiple levels billing, a Kit for salespersons to sell products, and more

Manufacturing ERP lets you transform into a complete paper-free company, feedback scheduling, so the employe ain't want waste time in the manufacturing process.

Manufacturing business management software is a transformative power in the manufacturing industry. Odoo ERP helps with the processing of quality products and product maintenance, Odoo holds an automatic feature in the IoT box to trigger a quality check of all products before sending them to the manufactory. and Odoo provides a full maintenance report calculated from statistics.

The control panel has several convenient options like production recording, worksheets, alerts, work order steps, etc. Also directly from the work center more processes can created such as scraping products, perform checking and quality alerts creation.

Simplify cost counting with ease

Odoo Simplifies the manufacturing cost counting as it firstly calculates the cost of the components and the cost of operations, for sample, labor or material, and then tracks the cost of manufacturing consequently. All the traceability reports of the components used in the manufacturing business are accessible. Odoo Allows users to identify trends, uncover opportunities for improvement, and continuously optimize.

Transines Solutions Provides Odoo ERP Solutions to UAE businesses to raise the quality of your manufacturing business to another level with our Odoo Manufacturing Software. To learn more contact us

Also Read: How Odoo ERP can benefit the manufacturing industry

0 notes

Text

"Boost Your Career with SAP PLM Online Training – Explore Exciting Possibilities!"

youtube

Unlock new possibilities with SAP PLM Online Training at Proexcellency! Our comprehensive course is designed to help you master SAP PLM, a powerful solution for managing a product's lifecycle from concept to retirement. Through interactive lessons and hands-on projects, you'll learn how to streamline product development processes, enhance collaboration, and improve overall efficiency. Whether you're new to SAP PLM or looking to deepen your knowledge, our flexible training options make it easy to fit learning into your busy schedule. Join us at Proexcellency and take the first step towards advancing your career with SAP PLM expertise

Why SAP PLM?

SAP PLM is a comprehensive solution that helps businesses manage the entire lifecycle of their products efficiently. From initial ideas and development to production and retirement, SAP PLM streamlines processes, enhances collaboration, and improves overall efficiency. By mastering SAP PLM, you become a valuable asset to any organization, significantly boosting your career prospects.

What You’ll Learn

Our SAP PLM Online Training is designed to provide you with practical, real-world skills that you can apply immediately. Here’s a snapshot of what you can expect:

Introduction to SAP PLM: Get a solid understanding of SAP PLM, its architecture, and its importance in product lifecycle management.

Product Development and Design: Learn how to manage product data, design processes, and document control.

Project Management: Gain insights into project planning, execution, and monitoring using SAP PLM tools.

Collaboration and Communication: Discover how to enhance teamwork and communication within and across departments.

Quality Management: Understand how to ensure product quality throughout the lifecycle.

Hands-On Projects: Apply your learning with hands-on projects that simulate real business scenarios.

Learn from Industry Experts

At Proexcellency, our trainers are seasoned professionals with extensive experience in SAP PLM and product management. They bring real-world insights and practical knowledge to the course, ensuring you get the best learning experience. You’ll benefit from their expertise, gaining skills that are highly sought after in the industry.

Flexible Learning

We know that everyone’s schedule is different. That’s why our SAP PLM Online Training is designed to be flexible. You can access the course materials anytime, anywhere, and learn at your own pace. Whether you prefer studying in the evenings, on weekends, or during your lunch breaks, our online platform makes it easy to fit learning into your life.

Interactive and Engaging

Learning should be fun and engaging! Our training includes interactive videos, quizzes, and hands-on assignments to make the material easy to understand and enjoyable to learn. Plus, you’ll be part of a supportive community of fellow learners where you can share insights, ask questions, and get feedback.

Comprehensive Career Support

At Proexcellency, we’re dedicated to your success. That’s why we offer comprehensive career support, including resume building, interview preparation, and job placement assistance. Our goal is to help you land your dream job and achieve your career goals. We’ll be with you every step of the way, from learning to landing that perfect job.

Success Stories

Hear from our graduates who have successfully transitioned into rewarding careers after completing our SAP PLM Online Training. Their stories are a testament to the value of this course and the impact it can have on your career. Many of our alumni have secured positions at top companies, thanks to the skills and knowledge they gained through our training.

Enroll Today

Why wait? Take the first step towards a brighter future by enrolling in our SAP PLM Online Training today. With expert guidance, flexible learning options, and comprehensive career support, you’ll be well on your way to exploring exciting new opportunities and achieving your career goals.

Conclusion

SAP PLM Online Training at Proexcellency is more than just a course – it’s a pathway to career growth and success. By gaining expertise in SAP PLM, you’ll open doors to new opportunities, enhance your professional skills, and position yourself as a valuable asset in any organization. Our expert-led training, flexible learning options, and comprehensive career support make this course the perfect choice for anyone looking to advance their career.

Reach out to us at +91 9148251978

Feel free to drop us an email: [email protected]

0 notes

Text

Difference Between AutoCAD and CATIA: Which is Better CAD Tool?

When it comes to Computer-Aided Design (CAD) tools, AutoCAD and CATIA stand out as two of the most prominent software options in the industry. Both tools are renowned for their robust capabilities, but they serve distinct purposes and excel in different areas. If you're trying to determine which CAD tool is best suited for your needs, understanding Catia vs AutoCAD key differences can guide your decision. In this blog, we'll explore the features, strengths, and typical applications of AutoCAD and CATIA to help you make an informed choice.

AutoCAD: The Versatile Workhorse

AutoCAD, developed by Autodesk, has been a staple in the CAD industry since its inception in 1982. It is renowned for its versatility and broad applicability across various industries, including architecture, engineering, and construction (AEC). Here are some of its standout features:

1. 2D Drafting and 3D Modeling: AutoCAD excels in 2D drafting, offering a range of tools for creating detailed floor plans, technical drawings, and schematics. While its 3D modeling capabilities are not as advanced as CATIA’s, AutoCAD still provides essential tools for creating and manipulating 3D models. This makes it suitable for projects that require a combination of 2D and basic 3D designs.

2. User-Friendly Interface: One of AutoCAD's significant advantages is its user-friendly interface. Its tools and features are relatively easy to learn and use, making it accessible for both beginners and experienced designers. Autodesk also offers extensive online resources, tutorials, and a large community that can assist with troubleshooting and tips.

3. Compatibility and Integration: AutoCAD supports various file formats and integrates well with other Autodesk products, such as Revit and Civil 3D. This compatibility is particularly beneficial for collaborative projects involving different software tools. Additionally, AutoCAD's widespread adoption means that file sharing and communication with other professionals are generally smooth.

4. Customization and Automation: AutoCAD allows for a high degree of customization through AutoLISP, VBA, and .NET programming. Users can create custom scripts and automation to streamline repetitive tasks, which can significantly enhance productivity.

CATIA: The Advanced Design Powerhouse

CATIA, developed by Dassault Systèmes, is renowned for its advanced capabilities in 3D design and is widely used in industries such as aerospace, automotive, and industrial design. It offers a suite of powerful tools tailored to complex design and manufacturing processes. Here’s what sets CATIA apart:

1. Advanced 3D Modeling and Simulation: CATIA excels in advanced 3D modeling and simulation. Its robust surface modeling, parametric design, and generative shape design tools make it ideal for creating intricate and highly detailed models. CATIA is particularly strong in handling complex geometries and assemblies, which is crucial for industries with demanding design requirements.

2. Integrated Product Lifecycle Management (PLM): CATIA is integrated with Dassault Systèmes' PLM solutions, offering comprehensive management of the entire product lifecycle. This integration provides tools for product design, simulation, and manufacturing, all within a unified platform. It’s particularly useful for managing complex projects and coordinating between different teams.

3. Industry-Specific Solutions: CATIA offers specialized tools and modules tailored to specific industries. For example, the automotive and aerospace industries benefit from CATIA’s advanced capabilities in creating and managing complex parts and assemblies. This industry-specific focus allows for optimized workflows and better alignment with sector-specific standards.

4. High-Precision Design: CATIA’s tools are designed for high precision and accuracy, making it ideal for projects that require detailed and exact design specifications. This precision is essential for industries where design errors can lead to significant costs or safety issues.

Choosing the Right Tool

Deciding between AutoCAD and CATIA depends largely on your specific needs and the nature of your projects:

For General Drafting and Basic 3D Modeling: If your work primarily involves 2D drafting with occasional 3D modeling, AutoCAD’s versatility and ease of use make it an excellent choice. It’s also a good fit if you need a tool that integrates well with other Autodesk products and provides robust support and community resources.

For Complex 3D Design and Industry-Specific Applications: If your work involves intricate 3D modeling, simulation, or product lifecycle management, CATIA is likely the better option. Its advanced features and industry-specific tools cater to complex design needs, especially in sectors like aerospace and automotive.

Ultimately, both AutoCAD and CATIA are powerful CAD tools with their own strengths and specializations. By evaluating the specific requirements of your projects and considering the features offered by each software, you can choose the CAD tool that aligns best with your needs and enhances your design capabilities.

0 notes

Text

CATIA vs SolidWorks: Making the Right Choice with Dynamic CAD CAM CAE in Chennai

Choosing the right CAD (Computer-Aided Design) software is crucial for engineering professionals and organizations that aim to excel in design, simulation, and manufacturing processes. Two of the most popular and powerful CAD software options available today are CATIA and SolidWorks. Both are developed by Dassault Systèmes and offer extensive features tailored to various industries and applications. However, each software has its unique strengths and caters to different user needs. In this blog, we will explore the key differences, advantages, and applications of CATIA and SolidWorks to help you make an informed decision. Additionally, we will highlight the best training institutes for both software in Chennai, such as Dynamic CAD CAM CAE, to support your learning journey.

Introduction to CATIA

CATIA (Computer-Aided Three-dimensional Interactive Application) is a comprehensive multi-platform suite developed by Dassault Systèmes. It is widely recognized for its robust capabilities in 3D design, engineering, and product lifecycle management. CATIA is extensively used in industries like aerospace, automotive, shipbuilding, and industrial equipment, where complex and high-precision designs are essential.

Key Features of CATIA

Advanced 3D Modeling: CATIA excels in creating highly detailed and complex 3D models. It supports a wide range of design processes, from conceptualization to detailed engineering.

Multidisciplinary Approach: CATIA integrates multiple disciplines within a single platform, including mechanical engineering, systems engineering, and electrical design. This holistic approach enables seamless collaboration among various engineering teams.

Product Lifecycle Management (PLM): CATIA is known for its strong PLM capabilities, allowing organizations to manage the entire lifecycle of a product from inception through engineering design and manufacturing.

Simulation and Analysis: The software provides advanced simulation tools for stress analysis, kinematics, and fluid dynamics, helping engineers validate designs and optimize performance.

Surface Modeling: CATIA offers powerful surface modeling tools, making it ideal for industries that require complex surface designs, such as automotive and aerospace.

Introduction to SolidWorks

SolidWorks is another powerful CAD software developed by Dassault Systèmes, designed primarily for mechanical engineering and product design. It is widely used in industries such as consumer products, machinery, and electronics due to its user-friendly interface and robust design capabilities.

Key Features of SolidWorks

User-Friendly Interface: SolidWorks is known for its intuitive and easy-to-use interface, which significantly reduces the learning curve for new users.

Parametric Design: The software uses parametric design principles, allowing designers to easily make changes and updates to their models. This feature is particularly beneficial for iterative design processes.

Extensive Library of Components: SolidWorks offers a vast library of pre-built components and parts, saving time and effort in the design process.

Simulation and Analysis: Similar to CATIA, SolidWorks provides powerful simulation tools for stress analysis, motion analysis, and thermal analysis, enabling engineers to test and validate their designs.

Integration with CAM: SolidWorks integrates seamlessly with Computer-Aided Manufacturing (CAM) tools, facilitating the transition from design to manufacturing.

Comparing CATIA and SolidWorks

While both CATIA and SolidWorks are highly capable CAD software, their distinct features and functionalities make them suitable for different types of projects and industries. Let’s compare some key aspects to help you determine which software is the right fit for your needs.

Complexity and Scope

CATIA: Designed for large-scale and complex projects, CATIA is ideal for industries that require high precision and intricate designs. Its advanced surface modeling and PLM capabilities make it the preferred choice for aerospace, automotive, and industrial equipment sectors.

SolidWorks: Best suited for small to medium-sized projects, SolidWorks is widely used in industries like consumer products, machinery, and electronics. Its user-friendly interface and parametric design capabilities make it an excellent choice for mechanical engineering and product design.

Learning Curve

CATIA: Due to its extensive features and advanced functionalities, CATIA has a steeper learning curve. It requires more time and effort to master, making it essential for users to undergo comprehensive training.

SolidWorks: Known for its intuitive interface, SolidWorks has a shorter learning curve. Users can quickly become proficient with the software, making it a popular choice for beginners and those who need to start designing without extensive training.

Cost

CATIA: As a more complex and feature-rich software, CATIA tends to be more expensive than SolidWorks. The cost includes not only the software license but also potential training and implementation expenses.

SolidWorks: Generally more affordable than CATIA, SolidWorks offers a cost-effective solution for small to medium-sized businesses. The lower cost makes it accessible to a wider range of users and organizations.

Industry Applications

CATIA: Primarily used in aerospace, automotive, shipbuilding, and industrial equipment industries, CATIA’s advanced features and capabilities make it the go-to choice for companies involved in complex and large-scale projects.

SolidWorks: Widely used in consumer products, machinery, and electronics industries, SolidWorks is ideal for mechanical engineering, product design, and manufacturing processes that require a straightforward and efficient design tool.

Training and Certification

Proper training is essential to maximize the potential of any CAD software. In Chennai, Dynamic CAD CAM CAE is a renowned training institute offering comprehensive courses for both CATIA and SolidWorks. Let’s explore the training programs offered by this institute.

CATIA Training at Dynamic CAD CAM CAE

Dynamic CAD CAM CAE provides in-depth CATIA training programs designed to equip students with the knowledge and skills required to excel in the industry. The training covers:

Introduction to CATIA: Basics of the software, interface navigation, and essential tools.

3D Modeling: Techniques for creating detailed 3D models, including part design and assembly design.

Surface Modeling: Advanced surface design tools and techniques for creating complex shapes.

Simulation and Analysis: Utilizing CATIA’s simulation tools for stress analysis, kinematics, and more.

PLM Integration: Understanding CATIA’s PLM capabilities and how to manage product lifecycles effectively.

SolidWorks Training at Dynamic CAD CAM CAE

Dynamic CAD CAM CAE also offers specialized SolidWorks training programs tailored to meet industry standards. The training includes:

Introduction to SolidWorks: Basics of the software, interface, and core functionalities.

Part and Assembly Design: Techniques for creating parametric models, assemblies, and detailed drawings.

Simulation and Analysis: Using SolidWorks simulation tools for stress analysis, motion analysis, and thermal analysis.

CAM Integration: Understanding the integration between SolidWorks and CAM tools for seamless manufacturing processes.

Advanced Features: Exploring advanced design features, such as sheet metal design, weldments, and surfacing.

Choosing between CATIA and SolidWorks depends on your specific needs, industry requirements, and project complexity. CATIA is the preferred choice for industries that require advanced 3D modeling, surface design, and PLM capabilities, such as aerospace and automotive. On the other hand, SolidWorks is ideal for mechanical engineering, product design, and manufacturing processes in industries like consumer products, machinery, and electronics.

For those looking to gain expertise in either software, Dynamic CAD CAM CAE in Chennai offers top-notch training programs to help you master CATIA and SolidWorks. Whether you are an individual seeking to enhance your skills or an organization looking to train your team, Dynamic CAD CAM CAE provides comprehensive training solutions to meet your needs.

By understanding the key differences and advantages of CATIA and SolidWorks, and with proper training from a reputable institute like Dynamic CAD CAM CAE, you can make an informed decision and excel in your CAD projects. Embrace the right CAD software and unlock your potential in the world of design and engineering.

Choosing Between CATIA and SolidWorks: FAQs to Guide Your Decision with Dynamic CAD CAM CAE in Chennai

1. What are the primary differences between CATIA and SolidWorks?

CATIA and SolidWorks are both powerful CAD software developed by Dassault Systèmes, but they cater to different needs and industries. CATIA is designed for large-scale and complex projects, particularly in aerospace, automotive, shipbuilding, and industrial equipment industries. It excels in advanced 3D modeling, surface modeling, and product lifecycle management (PLM). SolidWorks, on the other hand, is best suited for small to medium-sized projects in consumer products, machinery, and electronics industries. It is known for its user-friendly interface, parametric design capabilities, and cost-effective solutions.

2. How do the learning curves of CATIA and SolidWorks compare?

CATIA has a steeper learning curve due to its extensive features and advanced functionalities. It requires more time and comprehensive training to master, making it essential for users to undergo in-depth courses. SolidWorks is known for its intuitive and easy-to-use interface, which significantly reduces the learning curve. Users can quickly become proficient with the software, making it a popular choice for beginners and those who need to start designing without extensive training.

3. What industries are CATIA and SolidWorks most suitable for?

CATIA is primarily used in industries that require high precision and intricate designs, such as aerospace, automotive, shipbuilding, and industrial equipment. Its advanced features and PLM capabilities make it the preferred choice for companies involved in complex and large-scale projects. SolidWorks is widely used in consumer products, machinery, and electronics industries. It is ideal for mechanical engineering, product design, and manufacturing processes that require a straightforward and efficient design tool.

4. How much does it cost to get trained in CATIA and SolidWorks in Chennai?

The cost of training in CATIA and SolidWorks can vary based on the training institute and the depth of the course. At Dynamic CAD CAM CAE in Chennai, comprehensive training programs are offered for both software. While the exact costs can vary, investing in quality training ensures that you gain the necessary skills to excel in your career. It is advisable to contact Dynamic CAD CAM CAE directly for detailed pricing and course information.

5. Why should I choose Dynamic CAD CAM CAE for CATIA and SolidWorks training in Chennai?

Dynamic CAD CAM CAE is a renowned training institute in Chennai, offering in-depth courses for both CATIA and SolidWorks. The institute provides specialized training programs designed to meet industry standards and equip students with the knowledge and skills required to excel in their careers. With comprehensive courses covering everything from basic to advanced features, simulation and analysis, and integration with other tools, Dynamic CAD CAM CAE ensures that you receive top-notch training and are well-prepared for the demands of the industry.

0 notes

Text

Best Practices for Eco-Friendly Computer Recycling

The rapid pace of technological upgrades means that computers and other electronic devices quickly become obsolete. However, simply discarding these outdated machines is not only wasteful but also harmful to the environment. With electronic waste being a growing concern, it’s more important than ever to recycle computers in an eco-friendly manner.

Today, responsible computer recycling isn’t just about getting rid of old equipment—it’s about making a conscious choice to protect our planet. Here’s how you can do it effectively while ensuring your actions contribute positively to environmental sustainability.

The Importance of Eco-Friendly Computer Recycling

Recycling computers in an eco-friendly manner is crucial because electronic waste (e-waste) is one of the fastest-growing waste streams in the world. Improper disposal of computers can lead to harmful chemicals like lead, mercury, and cadmium seeping into the environment. This not only pollutes the soil and water but also poses serious health risks to humans and wildlife.

Eco-friendly computer recycling ensures that valuable materials like metals, plastics, and glass are recovered and reused, reducing the need for raw material extraction. Additionally, it minimizes the amount of waste that ends up in landfills, supporting a more sustainable approach to product lifecycle management.

Here are the best practices for eco-friendly computer recycling

Selecting A Certified Computer Recycling Service That Meets Your Environmental Goals

Selecting the right computer recycling service is crucial to ensure that your old devices are disposed of responsibly. Look for a service provider that is certified by recognized environmental standards, such as R2 (Responsible Recycling) or e-Stewards. These certifications ensure that the recycling process meets strict environmental and data security standards.

It's also important to choose a recycling service that aligns with your company’s environmental goals. Ask about their methods for data destruction, as well as their processes for recycling different components of computers. A certified provider will also offer documentation and reports that confirm your devices have been recycled according to regulatory guidelines.

Ensuring Data Security Before Recycling

One of the main concerns when recycling computers is ensuring that all data is securely wiped from the devices. Simply deleting files is not enough, as data can still be recovered. To protect your business or personal information, it's essential to use certified data destruction methods before recycling your computer.

Certified computer recycling services offer data destruction processes that ensure all data is permanently removed. This includes options like physical destruction of the hard drive or using software to overwrite data multiple times. Ensuring data security not only protects sensitive information but also aligns with product lifecycle management by responsibly handling the end-of-life stage of your computer.

Incorporating Computer Recycling into Your Product Lifecycle Management Strategy

Effective product lifecycle management (PLM) involves planning for the entire lifespan of a product, from design and manufacturing to end-of-life disposal. Incorporating computer recycling into your PLM strategy ensures that your business handles outdated technology in a way that supports sustainability and compliance.

Start by creating a recycling policy that outlines how computers and other electronic devices will be disposed of when they reach the end of their useful life. This policy should include steps for secure data destruction, selection of a certified recycling service, and documentation of the recycling process. By making computer recycling a part of your PLM strategy, you demonstrate a commitment to environmental responsibility and resource conservation.

Overcoming Common Challenges in Computer Recycling for Businesses & Individuals

Recycling computers can come with challenges, especially when it comes to ensuring that the process is both environmentally friendly and secure. One common issue is the lack of awareness about how and where to recycle computers. Many businesses and individuals are unsure of the options available to them or may assume that simply dropping off devices at a local recycling center is sufficient.

To overcome this, research and identify certified computer recycling services in your area. These services often provide pick-up options for businesses, making it easier to recycle large volumes of equipment. Additionally, consider partnering with organizations that specialize in product lifecycle management to ensure that your recycling efforts are efficient and effective.

Another challenge is ensuring compliance with data protection regulations during the recycling process. By partnering with a certified recycling provider that offers secure data destruction, you can address this concern and confidently recycle your old computers.

Ready to Recycle? Contact Us for Certified & Secure Computer Recycling Services

Recycling your old computers in an eco-friendly manner is an essential step toward reducing e-waste and protecting the environment. By following these best practices and incorporating computer recycling into your product lifecycle management strategy, you can ensure that your technology is disposed of responsibly.

If you’re ready to take the next step, contact 3R Technology today to learn more about our certified and secure computer recycling services. Let us help you meet your environmental goals while ensuring that your data is protected and your old devices are recycled the right way.

3R Technology

8002 S 208th St E105, Kent, WA 98032

+12065827100

0 notes

Text

PDM vs. PLM: Choosing the Right Data Management Solution for Your Business

This is an article that discusses the two data management solutions, PDM and PLM, and helps you decide which is best for your business needs. PDM stands for Product Data Management and focuses on managing data during the design and engineering phases of a product's life. PLM, or Product Lifecycle Management, has a broader scope and manages data across the entire lifecycle of a product, from design and engineering to manufacturing, marketing, and service.

0 notes

Link

1 note

·

View note

Text

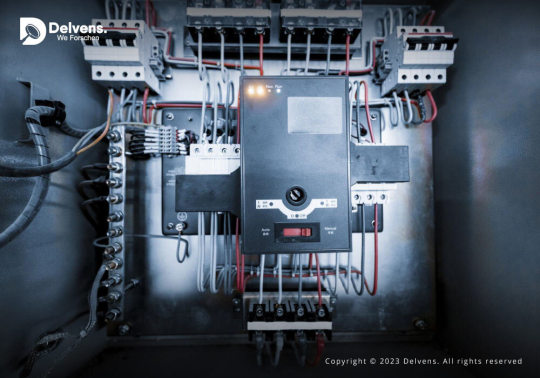

Industrial Controls Market – Trends Forecast Till 2030

Industrial Controls Market analysis report figures out market landscape, brand awareness, latest trends, possible future issues, industry trends and customer behaviour so that the business can stand high in the crowd. It includes extensive research on the current conditions of the industry, potential of the market in the present and the future prospects from various angles. This Industrial Controls Market report comprises of data that can be pretty essential when it comes to dominating the market or making a mark in the Semiconductors & Electronics industry as a new emergent. To bestow clients with the best results, Industrial Controls Market research report is produced by using integrated approaches and latest technology.

Download Free Sample Report at: https://www.delvens.com/get-free-sample/industrial-controls-market

Industrial Controls Market by Type (Distributed Control System, Supervisory Control & Data Acquisition System, Manufacturing Execution System, Programmable Logic Controller (PLC), Product Lifecycle Management (PLM), Enterprise Resource Planning (ERP), Human Machine Interface (HMI) and Others), Component (Modular Terminal Blocks, Relays & Optocouplers, Surge Protectors, Marking Systems, Printing, Ferulles Cable Lugs, Handtools, Testers, Enclosure Products, PCB Connectors & Terminals, Heavy Duty Connectors, Analog Signal Conditioner, Electronic Housings, Power Supplies, Industrial Ethernet, and Remote IO), Application and End User (Automotive, Utility, Electronics & Semiconductors, Oil and Gas, Chemical and Petrochemical, Power, Life Sciences, Food and Beverage and Mining), and region (North America, Europe, Asia-Pacific, Middle East and Africa and South America), global opportunity analysis and Industry Forecast, 2023-2030. The global Industrial Controls market size was estimated at USD 140 billion in 2023 and is projected to reach USD 239.9354 billion in 2030 at a CAGR of 8% during the forecast period 2023-2030.

Industrial Controls Market Competitive Landscape:

ABB Ltd.

Emerson Electric Corporation

Honeywell International Incorporation

Kawasaki Robotics control system

Mitsubishi Electric Factory Automation

Omron Corporation

Rockwell Automation Inc.

Siemens AG

Schneider Electric SA

Yokogawa Electric Corporation

Endress+Hauser AG

General Electric

GLC Controls Inc.

Industrial Controls Market Recent Developments:

In July 2022, IBM acquired Databand.ai, a leading provider of data observability software that helps organizations fix issues with their data, including errors, pipeline failures, and poor quality, before it impacts their bottom line.

In July 2022, Sap acquired Askdata to strengthen its ability to help organizations take better-informed decisions by leveraging AI-driven natural language searches. Users are empowered to search, interact, and collaborate on live data to maximize business insights.

Make an Inquiry Before Buying at: https://www.delvens.com/Inquire-before-buying/industrial-controls-market

Industrial controls systems refer to various automation devices, machines and equipment used in industry. They are developed to better control and monitor industrial processes and automate tasks to increase efficiency and reliability while improving quality. These systems include a variety of controls systems such as supervisory control and data acquisition or SCADA, programmable logic controllers or PLCs, and distributed controls systems or DCS.

They can help automate processes, critical infrastructure or remote monitoring and management. They also help collect data from remote devices, monitor the operation of distributed factories, and perform automated electromechanical processes. Rapid adoption of cloud-based services and growing automation trends in industry are important factors for the global industry. Market dominance. Automation helps industries achieve better accuracy and quality while reducing costs.

Growth is driven by the demand for intelligent controls systems and automation in various industries, mass production in industry and the adoption of industrial controls systems in various end-uses such as automotive and mining, as well as increasing R&D investments. in the industrial control market. However, increasing cyber-attacks, lack of authentication procedures, lack of experienced professionals and awareness of industrial security solutions are restraining the growth of the industrial controls market. In addition, the deployment of a smart grid to protect critical infrastructure against cyber-attacks and cloud computing for industrial controls systems creates lucrative opportunities for the industrial surveillance market.

Scope of the Industrial Controls Market Report:

The Industrial Controls Market is segmented into various segments such as type, component, End user and region:

Based on type

Distributed control system (DCS)

Supervisory control & data acquisition system (SCADA)

Manufacturing execution system (MES)

Programmable Logic Controller (PLC)

Product Lifecycle Management (PLM)

Enterprise Resource Planning (ERP)

Human Machine Interface (HMI)

Others

Based on the component

Modular terminal blocks

Relays & optocouplers

Surge protectors

Marking systems

Printing

Ferulles cable lugs

Handtools

Testers

Enclosure products

PCB connectors and terminals

Heavy duty connectors

Analog signal conditioner

Electronic housings

Power supplies

Industrial ethernet

Remote IO

Based on the End user

Automotive

Utility

Electronics & semiconductors

Mining

Oil and Gas

Chemical and Petrochemical

Power

Life Sciences

Food and Beverage

Others

Based on Application

Automotive

Pharmaceutical

Oil & Gas

Electrical Power

Others

Based on Network

Fieldbus

Communication Router

Firewall

MODEMS

Remote Access Points

Based on region

Asia Pacific

North America

Europe

South America

Middle East & Africa

Industrial Controls Market Regional Analysis:

North America to Dominate the Market

North America is on the brink of the fourth industrial revolution. The data generated is used for high-volume production, while the data is integrated into various production systems throughout the supply chain. The region is also one of the world's largest automotive markets, with more than 13 major automotive manufacturers operating. The automobile industry was one of the largest income generators in the region. Due to significant adoption of industrial control systems and automation technologies in the automotive industry, the region offers a huge opportunity for market growth.

Several key vendors operating in the country are launching new upgrades to support the growth of smart factories along with the development of industrial control systems. Such technological development indicates regional growth in the studied market.

Direct Purchase of the Industrial Controls Market Research Report at: https://www.delvens.com/checkout/industrial-controls-market

Browse Related Reports:

12V Lithium-Ion Battery Market

Pressure Sensor Market

Industrial Valves Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-3290-6466

#consulting company#strategic advisory firm#best market reports#trending reports#market analysis reports#syndicated reports#Industrial Controls Market#Industrial Controls

0 notes

Text

Ariba Product Sourcing

SAP Ariba Product Sourcing: Streamlining Direct Material Procurement

In the intricate world of manufacturing, effectively managing the sourcing and procurement of direct materials is paramount for efficiency, cost control, and seamless production. SAP Ariba Product Sourcing is designed to revolutionize this process, offering a powerful suite of tools specifically geared toward direct material sourcing. Let’s explore what it offers.

What is SAP Ariba Product Sourcing?

SAP Ariba Product Sourcing is a module within the larger SAP Ariba Strategic Sourcing Suite. It focuses on the unique challenges of sourcing raw materials and components used directly in manufacturing. It goes beyond traditional sourcing solutions with features tailored for handling Bills of Materials (BOMs), complex cost calculations, and deep integration with product lifecycle management (PLM) systems.

Key Features and Benefits

BOM Management: Ariba Product Sourcing lets you import and manage BOMs directly from your PLM system. This ensures data consistency and enables accurate cost roll-ups, where you can see the total potential cost of a manufactured product based on the prices of its components.

Cost Analysis: The platform allows you to track material prices over time and get insights into historical trends. This data will enable you to negotiate better prices with suppliers, identify cost-saving opportunities, and make smarter budgeting decisions.

BOM Comparison: Easily compare BOMs side-by-side to pinpoint price discrepancies between different versions or iterations of your product. This lets you track how design changes impact overall costs.

Collaborative Sourcing: Create sourcing events directly from BOMs. Invite relevant suppliers, gather bids, and track responses all within the platform, streamlining the bidding process.

Integration Power: Ariba Product Sourcing seamlessly integrates with your PLM, ERP, and other procurement systems. This minimizes manual data entry errors and ensures all systems work together.

Why Choose SAP Ariba Product Sourcing?

Improved Cost Management: The in-depth cost analysis abilities help you identify savings opportunities, get better deals from suppliers, and make data-driven decisions that impact your bottom line.

Faster Source-to-Contract Cycles: By streamlining the process from BOM import to awarding contracts, Ariba Product Sourcing accelerates your procurement timelines and keeps production schedules moving.

Enhanced Collaboration: The platform promotes collaboration between internal stakeholders (engineering, procurement) and enables efficient supplier communication, leading to better-informed sourcing choices.

Data-Driven Decision Making: With historical material pricing data, BOM analysis, and detailed sourcing metrics, you gain the insights to make intelligent, strategic procurement decisions.

Who Needs SAP Ariba Product Sourcing?

Ariba Product Sourcing is beneficial for any manufacturer dealing with complex BOMs and direct material procurement, particularly those in industries such as:

Automotive

Electronics

Industrial Machinery

Aerospace

Getting Started

If you’re using SAP Ariba Sourcing solutions, you might already have access to Product Sourcing. Consult your SAP Ariba representative or solution expert to learn more about implementing this module.

youtube

You can find more information about SAP ARIBA in this SAP ARIBA Link

Conclusion:

Unogeeks is the No.1 IT Training Institute for SAP Training. Anyone Disagree? Please drop in a comment

You can check out our other latest blogs on SAP ARIBA here – SAP ARIBA Blogs

You can check out our Best In Class SAP ARIBA Details here – SAP ARIBA Training

Follow & Connect with us:

———————————-

For Training inquiries:

Call/Whatsapp: +91 73960 33555

Mail us at: [email protected]

Our Website ➜ https://unogeeks.com

Follow us:

Instagram: https://www.instagram.com/unogeeks

Facebook: https://www.facebook.com/UnogeeksSoftwareTrainingInstitute

Twitter: https://twitter.com/unogeek

1 note

·

View note