#Manufacturing Software Development Company

Explore tagged Tumblr posts

Text

Lemonade’s success demonstrates the immense potential of AI-powered analysis and automation in revolutionizing traditional industries. SMBs have a unique opportunity to adopt similar strategies by partnering with Performix, a trusted AI software development company in the USA. With expertise in building AI assistants, leveraging predictive analytics, and empowering businesses with advanced AI tools, Performix is your partner in driving innovation and achieving sustainable growth.

#performix#software companies near me#web designers near me#manufacturing software development services#manufacturing software development company

0 notes

Text

Best Software Development Company for Manufacturing Industry

The manufacturing industry is undergoing a significant transformation with the integration of advanced technologies such as IoT, AI, and cloud computing. To stay competitive, manufacturers need robust software solutions that can streamline operations, improve productivity, and reduce costs. Choosing the right software development company for manufacturing industry can be the key to transforming your operations and enabling long-term success.

This article explores what makes a company the best software development partner for the manufacturing sector, and what specific manufacturing software development services they offer to help companies optimize their processes.

Why Manufacturing Industry Needs Specialized Software Development

Manufacturing is a complex industry with numerous processes, from procurement and production to inventory management and distribution. Standard off-the-shelf software may not address the intricacies of these workflows. Custom-built software solutions for manufacturing provide an integrated approach to handle the following:

Production Planning & Scheduling: Streamline the manufacturing process to optimize resources and ensure timely delivery.

Supply Chain Management: Maintain full control over suppliers, vendors, and distribution channels.

Inventory Control: Ensure real-time tracking of raw materials, in-progress items, and finished products.

Quality Assurance: Implement automation and monitoring tools to guarantee that products meet required standards.

Equipment Maintenance: Predictive maintenance tools can help reduce downtime and extend equipment life.

A trusted software development company with expertise in the manufacturing industry can offer tailored solutions that address all these needs.

Key Features of Software Development Company for Manufacturing Business

To determine the best software development company for manufacturing, it’s important to evaluate key factors that indicate reliability, technical expertise, and an understanding of the industry’s unique challenges. Here’s what to look for:

1. Industry-Specific Expertise

The manufacturing sector has its own set of challenges, from fluctuating supply chains to complex production schedules. The best software development company will have experience in working with manufacturing clients and possess a deep understanding of the industry’s specific requirements. They should be able to offer custom solutions that directly address issues like production efficiency, process automation, and supply chain optimization.

2. Proven Track Record

Look for companies with a proven track record of delivering successful manufacturing software projects. A portfolio of satisfied clients and case studies detailing previous work in the manufacturing domain can provide reassurance that the company can handle your unique software requirements.

3. Comprehensive Manufacturing Software Development Services

The best software development companies provide a range of services designed to meet the evolving needs of manufacturers. These include:

Enterprise Resource Planning (ERP) Systems: Fully integrated systems that help manufacturers manage everything from inventory to accounting in one place.

Manufacturing Execution Systems (MES): Software solutions that control and monitor production processes in real-time, ensuring maximum efficiency.

Supply Chain Management (SCM) Solutions: Platforms that allow manufacturers to track and manage every aspect of their supply chain, from raw materials to delivery.

Product Lifecycle Management (PLM) Software: Tools that help manufacturers manage the entire lifecycle of a product, from conception to disposal.

IoT Integration: Internet of Things (IoT) technologies that allow for real-time data collection and monitoring of manufacturing equipment.

4. Scalability and Flexibility

Manufacturing operations often change as businesses grow or enter new markets. The software development company you choose should provide scalable solutions that can adapt to your evolving needs. This means the software should be flexible enough to accommodate new processes, technologies, or increased production demands without major disruption.

5. Focus on Innovation

Technology is constantly evolving, and the manufacturing industry is no exception. The best software development companies stay up to date with the latest trends, such as Industry 4.0, AI-driven automation, and cloud-based solutions. They should be able to leverage these innovations to create cutting-edge software that gives manufacturers a competitive advantage.

Top Manufacturing Software Development Services

Leading software development companies offer a variety of services aimed at optimizing manufacturing processes and improving operational efficiency. Here are some core manufacturing software development services that are critical for modern manufacturers:

1. Custom ERP Solutions for Manufacturing

ERP systems are essential for coordinating different parts of the manufacturing process, including production, finance, human resources, and inventory. Custom ERP solutions can be tailored to meet the specific demands of each manufacturer, providing full integration across departments and improving overall efficiency.

2. Manufacturing Execution Systems (MES)

An MES tracks and documents the transformation of raw materials to finished products. These systems monitor real-time production, gather data, and analyze process performance. With an effective MES, manufacturers can reduce waste, increase production efficiency, and improve product quality.

3. Supply Chain Management Software

Supply chain visibility is crucial for manufacturers, especially in the face of global disruptions. Custom SCM solutions enable companies to optimize logistics, track inventory, predict demand, and manage suppliers in real time. With these tools, manufacturers can create more resilient supply chains and prevent bottlenecks.

4. Quality Management Systems (QMS)

Ensuring product quality is one of the most important aspects of manufacturing. A QMS helps track defects, monitor compliance, and implement corrective actions. Custom-built quality management systems ensure that products consistently meet customer and regulatory standards.

5. IoT Solutions for Smart Manufacturing

With the rise of the Internet of Things (IoT), manufacturers can now connect machines, equipment, and devices to the internet for real-time monitoring and control. IoT solutions enable predictive maintenance, remote monitoring, and data-driven insights that reduce downtime and increase productivity.

Conclusion

The best software development company for the manufacturing industry will understand the complexity of your business and offer customized solutions to meet your needs. By partnering with an experienced provider of manufacturing software development services, you can optimize your operations, reduce costs, and boost productivity. Be sure to choose a partner with a proven track record, industry expertise, and a commitment to innovation that will help take your manufacturing business to the next level.

👉 Contact Us Today for a Consultation and Turn Your Vision into Reality!

🌐 www.ebslon.com

#Manufacturing Software Development Company#Manufacturing Software Development#Software Development Company for Manufacturing Industry#Software Development for Manufacturing#Manufacturing Software Developer#Manufacturing Software Development services#Software#Software Development#Manufacture#Manufacturing

1 note

·

View note

Text

How is Industry 4.0 transforming manufacturing software development?

1 note

·

View note

Text

The Impact of a Skilled Manufacturing Software Developer on Operational Efficiency

Operational efficiency is key to success. Manufacturers are constantly seeking ways to enhance productivity, reduce costs, and streamline processes. One of the most impactful ways to achieve this is by integrating technology solutions into manufacturing operations. This is where the role of a skilled Manufacturing Software Developer comes in, revolutionizing the way businesses operate through custom solutions that meet their specific needs.

The Rise of Smart Manufacturing

The digital transformation in manufacturing has given rise to smart manufacturing, an industry trend that leverages data, automation, and software-driven processes. From managing supply chains to monitoring equipment and production lines, smart manufacturing relies heavily on specialized software to deliver seamless, efficient operations.

A Manufacturing Software Development Company plays a pivotal role in this transformation by developing robust software solutions tailored to meet the unique needs of each manufacturer. The result is improved operational efficiency, higher productivity, and reduced overhead costs.

How a Skilled Manufacturing Software Developer Drives Efficiency:

1. Custom Solutions for Unique Needs

Manufacturing environments are complex, with each business facing unique operational challenges. A skilled Manufacturing Software Developer possesses the expertise to analyze these challenges and design custom software solutions that address them. This personalized approach ensures that manufacturers get a solution that aligns perfectly with their workflow, helping to automate processes, reduce manual intervention, and eliminate inefficiencies.

2. Integration of Advanced Technologies

The integration of technologies like IoT (Internet of Things), AI (Artificial Intelligence), and ML (Machine Learning) into manufacturing processes is now critical for success. A proficient software developer understands how to integrate these technologies into existing systems, enabling real-time data monitoring, predictive maintenance, and advanced analytics. This helps manufacturers to anticipate potential issues, minimize downtime, and enhance overall equipment efficiency.

3. Scalability and Flexibility

As manufacturing operations grow, so do their software needs. A reputable Manufacturing Software Development Company ensures that their solutions are scalable, meaning that they can evolve in line with the business’s growth. Flexible software solutions allow manufacturers to adapt quickly to market changes, production demands, and new technologies, all of which play a vital role in maintaining long-term operational efficiency.

4. Enhanced Data Management

Data management is the backbone of any modern manufacturing operation. Effective data collection, processing, and analysis provide manufacturers with crucial insights into their operations. Skilled software developers design solutions that integrate seamlessly with existing enterprise systems, offering centralized data control, real-time reporting, and analytics. This not only helps in decision-making but also ensures compliance with industry regulations and quality standards.

Why Choose a Manufacturing Software Development Company?

Partnering with a Manufacturing Software Development Company offers a host of benefits beyond just technical support. These companies bring a wealth of industry-specific knowledge and experience that is crucial for understanding the nuances of the manufacturing sector. By offering end-to-end software development services, from initial consultation to post-implementation support, these companies ensure that the software performs optimally at all times.

Moreover, manufacturing businesses that work with specialized software development companies can reduce the risk of costly mistakes and improve their operational agility. This makes it easier to scale, innovate, and remain competitive in a fast-paced market.

Finishing Off

In the competitive world of manufacturing, operational efficiency can be the difference between success and failure. A skilled Manufacturing Software Developer can help manufacturers achieve this efficiency by delivering custom solutions that streamline processes, reduce downtime, and integrate cutting-edge technologies. Partnering with a trusted Manufacturing Software Development Company is the most effective way to harness the power of software and drive long-term business growth.

0 notes

Text

PhoenixBizz offers custom manufacturing software development services. We design and develop manufacturing software for all your manufacturing needs.

#Manufacturing Software Development Company#Manufacturing Software Development#Manufacturing Software Development Services#Custom Manufacturing Software Development#Manufacturing Software#Manufacturing#Software Development#PhoenixBizz

0 notes

Text

ERP in Manufacturing: What You Need to Know for Business Growth

In today's dynamic business landscape, manufacturing companies face numerous challenges, from volatile market demands to complex supply chain management. To thrive in this competitive environment, organizations are increasingly turning to Enterprise Resource Planning (ERP) systems. In this blog post, we will explore the significance of ERP systems for manufacturing companies, their role in software development companies, and the key factors that contribute to business growth.

Understanding ERP Systems for Manufacturing Companies

The Core of ERP: Integration and Automation

ERP systems are comprehensive software solutions designed to integrate and streamline various business processes within an organization. For manufacturing companies, ERP serves as a centralized platform that connects different departments such as production, inventory, procurement, finance, and human resources. The integration of these processes results in improved communication, data accuracy, and operational efficiency.

Key Features of ERP in Manufacturing

1. Production Planning and Scheduling:

ERP systems enable manufacturing companies to optimize production processes by providing real-time insights into resource availability, production capacity, and demand forecasting. This ensures that production schedules are aligned with market demands, reducing the risk of overproduction or stockouts.

2. Inventory Management:

Efficient inventory management is crucial for manufacturing companies. ERP software helps organizations maintain optimal inventory levels, minimize carrying costs, and prevent stockouts. It also facilitates better demand planning and order fulfillment.

3. Quality Control:

ERP systems play a vital role in maintaining product quality by tracking and managing every stage of the manufacturing process. This includes monitoring raw materials, production processes, and finished goods to ensure they meet industry standards and customer expectations.

4. Supply Chain Visibility:

With ERP, manufacturing companies gain better visibility into their supply chain. This visibility helps in identifying potential bottlenecks, reducing lead times, and enhancing collaboration with suppliers. A transparent supply chain is essential for meeting customer demands and maintaining a competitive edge.

5. Financial Management:

ERP systems provide robust financial modules that help manufacturing companies manage budgets, track costs, and generate accurate financial reports. This financial transparency enables informed decision-making and ensures compliance with regulatory requirements.

ERP for Software Development Companies: A Unique Perspective

While traditionally associated with manufacturing, ERP systems have found their way into software development companies as well. The principles of integration, automation, and streamlined processes are just as applicable in the software industry.

Project Management and Collaboration

In software development, ERP systems assist in project management by centralizing tasks, timelines, and resource allocation. This ensures that development teams work cohesively, deadlines are met, and resources are utilized efficiently. Collaboration is enhanced through shared data and communication channels, leading to improved project outcomes.

Resource Allocation and Time Tracking

ERP software allows software development companies to optimize resource allocation and track time spent on different projects. This data-driven approach enhances project planning, improves resource efficiency, and provides insights for future capacity planning.

Scalability and Flexibility

Software companies often face rapidly changing project scopes and client requirements. ERP systems provide the scalability and flexibility needed to adapt to these changes seamlessly. Whether it's adding new features, accommodating changes in project timelines, or expanding the scope, ERP systems empower software development companies to stay agile.

Key Considerations for Implementing ERP in Manufacturing

1. Customization and Flexibility:

Manufacturing companies should look for ERP solutions that offer customization options to align with specific industry needs. Flexibility is crucial, considering the diverse manufacturing processes and business models.

2. User Training and Change Management:

Successful ERP implementation requires thorough training of users and effective change management strategies. Employees need to understand the benefits of ERP and be comfortable with the new system to ensure smooth adoption.

3. Data Security and Compliance:

Given the sensitive nature of manufacturing data, security is a top priority. ERP systems must comply with industry regulations and provide robust security features to safeguard intellectual property, customer information, and business-critical data.

4. Integration with Existing Systems:

Seamless integration with existing software and systems is essential for a smooth transition to ERP. Compatibility with other tools and technologies ensures that there is no disruption in day-to-day operations during the implementation phase.

5. Scalability for Future Growth:

An ERP system should be scalable to accommodate the growing needs of a manufacturing company. It should support expansion into new markets, additional product lines, and increased production volumes without compromising performance.

Conclusion: Driving Business Growth with ERP

In conclusion, ERP systems have become indispensable tools for manufacturing companies seeking sustainable growth in a competitive market. By integrating and automating core business processes, ERP not only enhances operational efficiency but also provides valuable insights for strategic decision-making.

For software development companies, the adaptability of ERP systems offers a unique advantage in managing the dynamic and ever-evolving nature of the industry. The principles that make ERP effective in manufacturing—integration, automation, and streamlined processes—are equally applicable and beneficial in the software development landscape.

As businesses continue to evolve, embracing ERP is not just a technological choice; it's a strategic one. Those who invest in robust ERP solutions position themselves for improved competitiveness, increased profitability, and sustainable growth in the long run.

#ERP systems for manufacturing companies#ERP for manufacturing companies#ERP for software development company#ERP software for manufacturing companies#India#Gujarat#Vadodara#ERP India#Business Solutions#manufacurer#ERP software

9 notes

·

View notes

Text

ERP Trends 2024: What Engineering and Manufacturing Industries Need to Know

As we navigate through 2024, the landscape of Enterprise Resource Planning (ERP) systems continues to evolve, presenting both opportunities and challenges for engineering and manufacturing industries. Companies in this sector, especially those in key industrial regions like Maharashtra, Mumbai, Pune, and Gujarat, must stay abreast of the latest ERP trends to maintain competitive advantage and operational efficiency. In this blog, we’ll delve into the significant ERP trends of 2024 and their implications for the engineering and manufacturing sectors.

1. Increased Adoption of Cloud-Based ERP Solutions

One of the most significant trends in ERP software for engineering companies in Maharashtra and across India is the shift towards cloud-based solutions. Cloud ERP offers several advantages over traditional on-premise systems, including lower upfront costs, greater scalability, and enhanced accessibility.

Benefits of Cloud-Based ERP:

Cost Efficiency: Eliminates the need for expensive hardware and reduces IT maintenance costs.

Scalability: Easily adjusts to the growing needs of a manufacturing company in Gujarat or an engineering firm in Mumbai.

Accessibility: Provides access to real-time data from anywhere, facilitating better decision-making.

Leading ERP software companies in Pune are increasingly offering cloud-based solutions tailored to the needs of local engineering and manufacturing businesses. These solutions support remote work and ensure business continuity in an increasingly digital world.

2. Integration of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing ERP systems by providing intelligent insights and automating routine tasks. For ERP software for engineering companies in Mumbai, integrating AI can enhance predictive maintenance, optimize supply chain management, and improve production planning.

AI and ML Applications in ERP:

Predictive Analytics: Helps foresee equipment failures and reduce downtime.

Supply Chain Optimization: Enhances demand forecasting and inventory management.

Process Automation: Automates repetitive tasks, freeing up human resources for more strategic roles.

ERP solution providers in Pune are at the forefront of integrating AI and ML into their systems, enabling companies to leverage advanced analytics and improve overall operational efficiency.

3. Emphasis on Cybersecurity

With the increasing digitization of manufacturing processes, cybersecurity has become a critical concern. ERP systems, being the backbone of business operations, are prime targets for cyber-attacks. Engineering and manufacturing companies in regions like Gujarat and Maharashtra need robust cybersecurity measures to protect their sensitive data.

Key Cybersecurity Features:

Data Encryption: Protects data during transmission and storage.

Multi-Factor Authentication: Enhances user authentication processes.

Regular Security Audits: Ensures continuous monitoring and improvement of security protocols.

ERP software for engineering companies in Maharashtra must incorporate these advanced security features to safeguard against data breaches and cyber threats.

4. Enhanced User Experience (UX)

User experience has become a critical factor in ERP adoption and utilization. Modern ERP systems are focusing on intuitive interfaces and user-friendly designs to ensure that all employees, regardless of their technical expertise, can effectively use the system.

UX Improvements:

Intuitive Dashboards: Provide real-time insights and easy navigation.

Mobile Accessibility: Ensures that users can access ERP data on-the-go.

Customization Options: Allow users to tailor the system to their specific needs.

ERP software companies in Pune are prioritizing user experience in their solutions, making it easier for engineering and manufacturing firms to train their staff and increase productivity.

5. Internet of Things (IoT) Integration

The integration of IoT with ERP systems is another trend transforming the manufacturing industry. IoT devices collect vast amounts of data from production lines, equipment, and other operational areas, which can be analyzed by the ERP system to optimize performance.

IoT Benefits in ERP:

Real-Time Monitoring: Provides immediate insights into production processes.

Predictive Maintenance: Schedules maintenance activities based on equipment condition rather than time intervals.

Enhanced Quality Control: Monitors product quality throughout the manufacturing process.

For ERP for manufacturing companies in Gujarat, IoT integration offers a significant advantage by improving efficiency and reducing operational costs.

6. Sustainability and Green Manufacturing

Sustainability is becoming a critical focus for manufacturing companies worldwide. ERP systems are evolving to support green manufacturing practices by tracking and optimizing resource usage, reducing waste, and ensuring compliance with environmental regulations.

Sustainable ERP Features:

Resource Management: Tracks energy and material usage to minimize waste.

Regulatory Compliance: Ensures adherence to environmental laws and standards.

Sustainability Reporting: Provides detailed reports on sustainability metrics.

Engineering and manufacturing companies in regions like Mumbai and Maharashtra can benefit from ERP solutions that incorporate sustainability features, helping them achieve their environmental goals and enhance their corporate reputation.

7. Modular and Flexible ERP Solutions

In response to the diverse needs of engineering and manufacturing firms, ERP solution providers in Pune are developing more modular and flexible ERP systems. These systems allow companies to select and implement only the modules they need, which can be easily scaled and customized as their business grows.

Advantages of Modular ERP:

Cost-Effective: Pay only for the features you need.

Scalability: Easily add new modules as your business requirements evolve.

Customization: Tailor the system to fit specific operational needs.

This trend is particularly beneficial for small to medium-sized enterprises (SMEs) in the engineering and manufacturing sectors, enabling them to adopt ERP systems without the burden of high costs or complexity.

8. Focus on Customer-Centric Manufacturing

ERP systems are increasingly supporting customer-centric manufacturing practices, where production processes are aligned with customer needs and preferences. This approach enhances customer satisfaction and drives business growth.

Customer-Centric ERP Features:

Custom Order Management: Handles unique customer requirements and specifications.

Enhanced CRM Integration: Integrates with customer relationship management (CRM) systems for a holistic view of customer interactions.

Real-Time Order Tracking: Provides customers with real-time updates on their orders.

Manufacturing companies in Gujarat and engineering firms in Maharashtra are leveraging these customer-centric ERP features to improve their service levels and build stronger customer relationships.

9. Advanced Analytics and Business Intelligence (BI)

Advanced analytics and BI are becoming integral components of modern ERP systems. These tools provide deep insights into business operations, helping companies make data-driven decisions and improve performance.

Key BI Features:

Data Visualization: Converts complex data into easy-to-understand charts and graphs.

Dashboards: Offer a real-time overview of key performance indicators (KPIs).

Predictive Analytics: Forecasts future trends based on historical data.

ERP software companies in Pune are incorporating advanced analytics and BI capabilities into their systems, empowering engineering and manufacturing firms to gain a competitive edge through better insights and informed decision-making.

10. Globalization and Localization Support

As engineering and manufacturing companies expand their operations globally, ERP systems must support multiple languages, currencies, and regulatory requirements. Globalization and localization features are essential for companies operating in diverse markets.

Globalization Features:

Multi-Language Support: Accommodates users from different regions.

Multi-Currency Handling: Manages transactions in various currencies.

Compliance with Local Regulations: Ensures adherence to regional laws and standards.

ERP solution providers in Pune and other industrial hubs are enhancing their systems to support global operations, enabling companies to seamlessly manage their international business processes.

Conclusion

The ERP landscape for engineering and manufacturing industries is rapidly evolving, driven by advancements in technology and changing business needs. Companies in Maharashtra, Mumbai, Pune, and Gujarat must stay informed about these trends to leverage the full potential of ERP systems. By adopting cloud-based solutions, integrating AI and IoT, prioritizing cybersecurity, and focusing on sustainability, businesses can achieve greater efficiency, competitiveness, and growth in 2024 and beyond.

For engineering and manufacturing firms looking for the best ERP software for engineering companies in Maharashtra or ERP for manufacturing companies in Gujarat, it is crucial to partner with leading ERP solution providers in Pune who understand the unique challenges and opportunities in this sector. Embracing these trends will not only enhance operational efficiency but also drive innovation and sustainability in the engineering and manufacturing industries.

By staying ahead of these ERP trends, companies can position themselves for success in an increasingly digital and interconnected world. Whether you are an engineering firm in Mumbai or a manufacturing company in Gujarat, the right ERP system can transform your operations and pave the way for a prosperous future.

#ERP software in Vadodara#Manufacturing ERP software in Gujarat#ERP software companies in Vadodara#ERP software providers in Vadodara#ERP for manufacturing company in Gujarat#ERP software#ERP system#cloud ERP#ERP solutions#software development#engineering ERP#management software#engineering services#engineering industry

5 notes

·

View notes

Text

#erp#erp software#erp system#erp implementation#erp solutions#cloud erp#erp integration#erpsolutions#erp for manufacturing#erp development company

0 notes

Text

The Complete CRM Guide to Choosing the Right CRM for your Business in 2025

Why 2025 Demands Smarter Systems

As businesses accelerate toward digital maturity, the distinction between operational efficiency and customer satisfaction is blurring. A well-integrated ERP (Enterprise Resource Planning) and CRM (Customer Relationship Management) system is no longer a corporate luxury — it’s a business necessity.

In 2025, agility, automation, and data-driven decision-making are the gold standards. Whether you’re an ambitious startup or an established enterprise, selecting the right ERP and CRM can define your growth trajectory.

This comprehensive guide will walk you through everything you need to know about choosing the right ERP and CRM for your business, backed by insights from top-tier ERP Software Development Companies and CRM Software Development Companies.

Understanding ERP & CRM in the Modern Context

What is ERP?

Enterprise Resource Planning (ERP) is a suite of integrated applications designed to automate and streamline core business processes like finance, HR, inventory, procurement, and manufacturing.

What is CRM?

Customer Relationship Management (CRM) focuses on managing customer interactions, improving sales processes, marketing automation, and delivering exceptional customer support.

Together, ERP and CRM provide a 360-degree view of your organization, enhancing internal efficiency and external engagement.

Why Choosing the Right System Matters in 2025

Increased competition means businesses must be nimble.

Remote and hybrid work require cloud-based, accessible systems.

AI and automation are redefining workflows and customer journeys.

Data privacy regulations are tighter than ever.

Choosing an outdated or ill-suited system can stall your growth, frustrate users, and waste resources.

ERP for Startups vs Enterprises

ERP for Startups

Startups benefit from modular, scalable ERP systems. These systems offer just what you need to get started and scale as you grow. Look for:

Cloud deployment

Easy integration with existing tools

Real-time analytics

Affordable pricing

ERP for Enterprises

Enterprises demand robust, customizable ERP platforms. Features to consider include:

Advanced financial management

Supply chain optimization

Custom reporting

Role-based access controls

Top ERP Software Development Companies understand how to tailor solutions based on business size and industry

CRM for Startups vs Enterprises

CRM for Startups

Startups thrive on speed and relationships. Ideal CRM systems offer:

Lead tracking and scoring

Marketing automation

Email and social media integration

Mobile access

CRM for Enterprises

Larger businesses require deeper functionality:

Multi-channel support

Sales forecasting

Customer segmentation

Integration with ERP and BI tools

Must-Have Features in 2025

For ERP:

AI-powered forecasting

IoT integration (for manufacturing)

Blockchain for secure transactions

Custom dashboards

For CRM:

AI chatbots and virtual assistants

Real-time customer insights

Omnichannel communication

GDPR/CCPA compliance tools

Cloud vs. On-Premise ERP/CRM

Cloud Benefits:

Lower upfront cost

Faster deployment

Anywhere access

Automatic updates

On-Premise Benefits:

Full data control

Custom hosting environments

Higher initial cost but lower over time

Industry-Specific ERP/CRM Insights

Manufacturing

ERP for Manufacturing should include supply chain, production scheduling, and quality control.

CRM for Manufacturing should facilitate client relationship building through B2B tools and service tracking.

Retail

Inventory and POS integration

Customer loyalty tracking

Healthcare

Scheduling and compliance features

Patient engagement and EHR integration

Finance

Fraud detection

Regulatory reporting tools

Budgeting Considerations

Beyond licensing fees, consider:

Implementation and consultation

Training and onboarding

Customization and development

Annual support and maintenance

Start with essential modules and scale as ROI grows.

Integration with Existing Tools

Ensure your new ERP/CRM works seamlessly with:

Accounting systems

eCommerce platforms

HR management tools

Business Intelligence dashboards

Data Security and Compliance

By 2025, compliance is a cornerstone of IT strategy. Prioritize:

Role-based access control

End-to-end encryption

Data localization options

Built-in GDPR/CCPA modules

Implementation Best Practices

Set clear goals and KPIs before kickoff.

Appoint internal champions.

Avoid over-customization early on.

Train users in phases.

Conduct regular performance reviews post-launch.

Measuring Success and ROI

Evaluate ROI through:

Cost savings (manual vs. automated processes)

Sales growth

Customer satisfaction

Productivity metrics

Compliance benchmarks

A well-implemented ERP/CRM system delivers measurable returns within 6–12 months.

Make the Right Move in 2025

In a landscape driven by agility and digital fluency, ERP and CRM systems act as the operational and strategic command centres of modern business.

Whether you’re a fast-growing startup or a global brand, your investment in technology must reflect your ambition. Partnering with the right ERP Software Development Company or CRM Software Development Company is not a mere transaction — it’s a strategic alliance.

Choose wisely. Scale boldly.

#ERP Software Development Company#CRM Software Development Company#ERP for Manufacturing#CRM for Manufacturing

0 notes

Text

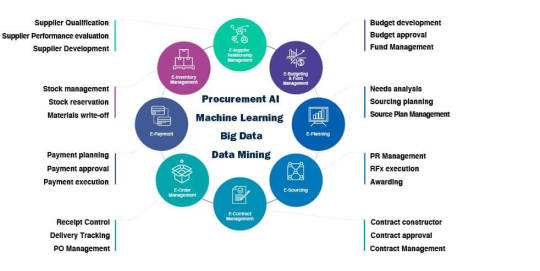

How AI in Procurement Revolutionizes Supply Chain Management?

Procurement is one of the most important components of supply chain management. It includes tasks like searching for the right products, making purchase decisions, overseeing inventories, etc. Traditional procurement is usually time-consuming and ineffective, leading to several manual errors. However, the situation is changing significantly due to artificial intelligence. Businesses are shifting towards AI to improve decision-making, streamline processes, and save on expenses. Read ahead, and we will discover how AI in procurement is changing supply chain management.

Table of Content

Clarifying Procurement and Supply Chain Management

How is AI Changing Procurement?

How is AI Changing Supply Chain Management?

Use Cases of AI in Procurement

Challenges to Implement AI in Procurement

Future of AI in Procurement

Wrapping Up

Clarifying Procurement and Supply Chain Management

Let's clarify the procurement and supply chain concept before diving into how AI is changing its face.

What is Procurement?

It is a process companies use to purchase the goods and services they need. It includes every product, from raw materials to office supplies. From the service point, it includes consulting to marketing. Procurement is one of the key elements in supply chain management. A good procurement for a company consists of buying the best products at the best price at the right time. It ensures that the products are available when they are needed.

What is Supply Chain Management?

It is the process of getting the products from the supplier and making them reach the customers. It consists of everything from manufacturing the product to shipping it. Not to forget managing the inventory and working with the suppliers. Like good procurement, a good supply chain delivers the right product to the right customer at the right time and best rate.

How is AI Changing Procurement?

AI is bringing a significant transformation in procurement. Take a look at how:

Automation of Repetitive Tasks

Just like AI in banking has automated several manual repetitive tasks, AI in procurement also has the same effect. Processes like checking supplier details and processing invoices can be automated. AI-based software can manage these tasks automatically. It reduces manual efforts heavily. It saves time and lets the procurement team focus on more important strategic tasks.

Improved Supplier Selection and Relationship

Choosing the right supplier is very important. Artificial intelligence can review supplier's performance, pricing history, and delivery time. It makes the selection accurate. It also allows companies to identify the good performances of the suppliers and reward them, which results in improved supplier relationships. AI in procurement also will enable suppliers to communicate effectively.

Cost Saving

AI in procurement can also work as a cost-saving element. AI can be used to negotiate for a better price with the suppliers. Waste reduction and efficiency are also added benefits of artificial intelligence.

Risk Management

Trending technology like AI can help companies detect and combat risks related to the supply chain. For example, AI can be used to predict any upcoming disruptions in the supply chain. Businesses can take precautionary actions based on these predictions. This results in minimized impacts of the expected disruption.

Data Analysis

AI can analyze large data sets for any common pattern or an upcoming trend. It helps businesses in making buying decisions. For example, AI in recruitment can predict the forthcoming shortage of candidates using certain technologies. This insight leads to filing the positions of that technology early.

How is AI Changing Supply Chain Management?

There are several key factors through which the AI supply chain industry is transforming with AI. Check out how:

Demand Forecasting

One of the best effects of AI in the supply chain is the accurate prediction of future product demand. This insight can work wonders for the business if they are correct. They can plan their production and inventory levels with smart insights for higher profits.

Supply Chain Visibility

Businesses can gain improved visibility into their supply chain with artificial intelligence. Businesses know exactly where their products are and at what time. Deep insights like this help companies identify issues and solve them quickly.

Inventory Optimization

Businesses are sometimes stuck with the issue of too much stock or getting stock out. Both are not beneficial to the companies. Excess inventory means dead investment, and getting stock out means lost opportunities. But, with AI, it is possible to optimize inventory levels. With accurate insights, AI can help find the right balance.

Logistics Optimization

Plan your shipping routes and manage transportation with AI. Optimized logistics to reduce cost and improve delivery time with AI will enhance supply chain management.

Use Cases of AI in Procurement

The application of this technology in procurement is having a huge effect on the supply chain management industry. Here are some of the best use cases of the same:

Smart Contract Management

With AI, contracts can be managed smoothly. It is equipped with the ability to identify contract terms, monitor compliance, and suggest to teams about any violations or renewals.

Predictive Analytics

Predictive analytics is used to determine upcoming market changes. With AI, businesses can frame their procurement strategies based on these predictions. It helps in increasing profitability.

Fraud Detection

With the power of AI, it is easy to catch fraud transactions by keeping a close eye on the purchase patterns. AI draws attention to suspicious activities and avoids any financial losses.

Chatbots for Suppliers Communication

AI-based chatbots have the skills to manage supplier issues and orders and solve problems quickly.

Cost Analysis

Artificial intelligence checks spending patterns and suggests ideas that might help save added costs. Businesses can create a procurement budget based on these suggestions and can put an end to wasteful spending.

Challenges to Implement AI in Procurement

AI brings plenty of benefits to procurement. However, it also comes with its own set of challenges as well.

1. Integration with Existing Systems

Businesses are set with their old methods and comfortable with that, too. Hence, integrating AI with the existing legacy system is a challenge. Also, training the team to use the new system to adapt to the challenge is a drawback.

2. Data Security Concerns

AI systems are massively dependent on data. Data is crucial in several industries, and if generative AI is used in healthcare, patient data must be protected. Similarly, procurement data must also be kept confidential, including information on suppliers, contract details, and pricing agreements. With AI integration, the data is stored and processed in different ways. It leads to the possibility of cyber-attacks. Keeping security tight and adhering to data protection laws and legal standards might be challenges in integrating AI into procurement.

3. High Initial Cost

AI is an easy-to-use, highly efficient, and amazing solution. Which it is, of course. But it doesn't come on a plug-and-play basis. Setting up an AI system in procurement to enhance the entire supply chain management involves a good upfront investment. Buying the AI system for just the subscription and setting up the infrastructure, like servers and data storage, can be costly.

4. Difficulty in Accepting Change

There is a fear among team members that AI will take their jobs, which creates a constraint in its acceptance. There is also a lack of technical knowledge to learn and implement this technology daily.

Future of AI in Procurement

The future is bright and shining. Here's what AI holds for procurement and supply chain management.

Self-learning AI systems that improve over time.

Greater use of blockchain for secure and transparent transactions.

More advanced predictive analytics for better decision-making.

AI-driven supplier networks for enhanced collaboration.

Wrapping Up

There has been a major transformation with AI in procurement and supply chain management. Its advantages are better decision-making, lower expenses, and higher efficiency. There are plenty of benefits to implementing AI, notwithstanding certain difficulties. AI businesses will have a stronger competitive edge in the global economy. In the years to come, we should expect to see even more revolutionary applications of AI technology as it develops. Supply chain management and procurement will be smart, automated, and AI-powered in the future.

0 notes

Text

AI-Powered Predictive Maintenance in Pharmaceutical Manufacturing

In pharmaceutical manufacturing, keeping machines running smoothly is essential for producing high-quality medicines. Traditional maintenance methods, like fixing machines after they break or scheduling routine checkups, can lead to unexpected failures or unnecessary repairs. AI-powered predictive maintenance is changing this by helping manufacturers prevent problems before they happen, saving time and money.

#AI development company in Dallas#Artificial Intelligence#AI-powered predictive maintenance#Manufacturing efficiency#Preventive maintenance#AI-based software development

0 notes

Text

How Can a Software Development Company Help Manufacturing Business

In today's rapidly evolving industrial landscape, manufacturing businesses face the constant challenge of boosting productivity, improving product quality, and streamlining operations while keeping costs under control. Software development offers solutions that can help manufacturing businesses achieve their specific goals, and custom-built software can be aligned with unique business goals and operational demands.

Benefits of Manufacturing Software Solutions

Improved Product Quality: Manufacturing software helps companies improve their products by monitoring each production step and identifying potential issues early on. Real-time data collection and analysis enable businesses to maintain stringent quality control procedures and optimize processes for consistent product quality.

Accelerated Production Process: Software development in manufacturing can significantly speed up production. Companies can leverage automation and real-time tracking to streamline processes, optimize resource allocation, and improve production forecasts, resulting in faster delivery times, increased output, and higher customer satisfaction.

Minimized Unplanned Downtime: Manufacturing software solutions with predictive maintenance capabilities help avoid interruptions by recognizing wear and tear early on and planning maintenance in advance. By reducing unscheduled downtime, businesses can ensure uninterrupted operations and increase profits.

Enhanced Inventory Control: Effective inventory management is crucial for every industrial organization. Manufacturing software provides insights into supply chain logistics, production needs, and stock levels, helping optimize inventory.

Effective Monitoring: Manufacturing software solutions enable manufacturers to track and monitor machinery and process workflows to pinpoint even slight changes, allowing them to rectify issues before they become major problems.

Better Production Planning: With increasing customer demands for personalized products at minimal cost, manufacturing software helps businesses allocate internal resources such as machinery and manpower to optimize processes effectively.

Insightful Business Intelligence: Manufacturing software leverages technologies like IoT, machine learning, and AI to collect and process real-time data, providing actionable insights for informed decision-making in employee and inventory management.

Reduced Costs: Manufacturing software that provides a comprehensive administrative view can reduce time, resources, and costs through less waste, satisfied customers, and process improvement.

Streamlined Processes: Manufacturing software allows businesses to automate and streamline processes, enhancing overall productivity and efficiency.

Manufacturing Software Development Services

Custom Software Development: A manufacturing software development company can create programs tailored to a company's internal processes, allowing businesses to optimize their operations. Custom software can adapt to new requirements, and be modified, improved, and expanded as the business changes over time.

Process Optimization: Software development companies offer process optimization by creating custom software that streamlines workflows and eliminates inefficiencies. By developing programs and systems that specifically address the company's needs, all internal processes can be improved.

Technology Unification: Custom software development can unify tools to satisfy more of a company's internal requirements and strengthen its work model.

Data Control: Custom software development allows companies greater control over their data and implements high-security standards to protect customer information.

Gradual Investment: Software development companies allow businesses to plan and execute projects gradually, making investments as the company becomes profitable. Companies can start with a simple software version and add new functionality as needed.

Efficiency and Time Savings: Custom programs can automate tasks, saving time and increasing revenue and production.

Workflow Optimization: Custom software development focuses on workflow management by studying the current workflow and identifying areas where there are too many tools or tasks. In manufacturing, custom development can be highly efficient in production planning, inventory management, and supply chain processes.

Automation: By implementing custom software solutions, businesses can automate repetitive tasks such as data entry, payroll processing, inventory management, and CRM. Automation reduces errors and allows employees to focus on strategic tasks, enhancing productivity and job satisfaction.

Investing in manufacturing software solutions offers numerous benefits, including improved product quality, faster production, reduced downtime, and better inventory control. A software development Company for manufacturing industry can provide customized services, scalability, smooth integration, and dedicated support, enhancing a business's potential for innovation, growth, and long-term competitiveness.

👉 Contact Us Today for a Free Consultation and Turn Your Vision into Reality!

📞 +91-9999634388

🌐 www.ebslon.com

manufacturing software development services, software development for manufacturing, best manufacturing software development company, manufacturing software development company in India, Best Software Development Company India, Custom Software Development Company in India

#manufacturing software development company#Best manufacturing software development company in India

0 notes

Text

Choosing the right ERP is crucial for business growth. Odoo and SAP are top contenders, but which one suits your needs best? Our in-depth comparison explores key features, pricing, scalability, and industry suitability to help you make an informed decision. Whether you're a small business or an enterprise, discover the pros and cons of each system and find the perfect fit for your operations. Don’t invest blindly—read our expert guide now and choose the best ERP for your business success! To Read More click here

#erp#erp software#erp solution bd#erpsoftware#erp system#odoo development#odoo development company#odoo#odoo development services#odoo erp#dubai#dublin#software development#web development#development#technologies#developer#software#services#united states#america#united states of america#england#united kingdom#london#scotland#wales#businesssuccess#business#manufacturing

0 notes

Text

How Manufacturing Software Developers Drive Innovation?

In the realm of manufacturing, staying ahead of the curve is not just a competitive advantage; it's a necessity for survival. As industries evolve at an unprecedented pace, the role of technology, particularly manufacturing software, has become paramount. Amidst this digital transformation, manufacturing software developers emerge as the unsung heroes, driving innovation and propelling the industry forward.

The Evolution of Manufacturing Software Development

Gone are the days of manual processes and analog systems dominating the manufacturing floor. Today, the landscape is characterized by cutting-edge software solutions tailored to streamline operations, enhance efficiency, and foster innovation. This evolution wouldn't have been possible without the expertise of manufacturing software developers who continuously push the boundaries of what's possible.

Empowering Efficiency with Tailored Solutions

One of the primary ways manufacturing software developers contribute to innovation is through the creation of tailored solutions designed to address specific challenges within the industry. Whether it's optimizing production processes, automating repetitive tasks, or implementing real-time monitoring systems, these developers possess the expertise to tailor software solutions that align with the unique needs of manufacturing companies.

Harnessing the Power of Data Analytics

In the digital age, data reigns supreme, and manufacturing software developers understand its potential like no other. By harnessing the power of advanced analytics tools, these developers empower manufacturers to derive actionable insights from vast troves of data. From predictive maintenance to demand forecasting, data-driven decision-making becomes the cornerstone of innovation in manufacturing.

Pioneering Industry 4.0 Technologies

The fourth industrial revolution, often dubbed Industry 4.0, is characterized by the convergence of digital technologies and manufacturing processes. At the forefront of this revolution are manufacturing software developers who pioneered the adoption of disruptive technologies such as IoT (Internet of Things), AI (Artificial Intelligence), and cloud computing. Through seamless integration and interoperability, these developers enable manufacturers to embrace the future with confidence.

Driving Collaboration and Connectivity

Innovation thrives in environments where collaboration and connectivity are prioritized. Manufacturing software developers recognize this and strive to create solutions that foster seamless communication and collaboration across disparate systems and teams. Whether it's through interconnected supply chain networks or collaborative robotics platforms, these developers lay the groundwork for a more interconnected and agile manufacturing ecosystem.

Ensuring Scalability and Adaptability

The pace of change in the manufacturing industry is relentless, and flexibility is key to staying ahead. Manufacturing software developers understand this dynamic nature and design solutions that are not only scalable but also adaptable to evolving business needs. Whether it's scaling production capacity or accommodating new regulatory requirements, these developers provide the foundation upon which manufacturers can future-proof their operations.

Conclusion: Embracing the Digital Future with Manufacturing Software Developers

Innovation is the lifeblood of the manufacturing industry, driving progress and propelling businesses towards success. At the heart of this innovation are manufacturing software developers, whose expertise and dedication enable manufacturers to thrive in an increasingly digital world. As we continue to embrace the possibilities of technology, let us recognize the invaluable contributions of these developers in shaping the future of manufacturing.

The role of a Manufacturing Software Development Company cannot be overstated in driving innovation within the manufacturing industry. Through tailored solutions, data analytics, pioneering technologies, collaboration initiatives, and a commitment to scalability, these developers empower manufacturers to navigate the complexities of the modern landscape with confidence.

0 notes

Text

In the ever-evolving world of construction, managing complex projects, diverse teams, and intricate workflows is no easy feat. From tracking material costs to ensuring on-time project delivery, the construction industry faces unique challenges that demand efficient solutions. This is where ERP software for construction company becomes a game-changer. It’s not just a tool but a strategic asset that can revolutionize how your business operates.

Read more:

#profitacc365#erp software for construction company#erp software for small business#best erp software in uae#erp for real estate developers#manufacturing erp software

0 notes

Text

How Manufacturers Can Manage Growth with ERP

Introduction:

In the dynamic landscape of manufacturing, where growth is the ultimate goal, the ability to adapt and streamline operations is paramount. Enter ERP (Enterprise Resource Planning), a powerful solution that has revolutionized the way manufacturers operate. In this blog, we'll explore the significant role of ERP software for manufacturing industry and how it serves as a catalyst for sustainable growth. Whether you're in traditional manufacturing or a software development company, ERP solutions are key to optimizing processes and managing growth effectively.

Understanding the Essence of ERP Software for Manufacturing:

1. Efficiency Unleashed:

ERP system for manufacturing industry is designed to enhance operational efficiency by integrating various business processes. From order management and procurement to production planning and inventory control, ERP systems bring together disparate functions into a unified platform, eliminating silos and enhancing overall efficiency.

2. Real-time Insights:

One of the key advantages of ERP solutions is the ability to provide real-time insights into business operations. Manufacturers can make informed decisions based on up-to-date information, helping them respond swiftly to market changes, manage resources effectively, and capitalize on growth opportunities.

3. Scalability Matters:

As a manufacturer, scalability is a constant consideration. Whether you're a growing traditional manufacturing unit or a software development company expanding its operations, ERP systems offer scalability to accommodate changing needs. The modular nature of ERP solutions allows businesses to add or modify functionalities as they evolve.

4. Improved Collaboration:

Collaboration is the bedrock of successful manufacturing. ERP fosters better communication and collaboration by providing a centralized platform where employees across different departments can access and share information seamlessly. This not only enhances teamwork but also accelerates decision-making processes.

ERP Software for Manufacturing Industry: Tailoring Solutions for Success

1. Production Planning and Scheduling:

In the manufacturing realm, effective production planning and scheduling are crucial for meeting customer demands and maintaining optimal inventory levels. ERP systems facilitate streamlined production processes, enabling manufacturers to create realistic production schedules, allocate resources efficiently, and minimize downtime.

2. Supply Chain Management:

A well-integrated supply chain is essential for manufacturers. ERP solution for the manufacturing industry ensures smooth coordination between suppliers, manufacturers, and distributors. This results in better inventory management, reduced lead times, and ultimately, improved customer satisfaction.

3. Quality Control:

Maintaining consistent product quality is non-negotiable in manufacturing. ERP solutions provide tools for comprehensive quality control by enabling real-time monitoring of production processes, tracking defects, and ensuring adherence to quality standards. This not only boosts customer confidence but also reduces wastage and rework costs.

4. Financial Management:

The financial aspect is the backbone of any business. ERP systems for manufacturing offer robust financial management capabilities, including invoicing, expense tracking, and financial reporting. This level of financial control is invaluable for manufacturers looking to manage growth effectively and make strategic financial decisions.

ERP for Software Development Company: Tailoring Solutions to Tech

1. Project Management:

For software development companies, managing projects efficiently is critical. ERP solutions designed for the software development industry offer project management modules that help track project timelines, allocate resources effectively, and ensure that development projects stay on course.

2. Resource Planning:

In the software development realm, talent is a primary resource. ERP systems tailored for software companies facilitate resource planning by providing insights into employee availability, skills, and project commitments. This ensures optimal resource allocation for project success.

3. Version Control and Collaboration:

Version control and collaboration are key aspects of software development. ERP solutions for software companies include features that enable version control, code collaboration, and documentation management. This ensures that development teams work cohesively, leading to efficient project outcomes.

4. Compliance and Security:

In the software development industry, compliance and security are paramount. ERP systems for software companies often include modules that help manage compliance with industry standards and ensure data security. This is especially crucial in an era where data protection is a top priority.

Conclusion:

As manufacturers navigate the complexities of growth, ERP software emerges as an indispensable tool for success. Whether you're in traditional manufacturing or a software development company, the benefits of ERP systems are far-reaching. From enhancing operational efficiency and providing real-time insights to tailoring solutions for specific industry needs, ERP is the key to managing growth effectively. Embrace the power of ERP, and propel your manufacturing operations into a future of streamlined processes, informed decision-making, and sustained success.

#Go-To-Market#GTM#Supply-Chain-Management#Technology#India#ERP-India#ERP#Business-Solutions#Manufacturer#Engineering#Inventory-Management#ERP Software for Manufacturing Industry#ERP System for Manufacturing Industry#ERP for Software Development Company#ERP Solutions for Manufacturing

7 notes

·

View notes