#BottleFillingMachine

Explore tagged Tumblr posts

Text

Ribbon Blender Machine Supplier India - Vtech Enterprise

Introducing Vtech Enterprise, your trusted destination for high-quality Ribbon Blender Machines in India. Our cutting-edge technology ensures efficient blending for diverse industries, meeting stringent quality standards. Elevate your production with our reliable and precise blending solutions, tailored to meet your specific needs.

Call us today : +91-9998651196

0 notes

Text

#DrySyrupFillingMachine is a compact machine used for filling of dry syrup in the bottles and most widely used in pharmaceutical industries.

Visit - https://www.parthec.com/powder-filling-machine/dry-syrup-filling-machine/

0 notes

Text

Adinath International - Your Trusted Pharmaceutical Turnkey Project Partner

Adinath International is a leading and reliable pharmaceutical turnkey project partner, catering to the diverse needs of the pharmaceutical industry. With a proven track record of excellence, Adinath International has established itself as a trusted name in the field of turnkey solutions for pharmaceutical manufacturing and processing plants.

As your dedicated partner, Adinath International offers comprehensive services encompassing design, planning, equipment sourcing, installation, and commissioning. Their team of highly skilled professionals and engineers ensures that each project is executed with utmost precision and adheres to the highest quality standards.

Adinath International is committed to delivering cost-effective and innovative solutions tailored to meet the specific requirements of their clients. With a focus on cutting-edge technology and compliance with international regulations, they ensure seamless integration of processes, resulting in optimized efficiency and productivity.

Know more about Miscellaneous Equipments visit - https://www.adinath.co.in/products/miscellaneous-equipments/

#SealingMachine#FluidBedDryer#DryHeatSterilizer#ETOSterilizer#AutoclaveSterilizer#TrayDryer#DoubleConeBlender#LabelingMachine#CapsuleFillingMachine#FilterPress#CapsuleFillingMachines#RibbonBlender#LiquidFillingMachine#BottleFillingMachine#LiquidFillingMachines#VibroSifter#RapidMixerGranulator#MultiMill#StickerLabellingMachines#StickerLabelingMachine#SterilizationEquipment#ChemicalMachinery#CappingMachine#OctagonalBlender#BottleWashingMachine#BottleLabelingMachine#BottleCapSealingMachine#SterilizationEquipments#StickerLabelingMachines#PowderFillingMachine

0 notes

Text

Leading Manufacturer of High-Quality Machines for Global Industries

Harsiddh Engineering Co. is a reputable manufacturer and exporter that specialize in the production of Washing, Filling, Capping and labeling Machines for various industries. With a strong presence in the global market, Harsiddh Engineering Co. has earned recognition for its high-quality products, adherence to international standards, and commitment to customer satisfaction.

Harsiddh Engineering Co. has established itself as a world-class supplier of pharmaceutical equipment, catering to the needs of clients worldwide. Since its inception in 1988 under the name "Persist Pharma Engineers," the company has experienced significant growth and expanded its product portfolio.

Specialization in Washing, Filling, Capping and Labeling Machines

The core specialization of Harsiddh Engineering Co. lies in the manufacturing of Washing, Filling, Capping, and Labeling Machines. These machines find extensive applications in the pharmaceutical, cosmetic, and agrochemical industries. By providing reliable and efficient machines, Harsiddh contributes to the seamless production processes of its clients.

Know more about Liquid Filling Machines visit - https://www.harsiddhengineering.com/category/liquid-filling-machines

#WashingMachines#Sterilizers#LabelingMachines#CapsuleFillingMachine#BottleFillingMachine#LiquidFillingMachines#BottleLabeler#InductionSealingMachine#BottleLabeller#OilFillingMachines#BottleWashingMachine#OilFillingMachine#CappingMachine#BottleLabelingMachine#StickerLabelingMachine#CapperMachine#PowderFillingMachine

0 notes

Text

Precision Pharma Filling: Ensuring Accuracy in Every Dose

Explore our range of advanced bottle filling machines specifically engineered for the pharmaceutical industry. Achieve consistent and accurate filling of liquids, powders, and granules, maintaining the highest standards of quality and compliance.

0 notes

Text

Export of Heavy Duty Conveyor in Israel

Laxmi Pharma Equipment is a leading Manufacturer, Supplier, and Export of Heavy Duty Conveyor in Israel, specializing in pharmaceutical machinery. Established in 1985 in Phase III, Vatva, Ahmedabad, Gujarat, India, the company offers a comprehensive range of high-quality equipment, including Washing Machines, Filling Machines, Stoppering Machines, Capping Machines, Labelling Machines, Packaging Machines, Process Equipment, and more. Heavy-duty conveyors play a significant role in enhancing efficiency, safety, and productivity in the pharmaceutical sector. These conveyors operate using a motor to drive a belt or chain, facilitating the movement of materials or products within a facility. Features: Durability: Built to withstand demanding industrial environments, ensuring longevity. Handling Capacity: Engineered to handle substantial weights, suitable for transporting large and heavy products or materials. Variety: Available in various types, including belt conveyors, roller conveyors, and chain conveyors, catering to different material handling needs. Customization: Can be customized to fit specific requirements, offering flexibility in design and functionality. Variable Speed Control: Many heavy-duty conveyors feature variable speed control, allowing operators to adjust speed based on production or processing requirements. Directional Movement: Capable of moving materials in different directions (forward, reverse, incline/decline), providing flexibility in material flow. Ease of Maintenance: Designed for easy maintenance, with accessible components like bearings and belts for inspection and replacement. Geographical Availability: Laxmi Pharma Equipment Export of Heavy Duty Conveyor in Israel Including Ashdod, Ashqelon, Bat Yam, Beersheba, Bet Sheʾan, Bet Sheʿarim, Bnei Brak, Caesarea, Dimona, Dor, Elat, ʿEn Gedi, Givʿatayim, H̱adera, Haifa, Herzliyya, H̱olon, Jerusalem, Karmiʾel, Kefar Sava, Lod, Meron, Nahariyya, Nazareth, Netanya, Petaẖ Tiqwa, Qiryat Shemona, Ramat Gan, Ramla, Reẖovot, Rishon LeẔiyyon, Sedom, Tel Aviv–Yafo, Tiberias, Ẕefat. For inquiries and information, customers are welcome to contact Laxmi Pharma Equipment. Read the full article

#Ashdod#Ashqelon#BatYam#Beersheba#BetSheʾan#BetSheʿarim#BneiBrak#bottlefillingmachines#Caesarea#Cosmetics#Dimona#Dor#Elat#ExportofHeavyDutyConveyor#ExportofHeavyDutyConveyorinIsrael#Exporter#Givʿatayim#H̱adera#Haifa#HeavyDutyConveyorinIsrael#Herzliyya#H̱olon#India#Jerusalem#Karmiʾel#KefarSava#liquidfillingmachines#Lod#Manufacturer#ManufacturerofHeavyDutyConveyor

0 notes

Text

"Revolutionize Your Production with the Fully Automatic 16-16-6 Glass Bottle Filling Machine – Efficiency, Precision, and Quality in Every Bottle!"

FillingEquipment #BottleFillingMachine #LiquidFilling #FillingMachine #PackagingEquipment #AutomaticFilling #CappingMachine #FillingAndCapping #BeverageFilling #FillingSolutions #ProductionLine #PackagingTechnology #BottlingMachine #IndustrialFilling #FoodAndBeverageEquipment #FillingSystem #LiquidPackaging #AutomatedFilling #BottlePackaging #FillingProcess

0 notes

Video

youtube

ce certification dropper bottle filling machine #bottlefillingmachines #dropperbottle #oilfillingmachine

0 notes

Video

tumblr

Experience the Precision of Bottle-filling Machines on our Production Line! 🎯 Get ready to witness perfection in action! Our production line has reached new heights with our top-of-the-line bottle-filling machines. 🏭 Discover the ultimate precision behind every filled bottle and be amazed at the seamless result. 🌟 Don't miss this opportunity to experience the future of manufacturing. Join us on the journey towards excellence! ✨ #PrecisionInAction #BottleFillingMachines #ManufacturingEvolution

0 notes

Photo

Edible Oil Packing Line Consists of Linear Oil Filling Machine, Bottle Capping Machine, Bottle Sticker Labelling Machine Etc. With the Speed Up to 100 Bottles/Minute. Contact us:- [email protected] know for more info visit the site:- http://harikrushna.com #Oilfillingmachine #Bottlefillingmachine #Liquidfillingmachine #Attarfillingmachine #SemiAutoTwoHeadOilFillingMachine #EdibleOilBottleFillingMachine #hmpl #harikrushnamachinetech #VegetableOilFillingMachine #packagingmachinery

#Oilfillingmachine#Bottlefillingmachine#Liquidfillingmachine#Attarfillingmachine#SemiAutoTwoHeadOilFillingMachine#EdibleOilBottleFillingMachine#hmpl#harikrushnamachinetech#VegetableOilFillingMachine#packagingmachinery

1 note

·

View note

Photo

Glass bottle olive oil filling and capping machine is designed in accordance with the features requested by the customer. Glass Bottle to be filled; daily filling capacity, safety band and label features (Double or Single side) Glass bottle olive oil filling and closing machine stands out as the factors considered in the design phase. The manufacturing process of the glass bottle olive oil filling machine is carried out by coordination among technical teams.

3 notes

·

View notes

Text

AF 0005 bottle filling machine from Kbw-Packaging

Welcome To KBW Packaging LTD. One of the most useful products from us is AF 0005 bottle filling machine and this machine is also working as a small and portable vacuum filling machine utilized in wine, ink, spirit, perfume and cleansing fluid with twin nozzles, it comes with a choice of nozzle sizes. It is primarily used on glass or rigid plastic containers by companies with small-scale production runs. The product to be filled is drawn up a hose by vacuum and fills through a nozzle to an exact point the rest being drawn off to a recycling bowl. Check out some details of AF 0005 bottle filling machine.

Fills free flowing liquids into rigid plastic or glass bottles

Repeat filling accuracy of +/- 1ml

Simple to operate with minimal maintenance

Range of nozzles to suit a variety of container sizes

Product recycling for minimal product waste

Pneumatic operation suitable for hazardous products

Optional wander nozzle for vial filling

1 note

·

View note

Text

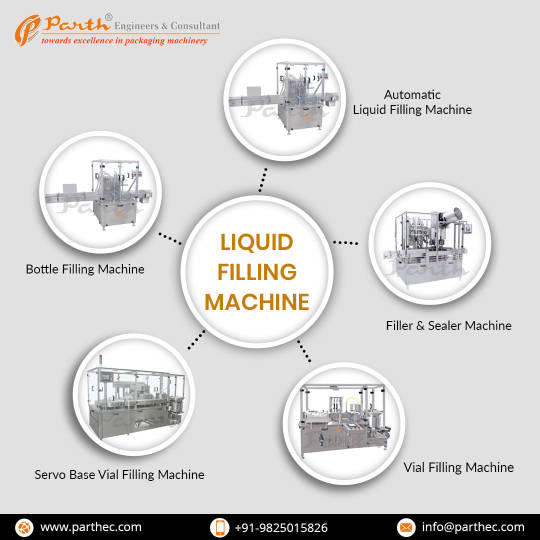

Explore with the different types of #LiquidFillingMachine used in various industries to filling liquid in different size & shape.

visit us at - https://www.parthec.com/liquid-filling-machine/

#Parthec#ParthengineersandConsultant#LiquidFiller#BottleFillingMachine#VialFillingMachine#servobasevialfillingmachine

0 notes

Text

A Liquid Bottle Filling Machine is a type of automated or semi-automatic machine that fills bottles with liquids. The machine has a three-phase control panel that contains electrical and system parts. Its user-friendly digital display and color-classified buttons make it easy to operate.

visit at - https://www.bhagwatipharma.com/liquid-bottle-filling-machine-automatic-semi-automatic-manual/

0 notes

Text

youtube

#Low price liquid filling machine#liquid filling machine#bottlefillingmachine#liquid bottle filling machine#Youtube

0 notes

Text

How do You choose a liquid filling machine?

The automatic bottle filling system actions product from to the ultimate bottles from a preserving tank. In the automated stuffing system, any agency can assume to boom the productivity of the packaging operation in a number of ways. Then, we are able to bandy approximately the ways.

Still, it's going to eliminate all of the questions from the system of stuffing, If you operate an automated padding.

It would not count number in case you're seeking out a in large part correct volumetric filler, function filler, or a few different form of unique criteria, because the automated system guarantees that each one the cycle is finished in a similar manner.

The thickness and trustability of the automatic bottle filling machine cannot be accomplished in case you plan to fill it through hand. Hence, thickness is critical with the bottle filling machines.

When the call for for a product reaches a factor of state, it without a doubt turns into now no longer practical which you lease home made hard work to finish the stuffing of every bottle.

In the maximum not unusual place sense, the trendy advantage and the maximum egregious bone as well, of the packaging system is the rate of the ministry to fill bottles.

The velocity maintains increasing. However, the product may be extraordinarily brisk and greater effective, If you operate electricity conveyors and more than one filler heads with right stuffing.

There are several organizations that use numerous bottles for one unmarried product. There are enormously some of organizations that run severa products.

In utmost cases, one unmarried liquid padding is made to deal with the stuffing of all of the bottles, and the goods are packed through a company.

There are a few machines that use easy variations to head from one bottle or product to another, even as there are a few different machines that endure enormously a while at the changeover to do the same. Hence, automated bottle filling machines are enormously protean.

Substantially, all of the computerized water filling machines include a PLC and are exceptionally smooth to perform with a stoner-pleasant interface.

The interface has touchscreen that permits the motive force to enter the colorful portions and instances that's demanded to finish every cycle. Once you input the figures, there might be a shape display screen so that it will appear.

Also, you simply want to certainly input the shape wide variety of the examiner interface, if there are any bodily adaptations, you may make it and additionally the examiner will do its work.

The Bottle Filling Machine is distinctly smooth to apply and is offered as well.

So, touch the fine device device industries in India and get top-exceptional automatic bottle filling machine to get your enterprise began out or to attain your enterprise to in addition heights.

#automatic best bottle filling machine#automaticbottlefillingmachine#bottlefillingmachine#bottle filling machine#filling machine

0 notes