#Bulk Storage Silos

Text

Bulk storage silos enhance productivity and profitability by optimizing storage efficiency, reducing overhead costs, increasing space utilization, cutting operational expenses, and improving safety measures.

0 notes

Text

Bulk Powder Handling

Transform your powder handling operations with Sodimate's comprehensive bulk powder handling systems. Our integrated mixers, valves, and detectors harmoniously blend powders like hydrated lime, soda ash, and powdered activated carbon (PAC) using gentle agitation, ensuring hassle-free handling. Contact us to optimize your powder handling today!

#screw conveyor#activated carbon#bulk handling#bulk handling systems#bulk material handling#pneumatic conveying systems#feeder hopper#bulk storage silos#sodimate

0 notes

Text

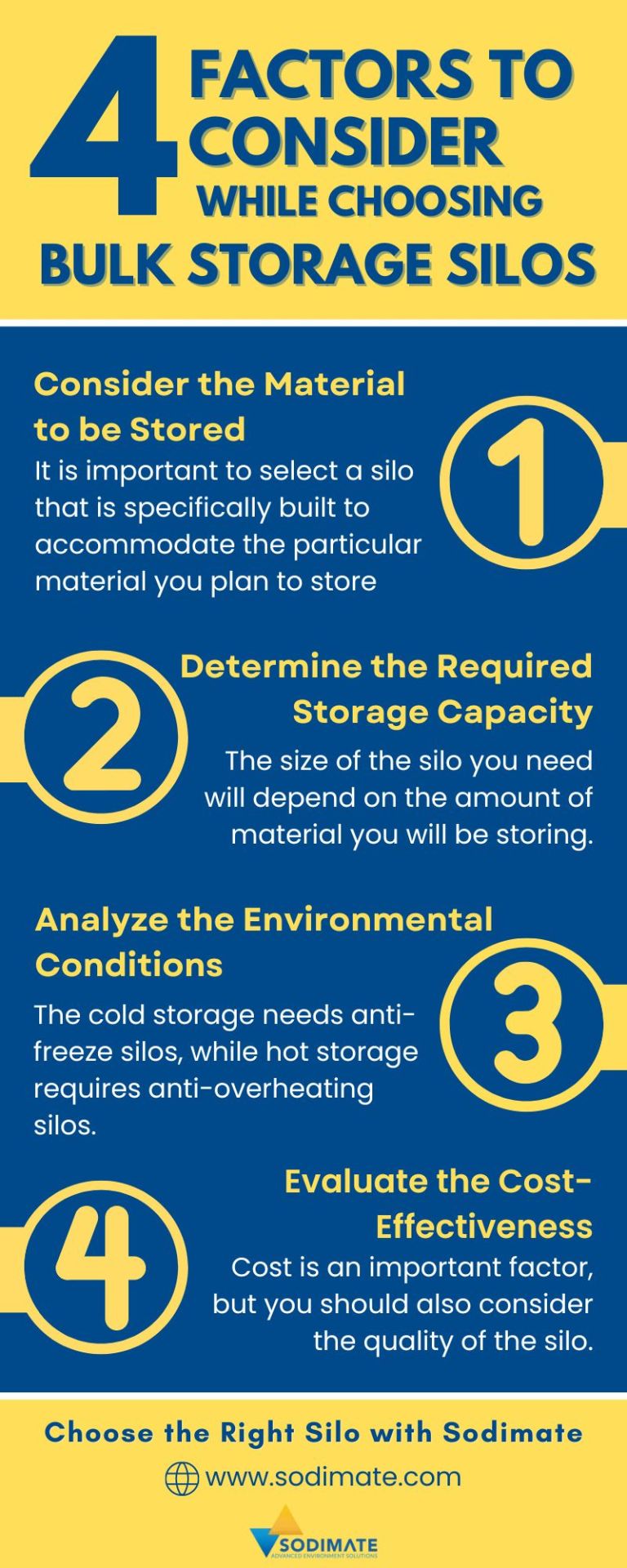

Factors to Consider While Choosing Bulk Storage Silos

When choosing a bulk storage silo, there are several factors to consider, including the type of material to be stored, the volume of material, the climate, and the budget. Read on to learn more about the perfect bulk storage silos solution tailor-made to meet your unique requirements.

1 note

·

View note

Text

Bulk Storage Silos Market Growth, Trends, and Forecast

In most of the economies, grains are considered as the important staple foods. Though they are produced on a regular basis, and there is only one production in a year in many places, which itself may subject to failure. This means to feed the world’s population, the global production of wheat, maize, rice, and sorghum must be detained in storage for periods changing from one month up to more than a year. Therefore, storage of grains inhabits an important place in the developing and developed economies, which in turn, influencing the usage of bulk storage silos shortly. Robust growth in food grain industry, increasing consumption of wheat, maize and rice products in the developed economies is intensifying the bulk storage silos market across the world. Furthermore, in the entire agriculture chain, the bulk storage silos has provided a powerful storage and logistics tool, facilitating the steady growth of grain production. Hence, agriculture is expected to expand with no limits, and that storage of grains is determined by the revolution of bulk storage grains.

Bulk storage silos is a flexible and rigid package, made up of conductive material and regular steel, designed for storing of various diverse bulk materials in the form of pellets, granules, grit and many other products. Bulk storage silos are specifically manufactured and designed by requirements of customers, which is a purely custom-made invention. Bulk storage silos are used for household applications as a container for wooden pellets in chemical industries, farming, food industry, building industry and pharmaceutical industries. The flexible silos are made from a durable and reliable special coated materials that are supported at constant intervals through form-frames. Additionally, to the flexible material, they can also be equipped with pneumatic activators to improve the product flow, resulting in higher accuracy and even quicker dosing. The stainless steel silos feature rounded internal corners for less residue and enhanced product flow, therefore reducing the contamination risk.

As compared to stainless steel cylindrical storage silos, the flexible storage silos offer up to 25% more capacity, and also up to 100% increased dosing size. This flexible design not only improves sterility since it certifies that minimal residue is left behind in the silos, but are also cheaper to transport and install. Hence, flexible silos prove to be ideal for poor flow characteristics, compressible and cohesive materials, which further helps in ensuring consistent weighing and avoid production loss. Generally, silo bags are composed of three to five layers of plastic material shaped like a 235 microns thick tubes.

Get a PDF Brochure – https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=21167

Regional Analysis:

By geography, the global bulk storage silos market is divided into majorly five regions namely North America, Latin America, Europe, Asia-Pacific and Middle East & Africa. Latin America is expected to dominate the overall bulk storage silos market with broad adoption scale of storage silo bags and tanks in Argentina from the past few years. According to the Food and Agricultural Organization (FAO), sales in the Brazil reached to about 45,000 silo bags, with 9 million tons of grain is stored annually. The potential in the Brazil market for the product is vast due to the lack of storage set-up and long distances between production areas and harbors. Next North America is anticipated to be the fastest growing market in the global bulk storage silos market. Most of the manufacturers, are planning to expand into Canada where food grain providers are experiencing strong competition, demanding low cost and economical bulk storage silos. Asia Pacific regions exhibit the fastest growth due to the significant developments in the usage of silo bags and tanks.

Leading Players:

Some of the key player of the global bulk storage silos market are CST Industries, Franklin Hodge Industries Ltd., The Eagle Group LTD, Balmoral Group Holdings Ltd, Pittsburgh Tank Corporation, Bulk Process Equipment and many more.

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

Get a Customised Report - https://www.transparencymarketresearch.com/sample/sample.php?flag=CR&rep_id=21167

The study is a source of reliable data on:

· Market segments and sub-segments

· Market trends and dynamics

· Supply and demand

· Market size

· Current trends/opportunities/challenges

· Competitive landscape

· Technological breakthroughs

· Value chain and stakeholder analysis

The regional analysis covers:

· North America (U.S. and Canada)

· Latin America (Mexico, Brazil, Peru, Chile, and others)

· Western Europe (Germany, U.K., France, Spain, Italy, Nordic countries, Belgium, Netherlands, and Luxembourg)

· Eastern Europe (Poland and Russia)

· Asia Pacific (China, India, Japan, ASEAN, Australia, and New Zealand)

· Middle East and Africa (GCC, Southern Africa, and North Africa)

Make an Enquiry Before Buying – https://www.transparencymarketresearch.com/sample/sample.php?flag=EB&rep_id=21167

The report has been compiled through extensive primary research (through interviews, surveys, and observations of seasoned analysts) and secondary research (which entails reputable paid sources, trade journals, and industry body databases). The report also features a complete qualitative and quantitative assessment by analyzing data gathered from industry analysts and market participants across key points in the industry’s value chain.

A separate analysis of prevailing trends in the parent market, macro- and micro-economic indicators, and regulations and mandates is included under the purview of the study. By doing so, the report projects the attractiveness of each major segment over the forecast period.

Browse Latest Packaging Industry Research Reports by TMR

QR Code Labels https://www.transparencymarketresearch.com/global-qr-code-labels-market.html

Functional Labels market https://www.transparencymarketresearch.com/functional-labels-market.html

Tri Panel Labels Market https://www.transparencymarketresearch.com/tri-panel-labels-market.html

Vinyl Labels Market

https://www.transparencymarketresearch.com/vinyl-labels-market.html

Veneer Labels Market

https://www.transparencymarketresearch.com/veneer-labels-market.html

Domed Labels Market https://www.transparencymarketresearch.com/domed-labels-market.html

Single-serve Water Packaging Market https://www.transparencymarketresearch.com/single-serve-water-packaging-market.html

Nail Care Packaging Market https://www.transparencymarketresearch.com/nail-care-packaging-market.html

Food Oil Packaging Market

https://www.transparencymarketresearch.com/food-oil-packaging-market.html

About Transparency Market Research

Transparency Market Research is a global market research reports company providing business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyze information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact Us:

Rohit Bhisey

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Blog: https://tmrblog.com

Email: [email protected]

0 notes

Text

bulk chemical storage silo

https://www.3d-labs.com/

Bolted Storage Tanks Steel Storage Tanks Bulk Storage Tank Dry Bulk Storage Elevated Water Tanks

Storage Tank Bolted Tank Steel Tanks Superior Bolted Tank Water Treatment Tank Bins Structural Engineering

Tank Structural Engineering Liquid Tank Crude Oil Tank Industrial Process Storage Municipal Liquid Storage

Shop-Welded Column Enclosures Industrial Waste Water Epoxy-Coated Tank

0 notes

Text

Types of Level Sensors

Title: Types of Level Sensors: A Comprehensive Overview

Level sensors are crucial instruments used in various industries to measure and monitor the levels of liquids, solids, and granular materials in tanks, vessels, and other containers. These sensors employ different technologies and operating principles to suit a wide range of applications and environmental conditions. Let's explore the various types of level sensors and their characteristics:

1. Float Level Sensors:

Operating Principle: Buoyant float attached to a stem or arm moves with the liquid level, triggering a switch or sensor.

Applications: Pump control, water tanks, oil and fuel tanks, chemical processing, wastewater management.

Benefits: Cost-effective, reliable, easy to install, suitable for diverse liquids.

2. Capacitive Level Sensors:

Operating Principle: Measures changes in capacitance caused by the presence or absence of a liquid or material.

Applications: Non-metallic tanks, food and beverage processing, pharmaceuticals, water treatment.

Benefits: High accuracy, suitable for various liquids and materials, immune to coating buildup.

3. Ultrasonic Level Sensors:

Operating Principle: Uses ultrasonic waves to measure distance and calculate liquid or material level.

Applications: Liquid storage tanks, open-channel flow measurement, solids level measurement.

Benefits: Non-contact, suitable for corrosive or hazardous environments, works well with foam or vapor.

4. Radar Level Sensors:

Operating Principle: Transmits microwave signals and measures time delay for liquid or material level determination.

Applications: Petrochemical tanks, bulk storage tanks, silos, sewage treatment plants.

Benefits: Accurate, suitable for high-pressure and high-temperature environments, works in harsh conditions.

5. Pressure Level Sensors:

Operating Principle: Measures hydrostatic pressure exerted by liquid to determine level.

Applications: Water wells, boreholes, liquid storage tanks, hydraulic systems.

Benefits: Simple design, suitable for wide temperature and pressure ranges, works well in confined spaces.

6. Conductive Level Sensors:

Operating Principle: Detects changes in electrical conductivity caused by the presence or absence of a liquid.

Applications: Water level control, chemical storage tanks, sump pumps, industrial process tanks.

Benefits: Simple operation, suitable for corrosive liquids, low cost.

7. Optical Level Sensors:

Operating Principle: Uses light transmission or reflection to detect liquid or material level changes.

Applications: Beverage dispensers, medical equipment, laboratory instruments, fuel tanks.

Benefits: Non-contact, high accuracy, suitable for small tanks and confined spaces.

8. Magnetic Level Sensors:

Operating Principle: Utilizes magnetic float or probe to detect changes in magnetic field caused by liquid level.

Applications: Oil and gas tanks, chemical processing, water treatment, industrial boilers.

Benefits: Suitable for high-temperature and high-pressure environments, reliable, low maintenance.

Each type of level sensor offers unique advantages and is best suited for specific applications and environmental conditions. By understanding the operating principles and characteristics of different level sensors, industries can select the most appropriate sensor to meet their level monitoring requirements effectively.

0 notes

Text

Supplier of Round Silo in Mumbai

Company Overview:

Invoit Plast is a prominent Manufacturer and Supplier of Round Silo in Mumbai, Maharashtra, India, established in 2018.

Widely acknowledged and trusted as a reliable supplier in domestic markets.

We offer Rotomolding Machines, Conveying Systems, Storage Equipment, Granulators, Screening Equipment, Pulverizers, Material Handling Equipment, and more.

Round silos, cylindrical storage structures, store bulk materials like grains, powders, pellets, and liquids.

They characterize their circular shape and typically consist of durable materials like steel or concrete.

Available in various sizes and capacities to accommodate different storage needs.

Equipped with features such as ventilation systems and safety measures for efficient and safe material storage.

Key Features:

Highly flexible storage system suitable for grains.

Various diameters and capacities are available.

Offers bird and rodent-proof grain storage.

A controlled environment minimizes post-harvest losses.

Available in different finishes with ancillary equipment like access, catwalk, and ladders.

Option for custom manufacturing to meet specific requirements.

Invoit Plast is one of the leading Manufacturer and Supplier of Round Silo in Mumbai, Maharashtra, and locations such as Sai udyog industrial estate, Mira Bhayander 2. Kandivali, Taloja, Vaibhav, Ghatkopar, Badlapur, Dombivali, Kalyan, Ambernath, Dombivali, Ulhasnagar, Bhiwandi, Panvel, Kharghar, Ahmednagar, Akola, Amravati, Aurangabad, Bhandara, Bhusawal, Buldhana, Chandrapur, Daulatabad, Dhule, Jalgaon, Kalyan, Karli, Kolhapur, Mahabaleshwar, Malegaon, Matheran, Mumbai, Nagpur, Nanded, Nashik, Osmanabad, Pandharpur, Parbhani, Pune, Ratnagiri, Sangli, Satara, Sevagram, Solapur, Thane, Ulhasnagar, Vasai-Virar, Wardha, Yavatmal.

Please feel free to contact us with any questions or for additional information.

Read the full article

#Ahmednagar#Akola#Ambernath#Amravati#Aurangabad#Badlapur#Bhandara#Bhiwandi#Bhusawal#Buldhana#Chandrapur#Daulatabad#Dhule#Dombivali#ExporterofRoundSilo#Ghatkopar#India#Jalgaon#Kalyan#Karli#Kharghar#Kolhapur#Mahabaleshwar#Maharashtra#Malegaon#Manufacturer#ManufacturerofRoundSilo#Matheran#MiraBhayander2.Kandivali#Mumbai

0 notes

Text

Applications of Pneumatic Conveying Systems: Revolutionizing Material Handling

In the vast expanse of industrial operations, the movement of materials stands as a critical backbone ensuring efficiency, safety, and sustainability. Pneumatic conveying systems, leveraging the power of air to transport materials through pipes, have emerged as a cornerstone in numerous sectors. These systems offer a blend of versatility, cleanliness, and automation, making them an indispensable tool in modern manufacturing and processing environments. Let’s explore the various applications of pneumatic conveying systems and how they are revolutionizing material handling across industries.

1. Food and Beverage Industry

In the food and beverage sector, maintaining product integrity and hygiene is paramount. Pneumatic conveying systems excel in this realm, offering a closed environment that minimizes contamination risks and ensures the gentle handling of delicate products like cereals, coffee beans, powdered milk, and spices. These systems can efficiently handle a wide range of materials, from granular to powder form, facilitating seamless processing, packaging, and distribution processes.

2. Pharmaceutical Industry

The pharmaceutical industry requires the highest standards of cleanliness and precision. Pneumatic conveyors are uniquely suited to meet these demands, providing a contamination-free transport solution for sensitive materials like powders, granules, and capsules. They ensure that active pharmaceutical ingredients (APIs) are handled in a controlled environment, safeguarding against external pollutants and cross-contamination, thereby upholding the integrity of medicinal products.

3. Chemical Industry

Handling chemicals poses a significant challenge due to the hazardous nature of many compounds. Pneumatic conveying systems offer a secure method to transport chemicals, whether they are in powder, granule, or pellet form. These systems minimize human exposure to harmful substances and reduce the risk of environmental contamination. Their enclosed design also mitigates the potential for explosive dust-air mixtures, enhancing plant safety.

4. Plastics and Polymer Industry

The plastics and polymer sector benefits immensely from pneumatic conveying in the transportation of raw materials like pellets, powders, and regrind. The efficiency and cleanliness of these systems allow for the rapid and safe movement of materials through various stages of production, from compounding to molding or extrusion processes. Pneumatic conveyors help in maintaining the quality of these materials by preventing degradation and contamination.

5. Construction and Cement Industry

In the construction and cement industry, the ability to move large volumes of materials like cement, sand, and aggregates is crucial. Pneumatic conveying systems provide a dust-free solution, significantly reducing the environmental impact associated with traditional material handling methods. They facilitate the efficient transfer of bulk materials over long distances, from storage silos to processing units or mixers, streamlining production workflows.

6. Power Generation

Pneumatic conveying finds its application in power plants for the handling of fly ash, a by-product of coal combustion. These systems enable the safe, clean, and efficient disposal or recycling of fly ash, thereby addressing environmental concerns and regulatory compliance. The enclosed nature of pneumatic conveyors prevents the escape of ash into the atmosphere, contributing to cleaner air and a healthier environment.

Conclusion

Pneumatic conveying systems have redefined material handling across diverse industries. Their ability to transport a wide array of materials with high efficiency, safety, and control makes them an essential component of modern industrial operations. As technology advances, these systems are set to become even more innovative, offering solutions that are not only effective but also environmentally responsible. The future of material handling lies in the air – quite literally – as pneumatic conveying continues to push the boundaries of what is possible in industrial automation and efficiency.

#pneumatic conveying system#pneumatic conveying#pneumatic conveyor process#pneumatic conveyor systems

0 notes

Text

Site conditions required for efficient powder filling

Powder filling requires management of the powder and the site to ensure successful packaging operations. If not managed properly, powder filling throws up challenges. Powder's physical properties are influenced by the way they are stored and transported. Constant loose bulk density and maintenance of flow rate are crucial in the performance of the dosing systems.

Therefore, ensuring the right site conditions is crucial for maintaining product quality and operational efficiency. Factors such as bulk density (BD), flow properties, ambient temperature, humidity, conveying methods, power quality, film storage, and cleaning routines all play pivotal roles in achieving successful powder-filling operations.

Here, we delve into each aspect and discuss best practices for ensuring an optimal powder-filling environment. Site conditions can broadly be classified into firstly, powder storage and transportation conditions; and, conditions required for the operation of the packaging equipment.

Powder storage and transportation requirements

Before we delve into the topic let us understand the key requirements to focus on.

Bulk density and flow properties – these are key characteristics that directly impact the efficiency and accuracy of powder filling. It is essential to maintain these properties throughout the filling process to prevent issues such as clogging, inconsistent filling, and product wastage.

Ambient temperature and humidity – the filling area should be controlled to ensure that the powder characteristics remain stable. Fluctuations in temperature and humidity can lead to changes in the powder's flow properties and bulk density, affecting the filling process’ accuracy and efficiency.

Powder storage is crucial – the powders need protection from humidity, sun light, oxygen depending upon their chemistry. The storage bins and or silos need to offer the required protection.

When ready for packing and before transportation, the powders need to be brought to their loose bulk density. The delta between loose and tapped density is normally 20%. Therefore, the powder needs to be blended to loosen up the powder before transportation. Blending also helps even out bulk density variation from different batches or powders from different sources. Large silos must have agitators, and these must be on to ensure the powder does not settle down.

Storage of the powder needs attention. Some of the steps highlighted above may be needed depending on the powder.

It is possible that in some cases the powders are taken up for packing in line. Therefore, the next step to focus is the technology to be used for conveying the product from the manufacturing (storage) area to the packaging units.

Conveying methods

Choosing the right conveying method is crucial for avoiding product breakage and changes in bulk density. The conveying systems need to offer the required protection as well. Let us look at some of the conveying systems used in the industry and look at their pros and cons.

Belt conveyors – These are normally used for horizontal conveying. These can be open to the atmosphere or can be enclosed to avoid contamination. Popular in non-food applications and also where the product is warm after production and the powder needs cooling. The powder quality will remain constant as long as the atmosphere will have no influence.

Pneumatic conveyors – These are enclosed conveyors and are conveyed using air. The air quality should be clean in order not to contaminate the product. These are popular, the only thing to remember is that pneumatic conveyors loosen up the powder therefore the bulk density is affected. Pneumatic conveyors can also help you move the powders vertically.

Cable conveyors – These are enclosed conveyors where discs attached to a cable at an equal distance move to transport the powder. The disc works like a piston in a cylinder. The biggest advantage of these conveyors is that they can incorporate bends. This will allow you to transport the powder from anywhere to anywhere.

Screw conveyors – By far the most popular feeding methodology for transporting powders. The powder is transported inside a tube using rotating screws. The conveyor is completely enclosed. Clearance between the screw and tube can be designed to minimize breakage.

Vibratory conveyors – These are normally used for conveying short distances in powder applications. The conveyors can induce bulk density variation and product separation.

There are options and when it comes to conveying it is imperative to understand the powder before choosing the right solution.

Let us now look at other important site conditions.

Power quality – Your equipment uses sophisticated electronics and expensive servo motors. Ensuring the right power infrastructure is crucial.

Proper earthing and maintenance of earth pits – Separating power and control electronics lines would be a prudent strategy. Earth to neutral voltage must be minimum. Spike busters and voltage management hardware are crucial.

Maintaining a stable power supply is essential for preventing disruptions in the filling process. Fluctuations in power can lead to downtime and product wastage, so it’s important to invest in reliable power backup systems and voltage stabilizers.

Film storage – Proper storage of film is essential for maintaining its quality and integrity. Film should be stored in a clean, dry environment, away from direct sunlight and contaminants. Regular inspections should be conducted to ensure that the film is in good condition and free from any defects that could affect the filling process. Maintaining the core is important in being able to load it onto the packaging machine. The storage area must be close to the filling station.

Cleaning routines – Frequent cleaning of the filling equipment is essential for preventing contamination and maintaining product quality. Cleaning should be done using approved cleaning agents and procedures to ensure that all surfaces are thoroughly cleaned and sanitized.

Spares for the equipment – Understanding the consumable spares and their storage will help minimize downtime. Understanding MTBF and main failures should help in designing a proactive preventive maintenance schedule.

Trained manpower – Manpower trained in operating and maintaining your equipment is crucial. These need to be managed. Challenges introduced by attrition need to be addressed through proper documentation and training manuals.

In conclusion, ensuring the right site conditions is essential for successful powder-filling operations. By paying attention to factors such as bulk density, flow properties, ambient temperature, humidity, conveying methods, power quality, film storage, and cleaning routines, you can optimize your powder-filling process for maximum efficiency and product quality.

0 notes

Text

What are the energy requirements for operating baby diapers manufacturing machine?

The energy requirements for operating a baby diaper manufacturing machine can vary depending on several factors, including the type of machine, production capacity, efficiency of the equipment, and the specific processes involved.

However, here are some general considerations regarding energy usage:

Electricity: Most baby diaper manufacturing machines are powered by electricity. The energy consumption for operating these machines can vary significantly based on factors such as the size of the machine, the number of components (e.g., motors, heaters, sensors), and the level of automation.

Heating Systems: Some diaper manufacturing machines may incorporate heating systems for processes such as material drying, adhesive application, or sealing. The energy requirements for heating depend on the type and capacity of the heating elements used and the duration and temperature settings required for the process.

Compressed Air: Many diaper manufacturing machines utilize compressed air for various pneumatic components and functions, such as controlling valves, actuators, and pneumatic cylinders. baby diapers manufacturing machine for sale The energy requirements for operating compressed air systems depend on factors such as air pressure, volume, and frequency of use.

Cooling Systems: Certain processes in diaper manufacturing machines may require cooling systems to maintain optimal operating temperatures and prevent overheating of components. The energy requirements for cooling depend on the type and capacity of the cooling equipment used and the duration of operation.

Lighting and Auxiliary Systems: Diaper manufacturing facilities may require lighting, ventilation, and other auxiliary systems to support the operation of the machines and ensure a safe and comfortable work environment. The energy consumption for these systems depends on factors such as the type and efficiency of the lighting fixtures, ventilation fans, and other equipment.

Energy Efficiency Measures: Manufacturers of diaper manufacturing machines continuously strive to improve energy efficiency and reduce energy consumption through various measures. This may include optimizing machine designs, incorporating energy-efficient components and controls, implementing waste heat recovery systems, and adopting energy management practices.

Monitoring and Optimization: Monitoring energy usage and identifying opportunities for optimization are essential for managing energy costs in diaper manufacturing operations. This may involve conducting energy audits, analyzing energy consumption data, implementing energy-saving measures, and investing in energy-efficient technologies.

Overall, while operating a baby diaper manufacturing machine requires energy, manufacturers can take steps to minimize energy consumption, improve efficiency, and reduce environmental impact through the adoption of energy-efficient technologies and practices. Additionally, regulatory requirements and industry standards may influence energy management strategies in diaper manufacturing facilities.

How do baby diapers manufacturing machine handle bulk material storage?

Baby diaper manufacturing machines typically handle bulk material storage through the integration of material handling systems that ensure a steady supply of raw materials for the production process.

Here's how these machines handle bulk material storage:

Raw Material Silos or Hoppers: Diaper manufacturing machines often incorporate silos or hoppers for storing bulk quantities of raw materials, such as fluff pulp, superabsorbent polymers (SAP), and other absorbent materials. These silos or hoppers are designed to accommodate large volumes of material and provide a constant supply to the production line.

Material Conveyance Systems: Material conveyance systems, such as conveyors, augers, or pneumatic transport systems, are used to transfer raw materials from the storage silos or hoppers to the processing equipment. These systems ensure a continuous flow of materials to the production line, minimizing downtime and interruptions in the manufacturing process.

Material Monitoring and Control: Diaper manufacturing machines may incorporate sensors, level indicators, and control systems to monitor and control the flow of raw materials from storage to processing. This helps maintain optimal material levels, prevent overfilling or underfilling of storage vessels, and ensure consistent material supply to the production line.

Automated Replenishment Systems: Some diaper manufacturing machines feature automated replenishment systems that automatically refill storage silos or hoppers when material levels are low. diaper production machine line manufacturer These systems may be programmed to trigger material deliveries based on predetermined inventory thresholds or production schedules, optimizing material availability and minimizing manual intervention.

Material Blending and Mixing: In cases where multiple raw materials are used in diaper manufacturing, such as blends of fluff pulp and SAP, the machine may incorporate material blending and mixing systems. These systems ensure thorough mixing and homogenization of materials before they are fed into the production line, ensuring consistent product quality.

Inventory Management: Diaper manufacturing machines may be equipped with inventory management systems to track raw material usage, monitor inventory levels, and facilitate timely reordering of materials. This helps prevent stockouts, minimize production delays, and ensure uninterrupted operation of the manufacturing process.

Safety and Environmental Considerations: Proper storage and handling of bulk materials are essential for ensuring workplace safety and minimizing environmental impact. Diaper manufacturing machines adhere to relevant safety regulations and guidelines for storing hazardous or flammable materials and implement measures to prevent spills, leaks, or contamination.

By incorporating these features and systems, baby diaper manufacturing machines effectively handle bulk material storage, ensuring a continuous and reliable supply of raw materials to the production line. This contributes to efficient manufacturing operations, consistent product quality, and optimized production throughput.

0 notes

Text

Trusted Stainless Steel Storage Tank Manufacturers and Suppliers

In today's industrial landscape, the demand for robust and reliable storage solutions has never been greater. Stainless steel storage tanks stand out as a cornerstone of efficiency, offering durability, corrosion resistance, and versatility. At Newtech Steels, we take pride in being among the foremost manufacturers and suppliers of premium-grade stainless steel storage tanks, catering to diverse industries worldwide.

Our dedication to excellence is evident in our comprehensive product lineup, which includes an array of innovative storage solutions designed to meet the specific needs of our clients. From Bolted Panel Storage Tanks to Zinc Aluminium Tanks, PVC Liners, and Grain Silos, we offer a wide range of options to accommodate various storage requirements.

Our Bolted Panel Storage Tanks exemplify our commitment to quality and functionality. Constructed from high-grade stainless steel, these tanks provide unmatched durability and corrosion resistance, ensuring long-term reliability in even the harshest environments. Whether for liquid or dry bulk storage, our tanks deliver superior performance, making them an ideal choice for a wide range of applications.

For applications requiring lightweight yet durable storage solutions, our Zinc Aluminium Tanks offer an excellent alternative. Combining the strength of steel with the corrosion resistance of aluminum-zinc alloy, these tanks provide exceptional longevity and reliability. They are particularly well-suited for agricultural, industrial, and municipal storage needs.

In addition to our standard offerings, we specialize in providing customized solutions tailored to meet the unique requirements of our clients. Whether it's modifying tank dimensions, adding specialized fittings, or incorporating advanced features, our experienced team works closely with customers to deliver bespoke solutions that exceed expectations.

At Newtech Steels, quality is our top priority. Our manufacturing processes adhere to stringent quality standards, ensuring that every stainless steel storage tank we produce meets or exceeds industry regulations and certifications. From initial design to final inspection, we maintain meticulous attention to detail to uphold our reputation for excellence.

We take pride in our track record of client satisfaction, with numerous success stories highlighting the reliability and performance of our storage solutions. By partnering with Newtech Steels, clients gain access to not only top-tier products but also exceptional customer service and support throughout the project lifecycle.

In conclusion, for unparalleled stainless steel storage tank solutions, look no further than Newtech Steels. Whether you're in need of standard or customized storage solutions, we have the expertise and resources to meet your requirements. Contact us today to discuss your project needs and discover why we're the trusted choice for stainless steel storage tanks.

1 note

·

View note

Text

Bulk storage silos are essential for businesses aiming to enhance efficiency and save costs. They maximize storage capacity, protect materials, and streamline production.

0 notes

Text

Bulk Storage Silos

When it comes to storing powdered reagents, steel silos are the ultimate solution. At Sodimate, we offer custom-designed bulk storage silos tailored to your site's specific needs, offering volumes ranging from 200 to 7,000 ft3. Reach out to us today to discover the ideal storage solution for your needs.

0 notes

Text

Advancements in Bulk Material Handling Products and Technologies Market: An Overview of Latest Developments, Size, Share and Trends

Bulk material handling products and technologies play a critical role in various industries, facilitating the efficient transport, storage, and processing of large quantities of materials such as minerals, chemicals, food products, and more. These systems encompass a diverse range of equipment, including conveyors, bucket elevators, stackers, reclaimers, and silos, designed to handle bulk materials in a systematic and controlled manner. The primary objectives of bulk material handling are to improve operational efficiency, reduce manual labor, and enhance safety across industries such as mining, construction, agriculture, and manufacturing.

𝐆𝐞𝐭 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐏𝐃𝐅: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=3816

The demand for bulk material handling products and technologies is on the rise, driven by the increasing need for streamlined and automated material handling processes. Industries worldwide are focusing on optimizing their supply chain and production workflows to meet growing demands efficiently. Bulk material handling equipment provides a scalable and cost-effective solution for handling large volumes of materials, contributing to improved productivity and overall operational effectiveness. Moreover, the adoption of bulk material handling technologies is prominent in sectors where the efficient management of raw materials is critical, such as in mining and construction, where the timely and reliable movement of materials is essential for project success.

The demand for bulk material handling products and technologies is further fueled by the rapid expansion of industries and the global push towards infrastructure development. As urbanization continues and construction projects increase, there is a growing requirement for efficient systems to handle and transport bulk materials. Additionally, the increasing emphasis on sustainability and environmental regulations has led industries to invest in technologies that not only enhance efficiency but also minimize energy consumption and environmental impact. Bulk material handling solutions contribute to reducing waste, enhancing resource utilization, and promoting overall sustainability in various industrial processes. Furthermore, the integration of digital technologies and automation in bulk material handling is shaping the future of this sector. The demand for smart technologies, such as sensors, IoT-enabled devices, and data analytics, is driving innovation in bulk material handling systems. These technologies enable real-time monitoring, predictive maintenance, and improved control over material handling processes. As industries continue to evolve towards smarter and more efficient operations, the demand for advanced bulk material handling products and technologies is expected to grow, creating opportunities for manufacturers and suppliers in the global market.

0 notes

Text

Efficient Materials Storage Solutions by Fleming

Explore Fleming's cost-effective materials storage solutions for 25kg bags, bulk bags, octabins, bins, and silos. Optimize your storage needs with us.

0 notes

Text

A rod-type level sensor

A rod-type level sensor, also known as a probe or rod-type level transmitter, is a type of level measurement device commonly used for determining the level of liquids or solids in tanks, vessels, or containers. It consists of a probe or rod that extends into the tank, with its length corresponding to the maximum desired level measurement. Here's an overview of rod-type level sensors:

Working Principle:

Rod-type level sensors operate based on the principle of conductivity or capacitance. When the probe comes into contact with the liquid or solid material, it completes an electrical circuit, which is detected by the sensor electronics. The change in conductivity or capacitance is proportional to the level of the material being measured. By measuring this change, the sensor can determine the level of the substance in the tank.

Key Components:

Probe or Rod: The sensing element that extends into the tank and comes into contact with the material whose level is being measured.

Electronics: The electronic circuitry that processes the signal from the probe and converts it into a level measurement. This may include amplifiers, filters, and signal conditioning circuits.

Output Interface: The interface through which the level measurement signal is transmitted to a display, controller, or data acquisition system. Common output signals include analog (4-20 mA) and digital (RS-485, Modbus, etc.).

Types of Rod-Type Level Sensors:

Conductivity-based Sensors: These sensors measure the conductivity of the material to determine its level. When the probe comes into contact with the material, it completes an electrical circuit, indicating the presence of the material.

Capacitance-based Sensors: Capacitance sensors measure changes in capacitance between the probe and the tank wall or a reference electrode. The dielectric constant of the material affects the capacitance, allowing for level measurement.

Advantages:

Simple Installation: Rod-type level sensors are easy to install, requiring only a mounting point on the tank and electrical connection.

Suitable for Various Materials: These sensors can be used to measure the level of liquids, powders, granules, and other solid materials.

Reliable Operation: Rod-type level sensors are robust and reliable, with minimal maintenance requirements.

Wide Range of Applications: They are suitable for use in various industries, including chemical processing, water treatment, food and beverage, pharmaceuticals, and more.

Cost-effective: Rod-type level sensors are often more cost-effective than other types of level measurement devices, making them a popular choice for many applications.

Applications:

Tank Level Monitoring: Used for monitoring the level of liquids or solids in storage tanks, silos, bins, and other containers.

Process Control: Integrated into industrial processes for controlling the level of materials in mixing tanks, reactors, and production vessels.

Inventory Management: Employed in warehouses and distribution centers for inventory control of bulk solids and liquids.

Safety and Alarm Systems: Used to trigger alarms or shutdown processes when the level of a material reaches critical levels.

In summary, rod-type level sensors are versatile and reliable devices used for measuring the level of liquids or solids in various industrial applications. With their simple installation, wide range of applications, and cost-effectiveness, they are a popular choice for level measurement needs.

0 notes