#CNC eps foam cutting machine

Text

CNC Knife Cutter Machine for PE and EVA Foams

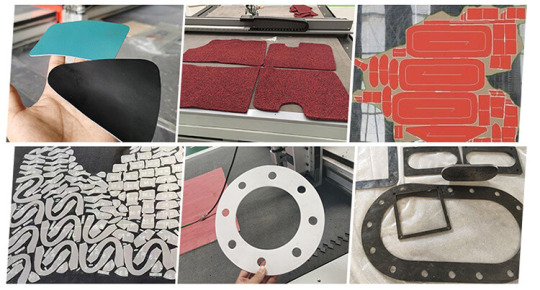

CNC knife cutter machines are widely used in industries such as packaging, textile, automotive, aerospace, and signage. They offer precise and efficient cutting capabilities, enabling the production of intricate shapes and patterns with minimal material waste.

Affordable cnc oscillating knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

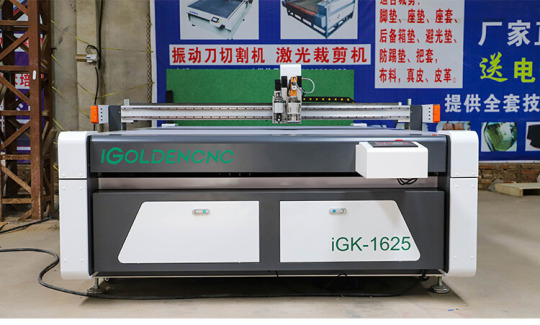

CNC Knife Cutter Machine

A CNC knife cutter machine, also known as a CNC cutting machine or a CNC oscillating knife cutter, is a computer-controlled cutting system specifically designed for precision cutting of various materials. It utilizes a vibrating or oscillating knife, which moves rapidly up and down to cut through the material.

Affordable cnc oscillating knife machine have two types: ① CNC Router machine add oscillating knife cutting knife head (Knife together with spindle independent work, compatible with cnc router cotrol system, and running perfectly, Solve the processing needs of soft materials); ② Professional oscillating knife cutting machine ( Professional and efficient ). Accordding to functions: can be divided into oscillating knife cutting , round knife cutting, pneumatic knife cutting. you need to accordding to different material shapes cutting, choose different knives.

CNC can provide all kinds CNC Knife Cutter Machine for sale:

CCD camera series: automatic edge finding, automatic scanning, automatic imaging system.

CNC knife cutter machine table size:

CNC oscillating knife cutting machine for sale have model: 6090, 1390, 1410, 1610, 1325, 1530, 2030, and working table size 600*900mm, 900*1300mm, 1000*1400mm, 1000*1600mm, 1300*2500mm, 1500*3000mm, 2000*3000mm etc, maybe some regions describe cnc knife cutter machine table size with feet: 3*4, 3*5, 4*8, 5*10 etc. We also accept custom table sizes,to meet customer needs.

CNC Knife Cutter Machine Processing advantages

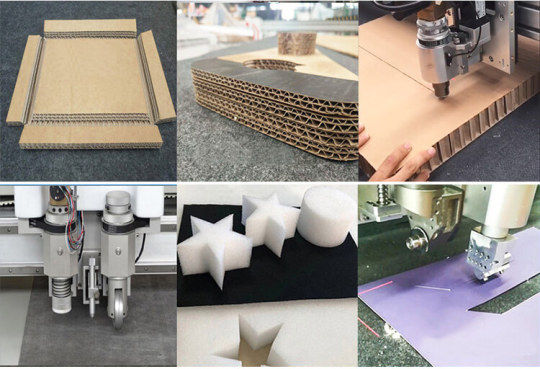

With the continuous development of numerical control technology, more and more customers choose to use smart cutting equipment instead of workers. It uses advanced oscillating knife cutting technology to select different tools according to material thickness and hardness. It can meet a variety of foam material cutting, such as EVA, EPE, sponge, EPS styrofoam and so on.

There are 6 advantages to using the CNC Knife Cutter Machine to cut the foam:

1. More flexible; EVA foam automatic cutting machine does not need a mold, just process the processing data (PLT, DXF, AI format) into the system to cut, and can modify the size and shape of the processing graphics arbitrarily;

2. Save materials; automatic nesting software can complete typesetting quickly and accurately without manual nesting. After actual testing, using an automatic cutting machine can save more than 10% of material compared to manual cutting;

3. Meet different foam cutting; can cut foam of different width, thickness, and material. High cutting precision and flat cutting to meet the cutting requirements of complex graphics.

4. The processing site is more humanized; AMOR EVA foam cutting machine adopts high-frequency oscillating knife cutting technology. Compared with laser cutting technology, the processing site has no soot, and the cutting speed is 3-4 times that of the laser. More environmentally friendly processing methods.

5. Different types of tools can be configured; customers can configure different processing tools according to the processing materials – round knife, pneumatic knife, punching knife, vibrating knife, and other cutter heads to configure freely to cut other materials except for foam;

6. Achieve higher cutting efficiency; AMOR EVA foam cutting machine adopts Japanese Mitsubishi servo motor with cutting speed of up to 2000mm/s. Customers can also choose dual-oscillating tools to cut at the same time, which doubles the processing efficiency.

CNC Knife cutter machine application

Affordable cnc Digital knife machine mainly used for PVC,leather, carbon fiber,carpet, seat cushion, floor mat, floor mat, cushion, soundproof cotton, XPE, EVA, KT board, luggage, clothing, Sponge composite skin and corrugated paper nonmetal cutting. suitable for car mats, footwear, leather goods, luggage and other industries.Because cnc knife cutter machine affordable price, low price, easy to use , so there is a big markets in recent years.

Oscillating Knife Details

Cutting Capabilities

CNC knife cutter machine are versatile and can cut a wide range of materials, including but not limited to:

Soft materials: Foam, rubber, gaskets, textiles, carpets, felt, leather, etc.

Rigid materials: Cardboard, corrugated board, honeycomb board, thin plastics, composite materials, etc.

Other materials: Vinyl, paper, cork, magnetic sheets, adhesive-backed materials, and more.

The oscillating knife’s high-frequency motion allows for clean and precise cuts, even in intricate designs or complex patterns.

Additional Tool Option

In addition to the oscillating knife, CNC knife cutter machines can often accommodate other cutting tools or attachments, expanding their capabilities. Some common additional tools include:

Creasing wheels: Used for creating creases or scoring lines in materials like cardboard or paper, enabling easier folding or bending.

Perforation wheels: Used to create perforated lines for tear-off sections in materials like paper or cardboard.

Routing attachments: Used for cutting harder materials like acrylic or wood, where an oscillating knife may not be suitable.

The ability to interchange tools allows for more versatility in the types of materials and applications that can be handled by the machine.

High Precision and Repeatability

CNC knife cutter machines offer excellent precision and repeatability in cutting. The computer-controlled nature of the machine ensures accurate cutting paths, resulting in consistent and high-quality finished products. This is especially beneficial for industries that require precise fitting, such as packaging or automotive interior components.

Design Flexibility

With the help of specialized software, CNC knife cutter machines can process various design file formats, allowing for flexibility in design creation. Designs can be imported from computer-aided design (CAD) software or created directly within the cutting software. This flexibility enables customization, prototyping, and small-batch production with ease.

Production Efficiency

CNC knife cutter machines streamline the cutting process, reducing manual labor and increasing production efficiency. Once the cutting program is set up, the machine can autonomously execute the cutting tasks, optimizing material usage and minimizing waste. This automation also allows for faster turnaround times, enabling manufacturers to meet tight deadlines and handle larger production volumes.

Integration with Workflow

CNC knife cutter machine can be integrated into a larger production workflow, connecting with other equipment or systems. This integration facilitates seamless material handling, automated nesting (arranging shapes to minimize material waste), and data exchange, enhancing overall productivity and efficiency.

0 notes

Text

How to Choose the Best Foam Cutting Machine for Your Business in India

In today's era of sustainability and innovation, businesses across various industries in India are increasingly turning towards foam cutting machines to streamline their operations. Whether you're in the packaging, furniture manufacturing, or construction industry, investing in the right foam cutting machine can significantly enhance productivity and efficiency while reducing costs. However, with a plethora of options available in the market, choosing the best foam cutting machine for your business can be a daunting task. To help you navigate through this decision-making process, we've compiled a comprehensive guide outlining key factors to consider when selecting a foam cutting machine tailored to your specific business needs.

Understand Your Business Requirements: Before diving into the selection process, it's crucial to assess your business requirements thoroughly. Determine the type and volume of foam materials you'll be working with, the desired cutting precision, production capacity, and budget constraints. Understanding these factors will provide clarity on the type of foam cutting machine that best suits your business operations.

Types of Foam Cutting Machines: Foam cutting machines come in various types, each designed for specific cutting applications. The commonly used types include:

Hot Wire Foam Cutters: Ideal for cutting through expanded polystyrene (EPS) foam with precision and smooth edges. Suitable for intricate shapes and designs.

CNC Foam Cutting Machines: Computer Numerical Control (CNC) machines offer unparalleled precision and versatility in cutting foam materials. They are programmable and can produce complex shapes with high accuracy.

Vertical Foam Cutting Machines: Suited for cutting large foam blocks into sheets or custom sizes. They are efficient for bulk production and are commonly used in the furniture and mattress manufacturing industries.

Horizontal Foam Cutting Machines: Designed for cutting foam blocks horizontally into uniform sheets. They are suitable for applications requiring consistent thickness, such as packaging and insulation materials.

Cutting Capacity and Efficiency: Consider the cutting capacity and efficiency of the foam cutting machine in relation to your business requirements. Assess factors such as cutting speed, throughput, and the ability to handle different foam densities and thicknesses. Opt for a machine that offers optimal performance and can meet your production demands without compromising on quality.

Precision and Cutting Quality: The precision and cutting quality of the foam cutting machine are paramount, especially for industries requiring intricate designs or high-quality finished products. Look for machines equipped with advanced cutting technologies, such as servo motors and precision guides, to ensure accurate and consistent cuts.

Ease of Operation and Maintenance: Choose a foam cutting machine that is user-friendly and easy to operate, minimizing training time and operational complexities. Additionally, consider the maintenance requirements of the machine, including access to spare parts and technical support. A reliable after-sales service network is essential to ensure smooth operation and timely troubleshooting.

Safety Features: Prioritize safety features when selecting a foam cutting machine to protect your workers and maintain a safe working environment. Look for features such as emergency stop buttons, safety guards, and automatic shutdown mechanisms to mitigate the risk of accidents and injuries.

Cost and Return on Investment (ROI): While cost is a significant factor, it's essential to evaluate the overall return on investment (ROI) of the foam cutting machine. Consider factors such as long-term operational costs, energy efficiency, and potential savings in material wastage. Investing in a quality foam cutting machine may entail a higher initial cost but can yield substantial returns through improved productivity and product quality over time.

Reputation and Customer Reviews: Research the reputation of the foam cutting machine manufacturer or supplier in the industry. Look for reviews and testimonials from other businesses who have used their products. A reputable manufacturer with positive customer feedback is more likely to deliver reliable and high-quality machines that meet your expectations.

Customization and Additional Features: Evaluate whether the foam cutting machine offers customization options or additional features that align with your business requirements. Some machines may come with optional accessories or software upgrades that enhance functionality and expand cutting capabilities.

Future Expansion and Scalability: Anticipate your future business growth and consider whether the chosen foam cutting machine can accommodate expansion or scalability. Selecting a machine with modular design or upgradeable features allows you to adapt to changing market demands and increase production capacity as needed.

In conclusion, choosing the best foam cutting machine for your business in India requires careful consideration of various factors, including your specific requirements, cutting applications, efficiency, precision, safety, and overall cost-effectiveness. By thoroughly evaluating these factors and conducting thorough research, you can select a foam cutting machine that maximizes productivity, enhances product quality, and drives long-term success for your business.

#Foam Cutting#Foam Cutting Machines#Santech Foam Machines#Vertical Foam Cutting Machines#Horizontal Foam Cutting Machines#Best Foam Cutting Machines in India

0 notes

Text

youtube

EPS foam is employed as geofoam in geotechnical and civil engineering applications. It is also EPS foam.

Geofoam is used to reduce the weight and pressure on the soil, providing lightweight fill in areas such as embankments, roadways, bridge approaches, and underground structures.,it can be cut by CNC foam cutting machine too. EPS geofoam offers advantages like load reduction, improved stability, and ease of installation

0 notes

Video

youtube

hot wire insulation eps foam block brick cutting machine styrofoam cnc c...

0 notes

Text

What is the best way to cut foam and fabric in Ulhasnagar for?

This article provides information on the reasons for foam cutting. Also, it explains what types of businesses use foam cut and the method of cutting. Also, it explains what types of materials are used as well as the machinery involved.

Today, foam cutting has a huge demand. This is especially true for fabrication and CNC machining. There is an increasing demand for foam cutting, especially for fabrication.

Foam cutting companies need top-of-the line equipment in order to offer an array of cutting services. You can use a laser or hot wire CNC foam cutter to cut your foam. It can also cut up to twelve feet of foam. However, the hot-wire cutter has the ability to make very small cuts of less than 3/4" and produce a quality surface finish. The type of foam that will be cut (such as Polyurethane or PU Foam can only be done with the Laser), its thickness and size, are all factors in deciding whether the hot-wire cutters should be used.

Hot wire CNC foam cutters cut all types of foam including EPS, EPP and XPS.

The smaller foam cutting machines are usually used for the creation of logos, wings, or letters. The medium foam cutters will also cut similar shapes, plus they can be used to make crown moldings for architectural purposes.

For example, laser cutters and engravers are able to cut a variety of types of foam and fabric in Ulhasnagar. These include Polyurethane, which is mainly used in packaging, insulation, and gun cases.

The use of CNC routers is required when the materials being cut are light metals or wood.

Cutting machines vary in size, dimensions and features, such as the hot wire's length and how many foam blocks can be sliced in a given time.

CNC Routers can be used for projects which require the fabrication or machining of foam. They are also useful in combination with hot wire CNC foam cutters. The machine can create foam molds for props, artwork, or even full scale racing vehicles.

CNC cutting machines include specialized software for cutting and they can be controlled via computer.

To cut the foam you will need a specialized program that includes the design of the object. It is important to have a DXF or STL file for 2D and 3D shapes. These files allow the user to view the entire shape in all its angles.

Once you have the file that's right, it is uploaded into the computer, and all the coordinates are sent to the foam cutting machine. After the cutting is complete, you can either choose a rough or smooth finish depending on what the customer wants. Large shapes can be made out of multiple pieces and then joined together. It is possible to paint or polyurea the cut. The product has to be tough, sturdy and lasting.

1 note

·

View note

Video

youtube

CNC Knife Cutting Machine for thick EPE foam

0 notes

Text

Free cam software for cnc

CAM System: Free Download | CADCAMPDM.

Free CNC CAD CAM software programs available.

Precision free cam software cnc For Precise Results - A.

Best CNC Software For All (Free) | CAD, CAM Softwares.

Free CAD-CAM CNC Demo Downloads by BobCAD-CAM | BobCAD-CAM.

CNC 3018 (Pro) Software: The Best Programs of 2022 | All3DP.

Free CNC software for 3 and 4 axis machines - rcKeith.

CAM Software | CNC Programming Software | CAMWorks.

Ezcam Cad Cam Software CNC Simplified CNC Mill,CNC Turn,EDM.

How to start CNC machining, with free CAM software - YouTube.

Mach3 (free version) download for PC - FreeDownloadManager.

10 Best Free CAD CAM Software for Beginners in 2022.

Best FREE CAD CAM Software for CNC Routers: Top 5 Picks.

CAM System: Free Download | CADCAMPDM.

The DeskProto Free edition is completely free of charge. The DeskProto Free edition offers basic CAM functionality (without any time-limitation). Nevertheless all toolpath types for your CNC milling machine are available: Vector machining based on a drawing in a DXF, EPS, AI or SVG file. Geometry machining based on the geometry in an STL file. Cnc cad cam software for sale - 2430 - cnc cad cam software wholesalers & cnc cad cam software manufacturers from China manufacturers.

Free CNC CAD CAM software programs available.

RhinoCAM is a CAM software plugin that combines the power of Rhino’s freeform modeling with the elite CAM functionality of VisualCAM. It offers full parametric modeling out of the box, built-in version control and cloud backups, and easy-to-use file format translators. CutLeader. Download. 4.1 on 7 votes. CutLeader is a CAD/CAM software for CNC cutting machine (laser, plasma, waterjet, router, foam cut) with true shape nesting.... /CAM software for CNC cutting machine... most advanced CNC programming software and benefit. FreeMILL, as the name indicates, is a free milling module for programming CNC mills & routers. FreeMILL running inside SOLIDWORKS design software, gives you a great entry level milling software product that is completely free of cost! Yes, completely free with no time limits, number of tries limit, number of saves limit or lines of code limit!.

Precision free cam software cnc For Precise Results - A.

Jun 23, 2022 · CNC machining is a great hobby, but the proper software can be pricey. Check out our roundup of the best free CAM software! This article is free for you and free from.

Best CNC Software For All (Free) | CAD, CAM Softwares.

Buy Your CAD CAM Software BEFORE Your CNC Machine. Big Tip: Get your CNC Software BEFORE your CNC Machine! Look, it’s going to take weeks to get at all proficient with your CNC Software. Plan to spend 4-6 weeks on it. Let’s say you purchase the software at the same time as your CNC Machine. Welcome to CamBam. CamBam is an application to create CAM files (gcode) from CAD source files or its own internal geometry editor. CamBam has many users worldwide, from CNC hobbyists to professional machinists and engineers. Reading from and writing to 2D DXF files. Drilling (Normal,Peck,Spiral Milling and Custom Scripts). Create 2-axis toolpath with optional constant taper, and 4-axis path with automatic or manual synchronization, for a range of applications including specialized piece parts, tooling, and punch and die work. What SmartCAM Users Are Saying. SmartCAM rises head and shoulders above the rest because of its unique way of treating toolpath as geometry.

Free CAD-CAM CNC Demo Downloads by BobCAD-CAM | BobCAD-CAM.

Free CAM software for newbies: G-simple was created by julius. After many researches I've found G-simple. A simple CAM software for generating gcode. More than this it's completely free. It has also elementary CAD features that are, in my opinion, not so bad at all. Even for machining some quite advanced "mechanical" parts. OpenBuilds CAM - GCODE Generator. OpenBuilds CAM is a web-based application for converting SVG, DXF and Bitmap drawings, to GCODE for use with your CNC, Laser, Plasma or Dragknife Machine. Browse to About. This will allow you to.

CNC 3018 (Pro) Software: The Best Programs of 2022 | All3DP.

PlanetCNC is a free CNC machine control software for controlling your CNC machine based on G-code files. However, PlanetCNC control software can only be used with the USB Mk3 or Mk 4 controllers sold by PlanetCNC. PlanetCNC software connects to its controller via a USB cable, unlike the LinuxCNC software.

Free CNC software for 3 and 4 axis machines - rcKeith.

Carbide Create is a free 2D CAM software from the makers of the Shapeoko CNC router. It quite easy to use and produces gcode that can be used pretty much any CNC router machine. Carbide Create is downloadable software so you don’t actually need an internet connection to run it.

CAM Software | CNC Programming Software | CAMWorks.

. I think Autodesk is doing something good here and valuable for all of us consumers. I recommend that you try the software out. It won't cost you anything and you really can keep it for free if you use it for non-profit applications (check the license to be sure you fit though). Upload by: Cutting Vision Team. CNC Softrware for 3018 CNC Machines. Easel is a powerful, accessible, cross-compatible CNC software that carries everything you need in one easy package. Easel is a powerful, easy-to-use tool for designing and creating projects using any 3018 CNC machine that runs on GRBL firmware. With the help of a thriving online community, find endless.

Ezcam Cad Cam Software CNC Simplified CNC Mill,CNC Turn,EDM.

Free 3d modeling software sketchup, cost 3d modeling software design cad 3d,alibre is a good software ,linuxcnc is free download. I use it to run my sherline 3 axis cnc mill ,linuxcnc is easy to install and use also mach 3 is good for about 200, I use solidedge which i have been using fo about 10 years but it is not cheap,you could try taking some classes in 3d modeling as a student. Free Cam Software FreeCAD path better then fusion 360 Cam ?????This YouTube channel is about micro manufacturing and teaching how to become a inventor and T.

How to start CNC machining, with free CAM software - YouTube.

Best Free CAM Software for CNC Routers 1. LinuxCNC Operating Systems – Linux Without a doubt, the LInuxCNC is the top competitor to the.

Mach3 (free version) download for PC - FreeDownloadManager.

Best Free Cam Software. Free Cad Cam Software Cnc. Free Cam Software For Cnc Router. Free Cnc Cam Software For Windows 10. MasterCAM is the best software for generating CNC Part. It is free available with easy installation. I would like to share my tutorial video for CNC Part by using MASTER CAM Software. Best CAM software free download. Manufacturing has changed so should your tools. Modernize your manufacturing workflows with the only truly unified CAD/CAM software for a fraction of the price.... Yes, Fusion 360 includes a full suite of CAM software to program a variety of CNC machines. Fusion 360 manufacturing has a modern interface and. The CAM programs enable turning with external and internal roughing, finishing, recessing, threading, transverse facing and drilling. The post processor offers you advanced post-processing functions. For example, for converting blade position data (APT-CL) into machine-specific code (GM code) that CNC machines require.

10 Best Free CAD CAM Software for Beginners in 2022.

These downloads provide 40 free, fully functional evaluation sessions. To make sure the evaluation works correctly, after installation, right click the CamBam program shortcut and select 'Run as administrator'. Even after the evaluation period has expired, you can continue to use CamBam to edit drawings and test your post processors and g-code. The Free edition of the DeskProto software allows you to start CNC machining free of charge: see how easy it is to create a nice stool by CNC machining a sla. Free 2D CAD system older version of their software. CoCreate. free personal edition 3D CAD modeler. Draft IT. Light version of their commercial CAD drawing product. GraphiteOne. Linux operating system only. Free 2D drafting and 3D design. Powershape-e.

Best FREE CAD CAM Software for CNC Routers: Top 5 Picks.

MastercamLearning Edition. Mastercam Learning Edition is free CAD/CAM software download for demo and educational purposes. It is a trial version of Mastercam that can be used to learn at home. Whether you are an industry professional, student, or teacher, if you are looking for a way to get more familiar with CAD/CAM software, Learning Edition. The "CNC Simulator" from is a great piece of software for 2D & 3D machining simulation. Best of all the CNCsimulator is absolutely FREE. WIth this CNC simulator you can simulate both turning and milling machines and applications. It is a perfect tool both learning how to program as well as training!. Investing in the nifty free cam software cnc on A enhances performance outputs. The top-rated free cam software cnc have irresistible offers.

See also:

Download Mortal Kombat Iso File For Ppsspp

Nuance Pdf Converter Free Download Full Version With Crack

Driver Easy Activation Key

Fnaf Ultimate Custom Night Download

Resident Evil 4 Game For Mac Free Download

0 notes

Text

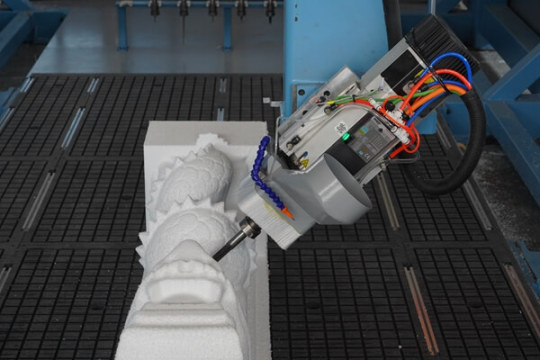

2021 New Type CNC Eps Foam Cutting Machine With A Good Price

EPS Foam CNC Machine as know as CNC EPS foam cutting machine or EPS foam cutting machine, it was designed to cut EPS expandable polystyrene foam into sign,3D, cornice etc.

The EPS Foam CNC Machine has the advantages of high strength structure, large capacity transformer, frequency control and so on. Its engraving and cutting adopts frequency conversion speed regulation and voltage independent adjustment device to realize multi-filament simultaneous cutting and speed cutting.IGOLDENCNC is one of the most professional eps foam cnc router manufacturers and suppliers in China. We warmly welcome you to buy the best quality eps foam cnc router for sale from our factory. Please feel free to check price with us!CN¥160,772.50-CN¥225,081.50

📷

CNC eps foam cutting machine features:

1. The Z axis can be heighten to 1000mm, which widens the working region so as to fit the large three-dimensional curved surface processing.

2. Big steel square tube structure,by seamless welding and hardening treatment, guarantee it to be strong, reliable and durable, with large bearing capacity and long working life.

3. EPS foam cnc router equipped with self-lubricating blocks,with four-row ball bearing and widened rail,so it can get equal force in all directions, to guarantee mechanical precision and strength.

4. Many optional configuration and OEM service available.According to your requirement, different configurations of foam cnc router will be offered.

5.Imported high-precision ball screw and Taiwan Hiwin linear square rails, which move smoothly to ensure the machining precision.

Basic Advantages of EPS Foam CNC Machine:

High soft, famous brand electric cables, with high Abrasion, fold, high temperature, acid and alkali resistant .

Original Imported Taiwan Hiwin Guide Rail , Taiwan and Germany Imported ball screw.

We will provide you several kinds software for free, with English and multilingual versions. Also you can get the perfect picture storage with thousands 2D and 3D designs, and some kinds of spare parts, work piece fixtures .

Perfect after sale service, timely reply to your any question, professional instructions for the machine, software and parts' using.

Any workstage is strictly processed according to Euro CE Quality Standard and ISO. Any set CNC Router will be done at least 72 hours careful testing and checking, from small part to the whole machine. After any part's quality inspection finishing Basic maintenance measures, then the machine can be packaged by the specialized workers for transport.

Our company has powerful strength in metal Machining. In order to make sure every detail's high quality level, most of the machine's metal parts are made by our own Machining Center imported from American .

📷

EPS Foam CNC Machine Configuration

1.Welded thick steel bed structure, Taiwan HIWIN square guide rails

2. 4.5KW or 6KW air cooling spindle

3. Servo motors, also can optional stepper motor and drivers

4.Ncstudio control system, can be optional DSP control system and Taiwan SYNTEC control system

5.Dust cover for ptecting guide rails and rack

6.Shenzhen SUNFAR inverter

7.2 collects and 15 pieces cutters

8.exporting plywood package

0 notes

Video

Automatic EPE/EVA/PO/PU/PP Foam Press Machine,Die Cutting Machine, Punching Machine,Presser (Veinas)

Application: The Press/Punching/Stamping/Die Cutting Machine is widely used in industrial,plastic,sponge,foam,EPE foam,EVA,PVC,PET, PAC, PVS,cardboard,paper products,fabric,home textiles, rubber, leather, packaging materials,non woven,carpet, automotive interior, car cushion,felt,synthetic materials, and other nonmetallic materials in various industries;Extremely suitable for cutting multiple layers of material at one time,etc. (Others: gloves, cleaning product, tape, gaskets, hats, bags and suitcases, puzzle, plastic floor, floor tile, car roof, foot pad, door mat, car seat, yoga mat, building decoration material, clothing/apparel, wood industry, cork wood, toys, balls, sand paper, medical accessories, corrugated board, sound proof cotton, filter screen, artificial flower, rubber and plastic, buffing wheel, polished section, polishing disc, shoes sole, insole, footware uppers, rubber slipper/flip flop sole, fibers, nylon, canvas, non-woven fabrics, cotton and linen textiles etc.) Use die cutters for cutting to shape the products. Performance advantage: 1. Four-column double cylinder mechanism design, supporting CNC feeding system, feeding length is more accurate, increase efficiency & safety and good consistency. 2. Discontinuous single trip operation, with emergency stop device, to ensure operation safety. 3. Simple Cutting die setting, accurate, fast and easy in cutting. 4. Automatic lubrication system, improve precision and more durability. Operating Principle: Using high precision imported controller and servo system. put large quantities of materials on feeding table, transfer to stamping by roller, complete cutting.

#epe foam die cutting machine#epe foam press machine#eva foam press machine#pe fom presser#veinas machinery#zhuhai huasu#guangdong huasu

1 note

·

View note

Text

The Most Popular Applications for CNC Cutting Machines

CNC cutting machines are cutting devices that can be controlled and managed by a computer system. Right this very moment, this is the method of choice of cutting method among various industries when dealing with MDF cutting, foam milling, plastics cutting, woodcutting and cutting of different types of metals.

One of the reasons why CNC plasma kits Australia is gaining extensive popularity and demand nowadays is because you can operate them at considerably higher speeds. In addition to that, they also deliver smoother edge finishes.

You can also make them deliver an array of identical products and also one-off pieces. Thus, it is safe to say this method of cutting can boast of a wide array of applications.

Below is a compilation of the common applications for CNC cutting machines.

Furniture Making

When it comes to furniture making, if you wish to produce large quantities of them, we will qualify CNC plasma kits Australia as among the best choice for the job. A CNC profile cutter can produce for you a wide array of custom-made furniture from dining sets, beds, staircases, chairs, windows, office furniture, and many more.

Cabinet Making

You can give your kitchen a much-needed makeover with the use of CNC router crafted cabinets. This cutting edge technology lends itself in making dados, side panels, shelves, custom doors, drawer fronts and many more.

Sign Making

Due to its versatile nature, CNC plasma kits Australia are perfect to use advertising sign carving. It can deliver perfect fluting, 3D carving, V-bit carving, engraving, and contour profiling.

Design

CNC technology is extensively applied in architectural millwork. Since CNC cutting machines can manage to deliver exquisite detail, they can be utilized for crafting delicate designs for many different kinds of architectural touches.

Art and Craft

There is a virtually inexhaustible amount of arts and crafts that you can create with your CNC profile cutter. This may include mirror, coins, picture frames, pieces of jewelry, plaques, Christmas decorations and a whole lot more.

Electrical Discharge Machining or the EDM Industry

The primary work of the EDM industry or electrical discharge machine is to remove metal components by virtues of sparks that burn the metal. With respect to the CNC operation, EDM comes in two types, the first is the vertical EDM and the second is the wire EDM.

The vertical EDM requires an electrode. This may come in the size and shape of the cavity that the job will make. Now, as for the wire EDM, you utilize it in making punch and die combinations. It is normally intended for the dies set being in industries where fabrication is the name of the game.

Mould Making and Prototyping

Nowadays we can see that the ideal for foam, milling epoxy, and clay 3D design models are 7 axis industrial robots, big gantry router, and 5-axis mill CNC cutting machines. Visit here to discover other usage of CNC machines.

You can utilize CNC foam cutting machine in cutting and shaping molds from EPS foam, EVA foam, polyurethane foam, plastic and many more. They can be of great help in robot fabrication and for building CNC foam molds. At present, there is an increasing number of digital studios that choose them.

Nowadays, the ubiquitous CNC cutting machine can be found in almost every major industry we have. Almost every aspect of the manufacturing space seems to have found their practical application for this type of cutting technique.

youtube

1 note

·

View note

Text

What do you need to know about the operation of the foam cutting machine?

https://www.igolden-cnc.com/product/cnc-foam-cutting-machine-for-eps-epp-xps/

0 notes

Text

ATC CNC Router for Plastics & Foam for Sale

Machining plastics and foam require specialized CNC Router Machine. You need a rigid and robust CNC Router Machine construction with a powerful driver system and high-performance CNC Cutting Machine controller to make sure the best cutting edge and working quality.EPS Foam CNC Router is one kind of foam CNC machines, it is mainly working as a CNC foam cutter for styrofoam carving, it has a big working dimension, does a good job in carving or cutting of large scale workpieces in different materials, such as wood, aluminum, styrofoam, but not for steel, iron, etc.

Our CNC Milling Machine delivers all types of applications from simple to 2D profile cut letters to complex 3D carvings and engravings, slotting, V-grooving and a variety of tooling for plastics and foams.

ATC CNC Foam Router

This is a type of foam CNC router equipped with an automatic tool changer magazine. Added with a linear auto changer magazine or carousel auto tool changer, it can not only automatically change different tools but also complete more patterns and complex engraves. It has the advantages of fast cutting speed, low maintenance cost, high engraving accuracy, etc. Moreover, it reduces the interference of manpower, which save a lot of labor and time, as well as improves work efficiency.

Advantages Of 4 Axis EPS CNC Router Machine:

1. Whole working table cast by resin sand. The annealing and other heat treatment methods ensure that the whole structure is tested to the limit for sturdiness and reliability.

2. Italian high-speed spindle, with top speed of 18000rpm, guaranteering maximum processing efficiency and productivity.

3. It adopts imported ball bearing, widening linear guide rail, self-lubricating sliding block. When engraving, equal force in all directions, to ensure the accuracy and strength.

4. Taiwan Syntec controller can read the codes in an efficient manner. On-line simulation and monitoring function are available. Processing efficiency and safety are guaranteed.

5. All of these models can be customized according to customer requirements.

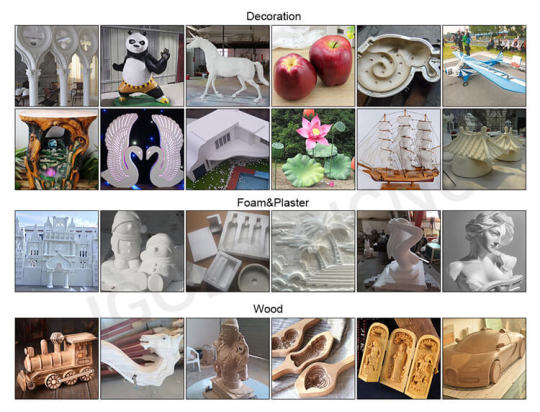

CNC Router for Plastics & Foam Application

CNC foam router is often applied to industries including Mould-making (lost foam, wood foundry pattern, aluminum casting pattern, Expanded Polystyrene Mold), Custom EPS EVA Molding, 3D Polystyrene Shapes, Foam Sculpture Props & Statues, Rapid Prototyping and more.

0 notes

Video

youtube

Hot Wire cnc foam cutter 2d 3d working styrofoam eps cutting machine

1 note

·

View note

Text

EPS2540 Heavy-Duty CNC Router

EPS2540 Heavy-Duty CNC Router

Overview

Heavy-duty designed Industry EPS CNC Routers for mold industry production available in either single or dual machine heads. The Routers features • Precision ball scree drives • Rack and pinion transmission • Italian ATC spindle• World renown HIWIN bearings • Windows® based easy-to-learn and use G-Code Interface (multiple languages).

Applications

Mold industry: Foam processing of automotive stamping dies, wooden model aviation, etc.

Materials Cut

Acrylic, ACM, Copper, Brass, Aluminum, PVC, MDF, Melamine plastic, Foam, Melamine, Phenoic, Plywood, HDPE, Solid Surface, Solid Wood, etc.

https://www.winwin-cnc.com/3Axis-CNC-Router-Industry/EPS2540-Heavy-Duty-CNC-Router.html

0 notes

Text

Cheap Eps Foam CNC Router For Sale

This Cheap eps foam cnc router a linear-type tool changer in the ATC engraving machine, which greatly improves production efficiency. In addition, the machine spindle can be swung 180, making the machine process some complex work pieces. And it is widely used in the processing of automotive foam molds, wooden boat models, wood mold aviation, trains and other molds.Price:15240-20130$📷Features of eps foam cnc router:

This eps foam cnc router use Japanese THK guide rail, it is maintenance-free and self-lubricating for life.This CNC Styrofoam cutter adopts Italian HSD high-speed electric spindle with high-altitude rotation speed reaches 12000RPM, which ensures the optimization of machining efficiency.The whole lost foam casting workbench of this CNT thermocol cutting machine has undergone strict annealing and other heat treatment processes to ensure the structural stability and rigidity of the bed.This CNC Polystyrene cutting machine uses new-generation system from Taiwan which is safe and reliable in operation, efficient in reading code, and it has an online simulation function and online monitoring function to ensure efficient and safe processing.Adopting original cross-beam triangle balanced guide rail structure and Z-axis balance auxiliary device, the eps foam cnc router can ensure fast and stable processing of multi-curved surfaces.eps foam cnc router adopts Taiwan’s integrated operating system, which is easy to operate and powerful, and has online simulation and online monitoring functions to ensure safe and efficient processing.Processing size of the foam CNC router can be customized according to processing needs. And whose Z-axis travel can be up to 2.2 meters and this machine can be upgraded to a 5 axis CNC machine.Adopting automatic oil lubrication system, it is easier to operate and maintain during the processing of the EPS CNC cutting machine.Adopting the high-power servo drive system in conjunction with the top accessories such as the Italian spindle to make the equipment stable and durable.Intelligent processing cross-border protection function can prevent mechanical collision caused by excessive design file processing.Advantage of eps foam cnc router:Self-lubricating, life-long maintenance-free Taiwan guide rail.Italian high-speed spindle, with top speed of 24000rpm, guaranteering maximum processing efficiency and productivity.Whole working table cast by resin sand. The annealing and other heat treatment methods ensure that the whole structure is tested to the limit for sturdiness and reliability.Taiwan controller reads the codes in an efficient manner. Online simulation and monitoring function are available. Processing efficiency and safety are guaranteed.Eps foam cnc router Detail imagesServo motorThe servo motor has the advantages of high accuracy, fast speed and long service life. In addition, it has strong anti-overload capability and can withstand a load that is three times the rated torque. When running at high speed, it has the advantages of stable operation and low noise. We provide a variety of imported brand servo motors such as Yaskawa, Panasonic, Siemens. This type of motor can not only ensure the fast and stable operation of the machine, but also ensure high precision and high quality machining results.Water cooling spindleThis type of spindle adopts water circulation to cool the heat generated after the spindle rotates at high speed, which has the advantages of good cooling effect, low noise, long service life and high accuracy. We can provide a variety of brands at home and abroad for customers to choose from, to meet the diverse processing needs of users.Computer-controlledThe computer-controlled method can not only preview the processing effect, and you can see the processing trajectory at any time, but also can correct the program loading errors during the operation in time. Each function is displayed on the control panel, which is very convenient to operate.Square railWith the advantages of strong load capacity and accuracy maintaining ability, stable operation, low friction resistance,

high positioning accuracy, and good reproduction.The square rail not only guarantees the high-speed and high-quality operation of the engraving machine, but also maintains high precision for a long time. So it is suitable for large format fine carving, and it is ideal for stone engraving machines, woodworking engraving machines, foam engraving machines, etcApplication of eps foam cnc router:wood, styrofoam (EPS), nonmetallic carbonation materials, density board, aluminum,copper,MDF, HDF, PVC, paraffin wax, gypsum,lamp,ceramic,etc.2D and 3D cutting and carving. wood , foam statue making, door furniture relief carving.

0 notes